Development of Environmentally Friendly and Economical Flood-Prevention Stones Based on the Sediments of the Yellow River

Abstract

:1. Introduction

2. Materials and Methods

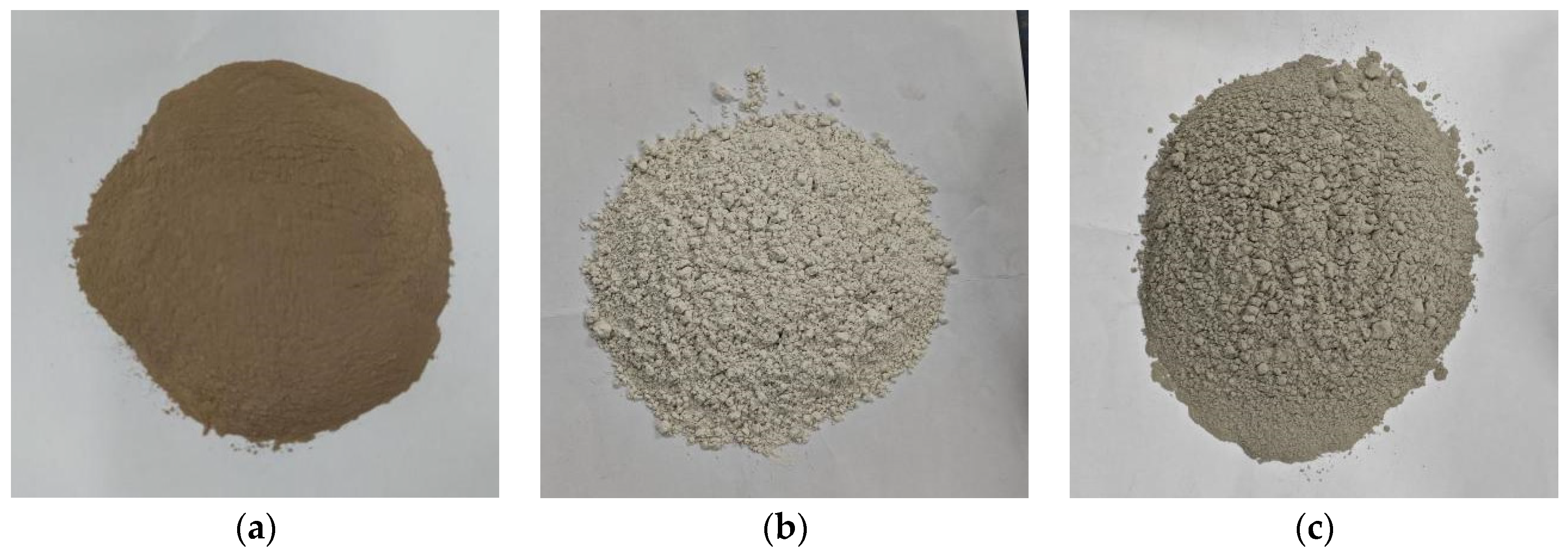

2.1. Materials

2.2. Sample Preparation

2.3. General Testing Methods

3. Results and Discussion

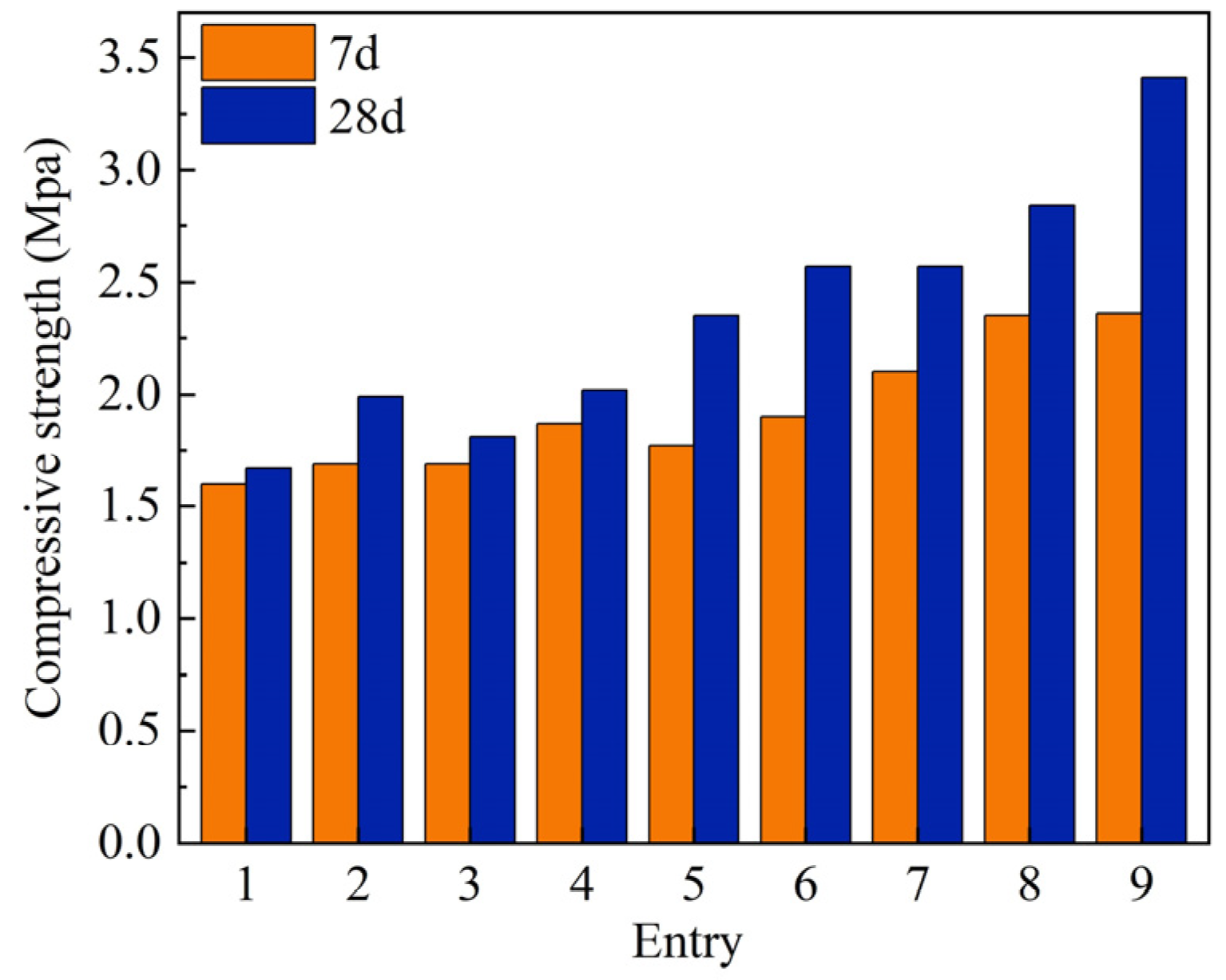

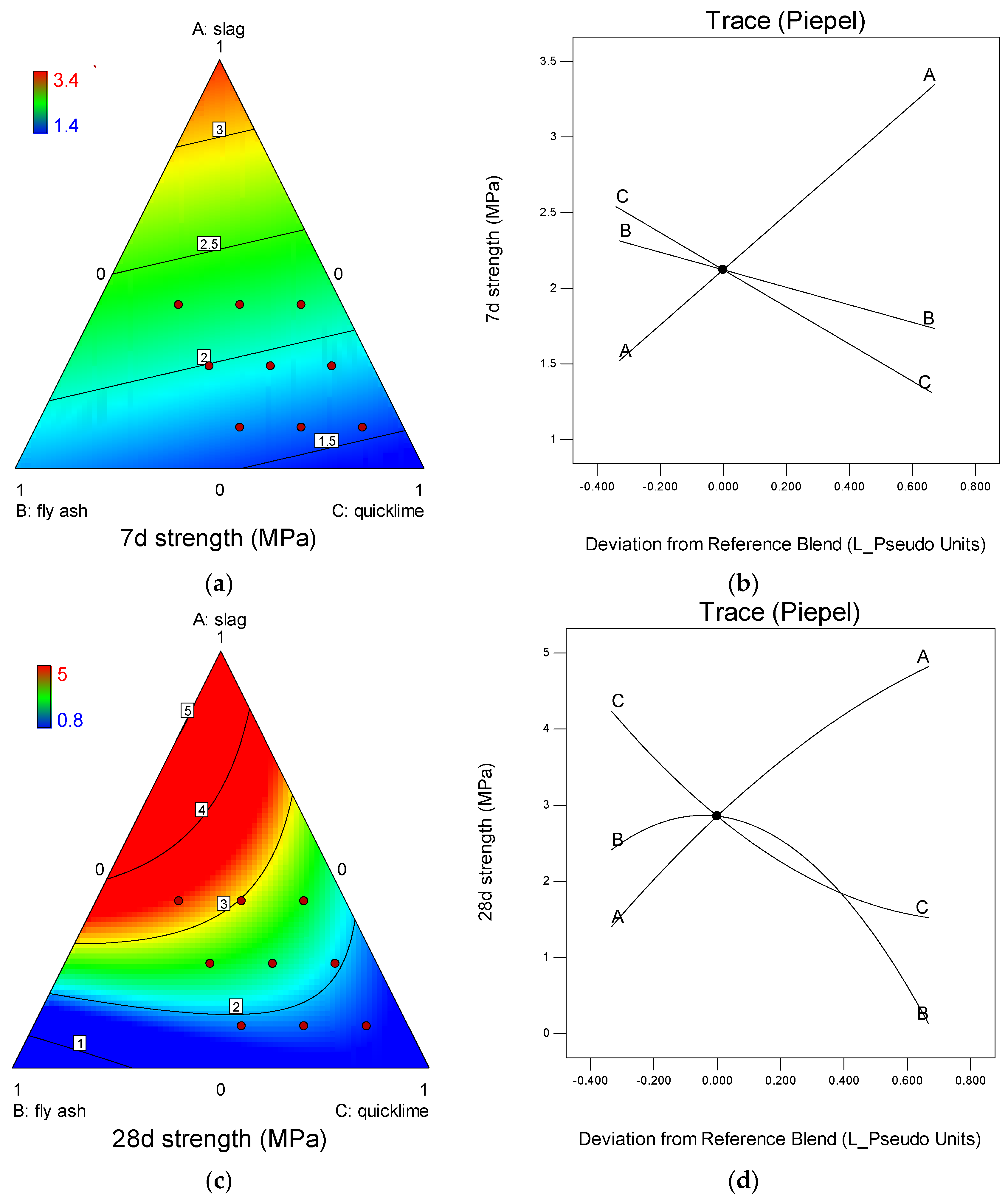

3.1. Analysis of Multi-Factor Compressive Strength Test Results

3.2. The Influence of Slag Content on Macroscopic Performance

3.2.1. Compressive Strength Testing

3.2.2. Leaching Solution pH Testing

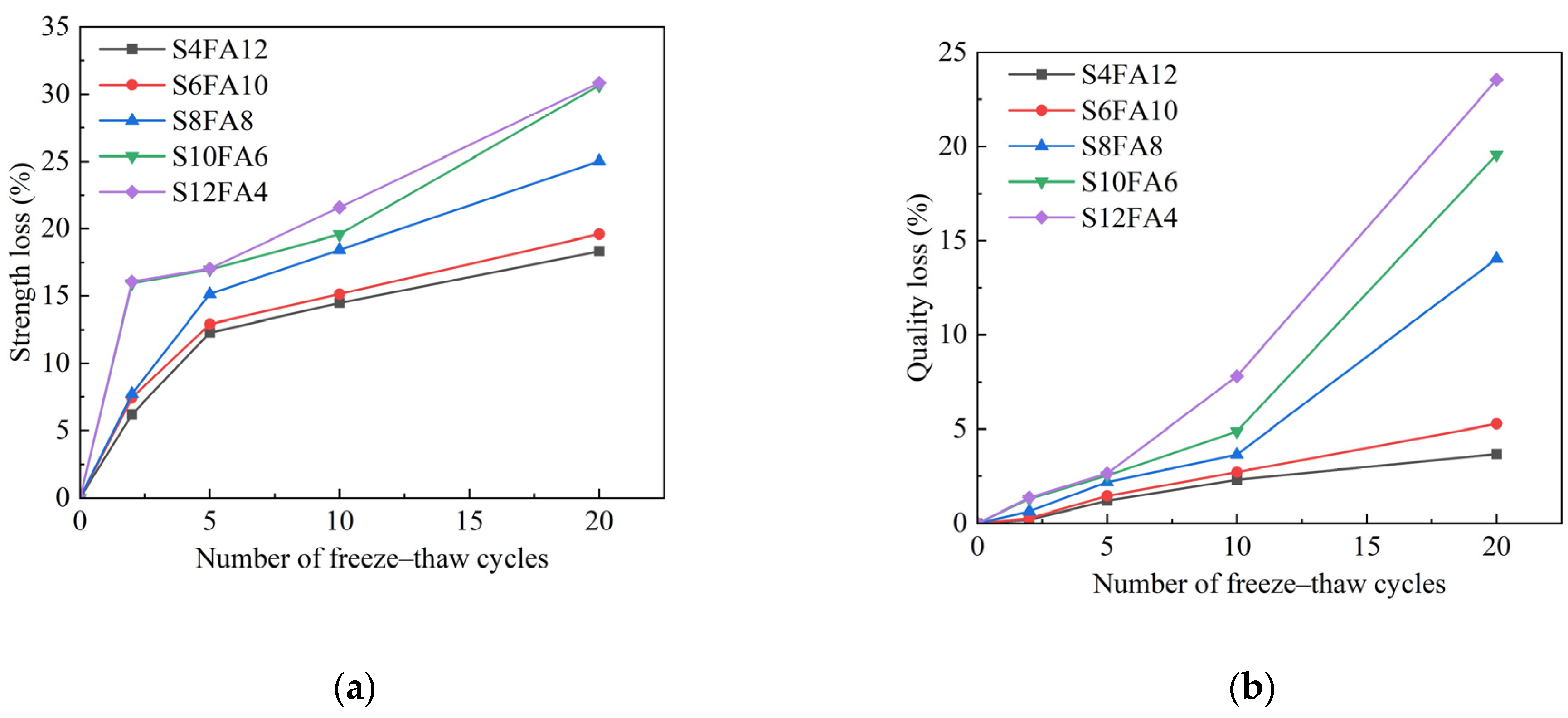

3.2.3. Rapid Freeze–Thaw Cycling Testing

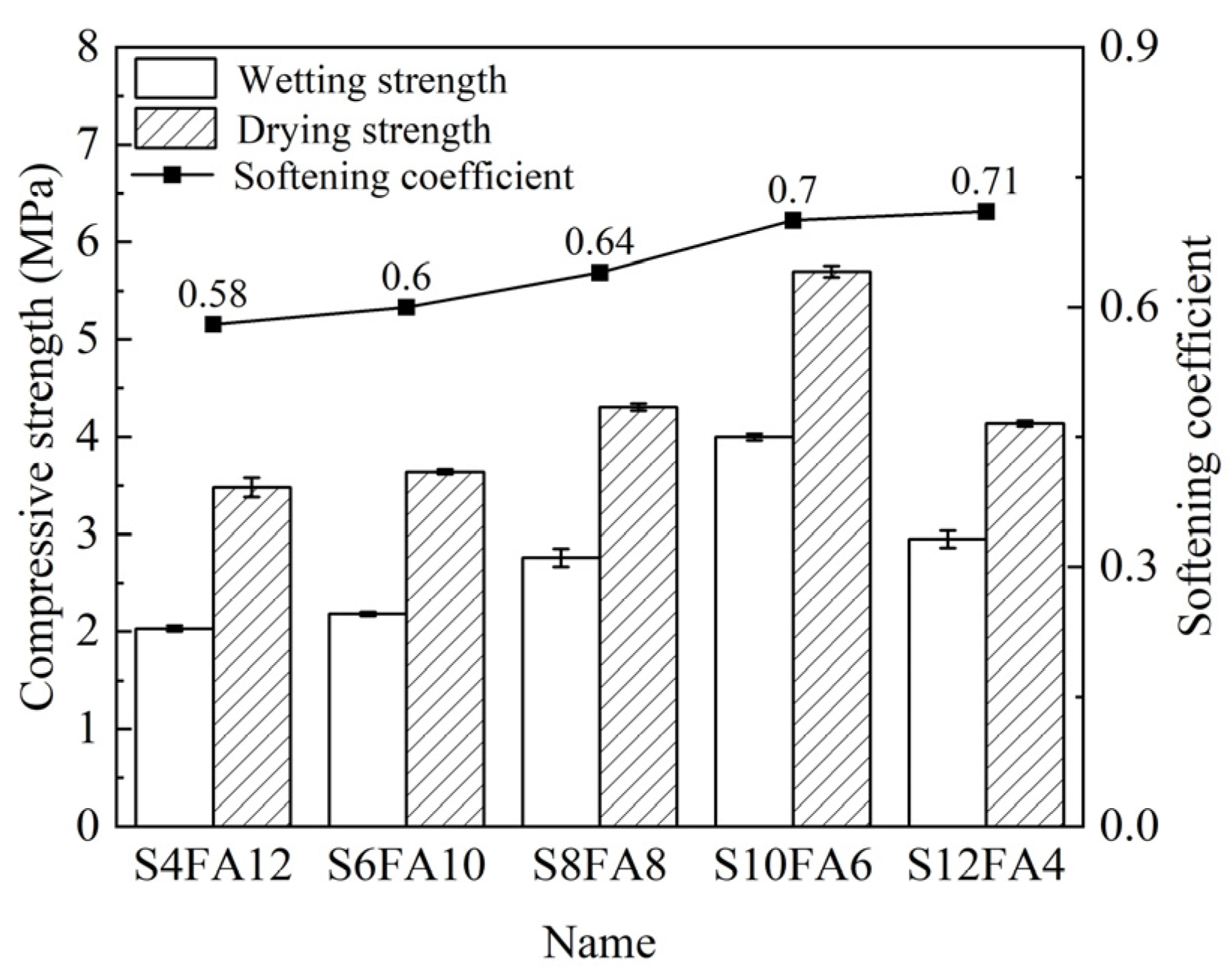

3.2.4. Softening Coefficient Testing

3.3. Effect of Slag Content Variation on Microstructure

3.3.1. Mechanism Analysis

3.3.2. Microscopic Structure

3.3.3. XRD Analysis for Composition of Flood-Prevention Stones

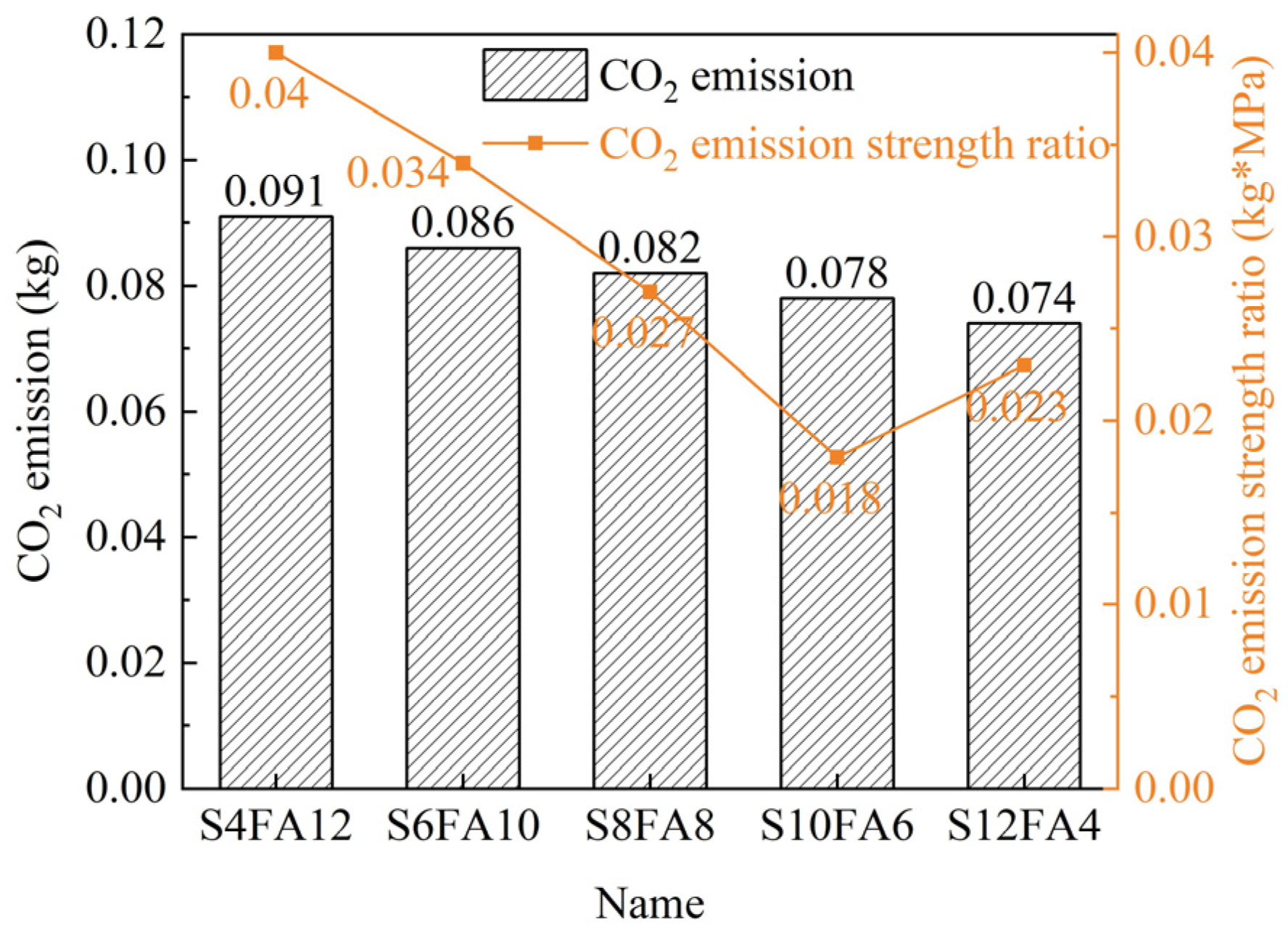

3.4. Environmental and Economic Evaluations

3.4.1. Environmental Evaluation

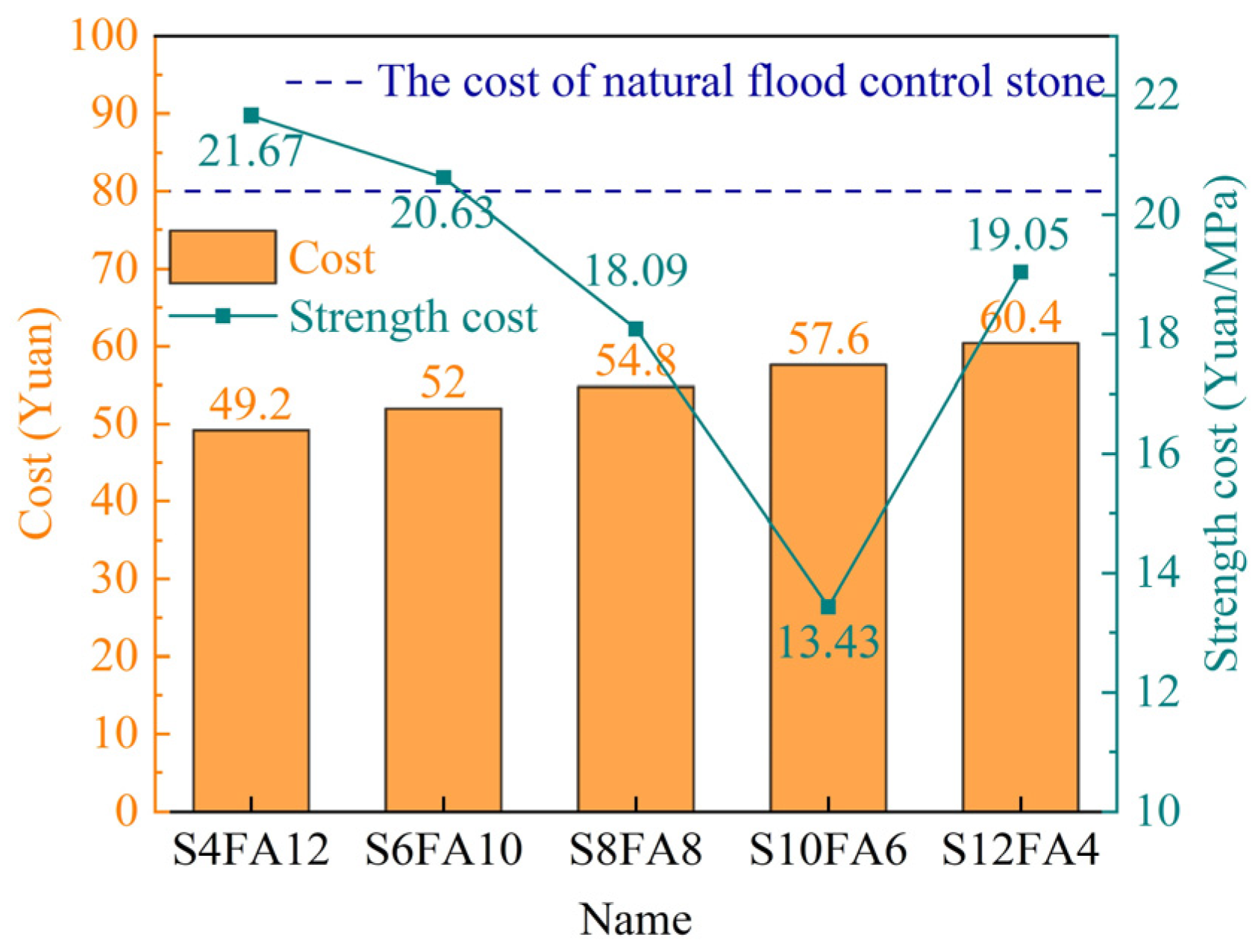

3.4.2. Economic Analysis

4. Summary and Conclusions

- Cross-verifying the theoretical and experimental results on compressive strength. The results of an orthogonal experimental design, in conjunction with Design-Expert for simulation prediction, were employed to ensure the compressive strength of a prepared artificial Yellow River sediment-based flood-prevention stone with a high degree of accuracy. Furthermore, the individual components of the binder that influence the compressive strength under different curing durations have been elucidated.

- Clarification of the mechanism of high compressive strength of prepared specimens. Analyses conducted using scanning electron microscopy (SEM) and X-ray diffraction (XRD) revealed the formation of C-A-S-H gel and its growth at different curing periods.

- Demonstration of the environmental friendliness and economy of artificial Yellow River sediment-based flood-prevention stones. The CO2 emissions associated with the preparation of the artificial flood-prevention stones were calculated. In accordance with the optimal compressive strength conditions, the emission on preparation of the desired stones was determined to be 0.18 kg (CO2)/(kg·MPa), which is considered to be typical of environmentally friendly production processes.

- Following the completion of the standard curing procedure over a 28-day period, the compressive strength of the prepared artificial stone was found to be 4.29 MPa. The pH of the identical specimen leachate was found to stabilize at 8.2 after 30 h of immersion. The softening coefficient of the S10FA6 specimen was tested with a value of over 0.7 under wet conditions. These important results confirmed that the prepared stones with the selected binder met the specifications for artificial flood-prevention stones.

- The pozzolanic reaction between CaO in slag and active SiO2 and Al2O3 in fly ash to form a C-A-S-H gel was proved as the main reason for the compressive strength enhancement of the specimens. The testing results on SEM and XRD of the tested specimens demonstrated a direct correlation between the alterations in the structure of the C-A-S-H gel and the compressive strength of the blocks.

- It has been determined that the cost of the produced artificial flood-prevention stones, utilizing various binders, is notably lower than the market price for commercially available natural stones. The cost-effectiveness of the artificial stones will facilitate their promotion in the market.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Chen, H.; Song, Y.; Wang, Z.; Zhong, Y.; Zhang, B. Experimental study on the stability of soybean urease-induced calcium carbonate solidification in sediment water in the Yellow River. J. Hydraul. Eng. 2024, 55, 71–79. [Google Scholar] [CrossRef]

- Wang, Z.J.; Ta, W.Q.; Zheng, J.; Zhang, K. Total sediment transport from an urbanizing watershed in the upper Yellow River. Environ. Sci. Pollut. Res. 2019, 26, 13702–13716. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.L.; Shang, Y.Z.; Liu, J.Y.; Lu, J.; Wei, S.T.; Wan, Z.W.; Luo, Q.S.; Chen, C.X.; Tong, L.; Wang, Q.; et al. Optimisation of reservoir operation mode to improve sediment transport capacity of silt-laden rivers. J. Hydrol. 2021, 594, 125951. [Google Scholar] [CrossRef]

- Nian, X.M.; Zhang, W.G.; Wang, X.T.; Wang, X.T.; Hutchinson, S.M.; Zhao, X.Q.; Liu, K.B. Multi-Centennial Variability of Yangtze Delta Growth Over the Last 2000 Years: Interplay of Climate and People. Earths Future 2022, 10, e2021EF002461. [Google Scholar] [CrossRef]

- Liu, H.Q.; Liu, G.J.; Wang, J.; Yuan, Z.J.; Da, C.N. Fractional distribution and risk assessment of heavy metals in sediments collected from the Yellow River, China. Environ. Sci. Pollut. Res. 2016, 23, 11076–11084. [Google Scholar] [CrossRef]

- Chen, C.X.; Fu, J.; Wu, M.X.; Gao, X.; Ma, L.M. High-efficiency Sediment Transport Requirements for operation of the Xiaolangdi Reservoir in the Lower Yellow River. Water Supply 2022, 22, 8572–8586. [Google Scholar] [CrossRef]

- Wu, P.; Liu, D.; Ma, J.; Gu, L.; Yong, J. Reconstructing the man-made Yellow River flood of Kaifeng City in 1642 AD using documentary sources. Int. J. Disaster Risk Reduct. 2019, 41, 101289. [Google Scholar] [CrossRef]

- Li, T.; Li, J.; Zhang, D.D. Yellow River flooding during the past two millennia from historical documents. Prog. Phys. Geogr. Earth Environ. 2020, 44, 661–678. [Google Scholar] [CrossRef]

- He, H.; Tian, Y.; Mu, X.; Zhou, J.; Li, Z.; Chen, N.; Zhang, Q.; Keo, S.; Oeurng, C. Confluent flow impacts of flood extremes in the middle Yellow River. Quat. Int. 2015, 380–381, 382–390. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, C. Two-thousand years of debates and practices of Yellow River training strategies. Int. J. Sediment Res. 2019, 34, 73–83. [Google Scholar] [CrossRef]

- Liu, G. On the geo-basis of river regulation in the lower reaches of the Yellow River. Sci. China-Earth Sci. 2012, 55, 530–544. [Google Scholar] [CrossRef]

- Tian, F.; Ma, B.; Yuan, X.; Wang, X.; Yue, Z. Hazard Assessments of Riverbank Flooding and Backward Flows in Dike-Through Drainage Ditches during Moderate Frequent Flooding Events in the Ningxia Reach of the Upper Yellow River (NRYR). Water 2019, 11, 1477. [Google Scholar] [CrossRef]

- Zhang, X.; Song, C.; Hu, D. Research on the periodic regularity of annual runoff in the Lower Yellow River. J. Water Clim. Chang. 2019, 10, 130–141. [Google Scholar] [CrossRef]

- Manopiniwes, W.; Irohara, T. Optimization model for temporary depot problem in flood disaster response. Nat. Hazards 2020, 105, 1743–1763. [Google Scholar] [CrossRef]

- Huang, L.; Yu, Z.; Wang, W.; Song, Y.; Wang, Y. Multiobjective programming model for a class of flood disaster emergency material allocation. J. Flood Risk Manag. 2023, e12918. [Google Scholar] [CrossRef]

- Ma, G.; Wang, J.; Yu, F.; Yang, W.; Ning, J.; Peng, F.; Zhou, X.; Zhou, Y.; Cao, D. Framework construction and application of China’s Gross Economic-Ecological Product accounting. J. Environ. Manag. 2020, 264, 109852. [Google Scholar] [CrossRef]

- Feng, C.; Cui, B.; Ge, H.; Huang, Y.; Zhang, W.; Zhu, J. Reinforcement of Recycled Aggregate by Microbial-Induced Mineralization and Deposition of Calcium Carbonate—Influencing Factors, Mechanism and Effect of Reinforcement. Crystals 2021, 11, 887. [Google Scholar] [CrossRef]

- Li, M.H.; Lu, Y.; Yang, S.; Chu, J.; Liu, Y. Study on the Early Effect of Excitation Method on the Alkaline Steel Slag. Sustainability 2023, 15, 4714. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.W.; Yan, P.Y. Influence of initial alkalinity on the hydration of steel slag. Sci. China-Technol. Sci. 2012, 55, 3378–3387. [Google Scholar] [CrossRef]

- Jiang, M.Y.; Qian, Y.F.; Sun, Q. Preparation of controlled low-strength materials from alkali-excited red mud-slag-iron tailings sand and a study of the reaction mechanism. Environ. Sci. Pollut. Res. 2023, 30, 22232–22248. [Google Scholar] [CrossRef]

- Wang, B.; Wang, W.; Liang, X.; Liu, H.; Han, J.; Zhao, L.; Yang, X.; Yan, J. Development of Cementitious Materials Utilizing Alkali-activated Yellow River Silt. J. Wuhan Univ. Technol. Mat. Sci. Edit. 2021, 36, 364–373. [Google Scholar] [CrossRef]

- Yan, J.; Zhong, S.; Chen, S.; Lv, Y.; Yang, L.; Peng, G.; Deng, A. Study on the Application of Sediment-Based Embankment Building and Ultra-High-Performance Concrete (UHPC) Preparation in the Resource Utilization of Yellow River Sediment. Materials 2022, 15, 5668. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Xu, J.; Song, Y.; Xu, Y. Alkali-activated fly ash foam concrete with Yellow River silt: Physico-mechanical and structural properties. Constr. Build. Mater. 2023, 373, 130879. [Google Scholar] [CrossRef]

- Wang, B.; Li, G.; Han, J.; Zheng, Y.; Liu, H.; Song, W. Study on the properties of artificial flood-prevention stone made by Yellow River silt. Constr. Build. Mater. 2017, 144, 484–492. [Google Scholar] [CrossRef]

- Zheng, L. Research on Consolidation and Gelling Technology of Flood Control Stone Made from Yellow River Sediment; Dalian University of Technology: Dalian, China, 2017; Available online: https://kns.cnki.net/kcms2/article/abstract?v=aHgEko1xHjjAposLR8iSE5IgyHPQi4toMJKniypW0HRp1z8PzmetegHlnqgSnmgBXA5lClyHMcTN7DhaYoOoQ3lr-Z_WKDHX9Vwzjvt3cptGPiNMbgL9l2NNXBDGx_nxoNjXa3ZazhKNDQqdIDdB0w==&uniplatform=NZKPT&language=CHS (accessed on 23 June 2024).

- Song, Y. Experimental Study on the Mechanical Properties and Durability of Alkali-Activated Fly Ash Concrete under Freeze-Thaw-Wind Erosion Environment; Inner Mongolia Agricultural University: Hohhot, China, 2023. [Google Scholar] [CrossRef]

- GB/T 9966.1-2020; Test Methods for Natural Stone—Part 1: Determination of Dry, Wet and after Freezing Compressive Strength. National Standardization Administration: Beijing, China, 2020.

- GB/T 23561.7-2009; Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 7: Methods for Determining the Uniaxial Compressive Strength and Counting Softening Coefficient. National Standardization Administration: Beijing, China, 2009.

- Zhang, T.; Cai, G.; Liu, S.; Puppala, A.J. Engineering properties and microstructural characteristics of foundation silt stabilized by lignin-based industrial by-product. KSCE J. Civ. Eng. 2016, 20, 2725–2736. [Google Scholar] [CrossRef]

- Tremblay, H.; Duchesne, J.; Locat, J.; Leroueil, S. Influence of the nature of organic compounds on fine soil stabilization with cement. Can. Geotech. J. 2002, 39, 535–546. [Google Scholar] [CrossRef]

- Rivera, J.F.; Orobio, A.; Cristelo, N.; de Gutiérrez, R.M. Fly ash-based geopolymer as A4 type soil stabiliser. Transp. Geotech. 2020, 25, 100409. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, M.; Disfani, M.M.; Horpibulsuk, S.; Bo, M.W.; Leong, M. Evaluation of fly ash- and slag-based geopolymers for the improvement of a soft marine clay by deep soil mixing. Soils Found. 2018, 58, 1358–1370. [Google Scholar] [CrossRef]

- Li, C.; Dong, J.; Zhao, S.; Liu, H.; Yao, W.; Wang, L. Development of low cost supplementary cementitious materials utilizing thermally activated Pisha sandstone. Constr. Build. Mater. 2018, 174, 484–495. [Google Scholar] [CrossRef]

- Sukmak, P.; Horpibulsuk, S.; Shen, S.-L. Strength development in clay–fly ash geopolymer. Constr. Build. Mater. 2013, 40, 566–574. [Google Scholar] [CrossRef]

- Ortega-Zavala, D.E. Chemically bonded ceramic/cementitious materials of alkali activated metakaolin processed by cold pressing. Constr. Build. Mater. 2021, 279, 121365. [Google Scholar] [CrossRef]

- Lv, Y.; Zhang, K.; Qu, J.; Yin, K.; Yang, C.; Zheng, H.; Xiang, T. Study on physicochemical and anti-corrosion performance of methylsiloxane-based hydrophobic powder modified mortar. Constr. Build. Mater. 2024, 425, 135999. [Google Scholar] [CrossRef]

| Chemical Composition (%) | Yellow River Sediment | Slag | Fly Ash |

|---|---|---|---|

| CaO | 11.09 | 49.42 | 7.20 |

| SiO2 | 57.02 | 25.57 | 46.44 |

| Fe2O3 | 6.47 | 0.31 | 3.12 |

| Al2O3 | 15.88 | 13.58 | 38.01 |

| TiO2 | 0.90 | 2.15 | 0.61 |

| Na2O | 1.17 | 0.44 | 0.33 |

| SO3 | 0.15 | 2.36 | 0.69 |

| K2O | 3.31 | 0.33 | 0.88 |

| MgO | 3.30 | 5.32 | 0.23 |

| Other | 0.71 | 0.52 | 2.19 |

| Entry | Slag (%) | Fly Ash (%) | Quicklime (%) |

|---|---|---|---|

| 1 | 2 | 2 | 16 |

| 2 | 2 | 5 | 13 |

| 3 | 2 | 8 | 10 |

| 4 | 5 | 2 | 13 |

| 5 | 5 | 5 | 10 |

| 6 | 5 | 8 | 7 |

| 7 | 8 | 2 | 10 |

| 8 | 8 | 5 | 7 |

| 9 | 8 | 8 | 4 |

| Name | Slag (%) | Fly Ash (%) | Quicklime (%) |

|---|---|---|---|

| S4FA12 | 4 | 12 | 4 |

| S6FA10 | 6 | 10 | 4 |

| S8FA8 | 8 | 8 | 4 |

| S10FA6 | 10 | 6 | 4 |

| S12FA4 | 12 | 4 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Xiao, H.; Jia, Y.; Lv, Y.; Dai, L.; Yang, C. Development of Environmentally Friendly and Economical Flood-Prevention Stones Based on the Sediments of the Yellow River. Gels 2024, 10, 622. https://doi.org/10.3390/gels10100622

Liu Y, Xiao H, Jia Y, Lv Y, Dai L, Yang C. Development of Environmentally Friendly and Economical Flood-Prevention Stones Based on the Sediments of the Yellow River. Gels. 2024; 10(10):622. https://doi.org/10.3390/gels10100622

Chicago/Turabian StyleLiu, Ying, Hao Xiao, Yongxiang Jia, Yajun Lv, Li Dai, and Chen Yang. 2024. "Development of Environmentally Friendly and Economical Flood-Prevention Stones Based on the Sediments of the Yellow River" Gels 10, no. 10: 622. https://doi.org/10.3390/gels10100622

APA StyleLiu, Y., Xiao, H., Jia, Y., Lv, Y., Dai, L., & Yang, C. (2024). Development of Environmentally Friendly and Economical Flood-Prevention Stones Based on the Sediments of the Yellow River. Gels, 10(10), 622. https://doi.org/10.3390/gels10100622