Green Strategies of Powdery Mildew Control in Hop: From Organic Products to Nanoscale Carriers

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Sites, Treatments and Experimental Design

2.2. Leaf Sampling

2.3. Cone Sampling

2.4. Statistical Analysis

3. Results

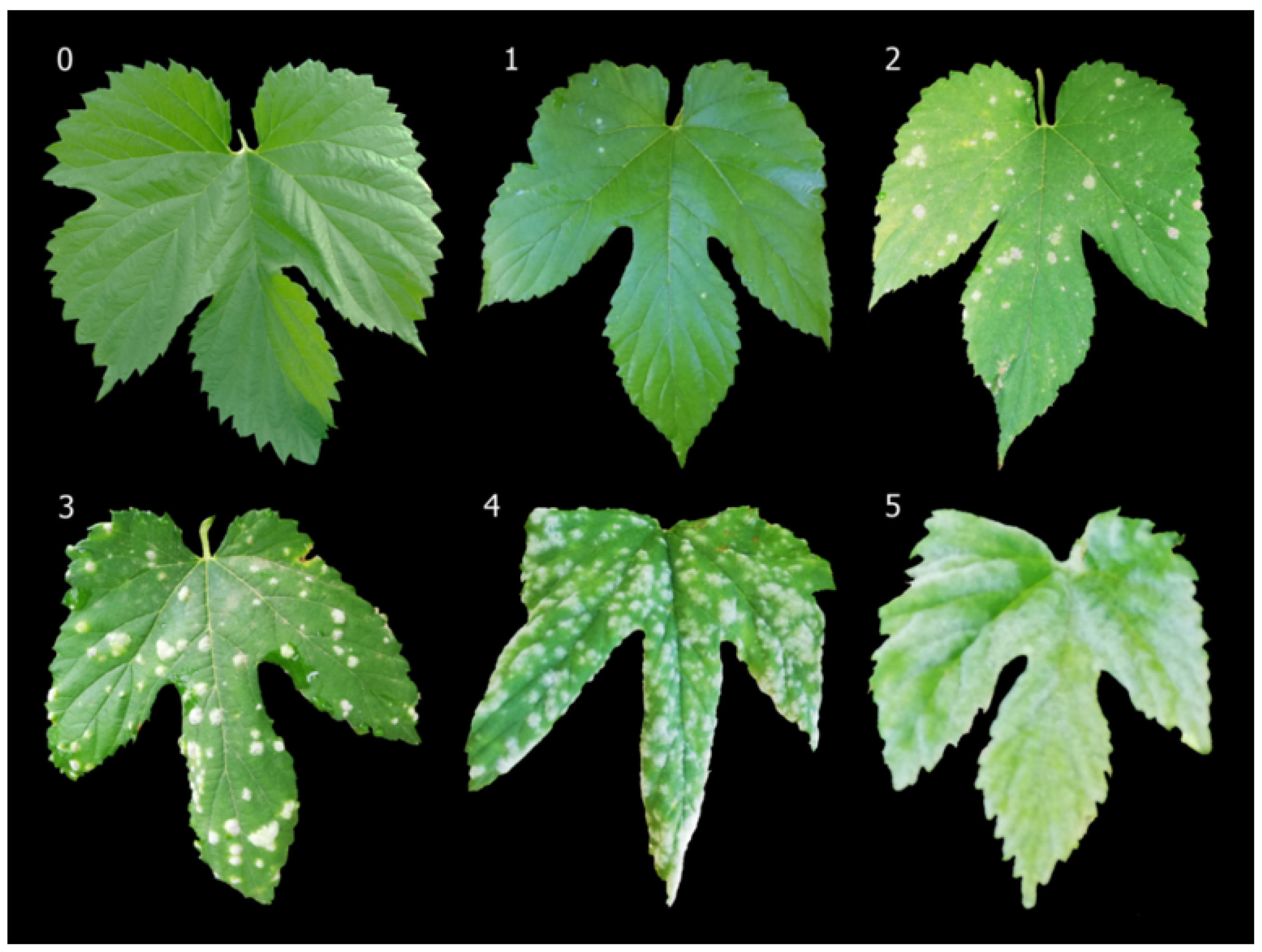

3.1. Control of Podosphaera macularis Colonization in Leaves

3.2. Control of Podosphaera macularis Colonization in Cones

3.3. Yield Index

3.4. α-acid Yield

3.5. Quality Index

3.6. Correlation Among Variables

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Delyser, D.Y.; Kasper, W.J. Hopped beer: The case for cultivation. Econ. Bot. 1994, 48, 166–170. [Google Scholar] [CrossRef]

- Henning, J.A.; Gent, D.H.; Townsend, M.S.; Woods, J.L.; Hill, S.T.; Hendrix, D. QTL analysis of resistance to powdery mildew in hop (Humulus lupulus L.). Euphytica 2017, 213, 98. [Google Scholar] [CrossRef]

- Lorenzana, A.; Hermoso-de-Mendoza, A.; Seco, M.V.; Casquero, P.A. Population dynamics and integrated control of the damson-hop aphid Phorodon humuli (Schrank) on hops in Spain. Spanish J. Agric. Res. 2013, 11, 505–517. [Google Scholar] [CrossRef]

- Lorenzana, A.; Hermoso De Mendoza, A.; Seco, M.V.; Campelo, M.P.; Casquero, P.A. Within-plant distribution of Phorodon humuli (Hemiptera: Aphididae) and natural enemies on hops with implications for sampling and management. Entomol. Sci. 2017, 20, 443–450. [Google Scholar] [CrossRef]

- Neve, R.A. Hops, 1st ed.; Chapman and Hall: Suffolk, UK, 1991; ISBN 9789401053754. [Google Scholar]

- Lorenzana, A.; Hermoso de Mendoza, A.; Seco, V.; Campelo, P.; Casquero, P.A. Within-field distribution of the damson-hop aphid Phorodon humuli (Schrank) (hemiptera: Aphididae) and natural enemies on hops in Spain. Spanish J. Agric. Res. 2017, 15. [Google Scholar] [CrossRef]

- Gent, D.H.; Mahaffee, W.F.; Turechek, W.W. Spatial heterogeneity of the incidence of powdery mildew on hop cones. Plant Dis. 2006, 90, 1433–1440. [Google Scholar] [CrossRef]

- Probst, C.; Nelson, M.E.; Grove, G.G.; Twomey, M.C.; Gent, D.H. Hop powdery mildew control through alteration of spring pruning practices. Plant Dis. 2016, 100, 1599–1605. [Google Scholar] [CrossRef] [PubMed]

- Gent, D.H.; Grove, G.G.; Nelson, M.E.; Wolfenbarger, S.N.; Woods, J.L. Crop damage caused by powdery mildew on hop and its relationship to late season management. Plant Pathol. 2014, 63, 625–639. [Google Scholar] [CrossRef]

- Royle, D.J.; Griffin, M.J. Side-effects of downy mildew fungicides on the incidence of hop powdery mildew (Sphaerotheca humuli). Plant Pathol. 1973, 22, 129–133. [Google Scholar]

- Royle, D.J. Powdery mildew of the hop. In The Powdery Mildews; D. M. Spencer: New York, NY, USA, 1978; pp. 381–409. [Google Scholar]

- Turechek, W.W.; Mahaffee, W.F.; Ocamb, C.M. Development of Management Strategies for Hop Powdery Mildew in the Pacific Northwest. Plant Heal. Prog. 2001, 2, 8. [Google Scholar] [CrossRef]

- Nelson, M.E.; Gent, D.H.; Grove, G.G. Meta-analysis reveals a critical period for management of powdery mildew on hop cones. Plant Dis. 2015, 99, 632–640. [Google Scholar] [CrossRef] [PubMed]

- Vega-Vásquez, P.; Mosier, N.S.; Irudayaraj, J. Nanoscale Drug Delivery Systems: From Medicine to Agriculture. Front. Bioeng. Biotechnol. 2020, 8, 1–16. [Google Scholar] [CrossRef]

- Jun Zhou, B.; Xu, N.; Wang, Z.L.; Wang, Z.L.; Zhou, J.; Xu, N.S.; Ding, Y.; Yang, R.; Liu, J.; Mai, W.; et al. Dissolving Behavior and Stability of ZnO Wires in Biofluids: A Study on Biodegradability and Biocompatibility of ZnO Nanostructures**. Adv. Mater 2006, 18, 2432–2435. [Google Scholar] [CrossRef]

- Vivek, R.; Thangam, R.; Nipunbabu, V.; Rejeeth, C.; Sivasubramanian, S.; Gunasekaran, P.; Muthuchelian, K.; Kannan, S. Multifunctional HER2-Antibody conjugated polymeric nanocarrier-based drug delivery system for multi-drug-resistant breast cancer therapy. ACS Appl. Mater. Interfaces 2014, 6, 6469–6480. [Google Scholar] [CrossRef] [PubMed]

- Sarath Chandra, V.; Baskar, G.; Suganthi, R.V.; Elayaraja, K.; Ahymah Joshy, M.I.; Sofi Beaula, W.; Mythili, R.; Venkatraman, G.; Narayana Kalkura, S. Blood compatibility of iron-doped nanosize hydroxyapatite and its drug release. ACS Appl. Mater. Interfaces 2012, 4, 1200–1210. [Google Scholar] [CrossRef]

- Martín, R.; Menchón, C.; Apostolova, N.; Victor, V.M.; Álvaro, M.; Herance, J.R.; García, H. Nano-jewels in biology. Gold and platinum on diamond nanoparticles as antioxidant systems against cellular oxidative stress. ACS Nano 2010, 4, 6957–6965. [Google Scholar] [CrossRef]

- Su, C.; Liu, S.; Cao, S.; Yin, S.; Zhou, C.; Gao, S.; Jia, C.; Ji, Y.; Liu, Y. Self-assembled bovine serum albumin nanoparticles as pesticide delivery vectors for controlling trunk-boring pests. J. Nanobiotechnol. 2020, 18, 165. [Google Scholar] [CrossRef]

- Zheng, Y.; You, S.; Ji, C.; Yin, M.; Yang, W.; Shen, J. Development of an Amino Acid-Functionalized Fluorescent Nanocarrier to Deliver a Toxin to Kill Insect Pests. Adv. Mater. 2016, 28, 1375–1380. [Google Scholar] [CrossRef] [PubMed]

- Carro-Huerga, G.; Rodríguez-González, Á.; Mayo-Prieto, S.; Álvarez-García, S.; Gutiérrez, S.; Casquero, P.A. Use of the carrier Nutragreen® for reducing fertilizers and pesticides in pear trees. In Proceedings of the 4° Simpósio Nacional de Fruticultura, Faro, Portugal, 29–30 November 2018; p. 121. [Google Scholar]

- Campbell, C.L.; Madden, L.V. Introduction to Plant Disease Epidemiology; John Wiley and Sons: New York, NY, USA, 1990. [Google Scholar]

- Twomey, M.C.; Wolfenbarger, S.N.; Woods, J.L.; Gent, D.H. Development of partial ontogenic resistance to powdery mildew in hop cones and its management implications. PLoS ONE 2015, 10, e0120987. [Google Scholar] [CrossRef]

- The Brewers of Europe Lead conductance value of hops, powders and pellets. Analytica EBC; Brussels, Belgium, 2019. Available online: https://brewup.eu/ebc-analytica/hops-and-hop-products/lead-conductance-value-of-hops-powders-and-pellets/7.4 (accessed on 19 April 2021).

- Abdel-Kader, M.M.; El-Mougy, N.S.; Embaby, E.I. Resistance inducers treatments against downy and powdery mildews of cucumber under commercial plastic houses conditions. Aust. J. Basic Appl. Sci. 2012, 6, 249–259. [Google Scholar]

- Ziv, O.; Zitter, T.A. Effects of bicarbonates and film-forming polymers on cucurbit foliar diseases. Plant Dis. 1992, 76, 513–517. [Google Scholar] [CrossRef]

- Jiang, X. (Ed.) Sulfur Chemistry; Topics in Current Chemistry Collections; Springer International Publishing: Cham, UK, 2019; ISBN 978-3-030-25597-8. [Google Scholar]

- Felsenstein, F.; Semar, M.; Stammler, G. Sensitivity of Wheat Powdery Mildew (Blumeria graminis f.sp. tritici) towards Metrafenone. Gesunde Pflanz. 2010, 62, 29–33. [Google Scholar] [CrossRef]

- Kunova, A.; Pizzatti, C.; Bonaldi, M.; Cortesi, P. Metrafenone resistance in a population of Erysiphe necator in northern Italy. Pest Manag. Sci. 2016, 72, 398–404. [Google Scholar] [CrossRef] [PubMed]

- Lewis, P.A.; Thomas, G.G. Investigation into Some Causes of Differing Alpha-Acid Content of Hop (Humulus Lupulus L.) Samples. J. Hortic. Sci. 1982, 57, 121–127. [Google Scholar] [CrossRef]

| Application Timing 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Treatment | Product Name | Active Ingredient | 1 2 | 2 | 3 | 4 | 5 | 6 |

| ECO | LECTUM | Soy lecithin (NON-GMO) + Equisetum arvense L. extract [EC] W/W | √ | √ | √ | √ | √ | √ |

| AGR | ACTILEAF | Cerevisane 94,1% [WP] W/W | √ | √ | √ | √ | √ | |

| HELIOSOUFRE | Sulfur 72% [+ Pinolene] [SC] W/V | √ | √ | √ | √ | √ | √ | |

| VITISAN | Potassium hydrogen carbonate 99,99% [SP] W/W | √ | √ | √ | √ | √ | ||

| IDA | NELA | Cinnamon extract [EC] W/W | √ | √ | √ | √ | √ | √ |

| S-SYSTEM | Bioassimilable sulfur 32% + Mn + Zn [EC] W/W | √ | √ | √ | √ | √ | √ | |

| SIP | ARAW | Eugenol 3.3%, Geraniol and Thymol 6.6% [CS] W/V | √ | √ | √ | √ | √ | √ |

| CER | ARMICARB | Potassium hydrogen carbonate 85% W/W | √ | √ | √ | √ | √ | √ |

| AMYLO-X | Bacillus amyloliquefaciens subsp. plantarum (strain D747) 25% [WG] W/W | √ | √ | √ | ||||

| IDM | HELIOSOUFRE | Sulfur 72% [+ Pinolene] [SC] W/V | √ | √ | √ | |||

| VITISAN | Potassium hydrogen carbonate 99,99% [SP] W/W | √ | √ | √ | ||||

| VIVANDO | Metrafenone 50% [SC] W/V | √ | √ 3 | |||||

| BELLIS | Boscalid 25.2% + Piraclostrobin 12.8% [WG] W/W | √ | √ 2 | |||||

| IDM + | IDM + Nutragreen | IDM + Nutragreen (10−4 volumen dilution) | ||||||

| CON MR | SYSTHANE FORTE | Myclobutanil 24% [EC] W/V | √ | √ | √ | |||

| VIVANDO | Metrafenone 50% [SC] W/V | √ | ||||||

| LUNA SENSATION | Fluopyram 25% + trifloxystrobin 25% [SC] W/V | √ | ||||||

| CON MR + | CON MR + Nutragreen | CON MR + Nutragreen (10−4 volumen dilution) | ||||||

| CON SAFE-ULE | NIMROD Quattro | Bupirimate 25% [EC] W/V | √ | √ | √ | |||

| Sulfur 80% [WP] 4 | Sulfur 80% [WP] W/W | √ | √ | |||||

| CON SAFE-ULE + | CON SAFE-ULE + Nutragreen | CON SAFE-ULE + Nutragreen (10−4 volumen dilution) | ||||||

| Treatment 1 | Leaf 2 | Cone 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| SAUDPC | DIIL | DIL (%) | DIIC | DIC (%) | Yield Index (kg cone/kg Plant) | α-acid Yield (%) | Quality Index | |

| CON | 0.28d | 4.44c | 20.83cd | 39.9bcd | 95.27a | 0.37a | 7.81abc | 2.89a |

| CON+ | 0.52cd | 7.72bc | 35.28bcd | 29.01e | 74.27d | 0.33ab | 8.67a | 2.86a |

| CC | 1.20a | 31.39a | 96.11a | 44.97ab | 93.30ab | 0.26c | 7.81abc | 2.03cd |

| ECO | 0.80bc | 15.56b | 52.78b | 45.06ab | 86.99abc | 0.24c | 6.85d | 1.64d |

| AGR | 0.53cd | 10.50bc | 44.17bc | 46.34a | 91.13abc | 0.26c | 7.50bcd | 1.95cd |

| IDA | 0.25d | 3.11c | 14.44d | 45.50ab | 85.44bc | 0.27c | 7.55bcd | 2.04cd |

| SIP | 1.05ab | 27.67a | 84.17a | 39.18cd | 83.24cd | 0.26c | 7.19cd | 1.87cd |

| CER | 0.44d | 6.61bc | 28.06bcd | 46.87a | 92.43abc | 0.29bc | 7.32bcd | 2.12c |

| IDM | 0.52cd | 10.22bc | 45.56bc | 35.4d | 85.05bc | 0.34ab | 8.19ab | 2.78ab |

| IDM+ | 0.55cd | 11.72bc | 51.94b | 41.76abc | 90.12abc | 0.29bc | 7.76abc | 2.25bc |

| Treatment 1 | Leaf 2 | Cone 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| SAUDPC | DIIL | DIL (%) | DIIC | DIC (%) | Yield Index (kg cone/kg plant) | α-acid Yield (%) | Quality Index | |

| CON | 0.80c | 16.27b | 65.66bcd | 33.29c | 89.61b | 0.45a | 7.79a | 3.51ab |

| CON+ | 0.70c | 15.31b | 60.42bcd | 30.62c | 87.53b | 0.46a | 7.62a | 3.51a |

| CC | 1.32ab | 32.27ab | 81.33ab | 42.40ab | 93.43ab | 0.43abc | 6.84b | 2.94bcd |

| ECO | 0.73c | 21.4b | 59.33cd | 45.48ab | 95.67ab | 0.39bc | 6.96b | 2.71cd |

| AGR | 0.71c | 20.93b | 61.33bcd | 47.13a | 97.48a | 0.44ab | 6.65b | 2.93bcd |

| IDA | 0.87bc | 35.53ab | 79.67abc | 46.30ab | 96.98ab | 0.38c | 6.70b | 2.55d |

| SIP | 1.71a | 43.00a | 93.33a | 47.11a | 95.76ab | 0.42abc | 6.63b | 2.78bcd |

| CER | 0.72c | 21.13b | 65.66bcd | 47.79a | 96.38ab | 0.43abc | 6.75b | 2.90bcd |

| IDM | 0.83bc | 17.13b | 51.67d | 38.38bc | 94.60ab | 0.45a | 6.86b | 3.09abc |

| IDM+ | 1.02bc | 19.20b | 62.33bcd | 32.77c | 89.20b | 0.43abc | 6.79b | 2.92bcd |

| Leaf 1 | Cone 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| SAUDPC | DIIL | DIL (%) | Yield Index (kg cone/kg Plant) | DIIC | DIC (%) | α-acid Content (%) | ||

| Leaf 1 | SAUDPC | 1 | 0.99 | 0.98 | −0.54 | 0.07 | −0.01 | −0.25 |

| DIIL | 1 | 0.99 | −0.50 | 0.10 | 0.06 | −0.24 | ||

| DIL (%) | 1 | −0.47 | 0.04 | 0.04 | −0.17 | |||

| Cone 2 | Yield Index (kg cone/kg plant) | 1 | −0.66 | −0.09 | 0.71 | |||

| DIIC | 1 | 0.73 | −0.77 | |||||

| DIC (%) | 1 | −0.42 | ||||||

| α-acid content (%) | 1 | |||||||

| Leaf 1 | Cone 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| SAUDPC | DIIL | DIL (%) | Yield Index (kg cone/kg Plant) | DIIC | DIC (%) | α-acid Content (%) | ||

| Leaf 1 | SAUDPC | 1 | 0.80 | 0.83 | −0.13 | 0.21 | 0.09 | −0.36 |

| DIIL | 1 | 0.93 | −0.75 | 0.60 | 0.50 | −0.56 | ||

| DIL (%) | 1 | −0.39 | 0.42 | 0.26 | −0.32 | |||

| Cone 2 | Yield Index (kg cone/kg plant) | 1 | −0.61 | −0.57 | 0.50 | |||

| DIIC | 1 | 0.96 | −0.74 | |||||

| DIC (%) | 1 | −0.76 | ||||||

| α-acid content (%) | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porteous-Álvarez, A.J.; Maldonado-González, M.M.; Mayo-Prieto, S.; Lorenzana, A.; Paniagua-García, A.I.; Casquero, P.A. Green Strategies of Powdery Mildew Control in Hop: From Organic Products to Nanoscale Carriers. J. Fungi 2021, 7, 490. https://doi.org/10.3390/jof7060490

Porteous-Álvarez AJ, Maldonado-González MM, Mayo-Prieto S, Lorenzana A, Paniagua-García AI, Casquero PA. Green Strategies of Powdery Mildew Control in Hop: From Organic Products to Nanoscale Carriers. Journal of Fungi. 2021; 7(6):490. https://doi.org/10.3390/jof7060490

Chicago/Turabian StylePorteous-Álvarez, Alejandra J., M. Mercedes Maldonado-González, Sara Mayo-Prieto, Alicia Lorenzana, Ana I. Paniagua-García, and Pedro A. Casquero. 2021. "Green Strategies of Powdery Mildew Control in Hop: From Organic Products to Nanoscale Carriers" Journal of Fungi 7, no. 6: 490. https://doi.org/10.3390/jof7060490

APA StylePorteous-Álvarez, A. J., Maldonado-González, M. M., Mayo-Prieto, S., Lorenzana, A., Paniagua-García, A. I., & Casquero, P. A. (2021). Green Strategies of Powdery Mildew Control in Hop: From Organic Products to Nanoscale Carriers. Journal of Fungi, 7(6), 490. https://doi.org/10.3390/jof7060490