Effect of Transportation and Pre-Slaughter Handling on Welfare and Meat Quality of Cattle: Case Study of Kumasi Abattoir, Ghana

Abstract

:1. Introduction

Objective

2. Methodology

2.1. The Study Area

2.2. Data Collection

2.3. Interview of Stakeholders

2.4. Measurement of Cattle Behaviours and Methods of Handling

| Behaviour | Definition |

|---|---|

| Easily pulled | The number of animals allowing themselves to be moved from the Cattle Market into the Abattoir by cattle handlers. |

| Beatings (whips) | Animals which failed to move voluntarily were whipped/ lashed by cattle handlers with ropes and sticks or clubs until they moved. |

| Charging at handlers | Sometimes as the animals were being moved by cattle handlers, they charged at the handlers. |

| Defecation and urinating | Due to inappropriate handling by cattle handlers, animals mostly defecated and or urinated. |

| Ear erection | Some animals due to agitation and stress, raised their ears while they were being moved by cattle handlers into the Abattoir. |

| Foaming | Some animals foamed at the mouth due to stress from handling by cattle handlers as they were moved into the Abattoir. |

| Forcing animals to fall down | When some animals got to the entrance of the lairage or the entrance of the Abattoir, they resisted entry and the cattle handlers had to physically restrain those animals and force them to fall down before dragging them into the Abattoir for slaughter. |

| Head swings | Some animals swung their heads from one side to the other as an indication of being traumatised while they were being moved into the Abattoir. |

| Horn pulling | Sometimes some animals which failed to move voluntarily as they were sent into the Abattoir had to be held by the horn by cattle handlers and pulled. |

| Jumping | Sometimes some animals while in their natural environments, exhibit play behaviours such as jumping but when they are inhumanely handled, they jump as well in distress. |

| Kicking | Animals which were traumatised and were temperamental, tried to kick the cattle handlers with their hind legs while they were being moved into the Abattoir for slaughter. |

| Crippled during handling | Animals which became lame and could not continue walking due to inappropriate handling by cattle handlers as they were being moved into the Abattoir were counted and recorded. |

| Leg pulling | Some animals instead of being pulled by ropes attached to their horns were pulled by ropes attached to their leg(s) because those animals stopped, lay down and would not move. |

| Lying down and refusing to move | Sometimes some of the animals lay down and refused to move during handling. |

| Moving without pulling | Some animals moved voluntarily into the Abattoir without being pulled by cattle handlers. |

| Panting | At certain times, some of the animals panted for breath while being moved by cattle handlers into the Abattoir due to stress from inappropriate handling. |

| Raising of tail | Some animals due to agitation raised their tails while they were being moved by cattle handlers into the Abattoir. |

| Resistance to be lazooed | Before each animal was moved into the Abattoir for slaughter, it was tied by the horns with a rope. Some animals resisted these restrictions by running away from the cattle handlers. |

| Resistance to be pulled | Some of the animals resisted pulling by cattle handlers from the cattle market into the Abattoir. |

| Retreating | Due to fear and inappropriate handling by cattle handlers, some animals moved backwards while they were being moved into the Abattoir for slaughter. |

| Running | Some animals ran when being moved by cattle handlers into the Abattoir. |

| Slapping | Sometimes the cattle handlers had to use their bare hands to slap recalcitrant animals which offered some resistance to pulling. |

| Sniffing | Due to fear and inappropriate handling by cattle handlers, some animals sniffed while they were being moved into the Abattoir for slaughter. |

| Stoning | Hitting animals with stones when animals failed to move voluntarily |

| Stretching | Some animals stretched their bodies by extending their forelegs forward and their hind legs backwards and arched their bodies due to stress from inappropriate handling by cattle handlers. |

| Stamping of feet | Due to fear and inappropriate handling by cowboys, some animals remained stationary and kept stamping their feet on the ground while they were being moved into the Abattoir for slaughter. |

| Tail pulling/twisting and, Stumping on tail | Animals which lay down and refused to stand up while they were being sent into the Abattoir had to have their tails pulled, twisted or stamped upon by the cattle handlers before they stood up and began to move. |

| Vocalisations | At certain times, some of the animals vocalised not because they were badly handled or stressed (vocalisation level 1) while others vocalised because they were inappropriately handled by cattle handlers (vocalisation level 2). |

2.5. Measurement of pH of Meat from Poorly-Handled Cattle

2.6. Measurement of Cooking Loss of Meat from Poorly-Handled Cattle

2.7. Measurement of Carcass Bruising

2.8. Measurement of Proportion of Non-Ambulatory Cattle

2.9. Data Analysis

3. Results

3.1. Interview Results

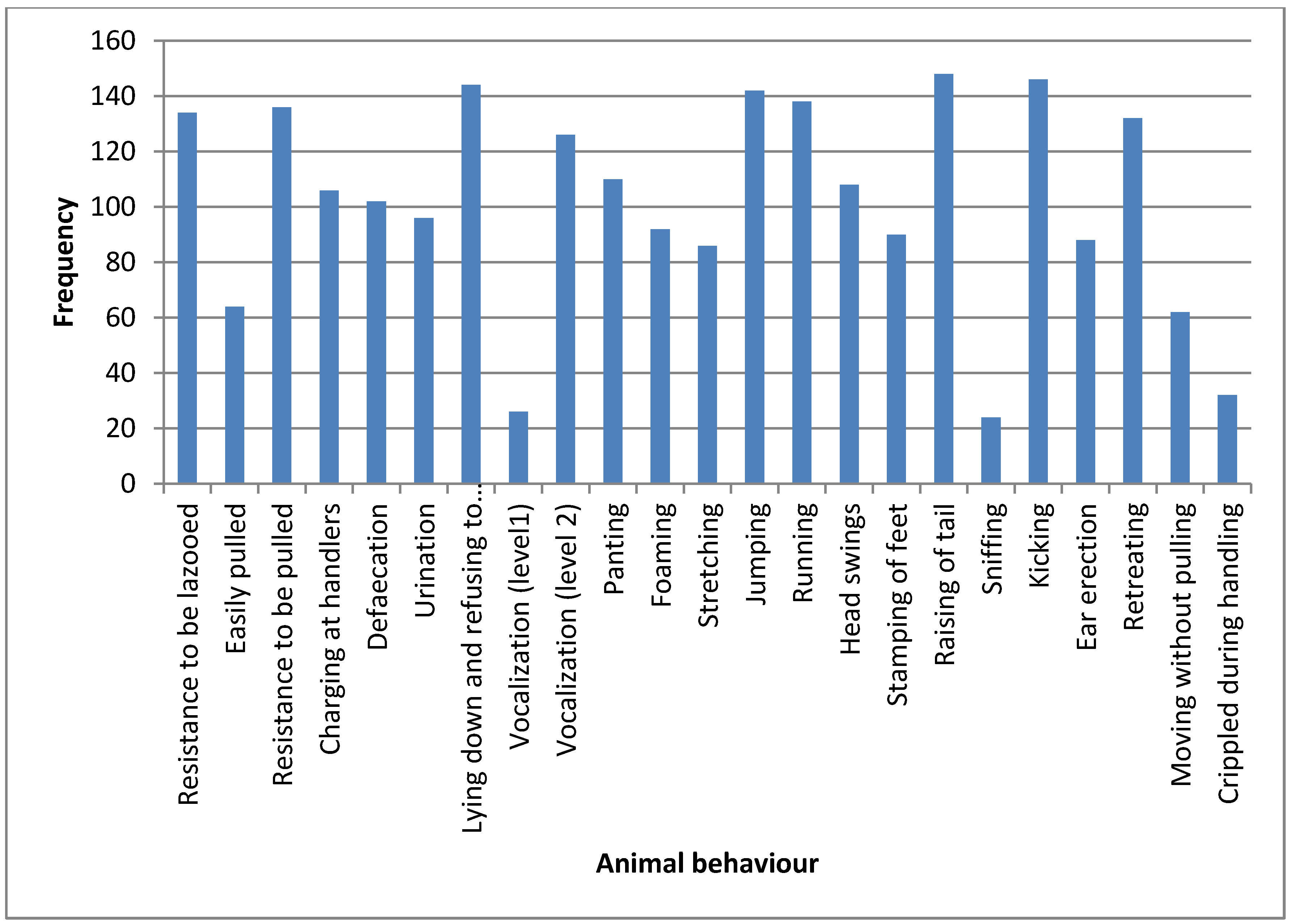

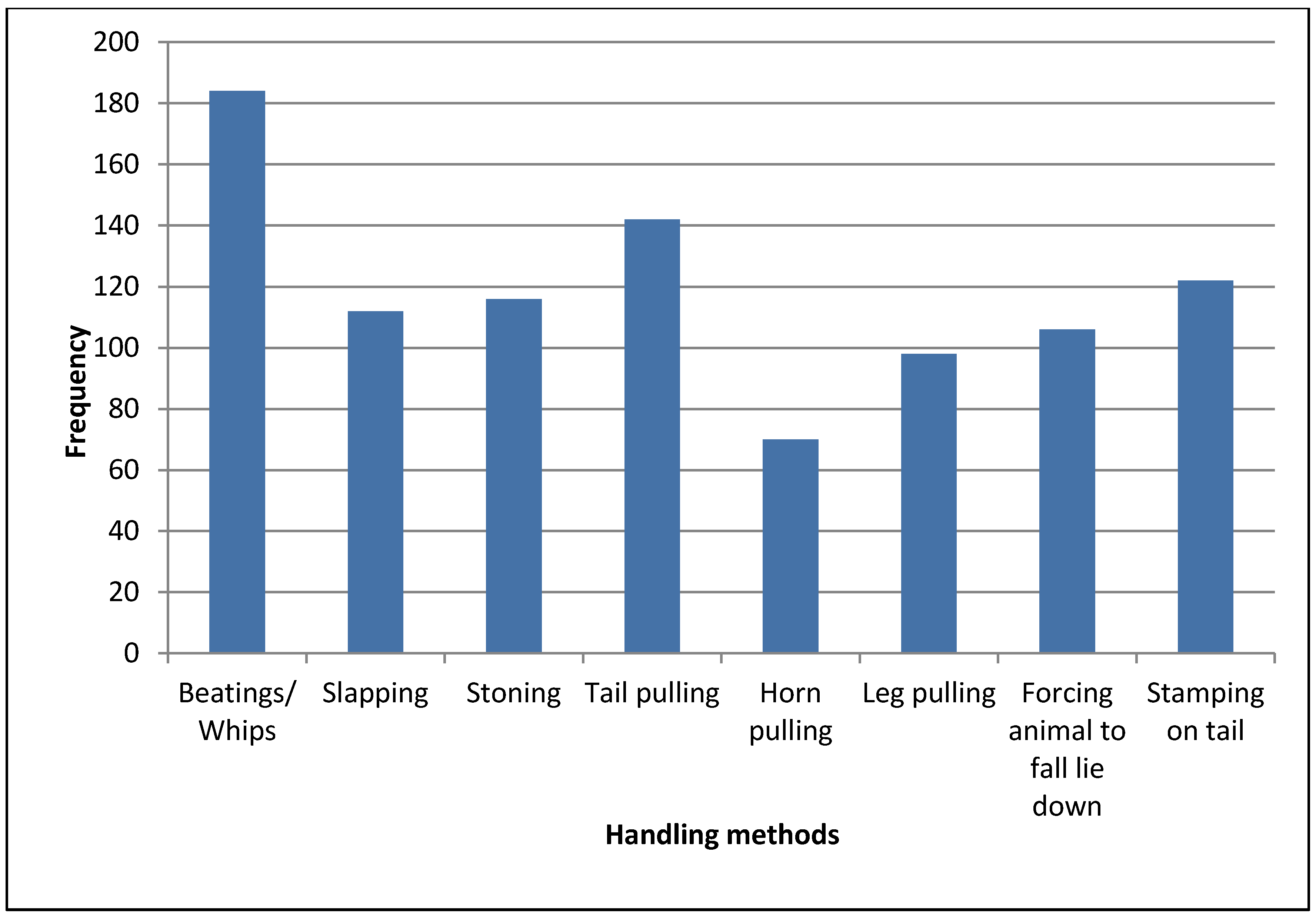

3.2. Behaviours Shown by Cattle and Pre-Slaughter Handling Methods

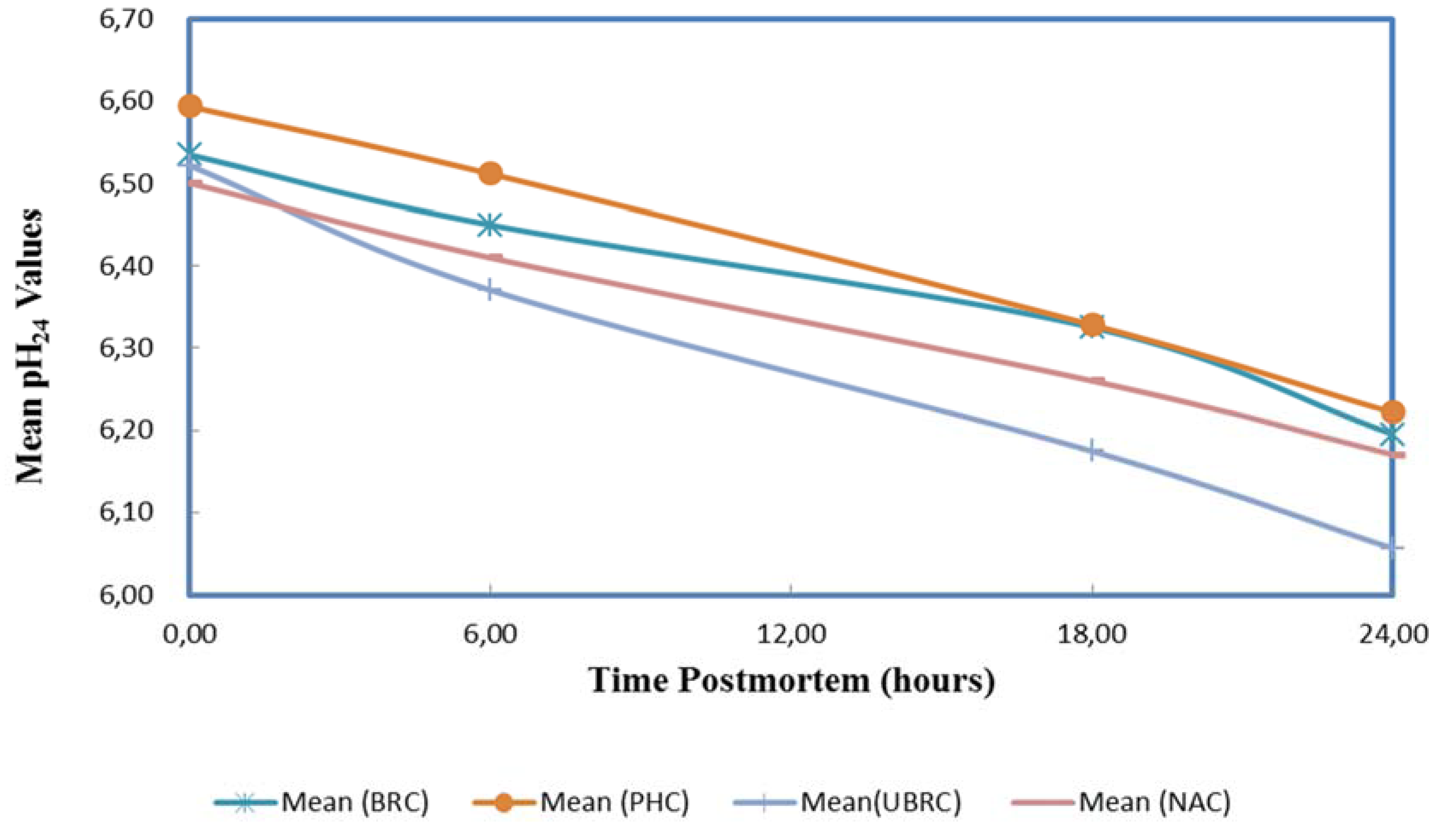

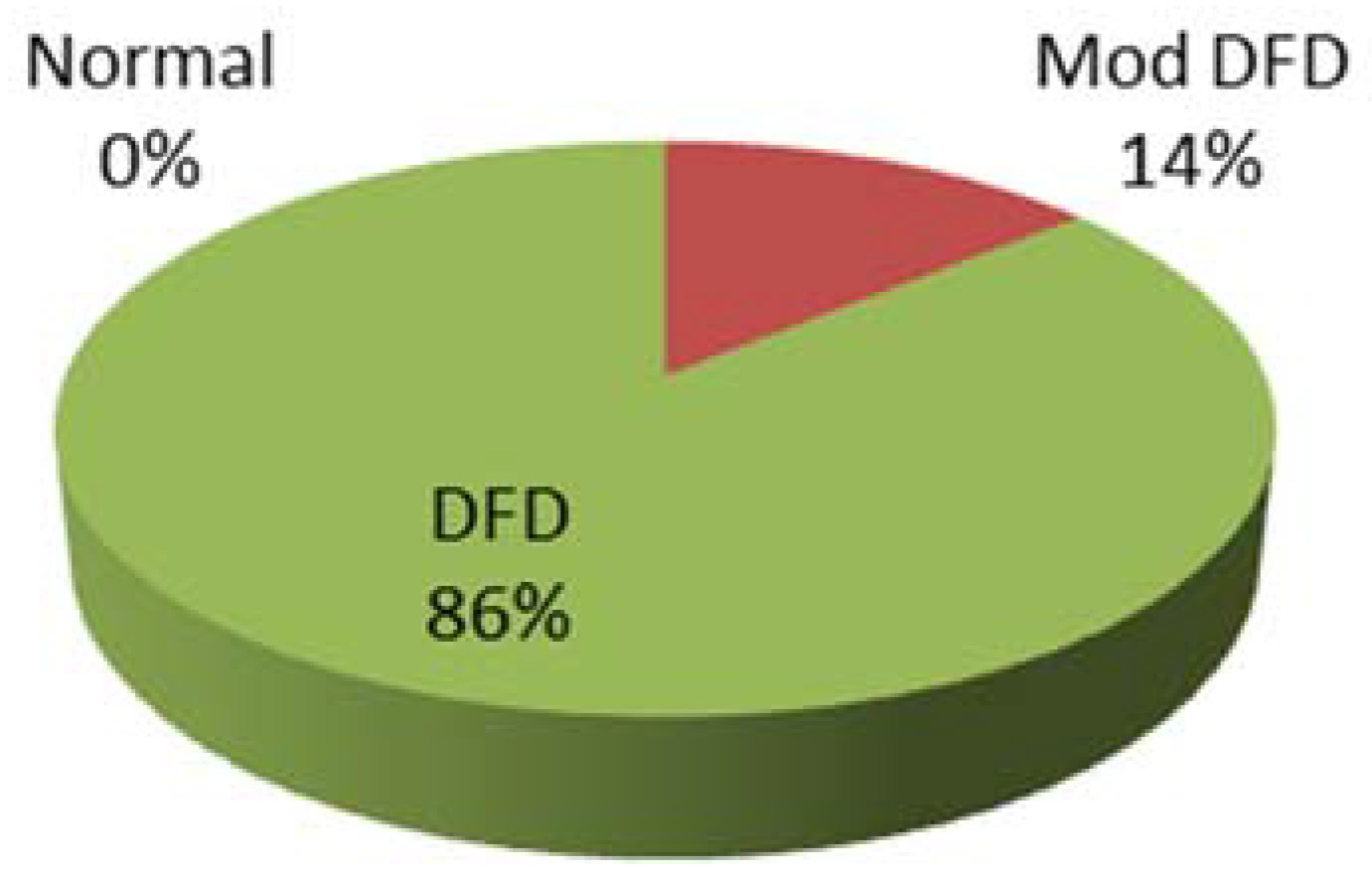

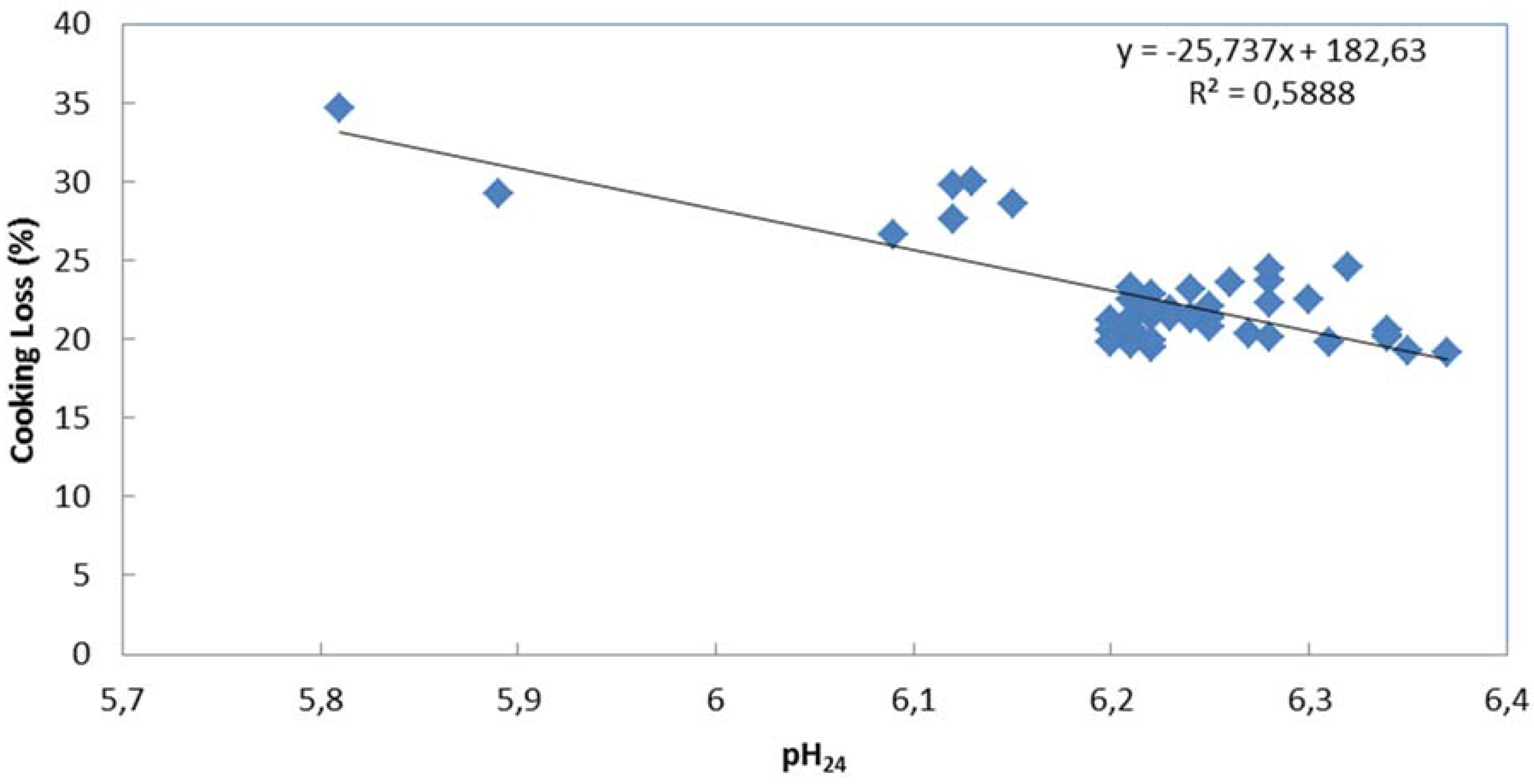

3.3. Meat Quality

| Bruising Category | Minimum No. of Carcasses/Day | Maximum No. of Carcasses/Day | Mean ± SD | n | Percentage of Carcasses (%) |

|---|---|---|---|---|---|

| None 1 | 5 | 13 | 8.9 ± 2.60 | 89 | 17.8 |

| Slight 2 | 21 | 37 | 30.3 ± 4.62 | 303 | 60.6 |

| Severe 3 | 5 | 17 | 10.8 ± 4.02 | 108 | 21.6 |

3.4. Non-Ambulatory Cattle

4. Discussion

4.1. Interview of Stakeholders

4.2. Behaviours Shown by Cattle and Pre-Slaughter Handling Methods

4.3. Meat Quality

4.4. Carcass Bruising

4.5. Non-Ambulatory Cattle

5. Conclusions and Recommendations

- The indications of compromised welfare of the cattle as deduced from the interviews conducted in this study were feed and water deprivation by some dealers and middlemen, avoidance of the use of animal rest stops by some dealers, overcrowding in vehicles, no protection against bad weather, and maltreatment of animals by handlers.

- The prominent methods of handling by cattle handlers which put stress on the animals were lashes/whips, pulling the tails of the animals, stamping on their tails, and hitting them with stones. As a result of these inhumane ways of handling the animals, they exhibited some behaviours to show that they were stressed. Prominent among those behaviours were raising of their tails, kicking, lying down and refusing to move, jumping, running, resistance to be lazooed and pulled, retreating, vocalisation (level 2), panting, head swings, charging at handlers, defecation, urination, and foaming at the mouth.

- Poor handling of cattle prior to slaughter might led to a high incidence of DFD meat (6.22 ± 0.10) and a low mean value of percent cooking loss (22.5 ± 3.25). This proves that poor handling of cattle immediately before slaughter had an effect on meat quality in terms of ultimate pH and percent cooking loss.

- In poorly-handled cattle, cooking loss increased as ultimate pH decreased (that is, an inverse relationship as can be seen from the correlation co-efficient).

- For a period of 7 days, 90 non-ambulatory cattle were sent by carts into the abattoir for slaughter among a total slaughtered animals of 1260. This represents 7.1% of the total number of animals slaughtered within that period. This to some extent is an indication of compromised welfare of cattle pre-slaughter. This study is useful in exposing the sufferings that slaughter animals suffer in the hands of handlers from some farms through transport to the abattoir in Kumasi.

- It is recommended that the preliminary results from this study concerning the compromised welfare situation of slaughter animals during transport, at lairage, and slaughter should be brought to the attention of stakeholders in the business. Further studies are recommended, for instance, to obtain more reliable scientific evidence to help guide legislation on animal welfare in Ghana.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ljungberg, D.; Gebresenbet, G.; Aradom, S. Logistics chain of animal transport and abattoir operations. Biosyst. Eng. 2007, 96, 267–277. [Google Scholar] [CrossRef]

- Gebresenbet, G.; Wikner, I.; Bobobee, E.Y.H.; Maria, G.; Villarroel, M. Effect of Transport Time and Handling on Physiological Responses of Cattle. J. Agric. Sci. Technol. A 2012, 2, 800–814. [Google Scholar]

- Ferguson, D.; Warner, R. Have we underestimated the impact of pre-slaughter stress on meat quality in ruminants? Meat Sci. 2008, 80, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Gregory, N. Animal welfare at markets and during transport and slaughter. Meat Sci. 2008, 80, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Gebresenbet, G.; Ljunberg, D.; Geers, R.; van de Water, G. Effective logistics to improve animal welfare in the production chain, with special emphasis on farm-abattoir system. Int. Soc. Anim. Hyg. 2004, 1, 37–38. [Google Scholar]

- Sossidou, E.; Broom, D.M.; Cziszter, L.T.; Geers, R.; Gebresenbet, G.; Szücs, E. Welfare of Long Distance Transportation of Cattle. Lucrări Ştiintifice Zootehnie Şi Biotehnologii 2009, 42, 603–613. [Google Scholar]

- Deiss, V.; Temple, D.; Ligout, S.; Racine, C.; Bouix, J.; Terlouw, C.; Boissy, A. Can emotional reactivity predict stress responses at slaughter in sheep? Appl. Anim. Behav. Sci. 2009, 119, 193–202. [Google Scholar] [CrossRef]

- Malena, M.; Voslářova, E.; Tomanová, P.; Lepková, R.; Bedáňová, I.; Večerek, V. Influence of travel distance and season upon transport-induced mortality in fattened cattle. Acta Vet. Brno 2006, 75, 619–624. [Google Scholar] [CrossRef]

- Warriss, P.D. The welfare of slaughter pigs during transport. Anim. Welf. 1998, 7, 365–381. [Google Scholar]

- Broom, D.M. The effects of land transport on animal welfare. Rev. Sci. Tech. 2005, 24, 683–691. [Google Scholar] [PubMed]

- Warriss, P.D. The handling of cattle pre-slaughter and its effects on carcass and meat quality. Appl. Anim. Behav. Sci. 1990, 28, 171–186. [Google Scholar] [CrossRef]

- Costa, L.N.; Lo Fiego, D.P.; Tassone, F.; Russo, V. The relationship between carcass bruising in bulls and behaviour observed during pre-slaughter phases. Vet. Res. Commun. 2006, 30 (Suppl. 1), 379–381. [Google Scholar] [CrossRef]

- van Donkergoed, J.; Jewison, G.; Mann, M.; Cherry, B.; Altwasser, B.; Lower, R.; Wiggins, K.; Dejonte, R.; Thorlakson, B.; Moss, E.; et al. Canadian Beef Quality Audit. Can. J. Anim. Sci. 1997, 38, 217–225. [Google Scholar]

- Chambers, P.G.; Grandin, T. Guidelines for Humane Handling, Transport and Slaughter of Livestock from the Food and Agriculture Organisation of the United Nations Regional Office for Asia and the Pacific. 2001. Available online: http://www.aphca.org/publications/files/2001-04_low.pdf (accessed on 7 July 2009).

- Cox, V.S.; Marsh, W.E.; Steurnagel, G.R. Downer cow occurrence in Minnesota dairy herds. Prev. Vet. Med. 1986, 4, 249–260. [Google Scholar] [CrossRef]

- Carolyn, L.S.; Payne, M.A.; Berry, S.L.; Reynolds, J.P. A review of the causes, prevention, and welfare of nonambulatory cattle. J. Am. Vet. Med. Assoc. 2007, 231, 227–234. [Google Scholar] [CrossRef] [PubMed]

- Zobil, B.B.; Acting Productions Manager, Kumasi Abattoir Company Limited. Kumasi, Ghana. Personal Communication, 17 March 2010.

- Adzitey, F. MiniReview-Effect of pre-slaughter animal handling on carcass and meat quality. Int. Food Res. J. 2011, 18, 485–491. [Google Scholar]

- Afful, C.R.; Kumasi Abattoir Company Limited, Kumasi, Ghana. Personal Communication, 13 July 2009.

- Obiri-Danso, K.; Hogarh, J.N.; Antwi-Agyei, P. Assessment of contamination of singed hides from cattle and goats by heavy metals in Ghana. Afr. J. Environ. Sci. Technol. 2008, 2, 217–221. [Google Scholar]

- Quilo, S.A.; Pohlman, F.W.; Dias-Morse, P.N. Instrumental colour characteristics of ground beef treated with potassium lactate, sodium metasilicate, peroxyacetic acid or acidified chlorite. AAES Res. Ser. 2006, 545, 31–33. [Google Scholar]

- Okeudo, N.J.; Moss, B.W. Interrelationships amongst carcass and meat quality characteristics of sheep. Meat Sci. 2005, 69, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Strappini, A.C.; Metz, J.H.M.; Gallo, C.B.; Kemp, B. Origin and assessment of bruises in beef cattle at slaughter. Anim. Sci. 2009, 3, 728–736. [Google Scholar]

- Miller, M. Dark, Firm and Dry Beef. Beef Facts-Product Enhancements. 2007. Available online: http://www.beefresearch.org/…/BeefResearch/DarkFirmDryBeef.pdf (accessed on 3 May 2010).

- Immonen, K.; Ruusunen, M.; Puolanne, E. Some effects of residual glycogen concentration on the physical sensory quality of normal pH beef. Meat Sci. 2000, 55, 33–38. [Google Scholar] [CrossRef] [PubMed]

- Grandin, T. Livestock-handling quality assurance. J. Anim. Sci. 2001, 79 (E Suppl.), E239–E248. [Google Scholar]

- SCAHAW. The Welfare of Animals during Transport. Scientific Report of the Scientific Panel on Animal Health and Welfare on a request from the Commission Related to the Welfare of Animals during Transport. 2004. Available online: http://www.efsa.europa.eu/en/efsajournal/doc/ahaw_report_animaltransportwelfare_en1.pdf?ssbinary=true (accessed on 8 September 2009).

- Grandin, T. Principles for Low Stress Cattle Handling. AG/Beef/06. 2005. Available online: http://extension.usu.edu/files/publications/beef6stress.pdf (accessed on 22 May 2009).

- Atkinson, S. The Importance of Animal Handling Technique and Animal Handling Facility Design for the Welfare of Slaughter Animals. NJF Report. 2005. Available online: http://www.njf.nu/filebank/files/20060904$211818$fil$TeQq2b6EMZ55RzFnx4YL.pdf (accessed on 7 April 2010).

- Maltin, C.; Balcerzak, D.; Tilley, R.; Delday, M. Determinants of meat quality: Tenderness. Proc. Nutr. Soc. 2003, 62, 337–347. [Google Scholar] [CrossRef] [PubMed]

- MSA. Australian Beef Carcass Appraisal System. Meat and Livestock Australia. 2006. Available online: http:www.primex.net.au/Primex_2/encoded/MSA%2016pp.pdf (accessed on 25 March 2010).

- Aradom, S.; Gebresenbet, G.; Bulitta, F.S.; Bobobee, E.Y.; Adam, M. Effect of Transport Times on Welfare of Pigs. J. Agric. Sci. Technol. A 2012, 2, 544–562. [Google Scholar]

- Grandin, T. Handling methods and facilities to reduce stress on cattle. Vet. Clin. North Am. Food Anim. Pract. 1998, 14, 325–341. [Google Scholar] [PubMed]

- Owens, C.M.; Sams, A.R. The influence of transportation on turkey meat quality. Poult. Sci. 2000, 79, 1204–1207. [Google Scholar] [CrossRef] [PubMed]

- Mallia, J.G.; Barbut, S.; Vainllancourt, J.P.; Martin, S.W.; McEwen, S.A. A dark, firm dry-like condition in turkeys condemned for cyanosis. Poult. Sci. 2000, 79, 281–285. [Google Scholar] [CrossRef] [PubMed]

- Costa, L.N.; Lo Fiego, D.P.; Russo, V. Study on the Relationship between Pre-Slaughter and Carcass Bruising in Calf and Bull Carcasses. NJF Report. 2005. Available online: http://www.njf.nu/filebank/files/20060904$211818$fil$TeQq2b6EMZ55RzFnx4YL.pdf (accessed on 7 April 2010).

- Grandin, T. Bruising on southwestern feedlot cattle. J. Anim. Sci. 1981, 53 (Suppl. 1), 213. [Google Scholar]

- Reynolds, J. Dealing with Downers. AABP Proc. 2006, 39, pp. 28–31. Available online: http://ansci.colostate.edu/files/dairy_news/v13_4/Downers.pdf (accessed on 26 March 2010).

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frimpong, S.; Gebresenbet, G.; Bobobee, E.; Aklaku, E.D.; Hamdu, I. Effect of Transportation and Pre-Slaughter Handling on Welfare and Meat Quality of Cattle: Case Study of Kumasi Abattoir, Ghana. Vet. Sci. 2014, 1, 174-191. https://doi.org/10.3390/vetsci1030174

Frimpong S, Gebresenbet G, Bobobee E, Aklaku ED, Hamdu I. Effect of Transportation and Pre-Slaughter Handling on Welfare and Meat Quality of Cattle: Case Study of Kumasi Abattoir, Ghana. Veterinary Sciences. 2014; 1(3):174-191. https://doi.org/10.3390/vetsci1030174

Chicago/Turabian StyleFrimpong, Samuel, Girma Gebresenbet, Emmanuel Bobobee, Elias D. Aklaku, and Ibrahim Hamdu. 2014. "Effect of Transportation and Pre-Slaughter Handling on Welfare and Meat Quality of Cattle: Case Study of Kumasi Abattoir, Ghana" Veterinary Sciences 1, no. 3: 174-191. https://doi.org/10.3390/vetsci1030174

APA StyleFrimpong, S., Gebresenbet, G., Bobobee, E., Aklaku, E. D., & Hamdu, I. (2014). Effect of Transportation and Pre-Slaughter Handling on Welfare and Meat Quality of Cattle: Case Study of Kumasi Abattoir, Ghana. Veterinary Sciences, 1(3), 174-191. https://doi.org/10.3390/vetsci1030174