The Impact of Collaborative Communication on the Physical Distribution Service Quality of Soft Drinks: A Case Study of Beverage Manufacturing Companies in Greece

Abstract

:1. Introduction

1.1. Background to the Study

1.2. Problem Statement

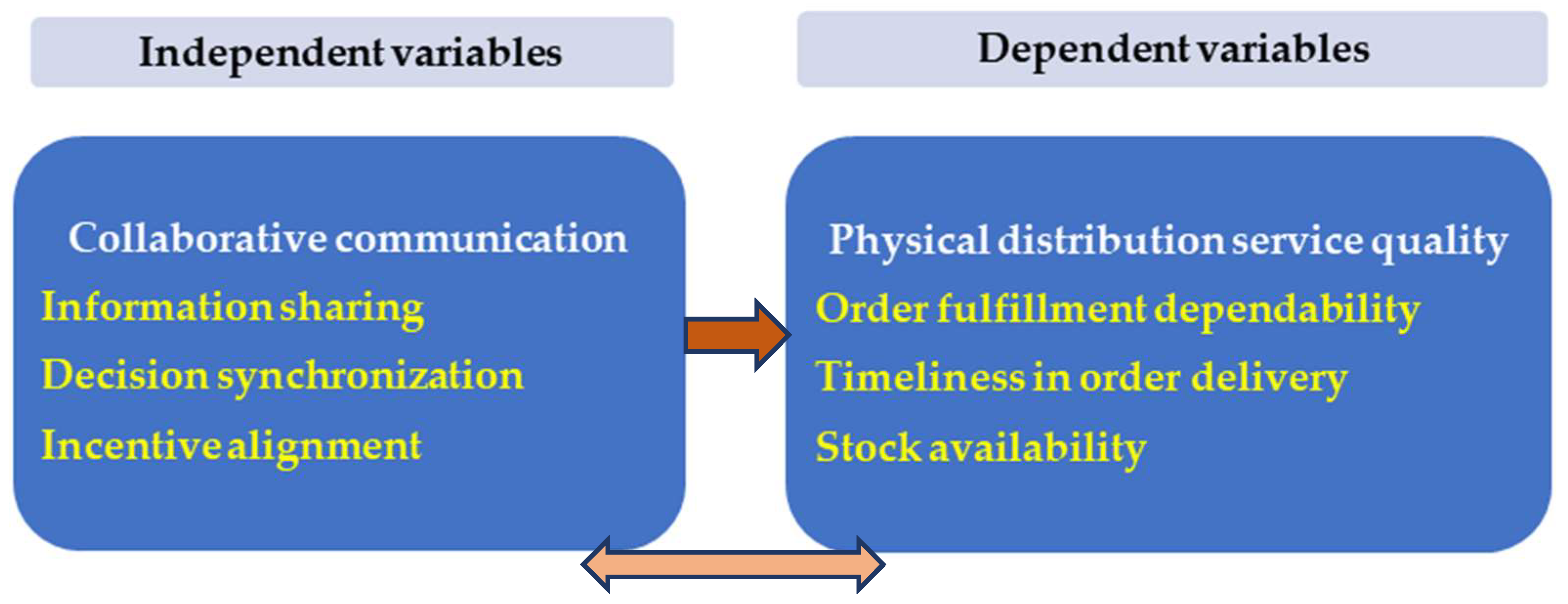

1.3. Objectives of the Study

- To explore the effect of information sharing on the quality of the physical distribution of beverages;

- To establish the relationship between decision synchronization and the quality of the physical distribution of beverages;

- To determine the effect of incentive alignment on the quality of the physical distribution of beverages.

- What is the effect of information sharing on the quality of the physical distribution of beverages?

- What is the relationship between decision synchronization and the quality of the physical distribution of beverages?

- What is the effect of incentive alignment on the quality of the physical distribution of beverages?

1.4. Significance of the Study

2. Literature Review

2.1. Theoretical Review

2.2. Empirical Review

2.2.1. Physical Distribution

2.2.2. Collaborative Communication

2.2.3. Information Sharing

2.2.4. Decision Synchronization

2.2.5. Incentive Alignment

2.3. Conclusion and Research Gap

3. Methodology

3.1. Research Design, Study Area, Target Population, and Data Collection

3.2. Data Analysis

- Y = Physical distribution service quality;

- β0 = constant (coefficient of intercept);

- Χ1 = Information Sharing;

- Χ2 = Decision Synchronization;

- Χ3 = Incentive Alignment;

- ε = Represents the error term in the multiple regression model.

3.3. Ethical Considerations

4. Results

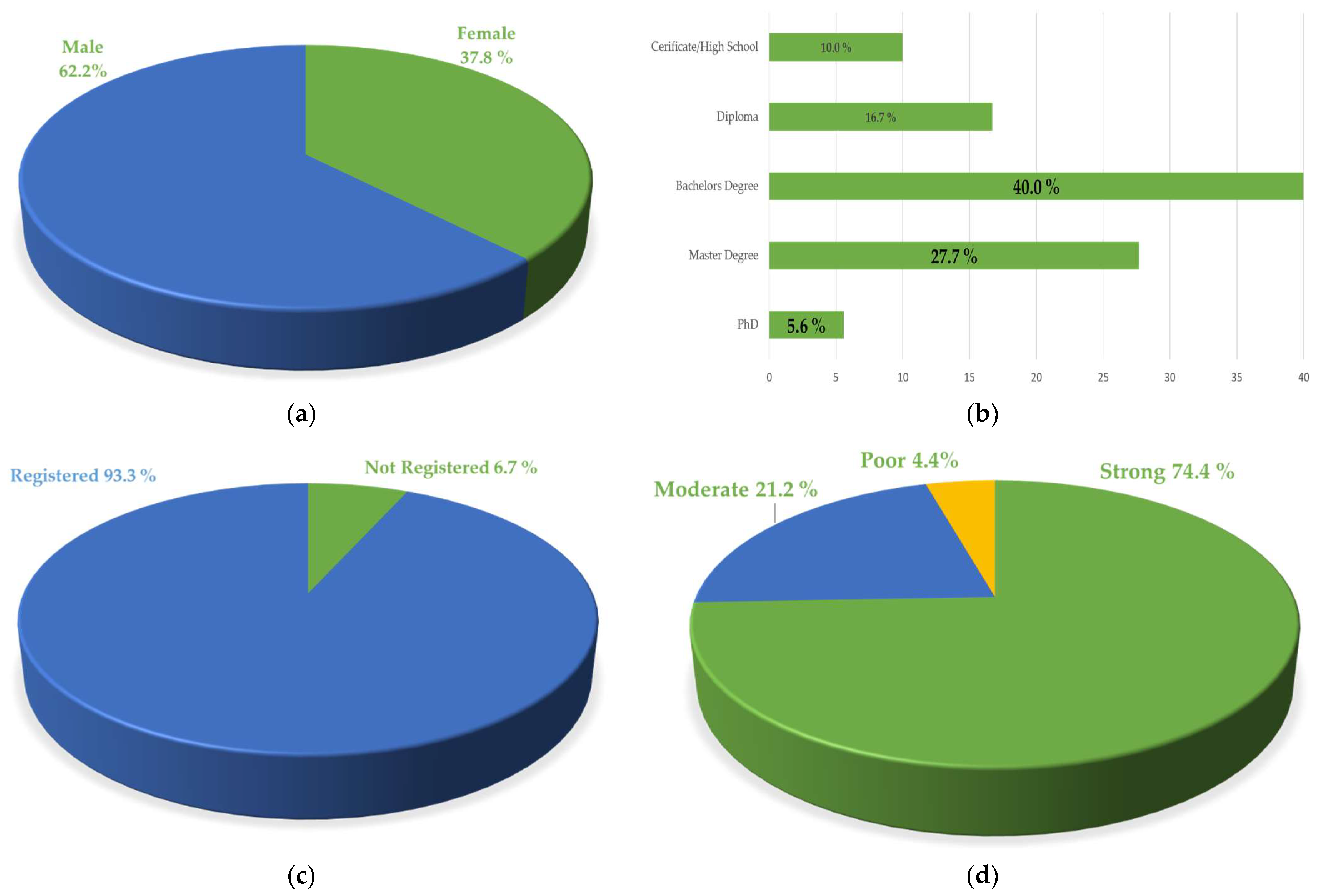

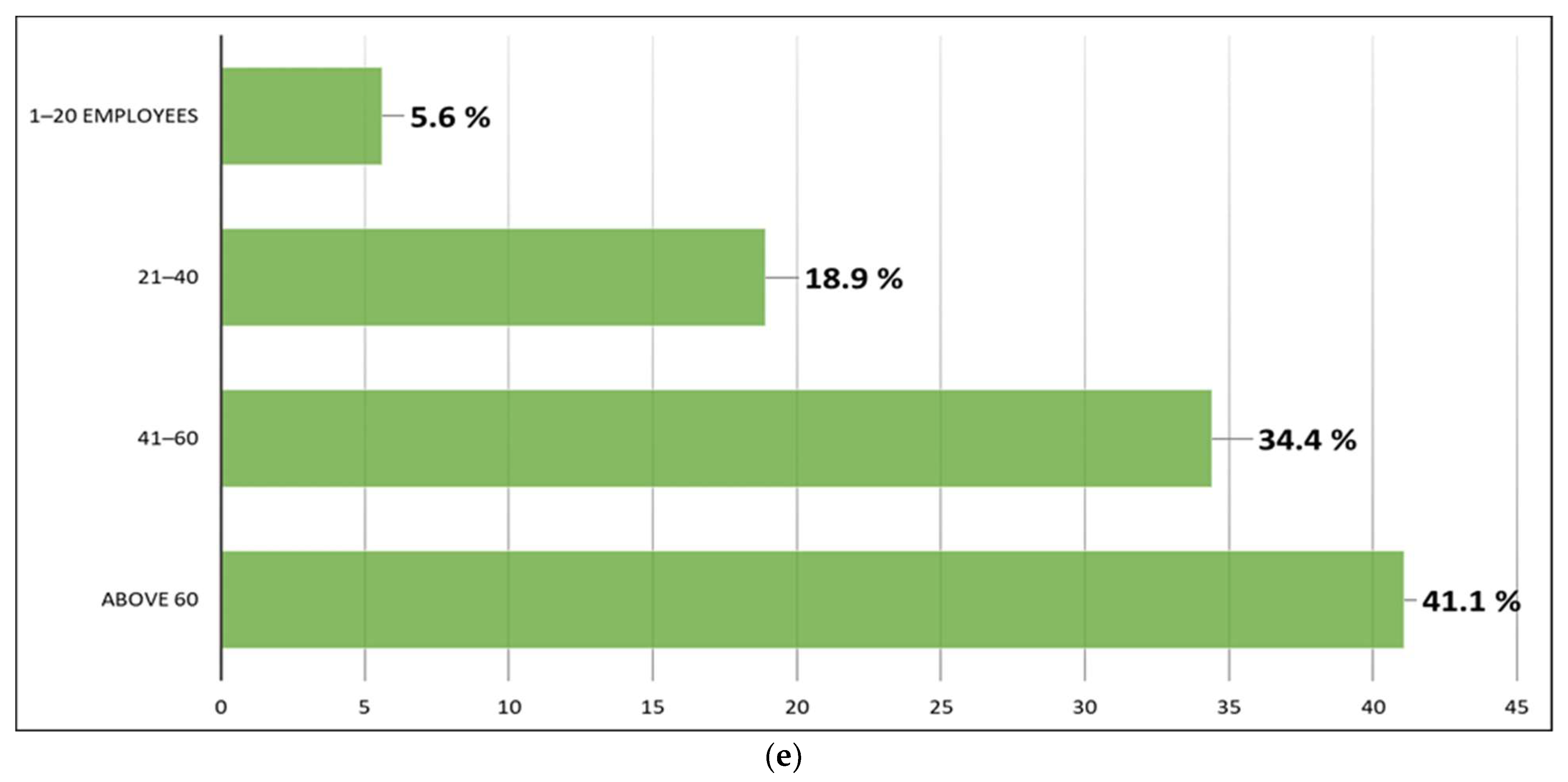

4.1. Demographic Characteristics

4.2. Descriptive Analysis

4.3. Correlation Analysis

4.4. Diagnostic Test for Autocorrelation

4.5. Results of Regression Analysis

5. Discussion

- A relatively high rate of unethical business activity is recorded in Greece, where employees and collaborators share confidential information with competing producers in order to be personally rewarded. This implies the possible leakage of important information between competing companies.

- A significant number of soft drink distributors are not sole distributors, which means that they carry and distribute brands from different companies and are not in a position to consult all the businesses whose products they sell when making decisions. Since distributors offer competing brands and may be tempted to reveal sensitive information to competitors in exchange for better terms, manufacturers are wary about sharing information and collaborative communication.

- Most of the time, distributors are informed about producers’ choices mainly for implementation reasons; the synchronizing of decisions is not critical to the Greek soft drinks industry. Distributors, for example, are required to follow the suggested retail price of a particular soft drink brand. The distributor may charge more than the listed retail price, but the products cannot be sold for less than that amount [1,3,4].

Recommendations and Proposals

- Establishing exclusive cooperation between producers and distributors;

- Agreement for the signing of confidentiality agreements between producers and distributors, as well as joint drafting of plans for quality and operational procedures in information and distribution;

- Adoption and training of personnel in modern means of communication and information;

- Joint training of the personnel of the manufacturers and distributors in common operational matters.

6. Conclusions

6.1. Limitations

6.2. Areas for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Igwe, S.R.; Robert, C.P.; Chukwu, G.C. Improving on-time delivery through supply chain collaboration: The experience of brewery firms in South-South, Nigeria. J. Asian Bus. Strateg. 2016, 6, 136–149. [Google Scholar] [CrossRef]

- Wetzel, P.; Hofmann, E. Toward a Multi-Sided Model of Service Quality for Logistics Service Providers. Adm. Sci. 2020, 10, 79. [Google Scholar] [CrossRef]

- Madzimure, J. Enhancing supplier integration through e-design and e-negotiation in small and medium enterprises. S. Afr. J. Entrep. Small Bus. Manag. 2020, 12, a300. [Google Scholar] [CrossRef]

- Madzimure, J. Examining the influence of supplier integration on supply chain performance in South African small and medium enterprises. S. Afr. J. Entrep. Small Bus. Manag. 2020, 12, a312. [Google Scholar] [CrossRef]

- Ibn El Farouk, I.; Moufad, I.; Frichi, Y.; Arif, J.; Jawab, F. Proposing a Supply Chain Collaboration Framework for Synchronous Flow Implementation in the Automotive Industry: A Moroccan Case Study. Information 2020, 11, 431. [Google Scholar] [CrossRef]

- Kontogeorgos, A.; Sergaki, P.; Chatzitheodoridis, F. An Assessment of New Farmers’ Perceptions about Agricultural Cooperatives. J. Dev. Entrep. 2017, 22, 1750003. [Google Scholar] [CrossRef]

- Chatzitheodoridis, F.; Kontogeorgos, A. Exploring of a Small-Scale Tourism Product under Economic Instability: The Case of a Greek Rural Border Area. Economies 2020, 8, 52. [Google Scholar] [CrossRef]

- Banomyong, R. Collaboration in Supply Chain Management: A Resilience Perspective; International Transport Forum Discussion Papers; OECD Publishing: Paris, France, 2018; Volume 6, pp. 10–18. [Google Scholar]

- Kempa, S.; Tanuwijaya, N.C.; Tarigan, Z.J.H. The Impact of Supply Chain Collaboration in Logistic Service for Small Medium Enterprise in East Java, Indonesia. KnE Life Sci. 2020, 5, 207–216. [Google Scholar] [CrossRef]

- Ijadi Maghsoodi, A.; Saghaei, A.; Hafezalkotob, A. Service quality measurement model integrating an extended SERVQUAL model and a hybrid decision support system. Eur. Res. Manag. Bus. Econ. 2019, 25, 151–164. [Google Scholar] [CrossRef]

- Ravichandran, K.; Tamil, M.; Arun Kumar, S.; Prabhakaran, S. Influence of service quality on customer satisfaction application of SERVQUAL model. Int. J. Bus. Manag. 2010, 5, 117–124. [Google Scholar] [CrossRef]

- Rezaei, J.; Kothadiya, O.; Tavasszy, L.; Kroesen, M. Quality assessment of airline baggage handling systems using SERVQUAL and BWM. Tour. Manag. 2018, 66, 85–93. [Google Scholar] [CrossRef]

- Mathong, P.; Sureeyatanapas, P.; Arunyanart, S.; Niyamosoth, T. The assessment of service quality for third-party logistics providers in the beverage industry. Cogent Eng. 2020, 7, 1785214. [Google Scholar] [CrossRef]

- Banomyong, R.; Supatn, N. Selecting logistics providers in Thailand: A shippers’ perspective. Eur. J. Mark. 2011, 45, 419–437. [Google Scholar] [CrossRef]

- Ramanathan, R.; Karpuzcu, H. Comparing perceived and expected service using an AHP model: An application to measure service quality of a company engaged in pharmaceutical distribution. OPSEARCH 2011, 48, 136–152. [Google Scholar] [CrossRef]

- Kahnali, R.A.; Esmaeili, A. An integration of SERVQUAL dimensions and logistics service quality indicators (A case study). Int. J. Serv. Oper. Manag. 2015, 21, 289–309. [Google Scholar] [CrossRef]

- Neo, H.-Y.; Xie, M.; Tsui, K.-L. Service quality analysis: Case study of a 3PL company. Int. J. Logist. Syst. Manag. 2004, 1, 64–80. [Google Scholar] [CrossRef]

- Parasuraman, A.; Zeithaml, V.A.; Berry, L.L. Alternative scales for measuring service quality: A comparative assessment based on psychometric and diagnostic criteria. J. Retail. 1994, 70, 201–230. [Google Scholar] [CrossRef]

- Cho, I.J.; Kim, Y.J.; Kwak, C. Application of SERVQUAL and fuzzy quality function deployment to service improvement in service centres of electronics companies. Total Qual. Manag. Bus. Excell. 2016, 27, 368–381. [Google Scholar] [CrossRef]

- Yadollahi, S.; Kazemi, A.; Ranjbarian, B. Identifying and prioritizing the factors of service experience in banks: A best-Worst method. Decis. Sci. Lett. 2018, 7, 455–464. [Google Scholar] [CrossRef]

- Lupo, T. A fuzzy ServQual based method for reliable measurements of education quality in Italian higher education area. Expert Syst. Appl. 2013, 40, 7096–7110. [Google Scholar] [CrossRef]

- Canciglieri Junior, O.; Zierhut, R.T.; Mattioda, R.A.; Estorilio, C.C.A.; Steiner, M.T.A.; Neto, P.J.S. Model for the diagnosis of quality in service processes: A case study applied to a private higher education institution. Cogent Eng. 2019, 6, 1702856. [Google Scholar] [CrossRef]

- Cuesta-Valiño, P.; Gutiérrez-Rodríguez, P.; García-Henche, B. Word of mouth and digitalization in small retailers: Tradition, authenticity, and change. Technol. Forecast. Soc. Change 2022, 175, 121382. [Google Scholar] [CrossRef]

- Pan, H.; Ha, H.-Y. Service Quality and Satisfaction in the Context of Varying Levels of Restaurant Image and Customer Orientation during the COVID-19 Pandemic. Sustainability 2021, 13, 9694. [Google Scholar] [CrossRef]

- Sirimongkol, T. The effects of restaurant service quality on revisit intention in pandemic conditions: An empirical study from Khonkaen, Thailand. J. Foodserv. Bus. Res. 2022, 25, 233–251. [Google Scholar] [CrossRef]

- Ogunjimi, A.; Rahman, M.; Islam, N.; Hasan, R. Smart mirror fashion technology for the retail chain transformation. Technol. Forecast. Soc. Chang. 2021, 173, 121118. [Google Scholar] [CrossRef]

- Sulphey, M.M.; Mohamed, J.K. Ascertaining service quality and medical practitioners’ sensitivity towards surgical instruments using SERVQUAL. Benchmarking 2021, 28, 370–405. [Google Scholar] [CrossRef]

- Júnior, D.S.G.; Soares, E.J.O.; de Oliveira, L.A.B.; de Medeiros, D.D. Determinants of Quality of Health Insurance Services in Brazil. J. Health Manag. 2021, 23, 401–413. [Google Scholar] [CrossRef]

- Akdag, H.; Kalaycı, T.; Karagöz, S.; Zülfikar, H.; Giz, D. The evaluation of hospital service quality by fuzzy MCDM. Appl. Soft Comput. 2014, 23, 239–248. [Google Scholar] [CrossRef]

- Kachwala, T.; Panchal, D.; Bali, A. The relationships among overall service quality, customer satisfaction and customer loyalty in library services. Int. J. Product. Qual. Manag. 2021, 33, 198–217. [Google Scholar] [CrossRef]

- Lupo, T. Fuzzy ServPerf model combined with ELECTRE III to comparatively evaluate service quality of international airports in Sicily. J. Air Transp. Manag. 2015, 42, 249–259. [Google Scholar] [CrossRef]

- Parasuraman, A.; Zeithaml, V.A.; Berry, L.L. A Conceptual Model of Service Quality and Its Implications for Future Research. J. Mark. 1985, 49, 41–50. [Google Scholar] [CrossRef]

- Pena, M.M.; da Silva, E.M.S.; Tronchin, D.M.R.; Melleiro, M.M. The use of the quality model of Parasuraman, Zeithaml and Berry in health services. Rev. Esc. Enferm. USP 2013, 47, 1227–1232. [Google Scholar] [CrossRef]

- Gouws, E.; Motala, T. Quality of service delivered by alcoholic beverage suppliers to customers in the South African hospitality industry. Afr. J. Hosp. Tour. Leis. 2019, 8, 1–13. [Google Scholar]

- Foundation for Economic & Industrial Research. Food and Beverages Industry. Facts & Figures 2021; IOBE: Athens, Greece, 2022. (In Greek) [Google Scholar]

- Ganatsios, V.; Nigam, P.; Plessas, S.; Terpou, A. Kefir as a Functional Beverage Gaining Momentum towards Its Health Promoting Attributes. Beverages 2021, 7, 48. [Google Scholar] [CrossRef]

- Syrokou, M.K.; Papadelli, M.; Ntaikou, I.; Paramithiotis, S.; Drosinos, E.H. Sugary Kefir: Microbial Identification and Biotechnological Properties. Beverages 2019, 5, 61. [Google Scholar] [CrossRef]

- Zerva, I.; Remmas, N.; Ntougias, S. Biocatalyst Potential of Cellulose-Degrading Microorganisms Isolated from Orange Juice Processing Waste. Beverages 2019, 5, 21. [Google Scholar] [CrossRef]

- Lakka, A.; Bozinou, E.; Stavropoulos, G.; Samanidis, I.; Athanasiadis, V.; Dourtoglou, V.G.; Makris, D.P.; Lalas, S.I. Enhancement of Polyphenols Recovery from Rosa canina, Calendula officinalis and Castanea sativa Using Pulsed Electric Field. Beverages 2021, 7, 63. [Google Scholar] [CrossRef]

- Pappas, V.M.; Lakka, A.; Palaiogiannis, D.; Bozinou, E.; Ntourtoglou, G.; Batra, G.; Athanasiadis, V.; Makris, D.P.; Dourtoglou, V.G.; Lalas, S.I. Use of Pulsed Electric Field as a Low-Temperature and High-Performance “Green” Extraction Technique for the Recovery of High Added Value Compounds from Olive Leaves. Beverages 2021, 7, 45. [Google Scholar] [CrossRef]

- Alibante, A.; Lakka, A.; Bozinou, E.; Chatzilazarou, A.; Lalas, S.; Makris, D.P. Integrated Green Process for the Extraction of Red Grape Pomace Antioxidant Polyphenols Using Ultrasound-Assisted Pretreatment and β-Cyclodextrin. Beverages 2021, 7, 59. [Google Scholar] [CrossRef]

- Ferretti, F.; Mariani, M.; Sarti, E. Does the Prevalence of Obesity Affect the Demand for Soft Drinks? Evidence from Cross-Country Panel Data. Int. J. Environ. Res. Public Health 2022, 19, 938. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-M.; Lee, E. Association between Soft-Drink Intake and Obesity, Depression, and Subjective Health Status of Male and Female Adults. Int. J. Environ. Res. Public Health 2021, 18, 10415. [Google Scholar] [CrossRef] [PubMed]

- Lieder, B.; Čonka, J.; Reiner, A.T.; Zabel, V.; Ameur, D.; Somoza, M.M.; Šebeková, K.; Celec, P.; Somoza, V. Long-Term Consumption of a Sugar-Sweetened Soft Drink in Combination with a Western-Type Diet Is Associated with Morphological and Molecular Changes of Taste Markers Independent of Body Weight Development in Mice. Nutrients 2022, 14, 594. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.-P.; Jia, C.-X.; Li, S.-X. The Association of Soft Drink Consumption and the 24-Hour Movement Guidelines with Suicidality among Adolescents of the United States. Nutrients 2022, 14, 1870. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.A.; Qamar, B.; Fituri, S.; Akbar, Z.A.; Al-Abdi, T.; Shi, Z. Association between Soft Drink Consumption and Asthma among Qatari Adults. Nutrients 2019, 11, 606. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S.; Kim, T.J.; Hong, S.K.; Min, C.; Yoo, D.M.; Wee, J.H.; Choi, H.G. Impact of Coffee/Green Tea/Soft Drink Consumption on the Risk of Hyperuricemia: A Cross-Sectional Study. Int. J. Environ. Res. Public Health 2021, 18, 7299. [Google Scholar] [CrossRef] [PubMed]

- Crichton, G.; Alkerwi, A.; Elias, M. Diet Soft Drink Consumption is Associated with the Metabolic Syndrome: A Two Sample Comparison. Nutrients 2015, 7, 3569–3586. [Google Scholar] [CrossRef]

- Katzmarzyk, P.T.; Broyles, S.T.; Champagne, C.M.; Chaput, J.-P.; Fogelholm, M.; Hu, G.; Kuriyan, R.; Kurpad, A.; Lambert, E.V.; Maia, J.; et al. Relationship between Soft Drink Consumption and Obesity in 9–11 Years Old Children in a Multi-National Study. Nutrients 2016, 8, 770. [Google Scholar] [CrossRef]

- Pengpid, S.; Peltzer, K. High Carbonated Soft Drink Intake is Associated with Health Risk Behavior and Poor Mental Health among School-Going Adolescents in Six Southeast Asian Countries. Int. J. Environ. Res. Public Health 2020, 17, 132. [Google Scholar] [CrossRef]

- Shi, Z.; Malki, A.; Abdel-Salam, A.-S.G.; Liu, J.; Zayed, H. Association between Soft Drink Consumption and Aggressive Behaviour among a Quarter Million Adolescents from 64 Countries Based on the Global School-Based Student Health Survey (GSHS). Nutrients 2020, 12, 694. [Google Scholar] [CrossRef]

- Marro, F.; Bottenberg, P.; Jacquet, W.; Martens, L. School Food Policies Related to Soft Drink and Fruit Juice Consumption as a Function of Education Type in Flanders, Belgium. Int. J. Environ. Res. Public Health 2019, 16, 2718. [Google Scholar] [CrossRef] [PubMed]

- Campos-Ramírez, C.; Ramírez-Amaya, V.; Olalde-Mendoza, L.; Palacios-Delgado, J.; Anaya-Loyola, M.A. Soft Drink Consumption in Young Mexican Adults Is Associated with Higher Total Body Fat Percentage in Men but Not in Women. Foods 2020, 9, 1760. [Google Scholar] [CrossRef] [PubMed]

- Azizi, S.; Jamali Kapak, S.; Tarhandeh, F. Physical Distribution Service Quality through Iranian Convenience Stores Retailers Perspectives: A Mixed Method Approach. Iran. J. Manag. Stud. 2014, 7, 121–150. [Google Scholar]

- Ahimbisibwe, A.; Ssentamu, A.; Kalekyezi, B. Supplier delivery performance of public procurement contracts in ugandan central government procuring and disposing entities (pdes). Eur. J. Logist. Purch. Supply Chain Manag. 2019, 7, 12–39. [Google Scholar]

- Boyce, W.S. Supply Chain Relationships in Procurement: Is Collaboration Reality? Ph.D. Thesis, University of Missouri, St. Louis, MO, USA, 2014. [Google Scholar]

- Le, T.M.H.; Nguyen, T.H.; Quy, N.L.D. Upstream Supply Chain Collaboration (SCC): A Case Study in Danang City, Viet Nam. Acad. Strateg. Manag. J. 2021, 20, 1–10. [Google Scholar]

- Derek, F.; Tukamuhabwa, B.R.; Eyaa, S. The effect of trust and commitment on vertical collaboration and physical distribution service quality. Int. J. Bus. Behav. Sci. 2012, 2, 49–67. [Google Scholar]

- Naspetti, S.; Lampkin, N.; Nicolas, P.; Stolze, M.; Zanoli, R. Organic supply chain collaboration: A case study in eight EU countries. J. Food Prod. Mark. 2011, 17, 141–162. [Google Scholar] [CrossRef]

- Baihaqi, I.; Sohal, A.S. The impact of information sharing in supply chains on organisational performance: An empirical study. Prod. Plan. Control 2013, 24, 743–758. [Google Scholar] [CrossRef]

- Van der Vorst, J.G.A.J.; Da Silva, C.; Trienekens, J.H. Agro-Industrial Supply Chain Management: Concepts and Applications; FAO: Rome, Italy, 2008; p. 17. [Google Scholar]

- Kontogeorgos, A.; Chatzitheodoridis, F.; Loizou, E. Adaptation strategies for the greek agricultural cooperatives during the economic crisis. Agric. Econ. 2016, 62, 26–34. [Google Scholar] [CrossRef]

- Kalfas, D.; Zagkas, D.; Dragozi, E.; Zagkas, T. Estimating value of the ecosystem services in the urban and peri-urban green of a town Florina-Greece, using the CVM. Int. J. Sustain. Dev. World Ecol. 2020, 27, 310–321. [Google Scholar] [CrossRef]

- Kalfas, D.; Chatzitheodoridis, F.; Loizou, E.; Melfou, K. Willingness to Pay for Urban and Suburban Green. Sustainability 2022, 14, 2332. [Google Scholar] [CrossRef]

- Kalogiannidis, S.; Toska, E.; Chatzitheodoridis, F.; Kalfas, D. Using School Systems as a Hub for Risk and Disaster Management: A Case Study of Greece. Risks 2022, 10, 89. [Google Scholar] [CrossRef]

| SD | D | U | A | SA | |

|---|---|---|---|---|---|

| % | % | % | % | % | |

| 1. Information Sharing | |||||

| The distributor is well informed about the different items that are on sale. | 1.2 | 1.5 | 2.6 | 33.5 | 61.2 |

| Price modifications for specific items are communicated to distributors. | 1.5 | 4.7 | 6.8 | 24.1 | 62.9 |

| The distributor is open to providing sensitive information about on-hand inventory levels. | 23.9 | 69.2 | 4.3 | 0.9 | 1.7 |

| Every distributor in the distribution chain receives data from the point of sale. | 10.3 | 11.7 | 4.2 | 18.2 | 55.6 |

| For the expected products to be distributed, there is an aggregate demand projection. | 2.0 | 2.7 | 1.3 | 73.5 | 20.5 |

| 2. Decision Synchronization | |||||

| Promotional activities are planned in collaboration with the distributor. | 33.3 | 46.2 | 3.4 | 6.8 | 10.2 |

| The price policy is agreed upon with the distributor. | 26.5 | 47.0 | 17.1 | 4.6 | 2.8 |

| Demand predictions are resolved together with the distributor. | 2.3 | 6.2 | 7.5 | 53.3 | 30.8 |

| On order processing time, there is an agreement with the distributor. | 1.9 | 4.3 | 6.7 | 25.6 | 61.6 |

| SD | D | U | A | SA | |

|---|---|---|---|---|---|

| % | % | % | % | % | |

| 1. Incentive Alignment | |||||

| Different subsidies are given to distributors in the form of reduced retail prices. | 2.6 | 9.4 | 26.5 | 36.8 | 24.8 |

| There are shared savings associated with reduced costs of inventory. | 3.8 | 6.5 | 15.7 | 61.5 | 12.5 |

| Distributors are always willing or ready to share risks with a manufacturer. | 22.6 | 47.7 | 20.5 | 16.2 | 3.1 |

| We are engaged in several shared investments with distributors. | 12.8 | 24.3 | 11.6 | 37.5 | 13.9 |

| 2. Physical distribution | |||||

| Distributors are informed about the plant’s inventory levels. | 33.3 | 46.2 | 3.4 | 6.8 | 10.2 |

| Sometimes we fail to meet orders of stock demands from our distributors. | 6.5 | 17.0 | 7.1 | 24.6 | 42.8 |

| The processing of orders is done manually through signing documents and filling out certain forms. | 2.3 | 6.2 | 7.5 | 53.3 | 30.8 |

| We deliver stock at the agreed time. | 1.9 | 4.3 | 6.7 | 25.6 | 61.6 |

| We always receive accurate information concerning order placement. | 2.5 | 4.3 | 16.7 | 25.5 | 51.1 |

| Information Sharing | Decision Synchronization | Incentive Alignment | Physical Distribution Service Quality | |

|---|---|---|---|---|

| Information Sharing | 1 | |||

| Decision Synchronization | 0.648 * | 1 | ||

| 0.00 | ||||

| Incentive Alignment | 0.551 * | 0.649 * | 1 | |

| 0.02 | 0.000 | |||

| Physical distribution service quality (dep.) | 0.517 * | 0.905 * | 0.846 * | 1 |

| 0.00 | 0.00 | 0.00 | 0.00 |

| Model | R | R-Squared | Adjusted R-Squared | Std. Error of the Estimate | Durbin–Watson |

|---|---|---|---|---|---|

| 1 | 0.913 a | 0.894 | 0.798 | 0.30191 | 1.172 |

| Model | R | R-Squared | Adjusted R-Squares | Std. Error of the Estimate |

|---|---|---|---|---|

| 1 | 0.913 a | 0.894 | 0.798 | 0.30191 |

| Model | Sum of Squares | df | Mean Square | F | Sig. | |

|---|---|---|---|---|---|---|

| 1 | Regression | 31.240 | 3 | 17.182 | 241.105 | 0.026 a |

| Residual | 3.108 | 197 | 0.046 | |||

| Total | 61.178 | 200 | ||||

| Model | Unstandardized Coefficients | Standardized Coefficients | t | Sig. | |

|---|---|---|---|---|---|

| B | Std. Error | Beta | |||

| (Constant) | 0.318 | 0.136 | 2.438 | 0.026 | |

| Information sharing | 0.218 | 0.057 | 0.397 | 3.736 | 0.003 |

| Decision synchronization | 0.276 | 0.067 | 0.213 | 3.195 | 0.021 |

| Incentive alignment | 0.172 | 0.049 | 0.282 | 3.511 | 0.002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalogiannidis, S.; Kalfas, D.; Chatzitheodoridis, F. The Impact of Collaborative Communication on the Physical Distribution Service Quality of Soft Drinks: A Case Study of Beverage Manufacturing Companies in Greece. Beverages 2022, 8, 47. https://doi.org/10.3390/beverages8030047

Kalogiannidis S, Kalfas D, Chatzitheodoridis F. The Impact of Collaborative Communication on the Physical Distribution Service Quality of Soft Drinks: A Case Study of Beverage Manufacturing Companies in Greece. Beverages. 2022; 8(3):47. https://doi.org/10.3390/beverages8030047

Chicago/Turabian StyleKalogiannidis, Stavros, Dimitrios Kalfas, and Fotios Chatzitheodoridis. 2022. "The Impact of Collaborative Communication on the Physical Distribution Service Quality of Soft Drinks: A Case Study of Beverage Manufacturing Companies in Greece" Beverages 8, no. 3: 47. https://doi.org/10.3390/beverages8030047

APA StyleKalogiannidis, S., Kalfas, D., & Chatzitheodoridis, F. (2022). The Impact of Collaborative Communication on the Physical Distribution Service Quality of Soft Drinks: A Case Study of Beverage Manufacturing Companies in Greece. Beverages, 8(3), 47. https://doi.org/10.3390/beverages8030047