Abstract

The 2020 pandemic caused by the novel coronavirus, SARS-CoV-2, also referred to as the COVID-19 [named for the disease caused by the virus] pandemic, shook the world to its core. Not only were populations hurt by the virus physically, the pandemic had deep repercussions economically as well. One of the industries severely impacted by the implications of the 2020 COVID-19 pandemic was the brewing industry, particularly that of the United States. The economic turmoil and uncertainty were felt by both macro and micro brewers alike. Draft beer sales virtually dried up overnight as state-imposed shutdowns closed bars, restaurants, and taprooms as a means to curb the spread of the virus. There were supply chain and logistical issues that arose during the pandemic due to not only closures within the brewing industry but supporting industries such as printers and shippers. In some cases, entire business models had to be turned completely on their head in an instant and business pivots had to be made. The year 2020 was wrought with challenges faced by the brewing industry. There was one saving grace however that kept many breweries afloat during the pandemic, and that was packaged beverage sales, especially those packages intended for off-site consumption. Set forth by trends of the pre-pandemic years aluminum cans and canning reigned supreme for the craft brewing market and allowed breweries to get product into the hands of consumers and ultimately allowed some breweries to stay open. Other options breweries had included the use of glass growlers or aluminum crowlers as a means to sell draft products to-go. The resourcefulness of many brewery owners was tested in 2020 and many rose to the challenge. This report aims to examine several of the challenges, pivots, and solutions packaging provided to the beer industry during the pandemic.

1. Introduction

Prior to the COVID-19 pandemic, caused by the novel coronavirus SARS-CoV-2, the alcoholic market in the United States was over $250 billion USD in 2019 [1]. Although most areas of the United States saw the closure of bars and restaurants that offered on premise sale and consumption of alcohol brought on as a means of curbing the spread of the virus in public and social settings, the consumption of alcohol by US citizens increased during the height of the pandemic [2]. One of these industries in this market is the US brewing industry. Beer producers and sellers had to make pivotal business adjustments to not only stay safe but to stay economically viable as well. Beer producers also had to provide their customers with a safe and high-quality product as well. As stated earlier, bars and restaurants were closed or restricted in most US states as a means of controlling the spread of the virus [3], this meant that this increase of alcohol consumption took place at home [4]. This increase of at-home consumption has been estimated to be a 14–19% increase [5]. In order for these brewing businesses to survive, packaging became an important tool utilized in order to manage the storm caused by the 2020 pandemic [6].

2. Draught Beer Packaging

In March of 2020, the early days of the pandemic, few knew what the true extent of what the coronavirus would impose. For many breweries, March marks the start of the popular spring and summer drinking seasons in the US and many breweries were in the process of ramping up beer production for these seasons. These seasons are notorious for their draft beer sales as taprooms and beer gardens open up and become popular locations for drinking. Although most draught beer is packaged [in kegs or some other large volume service vessel], the industry makes a clear distinction between product packaged for draught sale and that of single serving, single use consumer packaging [7]. Many breweries, both macro and micro level producers, had product slated for draught sales in March and April of 2020 [8,9]. There was a glut of kegged product at both the producer and distributor level because typical accounts [bars and restaurants] who bought draft product were not open and thus did not have a need for purchasing that product. Use of a home draft systems such as a kegerator or keezer has always been a niche and not very popular market in the US [10], but because of this glut in draught package product and the unavailability of public, on premise consumption, the retail market saw an influx of affordable draught options for home consumption both by the craft and macro sectors of the brewing industry for the first time, and retail draught beer sales for home consumption rose during the early parts of the pandemic [9].

With the uncertainty of the vector transmission of the virus as well as the closures and furloughs within the supporting industries of brewing industry, breweries looked towards an alternative to traditional, reusable, stainless steel kegs that [often] required the collection of a deposit, further customer interaction with the return of the keg, and keg maintenance [now often falling on the brewery instead of a keg leasing agency] [8,11]. The solution to this came with the use of a product that had been on the market for some time now, but had not taken a major foothold in the draught beer market; this was the use of the single use, one-way keg. These kegs are often made of recyclable Polyethylene Terephthalate (PET) and either work like a traditional keg with CO2 draught distribution service or by the compression of a flexible, plastic bladder containing the product where the distributing gas never touches the product [12]. These containers come internally pre-sanitized and are ready to be filled and used by the brewery. Since these PET kegs are intended for single use, there is no need for the consumer to return the package to the brewery and the consumer may dispose of or recycle the container. Due to these pain point corrections by single use kegs, demand for these kegs increased in 2020 and companies who manufacture these kegs had to increase production and distribution throughout the United States [13]. This also sparked these companies to increase the types of products offered such as plastic growlers and sanitizer bottles as breweries tried to find packaging solutions for product distribution. Although the market saw this increase in home draught sales, this market still remained [and remains] a micro-market within the industry and really only provided breweries a means to break even and not waste beer destined for the draught market during the early part of the pandemic.

3. Single Use, Single Serving, and Other Off-Premise Packaging

Despite the increase and innovation in home, draught beverage sales, single use and single serving packages became the most important form of packaging during the 2020 COVID-19 pandemic. For many craft breweries, the ability to package product for home consumption was the only source of income and provided the means for financial survival during the economic turmoil of the pandemic [14]. Recent history shows the business plan trend of a brewpud or tasting room, where on-site, over the bar sales outweighs the traditional production-style brewery where most beer sold is in packaged form were on the rise and showed the most financial success [15]. This all changed in March of 2020 as state and local governments closed businesses and stay-at-home orders were given. Businesses were forced to rewrite their business models in order to safely operate and comply with health orders. The brewing industry did not go unscathed by these mandates. In some cases, tasting rooms were converted into packaging halls in order to set up a facility where product could be packaged instead of being sold as a draught product [16].

Packaging has always been important to the brewing industry, especially the craft brewing market [17]. Even during the early days of the craft beer revolution, packaging has played an important role in getting the product to the masses. Although initially glass bottle driven, aluminum beer packaging, especially in the craft market, has been drastically increasing since 2004 [18]. This is because of advancements in aluminum packaging equipment and technology, the reduced cost and weight of the package, and the general benefit to beer quality such as no Ultra Violet (UV) light exposure and airtight seals [19]. This is not to say that glass containers have fallen drastically out of use within the industry. The industry’s packaging sales, as a whole, is split approximately 60–40 between aluminum and glass but with almost 95% of small to medium craft brewers choosing medium (12–16 fluid ounce) aluminum containers [9,19,20]. Despite the rising demand for aluminum, limitations in can production, and international trade disputes and tariffs causing aluminum prices to rise, the use of aluminum packaging is still on the rise within the brewing industry [17]. There has also been a shift in consumer preference to the use of aluminum packaging which has forced many [large (22 fluid ounce)] glass packages out of fashion, and subsequently out of use [9,18,20].

In 2020, this increased demand caused an aluminum package shortage across so many industries in the US market [21]. Large and small corporations were faced with either ramping up production, such as in the cleaning and sanitizing product market, or having to shift distribution methods to fit an at-home consumption and use lifestyle now faced in the wake of the pandemic. Due to this, and coupled with logistical and health and safety issues in the manufacturing and distribution of packaging, the brewing industry was struck with can shortages; the most heavily effected were the craft brewers who often could not order the minimum requirements by can manufactures [22]. This caused several small craft breweries to have to form cooperative purchasing agreements in order to fulfill the growing minimum unit orders. This was where multiple breweries would go in on one order of cans and then divide the order between those in the cooperative purchase [16]. Other breweries, who had made the switch to packaging products in aluminum, reverted to using glass bottles because there was less demand for glass and the packaging materials could be received in a timely fashion [22].

Another limitation in packaging that was faced during the pandemic was a scarcity of secondary packaging material such as beer cases, six-pack holders, and beer trays [9]. This limitation was faced by both macro and micro breweries. This came as a twofold issue. First, in the early days of the pandemic, as bars and restaurants closed, breweries [and distributors] had no market to send and sell plain packaged beer referred to as a “restaurant” and/or “bar pack”. These are often 24 count cases of beer that are in plain cardboard containers with not much more than the brand name and logo on it in monochrome color. These secondary packages differ from what is typically found on the retail market where cases typically have multiple colors printed on a shiny, multilayered case referred to as a “glossy”. Since distributors had a surplus of these plain “bar” packs, these cases were sent to retail accounts in lieu of typical “glossy” cases. This continued though as the pandemic progressed due to printing companies restricting production, and breweries having no other packaging options than to use what cases were available to them and certain case sizes and product format sizes were not available to consumers. Printing and packaging logistics on the macro brewing end of the industry stabilized around May 2020. This backlog in printing effected the craft market for a longer period of time and the use of unbranded beer trays by some breweries continued throughout the summer [20].

Within the brewing industry, two supplying subindustries came to the rescue of these pain points. The first being small scale-canning systems such as those produced by Wild Goose Filling and Cask Global Canning Solutions [16]. These are small, often six fill heads or less, canning systems that take up a relatively small footprint and can be operated by two or three people. Although these systems were popular before 2020, the pandemic exacerbated the demand as brewers changed from brewpubs to production-style breweries. In addition to the small logistical footprint these systems possess, these canning lines are also relatively inexpensive and allow for users to self-maintain any mechanical issues faced [8]. These systems can be upgraded and upsized fairly easily as well. This fact helped the brewing industry because brewers with existing systems in place could upgrade their system to fulfill the increased need for packaged product with relative ease, while also producing a secondary market of used equipment that breweries just starting out in packaging could take advantage of [16]. This was all well and good, however, during the early stages of the pandemic, there were a number of packaging quality issues, such as improperly seamed cans, hitting the market [9]. These issues were caused by breweries having Standard Operating Procedures (SOPs) for maintenance of packaging equipment that did not account for the sudden increase in use [8]. As the pandemic wore on, SOPs were modified to reflect the increase in mechanical use [to an hourly use rate rather than a daily or monthly schedule] and seam issues on small scale lines were rectified. The popularity of these lines in a post-pandemic brewing industry helped spur the sale of Wild Goose Filling to the Middleby Corporation in December 2020 [23].

The second supporting industry was mobile canning units. These units purchase, operate, and maintain canning lines and will travel to a beverage producers’ facility, set up their line, package the product, and breakdown the line, leaving the beverage producer no need for capital investment in a packaging system [18]. These mobile canning units often times utilize the above-described micro-canning lines and often times were able to purchase cans and materials for packaging more easily than breweries because the mobile canning units were servicing so many clients. The popularity of mobile canning soared during the pandemic as brewers who previously had no packaged product [or very little packaged product] scrambled to get their beer into packaging and onto the market.

This was all well and good, and allowed for breweries to have non-draught retail option for their product, but due to many local, state, and federal alcohol distribution laws and regulations as well as distributor contract restrictions and market limitations, many of these smaller breweries had trouble getting their packaged product on the retail market [24]. However, states where brewers are allowed to self-distribute and states and local municipalities that provided industry specific legislation that relaxed distribution laws were able to take advantage of the new market [25]. Although a number of large alcohol retailers were unable to take on new products during the pandemic [9], smaller retailers who focus on the craft beer market had greater freedom when it came to purchasing product and provided a marketplace for breweries to sell their packaged products [20].

Prior to the pandemic, there was a stigma within the industry about the use of mobile canning companies especially when it came to concerns about the quality of the packaging [9]. These concerns arose because of fear that a mobile canning line would provide improper seaming and higher dissolved oxygen levels because the line is small and mobile when compared to a stationary line. However, during the pandemic, there were less packaging issues observed by packages packed via mobile canning services than that packaged via stationary lines [9,20]. This is believed to be because the line is broken down, sanitized, reassembled, and recalibrated at each client and did not face the same maintenance scheduling issues faced by brewers with stationary packaging lines [16].

The final packaging solution that brewers used during the pandemic of 2020 was the use of growlers and crowlers. A growler is a reusable, glass container that is typically filled off a draught line [26]. A crowler is similar to a growler in that it is also filled off a draught line, however, these crowlers are made of aluminum and are intended for single use and are seamed like a traditional can. These are intended as a means for customers to take draught beer home with them as well as provide breweries a way to get product into the hands of customers without the worry or use of traditional packaging techniques and are often sold directly from the brewery or taproom without the need of a distributor or alcoholic retailer. Early on in the pandemic, crowlers were very popular and seemed to be one of the safer options in distributing beer to customers because of their single use nature and brewery personnel could limit the contact with a customer and their belongings [16]. However, just like the shortage of cans, these aluminum crowlers were also in short supply. This issue was circumnavigated by the industry in a similar fashion to the traditional can shortage where cooperative purchasing between multiple breweries increased chances of receiving shipments of crowlers.

Although one of the benefits to the use of glass growlers is that they are considered to be reusable, many breweries were hesitant to have customers bring used growlers back to the brewery to be refilled because of fear of SARS-CoV-2 coronavirus transmission [14]. Due to this, some breweries required customers to buy a new growler each time the customer purchased beer. This significantly added to the sale price of the beer; both for the seller and the consumer. Cheaper alternatives to reusable, glass growler, such as plastic PET growlers, were utilized by some breweries in order to curb the cost of purchasing new growlers with each sale. Despite this, breweries struggled to order more growlers in order to keep up with demand of to-go beer sales, and there were month long backlogs in order to get new growlers in. However, in May of 2020, the Brewers Association (BA), the American trade organization who supports independent and craft breweries, published a white paper citing Center for Disease Control methods for cleaning, advising breweries and taproom workers on how to safely receive, clean, sanitize, and fill used growlers brought in by customers [27]. This list of suggestions by the BA showed that breweries can in fact refill used growlers safely and elevated the constant pressure of breweries to order more growlers and for consumers to have to buy new growlers each time they purchased beer.

4. Outcomes and Conclusions

The pandemic of 2020 has not only shaken mankind physically, but economically as well. The brewing industry has not gone unscathed by the economic turmoil caused by the pandemic. It was estimated that over 650,000 jobs within the brewing industry were lost in the US due to the pandemic [28]. Despite the uptick of at-home consumption of alcohol, this did not outweigh the loss in on premise sales and it is expected that the US beer sales dropped by $22 billion USD in 2020. This drop in sales has been majorly felt by brewers, especially small breweries. Across the board, beer sales and production have been down; on the low end 5–10% [8], to the high end of 45–50% [22], to the extreme cases of loss of 80% in sales and production 14]. These extreme cases of loss were mostly felt by breweries with brewpubs or whose business model focused on on-premise sales and consumption. The craft market as a whole saw a 7–8% decrease in 2020 [29]. This loss has caused some breweries to furlough their workers [22], while other breweries had to close [8]. Those breweries who have weathered the tumultuous months of the 2020 pandemic did so thanks to some sort of packaging. If it was not for being able to package beer, these breweries would have had little to no sales in 2020. Very little growth happened in the beer market in 2020, and despite some breweries closing, many were able keep staff employed, get product to customers, and survive.

In total, 48 out of the 50 US states and the District of Columbia [in one form or another] have either changed, modified, or enacted new laws in 2020 regarding the sale and distribution of alcohol in order to benefit businesses whose income comes from the sale of alcohol during to the pandemic [30]. These law changes include [but not limited to]; allowance of curbside sale and pickup of alcohol, home delivery of alcohol, shipping of alcohol, e-commerce and online ordering of alcohol, direct to consumer sale of alcohol, changes in distribution laws, and to-go and off-premise sale options by bars, restaurants, and pubs. These changes came in different forms and carried different restrictions in each state and municipality but these modifications to the law were intended to help businesses who make and/or sell alcohol. All of these changes in law all surrounded getting packaged product safely to the consumer during the pandemic. No one knows if the law modifications will stay enacted after the state of emergency of the pandemic has passed but this has shown that governments should consider permanently reevaluating alcohol sale and distribution laws in the US.

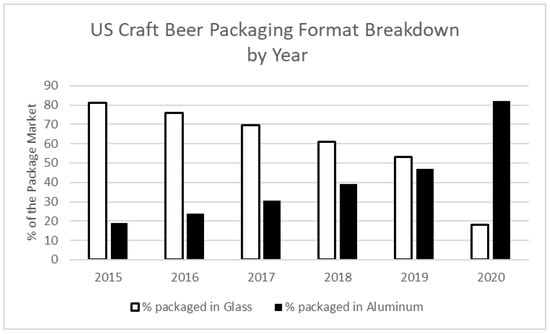

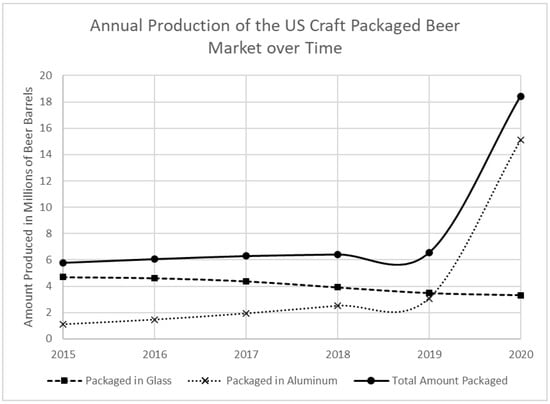

Figure 1 and Figure 2 show the breakdown between formats [in other terms glass versus aluminum can] of packaged beer in the United States as well as see the amounts of product that were packaged by the craft sector of the brewing industry in the US. As one can see, 2020 saw an exponential increase in packaged production predominantly in the form of aluminum cans. Most breweries were able to form some sort of pivot within their business models in order to weather the storm imposed by the pandemic of 2020. That being said, it is hard to predict what future repercussions might come of this that the brewing industry must face.

Figure 1.

The above figures showcase the annual packaged production by craft breweries per year since 2015. Additionally, shown are the percentage breakdown of the packaging format styles per year when comparing glass to aluminum packaging.

Figure 2.

The sudden upswing in packaged product production in 2020 was because of the need for off-premise sales and the limited market for on-premise sales due to the pandemic. Data provided by the Brewers Association, a trade organization that represents the craft brewing industry [31,32].

In conclusion the challenges presented by the COVID-19 pandemic were tough on everyone, and the brewing industry as a whole was no exception to that. However, despite the challenges, many were able to take advantage of packaging innovations, find solutions to logistical limitations, and change state and local laws in order for them to get their product to the masses. It was this resourcefulness and tenacity that allowed the brewing industry to survive in this post-COVID economy.

Author Contributions

E.R.P. and K.W. wrote the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

I would like to thank our industry resources and contacts for their information and insight into the current happening within the brewing industry. A special thanks to Jim Greve, beer buyer for Binny’s Beverage Depot, David Hawley, owner and proprietor of the Beer Cellar beer stores, beer writer, author, and educator, Marty Nachel, Mike Robinson and Craig Larson, cellarman and production manager respectively at Two Brothers Brewing Company, Gerrit J. Lewis, co-founder and co-owner of Pipeworks Brewing Company, and Nick Blew, owner and brewer at Molly’s Pint Brewpub. It was because of your hard work and tenacity that you and your businesses were able to survive 2020; best of luck in 2021.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The Beverage Information Group. The Beverage Information and Insights Group: EPG Media & Specialty Information. In Liquor Handbook 2020; The Beverage Information Group: Norwalk, CT, USA, 2020. [Google Scholar]

- Chodkiewicz, J.; Talarowska, M.; Miniszewska, J.; Nawrocka, N.; Bilinski, P. Alcohol consumption reported during the COVID-19 pandemic: The initial stage. Int. J. Environ. Res. Public Health 2020, 17, 4677. [Google Scholar] [CrossRef]

- Auger, K.A.; Shah, S.S.; Richardson, T.; Hartley, D.; Hall, M.; Warniment, A.; Timmons, K.; Bosse, D.; Ferris, S.A.; Brady, P.W. Association between statewide school closure and COVID-19 incidence and mortality in the US. JAMA 2020, 324, 859–870. [Google Scholar] [CrossRef] [PubMed]

- Pollard, M.S.; Tucker, J.S.; Green, H.D. Changes in adult alcohol use and consequences during the COVID-19 pandemic in the US. JAMA 2020, 3, e2022942. [Google Scholar]

- Grossman, E.R.; Benjamin-Neelon, S.E.; Sonnenschein, S. Alcohol Consumption during the COVID-19 Pandemic: A Cross-Sectional Survey of US Adults. Int. J. Environ. Res. Public Health 2020, 17, 9189. [Google Scholar] [CrossRef] [PubMed]

- Nguyen Ngoc, H.; Kriengsinyos, W. Impacts of COVID-19 Pandemic and Its Lockdown on Global Eating Behavior: A Google Trends Analysis. Preprints 2020, 2020120701. [Google Scholar] [CrossRef]

- Hogarty, T.F.; Elzinga, K.G. The demand for beer. Rev. Econ. Stat. 1972, 54, 195–198. [Google Scholar] [CrossRef]

- Lewis, G.J. (Pipeworks Brewing Company). Personal communication, 17 December 2020.

- Greve, J. (Binny’s Beverage Depot.) Personal communication, 1 November 2020.

- Calka, M. Fermenting Community. In Beer Culture in Theory and Practice: Understanding Craft Beer Culture in the United States; Lexington Books: Lanham, MD, USA, 2017. [Google Scholar]

- Hartwig, A. The Supply Chain Benefits of Using Non-Returnable PET Kegs. Available online: https://dispense.co.za/wp-content/uploads/petainer_keg_supply_chain_white_paper.pdf (accessed on 1 November 2020).

- Hartwig, A. Flavour Stability of Beer in Petainer Kegs an Investigation into the Impact of Aging on the Quality of Beer in PET Petainer Kegs. Available online: https://dispense.co.za/wp-content/uploads/white_paper_taste_test.pdf (accessed on 1 November 2020).

- Petainer. Petainer Expands Warehousing across the Americas. Available online: https://www.petainer.com/latest-news/petainer-expands-warehousing-across-the-americas/ (accessed on 12 August 2020).

- Blew, N. (Molly’s Pint). Personal communication, 26 December 2020.

- Yeager, C.; Gatrell, J.D. Brewpubs and Microbreweries: A Midwestern Geography of Local Craft Beer Markets by Firm Type. In The Geography of Beer; Springer: Berlin/Heidelberg, Germany, 2020; pp. 159–168. [Google Scholar]

- Nachel, M. (Two Brothers Brewing Company). Personal communication, 28 November 2020.

- Elzinga, K.G.; Tremblay, C.H.; Tremblay, V.J. Craft beer in the United States: History, numbers, and geography. J. Wine Econ. 2015, 10, 242. [Google Scholar] [CrossRef]

- Betts, B. Craft beer: The can-do revolution. Eng. Technol. 2015, 10, 50–53. [Google Scholar] [CrossRef]

- SEMCOR. Canning or Bottling: Which Is Better for Your Brewery’s Bottom Line? 2019. Available online: https://www.semcor.net/blog/canning-or-bottling-which-is-better-for-your-brewerys-bottom-line/#:~:text=A%20canning%20line%20costs%20significantly,is%20the%20most%20affordable%20option (accessed on 12 August 2020).

- Hawley, D. (Beer Cellar Beer Stores). Personal communication, 9 November 2020.

- Century Label. Aluminum Can Shortage: Thinking Ahead for a Very 2020 Problem. Available online: https://www.centurylabel.com/news/aluminum-can-shortage-thinking-ahead-for-a-very-2020-problem (accessed on 16 November 2020).

- Robinson, M.; Larson, C. (Two Brothers Brewing Company). Personal communication, 3 November 2020.

- Bretz, D. Middleby Acquires Wild Goose Filling. Business Wire; Berkshire Hathaway: Omaha, NE, USA, 2020; Available online: https://www.businesswire.com/news/home/20201208005464/en/Middleby-Acquires-Wild-Goose-Filling (accessed on 1 November 2020).

- Nurin, T. Beer Buyers Beware: Your Favorite Brands May Go Missing for the Rest of This Summer. Forbes, 3 July 2020. [Google Scholar]

- Lasbury, M.E. New Order Lets Growler USA in Jeffersonville Fill Growlers for the First Time, but What about after Coronavirus? Available online: IndianaOnTap.com (accessed on 23 April 2020).

- Star, A. Getting a Handle on Growler Laws. Seattle UL Rev. 2015, 39, 1079. [Google Scholar]

- Brewers Association. COVID-19 Safety Tips: To-Go Practices at the Brewery; Version 1.1; Brewers Association: Boulder, CO, USA, 2020. [Google Scholar]

- Davidson, A.; Obenchain, A.; Kane, L.; Duffy, S. 651,000 Jobs Supported by U.S. Beer Industry to be Lost Due to COVID-19 Pandemic. In By Year’s End, the COVID-19 Pandemic will Result in a $22 Billion Drop in Beer Sale; Beer Institute: Washington, DC, USA, 2020. [Google Scholar]

- Watson, B. 2020 Points and 2021 Predictions. In Insights & Analysis; Brewers Association: Boulder, CO, USA, 2020. [Google Scholar]

- Alcohol Policy Information System. State Alcohol-Related Laws During the COVID-19 Emergency for On-Premise and Off-Premise Establishments as of 13 April 2020 National Institute on Alcohol Abuse and Alcoholism: National Institutes of Health; Alcohol Policy Information System: Washington, DC, USA, 2020. [Google Scholar]

- Watson, B. 2019 Craft Beer Packaging Trends Recap. In Insights & Analysis; Brewers Association: Boulder, CO, USA, 2020. [Google Scholar]

- Watson, B. Craft Beer Packaging Trends Recap, 2020. In Insights & Analysis; Brewers Association: Boulder, CO, USA, 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).