Abstract

The study estimated the shelf life of specialty coffee packaged in six types of packaging (Tocuyo bag (TB), Double-bilaminate foil and aluminuim bag (DFAB), Ecotac vacuum bag (EV), Pressed cardboard box (PCB), Double-laminated bag without valve, with opening and zipper (DBOZ), Double-laminated bag with degassing valve and zipper (DBDVZ) and Triple-laminated bag with degassing valve and zipper (TBDVZ)). The estimation of shelf life was conducted by means of cup scores provided by six coffee tasters for coffee stored at 40, 50, and 60 °C. The Arrhenius equation was employed to obtain accelerated models for predicting shelf life. It was determined that green coffee beans are most effectively preserved in DBOZ, maintaining their freshness for a period of up to 55.13 days. The second-best option was EV, which has a shelf life of up to 35.21 days. The sole packaging alternative that was subjected to testing for roasted coffee beans was found to allow for their preservation for a period of up to 32 days. However, for roasted and ground coffee, of the four alternatives evaluated, the TBDVZ proved to be the optimal alternative, at 12.18 days. However, the other alternatives (DBOZ and DBDVZ) allow for very similar storage times, at 11.99 and 11.48 days, respectively. PCB does not appear to be a viable packaging alternative for roasted and ground coffee (7.85 days). Finally, we found that coffee stored in DFAB and aluminum bags at 20 °C has been shown to retain its quality for up to 250 days. Furthermore, if the temperature is reduced to 10 °C, the coffee’s shelf life is extended to more than 600 days. The insights derived from this research are of significant value to industry stakeholders, consumers, and developers of specialty coffee packaging.

1. Introduction

To illustrate, the process of coffee production involves a series of critical stages, including harvesting, pulping, fermentation, washing, drying, roasting, grinding, and packaging. These stages are instrumental in determining the quality and commercial viability of the coffee [1]. However, a significant element in the specialty coffee production process is the reduction in quality of the packaged product [2]. This is due to the fact that, during storage, the quality of the coffee beans diminishes, and factors such as temperature, relative humidity, and the type of packaging influence the shelf life [3]. This phenomenon results in economic losses for the producer in terms of marketing.

The degree of coffee processing directly correlates with the difficulty of maintaining aromatic compounds during storage [4]. However, the evaluation of diverse packaging types would facilitate the identification of the most suitable packaging option, thereby enabling the assessment of preservation parameters such as permeability, water vapor, and oxygen. These parameters are contingent upon the packaging type and exert an influence on the product’s stability [2].

A quality product, such as specialty coffee, requires not only a rigorous technological processing procedure but also special storage strategies to prevent deterioration [5]. The rate of deterioration is associated with intrinsic factors, including variety and production process, as well as external factors such as storage conditions (presence or absence of oxygen) [6]. The appropriate selection of packaging is imperative to preserving quality and prolonging the shelf life of coffee, given its limited shelf life post manufacture and packaging [7]. The most prevalent packaging methods include paper bags and double-laminated aluminum foil bags. However, these materials do not guarantee an extended shelf life for the product under various presentations [8].

Indeed, the mounting demand for specialty coffees [9] underscores the imperative to refine methodologies that ensure their effective transportation and marketing without compromising quality over time [10,11]. The quality of green beans is typically evaluated through a physical examination of the beans and a sensory evaluation of the coffee, which encompasses characteristics such as acidity and flavor [12,13,14]. This evaluation is further informed by considerations of production and marketing variables [15], which contribute to the enhancement of the coffee’s economic value.

The quality characteristics of a cup of coffee are attributes that can be perceived through the senses and evaluated organoleptically by professional tasters. These specialists employ established terminology to assess coffee quality, with parameters including flavor, acidity, body, and cleanliness in the cup. The classification of coffee is contingent upon various quality attributes and is subject to the specific guidelines established by each producing nation [9,16]. However, for coffee classified as specialty, a minimum score of 80 on a scale of 100 is requisite. This evaluation is conducted based on 10 criteria delineated by the Specialty Coffee Association (SCA) [17,18].

Despite the Peruvian government’s promotion of diverse coffee cultivation, the commercial sector primarily produces approximately 25 distinct coffee varieties classified as specialty coffee [19]. The most prevalent and extensively cultivated varieties, which account for the bulk of production, are Typica, Caturra, Bourbon, Pache, Catimor, and Geisha. Furthermore, the country boasts over 350,000 hectares dedicated to the cultivation of specialty coffees, as reported by Alvarado et al. [20].

The study and search for ways to extend the shelf life of food after processing and packaging are carried out in order to preserve the characteristics and qualities that make it acceptable for consumption [21]. In the case of green coffee beans, roasted beans, and ground roasted beans, different types of packaging are used to minimize physical, chemical, and sensory changes [7]. In the context of specialty coffee marketing, the utilization of bilaminate and trilaminate packaging, equipped with degassing valves, has become a standard practice. A plethora of studies have demonstrated that the shelf life of coffee can be influenced by packaging methodology, environmental factors, and storage conditions [22]. Permeable packaging has been shown to promote oxidation and the consequent loss of color in processed coffee, in contrast to the effect of airtight packaging, which is more effective for long-term storage [23,24] and better prevents lipid oxidation of the product [25]. It has been demonstrated that paper packaging can cause the loss of up to 80% of the volatile aromatic compounds present in coffee [26]. However, a multitude of factors, including cost, market availability, visual appearance and the advantages offered by the packaging in terms of sales (e.g., packaging with valves facilitates the release of aromas), often result in producers utilising diverse storage alternatives [27,28]. A further frequent contributing factor is a lack of information about existing technologies. This underscores the necessity for more precise studies to provide accurate information for the industry.

The objective of the present study was to estimate the shelf life of specialty coffee in different presentations and packaging with different alternatives [Tocuyo bag (TB); Double-laminated foil and aluminum bag (DFAB); Ecotac vacuum bag (EV); Pressed cardboard box (PCB); Double-laminated bag without valve, with opening and zipper (DBOZ); Dou-ble-laminated bag with degassing valve (DBDVZ) and zipper and Triple-laminated bag with de-gassing valve and zipper (TBDVZ)], using accelerated tests to obtain results in less time under controlled conditions and using mathematical models to predict the product’s useful life.

2. Materials and Methods

2.1. Materials and Conditioning of Coffee Samples

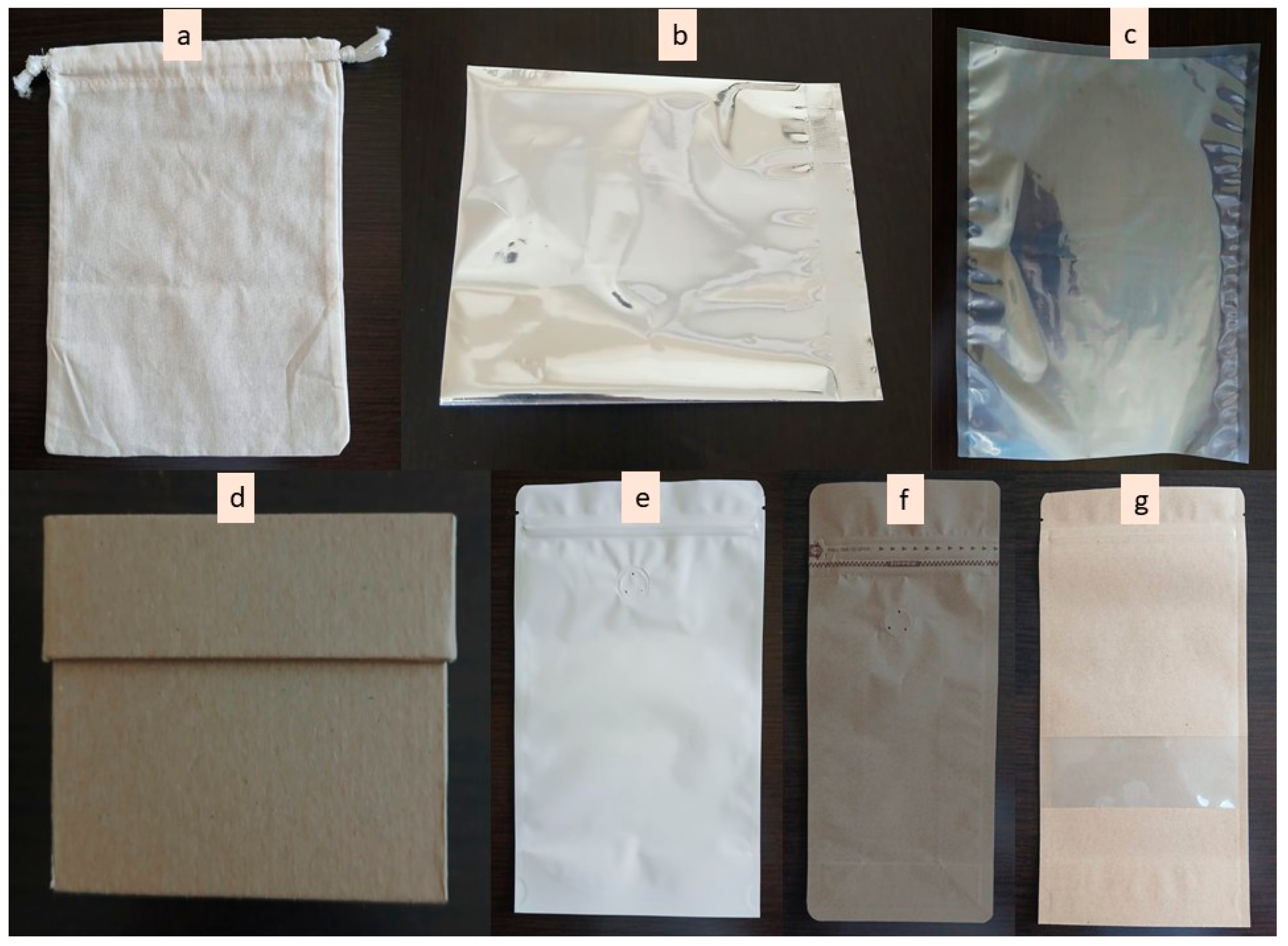

The coffee blend utilized in this study was 120 kg of Blend Gourmet green gold coffee, comprising 50% Geisha, 25% Caturra, and 25% Pache varieties. The coffee was harvested in 2024 and obtained from the Cenfrocafé Agricultural Coffee Cooperative in the Cajamarca department of Peru’s Jaén province. Notably, the cooperative holds organic and quality certification. The coffee batch was then subdivided into three distinct components: green beans, roasted beans, and ground roasted beans. The initial moisture content of the green beans was 10.5%. The coffee samples were roasted (medium dark) and ground (medium grind, particle size 10) following the procedure described by Chavez et al. [29] for preparing coffee drinks using filter techniques.; and packaged in various materials, as outlined in Table 1 (showed in Figure 1). Each package contained 250 g of coffee sample.

Table 1.

Experimental arrangement used for testing the shelf life of coffee using different base strategies.

Figure 1.

Types of packaging used to determine the shelf life of specialty coffee. (a) Tocuyo bag; (b) Double-laminated foil and aluminum bag; (c) Ecotac vacuum bag; (d) Pressed cardboard box; (e) Double-laminated bag without valve, with opening and zipper; (f) Double-laminated bag with degassing valve and zipper; and (g) Triple-laminated bag with degassing valve and zipper.

2.2. Sample Storage Conditions

Each batch of coffee packaged in one type of packaging consisted of 45 units, which were stored in three different ovens (FAITHFUL model GX-45BE, Faithful Instrument (Hebei) Co., Ltd., Huanghua, China), 15 per oven, stored at three different temperatures (40, 50, and 60 °C), temperature range previously used by Rosillo et al. [2].

2.3. Determination of the Cup Profile of Specialty Coffee

The procedure delineated by Louzada et al. [30] was adhered to, albeit with certain adaptations. To obtain the cup score for the coffee beverage, a tasting method was employed by six certified tasters (Q Arabica Grader), who assigned the respective score on a scale of 0 to 10 points based on the attributes of fragrance/aroma, flavor, aftertaste, acidity, body, balance, uniformity, cleanliness, sweetness, defects, and overall impression. The procedure was adhered to, and the standardized instrument of the Specialty Coffee Association (SCA) was utilized [31,32]. To identify the coffee category, the classification system outlined in Table 2 was employed. According to this system, coffee is deemed to lose its specialty status if it receives a score of less than 80 points, and is deemed unfit for consumption if the final score reaches 30 or less.

Table 2.

Coffee classification based on the total rating of attributes.

2.4. Estimation of the Shelf Life of Specialty Coffee

The following text is intended to provide a comprehensive overview of the subject matter.

This was accomplished by implementing the accelerated shelf life test (ASLT) method adjusted to the Arrhenius model, a technique that enabled the prediction of the actual shelf life through the simulation of the quality degradation data obtained during observation [3]. The Arrhenius equation demonstrates the correlation between the rate of deterioration and temperature, employing Equations (1)–(5):

where

K = reaction rate constant at temperature T

K0 = pre-exponential constant

Ea = activation energy (cal/mol)

T = absolute temperature (°K)

R = gas constant (1.986 cal/mol °K).

The order of the chemical kinetic reaction (zero or first order) for the loss of desirable compounds was determined based on the result with the highest coefficient of determination (R2) for the regression constructed with storage temperatures and each type of container.

The values of Ea and K0 were obtained from Equation (5), which was constructed using the slopes of the straight-line graphs of ln(K) versus 1/T for each type of packaging in the study.

2.5. Estimated Useful Life

The shelf life of green coffee beans, roasted beans, and ground roasted coffee based on the cup profile was obtained by introducing the deterioration rate constant (K) into Equation (6) or Equation (7), where A0 is the initial value of the coffee’s cup profile and A is the acceptability limit for the cup profile, considered to be 79.99, at which point the coffee loses its specialty status.

Using predictive models, the shelf life was calculated at normal storage temperatures (including refrigeration).

2.6. Statistical Analysis

The experiments and measurements were performed in triplicate, and the results were expressed as means ± standard deviations. The software used was Python V. 3.14 through Google Collaboratory [33].

3. Results and Discussion

3.1. Initial Cup Score of the Coffee Beverage

All of the coffee samples that were evaluated received cup scores above 80 points. More specifically, the scores were 83.82, 83.96, 83.93, and 84.29 for green beans packaged in tocuyo, aluminum foil laminate, and a vacuum-packed Ecotac bag, as well as for roasted beans in a vacuum-packed Ecotac bag, respectively. These scores clearly indicate that specialty coffee was used [34]. Similar scores were obtained for all roasted ground coffee samples (ranging from 82.90 to 83.94 points).

3.2. Sensory Profile of Coffee Beverages Under Accelerated Conditions

Table 3, Table 4 and Table 5 present the results of the sensory profile evolution in the storage of coffee packaged at varying temperatures. A decreasing cup score was observed as the storage temperature and time increased. The impact of temperature on coffee quality has been extensively researched. Previous studies have demonstrated that elevated temperatures can alter the composition of coffee, ultimately leading to a decline in its quality [35]. Additionally, prolonged storage time has been shown to adversely affect the sensory attributes of coffee [36]. Furthermore, an analysis of the time period under consideration (12 days) reveals that the scores obtained under accelerated conditions remain proximate to values that would permit the samples to be designated as specialty coffee [34].

Table 3.

Changes in coffee cup score during storage at 40 °C/Relative humidity 85%.

Table 4.

Changes in coffee cup score during storage at 50 °C/Relative humidity 85%.

Table 5.

Changes in coffee cup score during storage at 60 °C/Relative humidity 85%.

3.3. Shelf Life of Coffee Packaged in Different Materials

The data concerning the degradation of the cup score was obtained for each storage temperature and packaging material. The order of the chemical reaction kinetics of sensory quality loss was determined, defined as first order by the highest R2 value, and linear regression was used with the lnK and 1/T values. The value of the degradation rate constant for each temperature and type of packaging was obtained from the slope value of each first-order and zero-order graph. The lnK value was plotted on a semi-logarithmic graph and fitted to the Arrhenius model, where lnK is the ordinate and 1/T is the abscissa. This method was employed to obtain the −Ea/R value for each type of packaging (see Table 6).

Table 6.

Reaction order for determining deterioration.

The linear regression models are displayed in Figure 1 for samples with different packaging strategies. As illustrated in Table 7, the activation energy for each treatment is indicated.

Table 7.

Values of −/R, , ln and for each type of packaging.

Subsequent to the attainment of the Arrhenius model for each type of packaging, the cup scores for roasted and ground coffee were computed based on the storage temperature and type of packaging, as demonstrated in Table 6. The K values obtained from the calculations with Equation (1) and the estimated shelf life of the coffee in the different presentations were obtained by entering the deterioration rate into Equation (4).

The initial cup score value was designated as A0. Coffee is classified as a specialty coffee if its cup score value is 80 or higher [37] or has reached a value of 79.99. This value is henceforth referred to as the critical cup score value (A). The results of the estimation of the shelf life of coffee in the eight presentations at storage temperatures of 40, 50, and 60 °C were estimated in days for the containers, respectively.

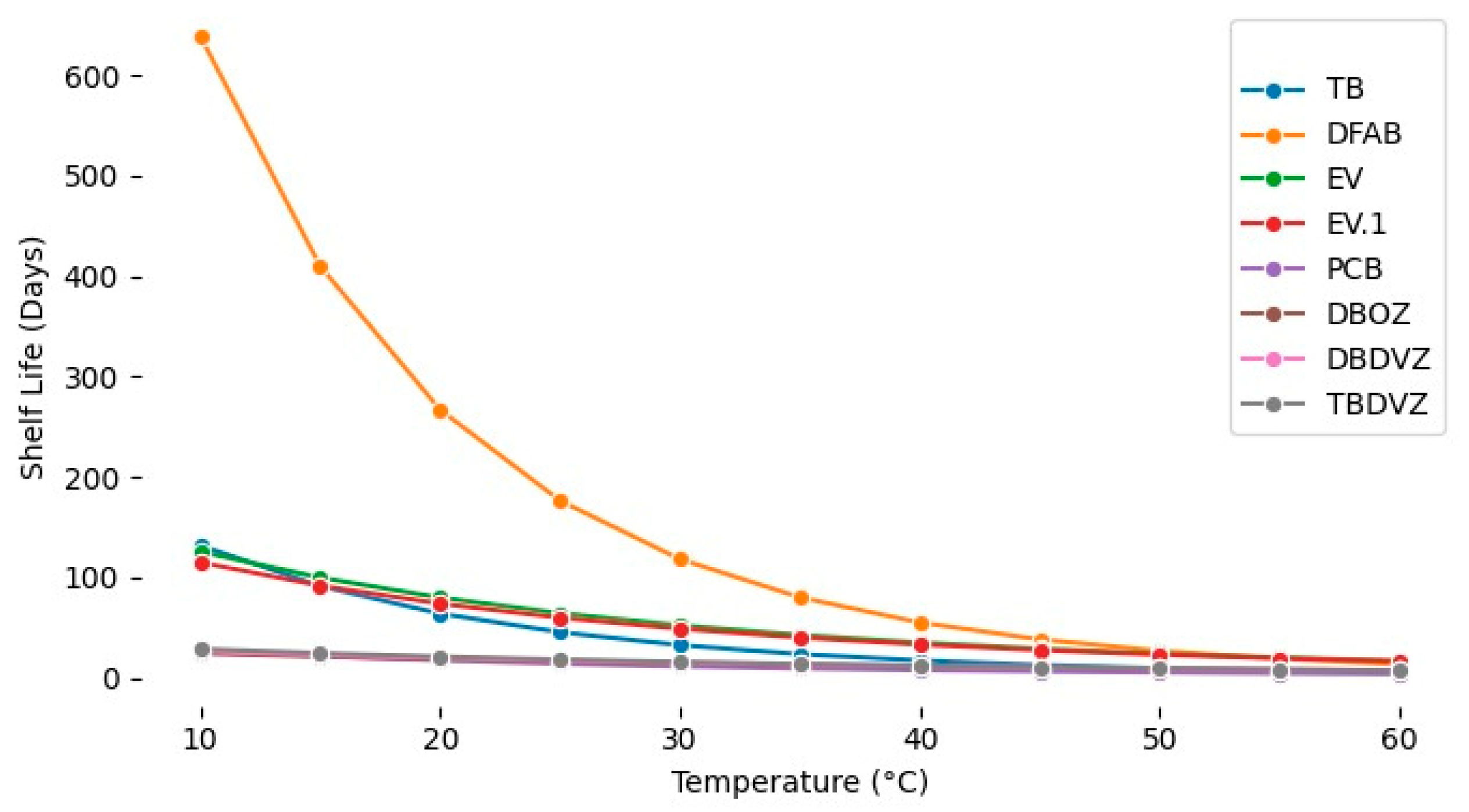

As illustrated in Figure 2, Table 8 presents the shelf life in days of coffee in its three forms, with different packaging strategies, for storage temperatures ranging from 40 to 60 °C. Green coffee beans have been demonstrated to be most effectively preserved in bilaminate foil and aluminum bags (BBFA), exhibiting prolonged stability for up to 55.13 days. The second-best option is vacuum packaging (VE), which has a shelf life of up to 35.21 days, while the least recommended option is storage in a tocuyo (BT), with 17.38 days.

Figure 2.

Estimated shelf life based on storage temperature. TB: Tocuyo bag; DFAB: Double-laminated foil and aluminum bag; EV and EV.1: Ecotac vacuum bag; PCB: Pressed cardboard bag; DBOZ: Double-laminated bag without valve, with opening and zipper; DBDVZ: Double-laminated bag with degassing valve and zipper; TBDVZ: Triple-laminated bag with degassing valve and zipper.

Table 8.

K values and shelf life for each temperature and type of container.

The sole packaging option that was subjected to testing for roasted coffee beans was found to allow for their preservation for a period of up to 32 days. However, for roasted and ground coffee, of the four alternatives evaluated, the trilaminate bag (BTCV) emerged as the optimal alternative, with a storage duration of 12.18 days. The other alternatives (BBCV and BBSV) exhibited comparable storage capabilities, with storage durations of 11.99 and 11.48 days, respectively. The cardboard box (CC) does not appear to be a viable packaging alternative for roasted and ground coffee (7.85 days).

As illustrated in Figure 2, the models demonstrate the projected shelf life for a higher storage temperature range. The bilaminate bag with aluminum foil has been identified as the optimal packaging solution for coffee, as it maintains its quality for more than 600 days when stored at temperatures close to 10 °C. These results suggest that sensory attributes can be sustained over an extended period if packaging and storage temperature are meticulously synchronized. However, prior studies have demonstrated that coffee undergoes chemical transformations during this process [35,38,39].

The present study demonstrates that the type of packaging directly affects the shelf life of coffee when using an accelerated technique. Further research could encompass additional variables that were not contemplated in this study, such as the color of the container [27], the degree of processing (e.g., roasting), and even the coffee variety [40]. These could include its chemical and bioactive composition, which may not be inherently associated with sensory attributes [41].

4. Conclusions

It was determined that green coffee beans are most effectively preserved in a double-laminated foil and aluminum bag (DFAB), maintaining their freshness for a period of up to 55.13 days. The second-best option is the Ecotac vacuum bag (EV), which can extend the shelf life of the product to up to 35.21 days. The sole packaging alternative that was subjected to testing for roasted coffee beans was found to allow for their preservation for a period of up to 32 days. However, an evaluation of four alternatives revealed that the Triple-laminated bag with a degassing valve and zipper (TBDVZ) exhibited the optimal performance for roasted and ground coffee, with a storage duration of 12.18 days. The other alternatives (DBOZ and DBDVZ) demonstrated comparable storage times of 11.99 and 11.48 days, respectively. A study was conducted to determine the efficacy of pressed cardboard boxes (PCBs) as a packaging alternative for roasted and ground coffee. The results indicated that PCBs do not appear to be a suitable packaging option for coffee, with an estimated storage duration of 7.85 days.

Coffee stored in double-laminated aluminum foil and aluminum bags at 20 °C has been shown to retain its quality for up to 250 days. Furthermore, if the temperature is reduced to 10 °C, the coffee’s shelf life is extended to more than 600 days.

In conclusion, it can be posited that packaging alternatives allow coffee with less processing to better preserve its sensory quality, irrespective of the packaging alternative employed. The insights derived from this research are of significant value to industry stakeholders, consumers, and developers of specialty coffee packaging.

Author Contributions

Conceptualization, F.F.-R. and L.Q.-H.; methodology, S.G.C. and L.Q.-H.; validation, S.G.C. and L.Q.-H.; writing—original draft preparation, F.F.-R., E.M.C.-B., M.A.L. and Y.L.C.F.; writing—review and editing, S.G.C. and L.Q.-H.; supervision, E.M.C.-B. and F.F.-R. All authors have read and agreed to the published version of the manuscript.

Funding

The research received funding from the National Council for Science and Technology, Peru, through the project “Estimating the shelf life of specialty coffees in storage, production, and marketing, using accelerated testing and data mining algorithms” under Contract No. PE501087000-2024.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by comité institucional de ética en investigación de la Universidad Nacional (protocol code RCO N°065-2025 CCO-UNJ and date of approval 21 April 2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sanz-Uribe, J.R.; Yusianto; Menon, S.N.; Peñuela, A.; Oliveros, C.; Husson, J.; Brando, C.; Rodriguez, A. Postharvest Processing-Revealing the Green Bean. In The Craft and Science of Coffee; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 51–79. ISBN 9780128035580. [Google Scholar]

- Rosillo, F.F.; Ríos, M.A.C.; Huatangari, L.Q.; Lalangui, C.G.S. Shelf-Life Prediction of Specialty Coffees Using the Arrhenius Model. Online J. Biol. Sci. 2023, 23, 17–24. [Google Scholar] [CrossRef]

- Mardjan, S.; Hakim, F.R. Prediction Shelf Life of Arabica Java Preanger Coffee Beans under Hermetic Packaging Using Arrhenius. In Proceedings of the IOP Conference Series: Materials Science and Engineering PAPER, Bogor, Indonesia, 15–16 December 2018; IOP Publishing: Bristol, UK, 2019; p. 012077. [Google Scholar]

- Smrke, S.; Adam, J.; Mühlemann, S.; Lantz, I.; Yeretzian, C. Effects of Different Coffee Storage Methods on Coffee Freshness after Opening of Packages. Food Packag. Shelf Life 2022, 33, 100893. [Google Scholar] [CrossRef]

- Oscco, I.; Roldan, E.P.; Quispe, E.; Camacho, A.; Marmolejo, D.; Marmolejo, K.J. Selection, Identification and Zoning of Coffee (Coffea Arabica L.) for Its Adaptability, Yield, Sensory Quality and Resistance to Pests and Diseases. Agroindustrial Sci. 2020, 10, 249–257. [Google Scholar] [CrossRef]

- Tripetch, P.; Borompichaichartkul, C. Effect of Packaging Materials and Storage Time on Changes of Colour, Phenolic Content, Chlorogenic Acid and Antioxidant Activity in Arabica Green Coffee Beans (Coffea Arabica L. Cv. Catimor). J. Stored Prod. Res. 2019, 84, 101510. [Google Scholar] [CrossRef]

- Giulia, S.; Eloisa, B.; Giulia, R.; Gloria, P.; Carlo, B.; Erica, L. Evaluation of the Behaviour of Phenols and Alkaloids in Samples of Roasted and Ground Coffee Stored in Different Types of Packaging: Implications for Quality and Shelf Life. Food Res. Int. 2023, 174, 113548. [Google Scholar] [CrossRef] [PubMed]

- Massulo, R.; Quartaroli, C.; Coltro, L.; Maria, R.; Alves, V. Alternative Flexible Plastic Packaging for Instant Coffees. Food Res. Int. 2023, 172, 113165. [Google Scholar] [CrossRef]

- Samoggia, A.; Fantini, A. Revealing the Governance Dynamics of the Coffee Chain in Colombia: A State-of-the-Art Review. Sustainability 2023, 15, 13646. [Google Scholar] [CrossRef]

- Gallardo-Ignacio, J.; Santibáñez, A.; Oropeza-Mariano, O.; Salazar, R.; Montiel-Ruiz, R.M.; Cabrera-Hilerio, S.; Gonzáles-Cortazar, M.; Cruz-Sosa, F.; Nicasio-Torres, P. Chemical and Biological Characterization of Green and Processed Coffee Beans from Coffea Arabica Varieties. Molecules 2023, 28, 4685. [Google Scholar] [CrossRef]

- Ragab, T.I.M.; Hassan, N.S.Y. A Comparative Study between Different Additives for Date Pits Coffee Beverage: Health and Nutritional Evaluation. Egypt. J. Chem. 2020, 63, 777–790. [Google Scholar] [CrossRef]

- Acuña, G.; Badilla, C.; Mora, A. Sistema de Gestión de La Calidad Basado En La Norma Internacional ISO 9001:2015 Para La Mejora Del Proceso de Beneficiado Húmedo de Café Arábigo Para La Exportación Al Mercado Internacional: El Caso de La Empresa La Chelita; Universidad Nacional: Heredia, Costa Rica, 2023. [Google Scholar]

- Mateos-aparicio, G. Communications in Statistics—Theory and Methods Partial Least Squares (PLS) Methods: Origins, Evolution, and Application to Social Sciences Partial Least Squares (PLS) Methods: Origins, Evolution, and Application to Social Sciences. Commun. Stat.-Theory Methods 2011, 40, 37–41. [Google Scholar] [CrossRef]

- Tolessa, K.; Rademaker, M.; De Baets, B.; Boeckx, P. Prediction of Specialty Coffee Cup Quality Based on near Infrared Spectra of Green Coffee Beans. Talanta 2016, 150, 367–374. [Google Scholar] [CrossRef]

- Ramírez-Correa, P.; Rondán-Cataluña, F.J.; Moulaz, M.T.; Arenas-Gaitán, J. Purchase Intention of Specialty Coffee. Sustainability 2020, 12, 1329. [Google Scholar] [CrossRef]

- Adugna, B.G. Review on Coffee Production and Quality in Ethiopia. Agric. For. Fish. 2021, 10, 208. [Google Scholar] [CrossRef]

- Lingle, T.R.; Menon, S.N. Cupping and Grading-Discovering Character and Quality. Cr. Sci. Coffee 2017, 181–203. [Google Scholar] [CrossRef]

- Quispe, M. Study of Physical Quality and Quality of Cup of Coffee (Coffea Arabica L.) in Two Growing Areas of the Province of Sandia Harvest 2019. Rev. Científica I+D Aswan Sci. 2020, 1, 1–7. [Google Scholar] [CrossRef]

- Julca-Otiniano, A.; Alvarado-Huamán, L.; Borjas-Ventura, R.; Castro-Cepero, V.; León, F.; Valderrama, D.; Bello, S. Coffee Varieties (Coffea Arabica), a Review and Some Experiences in Perú. Rev. Investig. Innovación Agropecu. Recur. Nat. 2023, 10, 134–155. [Google Scholar] [CrossRef]

- Alvarado, W.; Bobadilla, L.G.; Valqui, L.; Silva, G.; Valqui-Valqui, L.; Vigo, C.N.; Vásquez, H.V. Characterization of Coffea Arabica L. Parent Plants and Physicochemical Properties of Associated Soils, Peru. Heliyon 2022, 8, e10895. [Google Scholar] [CrossRef]

- Nicoli, M.C. (Ed.) Shelf Life Assessment of Food; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Manzocco, L.; Calligaris, S.; Anese, M.; Nicoli, M.C. The Stability and Shelf Life of Coffee Products. In The Stability and Shelf Life of Food; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 375–398. ISBN 9780081004357. [Google Scholar]

- de Oliveira Silva, L.; Borém, F.M.; Heinerici, G.C.; Cirillo, M.Â.; de Carvalho Alves, A.P.; Haeberlin, L.; Dos Santos, C.M. Stability of the Color of Roasted Coffees Stored in Different Packaging. Coffee Sci. 2025, 20, e202296. [Google Scholar] [CrossRef]

- Eshete, F.A.; Tola, Y.B.; Kuyu, C.G.; Tolessa, K.; Mulugeta, D.; Gure, S. Physicochemical Stability and Sensory Quality of Selected Ethiopian Coffee (Coffea Arabica L.) Brands as Affected by Packaging Materials during Storage. Heliyon 2024, 10, e29323. [Google Scholar] [CrossRef]

- Aung Moon, S.; Wongsakul, S.; Kitazawa, H.; Saengrayap, R. Lipid Oxidation Changes of Arabica Green Coffee Beans during Accelerated Storage with Different Packaging Types. Foods 2022, 11, 3040. [Google Scholar] [CrossRef]

- Trenzová, K.; Gross, M.; Vítová, E.; Pořízka, J.; Diviš, P. Exploring the Impact of Different Packaging Types and Repeated Package Opening on Volatile Compound Changes in Ground Roasted Coffee. J. Microbiol. Biotechnol. Food Sci. 2024, 14, e11022. [Google Scholar] [CrossRef]

- Carvalho, F.M.; Forner, R.A.S.; Ferreira, E.B.; Behrens, J.H. Packaging Colour and Consumer Expectations: Insights from Specialty Coffee. Food Res. Int. 2025, 208, 116222. [Google Scholar] [CrossRef]

- Zurita, C.A.; Foster, K.; Baributsa, D.; Parra, C.A.; Donovan, N. Coffee Storage in Hermetic Bags and Its Influence on Prices and Sensory Scores. Rev. Cienc. Agric. 2022, 39, 14–32. [Google Scholar] [CrossRef]

- Chavez, S.G.; Mendoza, M.M.; Caetano, A.C. Antioxidants, Phenols, Caffeine Content and Volatile Compounds in Coffee Beverages Obtained by Different Methods. Food Sci. Technol. 2022, 42, e47022. [Google Scholar] [CrossRef]

- Louzada, L.; Carvalho, R.; Soares DeSouza, G.; Brioschi, D.; Rizzo, T.; Schwengber, C. Propositions on the Optimal Number of Q-Graders and R-Graders. J. Food Qual. 2018, 2018, 7. [Google Scholar] [CrossRef]

- Fernández-Alduenda, A.; Giuliano, P. Coffee Sensory and Cupping Handbook; Specialty Coffee Association: E-book: Singapore, 2021; ISBN 978-1-3999-0329-5. [Google Scholar]

- Torres, P.R.; Lázaro, J.J.; Jara, W. Guía Motodológica de Catación Móvil de Café; CAC Pangoa Ltd.: Pangoa, Peru, 2017; Volume 1. [Google Scholar]

- Google Google Colaboratory. Available online: https://colab.research.google.com/ (accessed on 13 February 2025).

- Bressani, A.P.P.; Martinez, S.J.; Batista, N.N.; Simão, J.B.P.; Schwan, R.F. Into the Minds of Coffee Consumers: Perception, Preference, and Impact of Information in the Sensory Analysis of Specialty Coffee. Food Sci. Technol. 2021, 41, 667–675. [Google Scholar] [CrossRef]

- Błaszkiewicz, J.; Nowakowska-Bogdan, E.; Barabosz, K.; Kulesza, R.; Dresler, E.; Woszczyński, P.; Biłos, Ł.; Matuszek, D.B.; Szkutnik, K. Effect of Green and Roasted Coffee Storage Conditions on Selected Characteristic Quality Parameters. Sci. Rep. 2023, 13, 6447. [Google Scholar] [CrossRef] [PubMed]

- Kreuml, M.T.L.; Majchrzak, D.; Ploederl, B.; Koenig, J. Changes in Sensory Quality Characteristics of Coffee during Storage. Food Sci. Nutr. 2013, 1, 267–272. [Google Scholar] [CrossRef]

- Bemfeito, C.M.; Guimarães, A.S.; de Oliveira, A.L.; Andrade, B.F.; de Paula, L.M.A.F.; Pimenta, C.J. Do Consumers Perceive Sensory Differences by Knowing Information about Coffee Quality? Lwt 2021, 138, 110778. [Google Scholar] [CrossRef]

- Aung Moon, S.; Wongsakul, S.; Kitazawa, H.; Kittiwachana, S.; Saengrayap, R. Application of ATR-FTIR for Green Arabica Bean Shelf-Life Determination in Accelerated Storage. Foods 2024, 13, 2331. [Google Scholar] [CrossRef]

- Cotter, A.R.; Hopfer, H. The Effects of Storage Temperature on the Aroma of Whole Bean Arabica Coffee Evaluated by Coffee Consumers and Hs-Spme-Gc-Ms. Beverages 2018, 4, 68. [Google Scholar] [CrossRef]

- Mestanza, M.; Mori-Culqui, P.L.; Chavez, S.G. Changes of Polyphenols and Antioxidants of Arabica Coffee Varieties during Roasting. Front. Nutr. 2023, 10, 1078701. [Google Scholar] [CrossRef]

- Agustini, S.; Yusya, M.K. The Effect of Packaging Materials on the Physicochemical Stability of Ground Roasted Coffee. Curr. Res. Biosci. Biotechnol. 2020, 1, 66–70. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).