Economic Perspectives of Biogas Production via Anaerobic Digestion

Abstract

1. Introduction

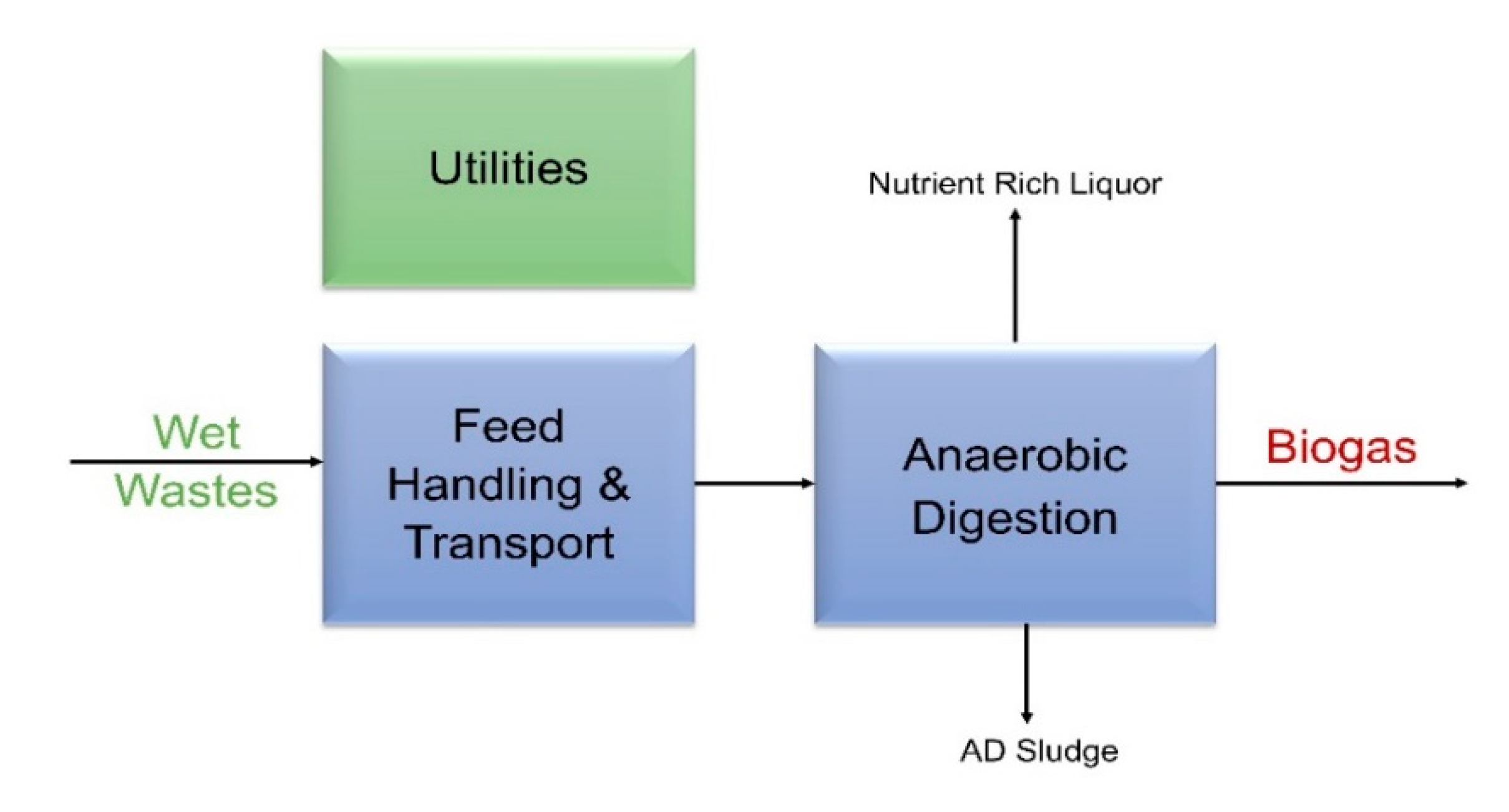

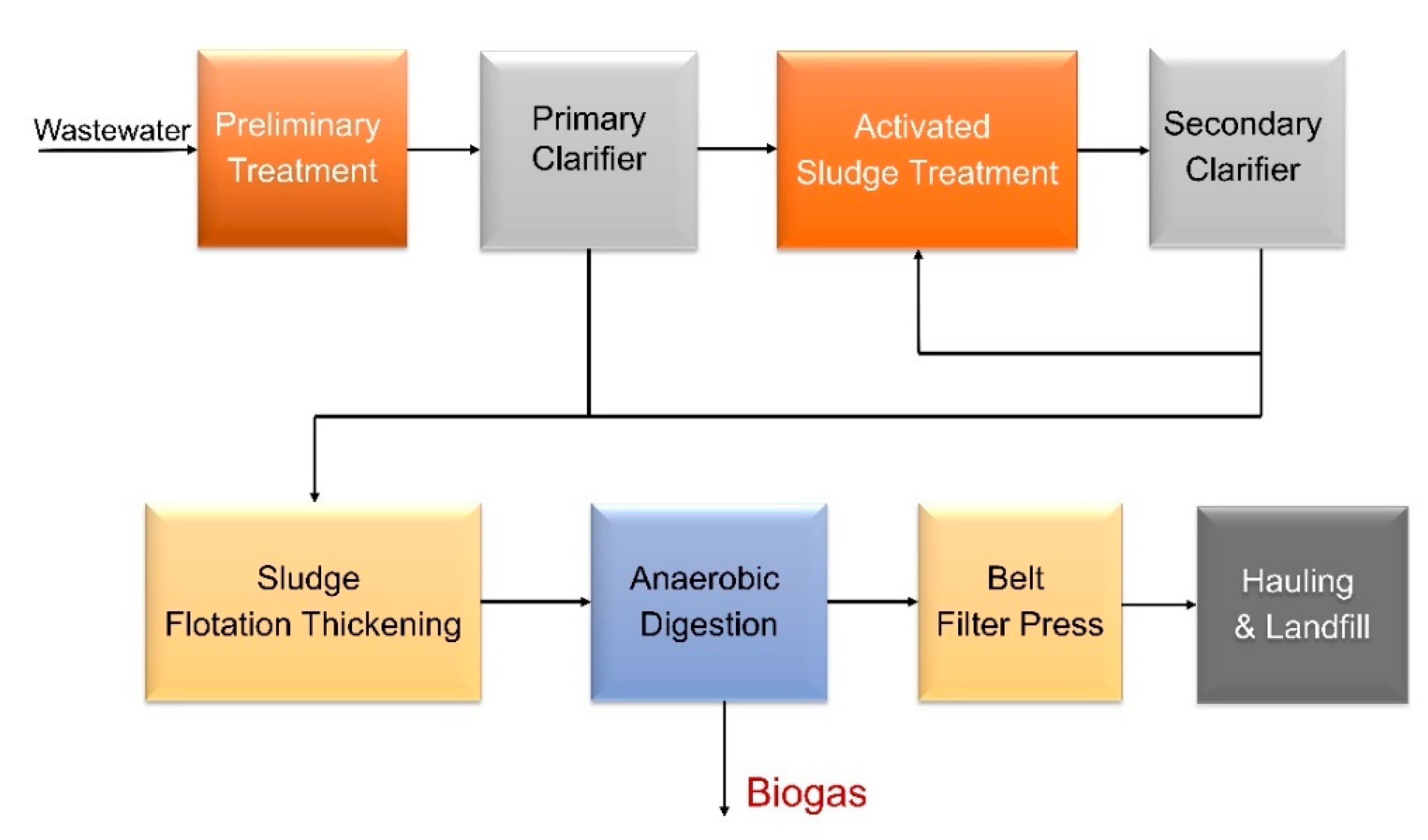

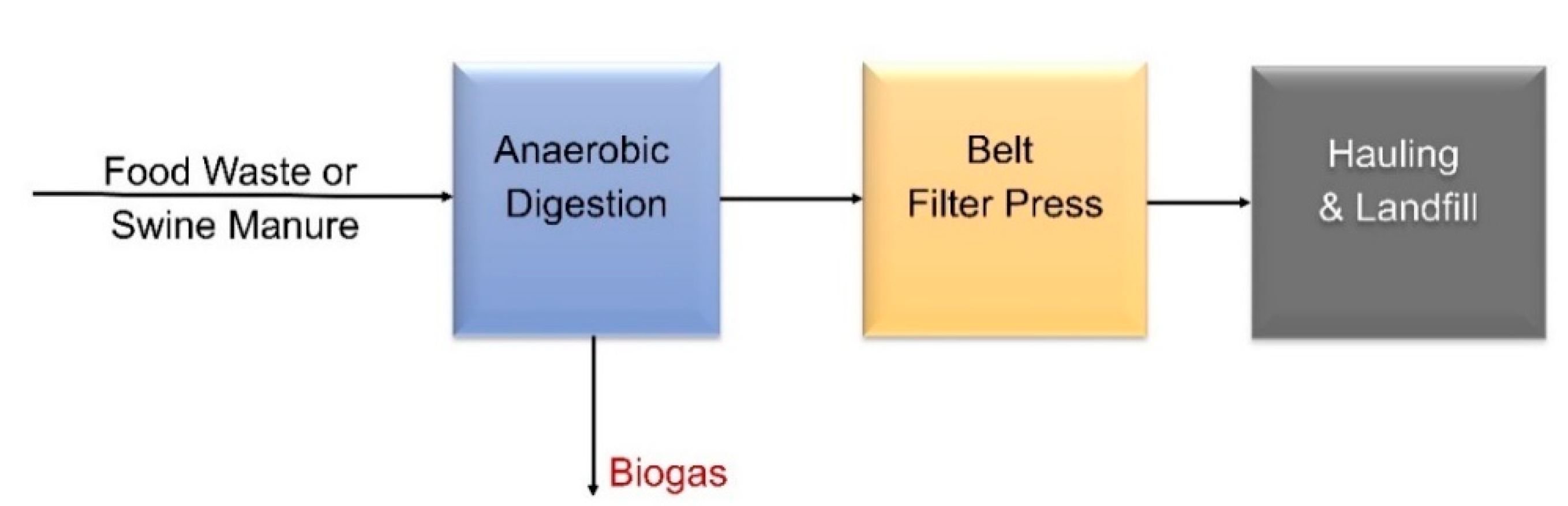

2. Current Practices—Anaerobic Digestion for Biogas Production

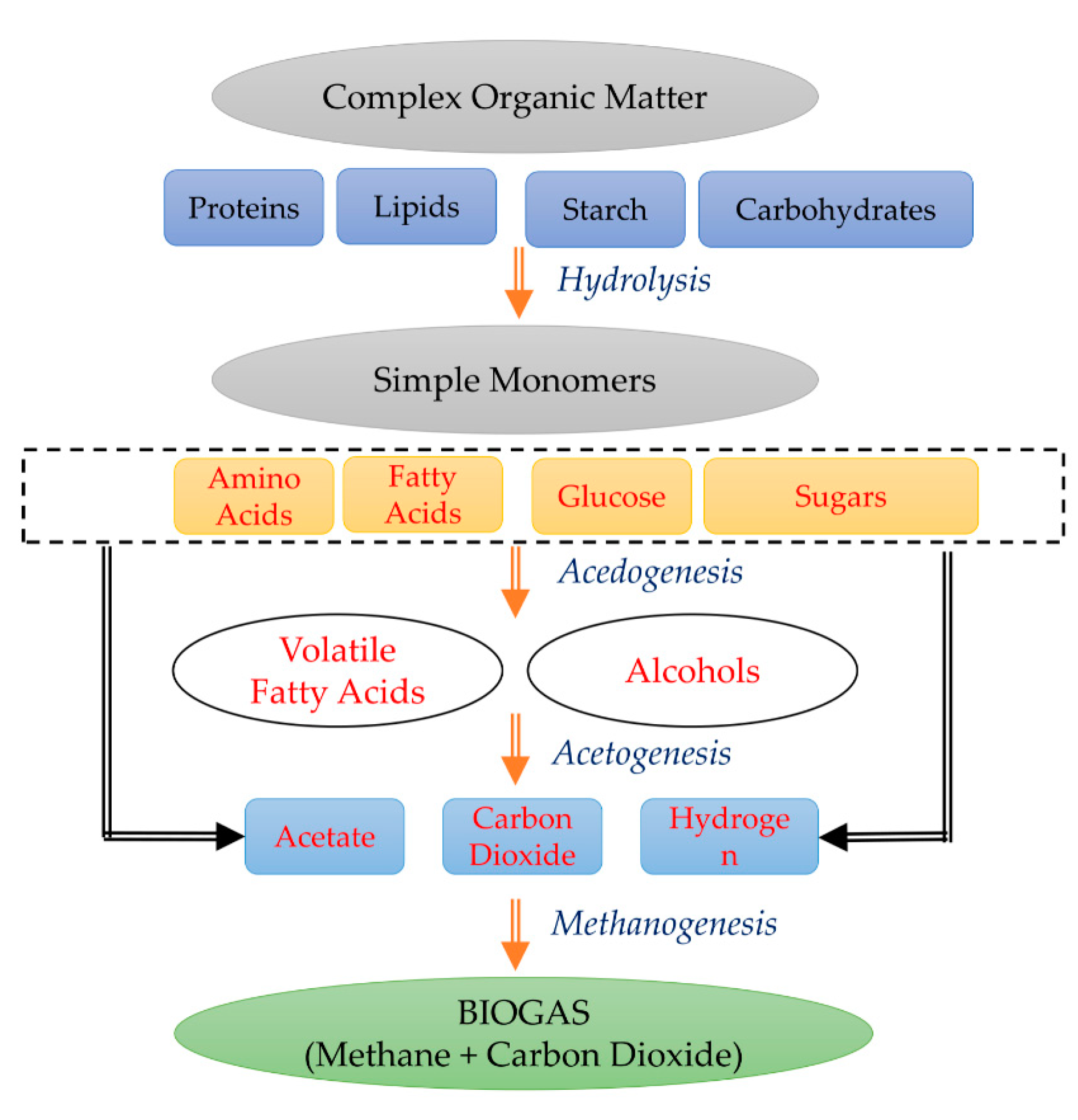

2.1. Steps Involved in AD Process

2.2. Factors Affecting the AD Process

3. Methods

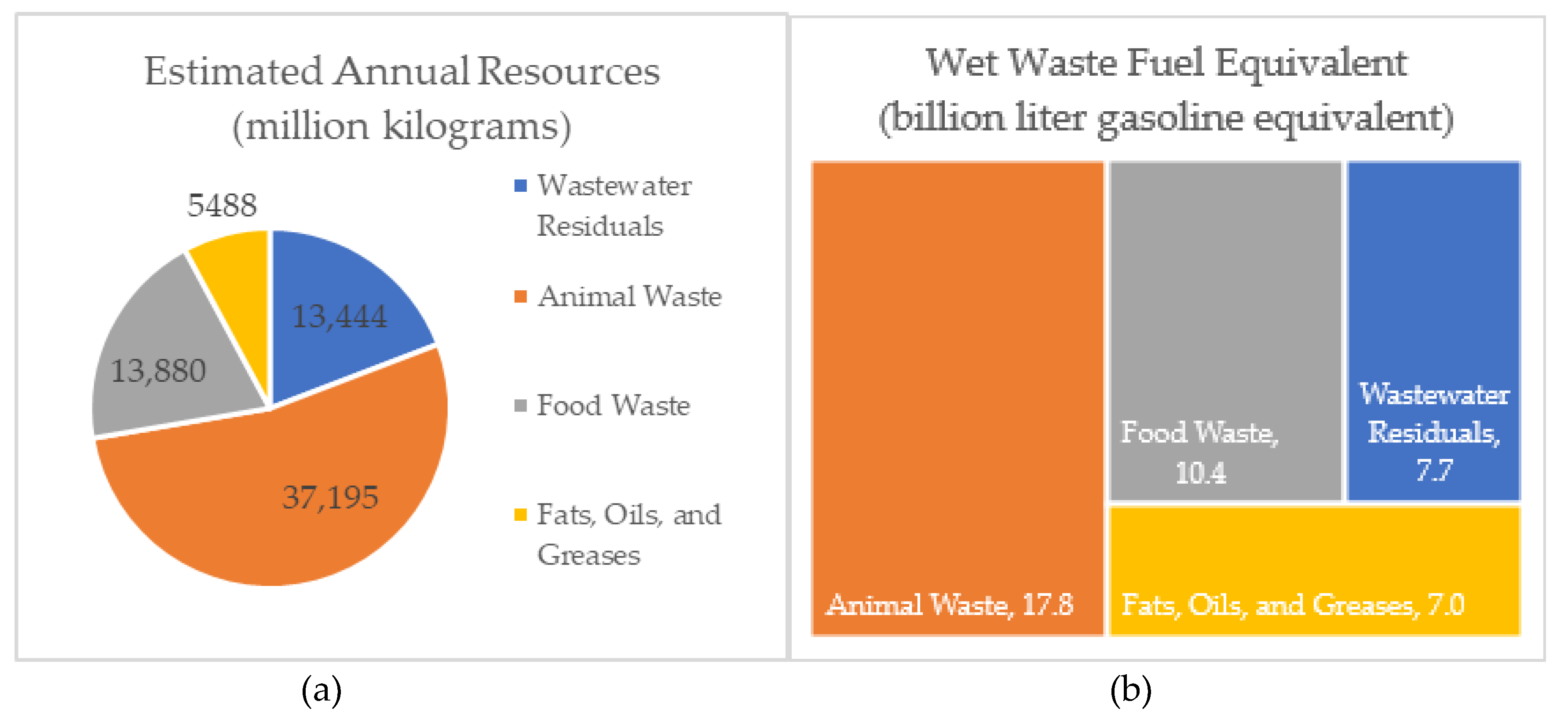

3.1. Feedstock Composition

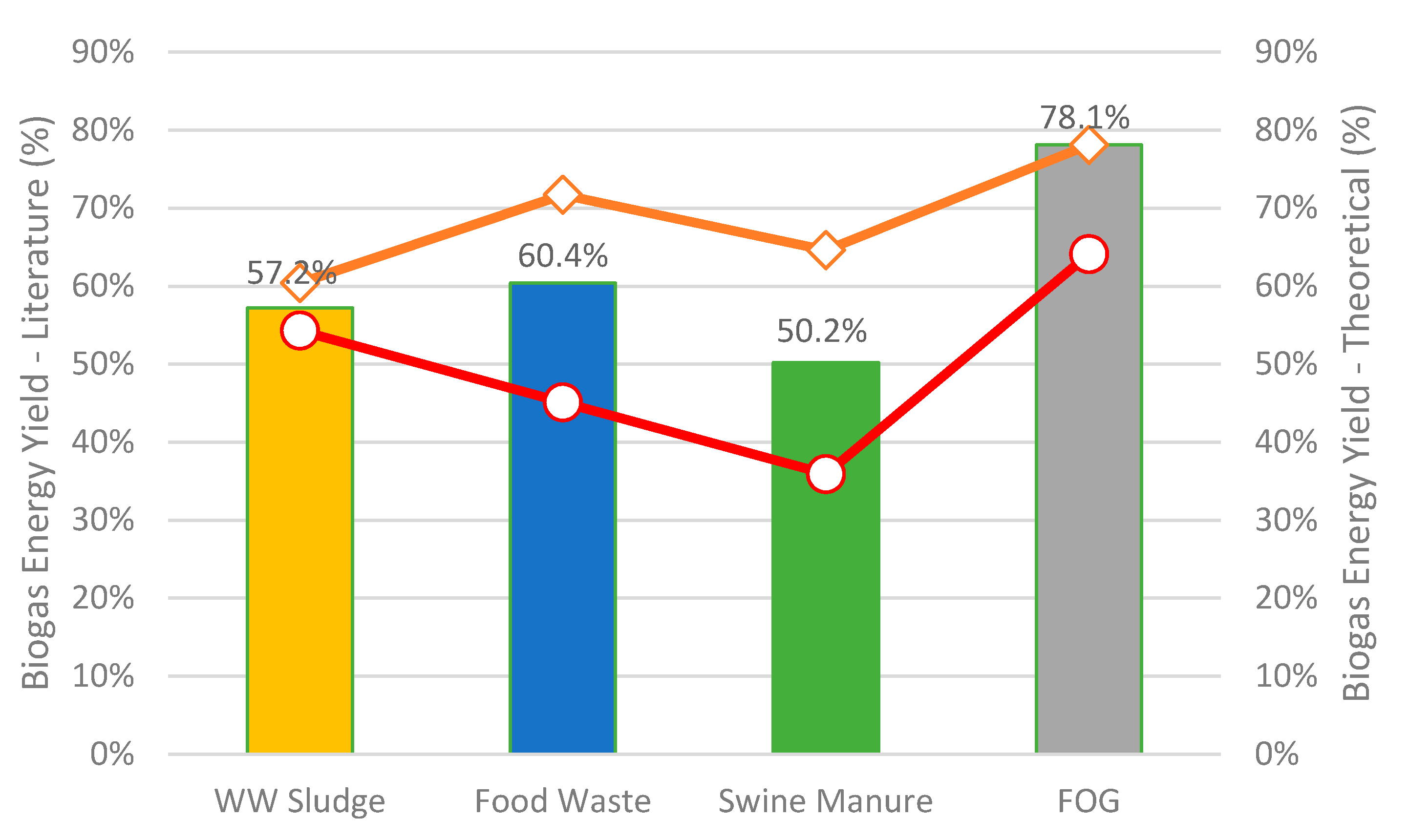

3.2. Biogas Composition and Energy Yield

3.3. Biogas Cost Analysis

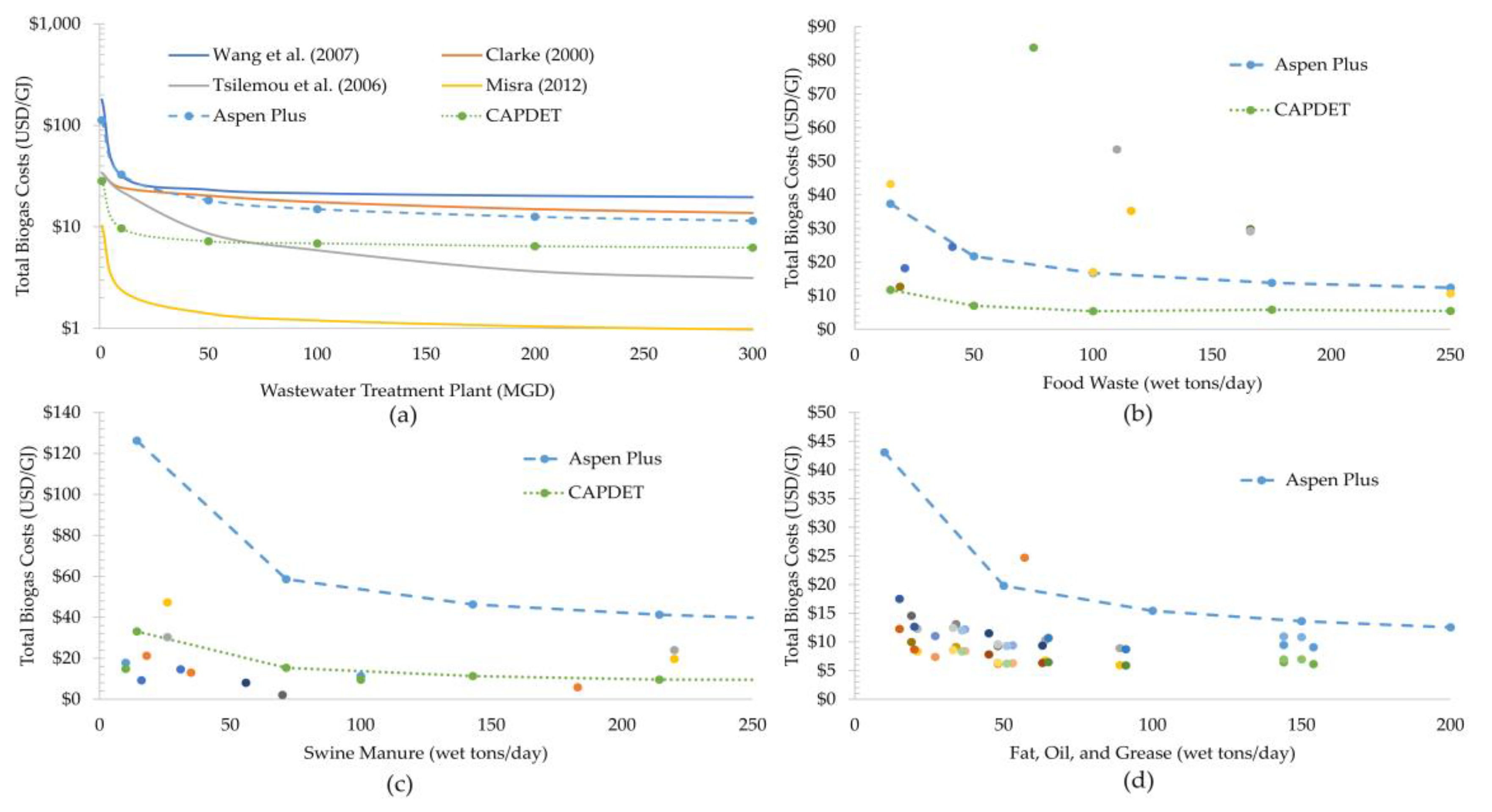

3.3.1. Cost Data from Open Literature

3.3.2. Cost Data from Aspen Plus Simulation

3.3.3. Cost Data from CapdetWorks

4. Results

4.1. Biogas Composition and Energy Yields

4.2. Biogas Economics

5. Discussion

Current Uses and Critical Issues Related to Biogas

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mazur, A. How does population growth contribute to rising energy consumption in America? Popul. Environ. 1994, 15, 371–378. [Google Scholar] [CrossRef]

- Graham, Z. Peak People: The Interrelationship between Population Growth and Energy Resources; Energy Bulletin: Leederville, Australia, 2009. [Google Scholar]

- Kataki, R.; Chutia, R.S.; Bordoloi, N.J.; Saikia, R.; Sut, D.; Narzari, R.; Gogoi, L.; Nikhil, G.N.; Sarkar, O.; Venkata Mohan, S. Biohydrogen Production Scenario for Asian Countries. In Biohydrogen Production: Sustainability of Current Technology and Future Perspective; Singh, A., Rathore, D., Eds.; Springer: New Delhi, India, 2017; pp. 207–235. [Google Scholar] [CrossRef]

- Stern, D. The Role of Energy in Economic Growth. Ecol. Econ. Rev. 2011, 1219, 26–51. [Google Scholar]

- Koberg, M.; Gedanken, A. Optimization of bio-diesel production from oils, cooking oils, microalgae, and castor and jatropha seeds: Probing various heating sources and catalysts. Energy Environ. Sci. 2012, 5, 7460–7469. [Google Scholar] [CrossRef]

- BETO. Biofuels and Bioproducts from Wet and Gaseous Waste Streams: Challenges and Opportunities; Bioenergy Technologies Office (BETO): Washington, DC, USA, 2017.

- Liu, A.; Ren, F.; Lin, W.Y.; Wang, J.-Y. A review of municipal solid waste environmental standards with a focus on incinerator residues. Int. J. Sustain. Built Environ. 2015, 4, 165–188. [Google Scholar] [CrossRef]

- Rushton, L. Health hazards and waste management. Br. Med. Bull. 2003, 68, 183–197. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Steyer, J.-P.; Delgenès, J.-P.; Escudié, R. Food waste valorization via anaerobic processes: A review. Rev. Environ. Sci. Biotechnol. 2016, 15, 499–547. [Google Scholar] [CrossRef]

- Harrad, S.H.R.M. The Health Effects of the Products of Waste Combustion; Institute of Public and Environmental Health, University of Birmingham: Birmingham, UK, 1996. [Google Scholar]

- WorldBank. Chapter 5—Waste Composition. In Urban Development Series—Knowledge Papers; World Bank Group: Washington, DC, USA, 2009. [Google Scholar]

- Börjesson, M.; Ahlgren, E.O. Cost-effective biogas utilisation—A modelling assessment of gas infrastructural options in a regional energy system. Energy 2012, 48, 212–226. [Google Scholar] [CrossRef]

- Tilche, A.; Galatola, M. The potential of bio-methane as bio-fuel/bio-energy for reducing greenhouse gas emissions: A qualitative assessment for Europe in a life cycle perspective. Water Sci. Technol. J. Int. Assoc. Water Pollut. Res. 2008, 57, 1683–1692. [Google Scholar] [CrossRef]

- Kleerebezem, R.; Joosse, B.; Rozendal, R.; Van Loosdrecht, M.C.M. Anaerobic digestion without biogas? Rev. Environ. Sci. Bio/Technol. 2015, 14, 787–801. [Google Scholar] [CrossRef]

- Chiumenti, R.; Chiumenti, A.; da Borso, F.; Limina, S. Anaerobic Digestion of Swine Manure in Conventional and Hybrid Pilot Scale Plants: Performance and Gaseous Emissions Reduction; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2009; Volume 4. [Google Scholar]

- Global Methane Initiative. Overview of Anaerobic Digestion for Municipal Solid Waste; Global Methane Initiative: Washington, DC, USA, 2016. [Google Scholar]

- Chen, L.N.H. Anaerobic Digestion Basics; University of Idaho Extension: Moscow, ID, USA, 2014. [Google Scholar]

- Water Environment Federation. Anaerobic Digestion Fundamentals—Fact Sheet; Water Environment Federation: Alexandria, VA, USA, 2017. [Google Scholar]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef]

- Mao, C.; Feng, Y.; Wang, X.; Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 2015, 45, 540–555. [Google Scholar] [CrossRef]

- Jain, M.K.; Singh, R.; Tauro, P. Anaerobic digestion of cattle and sheep wastes. Agric. Wastes 1981, 3, 65–73. [Google Scholar] [CrossRef]

- Bowen, E.J.; Dolfing, J.; Davenport, R.J.; Read, F.L.; Curtis, T.P. Low-temperature limitation of bioreactor sludge in anaerobic treatment of domestic wastewater. Water Sci. Technol. 2014, 69, 1004–1013. [Google Scholar] [CrossRef] [PubMed]

- Mtui, G.Y.S. Trends in Industrial and Environmental Biotechnology Research in Tanzania. Afr. J. Biotechnol. 2007, 6, 2860–2867. [Google Scholar]

- Singh, S.K.; Kadi, S.; Prashanth, B.; Nayak, S.K. Factors Affecting Anaerobic Digestion of Organic Waste. Int. J. Eng. Res. Mech. Civ. Eng. 2018, 3. [Google Scholar]

- Rincón, B.; Borja, R.; González, J.M.; Portillo, M.C.; Sáiz-Jiménez, C. Influence of organic loading rate and hydraulic retention time on the performance, stability and microbial communities of one-stage anaerobic digestion of two-phase olive mill solid residue. Biochem. Eng. J. 2008, 40, 253–261. [Google Scholar] [CrossRef]

- Kougias, P.; Tiwari, V.; Barshes, N.R.; Bechara, C.F.; Lowery, B.; Pisimisis, G.; Berger, D.H. Modeling anesthetic times. Predictors and implications for short-term outcomes. J. Surg. Res. 2013, 180, 1–7. [Google Scholar] [CrossRef]

- Kim, J.; Park, C.; Kim, T.H.; Lee, M.; Kim, S.; Kim, S.W.; Lee, J. Effects of various pretreatments for enhanced anaerobic digestion with waste activated sludge. J. Biosci. Bioeng. 2003, 95, 271–275. [Google Scholar] [CrossRef]

- Lee, D.H.; Behera, S.K.; Kim, J.W.; Park, H.S. Methane production potential of leachate generated from Korean food waste recycling facilities: A lab-scale study. Waste Manag. 2009, 29, 876–882. [Google Scholar] [CrossRef]

- Turovskiy, I.S.; Mathai, P.K. Wastewater Sludge Processing; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 354. [Google Scholar]

- Seiple, T.E.; Coleman, A.M.; Skaggs, R.L. Municipal wastewater sludge as a sustainable bioresource in the United States. J. Environ. Manag. 2017, 197, 673–680. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Ebner, J.H.; Labatut, R.A.; Lodge, J.S.; Williamson, A.A.; Trabold, T.A. Anaerobic co-digestion of commercial food waste and dairy manure: Characterizing biochemical parameters and synergistic effects. Waste Manag. 2016, 52, 286–294. [Google Scholar] [CrossRef] [PubMed]

- Nazlina, H.; Aini, A.N.; Ismail, F.; Yusof, M.; Hassan, M. Effect of different temperature, initial pH and substrate composition on biohydrogen production from food waste in batch fermentation. Asian J. Biotechnol. 2009, 1, 42–50. [Google Scholar]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Wang, K.; Yin, J.; Shen, D.; Li, N. Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: Effect of pH. Bioresour. Technol 2014, 161, 395–401. [Google Scholar] [CrossRef]

- Uçkun Kiran, E.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Li, Y.; Jin, Y.; Li, H.; Borrion, A.; Yu, Z.; Li, J. Kinetic studies on organic degradation and its impacts on improving methane production during anaerobic digestion of food waste. Appl. Energy 2018, 213, 136–147. [Google Scholar] [CrossRef]

- Lu, X.; Jin, W.; Xue, S.; Wang, X. Effects of waste sources on performance of anaerobic co-digestion of complex organic wastes: Taking food waste as an example. Sci. Rep. 2017, 7, 15702. [Google Scholar] [CrossRef]

- ECN Database. Database for Biomass and Waste; Energy Research Center of the Netherlands: Petten, The Netherlands, 2012. [Google Scholar]

- Turner, C. How to Compost Dow Dung Manure. Available online: http://compost-turner.net/composting-technologies/how-to-compost-cow-dung-manure.html (accessed on 9 July 2019).

- Long, J.H.; Aziz, T.N.; De los Reyes, F.; Ducoste, J. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Saf. Environ. Prot. 2012, 90, 231–245. [Google Scholar] [CrossRef]

- EIA. Methodology for Allocating Municipal Solid Waste; Energy Information Administration: Washington, DC, USA, 2007.

- Chartier, P.; Palz, W. Energy from Biomass; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar]

- Nasr, F.A. Treatment and Resuse of Sewage Sludge. Environment 1997, 17, 109–113. [Google Scholar]

- Chua, K.H.; Cheah, W.L.; Tan, C.F.; Leong, Y.P. Harvesting biogas from wastewater sludge and food waste. IOP Conf. Ser. Earth Environ. Sci. 2013, 16. [Google Scholar] [CrossRef]

- Kuo, J.; Dow, J. Biogas production from anaerobic digestion of food waste and relevant air quality implications. J. Air Waste Manag. Assoc. 2017, 67, 1000–1011. [Google Scholar] [CrossRef] [PubMed]

- Nayono, S.E.; Gallert, C.; Winter, J. Co-digestion of press water and food waste in a biowaste digester for improvement of biogas production. Bioresour. Technol. 2010, 101, 6987–6993. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.D.; Chang, S.W.; Cha, J.H.; Jeong, S.Y.; Yoon, Y.S.; Lee, S.J.; Tran, M.C.; Ngo, H.H. Dry semi-continuous anaerobic digestion of food waste in the mesophilic and thermophilic modes: New aspects of sustainable management and energy recovery in South Korea. Energy Convers. Manag. 2017, 135, 445–452. [Google Scholar] [CrossRef]

- Xia, Y.; Masse, D.I.; McAllister, T.A.; Beaulieu, C.; Ungerfeld, E. Anaerobic digestion of chicken feather with swine manure or slaughterhouse sludge for biogas production. Waste Manag. 2012, 32, 404–409. [Google Scholar] [CrossRef]

- Cuetos, M.J.; Fernandez, C.; Gomez, X.; Moran, A. Anaerobic co-digestion of swine manure with energy crop residues. Biotechnol. Bioprocess Eng. 2011, 16, 1044–1052. [Google Scholar] [CrossRef]

- Chae, K.J.; Yim, S.K.; Choi, K.H.; Park, W.K.; Lim, D.K. Anaerobic Digestion of Swine Manure: Sung-Hwan Farm-Scale Biogas Plant in Korea; Division of Agriculture Environment and Ecology, National Institute of Agricultural Science and Technology: Kyungki, Korea, 2002; pp. 564–571. Available online: https://pdfs.semanticscholar.org/b51b/15d425e388daeccb6a5263b099ee8fad652a.pdf (accessed on 5 September 2019).

- Lobato, A.; Cuetos, M.; Gómez, X.; Morán, A. Improvement of biogas production by co-digestion of swine manure and residual glycerine. Biofuels 2014, 1. [Google Scholar] [CrossRef]

- Gonzalez-Fernandez, C.; Leon-Cofreces, C.; Garcia-Encina, P.A. Different pretreatments for increasing the anaerobic biodegradability in swine manure—ScienceDirect. Bioresour. Technol. 2008, 99, 8710–8714. [Google Scholar] [CrossRef]

- Martinez, E.J.; Redondas, V.; Fierro, J.; Gomez, X.; Moran, A. Anaerobic Digestion of High Lipid Content Wastes: FOG Co-digestion and Milk Processing FAT Digestion. J. Residuals Sci. Technol. 2011, 8, 53–60. [Google Scholar]

- Skaggs, R.L.; Coleman, A.M.; Seiple, T.E.; Milbrandt, A.R. Waste-to-Energy biofuel production potential for selected feedstocks in the conterminous United States. Renew. Sustain. Energy Rev. 2018, 82, 2640–2651. [Google Scholar] [CrossRef]

- USEPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2012; US Environmental Protection Agency: Washington, DC, USA, 2014.

- Zhang, Y.; Wang, X.C.; Cheng, Z.; Li, Y.; Tang, J. Effect of fermentation liquid from food waste as a carbon source for enhancing denitrification in wastewater treatment. Chemosphere 2016, 144, 689–696. [Google Scholar] [CrossRef]

- Nijaguna, B.T. Biogas Technology; New Age International: Kochi, India, 2007. [Google Scholar]

- Vranitzky, R.; Lahnsteiner, D.J. Sewage Sludge Disintegration Using Ozone—A Method of Enhancing the Anaerobic Stabilization of Sewage Sludge. 2003. Available online: https://www.semanticscholar.org/paper/SEWAGE-SLUDGE-DISINTEGRATION-USING-OZONE-A-METHOD-Vranitzky/50db49aefe72072c3b6584384efdc92d6d698162 (accessed on 5 September 2019).

- Ligero, P.; Soto, M. Sludge granulation during anaerobic treatment of pre-hydrolysed domestic wastewater. Water SA 2002, 28, 307–311. [Google Scholar] [CrossRef]

- Zitomer, D. Myths and Misconceptions of Digesters; Midwest Manure Summit, University of Wisconsin: Green Bay, Wisconsin, 2013. Available online: https://fyi.extension.wisc.edu/midwestmanure/files/2013/03/Myths-Minsconceptions-of-Digesters-Zitomer.pdf (accessed on 5 September 2019).

- Negre, J.; Jonsson, L. Sludge Treatment in an Anaerobic Bioreactor with External Membranes; Stockholm Vatten: Bromma, Sweden, 2010. [Google Scholar]

- Bachmann, N. Sustainable Biogas Production in Municipal Wastewater Treatment Plants; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Gray, D.; Suto, P.; Peck, C. Anaerobic Digestion of Food Waste. 2008. Available online: https://archive.epa.gov/region9/organics/web/pdf/ebmudfinalreport.pdf (accessed on 10 October 2019).

- Paritosh, K.; Kushwaha, S.K.; Yadav, M.; Pareek, N.; Chawade, A.; Vivekanand, V. Food Waste to Energy: An Overview of Sustainable Approaches for Food Waste Management and Nutrient Recycling. BioMed Res. Int. 2017, 2017. [Google Scholar] [CrossRef]

- ECN. Phyllis2—Pig Manure (#1715). Available online: https://www.ecn.nl/phyllis2/Biomass/View/1715 (accessed on 10 October 2019).

- Ministry of Agriculture, Natural Resources and Environment. Database on Waste Disposal Permits; Ministry of Agriculture, Natural Resources and Environment: Nicosia, Cyprus, 2011.

- Biogas Yields and Feedstock Productivity—Anaerobic Digestion. Available online: http://www.biogas-info.co.uk/about/feedstocks/ (accessed on 19 October 2019).

- Theofanous, E.; Kythreotou, N.; Panayiotou, G.; Florides, G.; Vyrides, I. Energy production from piggery waste using anaerobic digestion: Current status and potential in Cyprus. Renew. Energy 2014, 71, 263–270. [Google Scholar] [CrossRef]

- Brenan, J.; Pierce, C.; Hickey, D.R.O.S.M. Dairy Co-Digestion Using and Anaerobic Digester Research Project; California Energy Commission: Sacramento, CA, USA, 2016.

- Kabouris, J.C.; Tezel, U.; Pavlostathis, S.G.; Engelmann, M.; Dulaney, J.; Gillette, R.A.; Todd, A.C. Methane recovery from the anaerobic codigestion of municipal sludge and FOG. Bioresour. Technol. 2009, 100, 3701–3705. [Google Scholar] [CrossRef]

- Nas, M.N.; Mutlu, N.; Read, P.E. Random amplified polymorphic DNA (RAPD) analysis of long-term cultured hybrid hazelnut. Hortscience 2004, 39, 1079–1082. [Google Scholar] [CrossRef]

- SRI Consulting. U.S. Producer Price Indexes—Chemicals and Allied Products/Industrial Inorganic Chemicals Index. In Chemical Economics Handbook; IHS Markit: London, UK, 2008. [Google Scholar]

- Bureau of Labor Statistics Data Website. National Employment, Hours, and Earnings Catalog, Industry: Chemicals and Allied Products, 1980–2009; Bureau of Labor Statistics: Washington, DC, USA, 2009.

- AspenPlusTM; Release 7.2, Aspen Technology Inc.: Cambridge, MA, USA, 2007.

- Arsova, L. Anaerobic Digestion of Food Waste: Current Status, Problems and an Alternative Product; Columbia University: New York, NY, USA, 2010. [Google Scholar]

- Davis, R.; Kinchin, C.; Markham, J.; Tan, E.; Laurens, L.M.L.; Sexton, D.; Knorr, D.; Schoen, P.; Lukas, J. Process Design and Economics for the Conversion of Algal Biomass to Biofuels: Algal Biomass Fractionation to Lipid- and Carbohydrate-Derived Fuel Products; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2014.

- Birdsall Services Group. Anaerobic digestion of fats oils and grease to generate biogas biopower feasibility study. Available online: https://rucore.libraries.rutgers.edu/rutgers-lib/46247/PDF/1/play/ (accessed on 9 December 2019).

- Harris, R.W.; Cullinane, M.J., Jr.; Sun, P.T. Process Design and Cost Estimating Algorithms for the Computer Assisted Procedure for Design and Evaluation of Wastewater Treatment Systems (CAPDET); Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1982. [Google Scholar]

- Rossman, L.A. Computer-Aided Synthesis of Wastewater Treatment and Sludge Disposal Systems; Municipal Environmental Research Laboratory, Office of Research and Development, US Environmental Protection Agency: Washington, DC, USA, 1980; Volume 79.

- Chiumenti, A.; Chiumenti, R.; da Borso, F.; Limina, S. Comparison Between Dry and Wet Fermentation of Biomasses as Result of the Monitoring of Full Scale Plants; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2012; Volume 5. [Google Scholar]

- Riaño, B.; Molinuevo, B.; García-González, M.C. Potential for methane production from anaerobic co-digestion of swine manure with winery wastewater. Bioresour. Technol. 2011, 102, 4131–4136. [Google Scholar] [CrossRef]

- Molinuevo-Salces, B.; González-Fernández, C.; Gómez, X.; García-González, M.C.; Morán, A. Vegetable processing wastes addition to improve swine manure anaerobic digestion: Evaluation in terms of methane yield and SEM characterization. Appl. Energy 2012, 91, 36–42. [Google Scholar] [CrossRef]

- Li, J.; Jha, A.K.; Bajracharya, T.R. Dry Anaerobic Co-digestion of Cow Dung with Pig Manure for Methane Production. Appl. Biochem. Biotechnol. 2014, 173, 1537–1552. [Google Scholar] [CrossRef]

- East Bay Municipal Utility District. Anaerobic Digestion of Food Waste; EPA Region 9: San Francisco, CA, USA, 2008.

- EIA. Methodology for Allocating Municipal Solid Waste to Biogenic and Non-Biogenic Energy; Energy Information Administration: Washington, DC, USA, 2007.

- Wang, L.K.; Shammas, N.K.; Hung, Y.-T. Biosolids Treatment Processes; Humana Press: Totowa, NJ, USA, 2007; Volume 6. [Google Scholar]

- Clarke, W.P. Cost-benefit analysis of introducing technology to rapidly degrade municipal solid waste. Waste Manag. Res. 2000, 18. [Google Scholar] [CrossRef]

- Tsilemou, K.; Panagiotakopoulos, D. Approximate cost functions for solid waste treatment facilities. Waste Manag. Res. 2006, 24, 310–322. [Google Scholar] [CrossRef] [PubMed]

- Misra, K.B. Clean Production: Environmental and Economic Perspectives; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Moriarty, K. Feasibility Study of Anaerobic Digestion of Food Waste in St. Bernard, Louisiana. A Study Prepared in Partnership with the Environmental Protection Agency for the RE-Powering America’s Land Initiative: Siting Renewable Energy on Potentially Contaminated Land and Mine Sites; National Renewable Energy Lab (NREL): Golden, CO, USA, 2013.

- ILSR. Update on Anaerobic Digester Projects Using Food Waste in North America; Institute for Local Self-Reliance (ILSR): Washington, DC, USA, 2010. [Google Scholar]

- Davis, R.C. Anaerobic Digestion—Pathways for using Waste as Energy in Urban Settings; The University of British Columbia: Vancouver, BC, Canada, 2014. [Google Scholar]

- CalRecycle. Digesting Urban Residuals Forum; CalRecycle: City of San Jose, CA, USA, 2012.

- Zhang, Q.; Hu, J.; Lee, D.-J. Biogas from anaerobic digestion processes: Research updates. Renew. Energy 2016, 98, 108–119. [Google Scholar] [CrossRef]

- Colantoni, A.; Carlini, M.; Mosconi, E.; Castellucci, S.; Villarini, M. An Economical Evaluation of Anaerobic Digestion Plants Fed with Organic Agro-Industrial Waste. Energies 2017, 10, 1165. [Google Scholar] [CrossRef]

- Andriani, D.; Wresta, A.; Atmaja, T.D.; Saepudin, A. A review on optimization production and upgrading biogas through CO2 removal using various techniques. Appl. Biochem. Biotechnol. 2014, 172, 1909–1928. [Google Scholar] [CrossRef] [PubMed]

- Niesner, J.; Jecha, D.; Stehlík, P. Biogas Upgrading Technologies: State of Art Review in European Region. Chem. Eng. Trans. 2013, 35, 517–522. [Google Scholar]

- Krich, K.; Augenstein, D.; Batmale, J.P.; Benemann, J.; Rutledge, B.; Salour, D. Biomethane from Dairy Waste—A Sourcebook for the Production and Use of Renewable Natural Gas in California; Western United Dairymen: Modesto, CA, USA, 2005. [Google Scholar]

- Anthony, C. The Biochemistry of Methylotrophs; Academic Press: London, UK, 1982. [Google Scholar]

- Anthony, C. Bacterial oxidation of methane and methanol. Adv. Microb. Physiol. 1986, 27, 113–210. [Google Scholar]

- Dijkhuizen, L.; Levering, P.; De Vries, G. The Physiology and Biochemistry of Aerobic Methanol-Utilizing Gram-Negative and Gram-Positive Bacteria; Springer: Boston, MA, USA, 1992. [Google Scholar]

- Hanson, R.; Tsien, H.; Tsuji, K.; Brusseau, G.; Wackett, L. Biodegradation of low-molecular-weight halogenated hydrocarbons by methanotrophic bacteria. FEMS Microbiol. Lett. 1990, 87, 273–278. [Google Scholar] [CrossRef]

- Buswell, A.; Sollo , F., Jr. The mechanism of the methane fermentation. J. Am. Chem. Soc. 1948, 70, 1778–1780. [Google Scholar] [CrossRef]

- Hamer, G.; Hedén, C.G.; Carenberg, C.O. Methane as a carbon substrate for the production of microbial cells. Biotechnol. Bioeng. 1967, 9, 499–514. [Google Scholar] [CrossRef]

- Jiang, H.; Chen, Y.; Jiang, P.; Zhang, C.; Smith, T.J.; Murrell, J.C.; Xing, X.-H. Methanotrophs: Multifunctional bacteria with promising applications in environmental bioengineering. Biochem. Eng. J. 2010, 49, 277–288. [Google Scholar] [CrossRef]

- Hanson, R.S.; Hanson, T.E. Methanotrophic bacteria. Microbiol. Rev. 1996, 60, 439–471. [Google Scholar] [CrossRef] [PubMed]

- Schrader, J.; Schilling, M.; Holtmann, D.; Sell, D.; Villela Filho, M.; Marx, A.; Vorholt, J.A. Methanol-based industrial biotechnology: Current status and future perspectives of methylotrophic bacteria. Trends Biotechnol. 2009, 27, 107–115. [Google Scholar] [CrossRef] [PubMed]

- Op den Camp, H.J.; Islam, T.; Stott, M.B.; Harhangi, H.R.; Hynes, A.; Schouten, S.; Jetten, M.S.; Birkeland, N.K.; Pol, A.; Dunfield, P.F. Environmental, genomic and taxonomic perspectives on methanotrophic Verrucomicrobia. Environ. Microbiol. Rep. 2009, 1, 293–306. [Google Scholar] [CrossRef]

- Henard, C.A.; Smith, H.; Dowe, N.; Kalyuzhnaya, M.G.; Pienkos, P.T.; Guarnieri, M.T. Bioconversion of methane to lactate by an obligate methanotrophic bacterium. Sci. Rep. 2016, 6, 21585. [Google Scholar] [CrossRef]

- Anthony, C. How half a century of research was required to understand bacterial growth on C1 and C2 compounds; the story of the serine cycle and the ethylmalonyl-CoA pathway. Sci. Prog. 2011, 94, 109–137. [Google Scholar] [CrossRef]

- Chistoserdova, L. Modularity of methylotrophy, revisited. Environ. Microbiol. 2011, 13, 2603–2622. [Google Scholar] [CrossRef]

- Matsen, J.B.; Yang, S.; Stein, L.Y.; Beck, D.; Kalyuzhnaya, M.G. Global molecular analyses of methane metabolism in methanotrophic alphaproteobacterium, Methylosinus trichosporium OB3b. Part I: Transcriptomic study. Front. Microbiol. 2013, 4, 40. [Google Scholar] [CrossRef]

- EPA Regulatory Announcement. EPA Issues Final Rule for Renewable Fuel Standard (RFS) Pathways II and Modifications to the RFS Program, Ultra Low Sulfur Diesel Requirements, and E15 Misfueling Mitigation Requirements; EPA: Washington, DC, USA, 2014.

- USDA; EPA; DOE. Biogas Opportunities Roadmap; U.S. Department of Agriculture: Washington, DC, USA, 2014.

- Murray, B.C.; Galik, C.S.; Vegh, T. Biogas in the United States: An Assessment of Market Potential in a Carbon-Constrained Future; Nicholas Institute for Environmental Policy Solutions: Durham, NC, USA, 2014. [Google Scholar]

- Bhatt, A.H.; Ren, Z.; Tao, L. Value Proposition of Untapped Wet Wastes: Carboxylic Acid Production through Anaerobic Digestion. iScience 2020, 23, 101221. [Google Scholar] [CrossRef]

| Parameters | Wastewater Sludge | Food Waste | Swine Manure | FOG | |

|---|---|---|---|---|---|

| Composition (Dry Weight%) | |||||

| Ash | 7.5% | 5.0% | 15.2% | 0% | |

| Lipids | 18.0% | 21.0% | 3.8% | 78.0% | |

| Proteins | 24.0% | 19.0% | 20.0% | 7.0% | |

| Fermentable Carbohydrates | 16.0% | 55.0% | 36.5% | 15.0% | |

| Lignin | 0% | 0% | 21.0% | 0% | |

| Extractives (all non-fermentable components) | 34.5% | 0% | 3.5% | 0% | |

| Component Parameters | |||||

| Energy Density | MMBtu/t TS | 19.5 | 22.9 | 17.1 | 39.0 |

| MJ/kg TS | 20.6 | 24.2 | 18.0 | 41.1 | |

| Moisture Content (%) | 96% | 75% | 93% | 6–95% | |

| TS (%) | Primary—2–6% | 25% | 7% | 5–94% | |

| Secondary—2–10% | |||||

| COD (mg/L) | Range | 47,200–140,000 | 39,800–350,000 | 20,600–35,000 | 92,000–149,000 |

| Mean | 135,711 | 154,000 | 28,430 | 120,500 | |

| COD Reduction | 55.5% | 65.0% | 55.0% | 82.0% | |

| Biogas Yield | m3/t TS | 500–600 | 646 | 566 | 1168–1422 |

| L/kg TS | 500–600 | 646 | 565 | 1169–1422 | |

| MMBtu/t TS | 11–13 | 14 | 12 | 20–25 | |

| MJ/kg TS | 12–14 | 15 | 13 | 21–27 | |

| Typical Scale | wet US tons/day, unless noted | 1–300 MGD | 1–250 | 1–250 | 1–200 |

| wet metric tons/day, unless noted | 1–300 MGD | 0.9–227 | 0.9–227 | 0.9–181 | |

| kg/day, unless noted | 3785–1,135,500 m3/day | 907–227,000 | 907–227,000 | 907–181,000 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhatt, A.H.; Tao, L. Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering 2020, 7, 74. https://doi.org/10.3390/bioengineering7030074

Bhatt AH, Tao L. Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering. 2020; 7(3):74. https://doi.org/10.3390/bioengineering7030074

Chicago/Turabian StyleBhatt, Arpit H., and Ling Tao. 2020. "Economic Perspectives of Biogas Production via Anaerobic Digestion" Bioengineering 7, no. 3: 74. https://doi.org/10.3390/bioengineering7030074

APA StyleBhatt, A. H., & Tao, L. (2020). Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering, 7(3), 74. https://doi.org/10.3390/bioengineering7030074