Bioprocess Engineering Aspects of Sustainable Polyhydroxyalkanoate Production in Cyanobacteria

Abstract

1. Introduction

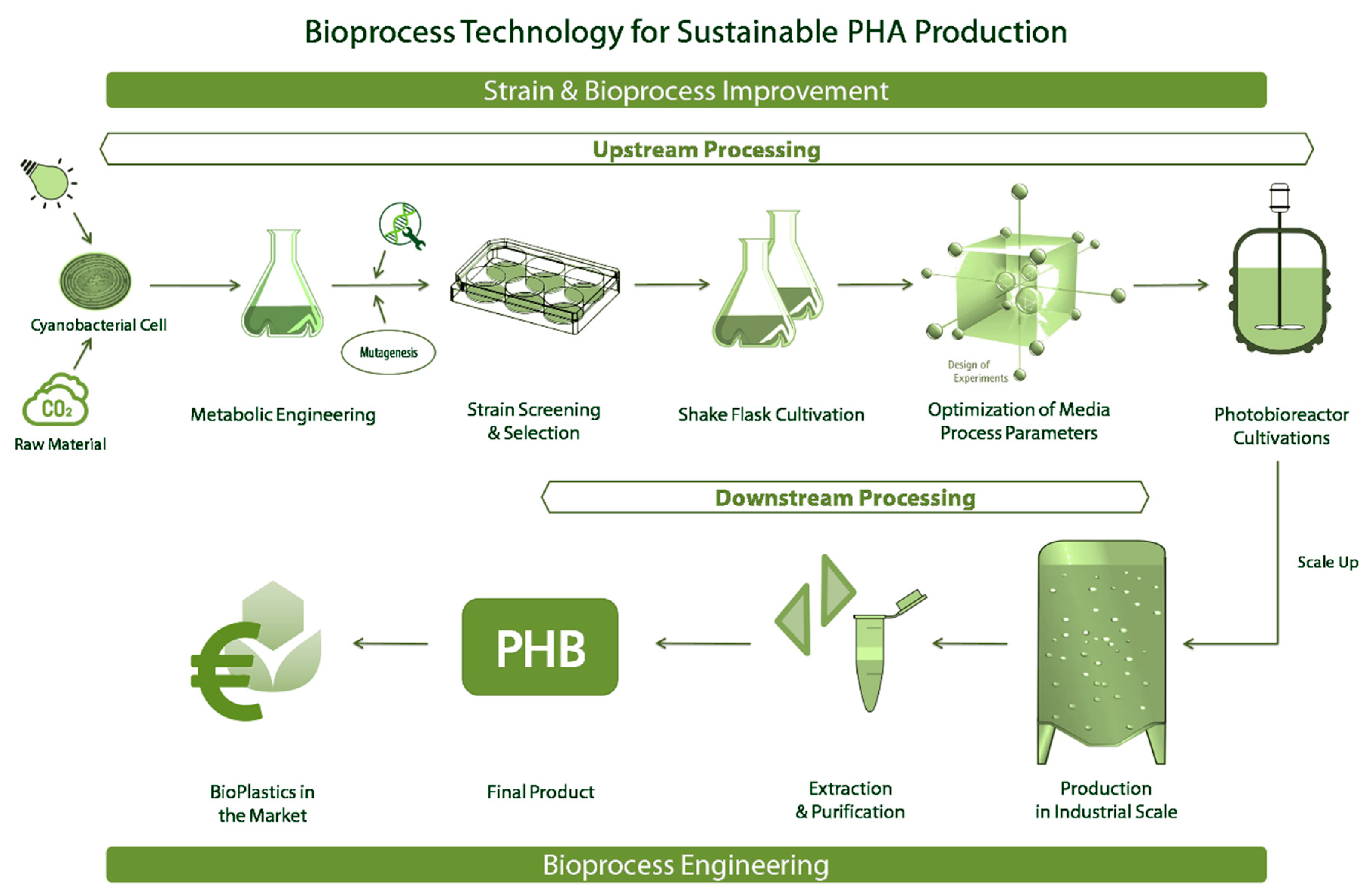

2. Cyanobacteria: The Future Host in Biotechnology

3. Challenges in Cyanobacterial Bioprocess Technology

3.1. Process Design and Optimization

3.1.1. Existing Wild-Type Strains and Their Reported PHB Content

3.1.2. More Competent Cyanobacterial Cell Lines

3.1.3. Genetic Engineering of Cyanobacteria for PHB Production

3.1.4. Randomly Mutated Strains with Improved PHB Content

3.1.5. CRISPR/Cas Based Genome Editing in Cyanobacteria

3.2. Process Design and Bioprocess Improvement Strategies

3.2.1. Media and Cultivation Conditions

3.2.2. PHB Production Using Mixed Photosynthetic Consortia

3.2.3. PHB Production Using Mixed Feed Systems

3.2.4. CO2 Sequestration

4. Production Strategies

4.1. Cultivation Modes

4.2. Cultivation Systems

5. Process Monitoring and Control

6. Production Scenarios

7. The Remaining Challenges in Photosynthetic PHB Production

8. Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De Koning, G.J.M. Prospects of Bacterial Poly[(R)-3-(Hydroxyalkanoates)]; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 1993. [Google Scholar]

- Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Bioplastics with a green agenda. Curr. Opin. Microbiol. 2010, 13, 321–326. [Google Scholar] [CrossRef] [PubMed]

- Lackner, M. Bioplastics. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Tan, G.-Y.; Chen, C.-L.; Li, L.; Ge, L.; Wang, L.; Razaad, I.; Li, Y.; Zhao, L.; Mo, Y.; Wang, J.-Y. Start a Research on Biopolymer Polyhydroxyalkanoate (PHA): A Review. Polymers 2014, 6, 706–754. [Google Scholar] [CrossRef]

- Getachew, A.; Woldesenbet, F. Production of biodegradable plastic by polyhydroxybutyrate (PHB) accumulating bacteria using low cost agricultural waste material. BMC Res. Notes 2016, 9, 509. [Google Scholar] [CrossRef] [PubMed]

- Madison, L.L.; Huisman, G.W. Metabolic Engineering of Poly(3-Hydroxyalkanoates): From DNA to Plastic. Microbiol. Mol. Biol. Rev. 1999, 63, 21–53. [Google Scholar] [PubMed]

- Ten, E.; Jiang, L.; Zhang, J.; Wolcott, M.P. 3—Mechanical Performance of polyhydroxyalkanoate (PHA)-based biocomposites. In Biocomposites; Misra, M., Pandey, J.K., Mohanty, A.K., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 39–52. [Google Scholar]

- Galia, M.B. Isolation and analysis of storage compounds. In Handbook of Hydrocarbon and Lipid Microbiology; Timmis, K.N., Ed.; Springer: Berlin, Germany, 2010. [Google Scholar]

- Barham, P.J.; Organ, S.J. Mechanical properties of polyhydroxybutyrate-hydroxybutyrate-hydroxyvalerate copolymer blends. J. Mater. Sci. 1994, 29, 1676–1679. [Google Scholar] [CrossRef]

- Harding, K.G.; Dennis, J.S.; Blottnitz, H.; Harrison, S.T. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-beta-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Lackner, M.; Markl, E.; Grünbichler, H. Cyanobacteria for PHB Bioplastics Production: A Review. Nov. Tech. Nutr. Food Sci. 2018, 2, 4. [Google Scholar]

- Balaji, S.; Gopi, K.; Muthuvelan, B. A review on production of poly β hydroxybutyrates from cyanobacteria for the production of bio plastics. Algal Res. 2013, 2, 278–285. [Google Scholar] [CrossRef]

- Grothe, E.; Chisti, Y. Poly (ß-hydroxybutyric acid) thermoplastic production by Alcaligenes latus: Behavior of fed-batch cultures. Bioprocess Biosyst. Eng. 2000, 22, 441–449. [Google Scholar] [CrossRef]

- Schubert, P.; Steinbüchel, A.; Schlegel, H.G. Cloning of the Alcaligenes eutrophus genes for synthesis of poly-beta-hydroxybutyric acid (PHB) and synthesis of PHB in Escherichia coli. J. Bacteriol. 1988, 170, 5837–5847. [Google Scholar] [CrossRef] [PubMed]

- Nonato, R.; Mantelatto, P.; Rossell, C. Integrated production of biodegradable plastic, sugar and ethanol. Appl. Microbiol. Biotechnol. 2001, 57, 1–5. [Google Scholar] [PubMed]

- Koller, M.; Salerno, A.; Reiterer, A.; Malli, H.; Malli, K.; Kettl, K.H.; Narodoslawsky, M.; Schnitzer, H.; Chiellini, E.; Braunegg, G. Sugar cane as feedstock for biomediated polymer production. In Sugarcane: Production, Cultivation and Uses; Nova Publishers: Hauppauge, NY, USA, 2012; pp. 105–136. [Google Scholar]

- Steinbüchel, A. PHB and Other Polhydroxyalkanoic Acids. In Biotechnology Set, 2nd ed.; Wiley: Hoboken, NJ, USA, 2008; pp. 403–464. [Google Scholar]

- Gurieff, N.; Lant, P. Comparative life cycle assessment and financial analysis of mixed culture polyhydroxyalkanoates production. Bioresour. Technol. 2007, 98, 3393–3403. [Google Scholar] [CrossRef] [PubMed]

- Reis, M.A.M.; Serafim, L.S.; Lemos, P.C.; Ramos, A.M.; Aguiar, F.R.; Loosdrecht, M.C.M. Production of polyhydroxyalkanoates by mixed microbial cultures. Bioprocess Biosyst. Eng. 2003, 25, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Alias, Z.; Tan, I.K. Isolation of palm oil-utilising, polyhydroxyalkanoate (PHA)-producing bacteria by an enrichment technique. Bioresour. Technol. 2005, 96, 1229–1234. [Google Scholar] [CrossRef] [PubMed]

- Oliver, N.J.; Rabinovitch-Deere, C.A.; Carroll, A.L.; Nozzi, N.E.; Case, A.E.; Atsumi, S. Cyanobacterial metabolic engineering for biofuel and chemical production. Curr. Opin. Chem. Biol. 2016, 35, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Costa, J.A.V.; Moreira, J.B.; Lucas, B.F.; Braga, V.D.S.; Cassuriaga, A.P.A.; Morais, M.G.D. Recent Advances and Future Perspectives of PHB Production by Cyanobacteria. Ind. Biotechnol. 2018, 14, 249–256. [Google Scholar] [CrossRef]

- Troschl, C.; Meixner, K.; Drosg, B. Cyanobacterial PHA Production—Review of Recent Advances and a Summary of Three Years’ Working Experience Running a Pilot Plant. Bioengineering 2017, 4, 26. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Mallick, N. Advances in cyanobacterial polyhydroxyalkanoates production. FEMS Microbiol. Lett. 2017, 364, fnx189. [Google Scholar] [CrossRef] [PubMed]

- Drosg, B.; Fritz, I.; Gattermayer, F.; Silvestrini, L. Photo-autotrophic Production of Poly(hydroxyalkanoates) in Cyanobacteria. Chem. Biochem. Eng. Q. 2015, 29, 145–156. [Google Scholar] [CrossRef]

- Koller, M.; Marsalek, L. Cyanobacterial Polyhydroxyalkanoate Production: Status Quo and Quo Vadis? Curr. Biotechnol. 2015, 4, 464–480. [Google Scholar] [CrossRef]

- Choi, J.; Lee, S.Y. Factors affecting the economics of polyhydroxyalkanoate production by bacterial fermentation. Appl. Microbiol. Biotechnol. 1999, 51, 13–21. [Google Scholar] [CrossRef]

- Lau, N.-S.; Matsui, M.; Al Abdullah, A.-A. Cyanobacteria: Photoautotrophic Microbial Factories for the Sustainable Synthesis of Industrial Products. BioMed Res. Int. 2015, 2015, 754934. [Google Scholar] [CrossRef] [PubMed]

- Dismukes, G.C.; Carrieri, D.; Bennette, N.; Ananyev, G.M.; Posewitz, M.C. Aquatic phototrophs: Efficient alternatives to land-based crops for biofuels. Curr. Opin. Biotechnol. 2008, 19, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Case, A.E.; Atsumi, S. Cyanobacterial chemical production. J. Biotechnol. 2016, 231, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Panda, B.; Jain, P.; Sharma, L.; Mallick, N. Optimization of cultural and nutritional conditions for accumulation of poly-β-hydroxybutyrate in Synechocystis sp. PCC 6803. Bioresour. Technol. 2006, 97, 1296–1301. [Google Scholar] [CrossRef] [PubMed]

- Kamravamanesh, D.; Pflügl, S.; Nischkauer, W.; Limbeck, A.; Lackner, M.; Herwig, C. Photosynthetic poly-β-hydroxybutyrate accumulation in unicellular cyanobacterium Synechocystis sp. PCC 6714. AMB Express 2017, 7, 143. [Google Scholar] [CrossRef] [PubMed]

- Campbell, J.; Stevens, S.E.; Balkwill, D.L. Accumulation of poly-beta-hydroxybutyrate in Spirulina platensis. J. Bacteriol. 1982, 149, 361–363. [Google Scholar] [PubMed]

- Toh, P.S.Y.; Jau, M.H.; Yew, S.P.; Abed, R.M.M.; Sidesh, K. Comparison of polyhydroxyalkanoates biosynthesis, mobilization and the effects on cellular morphology in Spirulina Platensis and Synechocystis sp. UNIWG. J. Biosci. 2008, 19, 21–38. [Google Scholar]

- De Philippis, R.; Sili, C.; Vincenzini, M. Glycogen and poly-β-hydroxybutyrate synthesis in Spirulina maxima. Microbiology 1992, 138, 1623–1628. [Google Scholar] [CrossRef]

- Stal, L.J.; Heyer, H.; Jacobs, G. Occurrence and Role of Poly-Hydroxy-Alkanoate in the Cyanobacterium Oscillatoria Limosa. In Novel Biodegradable Microbial Polymers; Dawes, E.A., Ed.; Springer: Dordrecht, The Netherlands, 1990; pp. 435–438. [Google Scholar]

- Bhati, R.; Mallick, N. Production and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) co-polymer by a N2-fixing cyanobacterium, Nostoc muscorum Agardh. J. Chem. Technol. Biotechnol. 2012, 87, 505–512. [Google Scholar] [CrossRef]

- Haase, S.M.; Huchzermeyer, B.; Rath, T. PHB accumulation in Nostoc muscorum under different carbon stress situations. J. Appl. Phycol. 2012, 24, 157–162. [Google Scholar] [CrossRef]

- Samantaray, S.; Mallick, N. Production of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) co-polymer by the diazotrophic cyanobacterium Aulosira fertilissima CCC 444. J. Appl. Phycol. 2014, 26, 237–245. [Google Scholar] [CrossRef]

- Samantaray, S.; Mallick, N. Production and characterization of poly-β-hydroxybutyrate (PHB) polymer from Aulosira fertilissima. J. Appl. Phycol. 2012, 24, 803–814. [Google Scholar] [CrossRef]

- Takahashi, H.; Miyake, M.; Tokiwa, Y.; Asada, Y. Improved accumulation of poly-3-hydroxybutyrate by a recombinant cyanobacterium. Biotechnol. Lett. 1998, 20, 183–186. [Google Scholar] [CrossRef]

- Troschl, C.; Meixner, K.; Fritz, I.; Leitner, K.; Romero, A.P.; Kovalcik, A.; Sedlacek, P.; Drosg, B. Pilot-scale production of poly-β-hydroxybutyrate with the cyanobacterium Synechocytis sp. CCALA192 in a non-sterile tubular photobioreactor. Algal Res. 2018, 34, 116–125. [Google Scholar] [CrossRef]

- Lama, L.; Nicolaus, B.; Calandrelli, V.; Manca, M.C.; Romano, I.; Gambacorta, A. Effect of growth conditions on endo- and exopolymer biosynthesis in Anabaena cylindrica 10 C. Phytochemistry 1996, 42, 655–659. [Google Scholar] [CrossRef]

- Mendhulkar, V.D.; Laukik, A.S. Synthesis of Biodegradable Polymer Polyhydroxyalkanoate (PHA) in Cyanobacteria Synechococcus elongates Under Mixotrophic Nitrogen- and Phosphate-Mediated Stress Conditions. Ind. Biotechnol. 2017, 13, 85–93. [Google Scholar] [CrossRef]

- Monshupanee, T.; Nimdach, P.; Incharoensakdi, A. Two-stage (photoautotrophy and heterotrophy) cultivation enables efficient production of bioplastic poly-3-hydroxybutyrate in auto-sedimenting cyanobacterium. Sci. Rep. 2016, 6, 37121. [Google Scholar] [CrossRef] [PubMed]

- Khetkorn, W.; Incharoensakdi, A.; Lindblad, P.; Jantaro, S. Enhancement of poly-3-hydroxybutyrate production in Synechocystis sp. PCC 6803 by overexpression of its native biosynthetic genes. Bioresour. Technol. 2016, 214, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Katayama, N.; Iijima, H.; Osanai, T. Production of Bioplastic Compounds by Genetically Manipulated and Metabolic Engineered Cyanobacteria. In Synthetic Biology of Cyanobacteria; Zhang, W., Song, X., Eds.; Springer: Singapore, 2018; pp. 155–169. [Google Scholar]

- Koksharova, O.; Wolk, C. Genetic tools for cyanobacteria. Appl. Microbiol. Biotechnol. 2002, 58, 123–137. [Google Scholar] [PubMed]

- Wilde, A.; Dienst, D. Tools for Genetic Manipulation of Cyanobacteria. In Bioenergetic Processes of Cyanobacteria: From Evolutionary Singularity to Ecological Diversity; Peschek, G.A., Obinger, C., Renger, G., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 685–703. [Google Scholar]

- Hauf, W.; Watzer, B.; Roos, N.; Klotz, A.; Forchhammer, K. Photoautotrophic Polyhydroxybutyrate Granule Formation Is Regulated by Cyanobacterial Phasin PhaP in Synechocystis sp. Strain PCC 6803. Appl. Environ. Microbiol. 2015, 81, 4411–4422. [Google Scholar] [CrossRef] [PubMed]

- Taroncher-Oldenburg, G.; Nishina, K.; Stephanopoulos, G. Identification and analysis of the polyhydroxyalkanoate-specific β-ketothiolase and acetoacetyl coenzyme A reductase genes in the cyanobacterium Synechocystis sp. strain PCC6803. Appl. Environ. Microbiol. 2000, 66, 4440–4448. [Google Scholar] [CrossRef] [PubMed]

- Hein, S.; Tran, H.; Steinbuchel, A. Synechocystis sp. PCC6803 possesses a two-component polyhydroxyalkanoic acid synthase similar to that of anoxygenic purple sulfur bacteria. Arch. Microbiol. 1998, 170, 162–170. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, E.; Ohkawa, H.; Moriya, K.; Matsubara, T.; Nagaike, Y.; Iwasaki, I.; Fujiwara, S.; Tsuzuki, M.; Nakamura, Y. Carbohydrate metabolism in mutants of the cyanobacterium Synechococcus elongatus PCC 7942 defective in glycogen synthesis. Appl. Environ. Microbiol. 2010, 76, 3153–3159. [Google Scholar] [CrossRef] [PubMed]

- Sudesh, K.; Taguchi, K.; Doi, Y. Effect of increased PHA synthase activity on polyhydroxyalkanoates biosynthesis in Synechocystis sp. PCC6803. Int. J. Biol. Macromol. 2002, 30, 97–104. [Google Scholar] [CrossRef]

- Lau, N.-S.; Foong, C.P.; Kurihara, Y.; Sudesh, K.; Matsui, M. RNA-Seq Analysis Provides Insights for Understanding Photoautotrophic Polyhydroxyalkanoate Production in Recombinant Synechocystis sp. PLoS ONE 2014, 9, e86368. [Google Scholar] [CrossRef] [PubMed]

- Carpine, R.; Du, W.; Olivieri, G.; Pollio, A.; Hellingwerf, K.J.; Marzocchella, A.; Branco dos Santos, F. Genetic engineering of Synechocystis sp. PCC6803 for poly-β-hydroxybutyrate overproduction. Algal Res. 2017, 25, 117–127. [Google Scholar] [CrossRef]

- Zhang, S.; Qian, X.; Chang, S.; Dismukes, G.C.; Bryant, D.A. Natural and Synthetic Variants of the Tricarboxylic Acid Cycle in Cyanobacteria: Introduction of the GABA Shunt into Synechococcus sp. PCC 7002. Front. Microbiol. 2016, 7, 1972. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Xiong, W.; Yu, J.; Maness, P.-C.; Meldrum, D.R. Unlocking the photobiological conversion of CO2 to (R)-3-hydroxybutyrate in cyanobacteria. Green Chem. 2018, 20, 3772–3782. [Google Scholar] [CrossRef]

- Hondo, S.; Takahashi, M.; Osanai, T.; Matsuda, M.; Hasunuma, T.; Tazuke, A.; Nakahira, Y.; Chohnan, S.; Hasegawa, M.; Asayama, M. Genetic engineering and metabolite profiling for overproduction of polyhydroxybutyrate in cyanobacteria. J. Biosci. Bioeng. 2015, 120, 510–517. [Google Scholar] [CrossRef] [PubMed]

- Jaeger, L.D. Strain Improvement of Oleaginous Microalgae; Wageningen University: Wageningen, The Netherlands, 2015; p. 200. [Google Scholar]

- Lee, B.; Choi, G.-G.; Choi, Y.-E.; Sung, M.; Park, M.S.; Yang, J.-W. Enhancement of lipid productivity by ethyl methane sulfonate-mediated random mutagenesis and proteomic analysis in Chlamydomonas reinhardtii. Korean J. Chem. Eng. 2014, 31, 1036–1042. [Google Scholar] [CrossRef]

- Kamravamanesh, D.; Slouka, C.; Limbeck, A.; Lackner, M.; Herwig, C. Increased carbohydrate production from carbon dioxide in randomly mutated cells of cyanobacterial strain Synechocystis sp. PCC 6714: Bioprocess understanding and evaluation of productivities. Bioresour. Technol. 2019, 273, 277–287. [Google Scholar] [CrossRef] [PubMed]

- Kamravamanesh, D.; Kovacs, T.; Pflügl, S.; Druzhinina, I.; Kroll, P.; Lackner, M.; Herwig, C. Increased poly-β-hydroxybutyrate production from carbon dioxide in randomly mutated cells of cyanobacterial strain Synechocystis sp. PCC 6714: Mutant generation and characterization. Bioresour. Technol. 2018, 266, 34–44. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Shen, C.R.; Huang, C.-H.; Sung, L.-Y.; Wu, M.-Y.; Hu, Y.-C. CRISPR-Cas9 for the genome engineering of cyanobacteria and succinate production. Metab. Eng. 2016, 38, 293–302. [Google Scholar] [CrossRef] [PubMed]

- Behler, J.; Vijay, D.; Hess, W.R.; Akhtar, M.K. CRISPR-Based Technologies for Metabolic Engineering in Cyanobacteria. Trends Biotechnol. 2018, 36, 996–1010. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Cengic, I.; Anfelt, J.; Hudson, E.P. Multiple Gene Repression in Cyanobacteria Using CRISPRi. ACS Synth. Biol. 2016, 5, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Pruvost, J.; Van Vooren, G.; Le Gouic, B.; Couzinet-Mossion, A.; Legrand, J. Systematic investigation of biomass and lipid productivity by microalgae in photobioreactors for biodiesel application. Bioresour. Technol. 2011, 102, 150–158. [Google Scholar] [CrossRef] [PubMed]

- García-Malea, M.C.; Acién, F.G.; Del Río, E.; Fernández, J.M.; Cerón, M.C.; Guerrero, M.G.; Molina-Grima, E. Production of astaxanthin by Haematococcus pluvialis: Taking the one-step system outdoors. Biotechnol. Bioeng. 2009, 102, 651–657. [Google Scholar] [CrossRef] [PubMed]

- Martins, R.G.; Goncalves, I.S.; de Morais, M.G.; Costa, J.A.V. Bioprocess Engineering Aspects of Biopolymer Production by the Cyanobacterium Spirulina Strain LEB 18. Int. J. Polymer Sci. 2014, 2014, 895237. [Google Scholar] [CrossRef]

- Samantaray, S.; Mallick, N. Role of cultural variables in tailoring poly (3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer synthesis in the diazotrophic cyanobacterium Aulosira fertilissima CCC 444. J. Appl. Phycol. 2015, 27, 197–203. [Google Scholar] [CrossRef]

- Silva, C.S.P.; Silva-Stenico, M.E.; Fiore, M.F.; de Castro, H.F.; Da Rós, P.C.M. Optimization of the cultivation conditions for Synechococcus sp. PCC7942 (cyanobacterium) to be used as feedstock for biodiesel production. Algal Res. 2014, 3, 1–7. [Google Scholar] [CrossRef]

- Ooijkaas, L.P.; Wilkinson, E.C.; Tramper, J.; Buitelaar, R.M. Medium optimization for spore production of coniothyrium minitans using statistically-based experimental designs. Biotechnol. Bioeng. 1999, 64, 92–100. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Q.; Shen, Z. Accumulation of poly-β-hydroxybutyrate in cyanobacterium Synechocystis sp. PCC6803. Bioresour. Technol. 2001, 76, 85–90. [Google Scholar] [CrossRef]

- Carpine, R.; Olivieri, G.; Hellingwerf, K.; Pollio, A.; Pinto, G.; Marzocchella, A. Poly-β-hydroxybutyrate (PHB) Production by Cyanobacteria. New Biotechnol. 2016, 33, S19–S20. [Google Scholar] [CrossRef]

- Kaewbai-Ngam, A.; Incharoensakdi, A.; Monshupanee, T. Increased accumulation of polyhydroxybutyrate in divergent cyanobacteria under nutrient-deprived photoautotrophy: An efficient conversion of solar energy and carbon dioxide to polyhydroxybutyrate by Calothrix scytonemicola TISTR 8095. Bioresour. Technol. 2016, 212, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Sharma, L.; Mallick, N. Accumulation of poly-beta-hydroxybutyrate in Nostoc muscorum: Regulation by pH, light-dark cycles, N and P status and carbon sources. Bioresour. Technol. 2005, 96, 1304–1310. [Google Scholar] [CrossRef] [PubMed]

- Coelho, V.C.; da Silva, C.K.; Terra, A.L.; Costa, J.A.V.; de Morais, M.G. Polyhydroxybutyrate production by Spirulina sp. LEB 18 grown under different nutrient concentrations. Afr. J. Microbiol. Res. 2015, 9, 1586–1594. [Google Scholar]

- Gopi, K.; Balaji, S.; Muthuvelan, B. Isolation Purification and Screening of Biodegradable Polymer PHB Producing Cyanobacteria from Marine and Fresh Water Resources. Iran. J. Energy Environ. 2014, 5, 94–100. [Google Scholar] [CrossRef]

- Markou, G.; Vandamme, D.; Muylaert, K. Microalgal and cyanobacterial cultivation: The supply of nutrients. Water Res. 2014, 65, 186–202. [Google Scholar] [CrossRef] [PubMed]

- Samantaray, S.; Nayak, K.J.; Mallick, N. Wastewater utilization for poly-β-hydroxybutyrate production by the cyanobacterium Aulosira fertilissima in a recirculatory aquaculture system. Appl. Environ. Microbiol. 2011, 77, 8735–8743. [Google Scholar] [CrossRef] [PubMed]

- Bhati, R.; Mallick, N. Carbon dioxide and poultry waste utilization for production of polyhydroxyalkanoate biopolymers by Nostoc muscorum Agardh: A sustainable approach. J. Appl. Phycol. 2016, 28, 161–168. [Google Scholar] [CrossRef]

- Chaiklahan, R.; Chirasuwan, N.; Siangdung, W.; Paithoonrangsarid, K.; Bunnag, B. Cultivation of Spirulina platensis using pig wastewater in a semi-continuous process. J. Microbiol. Biotechnol. 2010, 20, 609–614. [Google Scholar] [CrossRef] [PubMed]

- Phang, S.M.; Miah, M.S.; Yeoh, B.G.; Hashim, M.A. Spirulina cultivation in digested sago starch factory wastewater. J. Appl. Phycol. 2000, 12, 395–400. [Google Scholar] [CrossRef]

- Olguín, E.J.; Galicia, S.; Mercado, G.; Pérez, T. Annual productivity of Spirulina (Arthrospira) and nutrient removal in a pig wastewater recycling process under tropical conditions. J. Appl. Phycol. 2003, 15, 249–257. [Google Scholar] [CrossRef]

- Kourmentza, C.; Plácido, J.; Venetsaneas, N.; Burniol-Figols, A.; Varrone, C.; Gavala, H.N.; Reis, M.A.M. Recent Advances and Challenges towards Sustainable Polyhydroxyalkanoate (PHA) Production. Bioengineering 2017, 4, 55. [Google Scholar] [CrossRef] [PubMed]

- Fradinho, J.C.; Reis, M.A.M.; Oehmen, A. Beyond feast and famine: Selecting a PHA accumulating photosynthetic mixed culture in a permanent feast regime. Water Res. 2016, 105, 421–428. [Google Scholar] [CrossRef] [PubMed]

- Fradinho, J.C.; Oehmen, A.; Reis, M.A. Photosynthetic mixed culture polyhydroxyalkanoate (PHA) production from individual and mixed volatile fatty acids (VFAs): Substrate preferences and co-substrate uptake. J. Biotechnol. 2014, 185, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Arias, D.M.; Fradinho, J.C.; Uggetti, E.; García, J.; Oehmen, A.; Reis, M.A.M. Polymer accumulation in mixed cyanobacterial cultures selected under the feast and famine strategy. Algal Res. 2018, 33, 99–108. [Google Scholar] [CrossRef]

- Fradinho, J.C.; Domingos, J.M.; Carvalho, G.; Oehmen, A.; Reis, M.A. Polyhydroxyalkanoates production by a mixed photosynthetic consortium of bacteria and algae. Bioresour. Technol. 2013, 132, 146–153. [Google Scholar] [CrossRef] [PubMed]

- Stal, L.J.; Moezelaar, R. Fermentation in cyanobacteria1. FEMS Microbiol. Rev. 1997, 21, 179–211. [Google Scholar] [CrossRef]

- Stal, L.; Krumbein, W. Metabolism of cyanobacteria in anaerobic marine sediments. In Proceedings of the 2. Colloque International de Bacteriologie Marine, Brest, France, 1–4 October 1984; pp. 1–5. [Google Scholar]

- Rahman, A.; Putman, R.J.; Inan, K.; Sal, F.A.; Sathish, A.; Smith, T.; Nielsen, C.; Sims, R.C.; Miller, C.D. Polyhydroxybutyrate production using a wastewater microalgae based media. Algal Res. 2015, 8, 95–98. [Google Scholar] [CrossRef]

- Sharma, L.; Kumar Singh, A.; Panda, B.; Mallick, N. Process optimization for poly-beta-hydroxybutyrate production in a nitrogen fixing cyanobacterium, Nostoc muscorum using response surface methodology. Bioresour. Technol. 2007, 98, 987–993. [Google Scholar] [CrossRef] [PubMed]

- Mallick, N.; Sharma, L.; Kumar Singh, A. Poly-beta-hydroxybutyrate accumulation in Nostoc muscorum: Effects of metabolic inhibitors. J. Plant Physiol. 2007, 164, 312–317. [Google Scholar] [CrossRef] [PubMed]

- Mallick, N.; Gupta, S.; Panda, B.; Sen, R. Process optimization for poly(3-hydroxybutyrate-co-3-hydroxyvalerate) co-polymer production by Nostoc muscorum. Biochem. Eng. J. 2007, 37, 125–130. [Google Scholar] [CrossRef]

- Bhati, R.; Samantaray, S.; Sharma, L.; Mallick, N. Poly-β-hydroxybutyrate accumulation in cyanobacteria under photoautotrophy. Biotechnol. J. 2010, 5, 1181–1185. [Google Scholar] [CrossRef] [PubMed]

- Panda, B.; Sharma, L.; Mallick, N. Poly-β-hydroxybutyrate accumulation in Nostoc muscorum and Spirulina platensis under phosphate limitation. J. Plant Physiol. 2005, 162, 1376–1379. [Google Scholar] [CrossRef] [PubMed]

- Google Scholar. Earth System Research Laboratory. 2017. Available online: https://esrl.noaa.gov/ (accessed on 15 April 2017).

- Eberly, J.O.; Ely, R.L. Photosynthetic accumulation of carbon storage compounds under CO2 enrichment by the thermophilic cyanobacterium Thermosynechococcus elongatus. J. Ind. Microbiol. Biotechnol. 2012, 39, 843–850. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y. Bacterial polyhydroxyalkanoates. Biotechnol. Bioeng. 1996, 49, 1–14. [Google Scholar] [CrossRef]

- Lee, S.Y. Plastic bacteria? Progress and prospects for polyhydroxyalkanoate production in bacteria. Trends Biotechnol. 1996, 14, 431–438. [Google Scholar] [CrossRef]

- Koller, M.; Khosravi-Darani, K.; Braunegg, G. Advanced Photobioreactor Systems for the Efficient Cultivation of Cyanobacteria, in Photobioreactors Advancements, Applications and Research; Tsang, Y.F., Ed.; Nova Science Publishers: New York, NY, USA, 2017; pp. 35–90. [Google Scholar]

- Arias, D.M.; Uggetti, E.; García-Galán, M.J.; García, J. Production of polyhydroxybutyrates and carbohydrates in a mixed cyanobacterial culture: Effect of nutrients limitation and photoperiods. New Biotechnol. 2018, 42, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Riis, V.; Mai, W. Gas chromatographic determination of poly-?-hydroxybutyric acid in microbial biomass after hydrochloric acid propanolysis. J. Chromatogr. 1988, 445, 285–289. [Google Scholar] [CrossRef]

- Karr, D.B.; Waters, J.K.; Emerich, D.W. Analysis of Poly-beta-Hydroxybutyrate in Rhizobium japonicum Bacteroids by Ion-Exclusion High-Pressure Liquid Chromatography and UV Detection. Appl. Environ. Microbiol. 1983, 46, 1339–1344. [Google Scholar] [PubMed]

- Koller, M.; Rodríguez-Contreras, A. Techniques for tracing PHA-producing organisms and for qualitative and quantitative analysis of intra- and extracellular PHA. Eng. Life Sci. 2015, 15, 558–581. [Google Scholar] [CrossRef]

- Kansiz, M.; Billman-Jacobe, H.; McNaughton, D. Quantitative determination of the biodegradable polymer Poly(beta-hydroxybutyrate) in a recombinant Escherichia coli strain by use of mid-infrared spectroscopy and multivariative statistics. Appl. Environ. Microbiol. 2000, 66, 3415–3420. [Google Scholar] [CrossRef] [PubMed]

- Degelau, A.; Scheper, T.; Bailey, J.E.; Guske, C. Fluorometric measurement of poly-β hydroxybutyrate in Alcaligenes eutrophus by flow cytometry and spectrofluorometry. Appl. Microbiol. Biotechnol. 1995, 42, 653–657. [Google Scholar] [CrossRef]

- Stenholm, H.; Song, S.; Eriksen, N.T.; Iversen, J.J.L. Indirect Estimation of Poly-β-Hydroxybutyric Acid by Cell Carbon Analysis. Biotechnol. Tech. 1998, 12, 451–454. [Google Scholar] [CrossRef]

- Naumann, D.; Helm, D.; Labischinski, H. Microbiological characterizations by FT-IR spectroscopy. Nature 1991, 351, 81–82. [Google Scholar] [CrossRef] [PubMed]

- Schuster, K.C.; Mertens, F.; Gapes, J.R. FTIR spectroscopy applied to bacterial cells as a novel method for monitoring complex biotechnological processes. Vib. Spectrosc. 1999, 19, 467–477. [Google Scholar] [CrossRef]

- Randriamahefa, S.; Renard, E.; Guérin, P.; Langlois, V. Fourier transform infrared spectroscopy for screening and quantifying production of PHAs by Pseudomonas grown on sodium octanoate. Biomacromolecules 2003, 4, 1092–1097. [Google Scholar] [CrossRef] [PubMed]

- Jarute, G.; Kainz, A.; Schroll, G.; Baena, J.R.; Lendl, B. On-line determination of the intracellular poly(beta-hydroxybutyric acid) content in transformed Escherichia coli and glucose during PHB production using stopped-flow attenuated total reflection FT-IR spectrometry. Anal. Chem. 2004, 76, 6353–6358. [Google Scholar] [CrossRef] [PubMed]

- Song, J.H.; Murphy, R.J.; Narayan, R.; Davies, G.B.H. Biodegradable and compostable alternatives to conventional plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2127–2139. [Google Scholar] [CrossRef] [PubMed]

- Gerngross, T.U. Can biotechnology move us toward a sustainable society? Nat. Biotechnol. 1999, 17, 541. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.-I.; Lee, Y.S. Process analysis and economic evaluation for poly (3-hydroxybutyrate) production by fermentation. Bioprocess Eng. 1997, 17, 335–342. [Google Scholar] [CrossRef]

- Acién, F.G.; Fernández, J.M.; Magán, J.J.; Molina, E. Production cost of a real microalgae production plant and strategies to reduce it. Biotechnol. Adv. 2012, 30, 1344–1353. [Google Scholar] [CrossRef] [PubMed]

- Koller, M. Advances in Polyhydroxyalkanoate (PHA) Production. Bioengineering 2017, 4, 88. [Google Scholar] [CrossRef] [PubMed]

| Cyanobacteria | PHB Content (% DCW) | Substrate | Production Condition | Polymer Composition | Reference |

|---|---|---|---|---|---|

| Synechocystis sp. PCC 6803 | 38 | Acetate | P limitation and gas exchange limitation 1 | PHB | [31] |

| Synechocystis sp. PCC 6714 | 16 | CO2 | N 2 and P 3 limitation | PHB | [32] |

| Spirulina platensis | 6.0 | CO2 | Not given | PHB | [33] |

| Spirulina platensis UMACC 161 | 10 | acetate and CO2 | N starvation | PHB | [34] |

| Spirulina maxima | 7–9 | CO2 | N and P limitation | PHB | [35] |

| Gloeothece sp. PCC 6909 | 9.0 | acetate | Not given | Not specified | [36] |

| Nostoc moscorum Agardh | 60 | acetate and valerate | N deficiency | PHB-co-PHV | [37] |

| Nostoc moscorum | 22 | CO2 | P starvation | PHB | [38] |

| Alusira fertilisima CCC444 | 77 | fructose and valerate | N deficiency | PHB-co-PHV | [39] |

| Alusira fertilisima CCC444 | 85 | citrate and acetate | P deficiency | PHB | [40] |

| Synechocystis PCC 7942 | 3 | CO2 | N limitation | PHB | [41] |

| Synechocystis PCC 7942 | 25.6 | acetate | N limitation | PHB | [41] |

| Synechocystis sp. CCALA192 | 12.5 | CO2 | N limitation | PHB | [42] |

| Anabaena Cylindrica | <0.005 | CO2 | Balanced growth | PHB | [43] |

| Anabaena cylindrica | 2.0 | propionate | N limitation | PHB + PHV | [43] |

| Synechococcus elongatus | 17.2 | CO2 and sucrose | N deficiency | Not specified | [44] |

| Caltorix scytonemicola TISTR 8095 | 25 | CO2 | N deficiency | PHB | [45] |

| Cyanobacterial Strain (Recombinant) | PHB Content (% DCW) | Genetic Tool Used | Production Conditions | References |

|---|---|---|---|---|

| Synechococcus sp. PCC 7942 | 1.0 | Defective in glycogen synthesis | CO2 | [53] |

| Synechococcus sp. PCC 7942 | 26 | Introducing PHA biosynthetic genes from C. necator | Acetate and nitrogen limitation | [41] |

| Synechocystis sp. PCC 6803 | 26 | Overexpression of native pha genes | CO2 and nitrogen deprivation | [46] |

| Synechocystis sp. PCC 6803 | 11 | Introducing PHA biosynthetic genes from C. necator | Acetate and nitrogen limitation | [54] |

| Synechocystis sp. PCC 6803 | 14 | Overexpression of PHA synthase | Direct photosynthesis | [55] |

| Synechocystis sp. PCC 6803 | 12 | Increasing acetyl-CoA levels | CO2 | [56] |

| Synechococcus sp. PCC 7002 | 4.5 | Introduction of GABA Shunt | CO2 | [57] |

| Synechocystis sp. | 35 | Optimization of acetoacetyl-CoA reductase binding site | CO2 | [58] |

| Synechocystis sp. PCC 6803 | 7.0 | Transconjugant cells harboring expression vectors carrying pha genes | CO2 | [59] |

| Cyanobacterial Strain | Limiting Component | Temperature °C | pH | Light Condition | PHB Content % (DCW) | Cultivation Time (Days) | Volume (L) | References |

|---|---|---|---|---|---|---|---|---|

| Synechocystis sp. PCC 6803 | N and P starvation | 28–32 | 7.5–8.5 | dark/light cycle | 11 | 10 | 0.05 | [31] |

| Synechocystis sp. PCC6803 | N starvation | 30 | n.p | light | 4.1 | 7 | n.p | [73] |

| Synechocystis sp. PCC6803 | N limitation | 28 | n.p | 18:6 | 8 | 30 | 0.8 | [74] |

| Synechocystis sp. PCC 6714 | N and P limitation | 28 | 8.5 | light | 16.4 | 16 | 1 | [32] |

| Synechocystis salina CCALA192 | Optimized BG-11 media 4 | n.p 5 | 8.5 | light | 6.6 | 21 | 200 | [23] |

| Phormidium sp. TISTR 8462 | N limitation | 28 | 7.5 | light | 14.8 | 12 | n.p | [75] |

| Calothrix scytonemicola TISTR 8095 | N deprivation | 28 | 7.5 | light | 25.4 | 12 | n.p | [75] |

| Nostoc muscorum | Growth associated 6 | 25 | 8.5 | 14:10 | 8.6 | 21 | 0.05 | [76] |

| Nostoc muscorum | P depletion | 22 | n.p | light | 10.2 | 19 | n.p | [38] |

| Spirulina sp. LEB 18 | Defined media 7 | 30 | n.p | 12:12 | 30.7 | 15 | 1.8 | [77] |

| Aulosira fertilissima | P limitation | 28 | 8.5 | 14:10 | 10 | 4 | 0.05 | [40] |

| Anabaena sp. | n.p | 25 | 8 | 14:10 | 2.3 | n.p | 0.1 | [78] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamravamanesh, D.; Lackner, M.; Herwig, C. Bioprocess Engineering Aspects of Sustainable Polyhydroxyalkanoate Production in Cyanobacteria. Bioengineering 2018, 5, 111. https://doi.org/10.3390/bioengineering5040111

Kamravamanesh D, Lackner M, Herwig C. Bioprocess Engineering Aspects of Sustainable Polyhydroxyalkanoate Production in Cyanobacteria. Bioengineering. 2018; 5(4):111. https://doi.org/10.3390/bioengineering5040111

Chicago/Turabian StyleKamravamanesh, Donya, Maximilian Lackner, and Christoph Herwig. 2018. "Bioprocess Engineering Aspects of Sustainable Polyhydroxyalkanoate Production in Cyanobacteria" Bioengineering 5, no. 4: 111. https://doi.org/10.3390/bioengineering5040111

APA StyleKamravamanesh, D., Lackner, M., & Herwig, C. (2018). Bioprocess Engineering Aspects of Sustainable Polyhydroxyalkanoate Production in Cyanobacteria. Bioengineering, 5(4), 111. https://doi.org/10.3390/bioengineering5040111