De Novo Synthesis of Poly(3-hydroxybutyrate-co-3-hydroxypropionate) from Oil by Engineered Cupriavidus necator

Abstract

1. Introduction

2. Materials and Methods

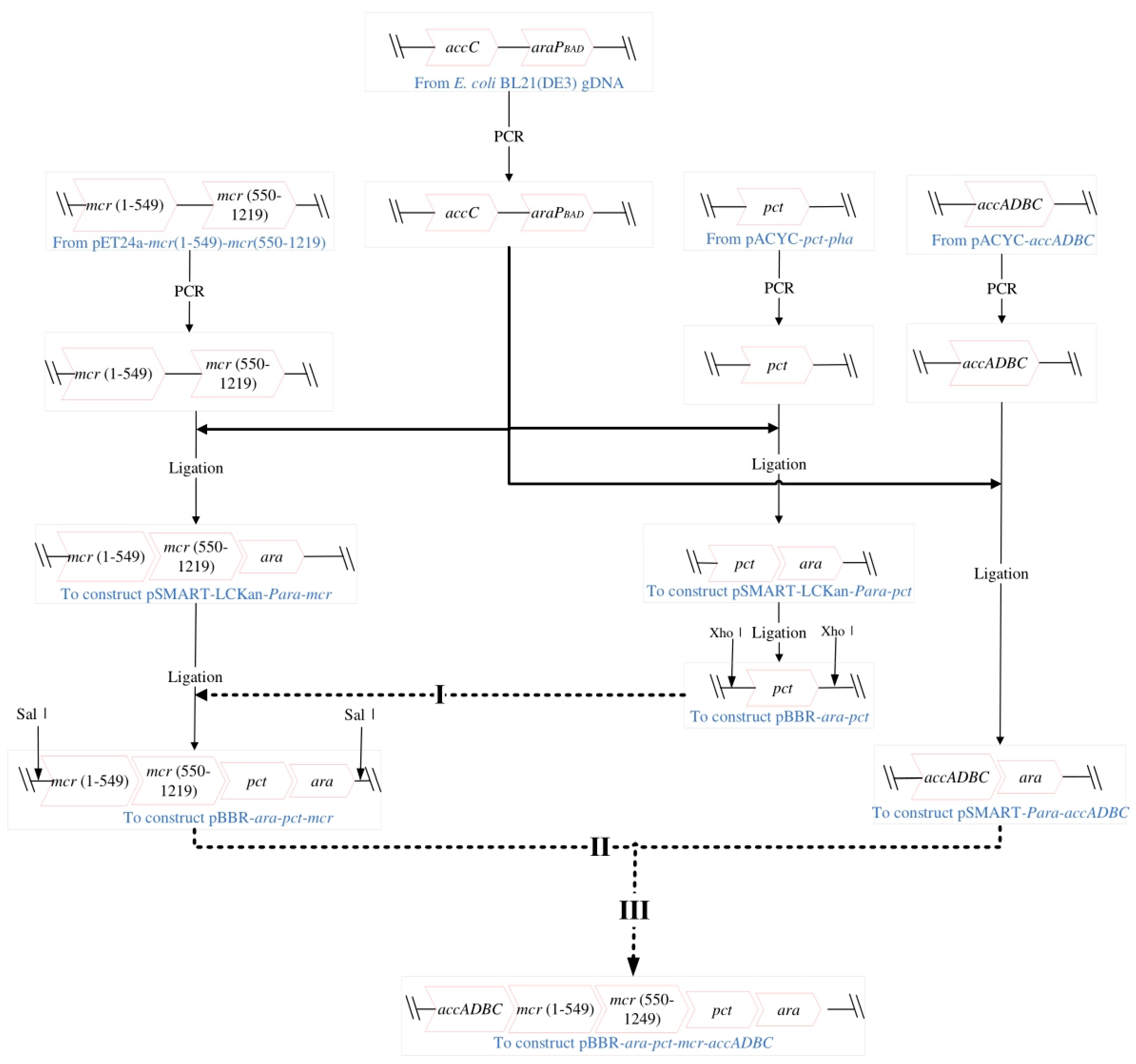

2.1. Strains and Plasmids

2.2. P(3HB-co-3HP) Fermentation and Purification

2.3. Analytical and Statistical Methods

3. Results and Discussion

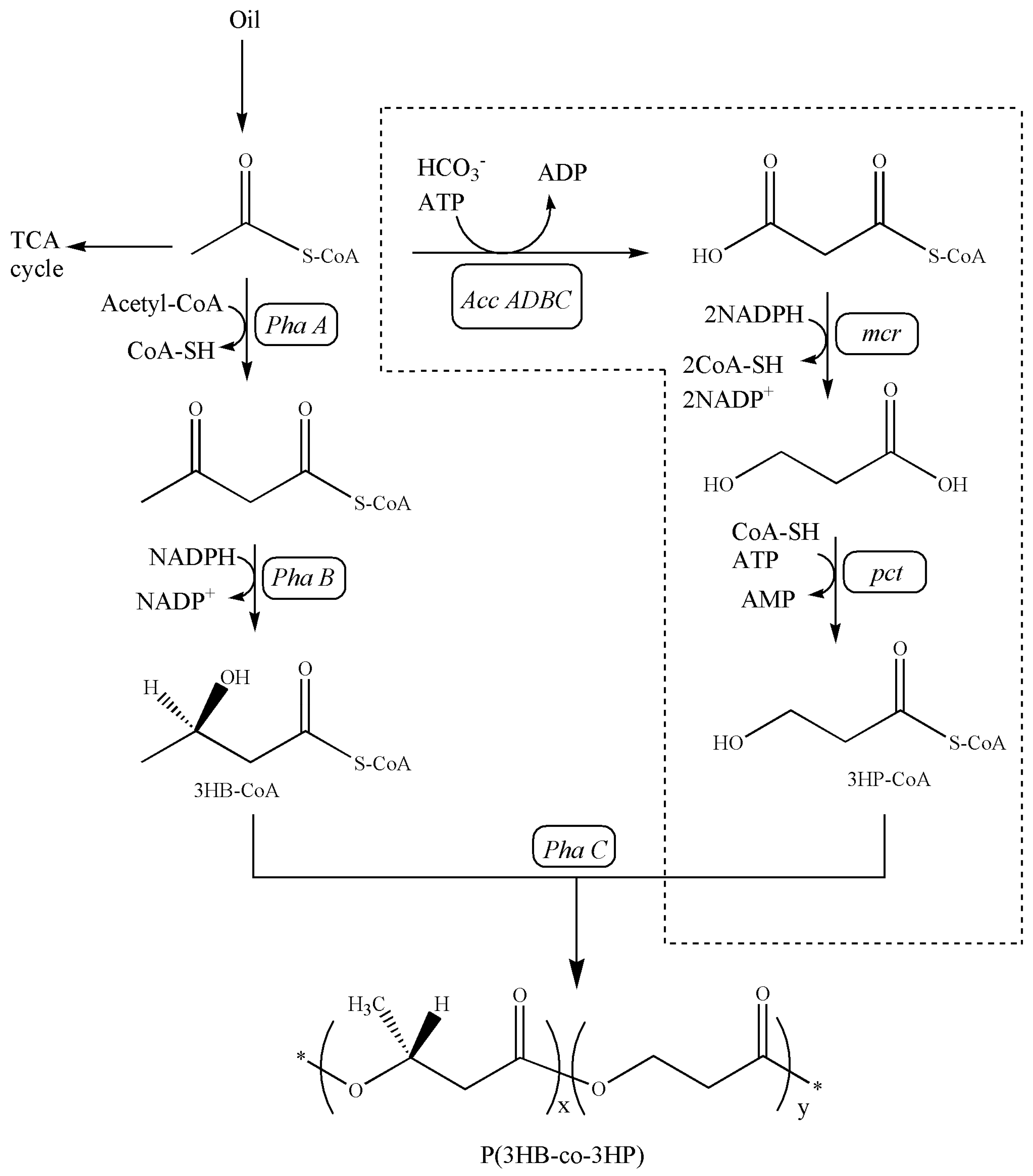

3.1. Engineering the Fragmentized MCR in C. necator Promoted P(3HB-co-3HP) Production in Mild Condition

3.2. Production of P(3HB-co-3HP) from Variable Oil Substrates

3.3. Fed-Batch Production of P(3HB-co-3HP)

4. Concluding Remarks and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, Y.; Chen, J.C.; Ma, Y.M.; Chen, G.Q. Engineering Biosynthesis of Polyhydroxyalkanoates (PHA) for Diversity and Cost Reduction. Metab. Eng. 2020, 58, 82–93. [Google Scholar] [CrossRef] [PubMed]

- Steinbuchel, A.; Fuchtenbusch, B. Bacterial and other biological systems for polyester production. Trends Biotechnol. 1998, 16, 419–427. [Google Scholar] [CrossRef] [PubMed]

- Pohlmann, A.; Fricke, W.F.; Reinecke, F.; Liesegang, B.H.; Cramm, R.; Eitinger, T.; Ewering, C.; Pötter, M.; Schwartz, E.; Strittmatter, A.; et al. Genome sequence of the bioplastic-producing “Knallgas” bacterium Ralstonia eutropha H16. Nat. Biotechnol. 2006, 24, 1257–1262. [Google Scholar] [CrossRef] [PubMed]

- Andreessen, B.; Steinbuchel, A. Biosynthesis and biodegradation of 3-hydroxypropionate-containing polyesters. Appl. Environ. Microb. 2010, 76, 4919–4925. [Google Scholar] [CrossRef] [PubMed]

- Chuah, J.A.; Yamada, M.; Taguchi, S.; Taguchi, S.; Sudesh, K.; Doi, Y.; Numata, K. Biosynthesis and characterization of polyhydroxyalkanoate containing 5-hydroxyvalerate units: Effects of 5HV units on biodegradability, cytotoxicity, mechanical and thermal properties. Polym. Degrad. Stab. 2013, 98, 331–338. [Google Scholar] [CrossRef]

- Satoh, K.; Kawakami, T.; Isobe, N.; Pasquier, L.; Tomita, H.; Zinn, M.; Matsumoto, K. Versatile aliphatic polyester biosynthesis system for producing random and block copolymers composed of 2-, 3-, 4-, 5-, and 6-hydroxyalkanoates using the sequence-regulating polyhydroxyalkanoate synthase PhaCAR. Microb. Cell Factories 2022, 21, 84. [Google Scholar] [CrossRef]

- Ichikawa, M.; Nakamura, K.; Yoshie, N.; Asakawa, N.; Inoue, Y.; Doi, Y. Morphological study of bacterial poly(3-hydroxybutyrate-co-3-hydroxypropionate). Macromol. Chem. Phys. 1996, 197, 2467–2480. [Google Scholar] [CrossRef]

- Salinas, A.; McGregor, C.; Irorere, V.; Arenas-López, C.; Bommareddy, R.R.; Winzer, K.; Minton, N.P.; Kovács, K. Metabolic engineering of Cupriavidus necator H16 for heterotrophic and autotrophic production of 3-hydroxypropionic acid. Metab. Eng. 2022, 74, 178–190. [Google Scholar] [CrossRef]

- Valentin, H.E.; Mitsky, T.A.; Mahadeo, D.A.; Tran, M.; Gruys, K.J. Application of a Propionyl Coenzyme A Synthetase for Poly(3-Hydroxypropionate-co-3-Hydroxybutyrate) Accumulation in Recombinant Escherichia coli. Appl. Environ. Microbiol. 2000, 66, 5253–5258. [Google Scholar] [CrossRef]

- Nakamura, S.; Kunioka, M.; Doi, Y. Biosynthesis and Characterization of Bacterial Poly(3-Hydroxybutyrate-co-3-hydroxypropionate). J. Macromol. Sci. Phys. 1991, A28, 15–24. [Google Scholar] [CrossRef]

- McGregor, C.; Minton, N.P.; Kovacs, K. Biosynthesis of Poly(3HB-co-3HP) with Variable Monomer Composition in Recombinant Cupriavidus necator H16. ACS Synth. Biol. 2021, 10, 3343–3352. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, P.; Xian, M.; Yang, Y.; Liu, C.; Xue, Y.; Zhao, G. Biosynthesis of poly(3-hydroxypropionate-co-3-hydroxybutyrate) with fully controllable structures from glycerol. Bioresour. Technol. 2013, 142, 741–744. [Google Scholar] [CrossRef]

- Meng, D.C.; Wang, Y.; Wu, L.P.; Shen, R.; Chen, J.C.; Wu, Q.; Chen, G.Q. Production of poly(3-hydroxypropionate) and poly(3-hydroxybutyrate-co-3-hydroxypropionate) from glucose by engineering Escherichia coli. Metab. Eng. 2015, 29, 189–195. [Google Scholar] [CrossRef]

- Fukui, T.; Suzuki, M.; Tsuge, T.; Nakamura, S. Microbial synthesis of poly((R)-3-hydroxybutyrate-co-3-hydroxypropionate) from unrelated carbon sources by engineered Cupriavidus necator. Biomacromolecules 2009, 10, 700–706. [Google Scholar] [CrossRef]

- Shi, M.X.; Li, M.D.; Yang, A.R.; Miao, X.; Yang, L.; Pandhal, J.; Zou, H.B. Class I Polyhydroxyalkanoate (PHA) Synthase Increased Polylactic Acid Production in Engineered Escherichia Coli. Front. Bioeng. Biotechnol. 2022, 10, 919–969. [Google Scholar] [CrossRef]

- Liu, C.S.; Ding, Y.M.; Zhang, R.B.; Liu, H.Z.; Xian, M.; Zhao, G. Functional balance between enzymes in malonyl-CoA pathway for 3-hydroxypropionate biosynthesis. Metab. Eng. 2016, 34, 104–111. [Google Scholar] [CrossRef]

- Brandl, H.; Gross, R.A.; Lenz, R.W.; Fuller, R.C. Pseudomonas oleovorans as a source of poly(b-Hydroxyalkanoates) for potential applications as biodegradable polyesters. Appl. Environ. Microbiol. 1988, 54, 1977–1982. [Google Scholar] [CrossRef]

- Wang, H.H.; Li, X.T.; Chen, G.Q. Production and characterization of homopolymer polyhydroxyheptanoate (P3HHp) by a fadBA knockout mutant Pseudomonas putida KTOY06 derived from P. putida KT2442. Process Biochem. 2009, 44, 106–111. [Google Scholar] [CrossRef]

- Braunegg, G.; Sonnleitner, B.; Lafferty, R.M. A rapid gas chromatographic method for the determination of poly- β -hydroxybutyric acid in microbial biomass. Eur. J. Appl. Microbiol. Biotechnol. 1978, 6, 29–37. [Google Scholar] [CrossRef]

- Kato, M.; Bao, H.J.; Kang, C.K.; Fukui, T.; Doi, Y. Production of a novel copolyester of 3-hydroxybutyric acid and medium-chain-length 3-hydroxyalkanoic acids by Pseudomonas sp. 61-3 from sugars. Appl. Microbiol. Biotechnol. 1996, 45, 363–370. [Google Scholar] [CrossRef]

- Herter, S.; Farfsing, J.; Gad’On, N.; Rieder, C.; Eisenreich, W.; Bacher, A.; Fuchs, G. Autotrophic CO2 Fixation by Chloroflexus aurantiacus: Study of Glyoxylate Formation and Assimilation via the 3-Hydroxypropionate Cycle. J. Bacteriol. 2001, 183, 4305–4316. [Google Scholar] [CrossRef]

- Herter, S.; Fuchs, G.; Bacher, A.; Eisenreich, W. A bicyclic autotrophic CO2 fixation pathway in Chloroflexus aurantiacus. J. Biol. Chem. 2002, 277, 20277–20283. [Google Scholar] [CrossRef] [PubMed]

- Hügler, M.; Menendez, C.; Schägger, H.; Fuchs, G. Malonyl-coenzyme A reductase from Chloroflexus aurantiacus, a key enzyme of the 3-hydroxypropionate cycle for autotrophic CO2 fixation. J. Bacteriol. 2002, 184, 2404–2410. [Google Scholar] [CrossRef] [PubMed]

- Guzman, L.M.; Belin, D.; Carson, M.J.; Beckwith, J. Tight regulation, modulation, and high-level expression by vectors containing the arabinose PBAD promoter. J. Bacteriol. 1995, 177, 4121–4130. [Google Scholar] [CrossRef]

- Ingram, H.R.; Martin, R.J.; Winterburn, J.B. Optimized cell growth and poly(3-hydroxybutyrate) synthesis from saponified spent coffee grounds oil. Appl. Microbiol. Biotechnol. 2022, 106, 6033–6045. [Google Scholar] [CrossRef] [PubMed]

| Strains/Plasmids | Description | Source |

|---|---|---|

| Strains | ||

| Cupriavidus necator H16 (Ralstonia eutropha H16) | Chassis strain | DSM 428 |

| Escherichia coli S17 | Donor strain for conjugational transfer | DSM 9079 |

| Escherichia coli BL21(DE3) | F- ompT hsdSB(rB-mB-) gal dcm rne131(DE3) | Invitrogen |

| Cupriavidus necator ZL1 | Engineered Cupriavidus necator H16 carrying pBBR-ara-pct-mcr-acc ADBC | This study |

| Plasmids | ||

| pSMART-LCKan | Cloning plasmid | Lucigen |

| pBBR1MCS-2 | Starting plasmid (broad host range) | Lab stored |

| pACYC-pct-pha | Carrying gene pct, evolved propionate CoA-transferase (V193A) from Clostridium propionicum | [15] |

| pACYC-acc ADBC | Carrying gene acc ADBC, acetyl-CoA carboxylase from Escherichia coli K-12 | [16] |

| pET24a-mcr(1–549)-mcr(550–1219) | Carrying gene mcr(1–549) and mcr(550–1219), evolved N-terminal and C-terminal of malonyl-CoA reductase from Chloroflexus aurantiacus | [16] |

| pSMART-LCKan-Para-pct | pSMART-LCKan derivative carrying genes ara, pct | This study |

| pSMART-LCKan-Para-mcr | pSMART-LCKan derivative carrying genes ara, mcr | This study |

| pSMART-LCKan-Para-acc ADBC | SMART-LCKan derivative carrying genes ara, acc ADBC | This study |

| pBBR-ara-pct | pBBR1MCS-2 derivative carrying genes ara, pct | This study |

| pBBR-ara-pct-mcr | pBBR1MCS-2 derivative carrying genes ara, pct, mcr(1–549)-mcr(550–1219) | This study |

| pBBR-ara-pct-mcr-acc ADBC | pBBR1MCS-2 derivative carrying genes ara, pct, mcr(1–549)-mcr(550–1219), acc ADBC | This study |

| Primer Name | Sequence |

|---|---|

| ara F | ATATCAAGCTTGAATTCGTTTTATGACAACTTGACGGCTAC |

| ara R | CTTTGCGCATCGTTTCACTCCATCCAAAAAAAC |

| araP F | ATATCAAGCTTGAATTCGTTAAGAAACCAATTGTCCATATTGC |

| araP R | CTTTGCGCATCGTTTCACTCCATCCAAAAAAAC |

| accB F1 | GAGACCTTAGGAGGTAAACATATGGATATTCGTAAGATTAAAAAACTGATC |

| accB R1 | ATTCTCTGCAGGCCTGTACAGTTACTCGATGACGACCAG |

| accD F2 | TGAGCTACGGTTACGCGTAAATGAGCTGGATTGAACGAATTAAAAGC |

| accD R2 | GAATATCCATTCAGGCCTCAGGTTCCTGAT |

| accADBC F | CCTCCGACCGGAGGCTTTTAGCTGGAAGAAACCAATTGTCCATATTGCATCAG |

| accADBC R | TTCGATATCAAGCTTATCGATACCGAGTCAAAAGCCTCCGGTCGG |

| accBC F | TGAGGCCTGAATGGATATTCGTAAGATTAAAAAAC |

| accBC R | CGATATCTAGAGAATTCGTCTTATTTTTCCTGAAGACCGAG |

| mcr R1 | GCTTATCGATACCGTCGACCAGTCAAAAGCCTCCGGTCGG |

| mcr F1 | TGACTGTACCGGGCCCCCCCAAGAAACCAATTGTCCATATTGCATCAG |

| Mcr(1–549)F1 | GGAGTGAAACGATGAGCGGAACAGGACGACTG |

| Mcr(550–1219)R1 | CGATATCTAGAGAATTCGTCTTACACGGTAATCGCCCGTCCGCG |

| M13 F | GTAAAACGACGGCCAGT |

| M13 R | CAGGAAACAGCTATGAC |

| pct F | GAGTGAAACGATGCGCAAAGTGCCGATTATTAC |

| pct R | CGATATCTAGAGAATTCGTCTTATGATTTCATTTCTTTCAGGCCC |

| SL1 | CAGTCCAGTTACGCTGGAGTC |

| SR1 | GGTCAGGTATGATTTAAATGGTCAGT |

| Level | Oil | Arabinose (g/L) | DCW (g/L) | PHA (wt%) | PHA (g/L) | 3HP (mol%) |

|---|---|---|---|---|---|---|

| Flask | Soybean oil | 0.25 | 1.52 ± 0.11 | 57.33 ± 5.11 | 0.87 ± 0.11 | 21.36 ± 4.11 |

| Flask | Soybean oil | 0.50 | 2.11 ± 0.13 | 62.42 ± 5.51 | 1.31 ± 0.12 | 27.57 ± 5.81 |

| Flask | Soybean oil | 1.00 | 1.56 ± 0.09 | 56.76 ± 4.51 | 0.89 ± 0.09 | 1.12 ± 0.05 |

| Flask | Soybean oil | 2.00 | 1.21 ± 0.11 | 52.41 ± 5.21 | 0.63 ± 0.06 | 0 |

| Flask | Palm oil | 0.50 | 1.56 ± 0.18 | 42.41 ± 6.21 | 0.66 ± 0.09 | 22.13 ± 6.05 |

| Flask | Olive oil | 0.50 | 2.35 ± 0.21 | 45.18 ± 4.11 | 1.06 ± 0.08 | 25.16 ± 5.15 |

| Fermenter | Soybean oil | 0.50 | 6.08 ± 0.51 | 51.15 ± 3.42 | 3.11 ± 0.29 | 32.25 ± 4.02 |

| Stain | Pathway | Substrate | Supplementation | Titer (g/L) | 3HP (mol%) | Reference |

|---|---|---|---|---|---|---|

| C. necator | malonyl-CoA | oil | No | 3.1 | 20–30 | This study |

| C. necator | malonyl-CoA | sugar and oil | No | 2.1 | trace | [13] |

| C. necator | β-alanine | gluconate, alanine | cysteine | 1.6 | 0–91 | [10] |

| E. coli | pduP | glycerol | VB12 | 9.8 | 10–95 | [11] |

| E. coli | pduP | glucose | VB12 (in LB) | 2.1 | 60–80 | [12] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Li, W.; Zhang, T.; Guo, K.; Feng, D.; Liang, F.; Xu, C.; Xian, M.; Zou, H. De Novo Synthesis of Poly(3-hydroxybutyrate-co-3-hydroxypropionate) from Oil by Engineered Cupriavidus necator. Bioengineering 2023, 10, 446. https://doi.org/10.3390/bioengineering10040446

Li M, Li W, Zhang T, Guo K, Feng D, Liang F, Xu C, Xian M, Zou H. De Novo Synthesis of Poly(3-hydroxybutyrate-co-3-hydroxypropionate) from Oil by Engineered Cupriavidus necator. Bioengineering. 2023; 10(4):446. https://doi.org/10.3390/bioengineering10040446

Chicago/Turabian StyleLi, Mengdi, Wei Li, Tongtong Zhang, Keyi Guo, Dexin Feng, Fengbing Liang, Chao Xu, Mo Xian, and Huibin Zou. 2023. "De Novo Synthesis of Poly(3-hydroxybutyrate-co-3-hydroxypropionate) from Oil by Engineered Cupriavidus necator" Bioengineering 10, no. 4: 446. https://doi.org/10.3390/bioengineering10040446

APA StyleLi, M., Li, W., Zhang, T., Guo, K., Feng, D., Liang, F., Xu, C., Xian, M., & Zou, H. (2023). De Novo Synthesis of Poly(3-hydroxybutyrate-co-3-hydroxypropionate) from Oil by Engineered Cupriavidus necator. Bioengineering, 10(4), 446. https://doi.org/10.3390/bioengineering10040446