Can We Structure Biomaterials to Spray Well Whilst Maintaining Functionality?

Abstract

1. The Evolution of Biomaterials

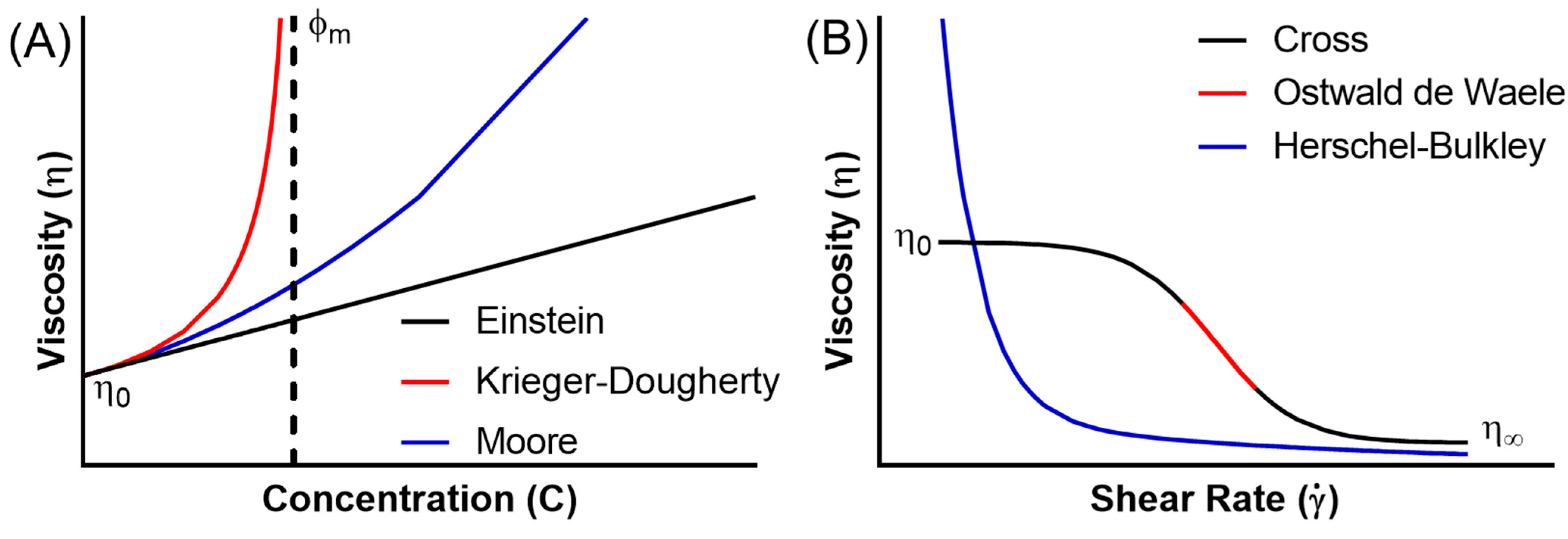

2. The Cohesive Forces in Structured Fluid Biomaterials

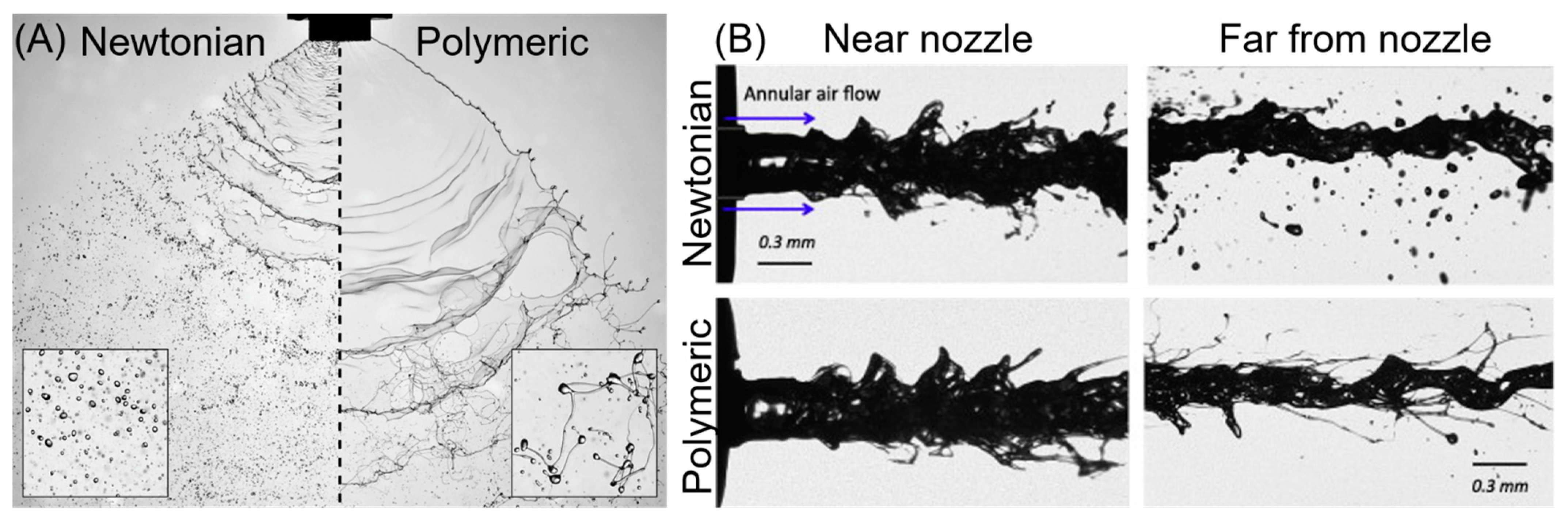

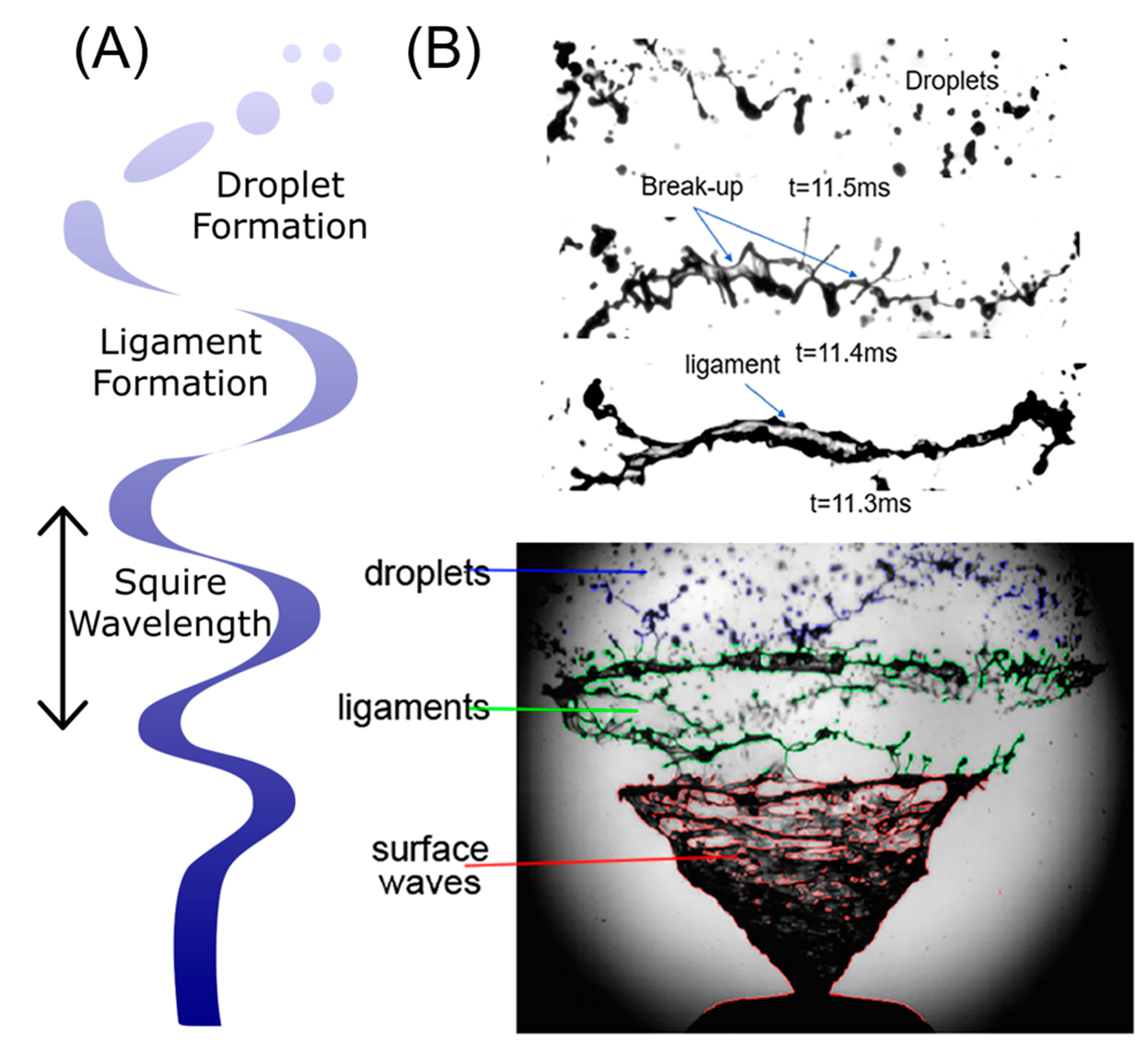

3. The Disruptive Forces in Spraying

4. Towards Spraying Structured Fluid Biomaterials

5. Conclusions and Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Becker, M.J. Early Dental Appliances in the Eastern Mediterranean. Berytus Archaeol. Stud. 1995, 42, 53–102. [Google Scholar]

- Marin, E.; Boschetto, F.; Pezzotti, G. Biomaterials and Biocompatibility: An Historical Overview. J. Biomed. Mater. Res. Part A 2020, 108, 1617–1633. [Google Scholar] [CrossRef] [PubMed]

- Ratner, B.D.; Zhang, G. A History of Biomaterials. In Biomaterials Science; Academic Press: Cambridge, MA, USA, 2020; pp. 21–34. [Google Scholar]

- Hench, L.L.; Thompson, I. Twenty-First Century Challenges for Biomaterials. J. R. Soc. Interface 2010, 7 (Suppl. S4), S379–S391. [Google Scholar] [CrossRef]

- Ratner, B.D. Biomaterials: Been There, Done That, and Evolving into the Future. Annu. Rev. Biomed. Eng. 2019, 21, 171–191. [Google Scholar] [CrossRef]

- Gholamali, I.; Yadollahi, M. Bio-Nanocomposite Polymer Hydrogels Containing Nanoparticles for Drug Delivery: A Review. Regen. Eng. Transl. Med. 2021, 7, 129–146. [Google Scholar] [CrossRef]

- Lin, C.C.; Metters, A.T. Hydrogels in Controlled Release Formulations: Network Design and Mathematical Modeling. Adv. Drug Deliv. Rev. 2006, 58, 1379–1408. [Google Scholar] [CrossRef] [PubMed]

- Fang, G.; Yang, X.; Wang, Q.; Zhang, A.; Tang, B. Hydrogels-Based Ophthalmic Drug Delivery Systems for Treatment of Ocular Diseases. Mater. Sci. Eng. C 2021, 127, 112212. [Google Scholar] [CrossRef]

- Cassano, R.; Di Gioia, M.L.; Trombino, S. Gel-Based Materials for Ophthalmic Drug Delivery. Gels 2021, 7, 130. [Google Scholar] [CrossRef]

- Van Gheluwe, L.; Chourpa, I.; Gaigne, C.; Munnier, E. Polymer-Based Smart Drug Delivery Systems for Skin Application and Demonstration of Stimuli-Responsiveness. Polymers 2021, 13, 1285. [Google Scholar] [CrossRef]

- Ahsan, A.; Tian, W.X.; Farooq, M.A.; Khan, D.H. An Overview of Hydrogels and Their Role in Transdermal Drug Delivery. Int. J. Polym. Mater. Polym. Biomater. 2021, 70, 574–584. [Google Scholar] [CrossRef]

- Purohit, T.J.; Hanning, S.M.; Wu, Z. Advances in Rectal Drug Delivery Systems. Pharm. Dev. Technol. 2018, 23, 942–952. [Google Scholar] [CrossRef] [PubMed]

- Osmałek, T.; Froelich, A.; Jadach, B.; Tatarek, A.; Gadzinski, P.; Falana, A.; Gralinska, K.; Ekert, M.; Puri, V.; Wrotynska-Barczynska, J.; et al. Recent Advances in Polymer-Based Vaginal Drug Delivery Systems. Pharmaceutics 2021, 13, 884. [Google Scholar] [CrossRef] [PubMed]

- Cook, M.T.; Brown, M.B. Polymeric Gels for Intravaginal Drug Delivery. J. Control. Release 2018, 270, 145–157. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Shen, J.; Sun, H.; Li, J.; Wang, X. Polymer-Based Hydrogels with Local Drug Release for Cancer Immunotherapy. Biomed. Pharmacother. 2021, 137, 111333. [Google Scholar] [CrossRef] [PubMed]

- Marques, A.C.; Costa, P.J.; Velho, S.; Amaral, M.H. Stimuli-Responsive Hydrogels for Intratumoral Drug Delivery. Drug Discov. Today 2021, 26, 2397–2405. [Google Scholar] [CrossRef]

- Sun, Z.; Song, C.; Wang, C.; Hu, Y.; Wu, J. Hydrogel-Based Controlled Drug Delivery for Cancer Treatment: A Review. Mol. Pharm. 2020, 17, 373–391. [Google Scholar] [CrossRef]

- Dimatteo, R.; Darling, N.J.; Segura, T. In Situ Forming Injectable Hydrogels for Drug Delivery and Wound Repair. Adv. Drug Deliv. Rev. 2018, 127, 167–184. [Google Scholar] [CrossRef]

- Rahimi, M.; Charmi, G.; Matyjaszewski, K.; Banquy, X.; Pietrasik, J. Recent Developments in Natural and Synthetic Polymeric Drug Delivery Systems Used for the Treatment of Osteoarthritis. Acta Biomater. 2021, 123, 31–50. [Google Scholar] [CrossRef]

- Ogay, V.; Mun, E.A.; Kudaibergen, G.; Baidarbekov, M.; Kassymbek, K.; Zharkinbekov, Z.; Saparov, A. Progress and Prospects of Polymer-Based Drug Delivery Systems for Bone Tissue Regeneration. Polymers 2020, 12, 2881. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Singh, J.; Ilyas, R.A.; Asyraf, M.R.M.; Razman, M.R. Critical Review of Biodegradable and Bioactive Polymer Composites for Bone Tissue Engineering and Drug Delivery Applications. Polymers 2021, 13, 2623. [Google Scholar] [CrossRef]

- Radhakrishnan, A.; Kuppusamy, G.; Karri, V.V.S.R. Spray Bandage Strategy in Topical Drug Delivery. J. Drug Deliv. Sci. Technol. 2018, 43, 113–121. [Google Scholar] [CrossRef]

- Moakes, R.J.A.; Davies, S.P.; Stamataki, Z.; Grover, L.M. Formulation of a Composite Nasal Spray Enabling Enhanced Surface Coverage and Prophylaxis of SARS-CoV-2. Adv. Mater. 2021, 33, 2008304. [Google Scholar] [CrossRef] [PubMed]

- Robinson, T.E.; Moakes, R.A.J.; Grover, L.M. Low Acyl Gellan as an Excipient to Improve the Sprayability and Mucoadhesion of Iota Carrageenan in a Nasal Spray to Prevent Infection with SARS-CoV-2. Front. Med. Technol. 2021, 3, 25. [Google Scholar] [CrossRef] [PubMed]

- He, J.J.; McCarthy, C.; Camci-Unal, G. Development of Hydrogel-Based Sprayable Wound Dressings for Second- and Third-Degree Burns. Adv. NanoBiomed Res. 2021, 1, 2100004. [Google Scholar] [CrossRef]

- Motamedi, S.; Esfandpour, A.; Babajani, A.; Jamshidi, E.; Bahrami, S.; Niknejad, H. The Current Challenges on Spray-Based Cell Delivery to the Skin Wounds. Tissue Eng. Part C Methods 2021, 27, 543–558. [Google Scholar] [CrossRef] [PubMed]

- Ter Horst, B.; Moakes, R.J.A.; Chouhan, G.; Williams, R.L.; Moiemen, N.S.; Grover, L.M. A Gellan-Based Fluid Gel Carrier to Enhance Topical Spray Delivery. Acta Biomater. 2019, 89, 166–179. [Google Scholar] [CrossRef] [PubMed]

- Gravante, G.; Di Fede, M.C.; Araco, A.; Grimaldi, M.; De Angelis, B.; Arpino, A.; Cervelli, V.; Montone, A. A Randomized Trial Comparing ReCell® System of Epidermal Cells Delivery versus Classic Skin Grafts for the Treatment of Deep Partial Thickness Burns. Burns 2007, 33, 966–972. [Google Scholar] [CrossRef]

- Umar, A.K.; Butarbutar, M.; Sriwidodo, S.; Wathoni, N. Film-Forming Sprays for Topical Drug Delivery. Drug Des. Devel. Ther. 2020, 14, 2909–2925. [Google Scholar] [CrossRef]

- Satia, M.; Mukim, A.; Tibrewala, K.; Bhavsar, M. A Randomized Two Way Cross over Study for Comparison of Absorption of Vitamin D3 Buccal Spray and Soft Gelatin Capsule Formulation in Healthy Subjects and in Patients with Intestinal Malabsorption. Nutr. J. 2015, 14, 1–9. [Google Scholar] [CrossRef]

- Colella, G.; Cannavale, R.; Vicidomini, A.; Rinaldi, G.; Compilato, D.; Campisi, G. Efficacy of a Spray Compound Containing a Pool of Collagen Precursor Synthetic Aminoacids (L-Proline, L-Leucine, L-Lysine and Glycine) Combined with Sodium Hyaluronate to Manage Chemo/radiotherapy-Induced Oral Mucositis: Preliminary Data of an Open Clinic. Int. J. Immunopathol. Pharmacol. 2010, 23, 143–151. [Google Scholar] [CrossRef]

- Hsin, Y.K.; Thangarajoo, T.; Choudhury, H.; Pandey, M.; Meng, L.W.; Gorain, B. Stimuli-Responsive in Situ Spray Gel of Miconazole Nitrate for Vaginal Candidiasis. J. Pharm. Sci. 2022. [Google Scholar] [CrossRef] [PubMed]

- Saxena, C.; Arora, K.; Chaurasia, L. Importance of Different Novel Nasal Drug Delivery System—A Review. Int. J. Pharm. Clin. Res. 2019, 11, 13–19. [Google Scholar]

- Wormald, P.J.; Cain, T.; Oates, L.; Hawke, L.; Wong, I. A Comparative Study of Three Methods of Nasal Irrigation. Laryngoscope 2004, 114, 2224–2227. [Google Scholar] [CrossRef] [PubMed]

- Collins, J.F.; Dartt, D.A.; Dana, R. Mist Delivery of Eye Medication to the Anterior Segment. Am. J. Ophthalmol. 2007, 144, 137–139. [Google Scholar] [CrossRef]

- McCallion, O.N.M.; Taylor, K.M.G.; Bridges, P.A.; Thomas, M.; Taylor, A.J. Jet Nebulisers for Pulmonary Drug Delivery. Int. J. Pharm. 1996, 130, 1–11. [Google Scholar] [CrossRef]

- Pal, R. New Generalized Viscosity Model for Non-Colloidal Suspensions and Emulsions. Fluids 2020, 5, 150. [Google Scholar] [CrossRef]

- Hughes, A.J. The Einstein Relation between Relative Viscosity and Volume Concentration of Suspensions of Spheres. Nature 1954, 173, 1089–1090. [Google Scholar] [CrossRef]

- De La Rosa, Á.; Ruiz, G.; Castillo, E.; Moreno, R. Calculation of Dynamic Viscosity in Concentrated Cementitious Suspensions: Probabilistic Approximation and Bayesian Analysis. Materials 2021, 14, 1971. [Google Scholar] [CrossRef]

- Baranau, V.; Tallarek, U. Random-Close Packing Limits for Monodisperse and Polydisperse Hard Spheres. Soft Matter 2014, 10, 3826–3841. [Google Scholar] [CrossRef]

- Wolf, B.; Frith, W.J.; Singleton, S.; Tassieri, M.; Norton, I.T. Shear Behaviour of Biopolymer Suspensions with Spheroidal and Cylindrical Particles. Rheol. Acta 2001, 40, 238–247. [Google Scholar] [CrossRef]

- Saiki, Y.; Prestidge, C.A.; Horn, R.G. Effects of Droplet Deformability on Emulsion Rheology. Colloids Surfaces A Physicochem. Eng. Asp. 2007, 299, 65–72. [Google Scholar] [CrossRef]

- Barnes, H.A. A Handbook of Elementary Rheology; University of Wales, Institute of Non-Newtonian Fluid Mechanics: Cardiff, Wales, 2000; ISBN 0953803201. [Google Scholar]

- Papanagopoulos, D.; Pierri, E.; Dondos, A. Influence of the Shear Rate, of the Molecular Architecture and of the Molecular Mass on the Critical Overlapping Concentration c. Polymer 1998, 39, 2195–2199. [Google Scholar] [CrossRef]

- Moore, W.R. Viscosities of Dilute Polymer Solutions. Prog. Polym. Sci. 1967, 1, 1–43. [Google Scholar] [CrossRef]

- Fedors, R.F. An Equation Suitable for Describing the Viscosity of Dilute to Moderately Concentrated Polymer Solutions. Polymer 1979, 20, 225–228. [Google Scholar] [CrossRef]

- Matsuoka, S.; Cowman, M.K. Equation of State for Polymer Solution. Polymer 2002, 43, 3447–3453. [Google Scholar] [CrossRef]

- Uman, S.; Dhand, A.; Burdick, J.A. Recent Advances in Shear-Thinning and Self-Healing Hydrogels for Biomedical Applications. J. Appl. Polym. Sci. 2020, 137, 4176–4185. [Google Scholar] [CrossRef]

- Ryder, J.F.; Yeomans, J.M. Shear Thinning in Dilute Polymer Solutions. J. Chem. Phys. 2006, 125, 194906. [Google Scholar] [CrossRef] [PubMed]

- Calabrese, V.; Haward, S.J.; Shen, A.Q. Effects of Shearing and Extensional Flows on the Alignment of Colloidal Rods. Macromolecules 2021, 54, 4176–4185. [Google Scholar] [CrossRef]

- Shapovalov, V.M. On the Applicability of the Ostwald–De Waele Model in Solving Applied Problems. J. Eng. Phys. Thermophys. 2017, 90, 1213–1218. [Google Scholar] [CrossRef]

- Hauswirth, S.C.; Bowers, C.A.; Fowler, C.P.; Schultz, P.B.; Hauswirth, A.D.; Weigand, T.; Miller, C.T. Modeling Cross Model Non-Newtonian Fluid Flow in Porous Media. J. Contam. Hydrol. 2020, 235, 103708. [Google Scholar] [CrossRef]

- Dinkgreve, M.; Paredes, J.; Denn, M.M.; Bonn, D. On Different Ways of Measuring “the” Yield Stress. J. Nonnewton. Fluid Mech. 2016, 238, 233–241. [Google Scholar] [CrossRef]

- Barnes, H.A. The Yield Stress-a Review or “Παντα Ρει”-everything Flows? J. Nonnewton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Souza Mendes, P.R.; Dutra, E.S.S. Viscosity Function for Yield-Stress Liquids. Appl. Rheol. 2004, 14, 296–302. [Google Scholar] [CrossRef]

- Mewis, J.; Wagner, N.J. Thixotropy. Adv. Colloid Interface Sci. 2009, 147–148, 214–227. [Google Scholar] [CrossRef] [PubMed]

- Barnes, H.A. Thixotropy—A Review. J. Nonnewton. Fluid Mech. 1997, 70, 1–33. [Google Scholar] [CrossRef]

- Christensen, R.M. Theory of Viscoelasticity: An Introduction, 2nd ed.; Academic Press: Cambridge, MA, USA, 1982; ISBN 9780121742508. [Google Scholar]

- Fansler, T.D.; Parrish, S.E. Spray Measurement Technology: A Review. Meas. Sci. Technol. 2015, 26, 12002. [Google Scholar] [CrossRef]

- Song, Y.; Sun, H.; Li, M.; Zhang, Q. Technology Application of Smart Spray in Agriculture: A Review. Intell. Autom. Soft Comput. 2015, 21, 319–333. [Google Scholar] [CrossRef]

- Dou, H.; Zhang, C.; Li, L.; Hao, G.; Ding, B.; Gong, W.; Huang, P. Application of Variable Spray Technology in Agriculture. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 186, p. 12007. [Google Scholar]

- Ahmad, F.; Khaliq, A.; Qiu, B.; Sultan, M.; Ma, J. Advancements of Spraying Technology in Agriculture. In Technology in Agriculture; IntechOpen: London, UK, 2021. [Google Scholar]

- Lewis, R.W.; Evans, R.A.; Malic, N.; Saito, K.; Cameron, N.R. Polymeric Drift Control Adjuvants for Agricultural Spraying. Macromol. Chem. Phys. 2016, 217, 2223–2242. [Google Scholar] [CrossRef]

- Makhnenko, I.; Alonzi, E.R.; Fredericks, S.A.; Colby, C.M.; Dutcher, C.S. A Review of Liquid Sheet Breakup: Perspectives from Agricultural Sprays. J. Aerosol Sci. 2021, 157, 105805. [Google Scholar] [CrossRef]

- Lorenze, R.V.; Kuhman, D.E. Correlation of Misdirected Satellite Drops and Resultant Print Quality Defects with Nozzle Face Geometries in Thermal Ink Jet Printheads. J. Imaging Sci. Technol. 1995, 39, 489–494. [Google Scholar]

- Song, J.H.; Nur, H.M. Defects and Prevention in Ceramic Components Fabricated by Inkjet Printing. J. Mater. Process. Technol. 2004, 155–156, 1286–1292. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, G.; Liu, Y.; Wang, J.; Yang, G.; Li, D. Suppression and Utilization of Satellite Droplets for Inkjet Printing: A Review. Processes 2022, 10, 932. [Google Scholar] [CrossRef]

- Kazama, S. Steady-State Paint Flow under High Centrifugal Force: Atomization in Spray Painting. JSAE Rev. 2003, 24, 489–494. [Google Scholar] [CrossRef]

- Pendar, M.R.; Páscoa, J.C. Numerical Modeling of Electrostatic Spray Painting Transfer Processes in Rotary Bell Cup for Automotive Painting. Int. J. Heat Fluid Flow 2019, 80, 108499. [Google Scholar] [CrossRef]

- Hines, R.L. Electrostatic Atomization and Spray Painting. J. Appl. Phys. 1966, 37, 2730–2736. [Google Scholar] [CrossRef]

- Chryssakis, C.; Assanis, D.N. A Unified Fuel Spray Breakup Model for Internal Combustion Engine Applications. At. Sprays 2008, 18, 375–426. [Google Scholar] [CrossRef]

- Soid, S.N.; Zainal, Z.A. Spray and Combustion Characterization for Internal Combustion Engines Using Optical Measuring Techniques—A Review. Energy 2011, 36, 724–741. [Google Scholar] [CrossRef]

- Suo, S.; Jia, M.; Liu, H.; Wang, T. Development of a New Hybrid Stochastic/Trajectory Droplet Collision Model for Spray Simulations in Internal Combustion Engines. Int. J. Multiph. Flow 2021, 137, 103581. [Google Scholar] [CrossRef]

- Valencia, A.; Zheng, Y.; Marshall, A.W. A Model for Predicting the Trajectory and Structure of Firefighting Hose Streams. Fire Technol. 2022, 58, 793–815. [Google Scholar] [CrossRef]

- Solomatin, Y.; Shlegel, N.; Strizhak, P. Secondary Atomization of Firefighting Liquid Droplets by Their Collisions. At. Sprays 2019, 29, 429–454. [Google Scholar] [CrossRef]

- Murugesan, R.; Orsat, V. Spray Drying for the Production of Nutraceutical Ingredients—A Review. Food Bioprocess Technol. 2012, 5, 3–14. [Google Scholar] [CrossRef]

- Mohammed, N.K.; Tan, C.P.; Manap, Y.A.; Muhialdin, B.J.; Hussin, A.S.M. Spray Drying for the Encapsulation of Oils—A Review. Molecules 2020, 25, 3873. [Google Scholar] [CrossRef] [PubMed]

- O’Sullivan, J.J.; Norwood, E.A.; O’Mahony, J.A.; Kelly, A.L. Atomisation Technologies Used in Spray Drying in the Dairy Industry: A Review. J. Food Eng. 2019, 243, 57–69. [Google Scholar] [CrossRef]

- Jaworek, A. Micro- and Nanoparticle Production by Electrospraying. Powder Technol. 2007, 176, 18–35. [Google Scholar] [CrossRef]

- Tanhaei, A.; Mohammadi, M.; Hamishehkar, H.; Hamblin, M.R. Electrospraying as a Novel Method of Particle Engineering for Drug Delivery Vehicles. J. Control. Release 2021, 330, 851–865. [Google Scholar] [CrossRef]

- Boda, S.K.; Li, X.; Xie, J. Electrospraying an Enabling Technology for Pharmaceutical and Biomedical Applications: A Review. J. Aerosol Sci. 2018, 125, 164–181. [Google Scholar] [CrossRef]

- Vardelle, M.; Vardelle, A.; Fauchais, P. Spray Parameters and Particle Behavior Relationships during Plasma Spraying. J. Therm. Spray Technol. 1993, 2, 79–91. [Google Scholar] [CrossRef]

- Fauchais, P.; Vardelle, M.; Vardelle, A.; Goutier, S. What Do We Know, What Are the Current Limitations of Suspension Plasma Spraying? J. Therm. Spray Technol. 2015, 24, 1120–1129. [Google Scholar] [CrossRef]

- Fauchais, P. Understanding Plasma Spraying. J. Phys. D Appl. Phys. 2004, 37, R86. [Google Scholar] [CrossRef]

- Tejero-Martin, D.; Rezvani Rad, M.; McDonald, A.; Hussain, T. Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings. J. Therm. Spray Technol. 2019, 28, 598–644. [Google Scholar] [CrossRef]

- Petrovicova, E.; Schadler, L.S. Thermal Spraying of Polymers. Int. Mater. Rev. 2002, 47, 169–190. [Google Scholar] [CrossRef]

- Toma, F.L.; Potthoff, A.; Berger, L.M.; Leyens, C. Demands, Potentials, and Economic Aspects of Thermal Spraying with Suspensions: A Critical Review. J. Therm. Spray Technol. 2015, 24, 1143–1152. [Google Scholar] [CrossRef]

- Aziz, F.; Ismail, A.F. Spray Coating Methods for Polymer Solar Cells Fabrication: A Review. Mater. Sci. Semicond. Process. 2015, 39, 416–425. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold Spray Coating: Review of Material Systems and Future Perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Bala, N.; Singh, H.; Karthikeyan, J.; Prakash, S. Cold Spray Coating Process for Corrosion Protection: A Review. Surf. Eng. 2014, 30, 414–421. [Google Scholar] [CrossRef]

- Le Brun, P.P.H.; De Boer, A.H.; Frijlink, H.W.; Heijerman, H.G.M. A Review of the Technical Aspects of Drug Nebulization. Pharm. World Sci. 2000, 22, 75–81. [Google Scholar] [CrossRef]

- Kooij, S.; Sijs, R.; Denn, M.M.; Villermaux, E.; Bonn, D. What Determines the Drop Size in Sprays? Phys. Rev. X 2018, 8, 31019. [Google Scholar] [CrossRef]

- Mun, R.P.; Young, B.W.; Boger, D.V. Atomisation of Dilute Polymer Solutions in Agricultural Spray Nozzles. J. Nonnewton. Fluid Mech. 1999, 83, 163–178. [Google Scholar] [CrossRef]

- Zhang, T.; Dong, B.; Chen, X.; Qiu, Z.; Jiang, R.; Li, W. Spray Characteristics of Pressure-Swirl Nozzles at Different Nozzle Diameters. Appl. Therm. Eng. 2017, 121, 984–991. [Google Scholar] [CrossRef]

- Dombrowski, N.; Fraser, R.P.; House, B.; Dombrowski, B.N. A Photographic Investigation into the Disintegration of Liquid Sheets. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1954, 247, 101–130. [Google Scholar] [CrossRef]

- Squire, H.B. Investigation of the Instability of a Moving Liquid Film. Br. J. Appl. Phys. 1953, 4, 167–169. [Google Scholar] [CrossRef]

- Shrestha, K.; Van Strien, J.; Singh, N.; Inthavong, K. Primary Break-up and Atomization Characteristics of a Nasal Spray. PLoS ONE 2020, 15, e0236063. [Google Scholar] [CrossRef] [PubMed]

- Elkotb, M.M. Fuel Atomization for Spray Modelling. Prog. Energy Combust. Sci. 1982, 8, 61–91. [Google Scholar] [CrossRef]

- Czernek, K.; Ochowiak, M.; Włodarczak, S. Effect of Rheological Properties of Aqueous Solution of Na-CMC on Spray Angle for Conical Pressure-Swirl Atomizers. Energies 2020, 13, 6309. [Google Scholar] [CrossRef]

- Robinson, T.E.; Hughes, E.A.B.; Bose, A.; Cornish, E.A.; Teo, J.Y.; Eisenstein, N.M.; Grover, L.M.; Cox, S.C. Filling the Gap: A Correlation between Objective and Subjective Measures of Injectability. Adv. Healthc. Mater. 2020, 9, 1901521. [Google Scholar] [CrossRef]

- Madlener, K.; Frey, B.; Ciezki, H.K. Generalized Reynolds Number for Non-Newtonian Fluids. Prog. Propuls. Phys. 2009, 1, 237–250. [Google Scholar]

- Grens, E.A.; Williams, M.C. Viscometric and Misting Properties of Polymer-Modified Fuel; NASA: Washington, DC, USA, 1982.

- Keller, A.; Odell, J.A. Turbulence Splits Polymers. Nature 1984, 312, 98. [Google Scholar] [CrossRef]

- Richardson, R.G. Control of Spray Drift with Thickening Agents. J. Agric. Eng. Res. 1974, 19, 227–231. [Google Scholar] [CrossRef]

- Bouse, L.F.; Carlton, J.B.; Jank, P.C. Effect of Water Soluble Polymers on Spray Droplet Size. Trans. Am. Soc. Agric. Eng. 1988, 31, 1633–1639. [Google Scholar] [CrossRef]

- Gaillard, A.; Sijs, R.; Bonn, D. What Determines the Drop Size in Sprays of Polymer Solutions? J. Nonnewton. Fluid Mech. 2022, 305, 104813. [Google Scholar] [CrossRef]

- Keshavarz, B.; Houze, E.C.; Moore, J.R.; Koerner, M.R.; McKinley, G.H. Ligament Mediated Fragmentation of Viscoelastic Liquids. Phys. Rev. Lett. 2016, 117, 154502. [Google Scholar] [CrossRef] [PubMed]

- Walker, L.M.; Christanti, Y. Quantifying air atomization of viscoelastic fluids through fluid relaxation times. At. Sprays 2006, 16, 777–790. [Google Scholar] [CrossRef]

- Negri, M.; Ciezki, H.K.; Schlechtriem, S. Spray Behavior of Non-Newtonian Fluids: Correlation between Rheological Measurements and Droplets/threads Formation. Prog. Propuls. Phys. 2013, 4, 271–290. [Google Scholar] [CrossRef]

- Yu, L.F.; Zuo, Z.G.; Li, L.; Liu, S.H.; Zhao, S.T. Experimental Breakup Characteristics of Round Liquid Jets of a Dilute Polymer Solution into Quiescent Air. J. Appl. Mech. Tech. Phys. 2020, 61, 676–684. [Google Scholar] [CrossRef]

- Keshavarz, B.; Sharma, V.; Houze, E.C.; Koerner, M.R.; Moore, J.R.; Cotts, P.M.; Threlfall-Holmes, P.; McKinley, G.H. Studying the Effects of Elongational Properties on Atomization of Weakly Viscoelastic Solutions Using Rayleigh Ohnesorge Jetting Extensional Rheometry (ROJER). J. Nonnewton. Fluid Mech. 2015, 222, 171–189. [Google Scholar] [CrossRef]

- Qian, L.; Lin, J.; Bao, F. Numerical Models for Viscoelastic Liquid Atomization Spray. Energies 2016, 9, 1079. [Google Scholar] [CrossRef]

- Harrison, G.M.; Mun, R.; Cooper, G.; Boger, D.V. A Note on the Effect of Polymer Rigidity and Concentration on Spray Atomisation. J. Nonnewton. Fluid Mech. 1999, 85, 93–104. [Google Scholar] [CrossRef]

- Williams, P.A.; English, R.J.; Blanchard, R.L.; Rose, S.A.; Lyons, L.; Whitehead, M. The Influence of the Extensional Viscosity of Very Low Concentrations of High Molecular Mass Water-Soluble Polymers on Atomisation and Droplet Impact. Pest Manag. Sci. 2008, 64, 497–504. [Google Scholar] [CrossRef]

- Zhu, H.; Dexter, R.W.; Fox, R.D.; Reichard, D.L.; Brazee, R.D.; Ozkan, H.E. Effects of Polymer Composition and Viscosity on Droplet Size of Recirculated Spray Solutions. J. Agric. Eng. Res. 1997, 67, 35–45. [Google Scholar] [CrossRef]

- Tan, H.; Tam, K.C.; Tirtaatmadja, V.; Jenkins, R.D.; Bassett, D.R. Extensional Properties of Model Hydrophobically Modified Alkali-Soluble Associative (HASE) Polymer Solutions. J. Nonnewton. Fluid Mech. 2000, 92, 167–185. [Google Scholar] [CrossRef]

- Xu, B.; Li, L.; Zhang, K.; Macdonald, P.M.; Winnik, M.A.; Jenkins, R.; Bassett, D.; Wolf, D.; Nuyken, O. Synthesis and Characterization of Comb Associative Polymers Based on Poly(ethylene Oxide). Langmuir 1997, 13, 6896–6902. [Google Scholar] [CrossRef]

- Jacob, S.; Nair, A.B.; Boddu, S.H.S.; Gorain, B.; Sreeharsha, N.; Shah, J. An Updated Overview of the Emerging Role of Patch and Film-Based Buccal Delivery Systems. Pharmaceutics 2021, 13, 1206. [Google Scholar] [CrossRef] [PubMed]

- Pinto, S.; Pintado, M.E.; Sarmento, B. In Vivo, Ex Vivo and in Vitro Assessment of Buccal Permeation of Drugs from Delivery Systems. Expert Opin. Drug Deliv. 2020, 17, 33–48. [Google Scholar] [CrossRef] [PubMed]

- Gänger, S.; Schindowski, K. Tailoring Formulations for Intranasal Nose-to-Brain Delivery: A Review on Architecture, Physico-Chemical Characteristics and Mucociliary Clearance of the Nasal Olfactory Mucosa. Pharmaceutics 2018, 10, 116. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, K.; Shukla, R. Drug Delivery and Targeting to the Brain Through Nasal Route: Mechanisms, Applications and Challenges. Curr. Drug Deliv. 2019, 16, 887–901. [Google Scholar] [CrossRef] [PubMed]

- Adepu, S.; Ramakrishna, S. Controlled Drug Delivery Systems: Current Status and Future Directions. Molecules 2021, 26, 5905. [Google Scholar] [CrossRef]

- Majumder, J.; Taratula, O.; Minko, T. Nanocarrier-Based Systems for Targeted and Site Specific Therapeutic Delivery. Adv. Drug Deliv. Rev. 2019, 144, 57–77. [Google Scholar] [CrossRef]

- Hazrati, R.; Davaran, S.; Omidi, Y. Bioactive Functional Scaffolds for Stem Cells Delivery in Wound Healing and Skin Regeneration. React. Funct. Polym. 2022, 174, 105233. [Google Scholar] [CrossRef]

- Lostalé-Seijo, I.; Montenegro, J. Synthetic Materials at the Forefront of Gene Delivery. Nat. Rev. Chem. 2018, 2, 258–277. [Google Scholar] [CrossRef]

- Dong, Y.; Siegwart, D.J.; Anderson, D.G. Strategies, Design, and Chemistry in siRNA Delivery Systems. Adv. Drug Deliv. Rev. 2019, 144, 133–147. [Google Scholar] [CrossRef]

- Xie, P.; Wang, Y.; Wei, D.; Zhang, L.; Zhang, B.; Xiao, H.; Song, H.; Mao, X. Nanoparticle-Based Drug Delivery Systems with Platinum Drugs for Overcoming Cancer Drug Resistance. J. Mater. Chem. B 2021, 9, 5173–5194. [Google Scholar] [CrossRef] [PubMed]

- Haque, S.T.; Saha, S.K.; Haque, M.E.; Biswas, N. Nanotechnology-Based Therapeutic Applications:: In Vitro and in Vivo Clinical Studies for Diabetic Wound Healing. Biomater. Sci. 2021, 9, 7705–7747. [Google Scholar] [CrossRef]

- Kaiser, P.; Wächter, J.; Windbergs, M. Therapy of Infected Wounds: Overcoming Clinical Challenges by Advanced Drug Delivery Systems. Drug Deliv. Transl. Res. 2021, 11, 1545–1567. [Google Scholar] [CrossRef] [PubMed]

- Lewis, R.W.; Malic, N.; Saito, K.; Evans, R.A.; Cameron, N.R. Ultra-High Molecular Weight Linear Coordination Polymers with Terpyridine Ligands. Chem. Sci. 2019, 10, 6174–6183. [Google Scholar] [CrossRef] [PubMed]

- Diba, M.; Spaans, S.; Ning, K.; Ippel, B.D.; Yang, F.; Loomans, B.; Dankers, P.Y.W.; Leeuwenburgh, S.C.G. Self-Healing Biomaterials: From Molecular Concepts to Clinical Applications. Adv. Mater. Interfaces 2018, 5, 1800118. [Google Scholar] [CrossRef]

- Bertsch, P.; Diba, M.; Mooney, D.J.; Leeuwenburgh, S.C.G. Self-Healing Injectable Hydrogels for Tissue Regeneration. Chem. Rev. 2022. [Google Scholar] [CrossRef]

- Loebel, C.; Rodell, C.B.; Chen, M.H.; Burdick, J.A. Shear-Thinning and Self-Healing Hydrogels as Injectable Therapeutics and for 3D-Printing. Nat. Protoc. 2017, 12, 1521–1541. [Google Scholar] [CrossRef]

- Brochu, A.B.W.; Craig, S.L.; Reichert, W.M. Self-Healing Biomaterials. J. Biomed. Mater. Res. Part A 2011, 96, 492–506. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moakes, R.J.A.; Grover, L.M.; Robinson, T.E. Can We Structure Biomaterials to Spray Well Whilst Maintaining Functionality? Bioengineering 2023, 10, 3. https://doi.org/10.3390/bioengineering10010003

Moakes RJA, Grover LM, Robinson TE. Can We Structure Biomaterials to Spray Well Whilst Maintaining Functionality? Bioengineering. 2023; 10(1):3. https://doi.org/10.3390/bioengineering10010003

Chicago/Turabian StyleMoakes, Richard J. A., Liam M. Grover, and Thomas E. Robinson. 2023. "Can We Structure Biomaterials to Spray Well Whilst Maintaining Functionality?" Bioengineering 10, no. 1: 3. https://doi.org/10.3390/bioengineering10010003

APA StyleMoakes, R. J. A., Grover, L. M., & Robinson, T. E. (2023). Can We Structure Biomaterials to Spray Well Whilst Maintaining Functionality? Bioengineering, 10(1), 3. https://doi.org/10.3390/bioengineering10010003