Parametric CFD Study of Spray Drying Chamber Geometry: Part II—Effects on Particle Histories

Abstract

1. Introduction

2. Design of Experiments Methodology (DOE)

2.1. Objectives of the Numerical Experiment

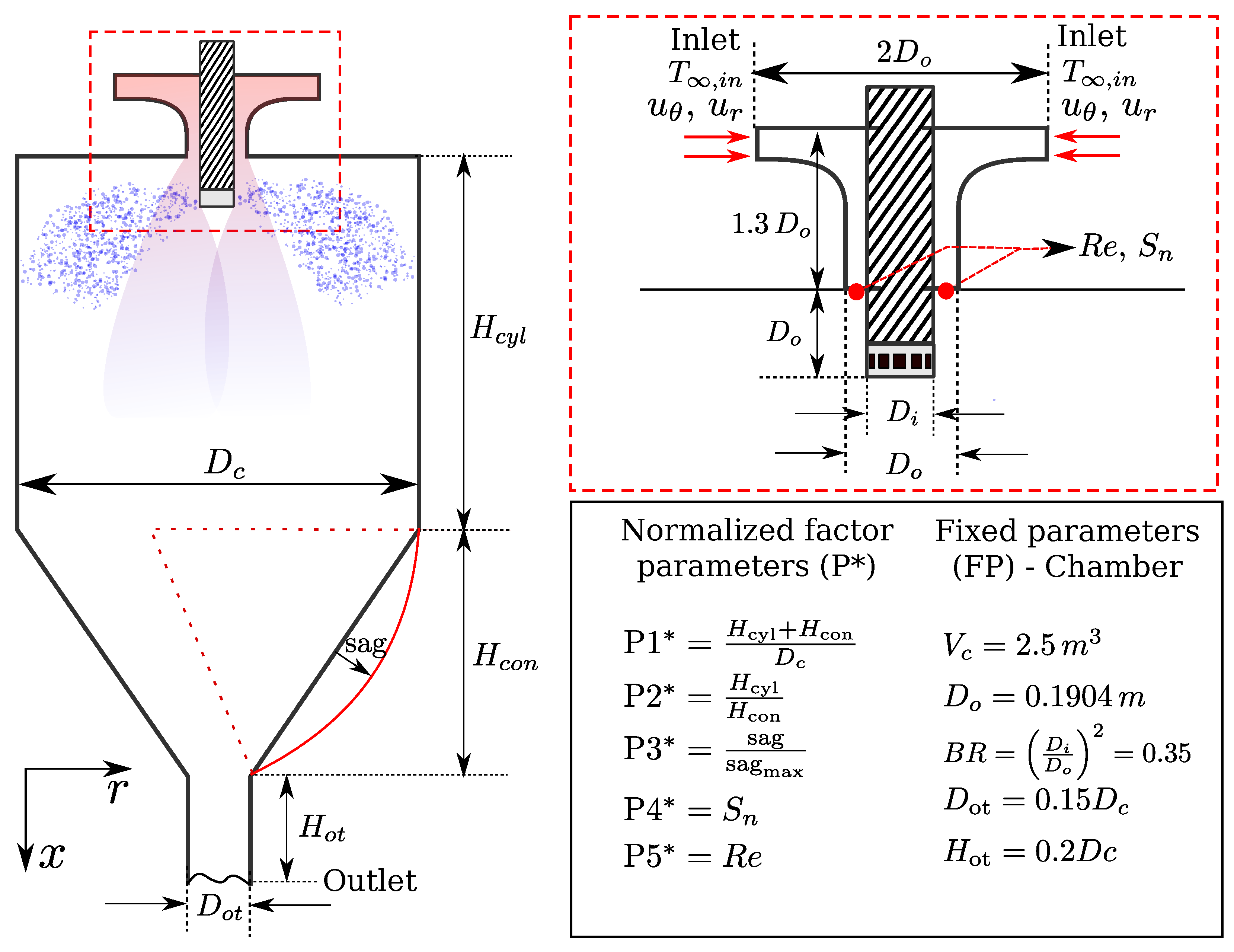

2.2. Parametrized Geometry of a Spray Drying Chamber

2.3. Factor Parameters and Ranges

2.4. Fixed (Held Constant) Parameters

2.4.1. Geometrical Design

2.4.2. External Heat Losses

| Category | Parameter | Value |

|---|---|---|

| Geometrical Design | Chamber volume () | 2.5 |

| Blockage ratio of the jet () | 0.35 | |

| External diameter of the jet (m) | 0.1904 | |

| Diameter of the outlet pipe | ||

| External Heat Losses | Outside air temperature (°C) | 26.85 |

| Convective heat coefficient—walls to exterior () | 3.5 | |

| Wall thickness (m) | 0.015 | |

| Wall heat conductivity (W/mK) | 45 | |

| Feed Product Characteristics | Wet-basis humidity | 0.5 |

| Solids product | Maltodextrin | |

| Solids density () | 1410 | |

| Solids heat capacity (J/kgK) | 1410 | |

| Feed temperature (°C) | 22 | |

| Process Operational Parameters | ARL (air-to-liquid ratio) (kg/kg) | 85 |

| Inlet air temperature (°C) | 170 | |

| Inlet air moisture content (kg/kg) | 0.014 | |

| Atomization Parameters—Droplet | Atomization velocity (m/s) | 70 |

| Atomizer disk RPM () | 11,950 | |

| Mean diameter (micron) | 70.5 | |

| Minimum diameter (micron) | 15 | |

| Maximum diameter (micron) | 138 | |

| Spread parameter () | 2.05 |

2.4.3. Feed Product Characteristics

- Few experimental studies on the drying kinetics of Maltodextrin solutions and their mixtures are available in the literature, especially at lower solid contents. To address this, the measurements performed by Adhikari et al. [28], one of the most comprehensive studies available, were used as reference. That study used droplets with 40% and 50% dissolved solids content.

- Previous experimental and CFD studies of spray drying processes have used similar initial solids contents for Maltodextrin and Maltodextrin/Sucrose mixtures, providing a basis for comparison. Examples include 40% in Gianfrancesco [30], 42.5% in Kieviet and Kerkhof [31] and Huang et al. [21], Kieviet and Kerkhof [31], and 50% in Huang et al. [32] (see Table 3).

- The adjusted coefficients of the REA model for droplet drying are valid only for the initial conditions (solids content) under which they were calibrated, as reported in previous studies [14,29]. This limitation, confirmed during preliminary simulations in the present study, prevents variation of the initial solids content.

- While some studies report drying kinetics for specific feed products (e.g., Guava juice [20]), the experimental design objectives of this study are better addressed by focusing on a drying agent used for various feed products rather than a specific one.

2.4.4. Process Operational Parameters

2.4.5. Atomization Parameters

2.5. Response Variables

2.5.1. Limitations in the Selection of the Response Variables

2.5.2. Description of the Response Variables

R-0 (Outlet Gas Characteristics)

R-1—Particle Residence Time (PRT)

R-2—Moisture Content

R-3—Temperature

R-4—Particle-to-Wall Collisions

2.5.3. Data Processing

2.5.4. Nuisance Factors and Modeling Limitations

2.5.5. Spreadsheet of Experiments

3. Computational Implementation

3.1. Assumptions

- Moisture loss from the particles occurs due to convective effects. A semi-empirical model with lumped parameters (REA) is used to perform this calculation [29].

- The particle diameter change is not strictly related to the moisture lost. A shrinkage model is included to adjust the change in particle diameter.

- The thermodynamic properties of the continuous phase are obtained from the mean value in the cell containing the particle. This reduces coupling problems that could arise as soon as the parcel is atomized into a small cell.

3.2. Gas-Phase Models

- The equation of state for perfect gases is used to relate thermodynamic properties :

- Partial pressures are used to extend the definition of the equation of state to a mixture of species.

- For all species , the heat capacities and enthalpies are evaluated by polynomial functions obtained from the JANAF thermophysical tables [48].

- For all species , the dynamic viscosities are modeled as a function of the carrier temperature using Sutherland’s formula.

3.3. Coupling with the Particle Phase

3.4. Particle-Phase Models

3.4.1. Particle Motion and Momentum Balances

3.4.2. Mass and Energy Balances

3.4.3. Particle Drying Model

3.4.4. Particle Shrinkage Model

3.5. Numerical Schemes and Methods

3.6. Computational Configuration

3.6.1. Boundary Conditions

- Drying air velocity () is prescribed at the inlet boundary using a fixed-value vector in cylindrical coordinates, with axial (), tangential (), and radial () velocity components. The radial velocity is set according to the value of the Reynolds number (P5*), using the corresponding air density and kinematic viscosity at the inlet temperature. The tangential velocity is adjusted to produce a swirl number equal to P4* at the jet discharge ( P4*). No-slip conditions are applied at the walls. Although, in real spray dryers, the rotary atomizer could potentially increase the rotational component of the jet, this factor was not considered in order to avoid uncertainties in the response due to the unknown impact magnitude.

- Pressure (p) is prescribed at the outlet with a fixed-value condition of , which matches the experimentally measured value from Gutiérrez Suárez [26].

- Temperature (T) is prescribed at the inlet with a fixed value of and zero-gradient conditions at the outlet. Heat-flux conditions are applied at the walls, defined in terms of a fixed convective coefficient, the material and thickness of the wall, and an external air temperature (see Table 2).

- Turbulent variables () are prescribed at the inlet using fixed-value conditions. These initial values are close to zero (), as turbulence is expected to develop along the inlet duct. Standard wall functions are applied at the chamber walls.

- Transported species () are adjusted to represent an inlet flow with a specific humidity of . This value is similar to the one reported by Huang et al. [21]. Zero-gradient conditions are prescribed at the walls and the outlet.

- All particles that impact the walls of the domain were removed from the simulation.

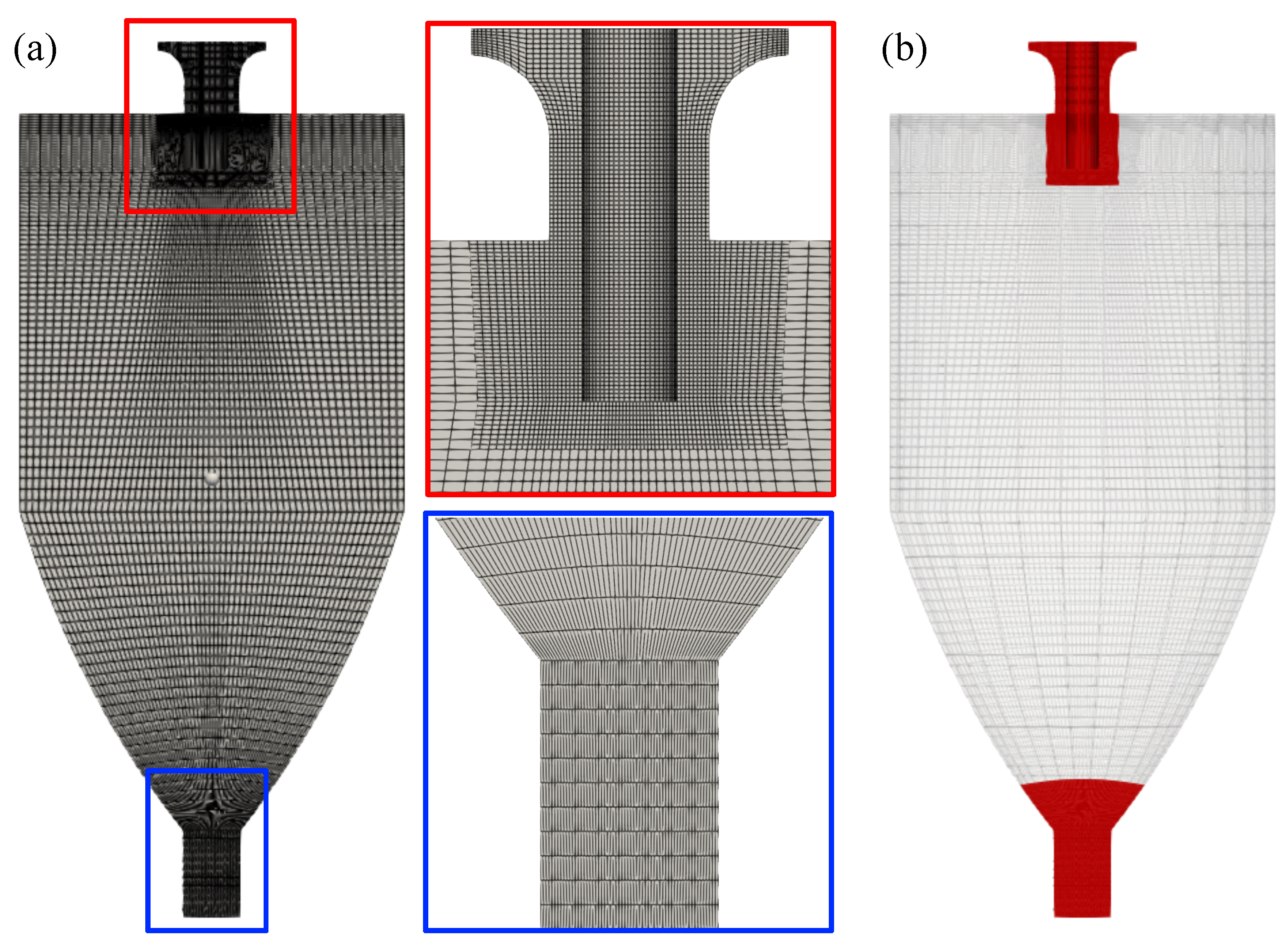

3.6.2. Mesh Configuration and Adaptive Mesh Refinement (AMR)

3.6.3. Particle Injection

Particle Size Distribution

Atomization Configuration

- It is assumed that the disk diameter of the atomizer is the same as the annular inlet . is calculated from the blockage ratio relation, which is a fixed parameter (see Figure 1).

- The particle ejection velocity is assumed to be equivalent to the tangential velocity of the disk [57]; givingSelecting this velocity is particularly relevant under the constraints of the DOE study, as high values in experiments where (narrow, tall-form drying chamber) may lead to excessive particle accumulation on the walls. Therefore, it was ensured that the obtained value remained consistent with typical values used in drying chambers of similar diameters.

- The Sauter mean diameter ( was calculated using the following expression, which considers some geometrical and operational parameters of the atomizer [34,36]In this expression, is the number of vanes, and is the height of each vane (m). The feed product mass flow, denoted as (kg/s), is determined by the air-to-liquid ratio (ARL) and the parameter P5*. As P5* is a factor parameter, varying it yields different values of and . However, to ensure a fair comparison in all study cases, is kept constant and calculated based on the most extreme case (P5*

- From the obtained value of , and using the correlations for the mass Rosin-Rammler distribution presented in Yoon et al. [56], the remaining parameters ( are calculated.

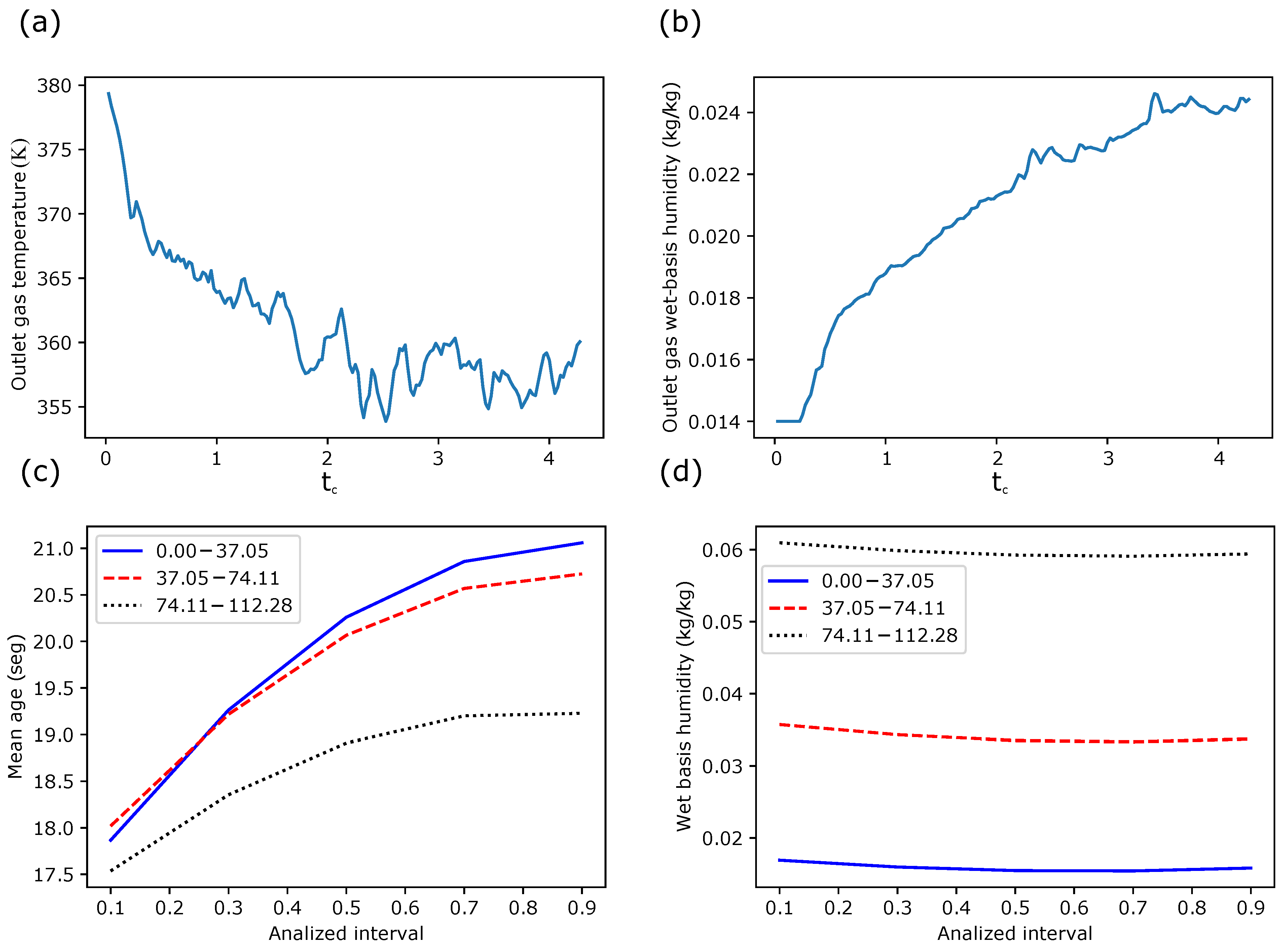

3.7. Running Setup and Sampling of Data

3.7.1. Running Setup

- All experiments were started at and were run until using the base grid with a fixed refinement along the annular entrance. This pre-refinement is presented in Figure 2.

- At AMR is activated and simulations are run until a converging trend is observed in the response variables (e.g., PRT, ). This trend was observed around , but variations were observed from case to case.

3.7.2. Data Collection and Post-Processing

3.8. Solver and Code Modifications

- A new OpenFOAM solver, relErrorSprayDyMFoam,based on the standard solver sprayFoam. This solver incorporates adaptive mesh refinement and the use of refinement-protected regions.

- A new phase change model, DropletEvaporationREA, to implement the REA drying model, along with a new drying material model, Maltodextrin.

- Bug fixes in the manualInjection, coneInjection, and particle classes of OpenFOAM. These are detailed in issues 2096, 2199, and 2289 on the OpenFOAM developers portal (OpenCFD).

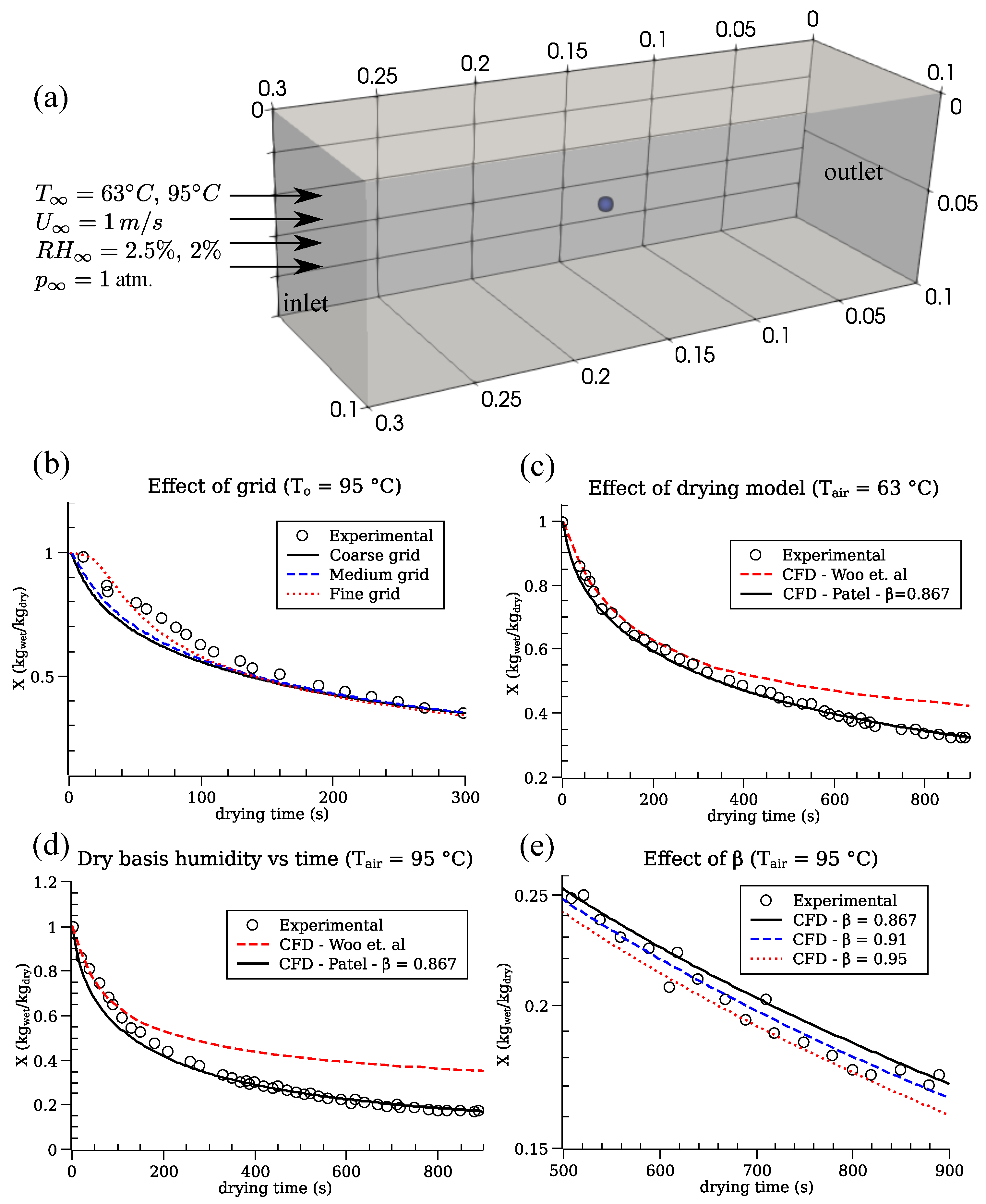

4. Verification and Calibration of the Drying Model for CFD Simulations

4.1. Domain, Grid, and Flow Conditions

4.2. Results and Discussion

5. Results of the Parametric Study and Discussion

5.1. Computational Costs

5.2. Flow and Particle Statistics Development

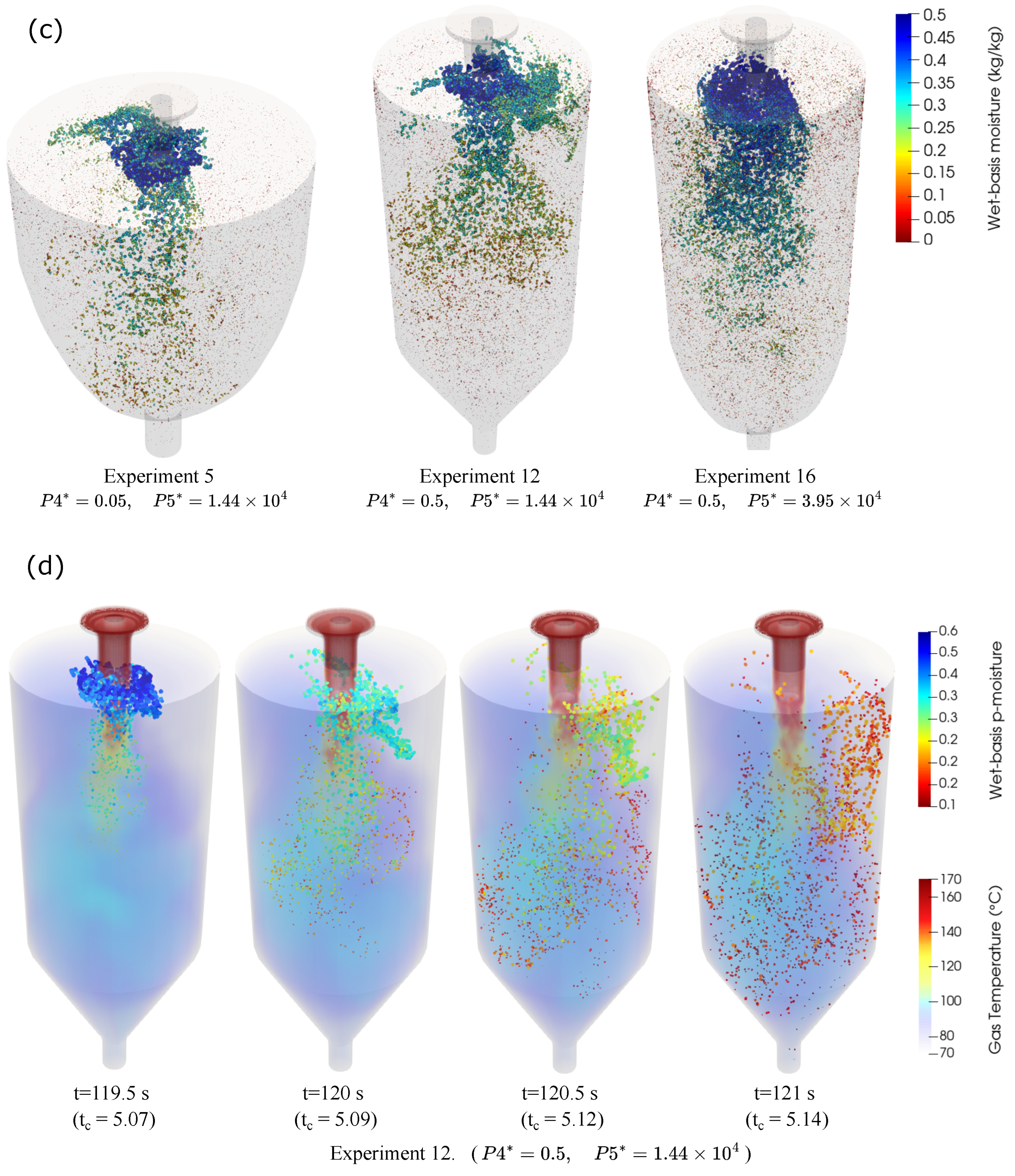

5.3. Velocity, Humidity, and Particle-Related Fields

Effect of the Particle Phase on the Velocity Field

Air Moisture Field

Particle Fields

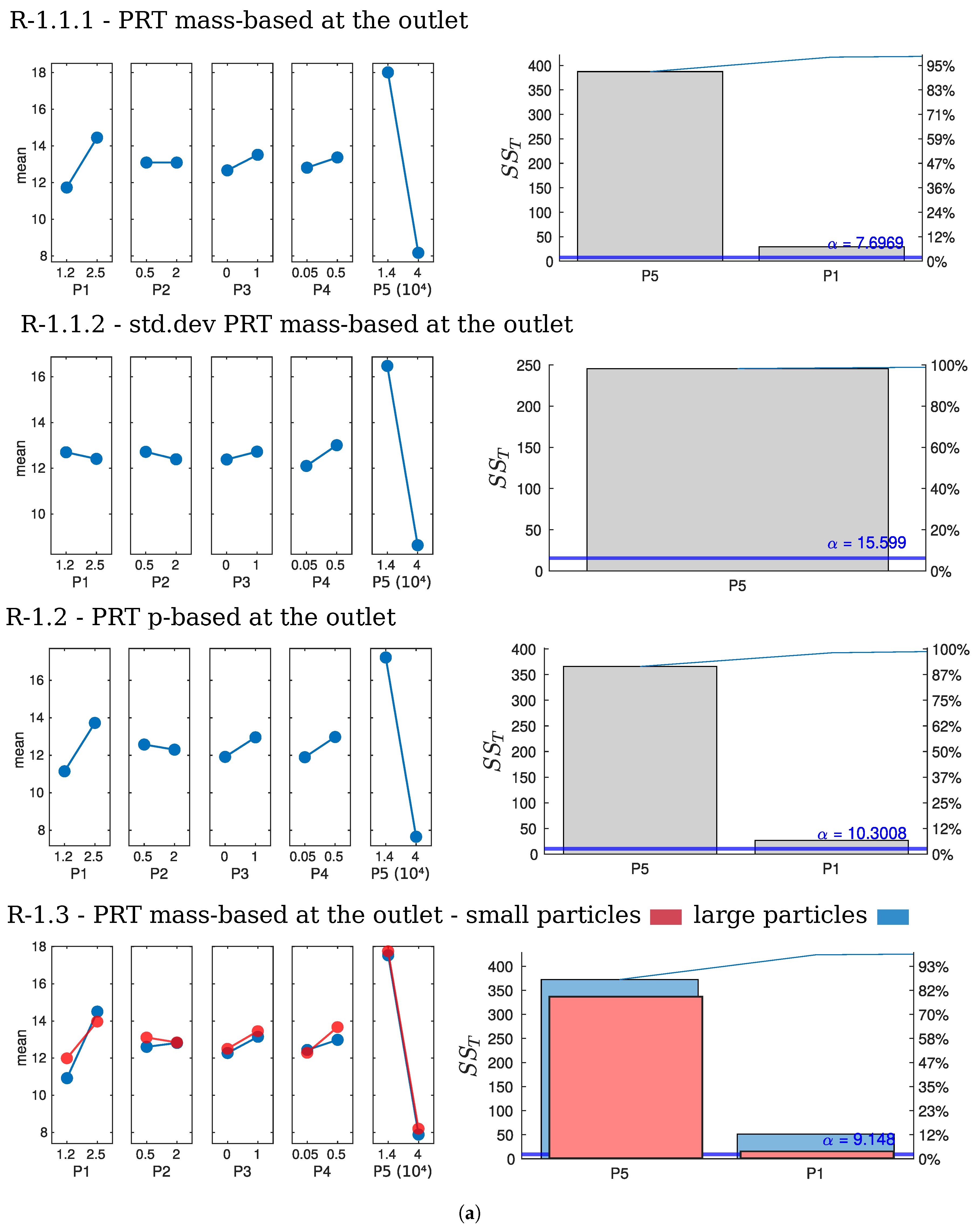

5.4. Main Effects and Pareto Plots

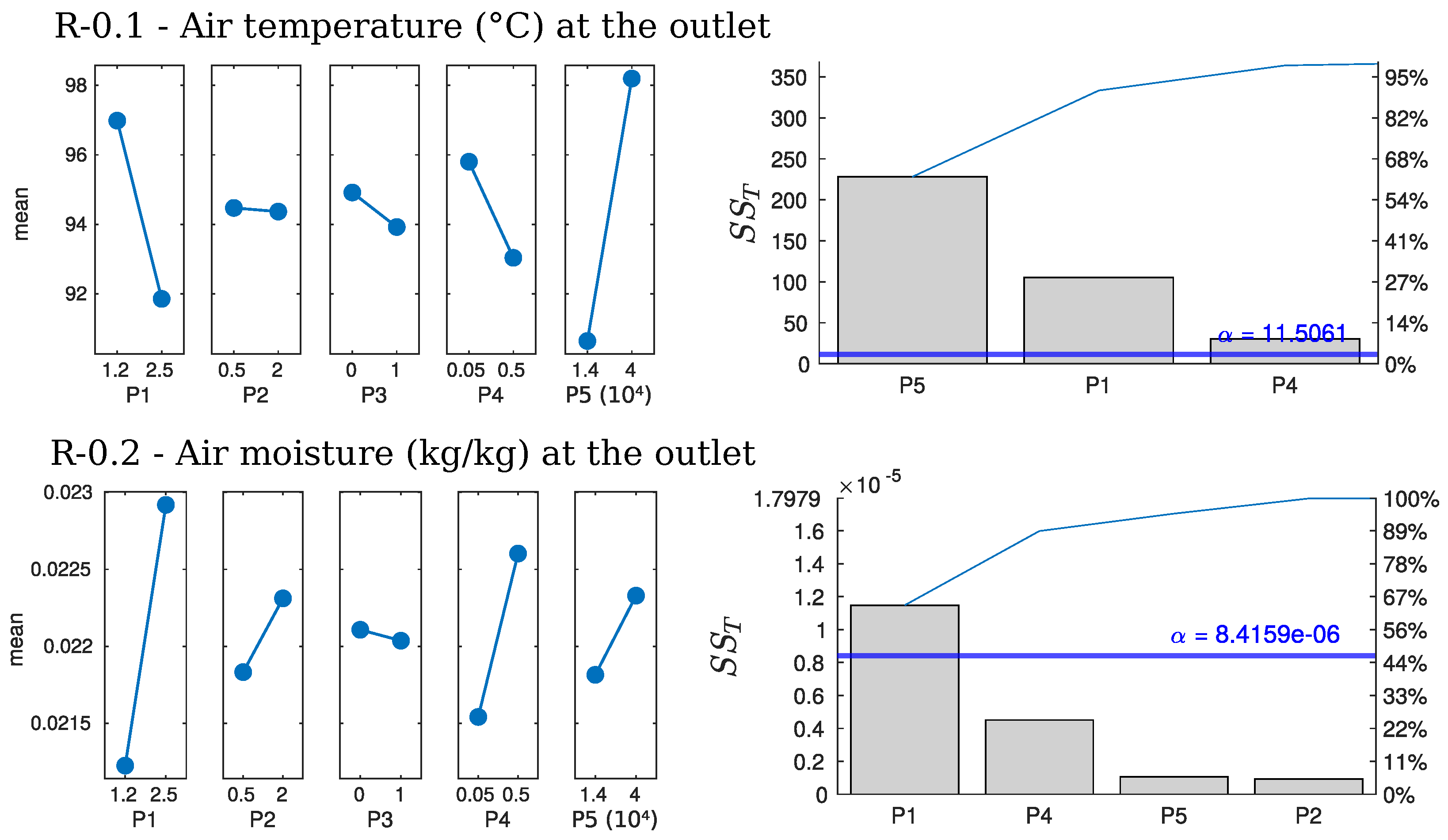

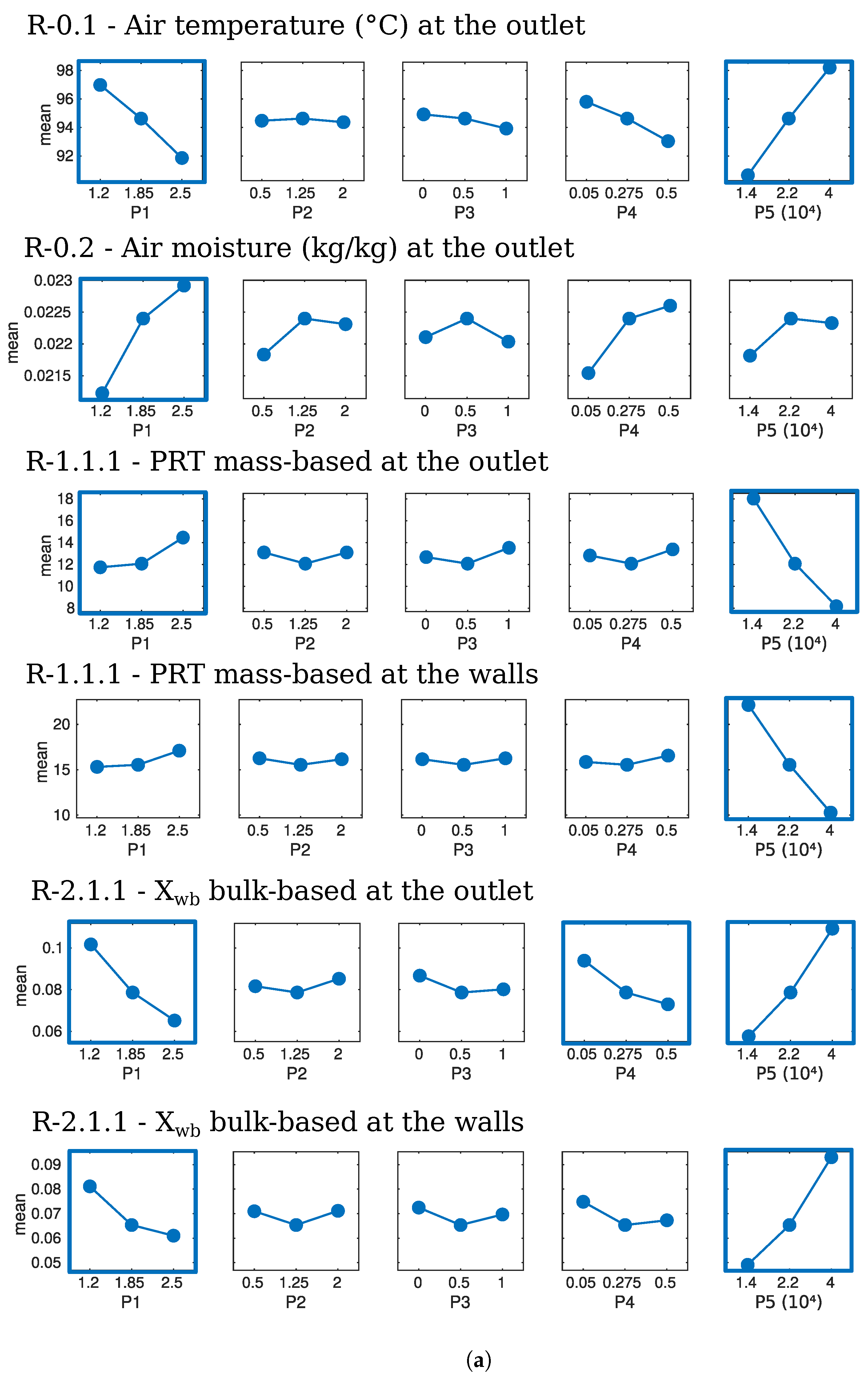

5.4.1. Global Responses (R-0)

R-0.1—Outlet Air Temperature (°C)

R-0.2—Outlet Air Moisture Content (kg/kg)

Discussion on Global Responses

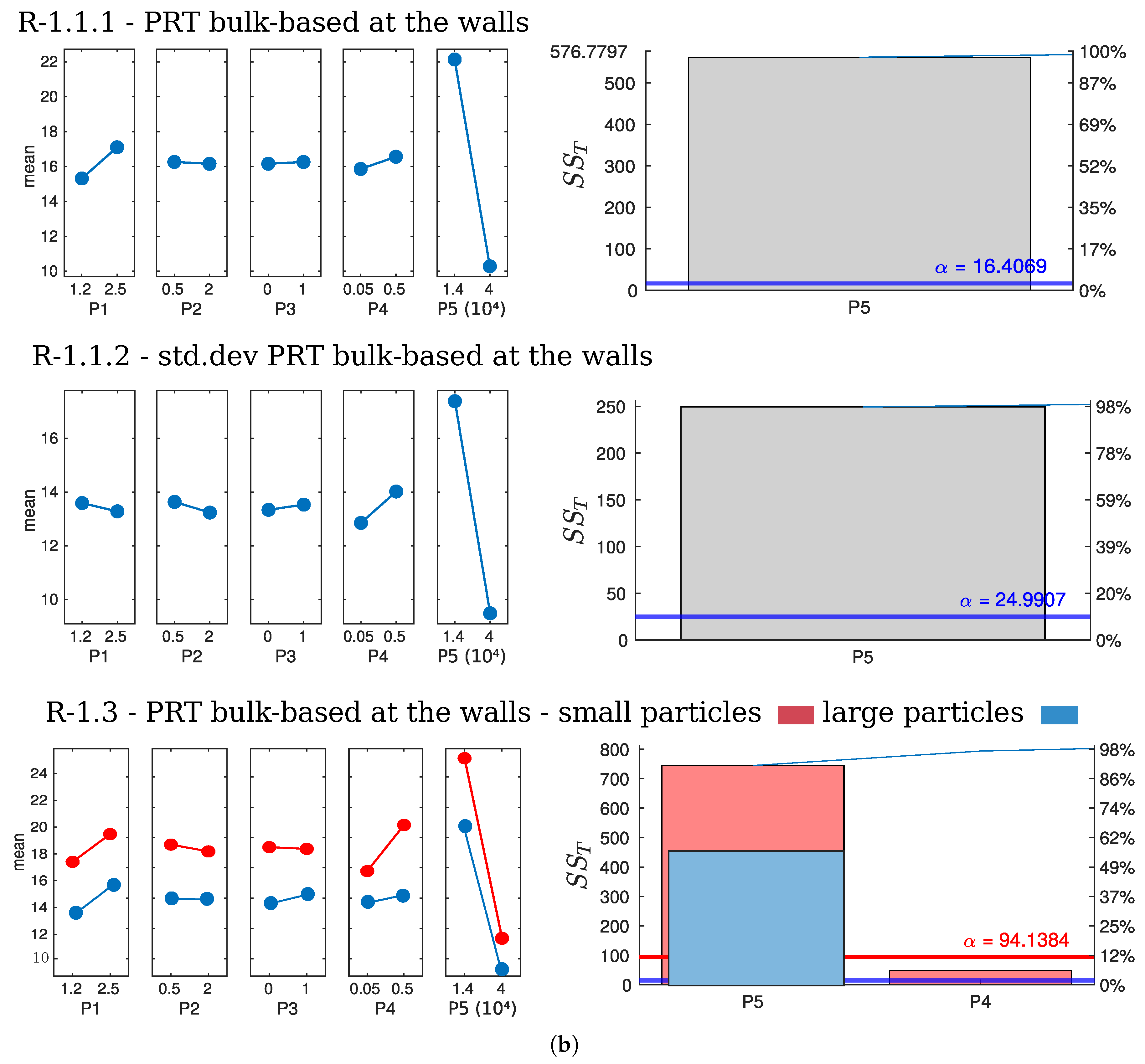

5.4.2. Particle Residence Times (R-1)

Primary Residence Times (Measured at the Outlet)

Particle Residence Times at the Chamber Walls

Discussion on Particle Residence Times

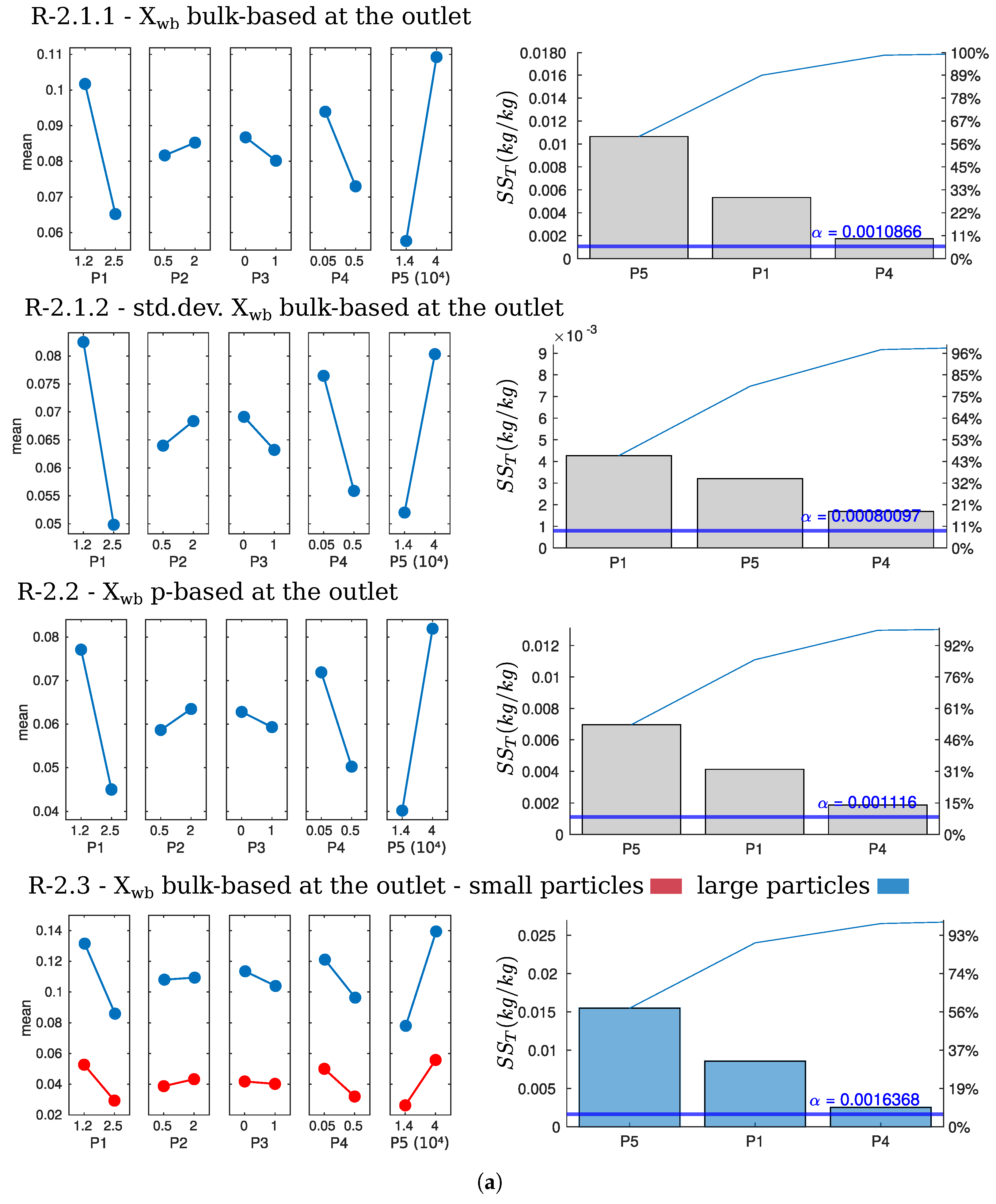

5.4.3. Particle Moisture Content

Particle Moisture Content at the Outlet

Particle Moisture Content at the Walls

Discussion on Particle Moisture Content

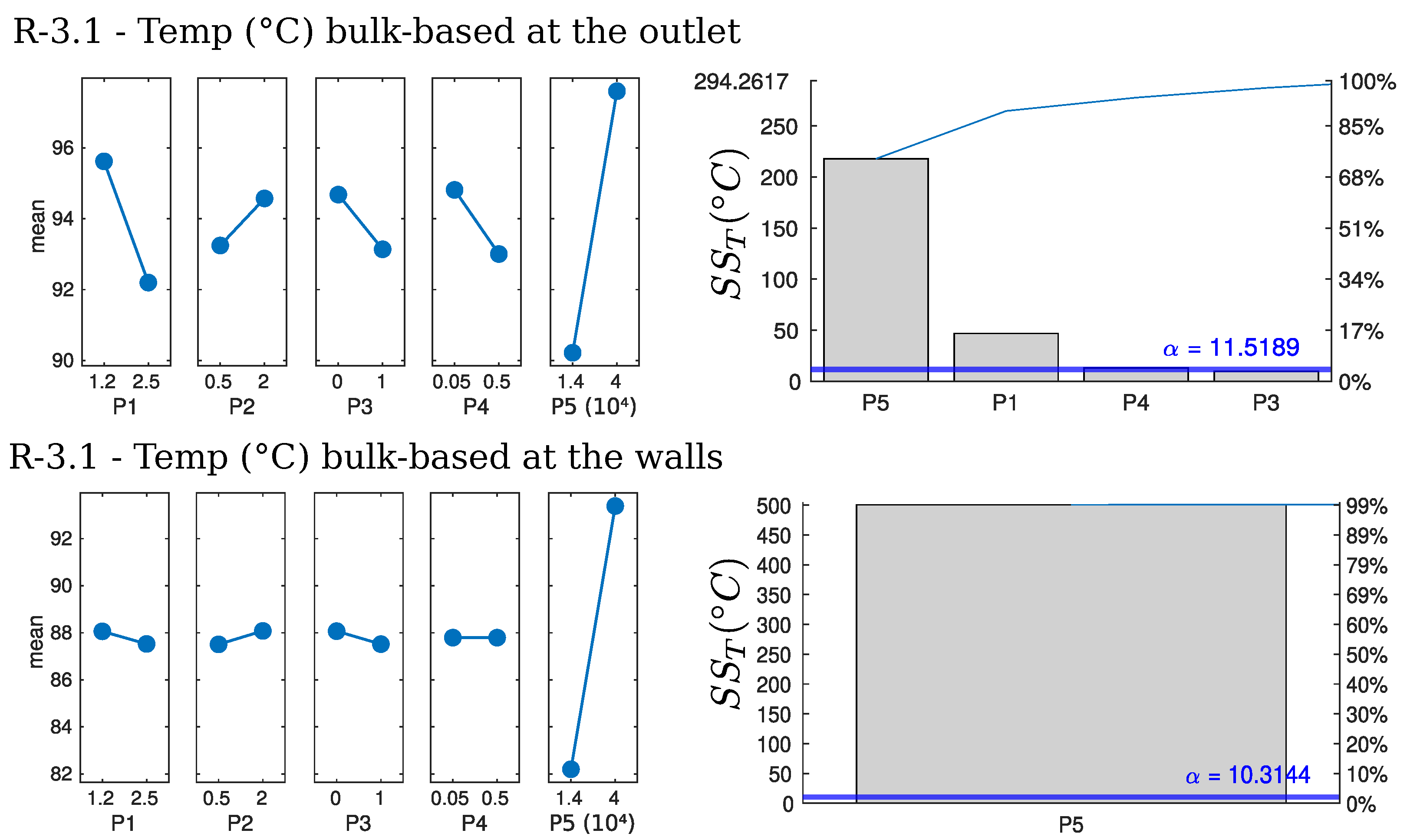

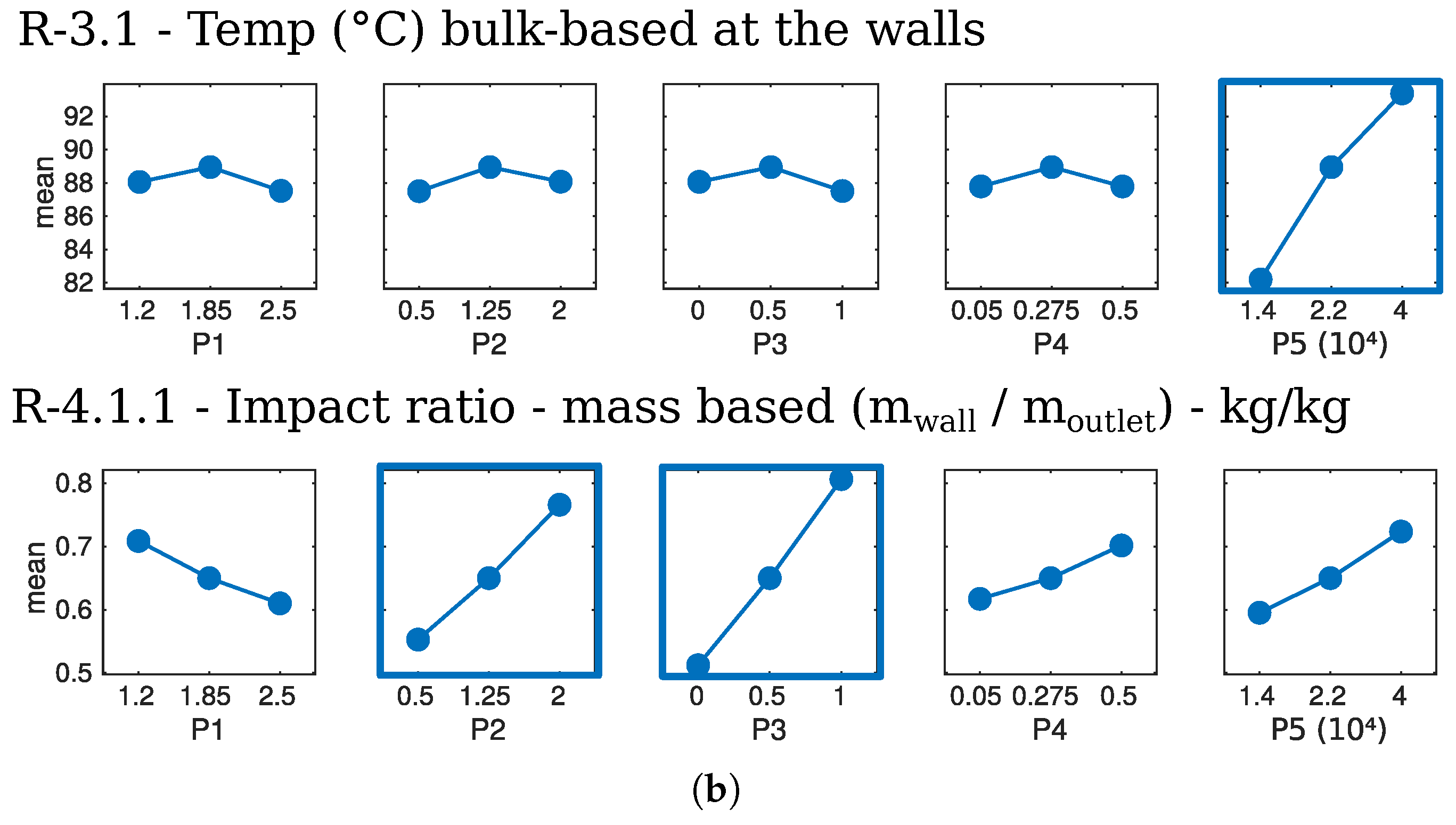

5.4.4. Particle Temperature

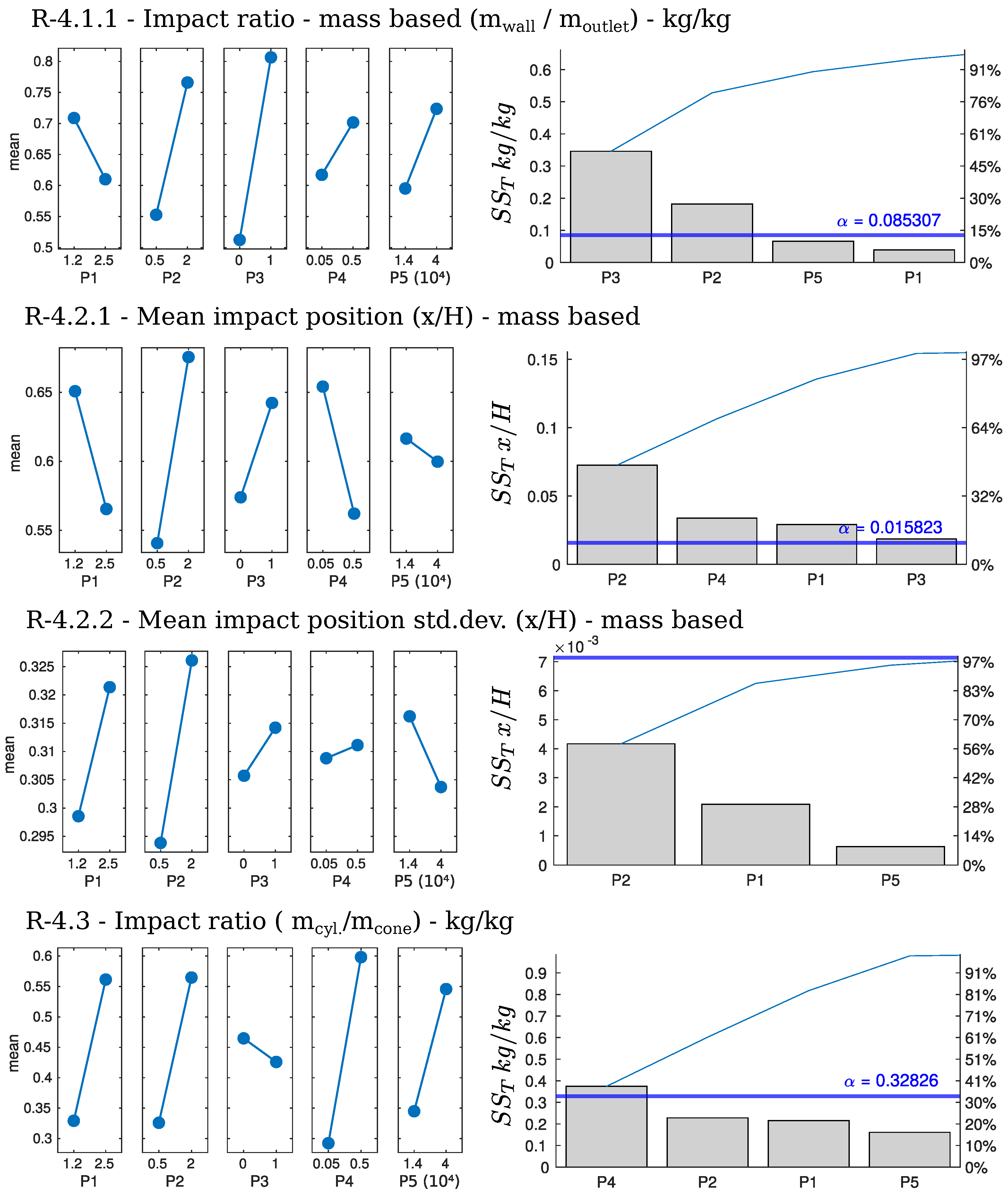

5.4.5. Particle-Wall Impacts (R-4)

Impact Ratio (R-4.1)—Walls vs. Outlet

Impact Position (R-4.2)

Impact Ratio (R-4.3)—Conical vs. Cylindrical Section

Discussion on Particle-Wall Impacts

5.5. Curvature in the Response

5.6. Possible Effects on Particle Accumulation in Walls

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutiérrez Suárez, J.A.; Galeano Urueña, C.H.; Gómez Mejía, A. Parametric CFD Study of Spray Drying Chamber Geometry: Part I—Effects on Airflow Dynamics. ChemEngineering 2025, 9, 5. [Google Scholar] [CrossRef]

- Anandharamakrishnan, C.; Gimbun, J.; Stapley, A.G.F.; Rielly, C.D. A study of particle histories during spray drying using computational fluid dynamic simulations. Dry. Technol. 2010, 28, 566–576. [Google Scholar] [CrossRef]

- Woo, M.; Che, L.; Daud, W.R.W.; Mujumdar, A.; Chen, X. Highly swirling transient flows in spray dryers and consequent effect on modeling of particle deposition. Chem. Eng. Res. Des. 2012, 90, 336–345. [Google Scholar] [CrossRef]

- Pawar, S.K.; Abrahams, R.H.; Deen, N.G.; Padding, J.T.; van der Gulik, G.J.; Jongsma, A.; Innings, F.; Kuipers, J. An experimental study of dynamic jet behaviour in a scaled cold flow spray dryer model using PIV. Can. J. Chem. Eng. 2014, 92, 2013–2020. [Google Scholar] [CrossRef]

- Fletcher, D.; Langrish, T. Scale-adaptive simulation (SAS) modelling of a pilot-scale spray dryer. Chem. Eng. Res. Des. 2009, 87, 1371–1378. [Google Scholar] [CrossRef]

- Langrish, T.; Zbicinski, I. The effects of air inlet geometry and spray cone angle on the wall deposition rate in spray dryers. Chem. Eng. Res. Des. 1994, 72, 420–430. [Google Scholar]

- Huang, L.; Kumar, K.; Mujumdar, A. Use of computational fluid dynamics to evaluate alternative spray dryer chamber configurations. Dry. Technol. 2003, 21, 385–412. [Google Scholar] [CrossRef]

- Keshani, S.; Montazeri, M.H.; Daud, W.R.W.; Nourouzi, M.M. CFD modeling of air flow on wall deposition in different spray dryer geometries. Dry. Technol. 2015, 33, 784–795. [Google Scholar] [CrossRef]

- Rhew, R.D.; Parker, P.A. A parametric geometry computational fluid dynamics (CFD) study utilizing design of experiments (DOE). Am. Insitute Aeronaut. Astronaut. (AIAA) 2007, 1615, 2007. [Google Scholar]

- Fletcher, D.; Guo, B.; Harvie, D.; Langrish, T.; Nijdam, J.; Williams, J. What is important in the simulation of spray dryer performance and how do current CFD models perform? Appl. Math. Model. 2006, 30, 1281–1292. [Google Scholar] [CrossRef]

- Woo, M.W.; Huang, L.X.; Mujumdar, A.S.; Daud, W.R.W. CFD Simulation of Spray Dryers; Volume 1; National University of Singapore: Singapore, 2010; Chapter 1; pp. 1–36. Available online: https://www.yumpu.com/en/document/view/32880341/spray-drying-technologypdf-national-university-of-singapore (accessed on 19 October 2025).

- Sommerfeld, M. Modelling requirements for CFD calculations of spray dryers. In Proceedings of the Jornada em Escoamentos Multifásicos 2015, Campinas, Brazil, 23–27 March 2015. [Google Scholar]

- Yoon, S.S. Lagrangian-based stochastic dilute spray modelling for drying applications. In Spray Drying Technology, Volume 1; Woo, M.W., Mujumdar, A.S., Daud, W.R.W., Eds.; World Scientific Publishing: Singapore, 2010; pp. 77–112. ISBN 978-981-08-6270-1. [Google Scholar]

- Woo, M.W.; Daud, W.R.W.; Mujumdar, A.S.; Talib, M.Z.M.; Hua, W.Z.; Tasirin, S.M. Comparative study of droplet drying models for CFD modelling. Chem. Eng. Res. Des. 2008, 86, 1038–1048. [Google Scholar] [CrossRef]

- Apte, S.V.; Mahesh, K.; Moin, P.; Oefelein, J.C. Large-eddy simulation of swirling particle-laden flows in a coaxial-jet combustor. Int. J. Multiph. Flow 2003, 29, 1311–1331. [Google Scholar] [CrossRef]

- Woo, M.W. Computational Fluid Dynamics Simulation of Spray Dryers: An Engineer’s Guide; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Ebrahim Zadeh, S. Extensive Study of the Interaction of a Hot Air Plume with a Water Spray by Means of CFD Simulations. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2016. [Google Scholar]

- Iannantuoni, L.; Ettorre, D.; Manzini, G.; Araneo, L. Validation and assessment of a water mist multi-hole nozzle model for fire simulations. Fire Technol. 2014, 50, 505–524. [Google Scholar] [CrossRef]

- Chen, X.; Xie, G. Fingerprints of the drying behaviour of particulate or thin layer food materials established using a reaction engineering model. Food Bioprod. Process. 1997, 75, 213–222. [Google Scholar] [CrossRef]

- Cubillos Varela, A. Modelación del Proceso de Deshidratación por Espray de Jugo de Guayaba. Ph.D. Thesis, Universidad Nacional de Colombia (UNAL), Bogota, Colombia, 2017. [Google Scholar]

- Huang, L.; Kumar, K.; Mujumdar, A. A comparative study of a spray dryer with rotary disc atomizer and pressure nozzle using computational fluid dynamic simulations. Chem. Eng. Process. Process Intensif. 2006, 45, 461–470. [Google Scholar] [CrossRef]

- Woo, M.; Daud, W.; Mujumdar, A.; Wu, Z.; Meor Talib, M.; Tasirin, S. CFD evaluation of droplet drying models in a spray dryer fitted with a rotary atomizer. Dry. Technol. 2008, 26, 1180–1198. [Google Scholar] [CrossRef]

- Gutiérrez Suárez, J.A.; Galeano-Urueña, C.H.; Gómez-Mejía, A. Low-Cost Eddy-Resolving Simulation in the Near-Field of an Annular Swirling Jet for Spray Drying Applications. ChemEngineering 2021, 5, 80. [Google Scholar] [CrossRef]

- Gutiérrez Suárez, J.A.; Galeano-Urueña, C.H.; Gómez-Mejía, A. Adaptive Mesh Refinement Strategies for Cost-Effective Eddy-Resolving Transient Simulations of Spray Dryers. ChemEngineering 2023, 7, 100. [Google Scholar] [CrossRef]

- Coleman, D.E.; Montgomery, D.C. A systematic approach to planning for a designed industrial experiment. Technometrics 1993, 35, 1–12. [Google Scholar]

- Gutiérrez Suárez, J.A. Modelación CFD y Validación Experimental del Proceso de Evaporación de Agua en un Secador por Aspersión. Master’s Thesis, Universidad Nacional de Colombia, Bogota, Colombia, 2015. [Google Scholar]

- Sidlagatta, V.; Chilukuri, S.V.V.; Devana, B.R.; Dasi, S.D.; Rangaswamy, L. Effect of maltodextrin concentration and inlet air temperature on properties of spray dried powder from reverse osmosis concentrated sweet orange juice. Braz. Arch. Biol. Technol. 2020, 63, e20190538. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Troung, V. Effect of addition of maltodextrin on drying kinetics and stickiness of sugar and acid-rich foods during convective drying: Experiments and modelling. J. Food Eng. 2004, 62, 53–68. [Google Scholar] [CrossRef]

- Patel, K.C.; Chen, X.D.; Lin, S.X.; Adhikari, B. A composite reaction engineering approach to drying of aqueous droplets containing sucrose, maltodextrin (DE6) and their mixtures. AIChE J. 2009, 55, 217–231. [Google Scholar] [CrossRef]

- Gianfrancesco, A. Spray Drying Engineering: Particle Stickiness in Relation with Agglomeration. Ph.D. Thesis, AgroParisTech, Paris, France, 2009. [Google Scholar]

- Kieviet, F.; Kerkhof, P. Air flow, temperature and humidity patterns in a co-current spray dryer: Modelling and measurements. Dry. Technol. 1997, 15, 1763–1773. [Google Scholar] [CrossRef]

- Huang, L.; Kumar, K.; Mujumdar, A. Simulation of a spray dryer fitted with a rotary disk atomizer using a three-dimensional computional fluid dynamic model. Dry. Technol. 2004, 22, 1489–1515. [Google Scholar] [CrossRef]

- Benavides-Morán, A.; Cubillos, A.; Gómez, A. Spray drying experiments and CFD simulation of guava juice formulation. Dry. Technol. 2020, 39, 450–465. [Google Scholar] [CrossRef]

- Masters, K. Spray Drying Handbook; Longman Scientific & Technical: London, UK, 1991; ISBN 978-0-470-21743-6. [Google Scholar]

- Phisut, N. Spray drying technique of fruit juice powder: Some factors influencing the properties of product. Int. Food Res. J. 2012, 19, 1297–1306. [Google Scholar]

- Huang, L.; Mujumdar, A. The effect of rotary disk atomizer RPM on particle size distribution in a semi-industrial spray dryer. Dry. Technol. 2008, 26, 1319–1325. [Google Scholar] [CrossRef]

- Kieviet, F. Modelling Quality in Spray Drying. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 1997. [Google Scholar]

- Schmitz-Schug, I.; Foerst, P.; Kulozik, U. Impact of the spray drying conditions and residence time distribution on lysine loss in spray dried infant formula. Dairy Sci. Technol. 2013, 93, 443–462. [Google Scholar] [CrossRef]

- Li, H.; Kuschel, M.; Sommerfeld, M. Experimental investigation and modeling of coalescence and agglomeration for spray drying of solutions. In Process-Spray: Functional Particles Produced in Spray Processes; Springer: Berlin/Heidelberg, Germany, 2016; pp. 205–233. [Google Scholar]

- Eijkelboom, N.M.; van Boven, A.P.; Siemons, I.; Wilms, P.F.; Boom, R.M.; Kohlus, R.; Schutyser, M.A. Particle structure development during spray drying from a single droplet to pilot-scale perspective. J. Food Eng. 2022, 337, 111222. [Google Scholar] [CrossRef]

- Anandharamakrishnan, C.; Ishwarya, P. Spray Drying Techniques for Food Ingredient Encapsulation; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Keshani, S.; Daud, W.R.W.; Nourouzi, M.; Namvar, F.; Ghasemi, M. Spray drying: An overview on wall deposition, process and modeling. J. Food Eng. 2015, 146, 152–162. [Google Scholar] [CrossRef]

- Gianfrancesco, A.; Turchiuli, C.; Flick, D.; Dumoulin, E. CFD modeling and simulation of maltodextrin solutions spray drying to control stickiness. Food Bioprocess Technol. 2010, 3, 946–955. [Google Scholar] [CrossRef]

- Huang, L.; Kumar, K.; Mujumdar, A. A parametric study of the gas flow patterns and drying performance of co-current spray dryer: Results of a computational fluid dynamics study. Dry. Technol. 2003, 21, 957–978. [Google Scholar] [CrossRef]

- Gianfrancesco, A.; Turchiuli, C.; Dumoulin, E. Powder agglomeration during the spray-drying process: Measurements of air properties. Dairy Sci. Technol. 2008, 88, 53–64. [Google Scholar] [CrossRef]

- Sánchez-Rocha, M.; Menon, S. The compressible hybrid RANS/LES formulation using an additive operator. J. Comput. Phys. 2009, 228, 2037–2062. [Google Scholar] [CrossRef]

- Germano, M. On the Hybrid RANS-LES of Compressible Flows. In Progress in Hybrid RANS-LES Modelling; Springer: Berlin/Heidelberg, Germany, 2015; pp. 253–263. [Google Scholar]

- Chase, M.W. NIST-JANAF Thermochemical Tables 4th ed. J. Phys. Chem. Reffernce Data 1998, 1529–1564. [Google Scholar]

- Jubaer, H.; Afshar, S.; Xiao, J.; Chen, X.D.; Selomulya, C.; Woo, M.W. On the importance of droplet shrinkage in CFD-modeling of spray drying. Dry. Technol. 2018, 36, 1785–1801. [Google Scholar] [CrossRef]

- Schiller, L. A drag coefficient correlation. Zeit. Ver. Deutsch. Ing. 1933, 77, 318–320. [Google Scholar]

- Chen, X.D.; Lin, S.X.Q. Air drying of milk droplet under constant and time-dependent conditions. AIChE J. 2005, 51, 1790–1799. [Google Scholar] [CrossRef]

- Lin, S.X.Q.; Chen, X.D. A model for drying of an aqueous lactose droplet using the reaction engineering approach. Dry. Technol. 2006, 24, 1329–1334. [Google Scholar] [CrossRef]

- Travin, A.; Shur, M.; Strelets, M.; Spalart, P. Physical and numerical upgrades in the detached-eddy simulation of complex turbulent flows. In Advances in LES of Complex Flows; Springer: Berlin/Heidelberg, Germany, 2002; pp. 239–254. [Google Scholar] [CrossRef]

- Moukalled, F.; Mangani, L.; Darwish, M. Temporal Discretization: The Transient Term. In The Finite Volume Method in Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 489–533. [Google Scholar] [CrossRef]

- Mozaffari, S.; Visonneau, M.; Wackers, J. Average-based Adaptive Grid Refinement in Hybrid LES. Direct Large Eddy Simul. XII 2020, 27, 449. [Google Scholar]

- Yoon, S.; Hewson, J.; DesJardin, P.; Glaze, D.; Black, A.; Skaggs, R. Numerical modeling and experimental measurements of a high speed solid-cone water spray for use in fire suppression applications. Int. J. Multiph. Flow 2004, 30, 1369–1388. [Google Scholar] [CrossRef]

- Westergaard, V. Milk Powder Technology: Evaporation and Spray Drying; Niro A/S: Copenhagen, Denmark, 2004; ISBN 87-981972-1-3. [Google Scholar]

- Lebarbier, C.; Kockel, T.; Fletcher, D.; Langrish, T. Experimental measurement and numerical simulation of the effect of swirl on flow stability in spray dryers. Chem. Eng. Res. Des. 2001, 79, 260–268. [Google Scholar] [CrossRef]

- Langrish, T.; Williams, J.; Fletcher, D. Simulation of the effects of inlet swirl on gas flow patterns in a pilot-scale spray dryer. Chem. Eng. Res. Des. 2004, 82, 821–833. [Google Scholar] [CrossRef]

| Parameter | Description | Middle Value | Max | Min |

|---|---|---|---|---|

| P1* | 1.68 | 2.5 | 1.2 | |

| P2* | 1.60 | 2.0 | 0.5 | |

| P3* | 0.5 | 1.0 | 0.0 | |

| P4* | 0.25 | 0.5 | 0.05 | |

| P5* () | 2.22 | 3.95 | 1.44 | |

| (s) | 15.30 | 23.54 | 8.60 |

| Reference | ARL (kg/kg) | (°C) | (m/s) | n | (µm) | Feed Product |

|---|---|---|---|---|---|---|

| Kieviet and Kerkhof [31] | 36.09 | 195 | 49 | 2.45 | 68.6 | H2O |

| 52.71–65.32 | 154–209 | 59 | 2.09 | 70.5 | MD | |

| Huang et al. [32] | 27.14 | 170 | 62 | 2.05 | 70.5 | MD + SC |

| 13.57 | 170 | 62 | 2.05 | 70.5 | H2O | |

| Huang et al. [21] | 42.04 | 195 | 105 | 2.05 | 70.5 | MD |

| Woo et al. [22] | 108.41 | 120–150 | 89.2 | 1.73 | 47 | MD + SC |

| Gutiérrez Suárez [26] | 39.71–67.91 | 140–200 | 68.07 | 2.05 | 59 | H2O |

| Benavides-Morán et al. [33] | 78.08 | 170 | 68.07 * | 1.9 | 64 | GJ + MD |

| Present study | 85 | 170 | 70.5 | 2.05 | 61.3 | MD |

| Response Variables | ||||

|---|---|---|---|---|

| Main Associate Response | Name | Description | Response Form | Location |

| Global responses (R-0) | R-0.1 | Air temperature () | (°C) | Outlet |

| R-0.2 | Air humidity () | (kg/kg) | ||

| Particle residence times—PRT (R-1) | R-1.1 | Bulk-based | , (s) | Outlet and walls |

| R-1.2 | Particle-based | (s) | ||

| R-1.3 | Bulk-based per particle size | (s) | ||

| Particle moisture (wet-basis) (R-2) | R-2.1 | —bulk-based | , (kg/kg) | Outlet and walls |

| R-2.2 | —particle-based | (kg/kg) | ||

| R-2.3 | —bulk-based per particle size | (kg/kg) | ||

| Particle temperature (R-3) | R-3.1 | - bulk-based | , (°C) | Walls |

| Particle—wall impacts (R-4) | R-4.1.1 | Impact ratio (mass based) | Impacted mass (kg)/atomized mass (kg) | Walls |

| R-4.1.2 | Impact ratio (particle based) | Impacted particles/atomized particles () | ||

| R-4.2 | Mean impact position (mass and particle based) | Mean position and std. dev. | ||

| R-4.3 | Impact location (mass and particle based) | Impacts in cylindrical section/conical section (() and kg/kg) | ||

| Experiment | P1* | P2* | P3* | P4* | P5* () |

|---|---|---|---|---|---|

| 1 | 1.2 | 0.5 | 0 | 0.05 | 3.95 |

| 2 | 2.5 | 0.5 | 0 | 0.05 | 1.44 |

| 3 | 1.2 | 2 | 0 | 0.05 | 1.44 |

| 4 | 2.5 | 2 | 0 | 0.05 | 3.95 |

| 5 | 1.2 | 0.5 | 1 | 0.05 | 1.44 |

| 6 | 2.5 | 0.5 | 1 | 0.05 | 3.95 |

| 7 | 1.2 | 2 | 1 | 0.05 | 3.95 |

| 8 | 2.5 | 2 | 1 | 0.05 | 1.44 |

| 9 | 1.2 | 0.5 | 0 | 0.5 | 1.44 |

| 10 | 2.5 | 0.5 | 0 | 0.5 | 3.95 |

| 11 | 1.2 | 2 | 0 | 0.5 | 3.95 |

| 12 | 2.5 | 2 | 0 | 0.5 | 1.44 |

| 13 | 1.2 | 0.5 | 1 | 0.5 | 3.95 |

| 14 | 2.5 | 0.5 | 1 | 0.5 | 1.44 |

| 15 | 1.2 | 2 | 1 | 0.5 | 1.44 |

| 16 | 2.5 | 2 | 1 | 0.5 | 3.95 |

| 17 | 1.85 | 1.25 | 0.5 | 0.275 | 2.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suárez, J.A.G.; Urueña, C.H.G.; Mejía, A.G. Parametric CFD Study of Spray Drying Chamber Geometry: Part II—Effects on Particle Histories. ChemEngineering 2025, 9, 121. https://doi.org/10.3390/chemengineering9060121

Suárez JAG, Urueña CHG, Mejía AG. Parametric CFD Study of Spray Drying Chamber Geometry: Part II—Effects on Particle Histories. ChemEngineering. 2025; 9(6):121. https://doi.org/10.3390/chemengineering9060121

Chicago/Turabian StyleSuárez, Jairo Andrés Gutiérrez, Carlos Humberto Galeano Urueña, and Alexánder Gómez Mejía. 2025. "Parametric CFD Study of Spray Drying Chamber Geometry: Part II—Effects on Particle Histories" ChemEngineering 9, no. 6: 121. https://doi.org/10.3390/chemengineering9060121

APA StyleSuárez, J. A. G., Urueña, C. H. G., & Mejía, A. G. (2025). Parametric CFD Study of Spray Drying Chamber Geometry: Part II—Effects on Particle Histories. ChemEngineering, 9(6), 121. https://doi.org/10.3390/chemengineering9060121