Abstract

Ultrafiltration is a well-known operation, widely used in food processing, especially to concentrate selectively liquid compounds. However, so far, it has been mainly used to change concentration and/or clarify liquids with low viscosity. Ultrafiltration has seldomly been applied to viscous fluids. In this study, it was used to increase the consistency of fruit pulps, without changing their taste and organoleptic properties. This paper reports the findings achieved in experimental runs carried out on a pilot plant, equipped with four ultrafiltration tubular membranes (total surface area = 0.8 m2). Raw fruit pulps, namely, apple, apricot, and pear, were used to study the influence of the operative parameters on the permeate flux and organoleptic properties of the final products (retentate and permeate). The flow rate was in the range of 3.0–5.1 m3/h, at 50 °C. The influence of temperature on the permeate flux was checked, with one run with apple pulp at 20 °C. As expected, the findings show that high flow rate and temperature improve the permeate flux. Membranes show different performance in permeate flux for the tested pulps. This is probably due to their different chemical and physical composition, which could be responsible for different fouling of the membrane and, as a consequence, a different resistance to the permeate flow. The final products have the same taste as the raw ones, and each of them can be used as it is or as an ingredient. These results have a technological relevance, and, besides, the study shows a methodology for future applications of ultrafiltration.

1. Introduction

In recent years, the food industry has adopted innovations to achieve products with particular organoleptic characteristics. This has been feasible thanks to technology and techniques with good performance to process raw materials.

In this frame, ultrafiltration is not new. In the literature, several studies can be found, especially on the clarification and/or purification of liquids with low viscosity [1,2,3,4,5]. However, its application to fruit pulps and viscous fluids is more recent and not so widely adopted yet [6,7,8,9]. It can be used to increase pulp consistency, which allows for the storage and transport of smaller quantities than raw fruits and final products with constant properties, notwithstanding the different ages and/or varieties of fruit. The second aim is linked to the well-known effect of storage on consistency reduction [10,11,12,13].

Therefore, ultrafiltration must allow an increase in the consistency of the pulp, but at the same time, the final product (concentrate) must have organoleptic characteristics similar to the starting product. In this way, the use of concentrate will not cause taste differences.

As is well known, ultrafiltration constitutes a valid alternative to evaporation, avoiding the main drawbacks of evaporation itself, namely, loss of color and aroma caused by the temperatures used during the process. In evaporation, the temperature is always higher than 60–65 °C; moreover, it must consider the elevation of the boiling point, which increases proportionally with the increase of the fluid concentration. In contrast, ultrafiltration is usually carried out at room temperature or slightly above room temperature.

Ultrafiltration is not exempt from drawbacks, the first of which is the cost of membrane substitution when the plant performance decreases. This occurs to a large extent when the membranes are not used in a continuous mode, and as a result, the fouling caused by the compounds accumulates on the membrane surface. Especially when ultrafiltered fluid is organic, the fouling can become irreversible, and no cleaning action is able to effectively remove it completely, as previously shown by several authors [14,15,16,17,18].

The parameter describing the performance of a membrane for a given fluid is the permeate flux. Its knowledge is compulsory to design a productive plant correctly and, specifically, the total area of the filtering surface. Permeate flux is strongly influenced by fluid properties, flow rate, and operative temperature.

Likewise, the membrane Molecular Weight Cut Off influences the characteristics of the final products, namely, retentate and permeate. When food products are treated, the composition of the final products influences their organoleptic properties and, therefore, their future use.

In the current study, a series of experimental runs were carried out on a pilot plant operated with raw apple, apricot, and pear pulp. The tested fruits were selected since they are widely farmed and consumed in Italy. They are typically used for non-filtered fruit juices and baby food.

The aims were to enhance the knowledge of the operation to optimize the operative parameters and assess the plant’s performance in terms of efficiency and product quality (organoleptic properties). Moreover, this study also has a methodological aim—a study protocol that can be applied to other pulps.

2. Materials and Methods

For this study, the tested pulps were apple, apricot, and pear. For the apricot, two pulps were tested, coming from apricots of different varieties since this entails a different total acidity. Total acidity is usually constant for the other fruits, whichever variety, whereas for apricot, its value can reach about 2% by weight, expressed as % citric acid monohydrated.

The main characteristics of the tested pulps are given in Table 1.

Table 1.

Main properties of the tested pulps.

2.1. Experimental Set-Up

The experimental runs were carried out in a pilot plant, equipped with a helicoidal screw, suitable for viscous fluids and containing suspended particles. The maximum flow rate was equal to 5.5 m3/h. The pulp was contained in a tank having a thermal control system. A flow rate counter was used to check the pulp flow rate, and two pressure transducers measured the pressure at the inlet and outlet of the membrane section to assess the pressure losses. The permeate flow rate was measured to calculate the permeate flux by dividing it by the filtering surface unit.

The ultrafiltration section was composed of four in-series tubular membranes of polyvinylidene fluoride (PVDF) with a total effective filtering surface of 0.8 m2. Each membrane had an inner diameter equal to 0.0254 m and a length equal to 3 m. Its maximum allowed pressure and temperature were 6 bar and 55 °C, respectively.

The membrane Molecular Weight Cut Off (MWCO), which represents the molar mass of a globular protein that is 90% retained by the membrane itself, was 200 kDalton (a value close to microfiltration). This value entails membrane pores with an average diameter of 50–60 nm.

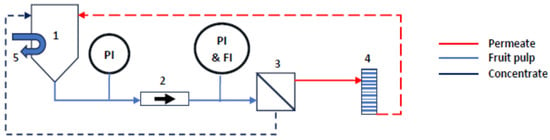

Figure 1 shows a simplified scheme of the experimental plant.

Figure 1.

Ultrafiltration pilot plant: 1—feed tank; 2—helicoidal screw pump; 3—ultrafiltration section (4 modules in series); 4—tank for the permeate collection; 5—thermal control system; PI—pressure indicator; FI—flow rate indicator. Dashed lines show the recirculation flows.

2.2. Experimental Runs

The runs were carried out in batch mode, recirculating permeate and concentrate to save pulp, with flow rates in the range of 3.0–5.1 m3/h, corresponding to cross-flow velocity v = 1.6–2.8 m/s. For each run, the transmembrane pressure was calculated from the values of pressure losses, too. The average values are reported in Table 2.

Table 2.

Average values of the transmembrane pressure achieved in the experimental runs.

Each run lasted one hour and used about 100 kg of commercial pulp. At the end of the run, this amount constituted liquid waste. For this reason, considering the cost and environmental issues, the runs were not repeated.

The test temperature was equal to 50 °C. To assess the influence of temperature, one run with apple pulp was carried out at 20 °C, too.

After each run, the plant was carefully cleaned to avoid fouling of the membranes and deposits in the pipelines that would have caused trouble for the following run.

The cleaning operation had three steps, namely:

- Rinsing with tap water for 30 min, to remove the pulp residues still present inside the set-up.

- Cleaning with NaOH solution (pH = 11) and NaClO (200 mg/L active chlorine) at 50 °C for one hour.

- Rinsing with water at 50 °C for one hour.

In each step, the flow rate of the cleaning agent was the highest allowed by the pump.

Moreover, the reduction of membrane performance over time was studied by carrying out cycles of 5 one-hour runs and washing the membranes with water before each run. These cycles were done only with apricot and pear pulp, at 50 °C, at low and high flow rates.

2.3. Analysis of Pulp and Permeate

Pulp was analyzed to get its main parameters, namely, consistency as Bostwick degree at 15 s (Bo), total acidity (TA) as citric acid monohydrated, and sugar content as Brix degree. Permeate was analyzed by total acidity and sugar content.

Each of these parameters was analyzed in triplicate.

2.3.1. Consistency as Bostwick Degree (Bo)

It was measured by a Bostwick consistometer, particularly suitable for fruit pulps, purees of vegetables, and baby foods [19]. It consists of a short channel with a rectangular section and standardized size. On one side, there is a small basin, separated from the other part of the channel by a gate. The sample at 20 °C is placed into the basin, and when the gate is opened, the fluid starts to flow. The distance in cm covered in 15 s gives the Bostwick degree, and the lower its value, the higher the consistency.

2.3.2. Total Acidity (TA)

The total acidity (also called titratable acidity) is usually expressed as % citric acid monohydrated. It was measured by titration with a solution of 0.1 M NaOH, as per AOAC Official Method 942.15 [20].

2.3.3. Sugar Content as Brix Degree

For this analysis, the refractometric method was used, as per AOAC Official Method 932.12 [20]. A drop of pulp is placed on the refractometer, which gives directly the result expressed in terms of the percentage of sucrose. The amount of 1 Brix degree corresponds to 1% by weight of sucrose.

3. Results and Discussion

3.1. Permeate Flux

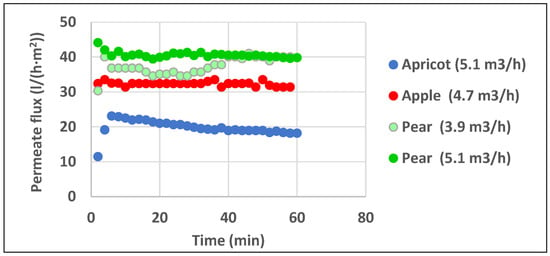

Figure 2 reports the results achieved with the tested fruit pulps.

Figure 2.

Permeate flux for the tested fruit pulps.

Some comments can be made:

- The kind of fruit strongly influences the permeate flux: pear pulp shows values of the permeate flux 60–100% higher than the values achieved with apricot pulp, even when the flow rate is just 3.9 m3/h, to say, lower than the value used for apricot pulp (5.1 m3/h). In terms of tangential velocity, these flow rates correspond to 2.1 m/s and 2.8 m/s, respectively. The data demonstrate that the kind of fruit influences the permeate flux more than the pulp flow rate, which is responsible for the tangential velocity. Satyannarayan and Kumar [17] found a similar influence by flow rate and kind of fruit. They processed lime and pineapple juice and evidenced that the permeate flux was different for the juices at the same flow rate. Moreover, they showed the need to reduce the pectin content to increase the permeate flux, demonstrating that different juice compositions influence the filtration performance, especially when colloids or macromolecules are present.

- For apple and apricot pulps, the results show a gap, too, with the permeate flux for pear pulp 10–30% higher than the flux achieved with apple pulp. The permeate flux for apple pulp shows a constant trend during the ultrafiltration time. These data are in line with the findings achieved by He et al. [21] with apple juice ultrafiltered at a tangential velocity equal to 2.5 m/s and MWCO equal to 50 kDa. These authors showed that raw apple juice did not evidence any permeate flux decline in the first minutes of ultrafiltration compared to the results obtained with pasteurized and pasteurized+hydrolyzed apple juices. The hypothesis was a very fast adsorption of colloids on the membrane that occurred when the apple juice was raw, and it was not appreciable by monitoring the permeate flux. A similar hypothesis was made by Bruijn and Borquez [22].

- The high values for pear pulp could be attributed to the cleaning action done on the membrane by the sclereids, the so-called “stone cells”. In membrane processes, the performance is heavily influenced by the material deposited on the membrane surface. For fruit pulps, this drawback is caused by fibers and pectins, more and more accumulated on the membrane and partially linked to it in a tight way, constituting one additional barrier to the membrane crossing to permeation (fouling). In this situation, the cleaning action is fundamental to keeping the membrane performance as constant as possible, notwithstanding the natural decrease in separation efficiency.

- The trend of the permeate flux of apricot pulp slowly decreases with time, whereas this does not occur for the other two pulps. One hypothesis is the fouling due to the deposition of pulp compounds on the membrane itself. At a local level on the membrane, jellying and/or strong bonds could occur, especially when the total acidity is high, like for apricot pulp.

For the same fruit pulp, permeate flux is also influenced by the variety, especially if the variety entails differences in the main chemical properties.

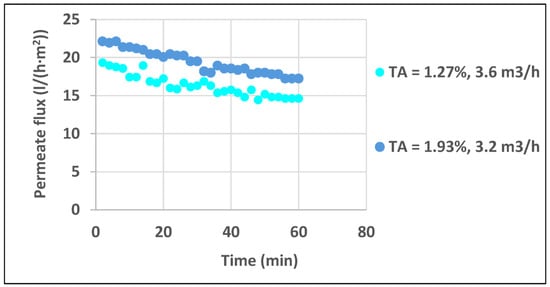

Among the tested fruits, apricot constitutes an example. Apricot varieties can have different values of total acidity, always higher than the values of the other tested fruits. Therefore, two apricot pulps with different total acidities were tested at similar flow rates. Total acidity was equal, respectively, to 1.27 and 1.93% by weight of citric acid monohydrated.

Figure 3 reports the achieved results.

Figure 3.

Permeate flux for apricot pulps with different total acidities.

The data show a stratified trend with the permeate flux decreasing with time, as confirmed by the data in Figure 2. This can be caused by the interactions between the membrane and the residues accumulated on it during filtration. The amount of these residues grows with time and has chemical properties depending on the kind of pulp. The resistance to the flux generated by this accumulation can be rather high to decrease the permeate flux. In Figure 3, the comparison between the runs shows a difference of 10–30% on the permeate flux, to the advantage of the highest total acidity (1.93% of citric acid monohydrated). In other words, the effect of acidity seems more influential than the flow rate (the apricot pulp with the lowest acidity is filtered at a bit higher flow rate, corresponding to a velocity equal to 2.0 m/s). One hypothesis is the effect of pH on the solubility of the residues accumulated on the membrane, for example, pectins form jelly when sugar content and pH (total acidity) have given values. For apricot pulp, the permeate flux slowly decreases during the run, and this has been evidenced also by other authors [23,24,25], who ascribed the trend to the deposit of macromolecules on the membrane, reducing the number of pores available for filtration.

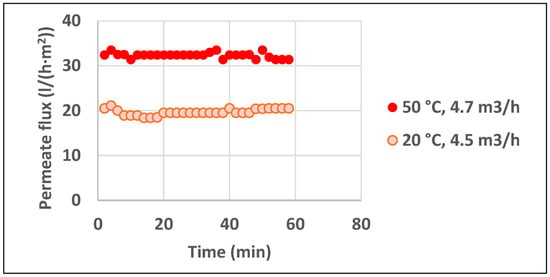

Operative temperature is another parameter that influences the permeate flux. To check this, two runs with apple pulp were done, respectively, at 50 and 20 °C, in the condition of similar flow rates (4.7 and 4.5 m3/h correspond to a tangential velocity equal to 2.6 and 2.5 m/s, respectively).

Figure 4 reports the results.

Figure 4.

Influence of temperature on permeate flux for apple pulp.

The plot shows that the highest operative temperature increases the permeate flux due to the decrease in viscosity. At the highest temperature, the permeate flux is 50–75% higher than the values at 20 °C. In their study on ultrafiltration of apple juice with a tangential velocity equal to 2.5 m/s, He et al. [21] tested the effect of temperature, too. The tested fluid was apple juice instead of apple pulp (this study). However, checking the ratio of permeate flux at 50 °C to the one at 20 °C, the result is rather similar to the value achieved in this study, to say, an average value equal to 1.6. This confirms the influence of the tangential velocity as one of the controlling parameters.

This finding suggests working at a temperature higher than room temperature. However, it must be considered that the value of 50 °C is almost a limit, both for preserving the organoleptic properties and avoiding thermal damage to the membranes.

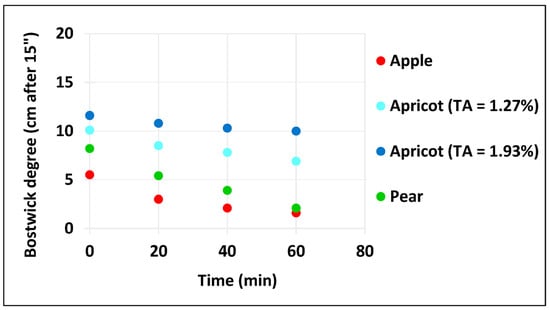

3.2. Consistency

Ultrafiltration can be used to increase the consistency of fruit pulp. Consistency reflects the viscosity, but it is measured with empirical systems specific for the kind of fluid, notwithstanding that they entail difficulties when experimental data must be compared or modeled to find a link with viscosity.

For viscous fluids, such as fruit pulps, consistency is measured in Bostwick degrees, as explained in Section 2. Materials and Methods.

Figure 5 shows the results achieved during ultrafiltration runs with the tested fruit pulps. The growth of viscosity is evidenced by the shorter path covered by a pulp sample in 15 s when ultrafiltration proceeds.

Figure 5.

Change of the pulp consistency versus ultrafiltration time.

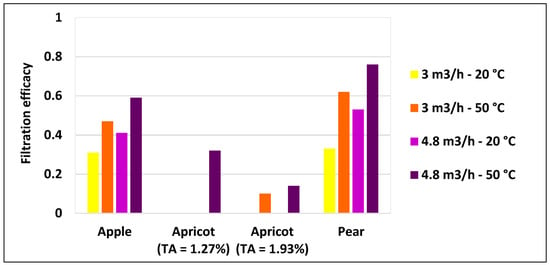

These experimental data can be modelled with mathematical functions. However, from an applicative point of view, it is more useful to define an expression able to describe the filtration efficacy to increase consistency, such as:

Bo(t = 0) − Bo(t = 60))/Bo(t = 0) = 1 − Bo(t = 60)/Bo(t = 0)

In this relationship, Bo(t = 0) and Bo(t = 60) are the consistency of the fruit pulp expressed in Bostwick degree at t = 0 (starting point of the run, to say raw fruit pulp) and t = 60 min (ending point of the run, to say concentrated fruit pulp), respectively. This relationship expresses the growth of the consistency achievable after 1 h of ultrafiltration, and it can be useful at the industrial level to roughly assess the use of the treatment to reach a given value of consistency.

Figure 6 shows the values of the filtration efficacy achieved with the tested pulps, showing the influence of temperature (20 and 50 °C) and flow rate (3 and 4.8 m3/h).

Figure 6.

Filtration efficacy to increase the consistency of the tested pulps.

It is well evident that:

- Pear pulp gives the best results, whereas apricot pulp shows the lowest efficacy, whichever parameter is considered for the comparison.

- The flow rate influences the filtration efficacy, but not to a large extent, except for pear pulp.

- The temperature always plays a relevant role for all the pulps, being responsible for a decrease in fluid viscosity. Its influence is higher than the flow rate.

- For apricot pulp, the consistency increase is limited compared to the values shown by the other pulps. The limitation is more evident with the highest total acidity. As aforesaid, this could be caused by the jellying of pectins on the membrane. Pectins can form when the concentration of sugars and acids has particular values. If this happens locally on the membrane, the permeation occurs with enormous difficulties due to the additional resistance generated by them.

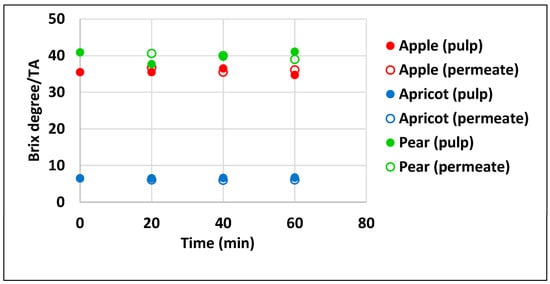

3.3. Taste

Ultrafiltration of fruit pulps must give final products that are acceptable for their organoleptic properties, mainly taste. Taste depends on the composition, and for fruits, the ratio of sugar content to acid content, as the ratio of Brix degree to Total acidity, gives the palatability. This ratio reflects the fruit’s maturity, and its value depends on the fruit kind. Usually, the ratio of fresh fruits for direct consumption is a bit lower than for the same fruits addressed to the juice/pulp production. In general, each fruit has its own proper ratio, ranging in a narrow interval to get the palatability typical of that fruit, with low values for sour fruits and high ones for sweet ones [26,27,28,29].

Thus, if ultrafiltration does not change this ratio for both flows (retentate and permeate), the operation can be considered successful in increasing consistency. This occurs if the proper MWCO is chosen, as in this study (MWCO = 200 kDalton).

Figure 7 shows the ratio of Brix degree to total acidity for the tested pulps in runs at a high flow rate (4.8 m3/h).

Figure 7.

Ratio Brix degree/Total acidity for the tested pulps and their permeates (flow rate = 4.8 m3/h).

It is evident that for each pulp, the ratio remains almost constant during the process, and this holds for retentate (pulp) as well as for permeate. This confirms that ultrafiltration just increases consistency, leaving the taste of the achieved flows unchanged. This finding allows the future use of both final flows, either directly as they are or as ingredients.

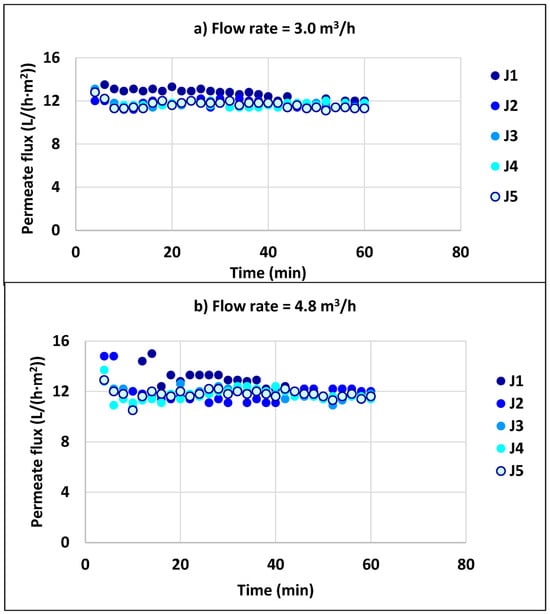

3.4. Influence of Working Time on Membrane Performance

Membrane fouling is a well-known drawback of all membrane processes. As seen in the previous subsections, ultrafiltration performance changes with the kind of fruit pulp but also during the same run due to the deposition of pulp compounds on the filtering surface and their interaction with the membrane materials. This means that many variables must be considered to have a better understanding and control of membrane performance.

Membranes were also tested to check their performance when cleaning between two runs was done with water alone. Each test was one element of a cycle composed of 5 one-hour runs. As stated in the Materials and Methods, the study was done only for apricot and pear pulp at a low and high flow rate at 50 °C. The reason was that these pulps constituted extreme opportunities among the tested pulps.

3.4.1. Apricot

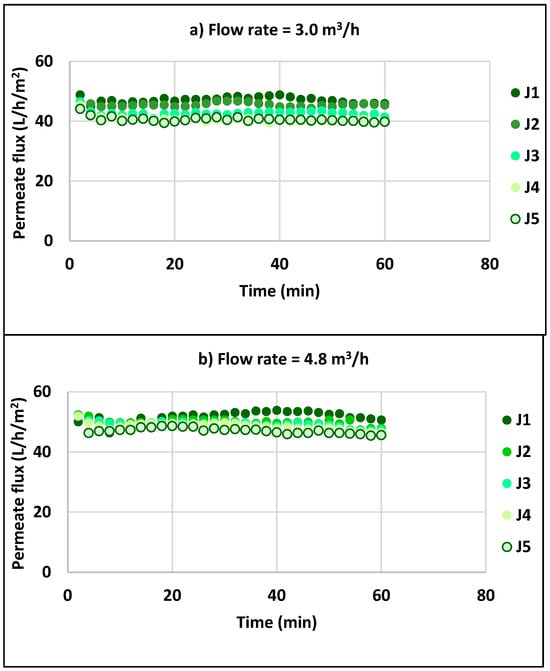

Figure 8 reports the monitoring of the permeate flux (Ji) achieved in cycle i (i = 1, … 5) with apricot pulps at low (3.0 m3/h) and high (4.8 m3/h) flow rates, respectively.

Figure 8.

Influence of working time on the permeate production for apricot pulp: (a) Flow rate = 3.0 m3/h; (b) Flow rate = 4.8 m3/h.

The runs show limited evidence of the influence of the flow rate. Besides, it seems that the run sequence does not affect the permeate flux. This holds for both flow rates, even if they give low values of permeate flux, as already seen in a previous section. In other terms, the permeate flux remains almost constant for a long time, even at low values.

It can also be noted that in both cycles, the first run has a decreasing trend, whereas the others show constancy during the test time.

3.4.2. Pear

The results for the permeate flux (Ji) achieved in cycle i (i = 1, … 5) for pear pulp are shown in Figure 9, with the same flow rates tested with apricot pulp, namely, 3 and 4.8 m3/h, respectively.

Figure 9.

Influence of working time on the permeate production for pear pulp: (a) flow rate = 3.0 m3/h; (b) flow rate = 4.8 m3/h.

As seen previously, unlike apricot pulp, the permeate flux is very high, with a net effect due to the flow rate. Moreover, at a low flow rate, the sequence of runs shows a stratified trend, with the first run having the highest permeate flux, and so on for the others. At a high pulp flow rate, this is less evident.

This could confirm the aforesaid hypothesis on the cleaning action done by the sclereids. However, the data in Figure 9 also shows that the action decreases over time. The reason could be the fouling of the membrane, caused by the high permeate flux. When it is relevant, the residues are removed by the sclereids with difficulty. Altogether, the action of the sclereids is useful only when the pulp ultrafiltration does not give a huge increase in consistency, otherwise, it becomes a drawback.

These findings show the need for a deep investigation of the mechanisms involved in fouling to find a systematic system to face it. Many researchers have studied the problem, but no general solution can be defined. However, a methodology was highlighted by Li et al. [30], who studied the fouling and cleaning of membranes used in the ultrafiltration of limed sugarcane juice. They suggested that the fouling must be analyzed in terms of deposited compounds and molecules to define the specific cleaning action. In other words, the solution is far too unique. Unfortunately, at an industrial scale, this is sustainable only if its costs are lower than the costs linked to membrane substitution and loss of permeability.

4. Conclusions

The results achieved in this study on apple, apricot, and pear pulp gave some evidence:

- For the tested pulps, the selection of MWCO equal to 200 kDalton was suitable to avoid changes to the composition of the final products compared to the raw ones.

- Permeate flux is always enhanced by high flow rates, due to the high cross-flow velocity. The operative limit is due to the growth of head losses and, therefore, the maximum pressure of the pumping system, which cannot be higher than the maximum value tolerated by the membranes (to avoid failures, a safety valve is placed on the discharge pipe). In this study, the best results were achieved with a cross-flow velocity in the order of 2.6 m/s.

- In addition, a temperature higher than the room temperature is beneficial due to the fluid viscosity decrease. However, this parameter must be chosen considering the organoleptic damage that it can cause to the pulp if its value grows too much and the maximum temperature acceptable for the membrane. A value around 50 °C is the maximum applicable value.

In addition to the findings, this study has methodological relevance. Other fruit pulps requiring higher consistency than the original could be processed similarly, paying attention to the operative parameters and the features gained in this study.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Ledur Alles, M.J.; Tessaro, I.C.; Zapata Norena, C.P. Concentration and Purification of Yacon (Smallanthus sonchifolius) Root Fructooligosaccharides Using Membrane Technology. Food Technol. Biotechnol. 2015, 53, 190–200. [Google Scholar] [CrossRef] [PubMed]

- Pereira, C.; Henriques, M.; Gomes, D.; Gomez-Zavaglia, A.; de Antoni, G. Novel Functional Whey-Based Drinks with Great Potential in the Dairy Industry. Food Technol. Biotechnol. 2015, 53, 307–314. [Google Scholar] [CrossRef] [PubMed]

- Rai, P.; De, S. Clarification of pectin-containing juice using ultrafiltration. Curr. Sci. 2009, 96, 1362–1371. [Google Scholar]

- Singh, V.; Das, C. Clarification of Citrus fruit (Mosambi) juice by hybrid (Pretreatment and Membrane) process. Mater. Today Proc. 2021, 47, 1384–1388. [Google Scholar] [CrossRef]

- Echavarría, A.P.; Falguera, V.; Torras, C.; Berdún, C.; Pagán, J.; Ibarz, A. Ultrafiltration and reverse osmosis for clarification and concentration of fruit juices at pilot plant scale. LWT Food Sci. Technol. 2012, 46, 189–195. [Google Scholar] [CrossRef]

- Paes, J.; da Cunha, C.R.; Viotto, L.A. Concentration of lycopene in the pulp of papaya (Carica papaya L.) by ultrafiltration on a pilot scale. Food Bioprod. Process. 2015, 96, 296–305. [Google Scholar] [CrossRef]

- Jin, L.; Zuo, F.; Gao, Y.; Sui, S.; Zhang, D. Purification of pectin by ultrafiltration in combination with sodium citrate. J. Food Eng. 2022, 335, 111158. [Google Scholar] [CrossRef]

- Fernández-Delgado, M.; del Amo-Mateos, E.; Coca, M.; López-Linares, J.C.; García-Cubero, M.T.; Lucas, S. Enhancement of industrial pectin production from sugar beet pulp by the integration of surfactants in ultrasound-assisted extraction followed by diafiltration/ultrafiltration. Ind. Crops Prod. 2023, 194, 116304. [Google Scholar] [CrossRef]

- Ai, C.; Meng, H.; Lin, J.; Zhang, T.; Guo, X. Combined membrane filtration and alcohol-precipitation of alkaline soluble polysaccharides from sugar beet pulp: Comparision of compositional, macromolecular, and emulsifying properties. Food Hydrocoll. 2020, 109, 106049. [Google Scholar] [CrossRef]

- Falguera, V.; Gatius, F.; Pascual, M.; Villar, J.M.; Cubero, M.Á.; Ibarz, A.; Rufat, J. Influence of fresh and processed fruit quality attributes on peach purée consistency index. LWT Food Sci. Technol. 2012, 45, 123–131. [Google Scholar] [CrossRef]

- Wani, S.; Bakshi, R.A.; Khan, Z.S.; Fayaz, S.; Muzaffar, K.; Dar, B.N. Physiochemical, sensorial and rheological characteristics of puree developed from Kashmiri peaches: Influence of sugar, KMS and storage conditions. Heliyon 2021, 7, e07781. [Google Scholar] [CrossRef] [PubMed]

- Balestra, F.; Cocci, E.; Marsilio, G.; Dalla Rosa, M. Physico-chemical and rheological changes of fruit purees during storage. Procedia Food Sci. 2011, 1, 576–582. [Google Scholar] [CrossRef]

- Chen, Z.; He, M.; Zhou, Y.; Chen, X.; Zhu, H.; Yang, B.; Jiang, Y.; Qu, H. Degradation of water-soluble polysaccharides in pulp of litchi during storage. Food Chem. 2023, 402, 134289. [Google Scholar] [CrossRef] [PubMed]

- Cai, M.; Lv, Y.; Luo, S.; Liu, Y.; Sun, P. Fouling behavior of polyphenols during model juice ultrafiltration: Effect of membrane properties. Food Bioprocess Technol. 2018, 11, 1787–1793. [Google Scholar] [CrossRef]

- Tarapata, J.; Dybowska, B.E.; Zulewska, J. Evaluation of fouling during ultrafiltration process of acid and sweet whey. J. Food Eng. 2022, 328, 111059. [Google Scholar] [CrossRef]

- Villeneuve, W.; B’erub’e, A.; Chamberland, J.; Pouliot, Y.; Labrie, S.; Doyen, A. Contribution of biofouling to permeation flux decline and membrane resistance changes during whey ultrafiltration. Int. Dairy J. 2021, 117, 105010. [Google Scholar] [CrossRef]

- Satyannarayana, K.V.V.; Kumar, R.V. Tangential microfiltration of lime and pineapple juices using inexpensive tubular ceramic membrane and analysis of fouling mechanism. Appl. Food Res. 2023, 3, 100284. [Google Scholar] [CrossRef]

- Qin, G.; Lü, X.; Wei, W.; Li, J.; Cui, R.; Hu, S. Microfiltration of kiwifruit juice and fouling mechanism using fly-ash-based ceramic membranes. Food Bioprod. Process. 2015, 96, 278–284. [Google Scholar] [CrossRef]

- Bourne, M.C.; Rao, M.A. Viscosity measurements of foods. In Instrumental Methods for Quality Assurance in Foods; Fung, D.Y.C., Matthews, R.E., Eds.; CRC Press: New York, NY, USA, 1991; pp. 211–229. [Google Scholar]

- AOAC. Method of Analysis; Association of Official Analytical Chemistry: Washington, DC, USA, 1995. [Google Scholar]

- He, Y.; Zhijuan, J.; Shunxin, L. Effective clarification of apple juice using membrane filtration without enzyme and pasteurization pretreatment. Sep. Purif. Technol. 2007, 57, 364–371. [Google Scholar] [CrossRef]

- Bruijn, J.; Bórquez, R.M. Analysis of the fouling mechanisms during cross-flow ultrafiltration of apple juice. Lwt Food Sci. Technol. 2006, 39, 861–871. [Google Scholar] [CrossRef]

- Sagu, S.T.; Karmakar, S.; Nso, E.J.; Kapseu, C.; De, S. Ultrafiltration of banana (Musa acuminata) juice using hollow fibers for enhanced shelf life. Food Bioprocess Technol. 2014, 7, 2711–2722. [Google Scholar] [CrossRef]

- Cassano, A.; Conidi, C.; Drioli, E. Clarification and concentration of pomegranate juice (Punica granatum L.) using membrane processes. J. Food Eng. 2011, 107, 366–373. [Google Scholar] [CrossRef]

- Rai, C.; Rai, P.; Majumdar, G.C.; De, S.; Dasgupta, S. Mechanism of permeate flux decline during microfiltration of watermelon (Citrullus lanatus) juice. Food Bioprocess Technol. 2010, 3, 545–553. [Google Scholar] [CrossRef]

- Kimball, D. The Brix/Acid Ratio. In Citrus Processing; Kimball, D., Ed.; Springer: Dordrecht, The Netherlands, 1991; pp. 55–65. [Google Scholar]

- Deep, L.; Narayana, C.K.; Karunakaran, G.; Rao, D.S.; Anuradha, S. Maturity determination of red and white pulp dragon fruit. J. Hortl. Sci. 2022, 17, 157–165. [Google Scholar] [CrossRef]

- Harker, F.R.; Marsh, K.B.; Young, H.; Murray, S.H.; Gunson, F.A.; Walker, S.B. Sensory interpretation of instrumental measurements 2: Sweet and acid taste of apple fruit. Postharvest Biol. Technol. 2002, 24, 241–250. [Google Scholar] [CrossRef]

- Jayasena, V.; Cameron, I. Brix/acid ratio as a predictor of consumer acceptability of Crimson Seedless table grapes. J. Food Qual. 2008, 31, 736–750. [Google Scholar] [CrossRef]

- Li, W.; Ling, G.; Lei, F.; Li, N.; Peng, W.; Li, K.; Lu, H.; Hang, F.; Zhang, Y. Ceramic membrane fouling and cleaning during ultrafiltration of limed sugarcane juice. Sep. Purif. Technol. 2018, 190, 9–24. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).