A Review of Recent Research on Contamination of Oil Well Cement with Oil-based Drilling Fluid and the Need of New and Accurate Correlations

Abstract

:1. Introduction

2. Material and Methods

2.1. Contamination of Oil Well Cement with OBF

2.2. Case Study 1

2.3. Case Study 2

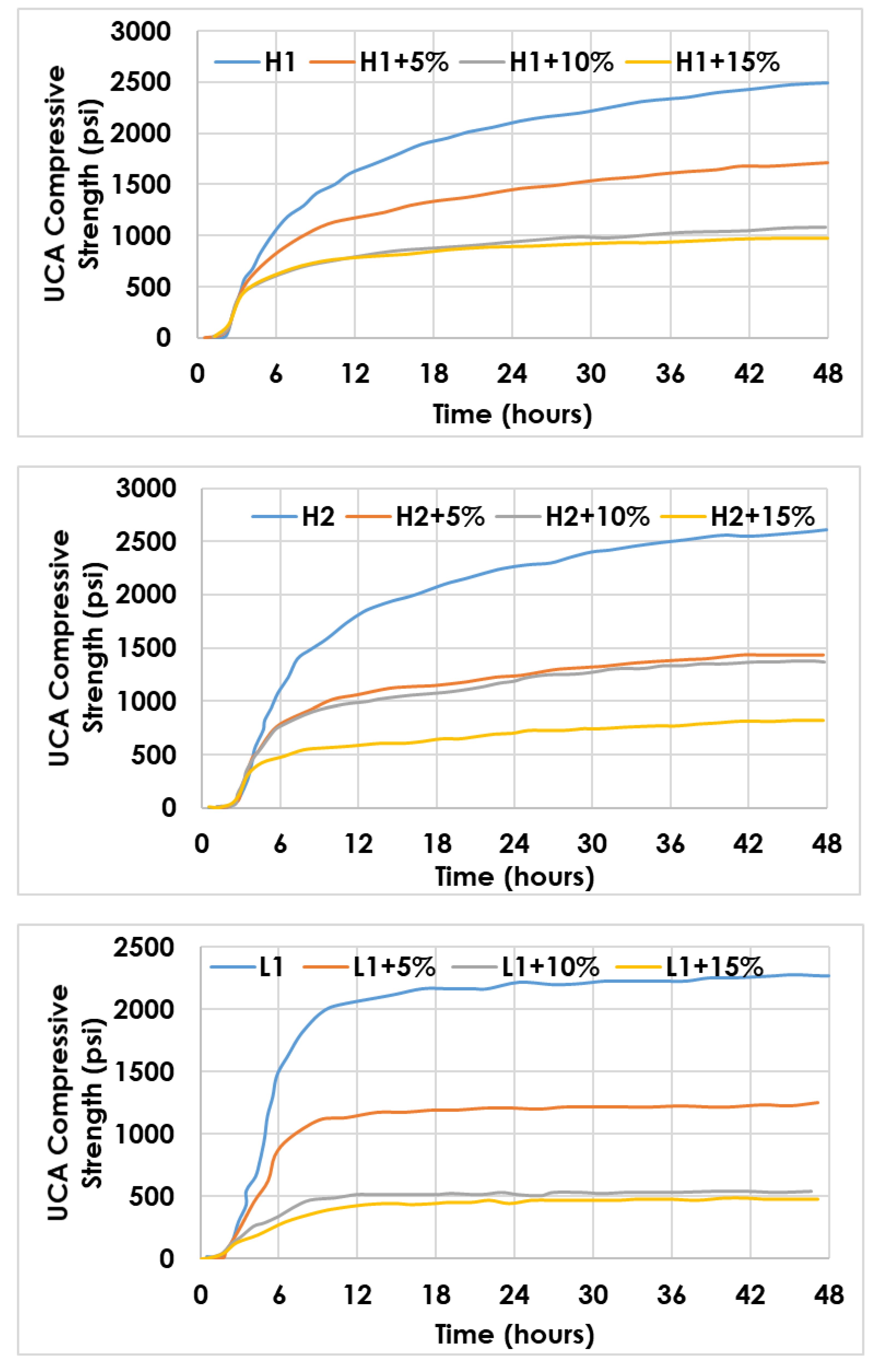

2.4. Case Study 3

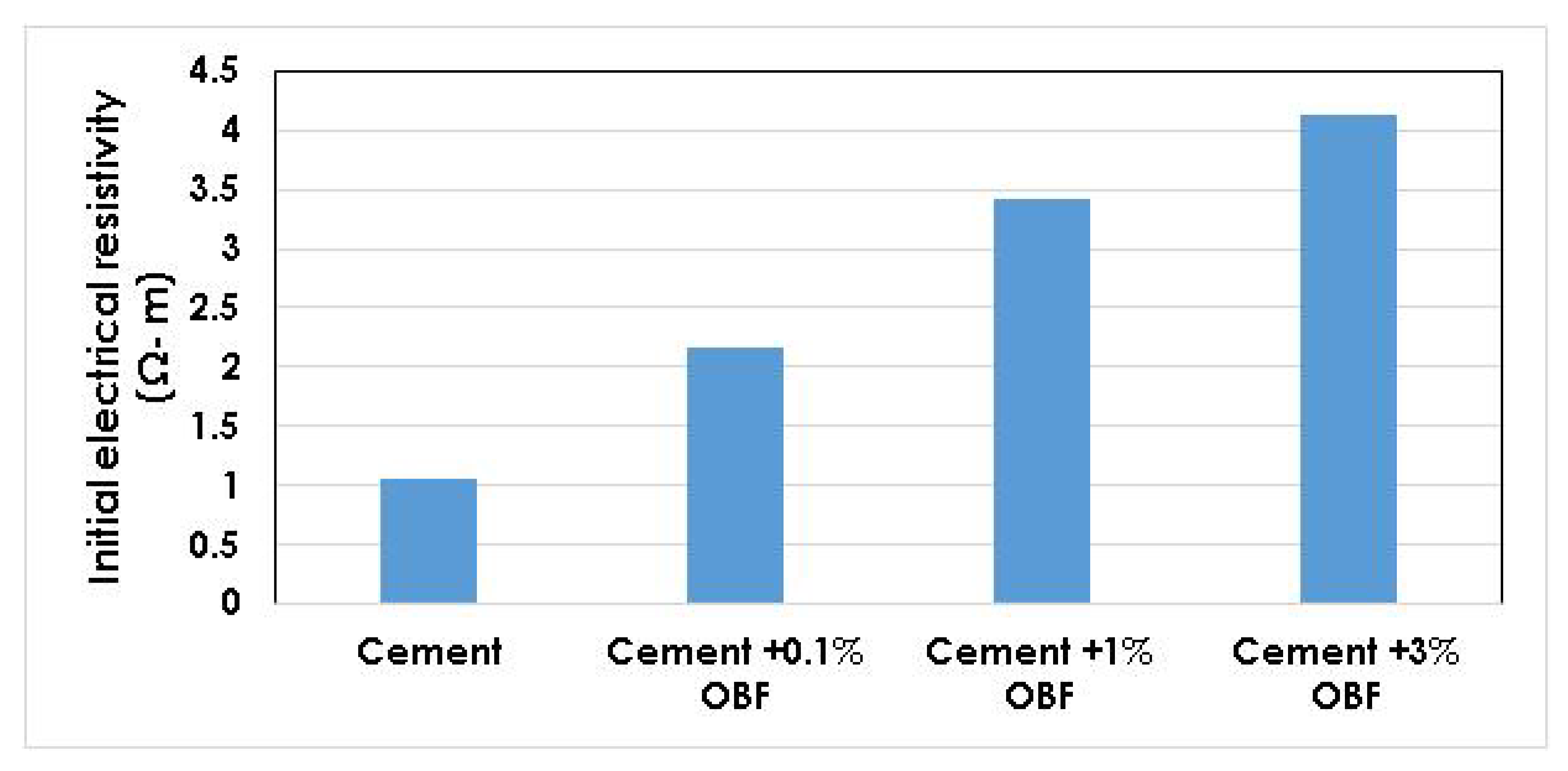

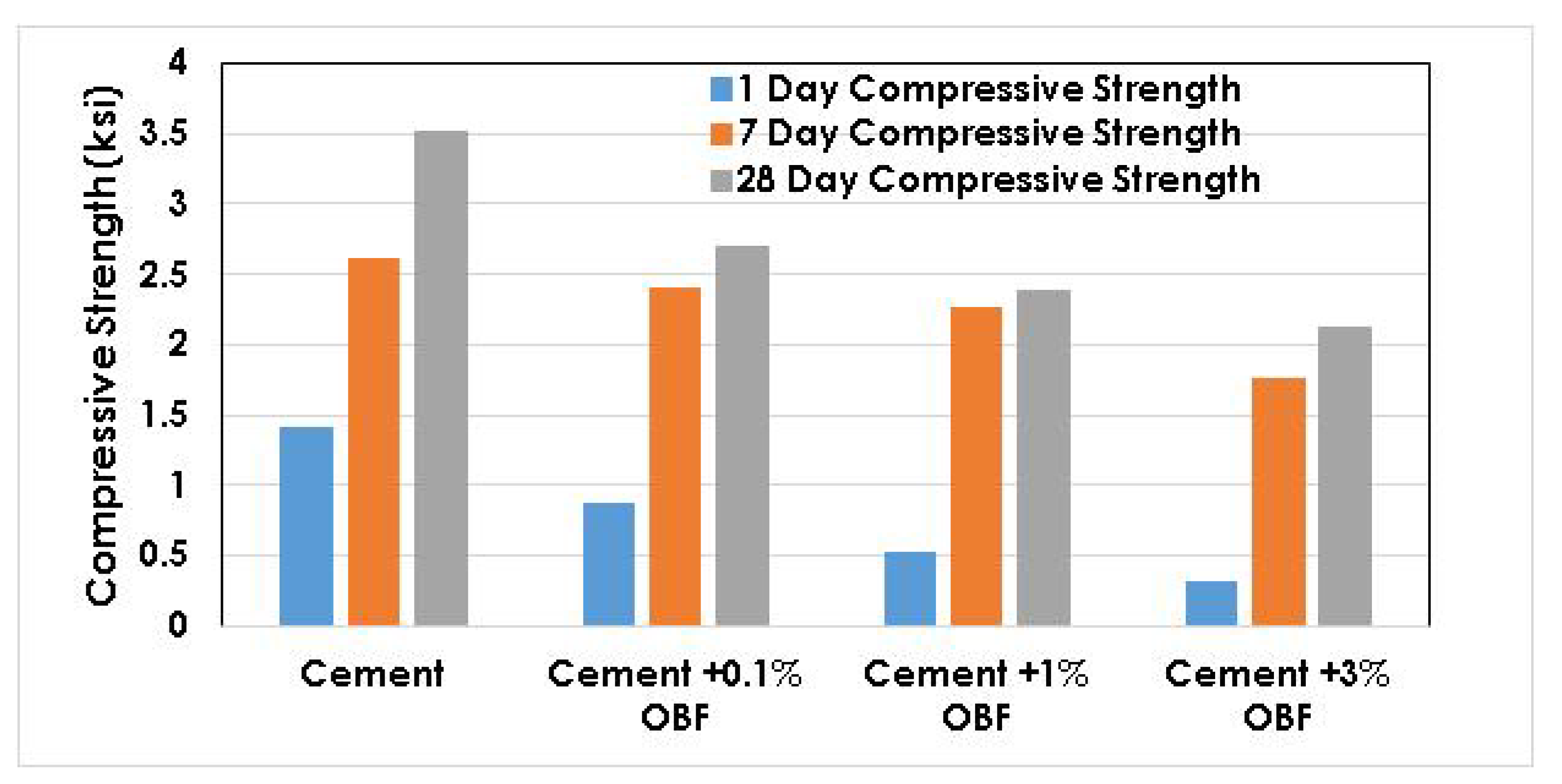

2.5. Case Study 4

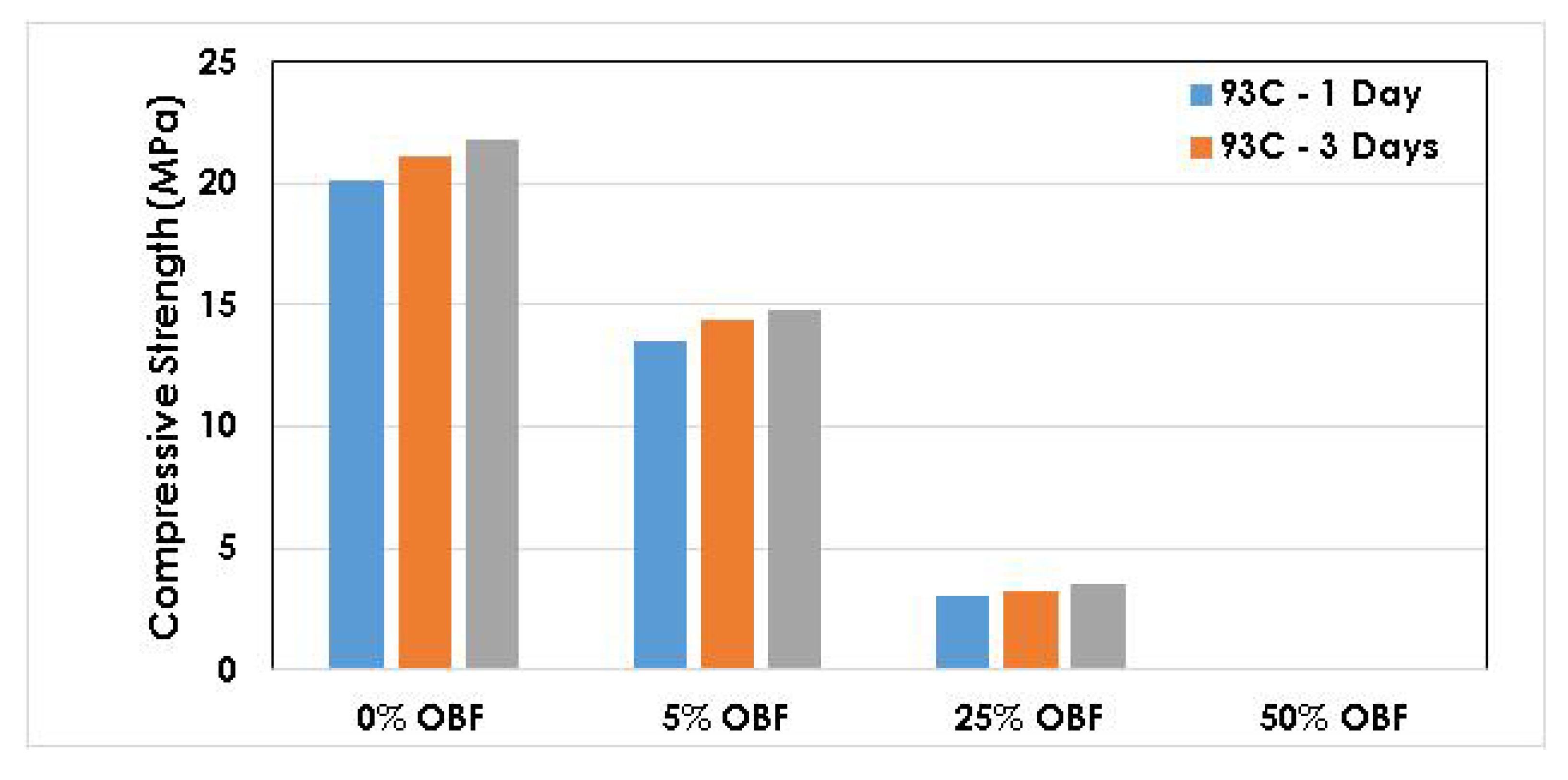

2.6. Case Study 5

2.7. Case Study 6

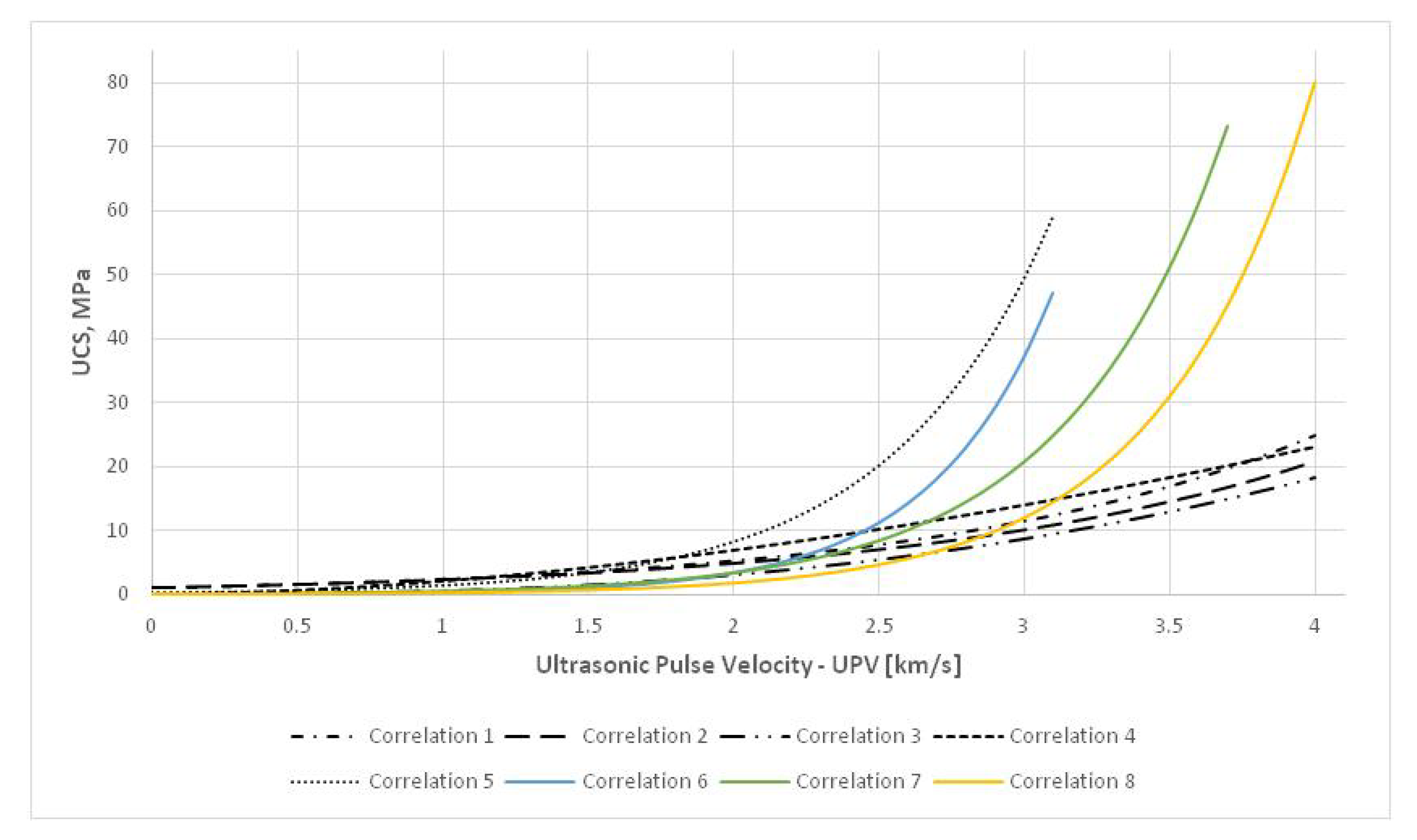

3. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| API | American Petroleum Institute |

| BHST | Bottom hole static temperature |

| EDS | Energy Dispersive Spectrometer |

| ESEM | Environmental scanning electron microscope |

| FLA | Fluid loss additive |

| FR | Friction reducer |

| FTIR | Fourier Transform Infrared Spectroscopy |

| HPHT | High Pressure, High Temperature |

| OBF | Diesel/oil-based drilling fluid |

| OBM | Oil-based mud |

| RS | Reference cement slurry |

| SBM | Synthetic-based mud |

| SEM | Scanning electron microscope |

| TG | Thermogravimetry |

| UCA | Ultrasonic Cement Analyzer |

| UCS | Unconfined compressive strength |

| UPV | Ultrasonic pulse velocity |

| WBM | Water-based mud |

| XRD | X-ray diffraction |

References

- Bourgoyne, A.; Millheim, K.; Chenevert, M. Applied Drilling Engineering; Society of Petroleum Engineers: Dallas, TX, USA, 1984. [Google Scholar]

- Rabia, H. Well Engineering & Construction Hussain Rabia; Entrac Consulting Publisher: USA, 2002; pp. 1–789. [Google Scholar]

- Scott, P.; Broussard, P.; Freeman, M.; Growcock, F.; Bland, R. Drilling Fluids Manual, 12th ed.; 2015; ISBN 9780991509546. [Google Scholar]

- Chambers, M.R.; International, M.; Services, D.; Hebert, D.B.; Shuchart, C.E. SPE 58743 Successful Application of Oil-based Drilling Fluids in Subsea Horizontal, Gravel-Packed Wells in West Africa; Society of Petroleum Engineers: Dallas, TX, USA, 2000. [Google Scholar]

- Fossum, P.V.; Van Der Zwaag, C.; Taugbøl, K.; Mjaaland, S.; Sletfjerding, E.; Høgstøl, H.; Olsen, P.A.; M-I, S. SPE 107754 Design and Utilization of Low Solids OBM for Aasgard Reservoir Drilling and Completion. In Proceedings of the European Formation Damage Conference, Scheveningen, The Netherlands, 30 May–1 June 2007. [Google Scholar]

- Kabanov, M.; Telford, E.; Gray, C.; Hughes, B. Designing and Running a Special Oil-Based Mud for a North Sea HPHT Campaign Planning the Wells; Society of Petroleum Engineers: Dallas, TX, USA, 2014. [Google Scholar]

- Emadi, H.; Soliman, M.; Heinze, L.; Moghaddam, R.; Samuel, R. An Experimental Study of the Swelling Properties of Unconventional Shale-Oil Rock Samples Using both Water-Based and Oil-Based Muds and Effects of Invasion on Rock Mechanical Properties. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015. [Google Scholar]

- Fleming, N.; Karunakaran, M.; Hireche, S. Qualification and Implementation of Oil-Based Mud as a Cost-Effective and Low-Damaging Perforation Fluid for Gudrun Case History; Society of Petroleum Engineers: Dallas, TX, USA, 2019; pp. 7–9. [Google Scholar]

- Harold, M.; Pe, E.I.I.I.; Partners, N.E. Case Study: Using Managed Pressure Drilling and Oil Based Mud to Efficiently Drill an Extremely Thick and Highly Fractured Carbonate Sequence Under an Extremely Thick and Highly Sensitive Laminated Shale. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015. [Google Scholar]

- Sheer, S.; Alotaibi, A.; Gadhiya, K.; Hughes, B.; Al-khaldy, M.; Abhijit, D.; Al-failkawi, K.; Al-saadi, D.; Al-saeedi, A.; Hamed, A.; et al. SPE-198582-MS The Dynamics of Drilling with Oil-Based Mud, 60:40 Oil-Water Ratio – Case History in South East Kuwait Fields. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, UAE, 21–23 October 2019. [Google Scholar]

- Sinha, P.; Kumar, V.; Prabhakaran, T.; Katre, A.; Patel, M.; Doodraj, S. A More Holistic Approach to Determine Economics of Using Synthetic Oil Based Mud over Water Based Mud System in Onshore Development Drilling Onshore drilling history in Rajasthan. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 4–6 April 2017. [Google Scholar]

- Degni, C. Drilling Practices; IADC: Houston, TX, USA, 2012; pp. 1–497. [Google Scholar]

- IADC. IADC Drilling Manual; IADC: Houston, TX, USA, 2000; pp. 1–1463. [Google Scholar]

- Patel, A.D.; Wilson, J.M.; Loughridge, B.W.; Services, H.E. SPE 50726 Impact of Synthetic-Based Drilling Fluids on Oilwell Cementing Operations. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Houston, TX, USA, 16–19 February 1999. [Google Scholar]

- Design, G.C. Improved primary cement jobs with a unique spacer design. J. Pet. Technol. 1997, 49. [Google Scholar] [CrossRef]

- Budiawan, A.; Farahani, H.S.; Anugrah, A.; Brandl, A. Innovative Cement Spacer Improves Well Cementing Integrity—60 Case. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Bangkok, Thailand, 25–27 August 2014; pp. 1–16. [Google Scholar]

- Chan, A.F.; Bell, R.W.; Morrison, E. Improved Primary Cement Jobs Through the Use of Unique Spacer Design Technology: Gulf of Mexico Case History Study. Spe 36486. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, Colorado, 6–9 October 1996; pp. 727–737. [Google Scholar]

- Harder, C.A.; Carpenter, R.B.; Freeman, E.R.; Brookey, T.E.; Gandy, R.G. Optimization of oil-base mud chemistry for cementing. In Proceedings of the 1993 SPE International Symposium on Oilfield Chemistry, New Orleans, Louisiana, 2–5 March 1993; pp. 329–338. [Google Scholar]

- Abdulrazzaq, W.; AlBuraikan, R.; Savari, S.; Whitfill, D.L. New methodology to evaluate the performance of chemical sealant loss circulation materials. In Proceedings of the SPE Kuwait Oil Gas Show Conference, Kuwait City, Kuwait, 15–18 October 2017. [Google Scholar]

- Garnier, A.; Fraboulet, B.; Bois, A. OTC 18754 Characterization of Cement Systems to E nsure Cement Sheath Integrity. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2007; pp. 1–11. [Google Scholar]

- Goodwin, K.J. Guidelines for ultrasonic cement-sheath evaluation. SPE Prod. Eng. 1992, 7, 280–284. [Google Scholar] [CrossRef]

- McDaniel, J.; Watters, L.; Shadravan, A. Cernent sheath durability: Increasing cement sheath integrity to reduce gas migration in the marcellus shale play. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014; pp. 904–916. [Google Scholar]

- Rao, P.P.; Sutton, D.L.; Childs, J.D.; Cunningham, W.C. Ultrasonic Device for Nondestructive Testing of Oilwell Cements At Elevated Temperatures and Pressures. Jpt. J. Pet. Technol. 1982, 34, 2611–2616. [Google Scholar] [CrossRef]

- Reddy, B.R.; Santra, A.; McMechan, D.; Gray, D.; Brenneis, C.; Dunn, R. Cement mechanical property measurements under wellbore conditions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005; pp. 9–12. [Google Scholar]

- Aughenbaugh, K.; Nair, S.; Cowan, M.; Van Oort, E. Contamination of deepwater well cementations by synthetic-based drilling fluids. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 10–11 September 2014; pp. 767–777. [Google Scholar]

- Vipulanandan, C.; Heidari, M.; Qu, Q.; Farzam, H.; Pappas, J.M. Behavior of piezoresistive smart cement contaminated with oil based drilling mud. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014; pp. 1360–1373. [Google Scholar]

- Soares, A.A.; de Freitas, J.C.O.; de Melo, D.M.A.; Braga, R.M.; Amaral-Machado, L.; Silva Santos, P.H.; Soares, L.W.O. Cement slurry contamination with oil-based drilling fluids. J. Pet. Sci. Eng. 2017, 158, 433–440. [Google Scholar] [CrossRef]

- Li, M.; Ou, H.; Li, Z.; Gu, T.; Liu, H.; Guo, X. Contamination of cement slurries with diesel-based drilling fluids in a shale gas well. J. Nat. Gas Sci. Eng. 2015, 27, 1312–1320. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; Guo, X.; Ou, H.; Gu, T. Contamination of cement slurries with oil based mud and its components in cementing operations. J. Nat. Gas Sci. Eng. 2016, 29, 160–168. [Google Scholar] [CrossRef]

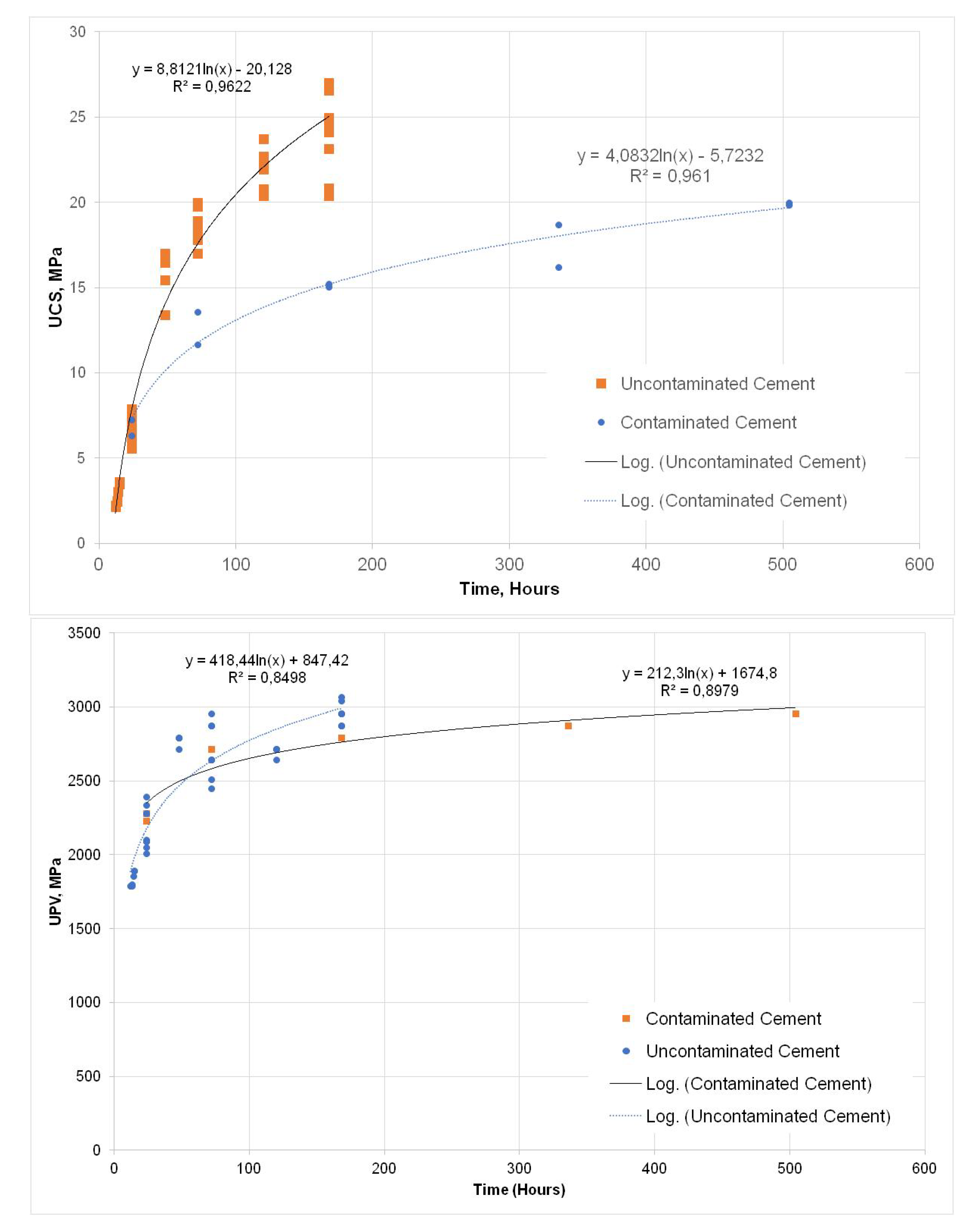

- Olteanu, A.; Teodoriu, C. Uncertainty in ultrasonic measurements of oil-based mud contaminated cement. Mater. Today Commun. 2020, 22, 100783. [Google Scholar] [CrossRef]

- Specification for Cements and Materials for Well Cementing API Specification 10A; API: Houston, TX, USA, 2010.

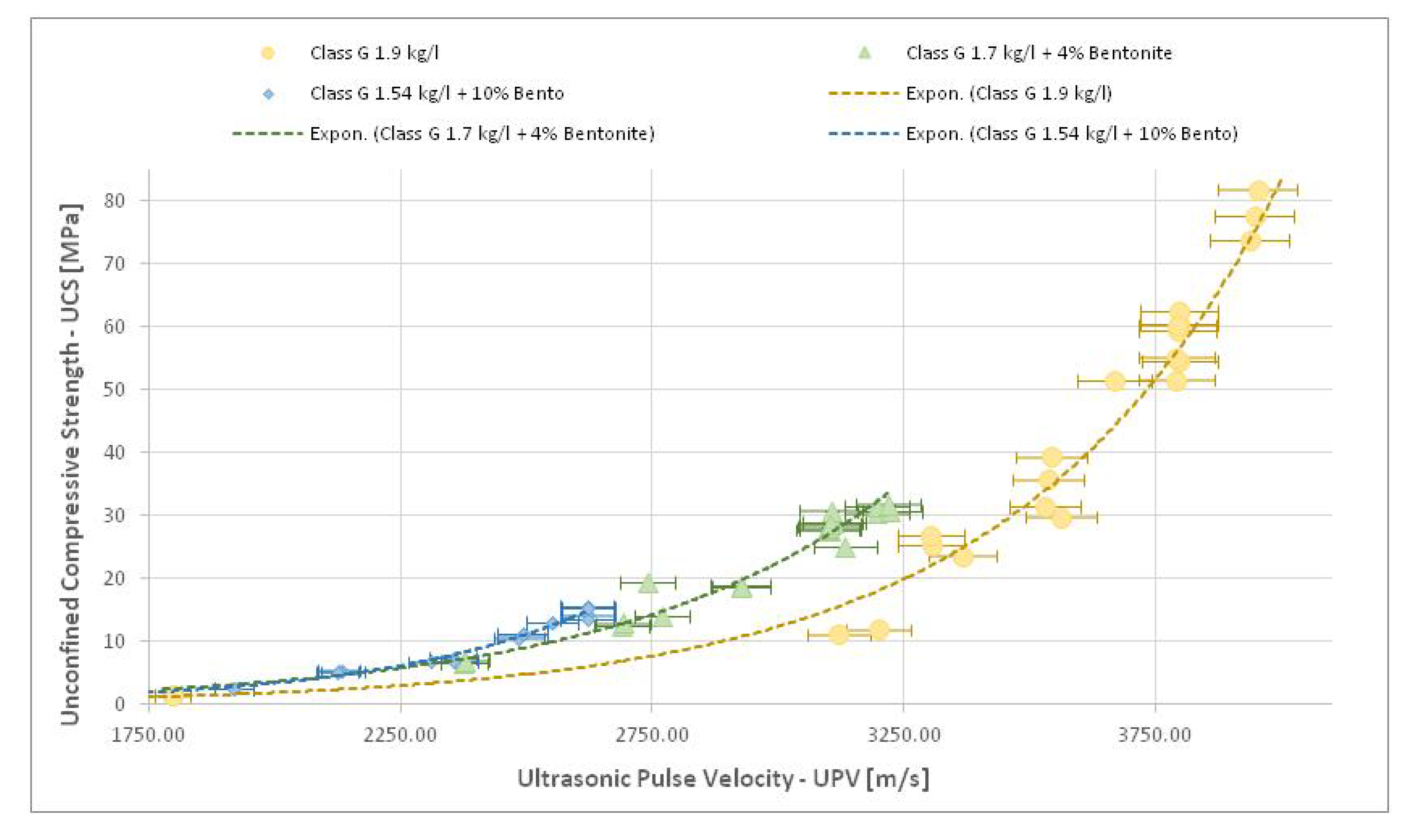

- Romanowski, N.; Ichim, A.; Teodoriu, C. Investigations on Oilwell Cement Strength Response to Ultrasonic Measurements in the Presence of Additives1. J. Sol. Energy Eng. Trans. ASME 2018, 140, 1–7. [Google Scholar] [CrossRef]

| OBF | Base Oil | Primary Emulsifier |

|---|---|---|

| Mud 1 | Mineral Oil | Alkanolamide |

| Mud 2 | Mineral Oil | Standard Fatty Acid |

| Mud 3 | Diesel Oil | Alkanolamide |

| Mud 4 | Diesel Oil | Standard Fatty Acid |

| Slurry Name | Composition |

|---|---|

| H-1 | API Class H-1 and tap water |

| H-2 | API Class H-2 and tap water |

| C-1 | API Class C and tap water |

| L-1 | Lightweight cement and tap water |

| S-1 | Blast furnace slag and alkaline activating solution |

| DW-H-2 | API Class H-2 and Tap water and Additives |

| % Contamination | Compressive Strength (MPa) | Bonding Strength (MPa) | Porosity % | Permeability (mD) |

|---|---|---|---|---|

| 0 | 17.2 | 3.4 | 11.2 | 0.04 |

| 5 | 13.5 | 2.2 | 16.8 | 0.19 |

| 25 | 4.1 | 0.7 | 32.1 | 0.41 |

| 50 | 0 | 0 | - | - |

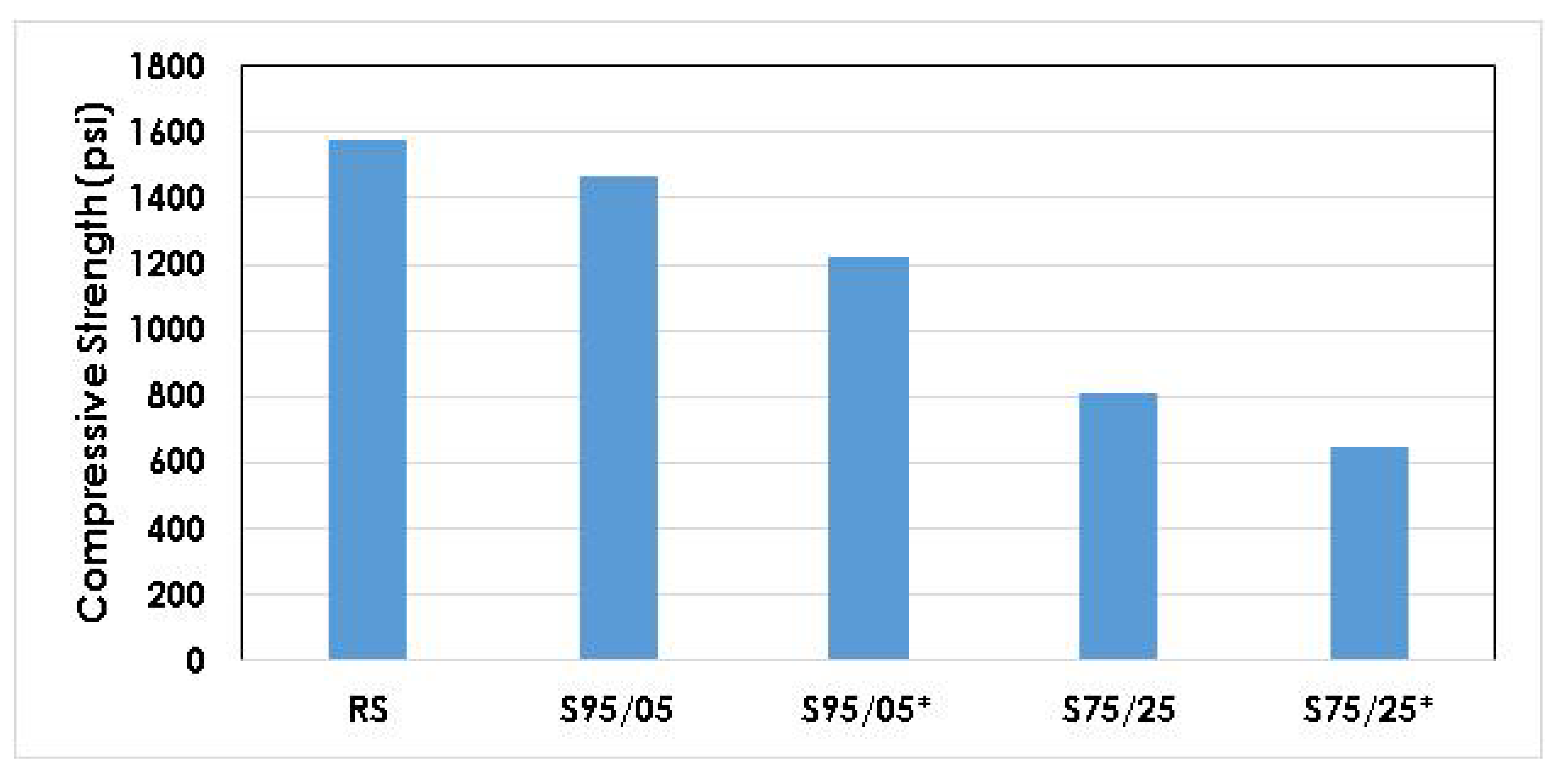

| Sample Name | RS/DF (%) | Sample Name | RS/DF * (%) |

|---|---|---|---|

| S95/05 | 95/05 | 95/05 * | 95/05 |

| S75/25 | 75/25 | 75/25 * | 75/25 |

| S50/50 | 50/50 | 50/50 * | 50/50 |

| S25/75 | 25/75 | 25/75 * | 25/75 |

| S05/95 | 05/95 | 05/95 * | 05/95 |

| Correlation | Equation | R2 |

|---|---|---|

| UCS vs. UPV (uncontaminated) | Y = 0.1392e0.0018× | 0.9115 |

| UCS vs. UPV (contaminated) | Y = 0.2094e0.0015× | 0.9758 |

| UCS vs. UPV (uncontaminated–thermal cycles) | Y = 0.2879e0.0016× | 0.9856 |

| Authors | Harder et al., 1993 | Aughenbaugh et al., 2014 | Vipulanandan et al., 2014 | Li et al., 2015 | Li et al., 2016 | Soares et al., 2017 | Olteanu et al., 2019 |

|---|---|---|---|---|---|---|---|

| Cement | API Class H (Slurry density—17 ppg) |

| API Class H | API Class G | API Class G | API Class G (Slurry Density—15 ppg) | API Class C (Slurry Density—14.77 ppg) |

| Additives | Fluid loss additive and friction reducers |

| 0.1% (BWOC) conductive fillers |

|

|

| - |

| Contamination | Four types of OBF formulated with combinations of base oil (Diesel oil and Mineral oil) and primary emulsifier (Alkanolamide and Calcium Soap). |

| Vegetable oil-based mud (75/25 invert emulsion) with 1% chemical surfactant | UDM-2 system diesel-based drilling fluid (85/15 invert emulsion) | VERSACLEAN system diesel-based drilling fluid |

| OBF |

| Amount of contaminant |

|

|

|

|

|

| 40 mL |

| Curing Temp. | ≈93 °C * | ≈77 °C * | Room temperature | 93 °C | 135 °C | 52 °C |

|

| Authors | Harder et al., 1993 | Aughenbaugh et al., 2014 | Vipulanandan et al., 2014 | Li et al., 2015 | Li et al., 2016 | Soares et al., 2017 | Olteanu et al., 2019 |

| Curing Press. | Atmospheric * | 20.7 MPa * | Atmospheric | Atmospheric | 20.7 MPa | Atmospheric | Atmospheric |

| Curing Time |

| 2 days |

|

| 2 days | 1 day | 8 h to 50 days |

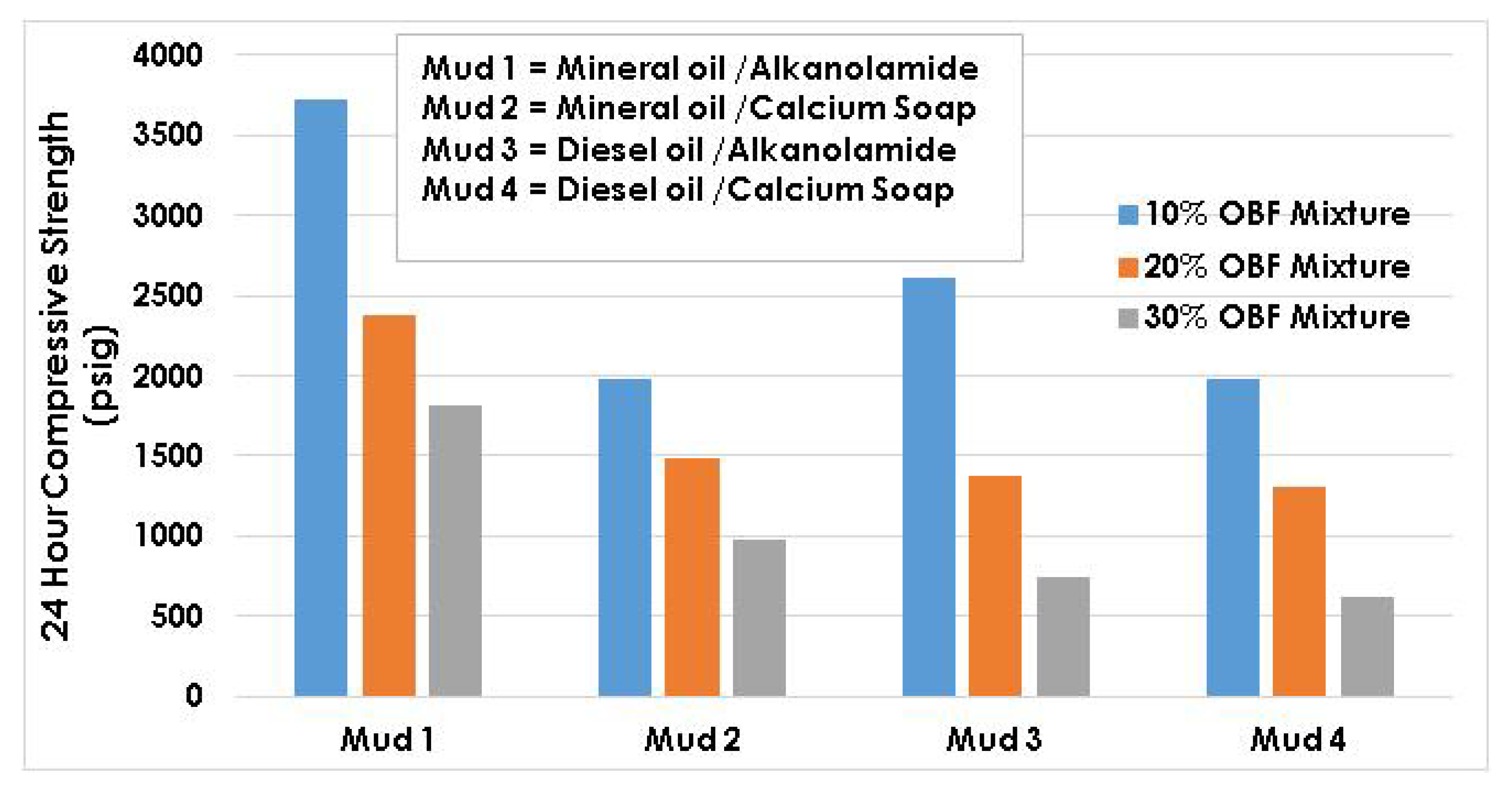

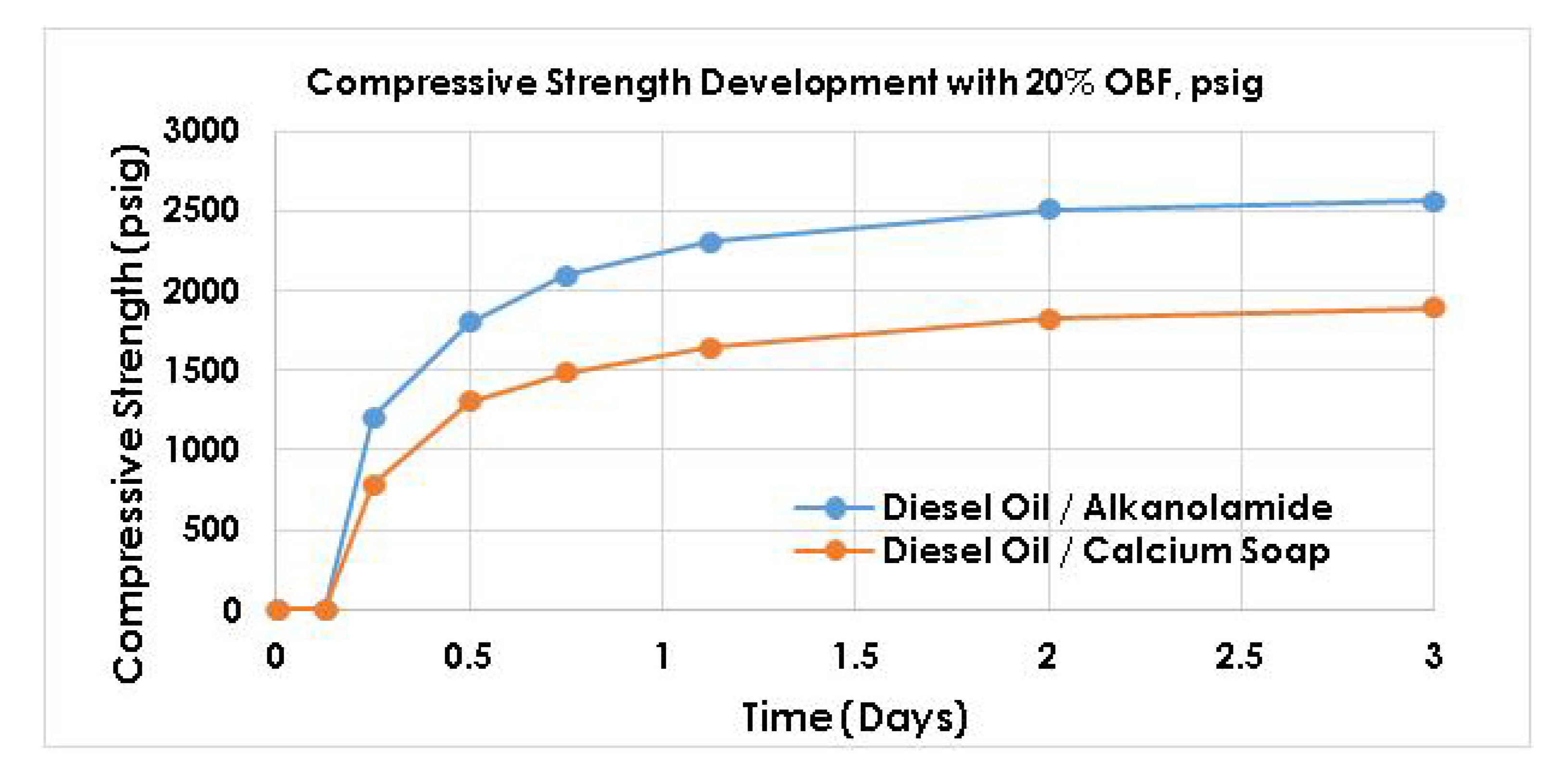

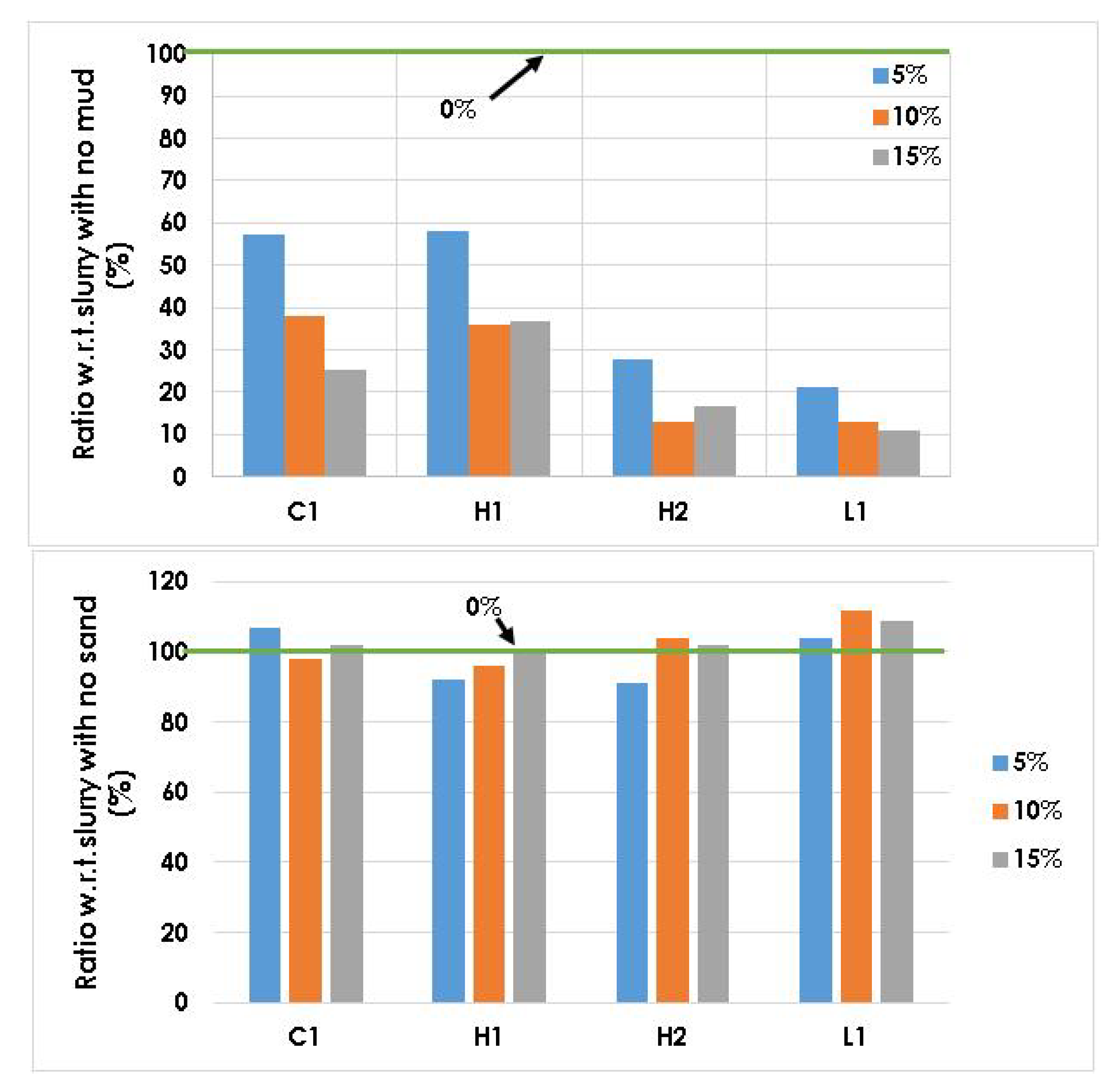

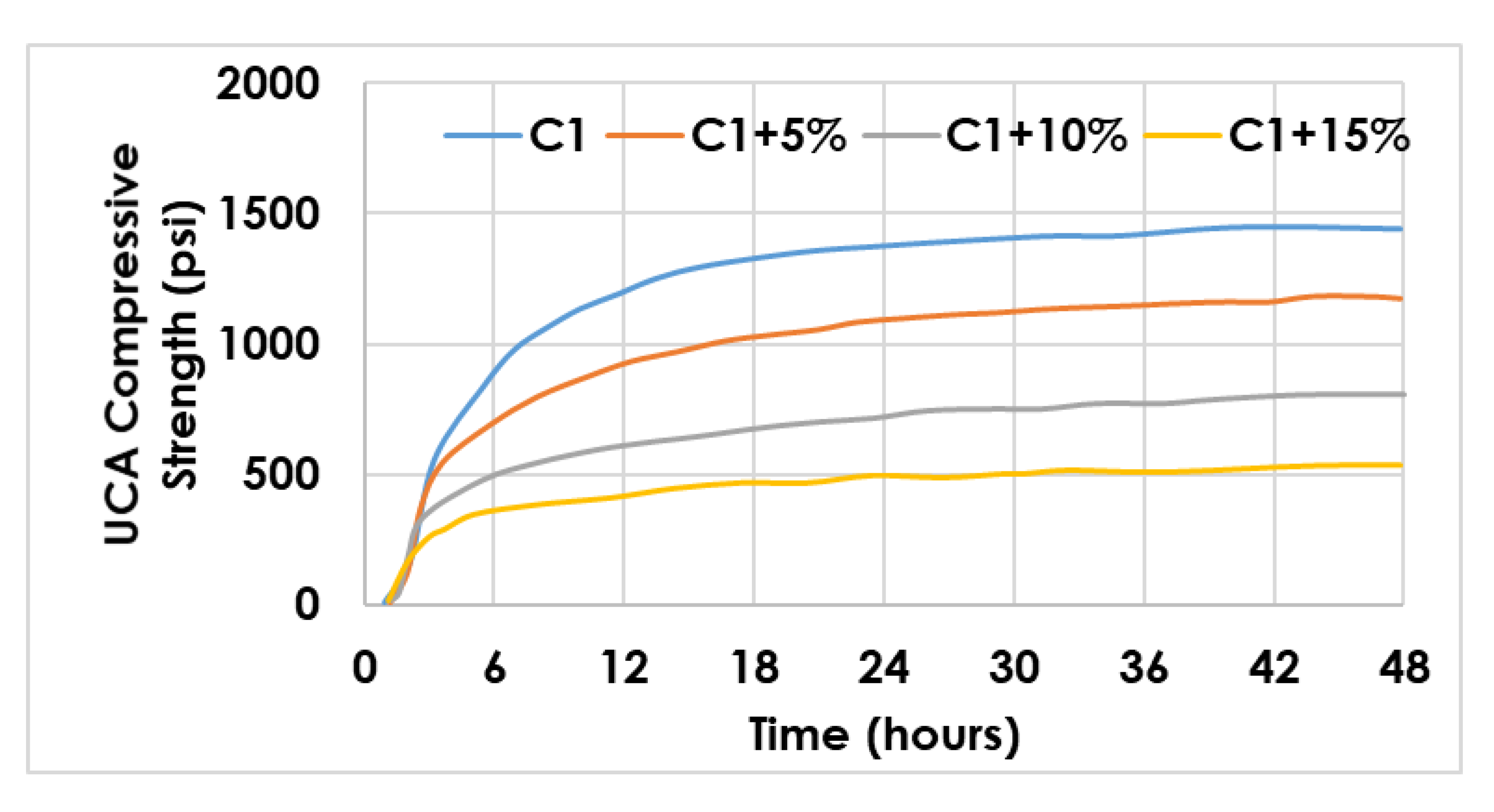

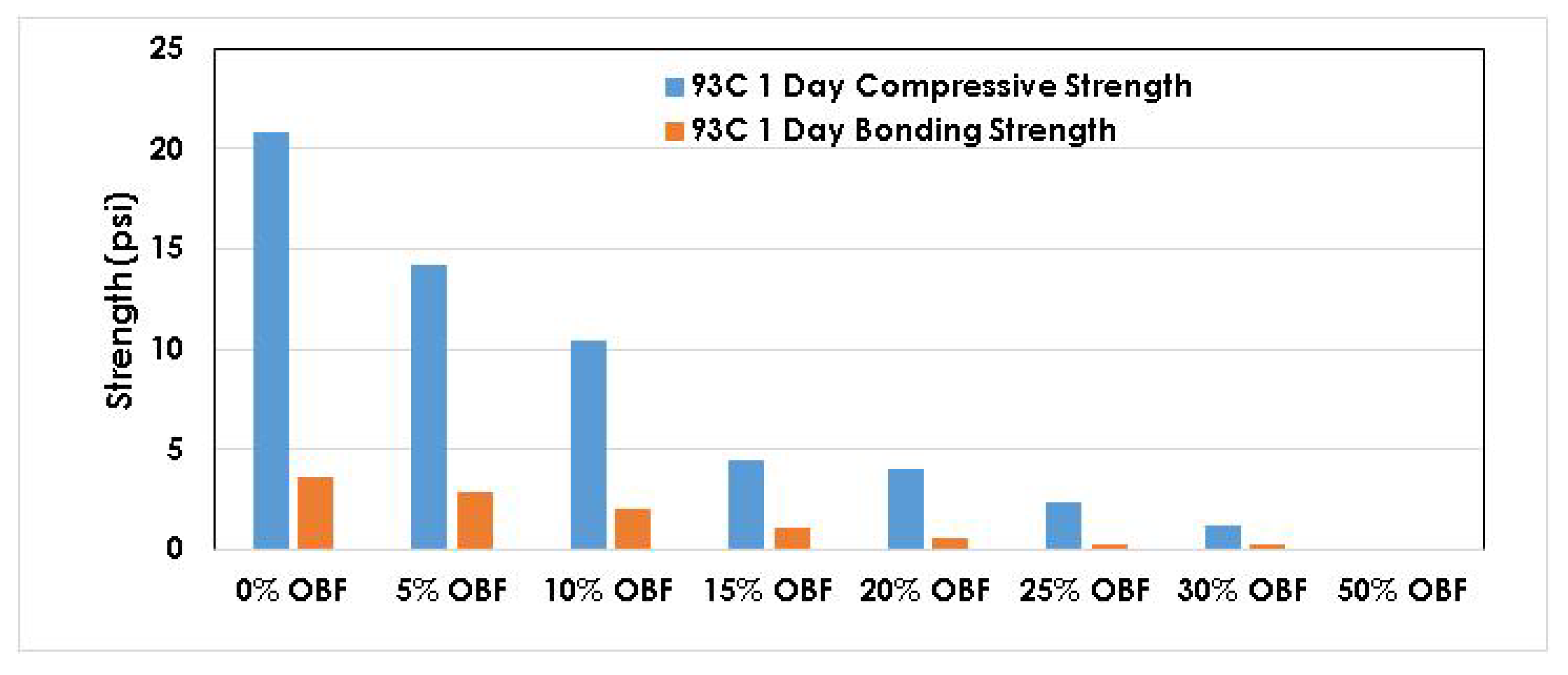

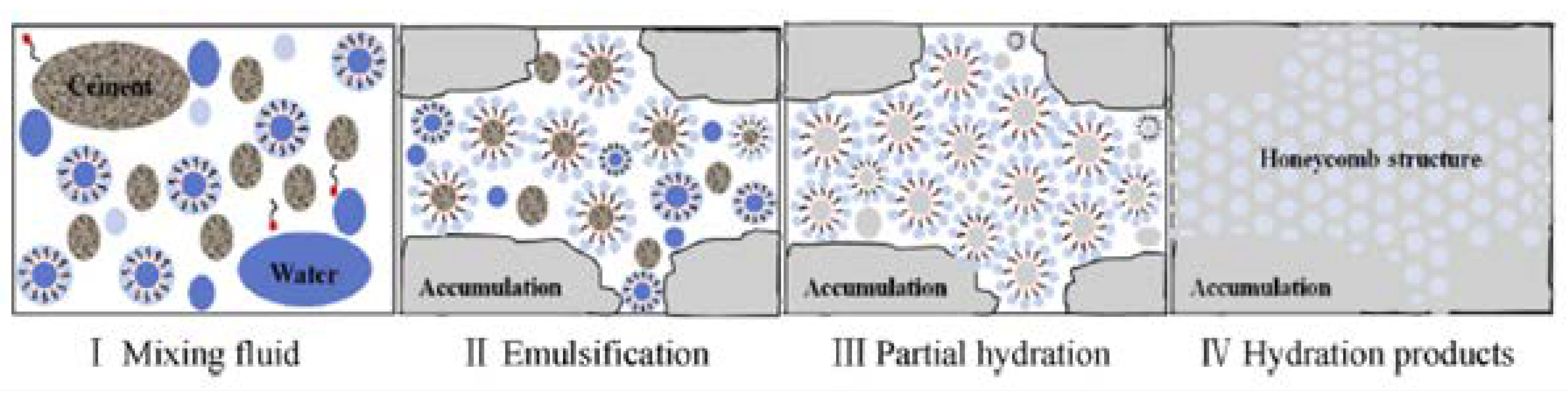

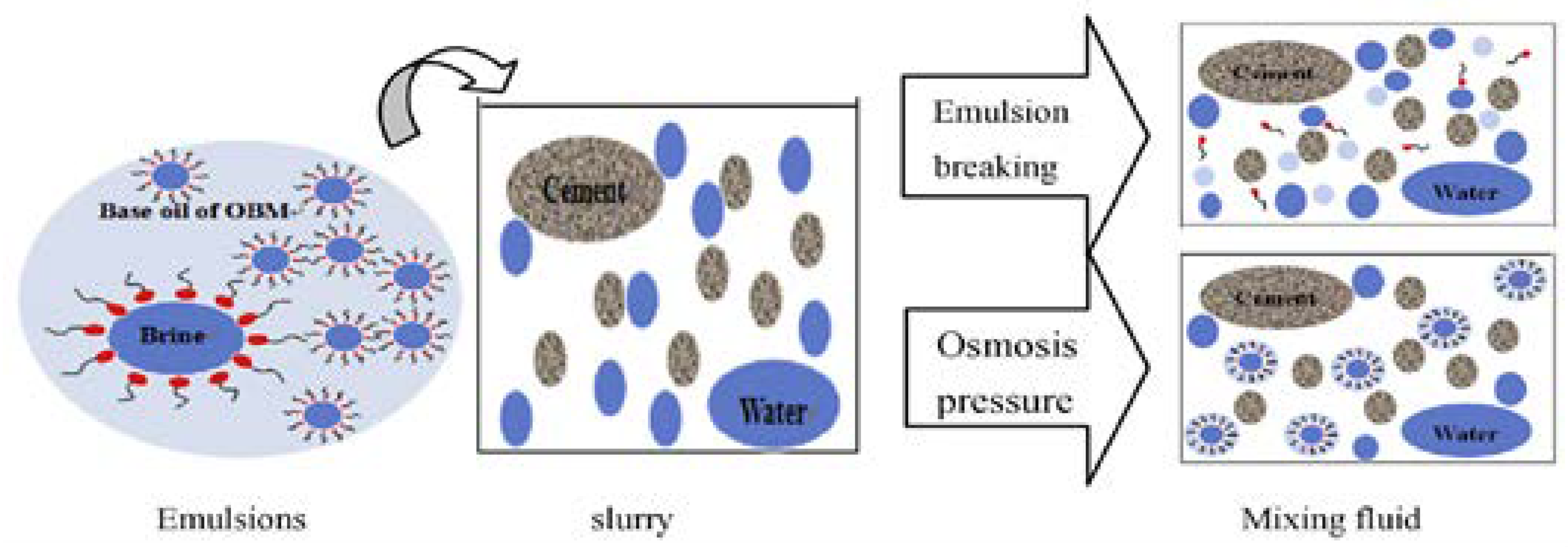

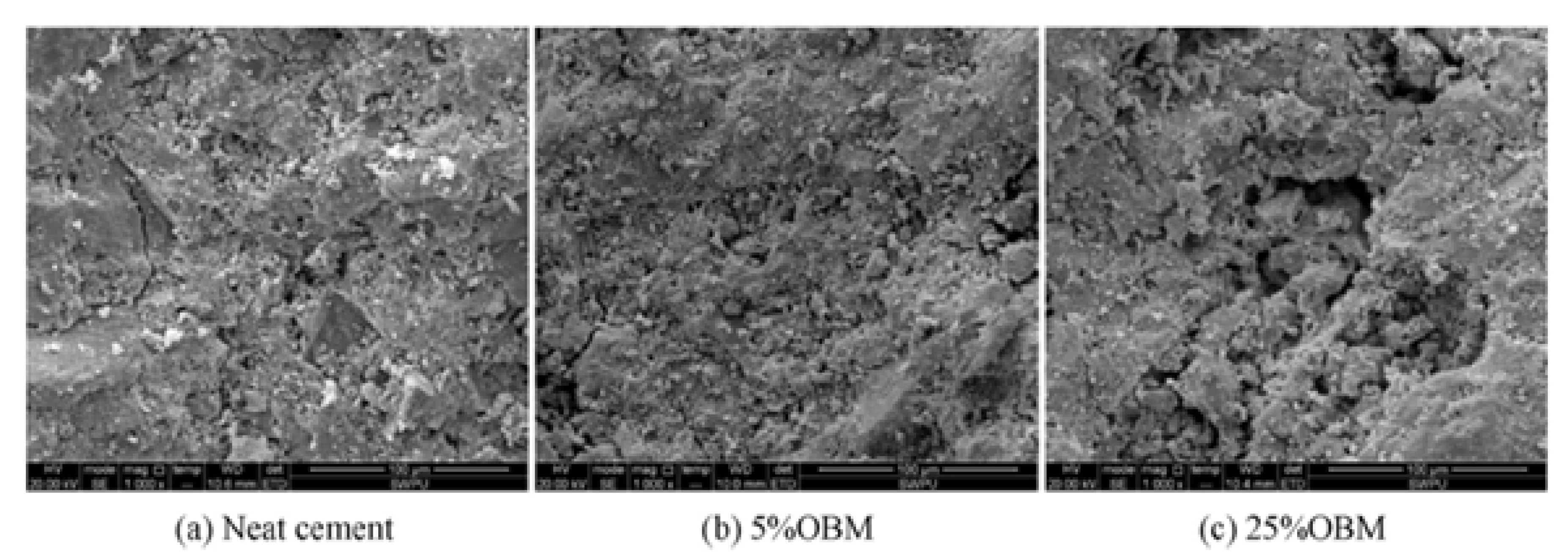

| Mechanical Properties | Diesel oil had a more adverse effects on the compressive strength compared to mineral oil. The presence of alkanolamide showed better strength development compared to standard fatty acid (calcium soap). | UCS reduction rate was 40% for C-1 and H-1 and for L-1 it was 80% at 5% contamination. While at 15% contamination reduction in C-1 was 25%, H-1 was 38% and L-1 was 90%. UCS remained same with 10% error margin for different contamination of silica. Brine affects the compressive strength negatively. For DW-H-2 at 5% contamination reduction is 5% while at 15% contamination reduction is 50%. | UCS reduction rate for 1 day of curing with 0.1% and 3% contamination is 40% and 75% respectively. Similarly, UCS reduction rate for 28 days of curing with 0.1% and 3% contamination is 25% and 35% respectively. | UCS reduction rate for 1, 3,7 days of curing with 5% contamination is 33.17%, 32.46% and 31.75% respectively. At 25% contamination it is 85.15%, 84.56% and 83.95% for 1,3,7 days of curing respectively reduced to 0 for 50% contamination. | UCS and bonding strength reduced by 76% and 79% for 25% contamination respectively; and reduced to 0 for 50% contamination. | For 5% and 25% contamination (comparing DF* vs. DF), UCS reduction was 15% and 25%. UCS reduced to 0 for 50% contamination. | 50% reduction in UCS after curing for 14 days |

| Authors | Harder et al., 1993 | Aughenbaugh et al., 2014 | Vipulanandan et al., 2014 | Li et al., 2015 | Li et al., 2016 | Soares et al., 2017 | Olteanu et al., 2019 |

| Rheological Properties | - | - | Proposed a Hyperbolic model over the Herschel–Bulkley and Bingham Models. | Bingham Plastic model used to characterize the mixtures at 25 °C and 93 °C. | Contamination increases initial consistency and decreases fluidity | Bingham and Power Law models used to characterize the mixtures. | - |

| Correlation | No | No | No | No | No | No | Yes * |

| Other findings | Addition of ethoxylated nonylphenol improves the strength of contaminated cement slurry. | Strength of contaminated samples was improved by addition of 10% (by weight of SBM) alkali. Mechanism behind the reduction in strength is osmotic dehydration. | Measurement of initial electrical resistivity of contaminated samples can help in understanding the amount of OBF contamination. | Demulsification and osmotic pressure change the rheological properties. Honeycomb structure is formed in the presence of OBF. Adding surfactant to contaminated slurry improves the rheological and mechanical properties. | At 25% contamination the porosity and permeability increased by 187% and 925% respectively. Out of all the components of OBF, emulsion and diesel had worst effects on rheological and mechanical properties compared to other OBF components. | Contamination in general increases plastic viscosity and yield point; decreases the max. pumpable consistency; formation of microcavities affect the UCS; Wetting agent modifies zeta potential values. | Up to 24 h both contaminated and uncontaminated samples have similar properties. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arbad, N.; Teodoriu, C. A Review of Recent Research on Contamination of Oil Well Cement with Oil-based Drilling Fluid and the Need of New and Accurate Correlations. ChemEngineering 2020, 4, 28. https://doi.org/10.3390/chemengineering4020028

Arbad N, Teodoriu C. A Review of Recent Research on Contamination of Oil Well Cement with Oil-based Drilling Fluid and the Need of New and Accurate Correlations. ChemEngineering. 2020; 4(2):28. https://doi.org/10.3390/chemengineering4020028

Chicago/Turabian StyleArbad, Nachiket, and Catalin Teodoriu. 2020. "A Review of Recent Research on Contamination of Oil Well Cement with Oil-based Drilling Fluid and the Need of New and Accurate Correlations" ChemEngineering 4, no. 2: 28. https://doi.org/10.3390/chemengineering4020028

APA StyleArbad, N., & Teodoriu, C. (2020). A Review of Recent Research on Contamination of Oil Well Cement with Oil-based Drilling Fluid and the Need of New and Accurate Correlations. ChemEngineering, 4(2), 28. https://doi.org/10.3390/chemengineering4020028