Experimental and CFD Studies of the Hydrodynamics in Wet Agglomeration Process

Abstract

1. Introduction

2. Materials and Methods

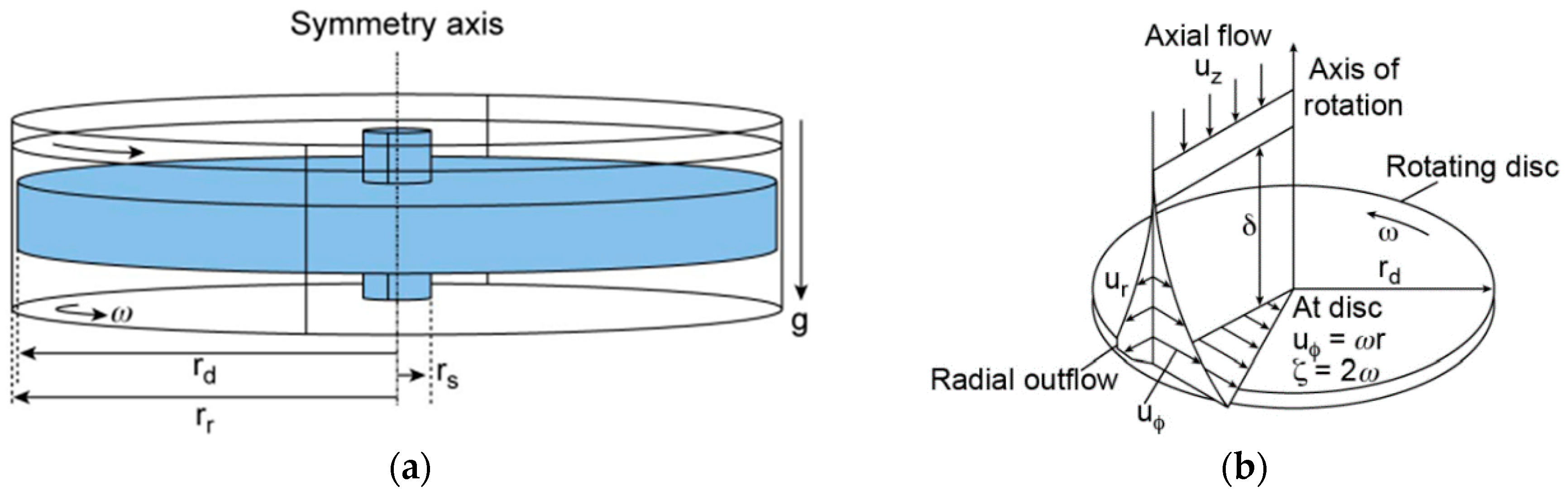

2.1. Description of the RVR Agglomeration Reactor

2.2. Theoretical Analysis of the Fluid Flow

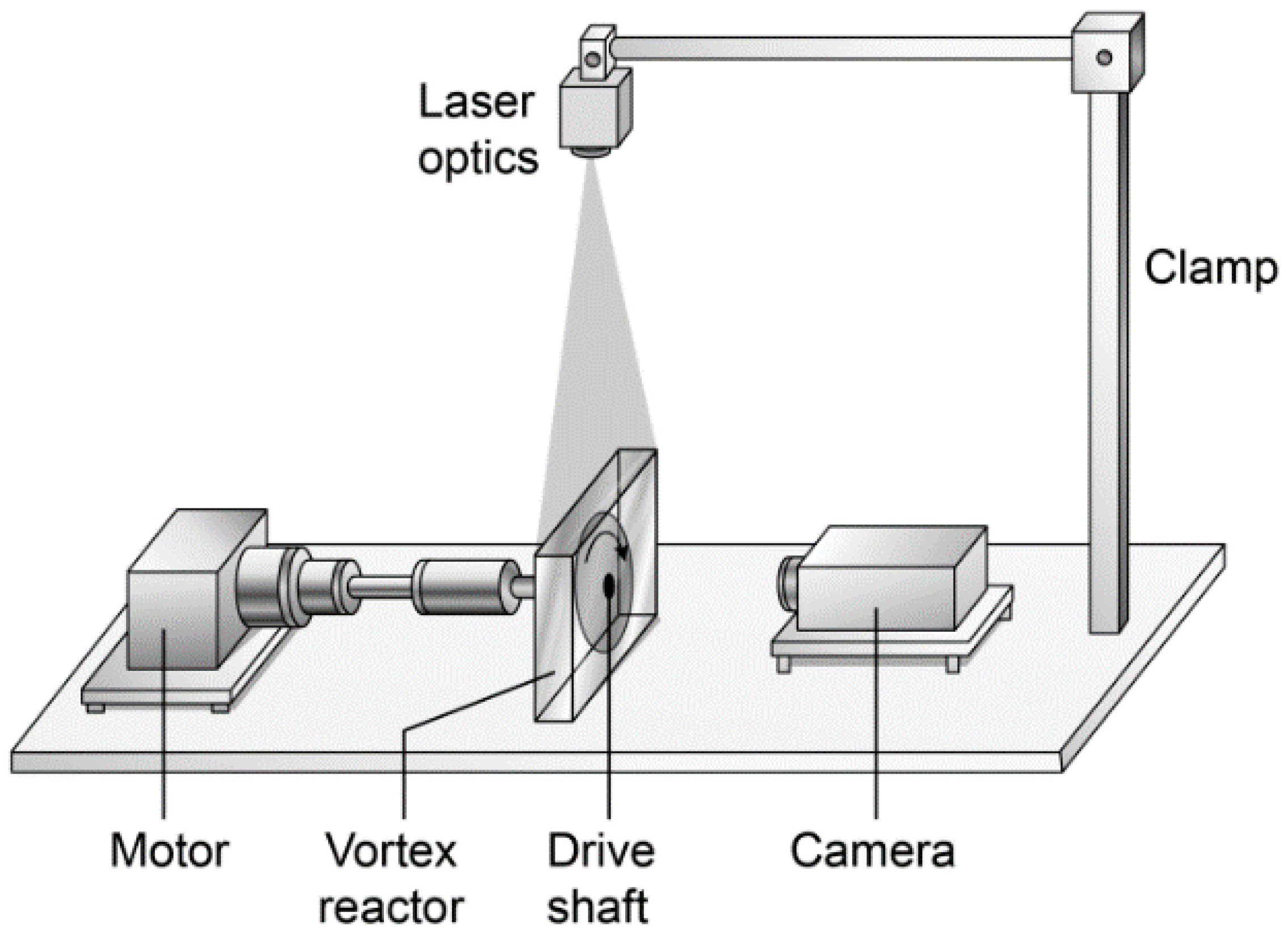

2.3. Experimental Fluid Flow Measurements

3. Numerical Simulation

3.1. Model Description

3.1.1. Governing Equations

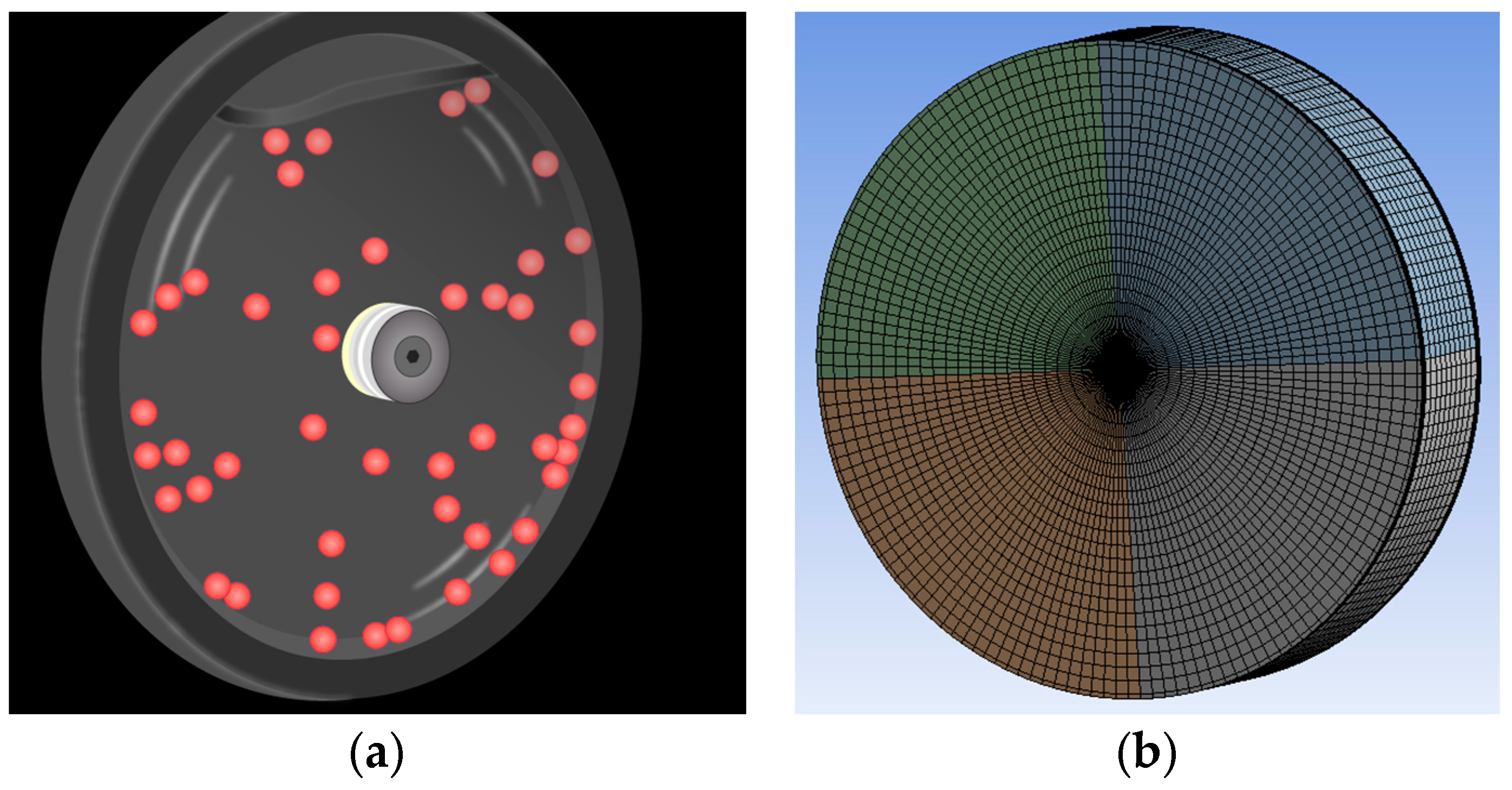

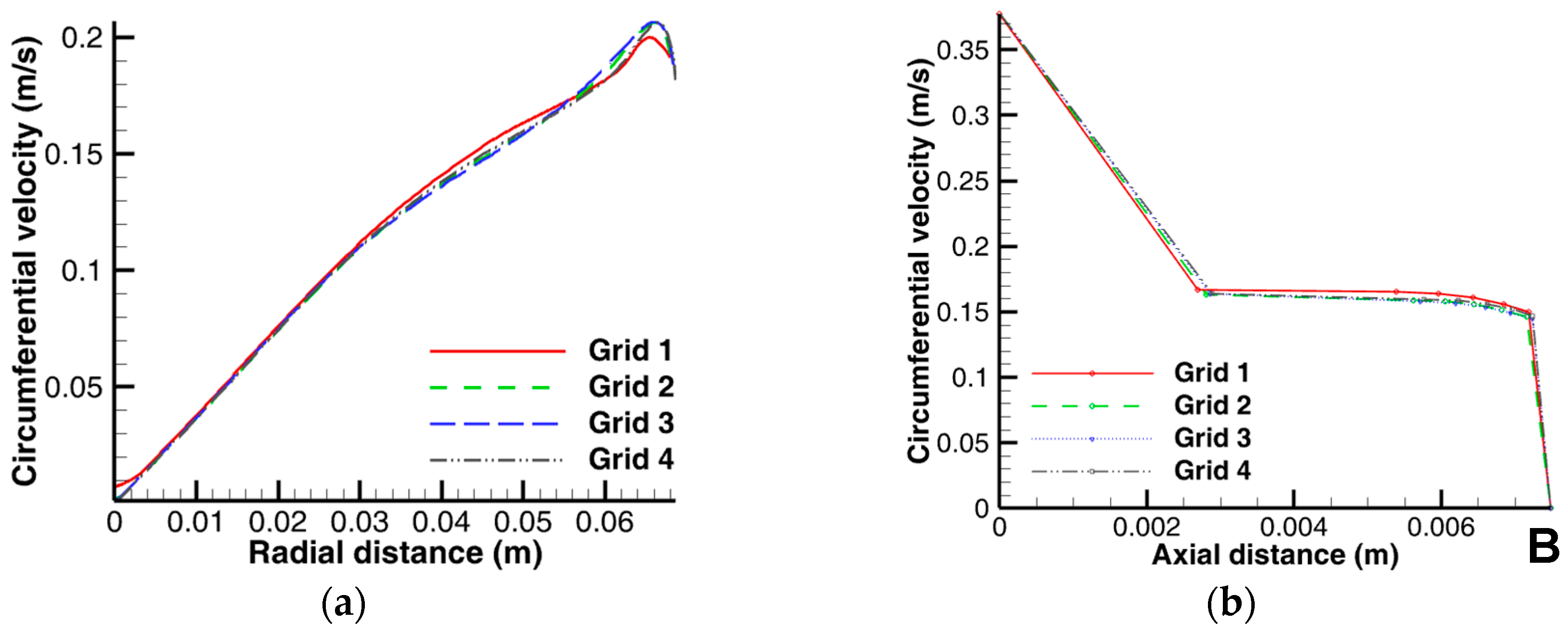

3.1.2. Fluid Flow Domain, Mesh and Grid Convergence

3.2. Numerical Methods and Boundary Conditions

4. Results and Discussion

4.1. Analysis of the Mean Flow Characteristics

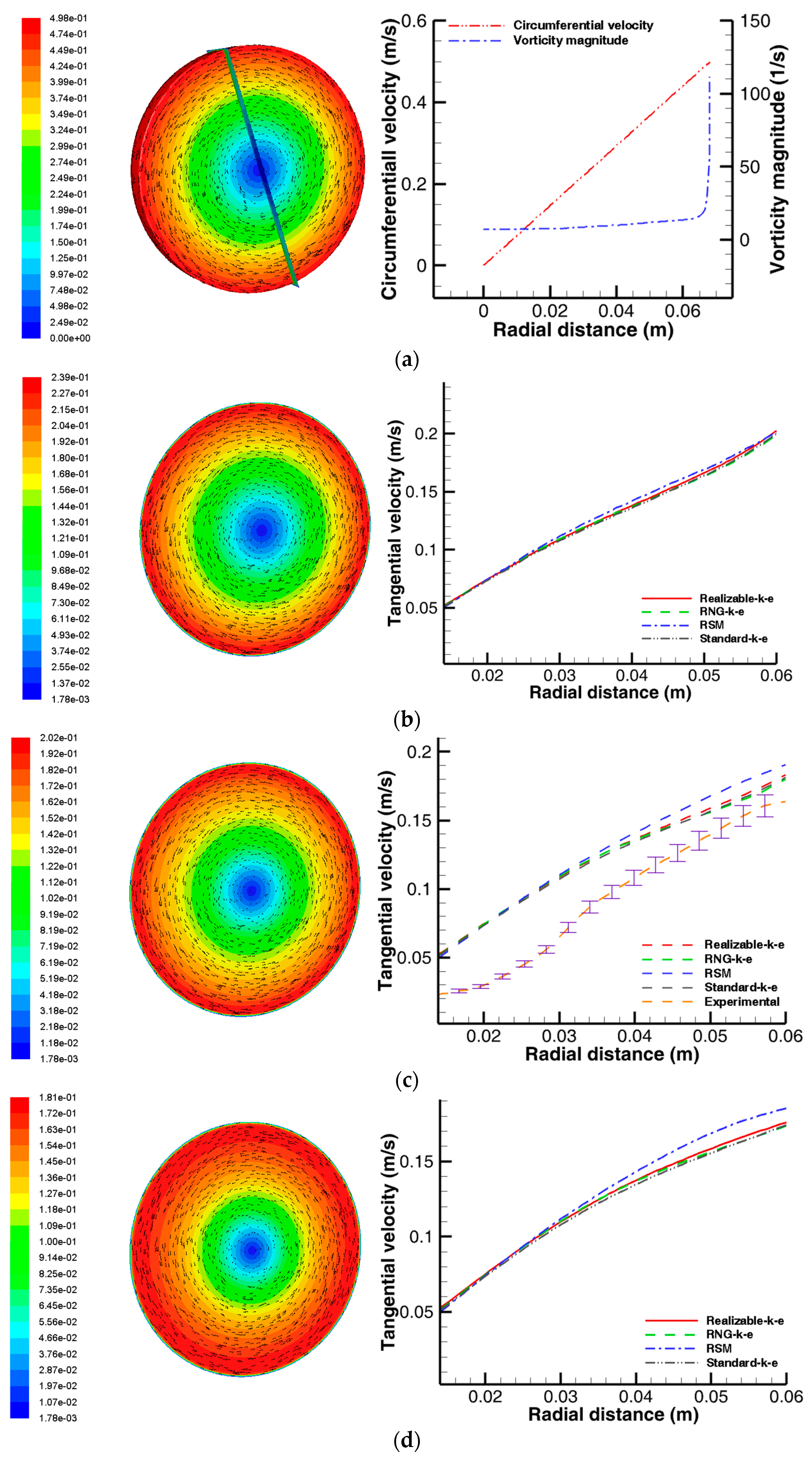

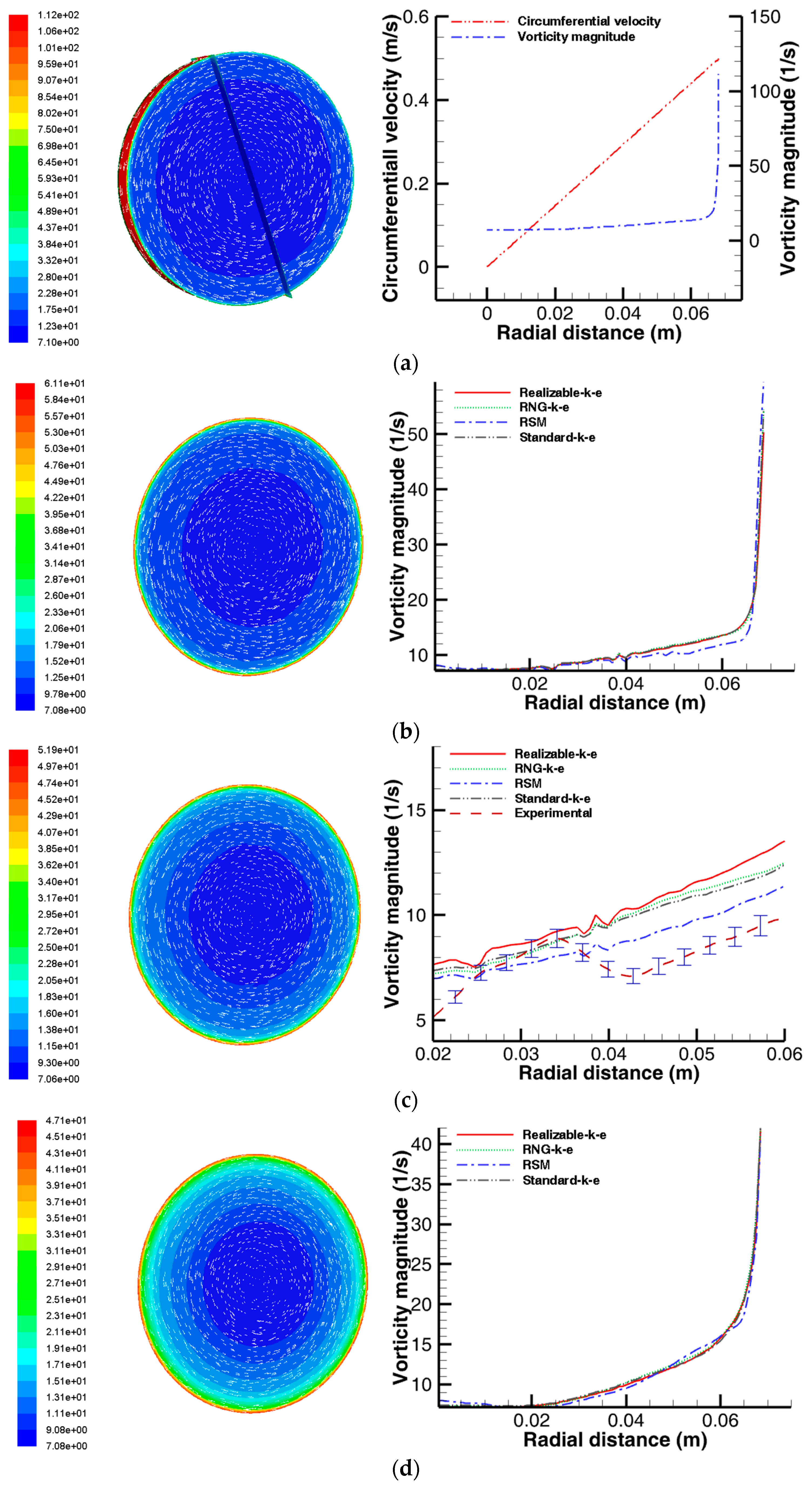

4.1.1. Radial Distribution of the Hydrodynamic Quantities

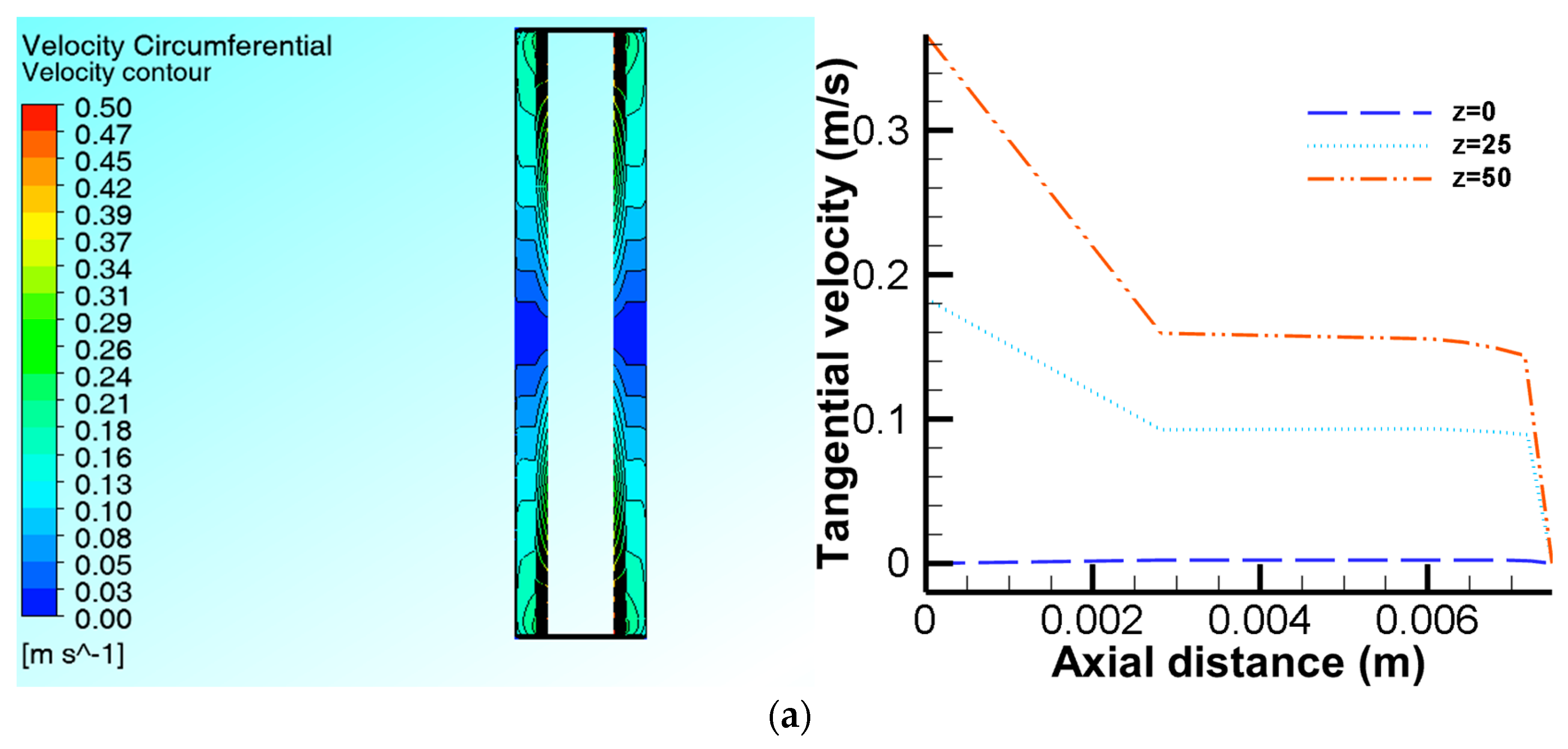

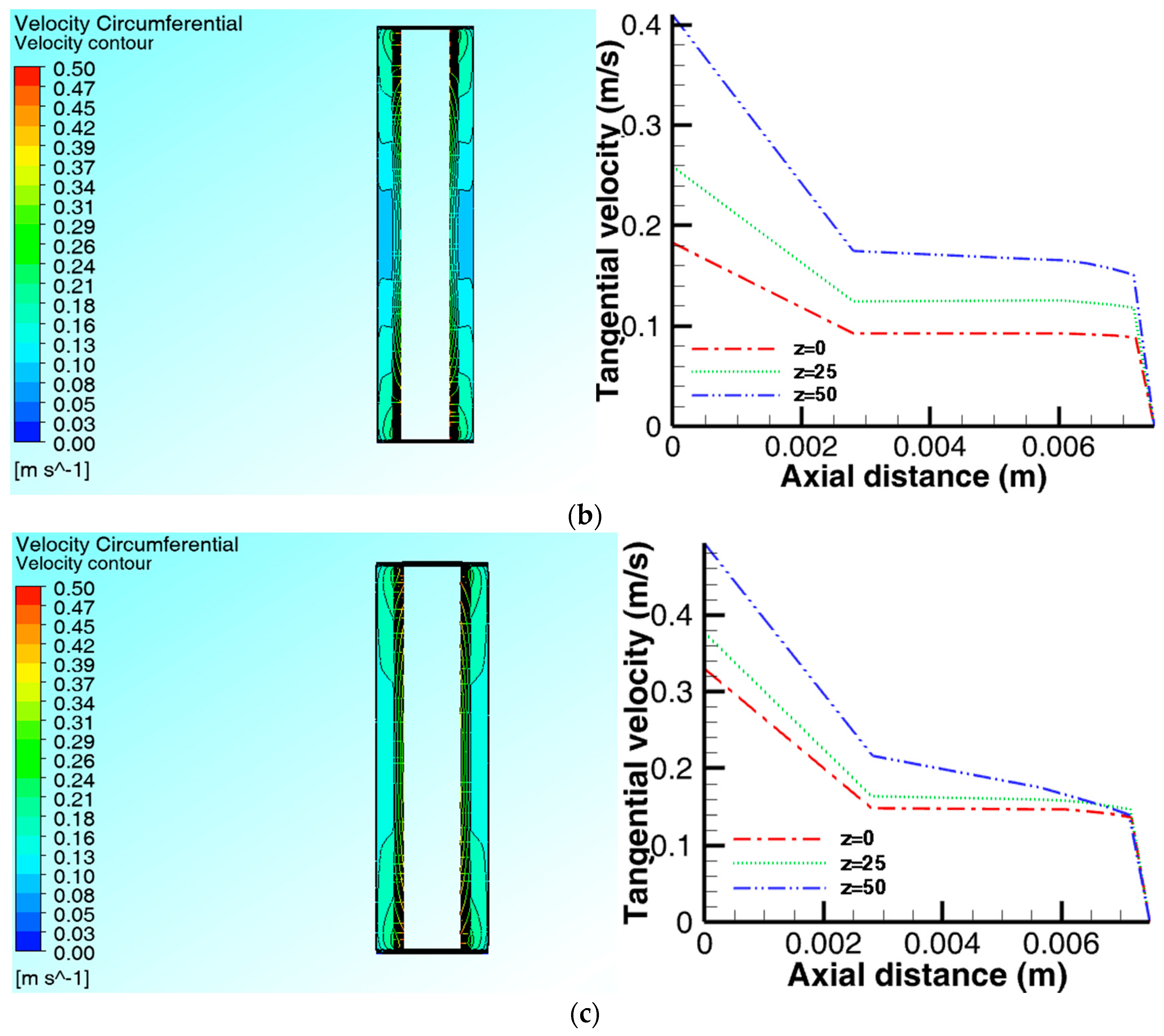

4.1.2. Axial Distribution of the Hydrodynamic Quantities

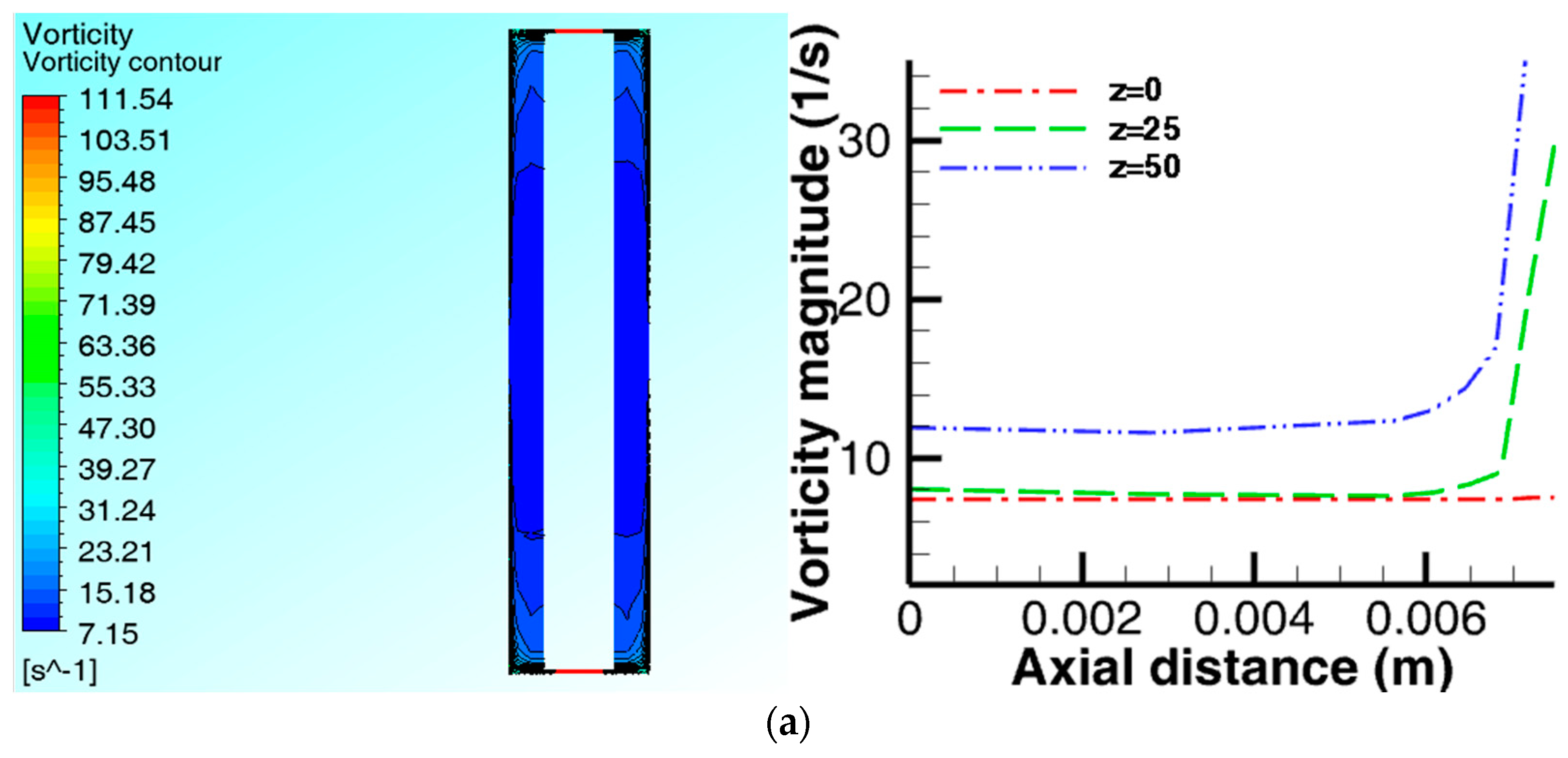

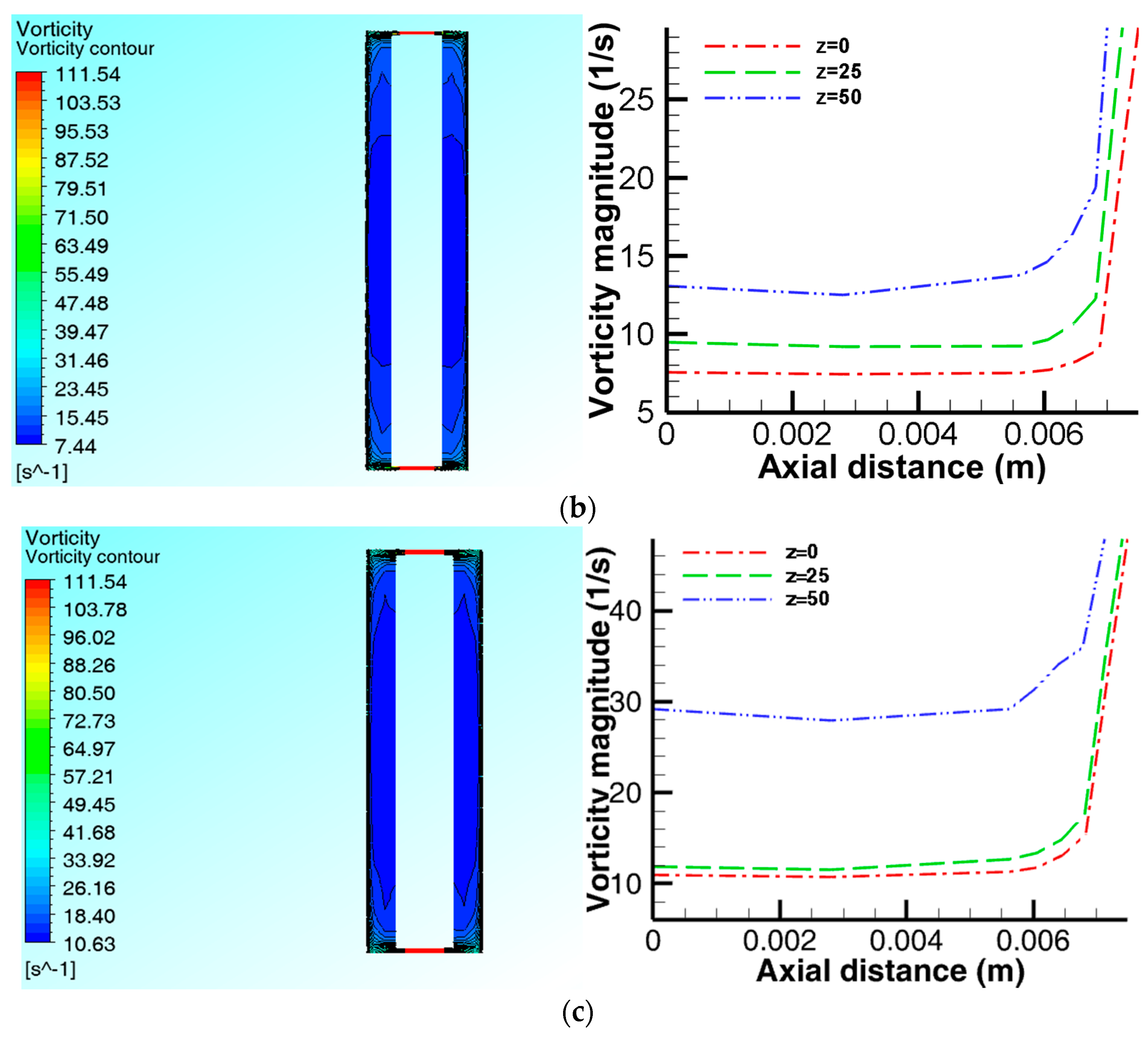

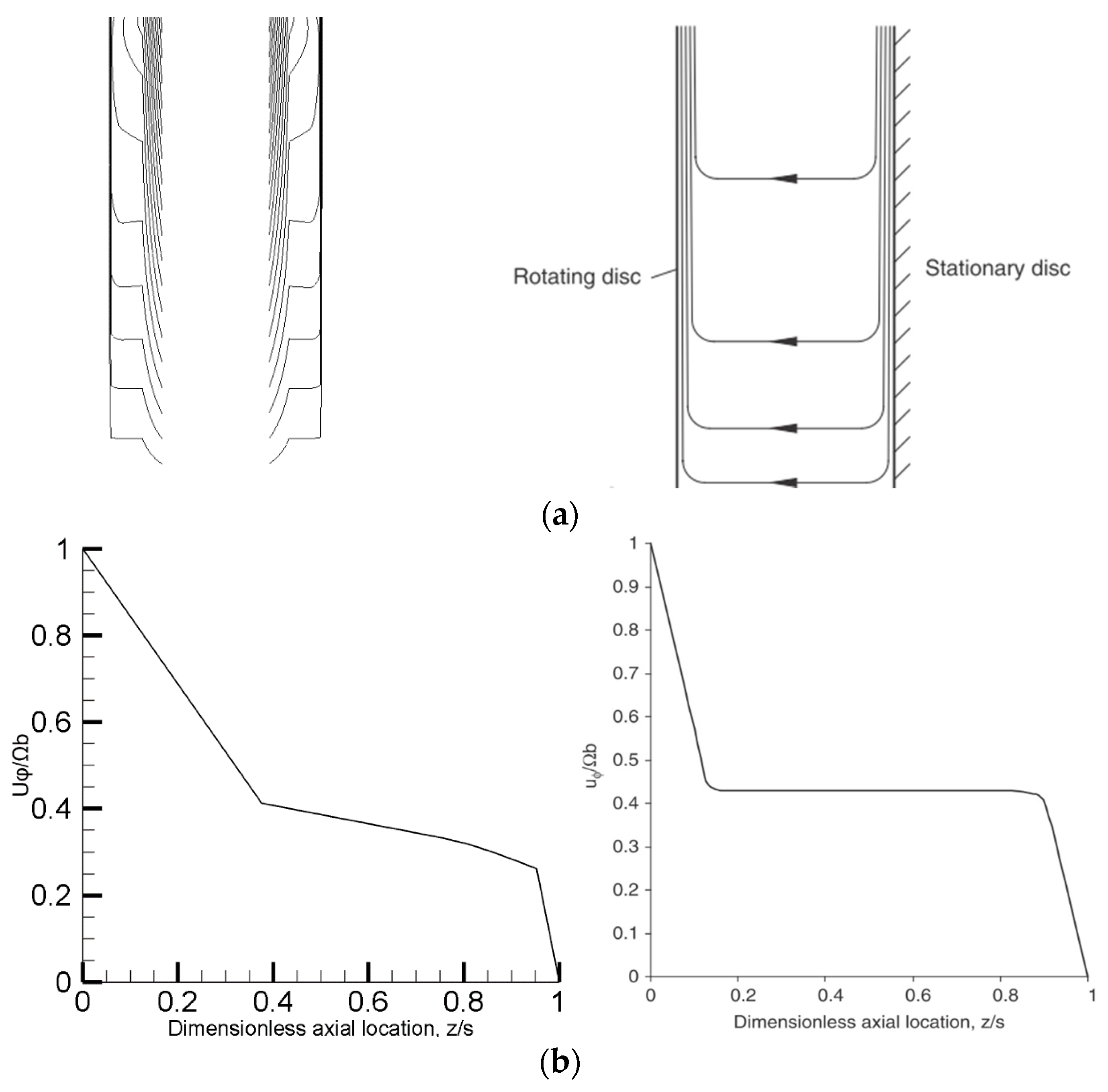

4.1.3. Spatial Distribution of Mixing and Turbulence Intensities

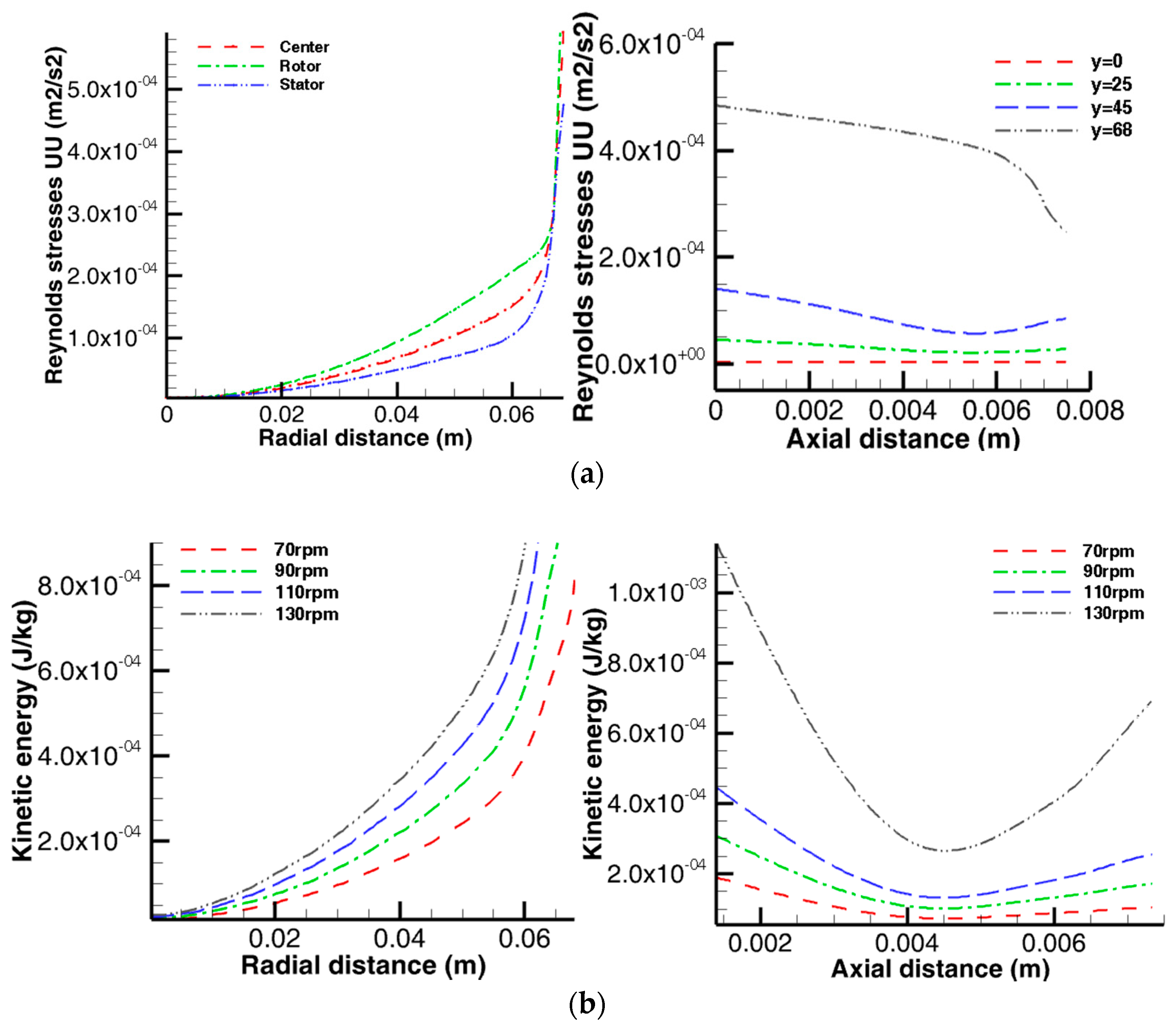

4.1.4. Theoretical Validation of the CFD Model

5. Conclusions

6. Patents

Author Contributions

Funding

Conflicts of Interest

Notations

| Reφ | Rotational Reynolds number (-) |

| ζ | Vorticity magnitude (s−1) |

| G | Gap ratio (-) |

| β | Swirl ratio (-) |

| ρ | Density (kg·m−3) |

| δ | Boundary layer thickness (m) |

| n | Disc rotational speed (s−1) |

| x | Radial coordinate (m) |

| z | Axial coordinate (m) |

| rd | Rotating disc outer radius (m) |

| s | Wheelspace or cavity width (m) |

| µ | Dynamic viscosity (kg·m−1·s−1) |

| ω | Disc or plate angular velocity (rad·s−1) |

| ω′ | Angular velocity of the rotating core (m·s−1) |

| Ω | Disc tangential or tip velocity (m·s−1) |

| Uφ | Tangential velocity component (m·s−1) |

| Ur | Radial velocity component (m·s−1) |

| Uz | Axial velocity component (m·s−1) |

| r | Distance along the r-axis (m) |

| rs | Shaft radius (m) |

| rr | Reactor shroud radius (m) |

| ϕ | Initial particle volume fractions (-) |

References

- Oyegbile, B. Optimization of Micro Processes in Fine Particle Agglomeration by Pelleting Flocculation; CRC Press: Leiden, The Netherlands, 2016; ISBN 978-1-138-02861-6. [Google Scholar]

- Bache, D.H.; Gregory, R. Flocs in Water Treatment; IWA Publishing: London, UK, 2007; ISBN 978-1-84339-063-3. [Google Scholar]

- Buwa, V.; Dewan, A.; Nassar, A.F.; Durst, F. Fluid Dynamics and Mixing of Single-Phase Flow in a Stirred Vessel with a Grid Disc Impeller: Experimental and Numerical Investigations. Chem. Eng. Sci. 2006, 61, 2815–2822. [Google Scholar] [CrossRef]

- Dewan, A.; Buwa, V.; Durst, F. Performance Optimizations of Grid Disc Impellers for Mixing of Single-Phase Flows in a Stirred Vessel. Chem. Eng. Res. Des. 2006, 84, 691–702. [Google Scholar] [CrossRef]

- Utomo, A.T.; Baker, M.; Pacek, A.W. Flow Pattern, Periodicity and Energy Dissipation in a Batch Rotor–Stator Mixer. Chem. Eng. Res. Des. 2008, 86, 1397–1409. [Google Scholar] [CrossRef]

- Utomo, A.; Baker, M.; Pacek, A.W. The Effect of Stator Geometry on the Flow Pattern and Energy Dissipation Rate in a Rotor-Stator Mixer. Chem. Eng. Res. Des. 2009, 87, 533–542. [Google Scholar] [CrossRef]

- Shevchuk, I.V. Modelling of Convective Heat and Mass Transfer in Rotating Flows; Springer: Heidelberg, Germany, 2016; ISBN 978-3-319-20960-9. [Google Scholar]

- Childs, R.N.P. Rotating Flow; Elsevier: Oxford, UK, 2011; ISBN 978-0-12-382098-3. [Google Scholar]

- Gan, X.P.; MacGregor, S.A. Experimental Study of the Flow in the Cavity between Rotating Disks. Exp. Therm. Fluid Sci. 1995, 10, 379–387. [Google Scholar] [CrossRef]

- Cheah, S.C.; Iacovides, H.; Jackson, D.C.; Ji, H.; Launder, B.E. Experimental Investigation of Enclosed Rotor-Stator Disk Flows. Exp. Therm. Fluid Sci. 1994, 9, 445–455. [Google Scholar] [CrossRef]

- Tu, J.; Yeoh, G.H.; Liu, C. Computational Fluid Dynamics: A Practical Approach, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2018; ISBN 978-0-08-101127-0. [Google Scholar]

- Crowe, C.T.; Schwarzkopf, J.D.; Sommerfeld, M.; Tsuji, Y. Multiphase Flows with Droplets and Particles, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2011; ISBN 978-1-4398-4050. [Google Scholar]

- Naessens, W.; Maere, T.; Nopens, I. Critical Review of Membrane Bioreactor Models—Part 1: Biokinetic and Filtration Models. Bioresour. Technol. 2012, 122, 95–106. [Google Scholar] [CrossRef] [PubMed]

- Naessens, W.; Maere, T.; Ratkovich, N.; Vedantam, S.; Nopens, I. Critical Review of Membrane Bioreactor Models—Part 2: Hydrodynamic and Integrated Models. Bioresour. Technol. 2012, 122, 107–118. [Google Scholar] [CrossRef] [PubMed]

- Oyegbile, B.; Hoff, M.; Adonadaga, M.; Oyegbile, B. Experimental Analysis of the Hydrodynamics, Flow Pattern and Wet Agglomeration in Rotor-Stator Vortex Separators. J. Environ. Chem. Eng. 2017, 5, 2115–2127. [Google Scholar] [CrossRef]

- Thomas, S.F.; Rooks, P.; Rudin, F.; Cagney, N.; Balabani, S.; Atkinson, S.; Goddard, P.; Bransgrove, R.M.; Mason, P.T.; Allen, M.J. Swirl Flow Bioreactor Containing Dendritic Copper-Containing Alginate Beads: A Potential Rapid Method for the Eradication of Escherichia Coli from Waste Water Streams. J. Water Process Eng. 2015, 5, 6–14. [Google Scholar] [CrossRef]

- Sievers, M.; Stoll, S.M.; Schroeder, C.; Niedermeiser, M.; Onyeche, T.I. Sludge Dewatering and Aggregate Formation Effects through Taylor Vortex Assisted Flocculation. Sep. Sci. Technol. 2008, 43, 1595–1609. [Google Scholar] [CrossRef]

- Wang, X.C.; Jin, P.K.; Yuan, H.L.; Wang, E.R.; Tambo, N. Pilot Study of a Fluidized-Pellet-Bed Technique for Simultaneous Solid/Liquid Separation and Sludge Thickening in a Sewage Treatment Plant. Water Sci. Technol. 2004, 49, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Dionysiou, D.D.; Balasubramanian, G.; Suidan(M), M.T.; Khodadoust, A.P.; Baudin, I.; Laîné, J.-M. Rotating Disk Photocatalytic Reactor: Development, Characterization, and Evaluation for the Destruction of Organic Pollutants in Water. Water Res. 2000, 34, 2927–2940. [Google Scholar] [CrossRef]

- Loraine, G.; Chahine, G.; Hsiao, C.-T.; Choi, J.-K.; Aley, P. Disinfection of Gram-Negative and Gram-Positive Bacteria Using DynaJets® Hydrodynamic Cavitating Jets. Ultrason. Sonochem. 2012, 19, 710–717. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, S.C.; Eibl, R.; Eibl, D. Engineering Characteristics of a Single-Use Stirred Bioreactor at Bench-Scale the Mobius Cellready 3L Bioreactor as a Case Study. Eng. Life Sci. 2011, 11, 359–368. [Google Scholar] [CrossRef]

- Gao, X.; Kong, B.; Vigil, R.D. Comprehensive Computational Model for Combining Fluid Hydrodynamics, Light Transport and Biomass Growth in a Taylor Vortex Algal Photobioreactor: Lagrangian Approach. Bioresour. Technol. 2017, 224, 523–530. [Google Scholar] [CrossRef] [PubMed]

- Escamilla-Ruíz, I.A.; Sierra-Espinosa, F.Z.; García, J.C.; Valera-Medina, A.; Carrillo, F. Experimental Data and Numerical Predictions of a Single-Phase Flow in a Batch Square Stirred Tank Reactor with a Rotating Cylinder Agitator. Heat Mass Transf. 2017, 53, 2933–2949. [Google Scholar] [CrossRef]

- Liu, Z.; Mahdi, R.; Fox, R.O.; Hill, J.C.; Olsen, M.G. Flow Characteristics in a Scaled-Up Multi-Inlet Vortex Nanoprecipitation Reactor. Ind. Eng. Chem. Res. 2015, 54, 4512–4525. [Google Scholar] [CrossRef]

- Liu, Z.; Fox, R.O.; Hill, J.C.; Olsen, M.G. A Batchelor Vortex Model for Mean Velocity of Turbulent Swirling Flow in a Macroscale Multi-Inlet Vortex Reactor. J. Fluids Eng. 2015, 137. [Google Scholar] [CrossRef]

- Oyegbile, B.; Ay, P.; Narra, S. Optimisation of Micro-Processes for Shear Assisted Solid-Liquid Separation in a Rotatory Batch Flow Vortex Reactor. J. Water Reuse Desalination 2016, 6, 125–136. [Google Scholar] [CrossRef]

- Serra, T.; Colomer, J.; Logan, B.E. Efficiency of Different Shear Devices on Flocculation. Water Res. 2008, 42, 1113–1121. [Google Scholar] [CrossRef] [PubMed]

- Raffel, M.; Willert, C.E.; Wereley, S.T.; Kompenhans, J. Particle Image Velocimetry: A Practical Guide; Springer: Heidelberg, Germany, 2007; ISBN 978-3-540-72307-3. [Google Scholar]

- Adrian, R.J.; Westerweel, J. Particle Image Velocimetry; Cambridge University Press: New York, NY, USA, 2011; ISBN 978-0-521-44008-0. [Google Scholar]

- Bridgeman, J.; Jefferson, B.; Parsons, S.A. Computational Fluid Dynamics Modelling of Flocculation in Water Treatment: A Review. Eng. Appl. Comput. Fluid Mech. 2009, 3, 220–241. [Google Scholar] [CrossRef]

- Marshall, E.M.; Bakker, A. Computational Fluid Mixing. In Handbook of Industrial Mixing: Science and Practice; Paul, E.L., Atiemo-Obeng, V.A., Kresta, S.M., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2004; pp. 257–343. ISBN 978-0-471-45145-7. [Google Scholar]

- ANSYS, Inc. ANSYS Fluent Theory Guide; 18 February 2017; ANSYS, Inc.: Cannonsburg, PA, USA, 2017. [Google Scholar]

- ANSYS, Inc. ANSYS Fluent User’s Guide; 18 February 2017; ANSYS, Inc.: Cannonsburg, PA, USA, 2017. [Google Scholar]

- Lian, G.; Moore, S.; Heeney, L. Population Balance and Computational Fluid Dynamics Modelling of Ice Crystallisation in a Scraped Surface Freezer. Chem. Eng. Sci. 2006, 61, 7819–7826. [Google Scholar] [CrossRef]

- Das, S.; Bai, H.; Wu, C.; Kao, J.-H.; Barney, B.; Kidd, M.; Kuettel, M. Improving the Performance of Industrial Clarifiers Using Three-Dimensional Computational Fluid Dynamics. Eng. Appl. Comput. Fluid Mech. 2016, 10, 130–144. [Google Scholar] [CrossRef]

- Schellander, D. CFD Simulations of Particle Laden Flow: Particle Transport and Separation; Anchor Academic Publishing: Hamburg, Germany, 2014; ISBN 978-3-95489-171-9. [Google Scholar]

- Norouzi, H.R.; Zarghami, R.; Sotudeh-Gharebagh, R.; Mostoufi, N. Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase Flows; John Wiley & Sons: Chichester, UK, 2016; ISBN 978-1-119-00513-1. [Google Scholar]

- Higashitani, K.; Shibata, T.; Matsuno, Y. Formation of Pellet Flocs from Kaolin Suspension and Their Properties. J. Chem. Eng. Jpn. 1987, 20, 152–157. [Google Scholar] [CrossRef]

- Walaszek, W.; Ay, P. Pelleting Flocculation—An Alternative Technique to Optimise Sludge Conditioning. Int. J. Miner. Process. 2005, 76, 173–180. [Google Scholar] [CrossRef]

- Liu, M. CFD Modeling of Stirred Tank Reactors. In Advances in Industrial Mixing: A Companion to the Handbook of Industrial Mixing; Etchells, A.W., Dickey, D.S., Atiemo-Obeng, V.A., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2016; ISBN 978-0-470-52382-7. [Google Scholar]

- Oyegbile, B.; Ay, P.; Narra, S. Flocculation Kinetics and Hydrodynamic Interactions in Natural and Engineered Flow Systems—A Review. Environ. Eng. Res. 2016, 21, 1–14. [Google Scholar] [CrossRef]

- Michaelides, E.; Crowe, C.T.; Schwarzkopf, J.D. (Eds.) Multiphase Flow Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-4987-0100-6. [Google Scholar]

| Operating Condition | Hydrodynamic Parameters | ||

|---|---|---|---|

| Operating Speeds (rpm) | Disc Rotational Reynolds Number (-) | Disc Tip Velocity (m·s−1) | Disc Vorticity (s−1) |

| 70 | 2.59 × 104 | 0.4985 | 14.662 |

| 90 | 3.33 × 104 | 0.6410 | 18.852 |

| 110 | 4.07 × 104 | 0.7834 | 23.041 |

| 130 | 4.81 × 104 | 0.9258 | 27.231 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oyegbile, B.; Akdogan, G.; Karimi, M. Experimental and CFD Studies of the Hydrodynamics in Wet Agglomeration Process. ChemEngineering 2018, 2, 32. https://doi.org/10.3390/chemengineering2030032

Oyegbile B, Akdogan G, Karimi M. Experimental and CFD Studies of the Hydrodynamics in Wet Agglomeration Process. ChemEngineering. 2018; 2(3):32. https://doi.org/10.3390/chemengineering2030032

Chicago/Turabian StyleOyegbile, Benjamin, Guven Akdogan, and Mohsen Karimi. 2018. "Experimental and CFD Studies of the Hydrodynamics in Wet Agglomeration Process" ChemEngineering 2, no. 3: 32. https://doi.org/10.3390/chemengineering2030032

APA StyleOyegbile, B., Akdogan, G., & Karimi, M. (2018). Experimental and CFD Studies of the Hydrodynamics in Wet Agglomeration Process. ChemEngineering, 2(3), 32. https://doi.org/10.3390/chemengineering2030032