Smart Systems: The Role of Advanced Technologies in Improving Business Quality, Performance and Supply Chain Integration

Abstract

:1. Introduction

- RQ 1.:

- What impact does IoT have on e-business?

- RQ 2.:

- How does IoT influence the quality and speed of information flow in the supply chain in the production environment?

- RQ 3.:

- How can companies measure the effective implementation of IoT in their supply chain?

- RQ 4.:

- Is IoT a business management tool that can accelerate innovation and change in a business model thereby driving organisational processes to deliver improved performance?

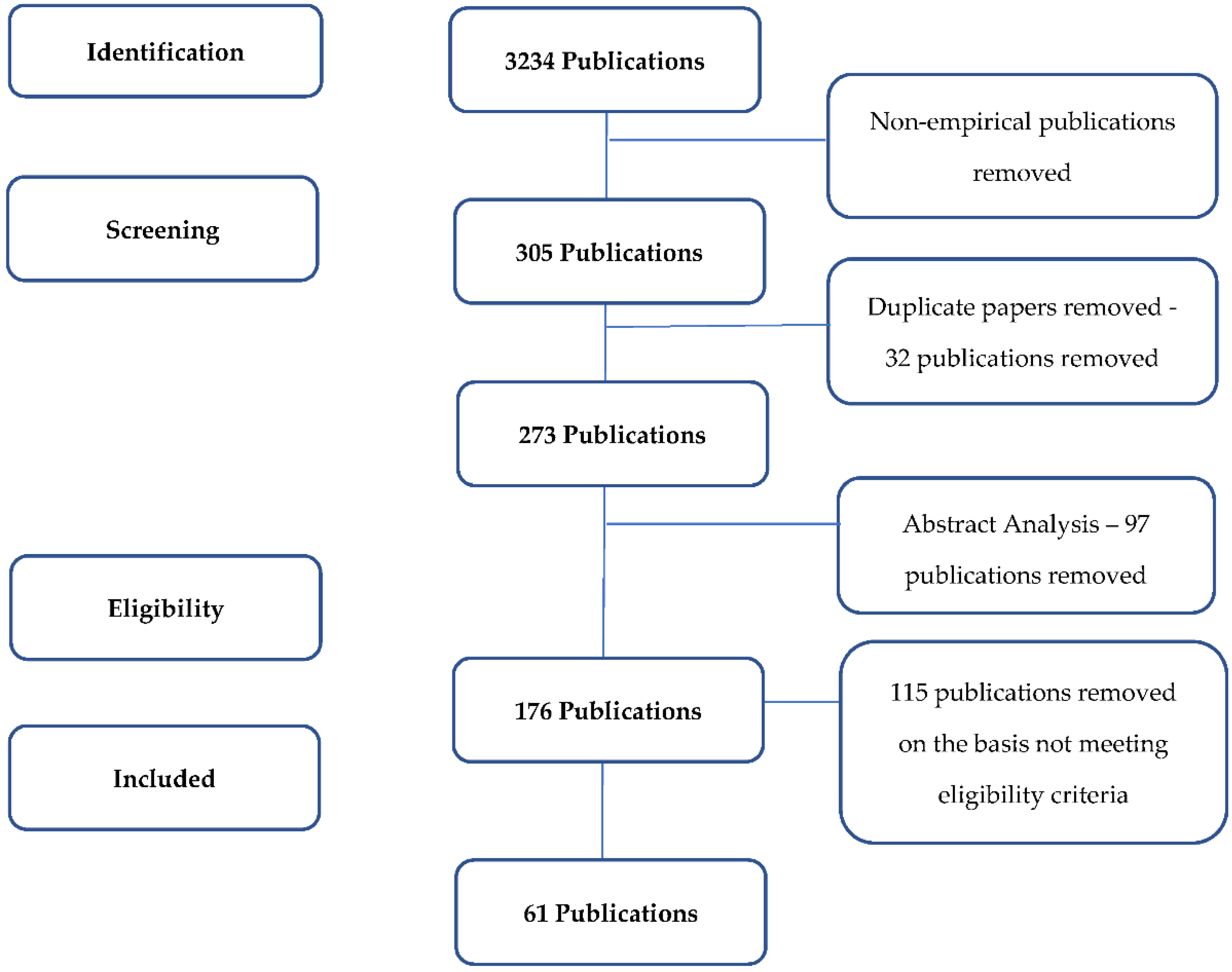

2. Materials and Methods

Systematic Literature Review Design

3. Results

3.1. Introduction

- Adequacy of managerial skills;

- Efficiency of the supply chain i.e., cooperation between the organisation and suppliers;

- Financial aspects, such as reduced costs, or increased profit;

- Performance of business i.e., productivity, quality of product, and service;

- Strategic or operational challenges related to technology such as privacy, security, and lack of skills;

- Technology use such as RFID.

3.2. Business Scenario: Amazon

- RQ1.:

- What impact does IoT make on e-business?

- RQ2.:

- How does IoT influence the quality and speed of information flow in the supply chain in the production environment?

- RQ3.:

- How can companies measure the effective implementation of IoT in their supply chain?

- RQ4.:

- Is IoT a business management tool that can accelerate innovation and change in a business model thereby driving organisational processes to deliver better performances?

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. List of Selected Journal Articles Following Systematic Review and Screening

- Adequacy of managerial skills;

- Efficiency of supply chain i.e., cooperation between the organisation and suppliers;

- Financial aspects such as reduced costs, or increased profit;

- Performance of business i.e., productivity, quality;

- Strategic or operational challenges related to technology such as privacy, security, and lack of skills;

- Technology use such as RFID.

| Authors | Title | Adequacy of Managerial Skills | Efficiency of Supply Chain | Financial Aspects | Performance of Business | Strategic or Operational Challenges | Technology Use | Number of Determinants Identified |

|---|---|---|---|---|---|---|---|---|

| [5] | Using the Internet of Things in a production planning context | X | X | 2 | ||||

| [6] | eBusiness and supply chain integration | X | 1 | |||||

| [7] | Using the Internet of Things in a production planning context | X | X | 2 | ||||

| [12] | A multi-domain trust management model for supporting RFID applications of IoT | X | X | 2 | ||||

| [18] | Exploring new technologies in procurement | X | X | 2 | ||||

| [34] | Toward Industry 4.0 with IoT: optimizing business processes in an evolving manufacturing factory | X | 1 | |||||

| [35] | IoT-based production logistics and supply chain system—Part 2. IoT-based cyber-physical system: a framework and evaluation. | X | X | X | 3 | |||

| [36] | IoT-based production logistics and supply chain system—Part 1. Modeling IoT-based manufacturing supply chain. IoT aware logistics Systems, could computing and agriculture | X | X | 2 | ||||

| [37] | The future of retail supply chains | X | 1 | |||||

| [38] | Radically rethink your strategy: How digital B2B ecosystems can help traditional manufacturers create and protect value | X | X | 2 | ||||

| [39] | The future of the Internet of Things: toward heterarchical ecosystems and service business models. | X | X | 2 | ||||

| [40] | Guide to IoT innovation (SME focus) Achieving innovation performance | X | X | 2 | ||||

| [42] | Digital economy report 2019. Value creation and capture: implications for developing countries. | X | X | 2 | ||||

| [46] | Supply chain inventory collaborative management and information sharing mechanism based on cloud computing and 5G Internet of Things | X | X | 2 | ||||

| [48] | Coronavirus: IoT in challenging times | X | X | 2 | ||||

| [49] | Review of RFID and IoT integration in supply chain management | X | 1 | |||||

| [56] | Internet of Things (IoT): Security Challenges, Business Opportunities & Reference Architecture for e-commerce | X | X | 2 | ||||

| [59] | Smart factory performance and Industry 4.0 | X | X | X | 3 | |||

| [63] | The Internet of Things (IoT): Applications, investments, and challenges for enterprises. | X | 1 | |||||

| [64] | Value co-creation practices in business-to-business platform ecosystems | X | X | 2 | ||||

| [65] | Smart e-commerce systems: current status and research challenges. | X | X | 2 | ||||

| [66] | Supply Chain 4.0—the next-generation digital supply chain, consumer goods | X | X | X | 3 | |||

| [67] | The IoT business index 2020: a step change in adoption | X | 1 | |||||

| [68] | Improving business process and functionality using IoT based E3-value business model. | X | 1 | |||||

| [69] | Reinventing workflows. Power your digital transformation and drive greater impact by modernizing processes | X | X | X | 3 | |||

| [70] | Taking the pulse of enterprise IoT | X | 1 | |||||

| [74] | The Internet of Things and the Modern Supply Chain | X | X | X | 2 | |||

| [75] | The future of retail supply chains | X | 1 | |||||

| [76] | Long and short supply chain co-existence in the agricultural food market on different scales: | X | 1 | |||||

| [77] | Food oligopolies, local economies and the degree of liberalisation of the global market. | X | 1 | |||||

| [78] | Improving business process and functionality using IoT based E3-value business model. | X | 1 | |||||

| [79] | Industries leading IoT revolution | X | X | 2 | ||||

| [80] | Knowledge and skills of industrial employees and managerial staff for the Industry 4-0 implementation | X | 1 | |||||

| [81] | Internet of Things and its impact on business analytics | X | X | 2 | ||||

| [82] | Interdisciplinarily exploring the most potential IoT technology determinants in the Omnichannel e-commerce purchasing decision-making processes | X | X | X | 3 | |||

| [83] | A case study: IoT in logistics and supply chain management: evaluating the adoption rate, associated challenges and impact on cost and business efficiency | X | X | X | X | 4 | ||

| [84] | The roles of internet of things technology in enabling servitized business models: A systematic literature review | X | X | X | X | 4 | ||

| [85] | From intelligent manufacturing to smart manufacturing for industry 4.0 driven by next generation artificial intelligence and further on. | X | X | X | X | X | 5 | |

| [86] | Internet of Things: vision, application areas and research challenges | X | 1 | |||||

| [87] | Circular dairy supply chain management through Internet of Things—enabled technologies | X | X | 2 | ||||

| [88] | Big data analysis of IoT-based supply chain management considering FMCG industries | X | X | 2 |

References

- Mason, T. ICT in business: Tim Mason reviews the various ways in which business use information and communications technology (ICT) particularly the internet, and looks at a variety of case studies. Gale General Onefile. Bus. Rev. 2004, 10, 3. [Google Scholar]

- Chaffey, D. E-Business and E-Commerce Management: Strategy, Implementation and Practice, 4th ed.; Pearson Education Limited: London, UK, 2009. [Google Scholar]

- Hill, T. Manufacturing Strategy. The Strategic Management of the Manufacturing Function, 2nd ed.; The Macmillian Press Ltd.: New York, NY, USA, 1993. [Google Scholar]

- Ayers, J.B. Handbook of Supply Chain Management; CRC Press LLC. St. Lucie Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Guillen, G.; Badell, M.; Puigjaner, L.A. Holistic Framework for Short-Term Supply Chain Management: Integrating Production and Corporate Financial Planning. Int. J. Prod. Econ. 2007, 106, 288–306. [Google Scholar] [CrossRef]

- Smart, A. E-Business and supply chain integration. Emerald Group Publ. J. Enterp. Inf. Manag. 2008, 21, 227–246. [Google Scholar]

- Asthana, D.S.G. E-Tools and Supply Chain Integration A Study of Trends and Opportunities in India. NOLEGEIN-J. Supply Chain Logist. Manag. 2018, 1, 10–14. [Google Scholar]

- Soumyalatha, S.G.H. Study of IoT: Understanding IoT Architecture, Applications, Issues and Challenges. Int. J. Adv. Netw. Appl. (IJANA) 2016, 478, 16. [Google Scholar]

- Borgia, E. The Internet of Things vision: Key features, applications and open issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Reaidy, P.J.; Gunasekaran, A.; Spalanzani, A. Bottom-up approach based on Internet of Things for order fulfillment in a collaborative warehousing environment. Int. J. Prod. Econ. 2015, 159, 29–40. [Google Scholar] [CrossRef]

- Wu, J.; Hisa, T. Developing e-business dynamic capabilities: An analysis of e-commerce innovation from I-, M-, to U-commerce. J. Orgnizational Comput. Electron. Commer. 2008, 18, 95–111. [Google Scholar] [CrossRef]

- Yang, H.; Kumara, S.; Bukkapatnam, S.T.; Tsung, F. The internet of things for smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- McKinsey The Great Re-Make: Manufacturing for Modern Times. McKinsey Company. Available online: https://www.mckinsey.com/~/media/McKinsey/Business%20Functions/Operations/Our%20Insights/The%20great%20remake%20Manufacturing%20for%20modern%20times/The-great-remake-Manufacturing-for-modern-times-full-compenium-October-2017-final.ashx (accessed on 18 May 2022).

- Avelar-Sosa, L.; García-Alcaraz, J.L.; Maldonado-Macías, A.A. Evaluation of Supply Chain Performance. A Manufacturing Industry Approach; Springer International Publishing AG: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Akkermans, H.A.; Bogerd, P.; Yucensan, E.; Wassenhove, L.N. The impact of ERP on supply chain management: Exploratory findings from a European Delphi study. Eur. J. Oper. Res. 2003, 146, 284–301. [Google Scholar] [CrossRef] [Green Version]

- Wagner, C.; Sweeney, E. E-Business in Supply Chain Management. In Electronic Supply Network Coordination in Intelligent and Dynamic Environments: Modelling and Implementation; IGI Global: Hershey, PA, USA, 2010; pp. 24–42. [Google Scholar]

- Chang, H.H.; Tsai, Q.; Hsu, C. E-Procurement and Supply Chain Performance. Supply Chain. Manag. Int. J. 2013, 18, 34–51. [Google Scholar] [CrossRef]

- Computerworld UK Staff. The Most Powerful Internet of Things (IoT) Companies to Watch; Computerworld: London, UK, 2020. Available online: https://www.computerworld.com/article/3412287/the-most-powerful-internet-of-things-iot-companies-to-watch.html (accessed on 20 June 2020).

- Verma, A. The Relationship between IoT, Big Data, and Cloud Computing. Available online: https://www.whizlabs.com/blog/relationship-between-iot-big-data-cloud-computing/#:~:text=IoT%20and%20cloud%20computing%20has,to%20collaborate%20in%20IoT%20development (accessed on 25 June 2020).

- PWC. Digital Factories 2020 Shaping the Future of Manufacturing. Available online: https://www.pwc.de/de/digitale-transformation/digital-factories-2020-shaping-the-future-of-manufacturing.pdf (accessed on 25 June 2020).

- Deloitte. The Future of Procurement in the Age of Digital Supply Networks; Deloitte Development LLC: Stanford, CT, USA. Available online: http://www.deloitte.com (accessed on 16 May 2022).

- Adams, H. How the IoT is Changing the Future of the eCommerce Industry. Available online: https://www.geospatialworld.net/blogs/how-the-iot-is-changing-the-future-of-the-ecommerce-industry/ (accessed on 23 June 2022).

- Fortune Business Insights. Internet of Things (IoT) in Manufacturing Market Size. Available online: https://www.fortunebusinessinsights.com/industry-reports/internet-of-things-iot-market-100307 (accessed on 20 June 2022.).

- Digiteum. The Internet of Things in Manufacturing: How IoT is Changing Manufacturing. Digiteum 2019. Available online: https://www.digiteum.com/iot-manufacturing (accessed on 20 June 2020).

- O’Gorman, K.; MacIntosh, R. Research Methods for Business & Management. A Guide to Writing Your Dissertation, 2nd ed.; Goodfellow Publishers Ltd.: Oxford, UK, 2015. [Google Scholar]

- McDonough, J.; McDonough, S. Research Methods for English Language Teachers; Arnold: London, UK, 1997. [Google Scholar]

- Dubois, A.; Salmi, A. A call for broadening the range of approaches to case studies in purchasing and supply management. J. Purch. Supply Manag. 2016, 22, 247–249. [Google Scholar] [CrossRef]

- Stake, R.E. The Art of Case Study Research; Sage Publications: London, UK, 1995. [Google Scholar]

- Creswell, J.W. Qualitative Inquiry and Research Design: Choosing among Five Approaches; Sage: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Mills, A.J.; Durepos, G.; Wiebe, E. Encyclopaedia of Case Study Research; SAGE Publications Inc.: Thousand Oaks, CA, USA, 2012. [Google Scholar] [CrossRef]

- Lund, T. Combining Qualitative and Quantitative Approaches: Some Arguments for Mixed Methods Research. Scand. J. Educ. Res. 2012, 56, 155–165. [Google Scholar] [CrossRef]

- Zainal, Z. Case Study as a Research Method. J. Kemanus. Bil 2007, 5, 1. Available online: http://psyking.net/htmlobj-3837/case_study_as_a_research_method.pdf (accessed on 10 May 2022).

- Tsang, E.W. Generalizing from Research Findings: The Merits of Case Studies. Int. J. Manag. Rev. 2013, 16, 369–383. [Google Scholar] [CrossRef]

- Belli, L.; Davoli, L.; Medioli, A.; Marchini, P.L.; Ferrari, G. Toward Industry 4.0 With IoT: Optimizing Business Processes in an Evolving Manufacturing Factory. Front. ICT 2019, 6. [Google Scholar] [CrossRef]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-Based Production Logistics and Supply Chain System—Part 2. IoT-Based Cyber-Physical System: A Framework and Evaluation. Emerald Insight. Ind. Manag. Data Systems. 2018, 118, 96–125. Available online: www.emeraldinsight.com/0263-5577.htm (accessed on 10 May 2022). [CrossRef] [Green Version]

- Patil, V.C.; Al-Gaardi, K.A.; Biradar, D.P.; Rangaswamy, M. Internet of Things (IoT) and cloud computing for agriculture: An overview. 2012. In Proceedings of the AIPA India Agro-Informatics and Precision Agriculture 2012, New Dehri, India, 3–8 June 2012. [Google Scholar]

- Zarrella, E.; Chamberlain, R.; Liddell, P. The Future of Retail Supply Chains KPMG 2016 May In Association with HSBC. Available online: http://www.kpmg.com (accessed on 15 July 2020).

- Meffert, J.; Patel, M.; Stuetzle, R. Radically Rethink Your Strategy: How Digital B2B Ecosystems Can Help Traditional Manufacturers Create and Protect Value. Available online: https://www.mckinsey.com/business-functions/mckinsey-digital/our-insights/radically-rethink-your-strategy-how-digital-b2b-ecosystems-can-help-traditional-manufacturers-create-and-protect-value (accessed on 10 May 2022).

- Silva, E.M.; Maló, P. IoT testbed business model Advances in Internet of Things. Sci. Res. 2014, 4, 37–45. [Google Scholar] [CrossRef]

- Lueth, K.L.; Glienke, D.; Williams, Z.D. Guide to IoT Innovation (SME focus) Achieving Innovation Performance IoT Analytics; Next Big Thing: Hongkong, China, 2017; Available online: http://www.iot-analytics.com (accessed on 25 June 2020).

- Aversa, P.; Haefliger, S.; Hueller, F.; Reza, D.G. Customer Complementarity in the Digital Space: Exploring Amazon’s Business Model Diversification Long Range Planning; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- UNCTAD. Digital Economy Report 2019; Value Creation and Capture: Implications for Developing Countries; United Nations: New York, NY, USA, 2020; Available online: http://www.un.org/publications (accessed on 25 June 2020).

- Amazon. Amazon Fulfillment. Available online: https://www.aboutamazon.com/amazon-fulfillment#what-is-a-fulfillment-center (accessed on 5 July 2020.).

- Amazon Staff. What Robots Do (and Don’t Do) at Amazon Fulfilment Centers. Available online: https://www.aboutamazon.com/amazon-fulfillment/our-innovation/what-robots-do-and-dont-do-at-amazon-fulfillment-centers/ (accessed on 5 July 2020).

- Simon, M. Inside the Amazon Warehouse where Humans and Machines Become One. 2019. Available online: https://www.wired.com/story/amazon-warehouse-robots/ (accessed on 10 July 2020).

- Zhang, J.; Onal, S.; Das, R. Fulfilment time performance of online retailers—An empirical analysis. Int. J. Retail. Distrib. Manag. 2019, 47, 493–510. [Google Scholar] [CrossRef]

- Material Handling and Logistics. Walmart Unveils Robot-Run Warehouse to Whisk Food to Your Car. Available online: https://www.mhlnews.com/technology-automation/article/21120053/walmart-unveils-robotrun-warehouse-to-whisk-food-to-your-car (accessed on 10 July 2020).

- Jagannath, J. Flipkart Raises $1.2bn in Walmart-Led Funding at Near $25 Billion Valuation. Available online: https://www.ft.com/content/0b50686d-a6e7-4a85-b984-d1029db23c5a (accessed on 23 June 2022).

- The Future Factory. An Analysis of Amazon’s Digital Supply Chain. Available online: https://www.thefuturefactory.com/blog/30 (accessed on 5 July 2020).

- Amazon. AWS Cloud Data Ingestion Patterns and Practices. Available online: https://docs.aws.amazon.com/whitepapers/latest/aws-cloud-data-ingestion-patterns-practices/aws-cloud-data-ingestion-patterns-practices.html?did=wp_card&trk=wp_card (accessed on 23 June 2022).

- Amazon. Manufacturing Operations in the Cloud. Available online: https://d1.awsstatic.com/Industries/Manufacturing/AWS_Infographic_Smart_Factory_Final2020.pdf (accessed on 5 July 2021).

- Amazon. What is Cloud Computing? Available online: https://aws.amazon.com/what-is-cloud-computing/?nc1=f_cc (accessed on 23 June 2022).

- Amazon. Siemens Uses AWS to Reduce Power Plant Alerts by 90%. Available online: https://aws.amazon.com/solutions/case-studies/siemens-ic/ (accessed on 23 June 2022).

- Amazon. Siemens on AWS Case Studies. Available online: https://aws.amazon.com/solutions/case-studies/siemens/ (accessed on 23 June 2022).

- Amazon. Shell Information Technology International BV Proactively Identifies Cybersecurity Threats Using AWS. Available online: https://aws.amazon.com/solutions/case-studies/royal-dutch-shell/ (accessed on 23 June 2022).

- Amazon. Pentair Uses AWS IoT to Improve Beer-Filtration Processes and Boost Performance by 10%. Available online: https://aws.amazon.com/solutions/case-studies/pentair/ (accessed on 23 June 2022).

- Amazon. Real Time Communication on AWS. Available online: https://docs.aws.amazon.com/whitepapers/latest/real-time-communication-on-aws/welcome.html?did=wp_card&trk=wp_car (accessed on 23 June 2022).

- Amazon. Security Best Practices in Manufacturing —Manufacturing Operations in the Cloud. Available online: https://aws.amazon.com/manufacturing/smart-factory/ (accessed on 5 June 2022).

- Amazon. Warehouse Management. Available online: https://aws.amazon.com/solutions/retail/warehouse-management/?marketplace-ppa-and-quickstart.sort-by=item.additionalFields.sortDate&marketplace-ppa-and-quickstart.sort-order=desc (accessed on 5 June 2022).

- Kim, E. Inside Jeff Bezos’ Delivery Drone Dreams: With Fake Team Names, Changing Leaders and Delays, Amazon Prime Air is Fighting to Finally Take Off. Available online: https://www.businessinsider.com/inside-amazons-prime-air-drone-delivery-team-2020-6?r=US&IR=T (accessed on 23 June 2022).

- Kumar, S.; Eidem, J.; Perdomo, D.N. Reflective Practice. Clash of the E-Commerce Titans. A New Paradigm for Consumer Purchase Process Improvement. Int. J. Product. Perform. Manag. 2012, 61, 805–860. Available online: https://www.emerald.com/insight/content/doi/10.1108/17410401211263872/full/pdf?title=clash-of-the-ecommerce-titans-a-new-paradigm-for-consumer-purchase-process-improvement (accessed on 21 June 2022). [CrossRef]

- Siemens. Additive Manufacturing Network. Available online: https://additive-manufacturing-network.sws.siemens.com/ (accessed on 10 July 2020).

- Lee, H.L. Creating Value through Supply Chain Integration. The Free Library 1 September 2000. Available online: https://www.thefreelibrary.com/CREATING%20VALUE%20through%20Supply%20Chain%20INTEGRATION.-a064972562 (accessed on 23 June 2022).

- Meyer, G.G.; Wortmann, J.; Szirbik, N.B. Production monitoring and control with intelligent products. Int. J. Prod. Res. 2011, 49, 1303–1317. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Alicke, K.; Rexhausen, D.; Seyfert, A. Supply Chain 4.0 in Consumer Goods. 2017. Available online: https://www.mckinsey.com/industries/consumer-packaged-goods/our-insights/supply-chain-4-0-in-consumer-goods (accessed on 12 June 2022).

- The Economist. The IoT Business Index 2020: A Step Change in Adoption; The Economist: London, UK, 2020. [Google Scholar]

- Shoukry, A.; Khader, J.; Gani, S. Improving Business Process and Functionality Using IoT Based E3-Value Business Model; Springer Electronic Markets: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Linthwaite, R. Reinventing Workflows. Power Your Digital Transformation and Drive Greater Impact by Modernizing Processes. A Forrester Consulting Thought Leadership Paper Commissioned By IBM. Available online: http://www.forrester.com (accessed on 7 June 2022).

- Chui, M.; Ganesan, V.; Patel, M. Taking the Pulse of Enterprise IoT; McKinsey&Company, High Tech: Chicago, MI, USA, 2017; Available online: https://www.mckinsey.com/featured-insights/internet-of-things/our-insights/taking-the-pulse-of-enterprise-iot (accessed on 12 May 2022).

- Lopes, A.; Polónia, D.; Gradim, A.; Cunha, J. Challenges in the Integration of Quality and Innovation Management Systems. Standards 2022, 2, 52–65. [Google Scholar] [CrossRef]

- Fukami, Y. Two Obstacle Factors for Technological Standardization: The Viewpoint of Technological Frame. Standards 2022, 2, 1–13. [Google Scholar] [CrossRef]

- Kahkönen, A.-K.; Lintukangas, K.; Virolainen, V.M. The effects of e-business on supply management. Oper. Supply Chain. Management. 2013, 6, 2. [Google Scholar] [CrossRef]

- Ayers, J.B.; Odegaard, M.A. Retail Supply Chain Management; Auerbach Publications, Taylor&Francis Group: Houston, TX, USA, 2008. [Google Scholar]

- DemandCaster. The Long and the Short of IT: Variables in Managing Long and Short Supply Chain Legs. DemandCaster 2019. Available online: https://www.demandcaster.com/blog-news/the-long-and-the-short-of-it-variables-in-managing-long-and-short-supply-chain-legs/#:~:text=Long%20and%20Short%20Supply%20Chain%20Impacts%20Cost%20%E2%80%93%20When%20supply%20chains,chain%20may%20impact%20product%20cost.&text=Short%20Supply%20Chain%20Legs%20are,legs%20are%20easier%20to%20manage (accessed on 27 June 2020).

- Xu, J.; Pero, M.E.P.; Ciccullo, F.; Sianesi, A. On relating big data analytics to supply chain planning: Towards a research agenda. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 656–682. [Google Scholar] [CrossRef]

- Barton, D. Keeping it Local: How Shorter Supply Chains Impact Supply Chain Planning. Available online: https://www.toolsgroup.com/blog/keeping-it-local-how-shorter-supply-chains-impact-supply-chain-planning/ (accessed on 22 June 2022).

- Denisco-Rayome, A. The Five Industries Leading the IoT Revolution. Available online: https://www.zdnet.com/article/the-five-industries-leading-the-iot-revolution/ (accessed on 22 June 2022).

- Saniuk, S.; Caganova, D.; Saniuk, A. Knowledge and Skills of Industrial Employees and Managerial Staff for the Industry 4.0 Implementation. Mob. Netw. Appl. 2021. [Google Scholar] [CrossRef]

- Yerpude, S.; Singhal, T.K. Internet of Things based Customer Relationship Management—A Research Perspective. Int. J. Eng. Technol. 2018, 7, 44. [Google Scholar] [CrossRef]

- Hsieh, N.-K.; Kang, T.-S.; Chen, T.-S.; Chang, J.-K.; Wang, M.C.; Chen, T.-S.; Chung, Y.-F. The Implementation of IoT-based Smart Laboratory Management System. In Proceedings of the 2020 ACM International Conference on Intelligent Computing and its Emerging Applications, GangWon, Korea, 12–15 December 2020. [Google Scholar]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A Model for Understanding the Mediating Association of Transparency between Emerging Technologies and Humanitarian Logistics Sustainability. Sustainability 2022, 14, 6917. [Google Scholar] [CrossRef]

- Suppatvech, C.; Godsell, J.; Day, S. The roles of internet of things technology in enabling servitized business models: A systematic literature review. Ind. Mark. Manag. 2019, 82, 70–86. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, J.; Zhang, J.; Boër, C.R. From Intelligent Manufacturing to Smart Manufacturing for Industry 4.0 Driven by Next Generation Artificial Intelligence and Further On. In Proceedings of the 2017 5th International Conference on Enterprise Systems (ES), Beijing, China, 22–24 September 2017; pp. 311–318. [Google Scholar] [CrossRef]

- Shahid, N.; Aneja, S. Internet of Things: Vision, application areas and research challenges. In Proceedings of the 2017 International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Tamil Nadu, India, 6–8 September 2017; pp. 583–587. [Google Scholar]

- Kazancoglu, Y.; Sagnak, M.; Mangla, S.K.; Sezer, M.D.; Pala, M.O. A fuzzy based hybrid decision framework to circularity in dairy supply chains through big data solutions. Technol. Forecast. Soc. Change 2021. [Google Scholar] [CrossRef]

- Nozari, H.; Fallah, M.; Kazemipoor, H.; Najafi, S.E. Big data analysis of IoT-based supply chain management considering FMCG industries. Bus. Inform. 2021, 15, 78–96. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmidt, I.; Morris, W.; Thomas, A.; Manning, L. Smart Systems: The Role of Advanced Technologies in Improving Business Quality, Performance and Supply Chain Integration. Standards 2022, 2, 276-293. https://doi.org/10.3390/standards2030020

Schmidt I, Morris W, Thomas A, Manning L. Smart Systems: The Role of Advanced Technologies in Improving Business Quality, Performance and Supply Chain Integration. Standards. 2022; 2(3):276-293. https://doi.org/10.3390/standards2030020

Chicago/Turabian StyleSchmidt, Ivett, Wyn Morris, Andrew Thomas, and Louise Manning. 2022. "Smart Systems: The Role of Advanced Technologies in Improving Business Quality, Performance and Supply Chain Integration" Standards 2, no. 3: 276-293. https://doi.org/10.3390/standards2030020

APA StyleSchmidt, I., Morris, W., Thomas, A., & Manning, L. (2022). Smart Systems: The Role of Advanced Technologies in Improving Business Quality, Performance and Supply Chain Integration. Standards, 2(3), 276-293. https://doi.org/10.3390/standards2030020