Abstract

Exhaust emissions from ships are significant threats to the environment and human health, necessitating effective control measures and treatment technologies. In response to the increasing stringency of emission regulations set by the International Maritime Organization (IMO) and national governments, the shipping industry must adopt advanced techniques to mitigate these emissions. The study focuses on the current status of exhaust pollution prevention and control on the Lijiang River and describes the latest progress in ship emission management. It summarizes the sources and hazards of nitrogen oxides (NOX), sulfur oxides (SOX), and particulate matter (PM) emitted from ships. The study introduces and compares several exhaust treatment key technologies for desulfurization, denitrification, and integrated desulfurization and denitrification to emphasize their principles, processes, and characteristics. It also demonstrates the future prospects for controlling exhaust gas pollution on inland ships and advocates for the development of integrated technologies that are efficient, space-saving, and cost-effective. The research aims to provide a valuable reference for inland ship exhaust pollution prevention and control.

1. Introduction

As a pillar of global trade, the shipping industry has an indispensable influence in promoting world economic growth. Nevertheless, the rapid development of inland river shipping has aroused great concern about its impact on air quality, because of its high maneuverability, wide voyage, and long duration of ship operation [1]. Inland ship benefits are based on environmental quality, scenic views of the nearby coastal areas, and the efficiency of the tourist services offered. They are, therefore, vulnerable to human activities that can adversely affect the ecosystem of the nearby areas. In addition, the poorer quality of marine fuels in comparison with vehicle fuels contributes to the increase in emissions. Currently, inland waterway vessels mainly use diesel engines as power sources, and the combustion of this oil releases a large number of harmful substances [2]. Annually, marine diesel engines emit around 20 million tons of nitrogen oxides (NOX), 10 million tons of sulfur oxides (SOX), and 1 million tons of particulate matter (PM) [3]. It is projected that by 2050, the international fleet’s global emissions of sulfur dioxide (SO2) and NOX will amount to 25.9 and 38.8 million tons, respectively [4]. China’s inland waterway shipping consists mainly of small-tonnage and older vessels that have long relied on low-quality fuel oil, leading to more serious and complex environmental pollution problems. Emissions from ships can contribute significantly to air pollution, especially along inland waterways in densely populated cities. Air pollution is a pressing global issue that casts a shadow over public health and attracts more and more attention around the world [5]. According to statistical reports from the World Health Organization (WHO), accessible via its health statistics portal, the Global Health Observatory, air pollution is responsible for approximately 7 million deaths globally each year [6]. Alarmingly, WHO claimed that almost all the people in the world (99%) breathe more air than the limit, especially in low-income and middle-income countries in 2024. At the same time, the latest State of Global Air (SoGA) report in June 2024 indicated that air pollution contributed to roughly 8.1 million fatalities globally [7]. In order to tackle the issue, a Code for the prevention of air pollution from ships (MARPOL 73/78 Annex VI) has been put in place by the International Maritime Organization (IMO). Countries around the world have also issued regional standards for ship emissions. In recent years, the EU and the US updated the emission standards for inland waterway vessels, while China also issued the first national standard for the control of emissions from ship engines. In response to increasingly stringent emissions regulations, marine diesel engines utilize three main strategies for reducing emissions: fuel technology advancements, in-cylinder purification methods, and exhaust gas aftertreatment processes [8]. Emissions can be reduced by exhaust gas aftertreatment with little or no impact on engine power and fuel economy. Therefore, it is an urgent problem to solve ship emissions, especially the pollution control of SOx and NOx, which is of great significance for the construction of green harbors [9].

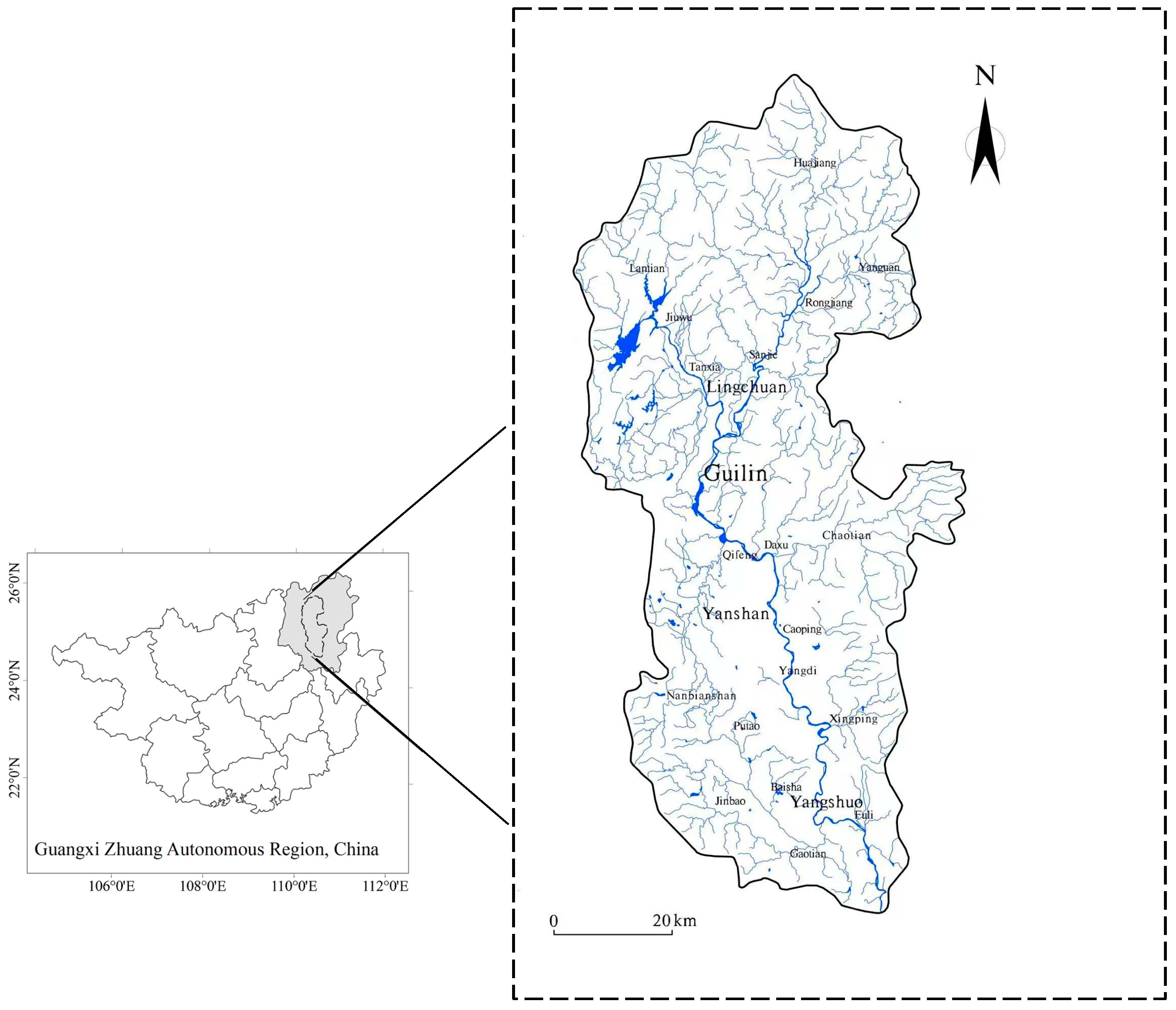

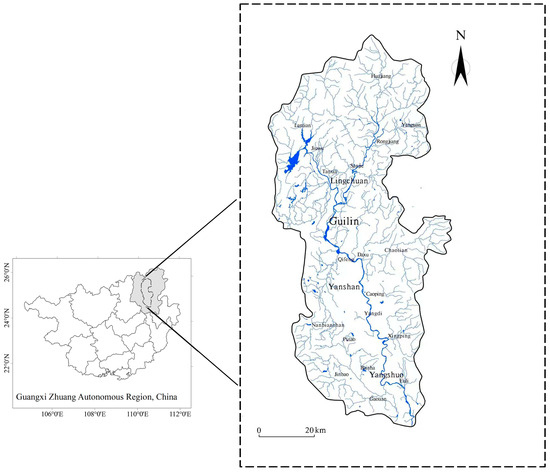

The Lijiang River, a renowned tourist destination in China, lies within the city of Guilin, positioned in the northeastern part of the Guangxi Zhuang Autonomous Region. The watershed map of the Lijiang River is shown in Figure 1. The Lijiang River Basin serves as the central hub for Guilin’s socioeconomic expansion. This development has primarily centered on bolstering the agricultural and tourism sectors. In the Lijiang River Basin, tourism stands out as a pivotal industry. Tourism has boomed in the basin since 2000. In 2010, the tourist reception exceeded 18 million and the total tourism revenue was 13 billion, with a growth rate of 13.9% per annum. In 2023, an unprecedented 1.39 billion tourists visited the Lijiang River Basin, among whom the water tourist flow of the Lijiang River exceeded 11.1 million. Data statistics show Lijiang River tourist ships set sail a total of 83,000 times and sent 4.2 million tourists in 2023. Recent studies have reported a wide range of adverse impacts on ecosystems as well as on human well-being as a result of the development of tourism, including water pollution, air pollution, water scarcity, and cultural effects [10]. Shipping activities are recognized as an important factor contributing to global air contamination [11,12]. At present, more studies focus on ship exhaust emissions from ocean transportation and fewer reports on inland waterway vessel exhaust and regulation. Due to the limited range of activities and close to densely populated areas, the requirements for inland ship exhaust emissions are more stringent, especially for cruise ships operating in scenic spots. The gas pollution emitted by them is more harmful to human beings. Balancing the interplay between tourism growth and environmental preservation is a crucial matter to consider in the sustainable development of tourism [10].

Figure 1.

Map of Lijiang River Basin. (black lines represent watershed, grey blue lines represent tributary and blue lines represent main stream in the right figure).

Taking the Lijiang River as an example, this paper reviews the exhaust emission status of ships on the Lijiang River, the regulations on ship exhaust emissions, and the positive measures that have been taken to deal with ship exhaust contamination in the Lijiang River. In addition, this review also systematically summarizes the control methods for SOX and NOX emissions and the desulfurization and denitrification processes, as well as the applicability of these technologies in marine diesel engines. The primary aim of this study is to offer vital guidance for research on optimizing methods and decision-making systems for ship energy consumption and emissions, so as to help the green development of the shipping sector in the future.

2. Lijiang River Ship Emission Status and Regulation

2.1. Lijiang River Emission Status

Ship exhaust pollution in the Lijiang River mainly originates from ship moving, ship stopping, diesel cooking, and shipbuilding enterprises. As of September 2022, there are 255 passenger boats for tourism, 40 boats for government use, 33 ferries for transporting passengers, three bunker tankers for fuel supply, 88 vessels of other types, and 1300 rafts for tourism. There are four main passenger docks in the tourist area, including Binjiang Road Dock, Mopanshan Dock, Zhujiang Dock, and Yangshuo Longtoushan Dock. In addition, there are simple terminals in Daxu, Caoping, Yangdi, and Xingping that can dock small passenger ships. Currently, most of the ships sailing on the Lijiang River use traditional low-speed diesel engines, and there are fewer new energy vessels. Most ship engines use inexpensive and inferior fuels with heavy metals, which are much heavier and stickier, with longer carbon chains and higher sulfur content than the fuels used by land-based vehicles [13]. The exhaust of diesel engine ships not only includes carbon dioxide (CO2), which contributes to the global greenhouse effect, but also includes a lot of NOX, SOX, and PM [14,15]. NOX and SOX are major harmful emissions from marine diesel engines [16]. Lijiang waterway is the basis of sightseeing in tourist areas, and boat tour is the core tourism project. At present, there are more than a dozen visitor terminals in the Lijiang River. Only during the summer vacation in July–August 2024 did the Lijiang River cruise ships and rafts receive 1.97 million tourists. The huge number of tourists has caused a large amount of polluted gas emissions while contributing to the economic development of the Lijiang River [17]. In recent years, the daily average ship flow on the Lijiang River from Mopanshan Wharf to Longtoushan Wharf in Yangshuo is 70 times, while the daily average ship flow from Zhujiang Wharf to Yangshuo Watergate Wharf is 15 times. Each ship needs about 0.24 tons of diesel for a round trip, and 1 ton of diesel combustion produces about 3.2 tons of exhaust gas. Accordingly, tourist ships emit as much as 23,827.2 tons of exhaust gas into the atmosphere of the Lijiang navigation area in a year, which does not include indoor tourist ships [18]. The Lijiang River raft emits 372 t of CO2, 234 tons of carbon monoxide (CO), 10 tons of hydrocarbons (HC), 20 tons of NOX, 1.2 tons of sulfide, lead, solid particles, and other pollutants in a year. The annual emissions of SO2 and CO from cooking on cruise ships reach more than 9.2 tons [19]. Moreover, marinas along the Lijiang River are not equipped with perfect shore power facilities for the safe use of vessels during berthing, which contributes to the Lijiang River Basin’s exposure to the risk of environmental pollution from ship exhaust [20]. Furthermore, China’s Lijiang River ship exhaust treatment work started late, and the equipment was backward, so there was no perfect anti-pollution emergency response capacity of the ship [20]. The Lijiang River offers recreational amenities and scenic views to millions of residents and visitors. Information on the pollution from ship exhaust is also vital for policymaking in these heavily populated regions.

2.2. Lijiang River Emission Regulation

The shipping industry has been recognized as a major source of global environmental contamination. Thus, there is a need to regulate and enforce international standards for maritime discharges. The NOX emission standards set by MARPOL apply to both existing and newly built marine diesel engines. The primary and secondary limits are applied to the whole world, but the tertiary standard applies only to NOX emission control areas. Furthermore, it is important to limit the sulfur content of fuels, which significantly increases emissions of SOX and respirable particulate matter (PM) [21].

To reduce the emission of pollutants by marine motors, China has developed as well as implemented several regulatory measures. For instance, China’s Stage I/II Standards, the IMO’s Annex VI Standards, and domestic Emission Control Areas. The Chinese Class I/II standards apply to both thrust and assist motors mounted on inland waterways and offshore vessels. Effective from 1 September 2018, every diesel motor fitted on Chinese-flagged vessels, as well as those imported vessels seeking to engage in internal commerce within the country’s ECAs, must comply with the Annex VI Tier II NOX emission limit values [22]. From 1 March 2020, all vessels not equipped with exhaust gas purification systems will be prohibited from transporting fuel oil with a sulfur content of more than 0.5% [23]. The sulfur limit of 0.1% will also apply to ships entering inner channels and Hainan Island [24].

To improve the status of ship exhaust pollution in the Lijiang River, Guilin Maritime Safety Bureau has issued the “Guilin Maritime Safety Administration’s Three-Year Action Plan for Lijiang River Ship Pollution Prevention (2021.9–2024.8)”, and implemented some positive measures to ensure that the Lijiang River creates the “LiQing” brand [25].

2.2.1. Promoting New Energy Ships

In the past, most of the Lijiang River docks used diesel generators, which were not only costly and inefficient but also produced a huge volume of waste gas and noise, becoming the source of air pollution in the Lijiang River. Guilin Power Supply Bureau actively publicizes and advocates the concept of replacing energy consumption with electricity. At the same time, they investigated the need for the renovation of the Lijiang River cruise terminal and conducted basic data analysis on the shore power projects at Zhujiang Terminal and Mopanshan Terminal. By designing shore power access solutions with different voltage levels, strong technical support is provided. In 2022, “Lijiang River Tourism Raft Inspection and Management Measures” were issued and represented the end of internal combustion engine rafts. Electric instead of fuel has become a major tool for the development of high-quality ship tourism in Guilin, Guangxi [20]. The optimization of ship power structures was promoted, and nearly 1200 rafts have completed the “diesel-to-electricity” conversion, and more than 1100 battery-powered rafts are put into daily operation, accounting for 93% of the total number of rafts currently in operation on the Lijiang River. The first voyage of the Lijiang River pure electric-powered sightseeing raft was held at the Yangdi Wharf on 20 April 2023 [26]. Guangxi’s new energy cruise ship “Guilin Tourism” started its first voyage on 16 May 2022 at Zhujiang Wharf. After the shore power transformation was implemented, the shore power consumption of 21 berths was 2520 Kw/h. Compared with diesel power generation, it can reduce energy costs by 2.9 × 105 yuan per month, and carbon emissions can be reduced by 22.7 tons if calculated based on a total load of 6 kW for each ship at a berthing time of 10 h per day [27].

Meanwhile, the Guangxi Maritime Administration is working with several research institutes to actively promote liquefied natural gas (LNG) as ship power and to explore the possibility of using clean energy and new technologies such as electricity, hydrogen, natural gas, and methanol on Lijiang River vessels.

2.2.2. Adjusting the Ship Structure

Ships that have exceeded their service life are required to be scrapped by law, and old and outdated ships will be eliminated [28]. The policy encourages the construction of energy-saving and environmentally friendly ships and the modification of pollutant storage and treatment equipment on ships. Ships that have been put into operation since 2021 must strictly implement related requests of the “Discharge Standard for Water Pollutants from Ships” (GB3552-2018) [29] and “Management Measures for the Prevention and Control of Water Pollution by Inland Vessels with a Gross Tonnage of less than 400 t”, and newly built substandard ships are strictly prohibited into the Lijiang River. To prevent pollution caused by ship exhaust on the Lijiang River, 199 substandard ships were regularized. At the same time, it promoted the phasing out and replacement of 13 obsolete tourist vessels under the ‘Xingping Fishing Village Tour’ project and actively promoted the adoption of shore-based electricity by docked vessels to reduce their reliance on marine fuels, thereby reducing the carbon footprint of the vessels. Old passenger ships over 20 years on the stream of the Lijiang River have been eliminated to upgrade the quality of tourist passenger ships and improve the ship safety and pollution prevention levels [30].

2.2.3. Construction of Ship Exhaust Monitoring System

To make sure that ships comply with international regulatory standards, it is the importance of air pollution monitoring caused by ships by all law enforcement agencies. The introduction of an advanced vessel exhaust monitoring system makes the exhaust emission data visible and clear, which facilitates the management of law enforcement and environmental protection departments. The traditional monitoring methods (bench method and shipboard method) are to install fixed monitoring probes in places with dense ship traffic, such as docks, port areas, main bends, and river beaches. They are not cost-effective and lack sufficient competitiveness. Intelligent remote sensing monitoring equipment for ship exhaust can continuously measure and analyze the exhaust data from ships. Wireless radio frequency technology, ship exhaust telemetry [31], mobile measurements with unmanned aerial vehicles (UAVs) [32], UAV-based sensor sniffing method, remote monitoring [33], computer and network technology, which were used to strengthen the monitoring of ship exhaust, reduce ship exhaust emissions, and improve the comfort of coastal residents [34].

In 2021, the Guilin Maritime Safety Administration and technology manufacturers carried out a drone telemetry test of ship exhaust on the Lijiang River for the first time. The unmanned aerial vehicle remote sensing monitoring method is based on the gas monitoring equipment carried on board, using advanced infrared smoke sniffing technology to sample and analyze the smoke plumes emitted by ships. By measuring the values of sulfur dioxide, nitrogen oxides, and other pollutants in the exhaust gas, a preliminary analysis is conducted on whether the sulfur content, nitrogen oxides, and other indicators of ship fuel exceed the standard [35]. Technicians selected different ship types in the urban section and the waters of Zhujiang Wharf and carried out the remote measurement of the exhaust emissions of the ships under different driving conditions. Guilin Maritime Safety Administration and technology manufacturers supervise and manage the quality of ship fuel by means of drone sniffing and rapid detector sampling, urging ships to use compliant fuel, ensuring that sulfur oxides in ship exhaust can be reduced by more than 80% compared with the same period.

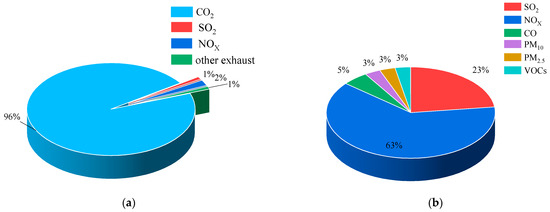

3. Ships’ Exhaust Emissions

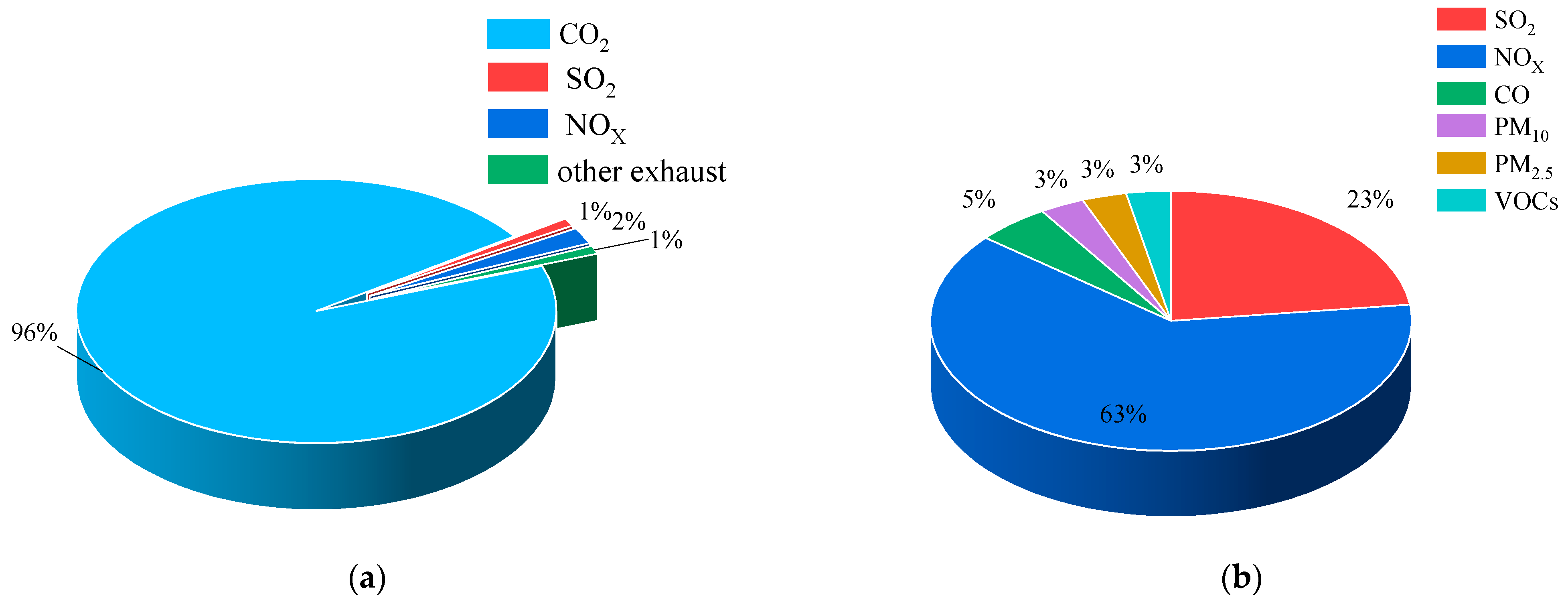

In China, vessel emissions are progressively emerging as a significant contributor to air pollution in advanced waterway transport areas such as the Pearl River Delta, the Yangtze River Delta, and the Bohai Rim region [36,37]. Exhaust emissions from ships mainly include SOX, NOX, PM, volatile organic compounds (VOCs), CO, CO2, HC, and ozone-depleting substances (ODS) [38,39]. Among these, SOX and NOX constitute the main components of ship emissions, which were listed as a priority for controlling ship exhaust pollutants by the IMO. Lu et al. studied the emission trends of SO2, NOX, PM10, and other pollutants from 2000 to 2009, as well as the changes in their sources, using a dynamic approach in the Pearl River Delta. The results show that the marine mobile sources of SO2 emissions are mainly from the ship tailpipe, accounting for an average of 8%, with an average annual growth of 12%. Similarly, ship tailpipe emissions account for 69% of NOX emissions in this region [40]. Fan et al. developed an automatic identification system (AIS)-based model for calculating the total emissions from ships in 2010 in the Yangtze River Delta region and in the sea area within 400 km of the East China Sea coastline. The SO2 and NOX emitted from ships in key areas such as ports and shipping centers accounted for 15% and 14% of the anthropogenic emissions, far exceeding land-based emission levels [41]. Song et al. estimated the emissions of PM10, PM2.5, NOX, SOX, CO, HC, and CO2 from ships in the ports of Tianjin, Tangshan, Qinhuangdao, and Huanghua. The results showed that the emissions from ships increased with the distance of proximity to the port, and, in particular,, the concentration of emissions reached highest in the area within 15 nautical miles of the port. Based on the ship AIS data and fitting outcomes, the emissions from ships in the western part of Shenzhen port in 2018 were evaluated [42]. At the western part of Shenzhen port, the predominant ship exhaust component is CO2, which makes up 97% of total emissions. Followed by NOX and SOX, they accounted for 2% and 1% of total emissions, respectively. Despite NOX only accounting for 2%, its volume significantly surpasses that of other pollutants (Figure 2). By examining various ship types entering and exiting the western area of Shenzhen port, it is found that cargo ships have the highest contribution rate. Specifically, they account for 39.0% of CO2, 43.3% of SOX, 39.0% of NOX, 38.9% of CO, and 41.4% of PM emissions [43]. Among all ship types, the temporal emission intensity of CO2 from cargo ships sees the largest increase, followed by container ships and then tankers. When a cargo ship’s speed hits 10 knots, its CO2 emission rate is 13.18 tons per hour [44]. The temporal emissions of CO, CO2, NOX, PM2.5, and SO2 from cargo ships spike sharply when the speed reaches 15 knots, with container and tanker ships showing a similar pattern but to a lesser extent. Table 1 shows the contribution of air pollutant emissions from ships in major port cities of China measured over the years, where the pollutants with higher contributions are NOX, SOX, and PM.

Figure 2.

Ship exhaust emissions: Comparison of CO2, SOX, NOX, CO, and PM (a) containing CO2, (b) containing CO2.

Table 1.

Contribution rate of pollutant emission from ships in some regions [45,46].

3.1. Sources and Hazards of SOX

SO2 and SO3 are the major components of SOX, of which SO2 accounts for the vast majority (93%), and SO2 emissions are largely dependent on the sulfur content of the fuels used [47]. In a port site in Shanghai, SO2 accounted for 36.4% of ship exhaust emissions [48]. Sulfur is highly irritating and corrosive and is capable of damaging the human respiratory tract when its content exceeds the standard. It can also form sulfate aerosols within the atmosphere, which increases human health risks and the deterioration of land and waterborne environments [49]. Burning low-sulfur fuels is a straightforward approach to reducing sources of SOX releases, but its price is higher than traditional heavy fuel oil, and the lower viscosity will lead to cylinder wear [50].

3.2. Sources and Hazards of NOX

NOX is a very reactive gas that participates in a variety of chemical reactions in the atmosphere and is a greenhouse gas, mainly due to the combustion of nitrogen in the air when the engine is operated at high temperatures and high oxygen concentration [51,52,53]. The proportion of NO in NOX emitted by the ship is 95%, and NO2 accounts for 5%. Moreover, the NO emitted from the engine is gradually oxidized to NO2 in the atmosphere, which adversely affects the breathing system, as well as reacting to form nitric acid and other compounds. Even though NO2 is approximately five times more soluble in water than NO under normal atmospheric conditions, typically only a portion of it can be removed [54]. Atmospheric NOX emissions combine with chemical substances to form ground-level ozone as a result of heat and solar radiation. The shipping industry contributes significantly toward total NOX releases, resulting in high ambient air concentrations of NOX near port neighborhoods [55]. Overcoming this issue can be distilled into two main strategies: either further oxidizing NO2 into compounds with even greater solubility or employing a reducing agent to eliminate NO2 [56].

3.3. Sources and Hazards of PM

The high sulfur levels in the fuel result in high levels of PM and SOX emissions from ship motors [57]. PM, which includes PM2.5 and PM10, primarily means smoke and dust particles from ship emissions, and may also result from the conversion of sulfur and NOX [58]. PM emitted by ships has significant negative impacts on human health and the global climate [59]. Particulate matter emissions are associated with cardiac and lung diseases and, recently, with Alzheimer’s disease [53]. Particles may contain organisms associated with oncogenic and mutagenic activity, such as polycyclic aromatic hydrocarbons (PAHs) [60]. Ship PM2.5 emissions in the vicinity of port neighborhoods create racial and health risk disparities because low-income families are disproportionately represented in the affected population near the ports [61].

4. Ship Flue Gas Terminal Treatment Technology

As the IMO has clear limits on SOX and NOX emissions from marine diesel engines, desulfurization, and denitrification (FGD and N) technology has become the key to reducing atmospheric pollution from ship exhaust. Countries and regions around the globe are currently working on researching and improving flue gas FGD and N technologies to enhance ship exhaust treatment efficiency. Based on the chemicals utilized in the desulfurization process and the form of the end products, conventional desulfurization techniques can be categorized into wet, dry, and semi-dry methods. Numerous flue gas denitrification techniques have been devised, such as SCR, non-SCR, SNCR, catalytic oxidation, electron beam method, adsorption method, and microbial method [62].

4.1. Desulfurization Technology of Exhaust Gases

4.1.1. Dry Exhaust Gas Desulfurization Technology

Dry exhaust gas desulfurization technology (FGD) implies that the entire reaction process is predominantly conducted in a dry condition [63]. The principle of dry desulfurization is that CaO or Ca(OH)2 reacts with sulfide to form CaSO3 and CaSO4 to achieve desulfurization. Compared with wet flue gas desulfurization, this method requires lower investment and operational expenses, and dry desulfurization products are more readily reprocessed [64]. Osaka et al. studied the capture of SO2 by a dry desulfurization filter of manganese oxide. The technology with this material has a large enough SO2 adsorption rate to capture significant amounts of SO2 gas [65]. However, the application of dry FGD on ships is affected by the limited space available and the difficult treatment of by-products generated by the reaction, so it is less suitable for the desulfurization of ship exhaust. Due to the lower response rate and higher residence time, the size of a dry FGD plant is about twice that of a wet FGD.

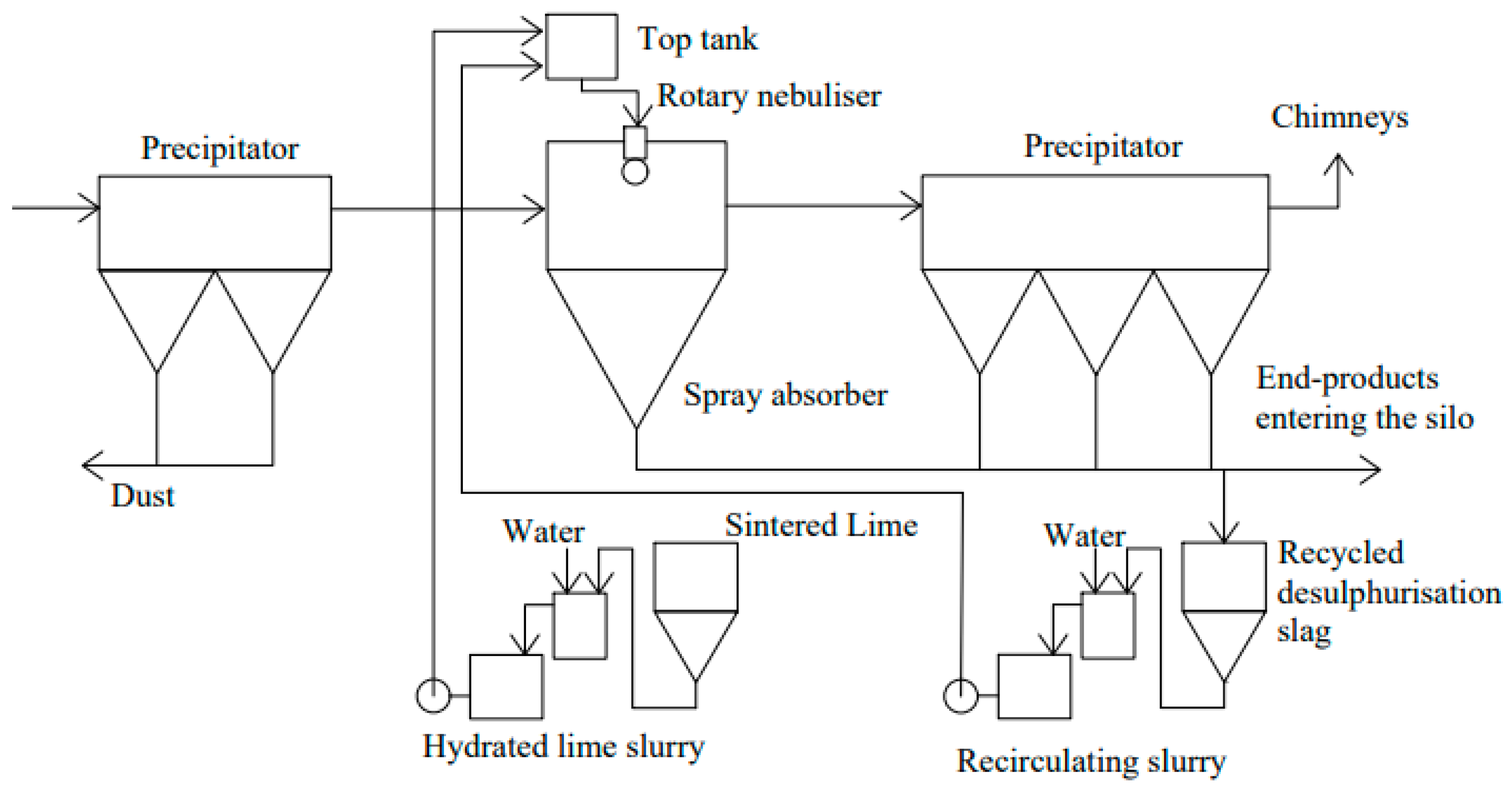

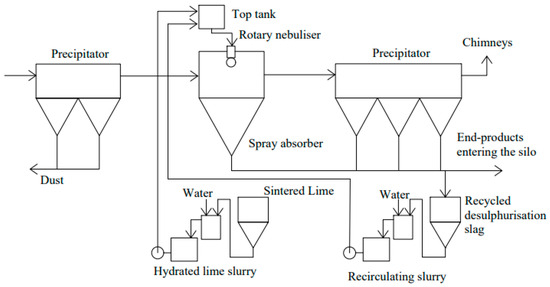

Spray Dryer Absorber (SDA) is one of the dry desulfurization technologies, which uses Ca(OH)2 to neutralize sulfur oxides [66]. In this process, exhaust gases from ships interact with an atomized limestone slurry in a rotating spray drying tower to achieve effective neutralization of SO2 (Figure 3). As the solvent evaporates, the reaction produces a dry solid by-product (CaSO3) [67]. The SDA system is used in conjunction with a bag filter to achieve simultaneous desulfurization and dedusting, resulting in an integrated flue gas purification effect. In addition, SDA technology eliminates facilities such as post-treatment systems, post-treatment facilities, and flue gas heating links. The treatment process is suitable for ships with sufficient space and low requirements for by-product treatment, such as large cargo ships or tankers. It utilizes Ca(OH)2 to react with SO2 to achieve 90% to 95% desulfurization efficiency, with both dust removal effect, low energy consumption, and simplified equipment. However, due to the large size of the equipment, low reaction rate, and complex by-product treatment, it is not suitable for small and medium-sized ships with space constraints [68]. The reaction mechanisms for the reduction of SO2 can be summarized as follows [69]:

SO2 + Ca(OH)2→CaSO3 + H2O

Figure 3.

The main process of rotary spray drying technology.

Some of the SO2 completes the following reaction:

SO2 + 1/2O2 + Ca(OH)2→CaSO4 + H2O

4.1.2. Wet Exhaust Gas Desulfurization Technology

Wet flue gas desulfurization technology is commonly performed in many thermal power plants and has a high desulfurization efficiency. Alkaline solutions (Ca(OH)2, Mg(OH)2) are used as neutralizing agents to absorb sulfur oxides that come into contact with the exhaust gas emitted from ships, thus scrubbing them to generate sulfite slurry. The desulfurization efficiency of wet exhaust gas desulphurization technology is usually over 95%. Wet FGDs mainly include open seawater scrubbing FGDs, closed cycle scrubbing FGDs (magnesium, sodic alkali), mixed scrubbing system FGDs, lime gypsum, and ammonia [70].

- (1)

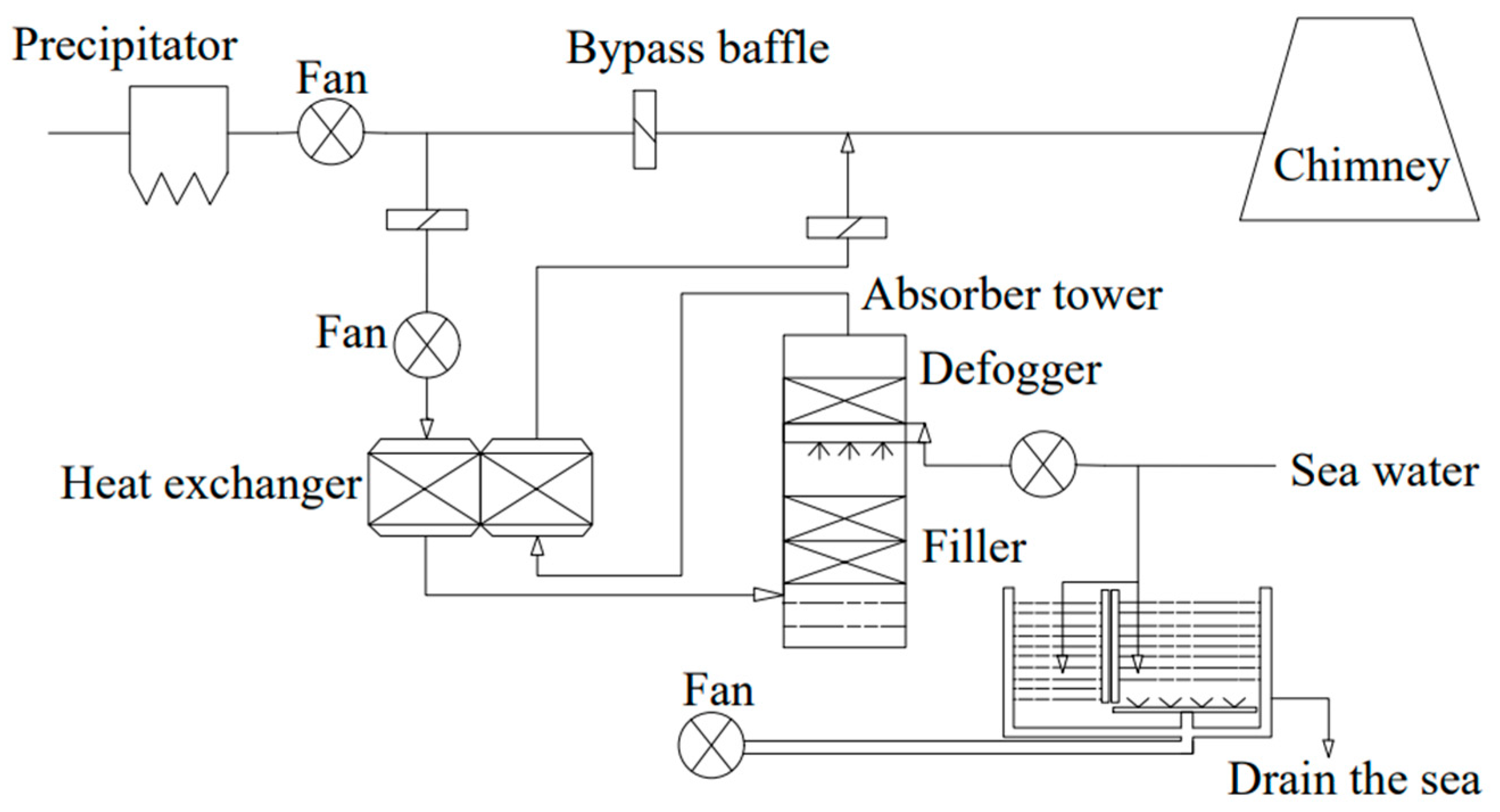

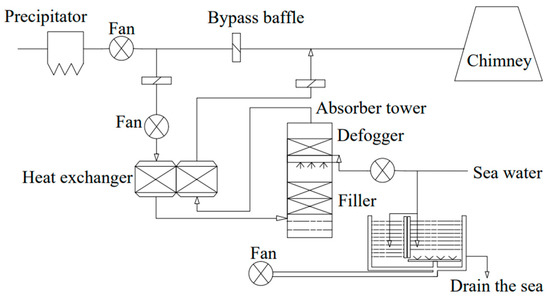

- Seawater exhaust gas desulfurization

The open seawater scrubbing desulfurization system is relatively straightforward. Seawater desulfurization uses seawater as a scrubber, where the naturally occurring basic components(Na2CO3, NaHCO3) combine with SOX from ship emissions to form bisulfates and sulfates, which are discharged directly to the sea. Seawater desulfurization is suitable for ocean voyages. It essentially discharges SO2 emitted into the atmosphere into seawater, and the main process is shown in Figure 4. The seawater desulfurization process solely requires seawater and air, with no additional chemicals needed, and generates no solid or liquid waste. However, this process has drawbacks such as a relatively low overall sulfur dioxide removal efficiency and the necessity for a large volume of seawater when treating gases with high sulfur content [71,72,73]. Zhao et al. [74] discussed the feasibility of using seawater resources combined with BAD (C12H25NO) for simultaneous desulfurization and denitrification of ship exhaust. The average removal rate of SO2 and NOX was 97.10% and 74.28%. Because of the low alkalinity of natural seawater with limited buffering ability between acid and alkali, this is only applicable to ship exhausts containing low-sulfur content. According to “2020 Implementation Plan of International Marine Fuel Oil Sulphur Limitations”, it is prohibited for ships to discharge scrubber water treated by an open exhaust gas cleaning system in the air pollutant emission control zones delineated in China’s maritime areas [75]. Therefore, seawater scrubbing desulfurization is no longer suitable for ship tail gas treatment under the new standard. The SO2 removal mechanism is as follows [76]:

SO2 + H2O→H2SO3

H2SO3↔HSO3− + H+

HSO3− + H2O↔SO32− + H3O+

HCO3− + H+↔CO2 + H2O

H2CO3 + H2O↔HCO3− + H3O+

HCO3− + H2O↔CO32− + H3O+

CO32− + 2H+↔CO2 + H2O

Figure 4.

Process flow chart of seawater desulfurization.

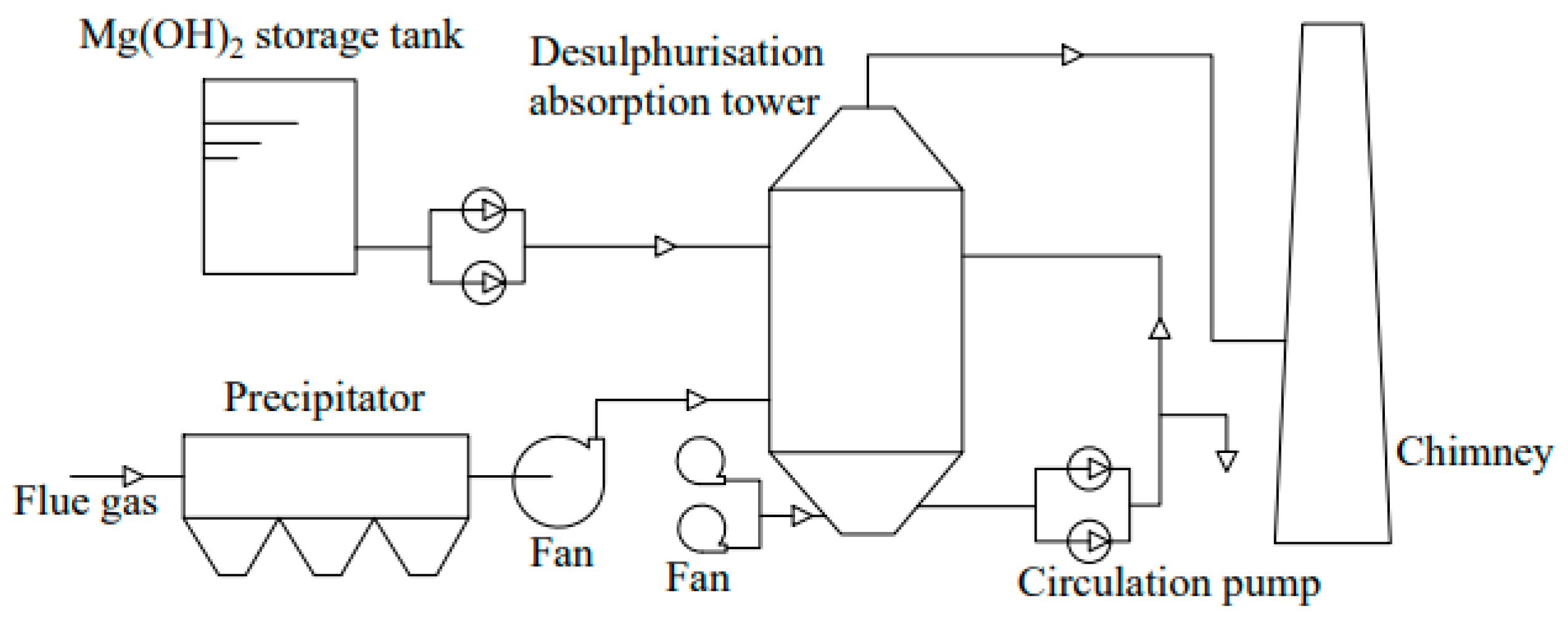

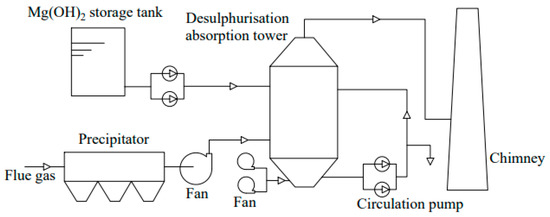

The method uses magnesium oxide as the desulfurizing agent. As shown in Figure 5, a magnesium hydroxide (Mg(OH)2) solution is first prepared in the pulping equipment, followed by the reaction of Mg(OH)2 and SO2 in the absorption tower. Lastly, the absorption liquid and sediment are treated [77]. Regarding the byproducts of Mg-based desulfurization, commonly referred to as magnesium gypsum, magnesium sulfate (MgSO4), and magnesium sulfite (MgSO3) constitute the primary components [78,79]. The magnesium sulfate is dehydrated and dried and can be used for other purposes. China ranks among the top magnesite-producing countries globally [80]. The solid magnesium oxide is small, safe, cheap, environmentally friendly, and has a large adsorption capacity. The magnesium oxide wet flue gas desulfurization technology represents an economical and effective method for desulfurization. It is characterized by high desulfurization efficiency, low investment costs, compact unit size, and minimal environmental impact. Magnesium oxide, nevertheless, is more expensive and has a concentrated origin. Various manganese oxide samples with different physical and chemical structures were prepared using template, precipitation, and microwave methods for the desulfurization of ship exhaust. Manganese oxide prepared using the template method presented a rich 3D pore structure, a large specific surface area, and excellent desulfurization performance [81].

Figure 5.

Process flow chart of magnesium oxide desulfurization.

- (2)

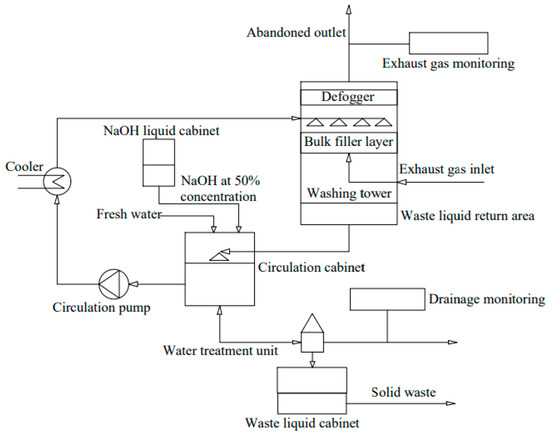

- Sodium alkali exhaust gas desulfurization

Sodium alkali desulfurization is a wet FGD process, and the main chemical equations are [82]:

2NaOH + SO2→Na2SO3 + H2O

Na2SO3 + H2O + SO2→NaHSO3

Na2SO3 + SO2→Na2S2O5

(Since there is some oxygen in the flue gas)

2Na2SO3 + O2→2Na2SO4

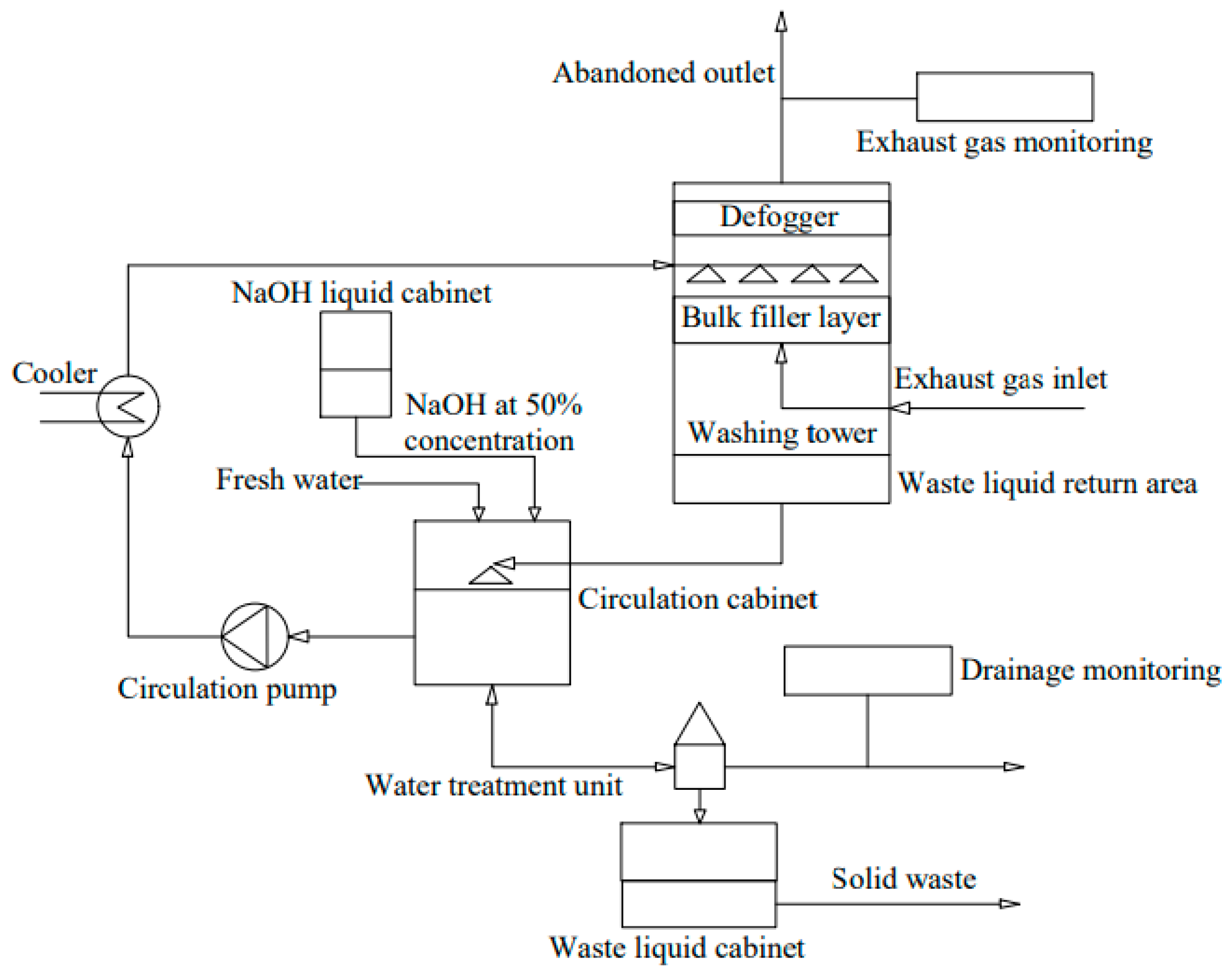

In the reaction process, NaOH is used as the initial absorber, and it reacts with SO2 in ship exhaust gas to generate Na2SO3, NaHSO3, Na2S2O5, and Na2SO4 to achieve the purpose of desulfurization, sequentially [83]. The temperature directly affects the removal efficiency of the desulfurizing agent [84]. NaHSO3 absorption solution after desulfurization is evaporated, filtered, and cooled to precipitate Na2SO3, which is soluble in the condensate, and then is pumped into the scrubber tower for recycling. Sodium alkali has a strong affinity with SO2 and can achieve a high desulfurization rate [85]. Desulfurization produces sodium salt, which can avoid clogging in the absorption tower. However, NaOH is hazardous and corrosive and should not be stored in large quantities on board. The treatment process is suitable for large ocean-going vessels and less suitable for small ships or inland waterway vessels. When the liquid–gas ratio of seawater sodium alkali absorption solution is 5 L/m3, the desulfurization rate can reach more than 99% [86]. It can efficiently remove SO2 from the exhaust gas, but its application is limited due to the limitations of high cost, high corrosiveness, and non-recyclability of the desulfurizer [87]. The process flow is depicted in Figure 6.

Figure 6.

Schematic diagram of the sodium alkali desulfurization process.

- (3)

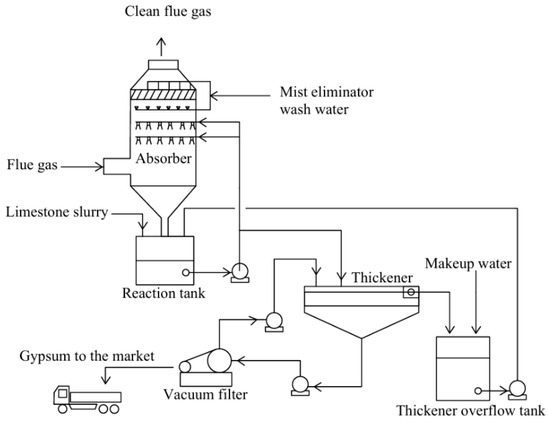

- Limestone–gypsum exhaust gas desulfurization

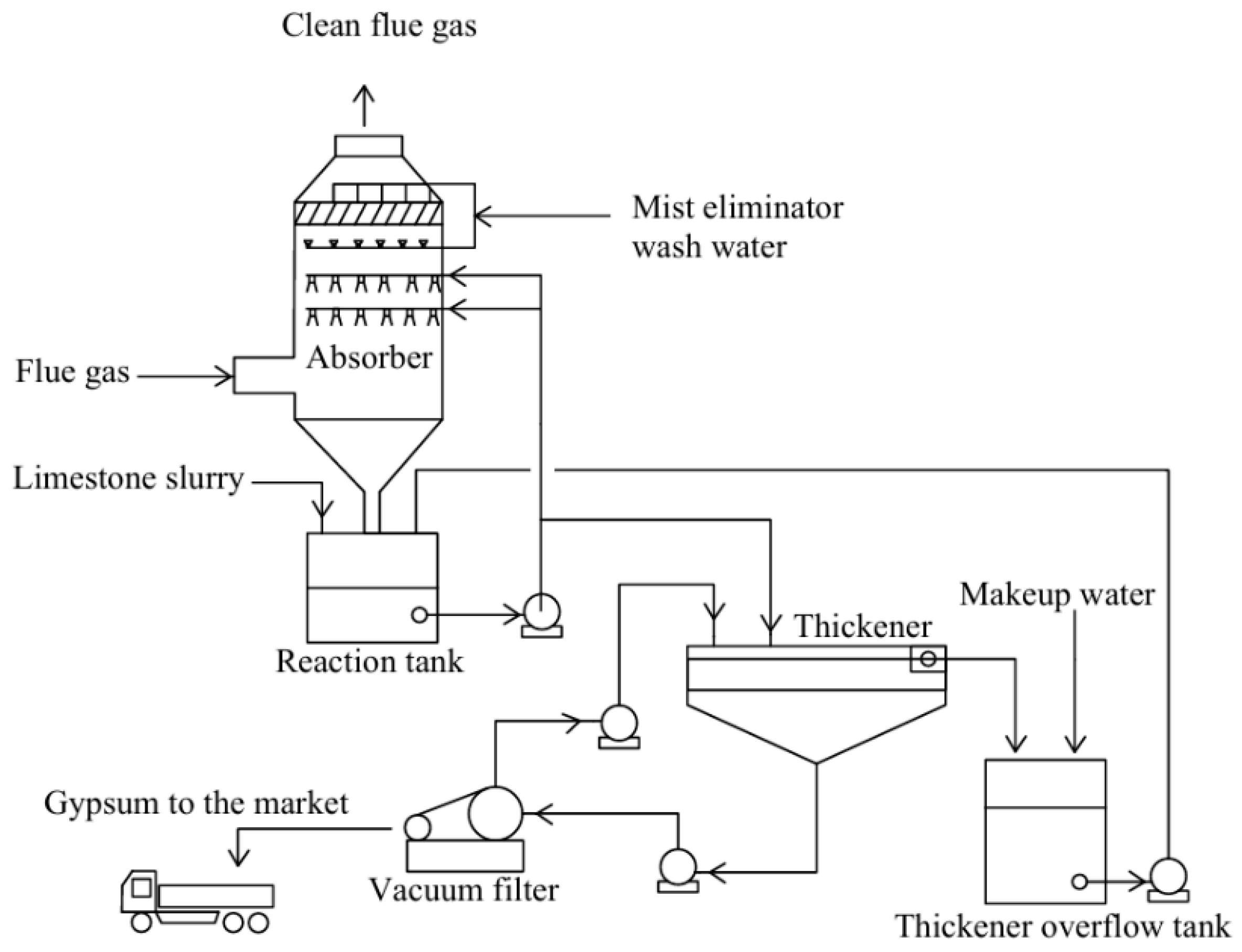

In the limestone–gypsum wet FGD process, SO2 in the emitted ship exhaust reacts with calcium hydroxide, Ca(OH)2, to produce calcium sulfite (CaSO3). Subsequently, the remaining CaSO3 is completely converted to calcium sulfate (CaSO4) after sufficient contact with oxygen in the air (Figure 7). The main chemical equation is [84]:

SO2 + Ca(OH)2→2CaSO3 + H2O

CaSO3 + 2H2O→CaSO4·2H2O

2CaSO3·1/2H2O + O2 + 4H2O→2CaSO4·2H2O + H2O

Figure 7.

Typical process of limestone–gypsum desulfurization.

The core part of the reaction process is that the flue gas enters the interior of the absorber tower, and the desulfurization reaction occurs by mixing the desulfurizing agent with the flue gas through a spray system to remove SO2 and SO3 [88]. The limestone–gypsum process allows the oxidation of CaSO3 to be controlled, thus ameliorating the problem of fouling and clogging of the absorber tower and pipework in the conventional lime process. Limestone–gypsum wet FGD technology is suitable for large ships, as it can efficiently remove SO2 from the exhaust gas and convert it into gypsum with high desulfurization efficiency (more than 90%). However, the large size of the equipment, its susceptibility to wear and clogging, and complicated wastewater treatment limit its wide application on ships [89].

- (4)

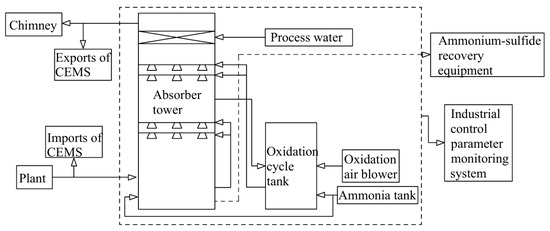

- Ammonia exhaust gas desulfurization

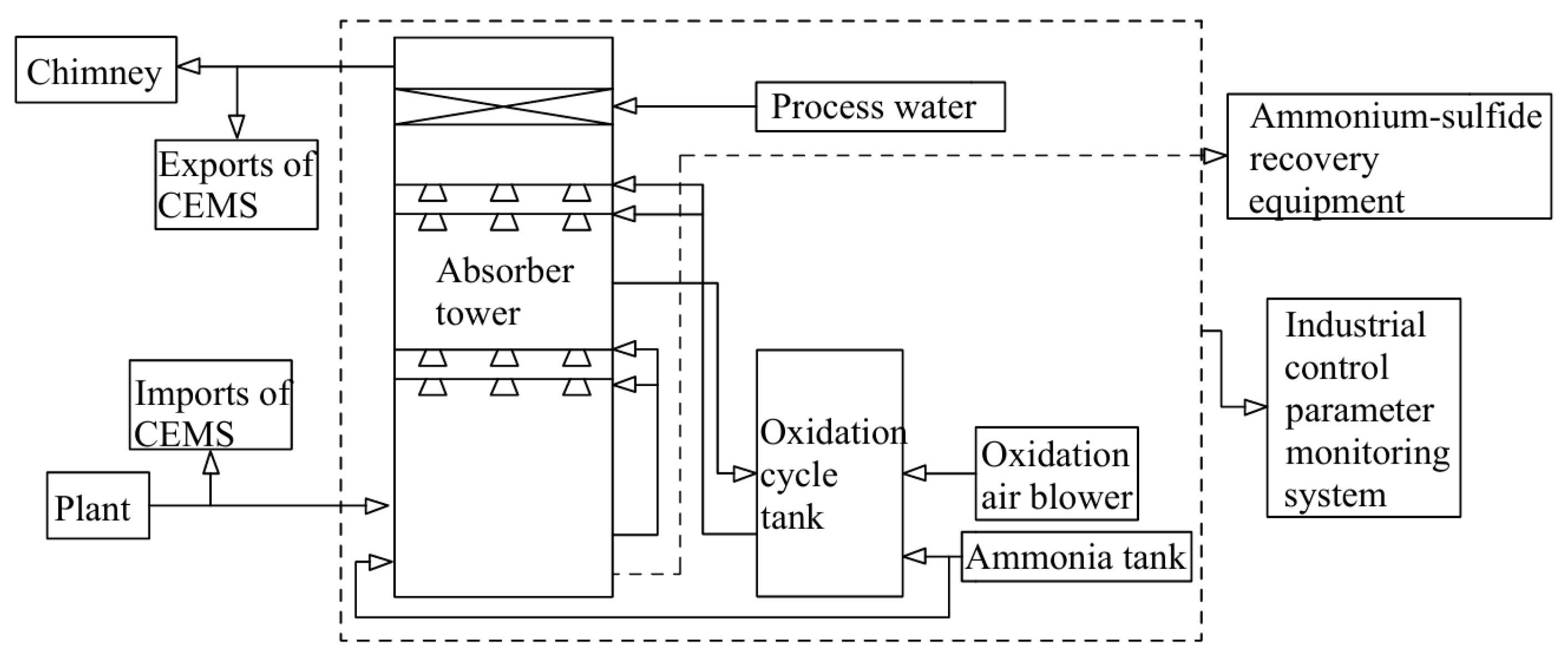

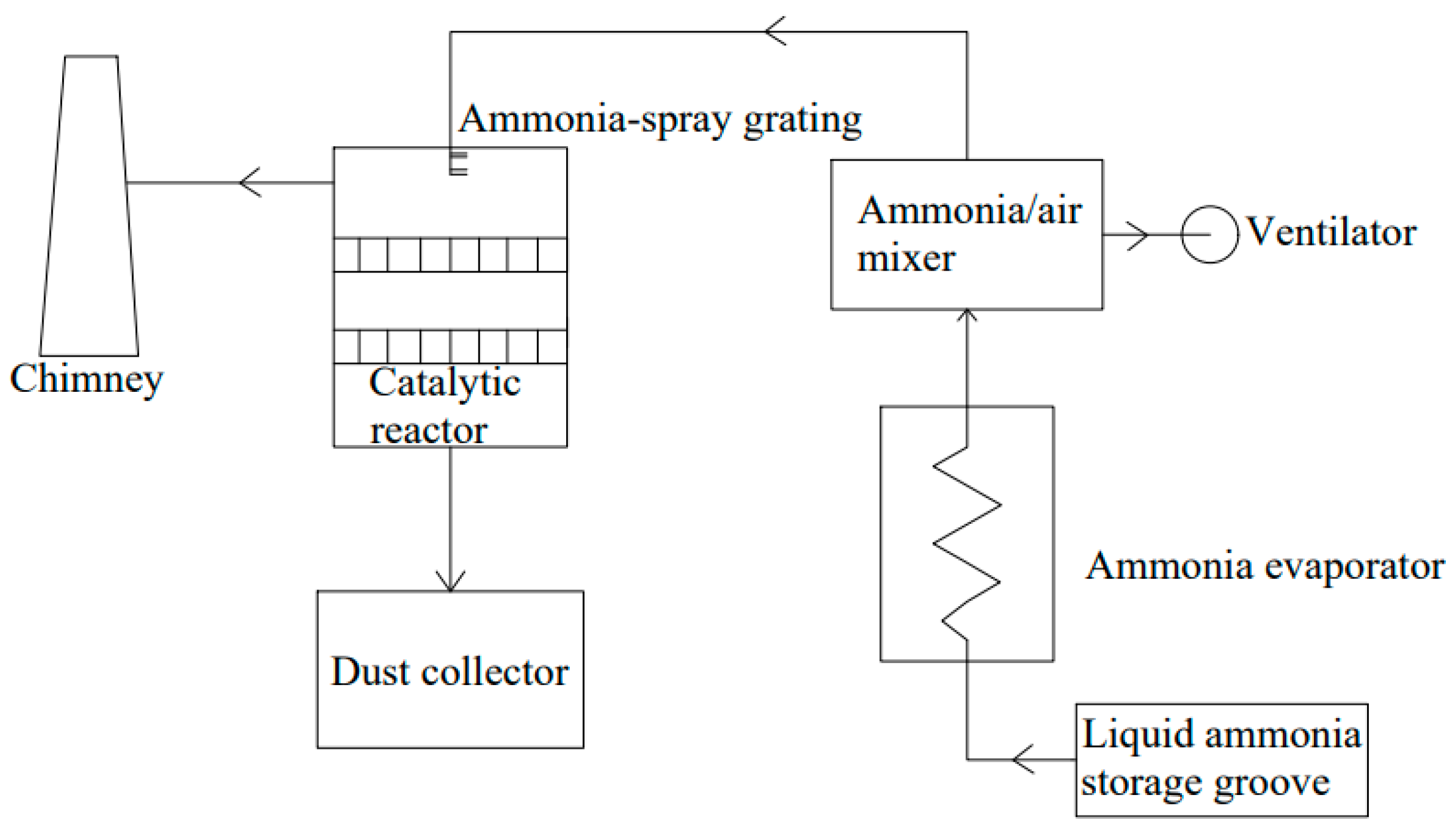

The ammonia FGD technology, which has intellectual property rights in China, can achieve a 98% desulfurization rate and a 50% denitrification rate under optimal operating conditions [90]. Ammoniated desulfurization can ultimately convert SO2 from exhaust gases into an environmentally friendly ammonium sulfate ((NH4)2SO4) fertilizer product. The flue gas is sprayed and scrubbed into an ammonia suction tower for desulfurization of the mother liquor, followed by acid digestion and neutralization of the mother liquor to produce (NH4)2SO4, and the gas is discharged after meeting the standard [91]. Ammonia exhibits high reactivity, a rapid reaction rate, a straightforward process, is resistant to fouling and clogging, and is easy to start, stop, and maintain [92]. As the production of synthetic ammonia gas increases, ammonia flue gas desulfurization technology has seen rapid development and garnered extensive attention in China. Ammonia can be used by low- and medium-speed engines to reduce emissions by 90% [93]. The process flow is illustrated in Figure 8. The technological principle is outlined as follows [94]:

2NH3 + H2O + SO2→(NH4)2SO3

(NH4)2SO3 + SO2→2NH4HSO3

NH4HSO3 + NH3→(NH4)2SO3

2(NH4)2SO3 + O2→2(NH4)2SO4

Figure 8.

Process flow chart of ammonia desulfurization system.

4.2. Denitrification Technology of Exhaust Gas

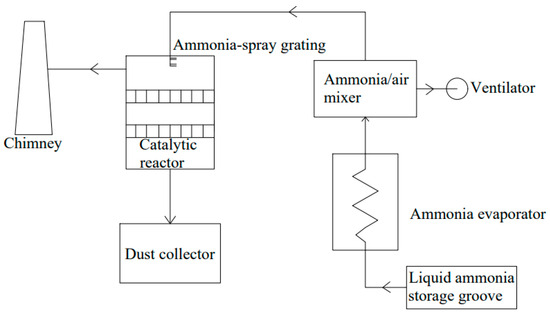

4.2.1. Selective Catalytic Reduction (SCR) Exhaust Denitrification Technology

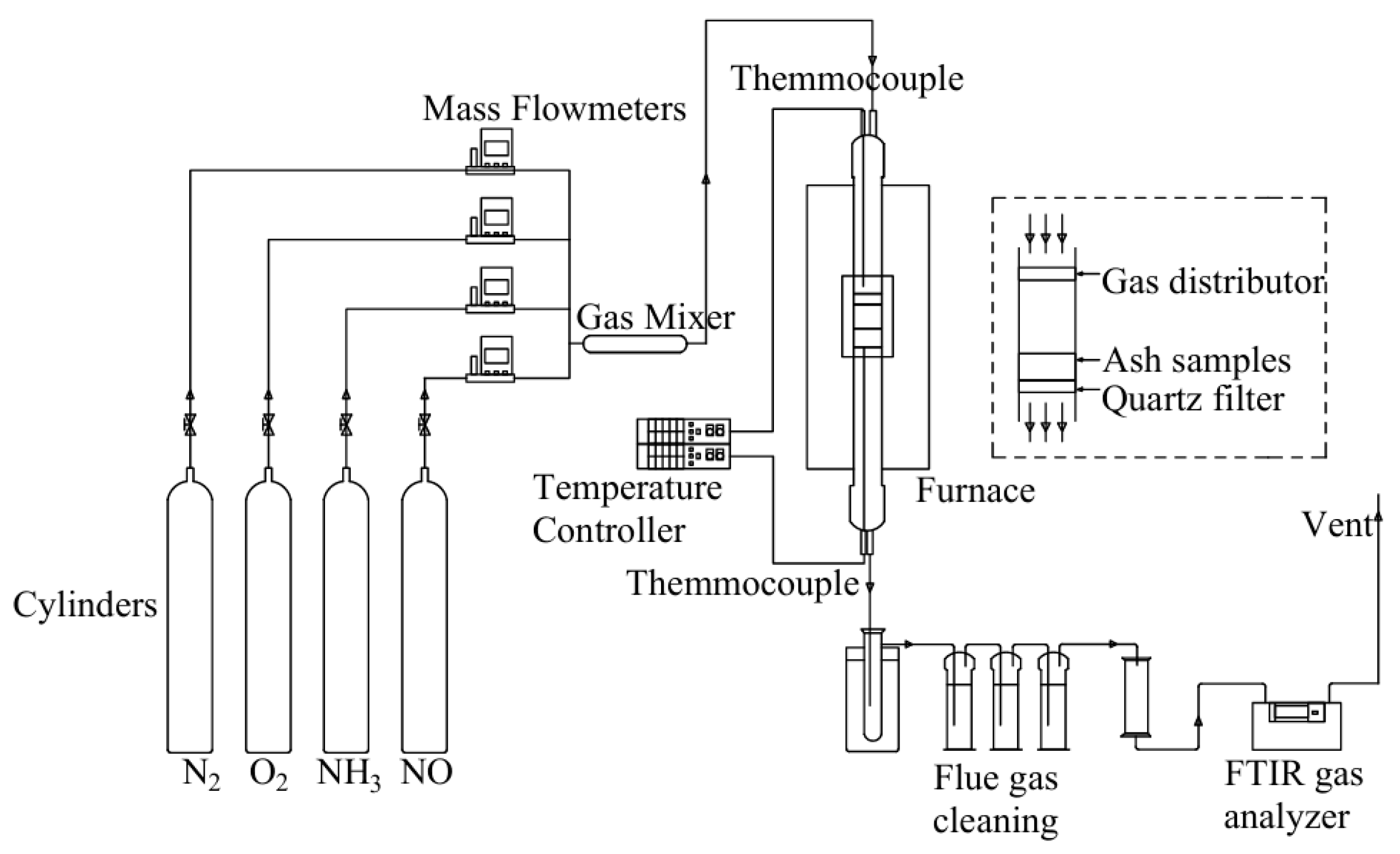

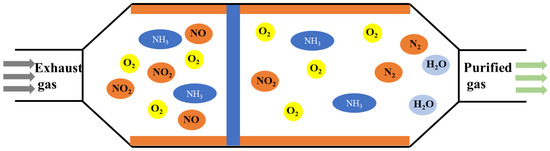

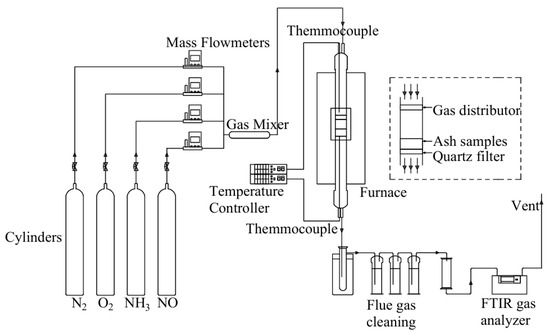

SCR technology is considered to be one of the most advanced and effective ways to reduce NOx emissions by using reductants in the presence of oxygen. It is mainly used in ships with four-stroke engines [95]. SCR technology employs carbamide or ammonia solution (NH3-SCR) as a reducing agent to transform NOX into N2 and H2O, as shown in Figure 9. For SCR reactions, an aqueous ammonia solution is the preferred choice. In addition to NH3-SCR, carbon monoxide (CO-SCR), hydrogen (H2-SCR), and hydrocarbons (HC-SCR) are also used as marine SCR technology suitable reduction agents [96]. Selecting the right catalyst is crucial for the operation and effectiveness of an SCR system. Various types of catalysts are employed in NH3-SCR processes, including precious metals, metal oxides such as titanium, vanadium, iron, activated carbon (which can be pulverized high carbon coal or coke mixed with inert elements), and zeolites (which are crystalline, highly porous, and naturally or synthetic aluminosilicates) [97]. Vanadium pentoxide (V2O5) is the most frequently used industrial catalyst for the elimination of NOx and has been commercialized with titanium dioxide (TiO2) as a carrier, owing to its excellent sulfur resistance and long-term stability [98]. SCR catalysts for marine operations are often V2O5 catalysts that exhibit high activity and are sulfur resistance [99,100,101]. The reaction equation with ammonia as a reducing agent is as follows:

4NH3 + 4NO + O2→4N2 + 6H2O

8NH3 + 6NO2→7N2 + 12H2O

SCR technology can be compatible even with remnant marine fuels, as the integral stationary base has square holes, and the holes are large enough to prevent plugging and toxicity [102]. SCR technology is favored by the market because of its no by-products, no secondary pollution, simple equipment design, mature technology, high denitrification efficiency, stable operation, and easy maintenance. But SCR catalyst materials are easy to scale, block, and poison. The method is mainly applicable to ocean-going vessel navigation, but it is seldom used by two-stroke ships sailing in the Lijiang River inland waterways. Significant NOX reductions of nearly 90% are reported for ships using SCR [103,104]. However, on the two ferry motors with SCR units, the conversion of NOX ranged from 36% to 94%, according to the temperature of the catalyst [83]. SCR system’s optimal operating temperature is 300–400 °C; if the system temperature is too high or too low, it cannot function properly. The process flow is shown in Figure 10.

Figure 10.

Process flow chart of selective catalytic reduction.

Figure 9.

Schematic diagram of SCR catalytic mechanism [105].

Figure 9.

Schematic diagram of SCR catalytic mechanism [105].

4.2.2. Selective Non-Catalytic Reduction Denitrification Technology

Selective non-catalytic reduction (SNCR) involves reducing NOX to N2 within a temperature range of 800–1100 °C by reacting with an amine reagent in the presence of oxygen. Since this process occurs at elevated temperatures, it does not need a catalyst to trigger the reaction. The reagent, either ammonia or urea, can be directly injected into the combustion chamber. Urea-based SNCR offers advantages over ammonia-based systems because urea is safer to store and handle due to its non-toxic nature and lower volatility. However, urea is more expensive than ammonia, and the urea reduction process generates more nitrous oxide compared to the ammonia reduction process [106]. The main reaction mechanism is listed as follows:

CO(NH2)2 + 2NO + 0.5O2→2N2 + CO2 + 2H2O

Technology has gained traction because of its relative simpleness, lack of need for a catalyst system, easy arrangement in existing power stations, wide application range, low cost, immunity to fly ash, and can be used in conjunction with other NOx emission control technologies [107]. In commercial applications, the NOx concentration in the gas emitted at the stack is 60% lower with SCR than with SNCR, suggesting that SNCR uses significantly more reductant than SCR, typically three to four times more than SCR [108]. Since the emission temperature of ship exhaust is 300–400 °C, and the temperature window of SNCR denitrification is generally 800~1100 °C, the method is not applicable to the treatment of ship exhaust. The SNCR denitrification process is shown in Figure 11.

Figure 11.

Process flow chart of selective non-catalytic reduction.

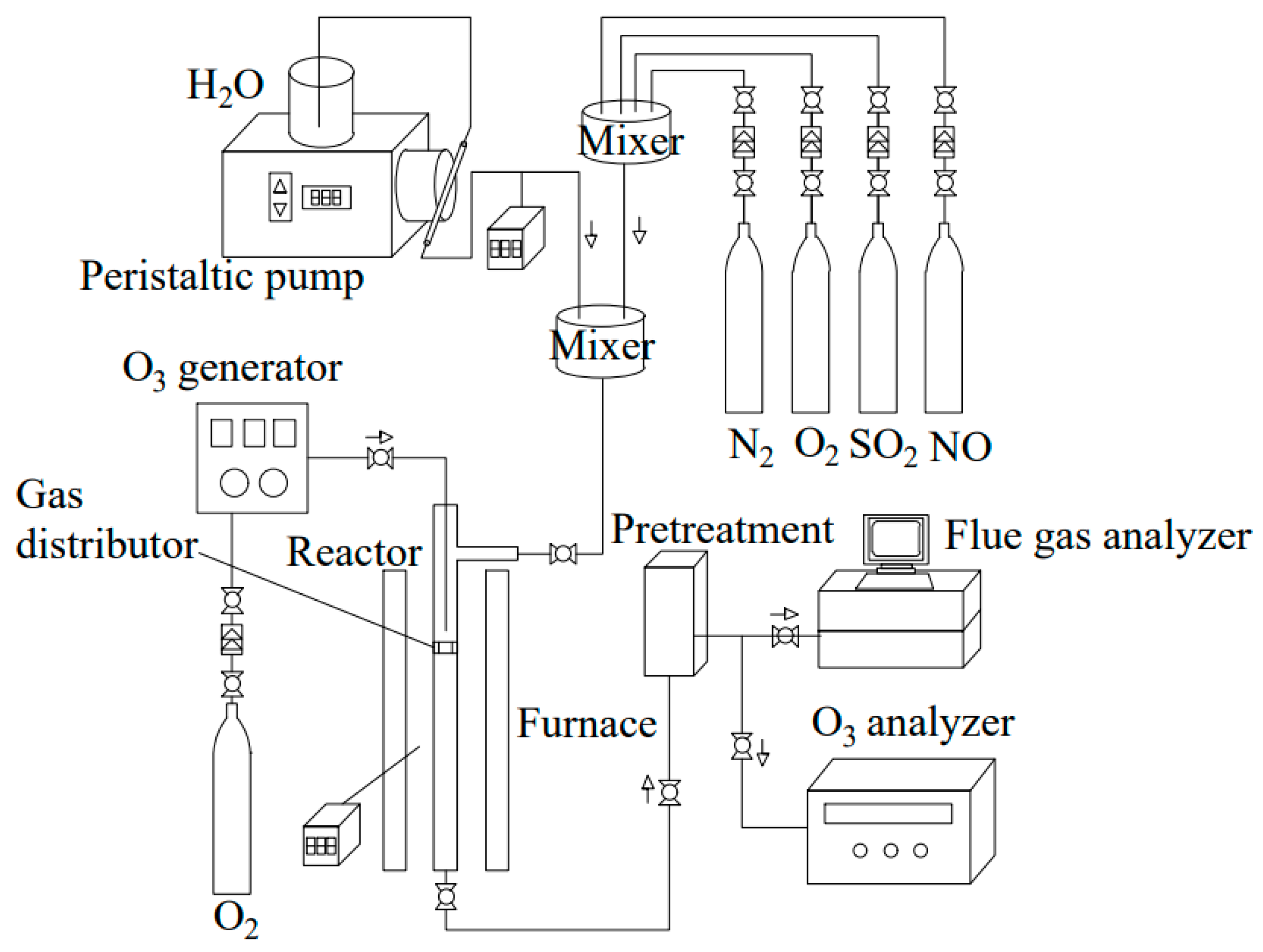

4.2.3. Ozone Oxidation Denitrification Technology

Based on the highly efficient oxidizing capacity of O3, ozone oxidative denitrification technology converts nearly 95% of the nitric oxide (NO) in ship exhaust to higher order nitrogen oxides (NOX) that are soluble in water and react with alkaline solutions, followed by subsequent treatment using solution absorption [109]. The method boasts strong selectivity and rapid oxidation rates [110]. Additionally, it is capable of oxidizing mercury and volatile organic compounds in flue gas, thereby achieving integrated denitrification [111,112,113]. The specific chemical equation is:

O3 + NO→NO2 + O2

O2 + 2NO2→2NO3

NO2 + NO3→N2O5

N2O5 + 2OH−→2NO3− + H2O

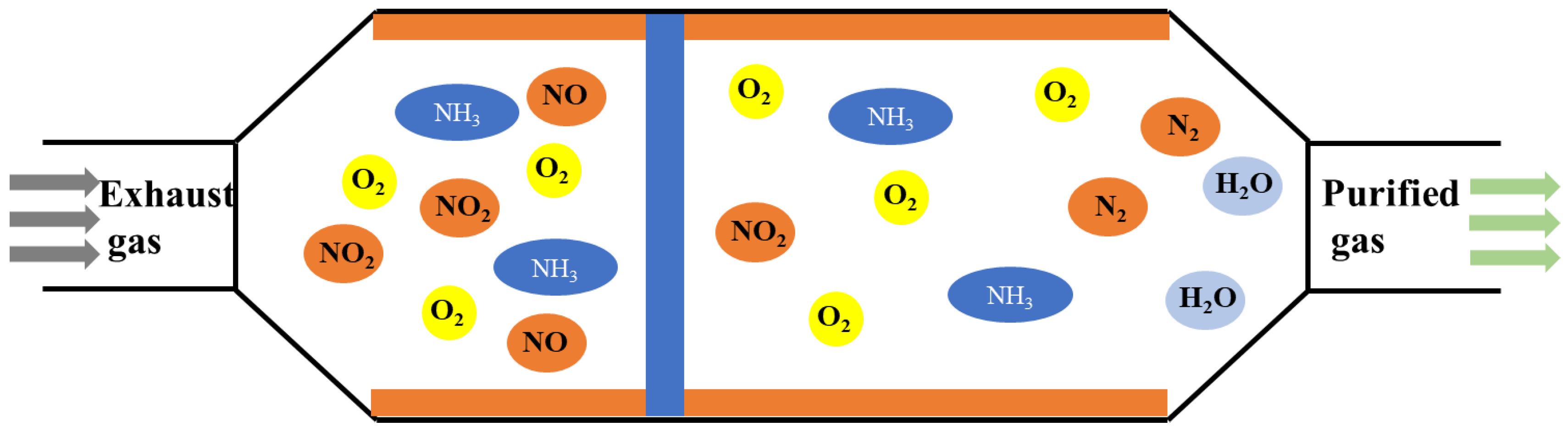

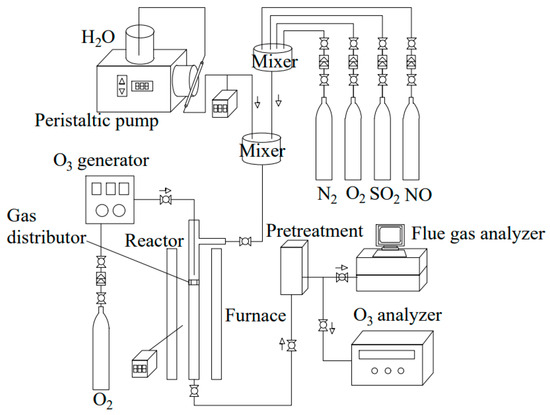

Wang et al. [114] investigated the oxidation of NO by O3 using simulated fuel gas. Their findings indicated that the oxidation efficiency exceeded 90% at a reaction temperature of 150 °C. Xia et al. [115] studied co-oxidized O3 with NaClO scrubbing liquid for ship exhaust, using the liquid to lower the temperature of the exhaust gas, less decomposition of O3, and optimize the reaction effect, while reducing the consumption of electrical energy. The ozone denitrification equipment is divided into three main segments, which are the ozone preparation system, ozone oxidation system, and absorption system (Figure 12). Both oxidation and adsorption processes have a direct impact on the efficiency of NOX removal and the operational economy [116]. Currently, O3 is typically produced through dielectric barrier discharge. But only a small fraction of O2 molecules is ionized to form O3, leading to high energy consumption, significant O2 usage, and high costs [117,118,119]. These factors limit the popularization and application of O3 oxidation denitrification technology.

Figure 12.

Process flow chart of ozone denitrification [117].

4.3. Integrated Exhaust Gas Desulfurization and Denitrification Technology

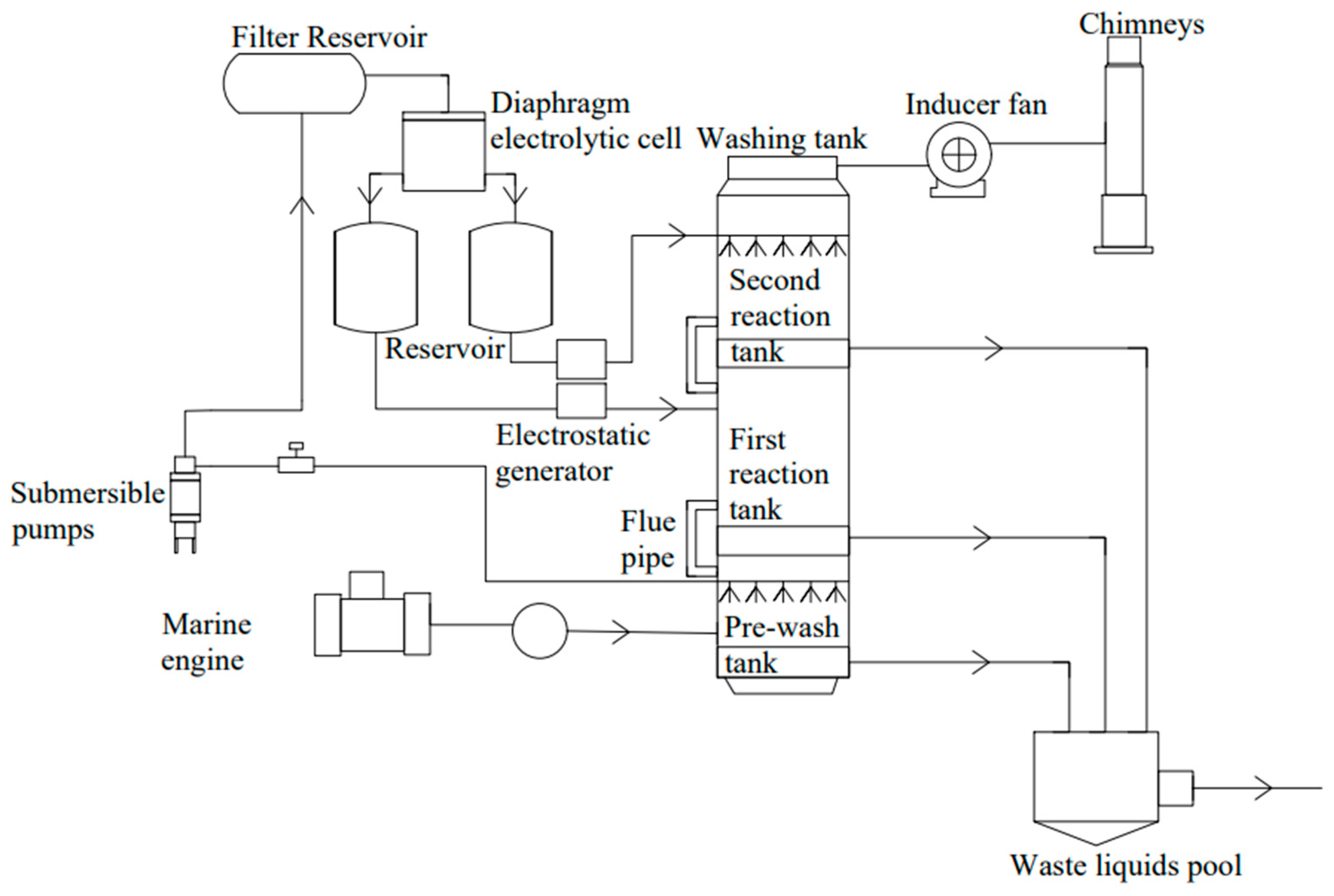

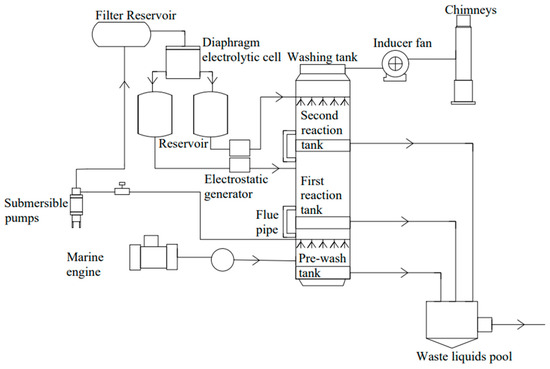

4.3.1. Electrostatic Spray Technology

Electrostatic spraying is used to remove pollutants from ship exhaust gas, based on traditional wet scrubbers. The dust is charged by corona charging and the spray droplets are directly charged by an electrostatic generator (Figure 13). The opposite charges between the two generate electrostatic attraction, so the droplets can more easily combine with pollutants, thereby improving the efficiency of the droplets in removing fine dust [120]. Oh et al. assessed the applicability of electrostatic spray technology for eliminating particulate matter produced following the electron beam treatment of NOX and SOX. In conditions with low particle number concentration (additive: NaOH, gas: NO, and NO2), even at an applied voltage of 5 kV, high removal efficiencies (ranging from 86.1% to 96.5%) were achieved [121]. The electrostatic atomization equipment is added to the traditional water washing tower. The device has two characteristics: (1) It uses seawater for desulfurization and denitrification, and the raw materials are inexhaustible. At the same time, it reduces the space occupied by traditional desulfurization and denitrification reactants, saves costs, and improves efficiency. (2) The introduction of electrostatic atomization equipment into ship exhaust treatment can better remove dust and make the droplets uniform and fine, increase the spatial density of the droplets, thereby increasing the contact reaction surface with sulfides and nitrates, and improve the capacity and efficiency of traditional desulfurization and denitrification equipment [122].

Figure 13.

Process flow chart of desulfurization and denitrification integration with electrostatic spray technology.

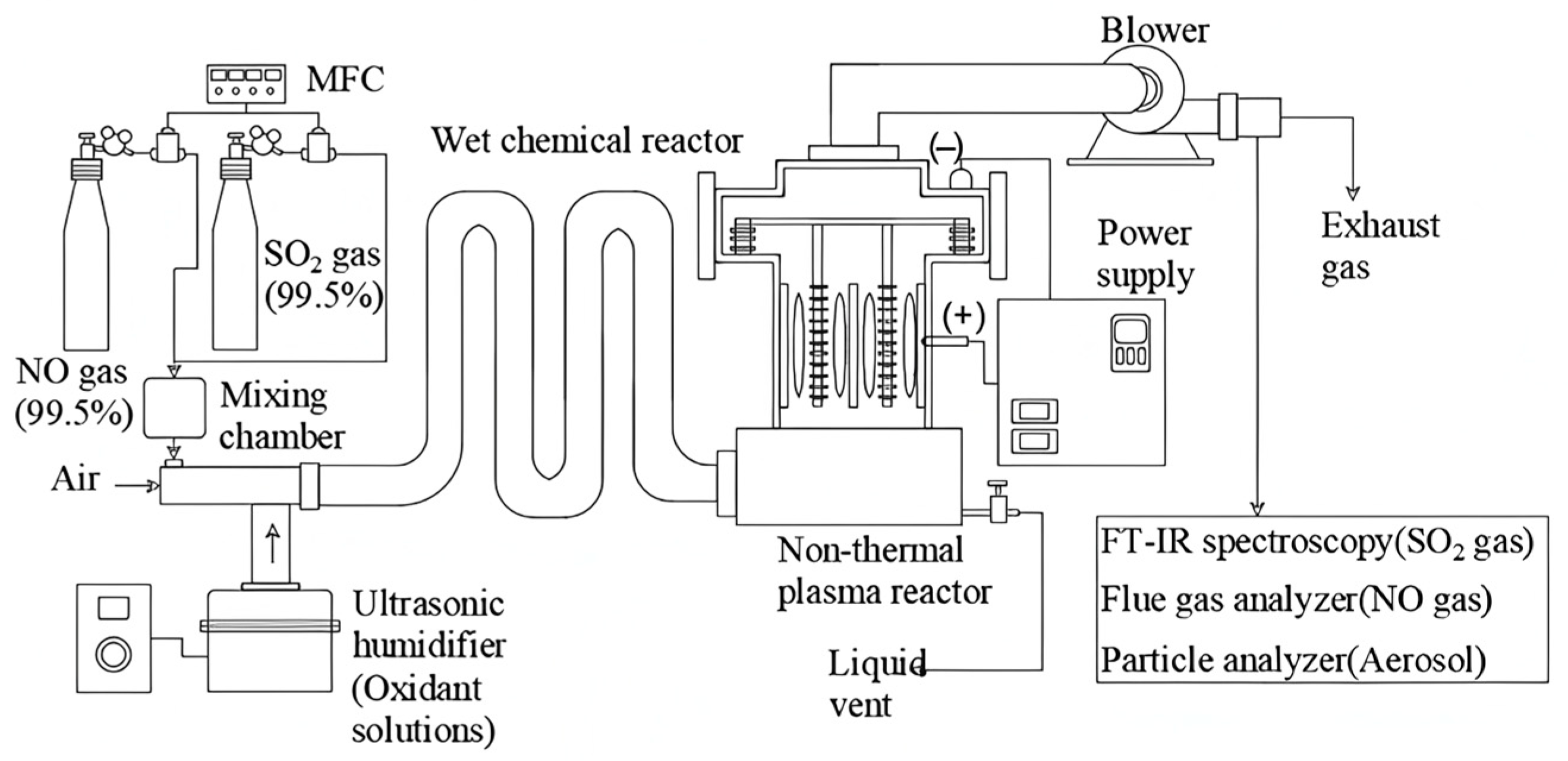

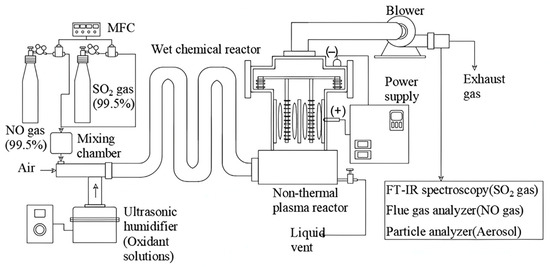

4.3.2. Plasma Oxidation Process

Plasma oxidation mainly employs high-energy electrons to energize, ionize, or even break apart SO2 and NOX molecules in flue gas, thereby producing a substantial amount of reactive particles, such as ions and radicals. The plasma oxidation process includes electron beam irradiation and a pulsed corona-induced plasma chemical process, which removes NOX and SO2 by oxidizing NOx and SO2 to highly valent oxides. (NH4)2SO4, and ammonium nitrate (NH4NO3) fertilizer are formed when ammonia is injected (Figure 14) [123,124]. However, the method has also technical challenges: (1) the NOx removal efficiency may drop to 0 or a negative value under certain oxygen concentrations; (2) CO2 and water vapor in the tail gas can also have a negative impact on the effectiveness of desulfurization and denitrification. Therefore, for the successful application of plasma oxidation for desulfurization and denitrification of ships, its use in combination with adsorption and catalysis needs to be continuously explored [111]. Cui et al. devised an integrated system for the removal of NO and SO2, combining a wet electrostatic precipitator (WESP) with dielectric barrier discharge (DBD) [125]. The oxidizing agents produced in the DBD process oxidize SO2 and NO. In the presence of water vapor in the flue gas, these oxidation products can further transform into acid mist, which the WESP can subsequently absorb and capture, along with any residual free radicals. The system demonstrated enhanced removal capabilities, achieving a peak removal efficiency of 98.9% for SO2 and 87.1% for NO. The integration of plasma technology significantly boosts the removal efficiency of SO2 and NOX. However, as evident from Figure 14, the addition of the electrostatic component complicates the system and leads to increased investment and operational costs.

Figure 14.

Facility diagram of wet scrubber combined with plasma electrostatic precipitator [126].

4.3.3. Oxidation–Reduction–Absorption Technology

The SO32− based oxidation–reduction–absorption process is preferred for its high removal efficiency and the ease with which it can modify existing wet FGD and N equipment [122]. Approximately 90% of the NOX in flue gas is NO, which has limited solubility in solutions [127]. Therefore, NO is typically oxidized using oxidizing agents in the initial stage of the oxidation–reduction–absorption process [128]. Subsequently, the higher-valent NOX can be more readily removed by adsorbents like Na2S, NaOH, or (NH4)2SO3 [129,130,131]. Reports indicate that Na2SO3 solutions demonstrate outstanding efficiency in removing NOX and SOX [132,133]. However, certain issues warrant attention: firstly, sulfite is prone to oxidation by O2 in the presence of NOX as a catalyst, which results in reduced effectiveness for NOX absorption. Secondly, there is competitive absorption between NOXand SO2 when using Na2SO3. SO2 can also consume a significant amount of SO32−, leading to a considerable decrease in the amount of NOx absorbed [134]. NaClO2 and Na2S2O3 were used for oxidizing and reducing sections to remove SO2 and NOX from simulated ship emissions. It was shown that although the more well-known sulfite (Na2SO3) was about 15% more efficient in removing NO2 compared to thiosulfate, the latter had a very low reactant consumption rate [135]. The reaction equation is as follows:

2NO + O2→2NO2

NO2 + 2NaOH→NaNO2 + NaNO3 + H2O

SO2 + H2O→HSO3− + H+

HSO3−→SO32− + H+

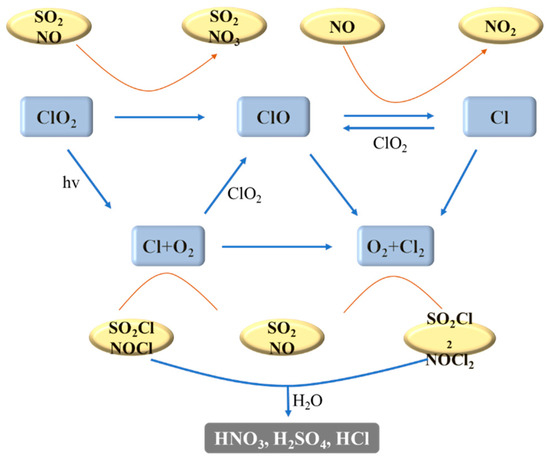

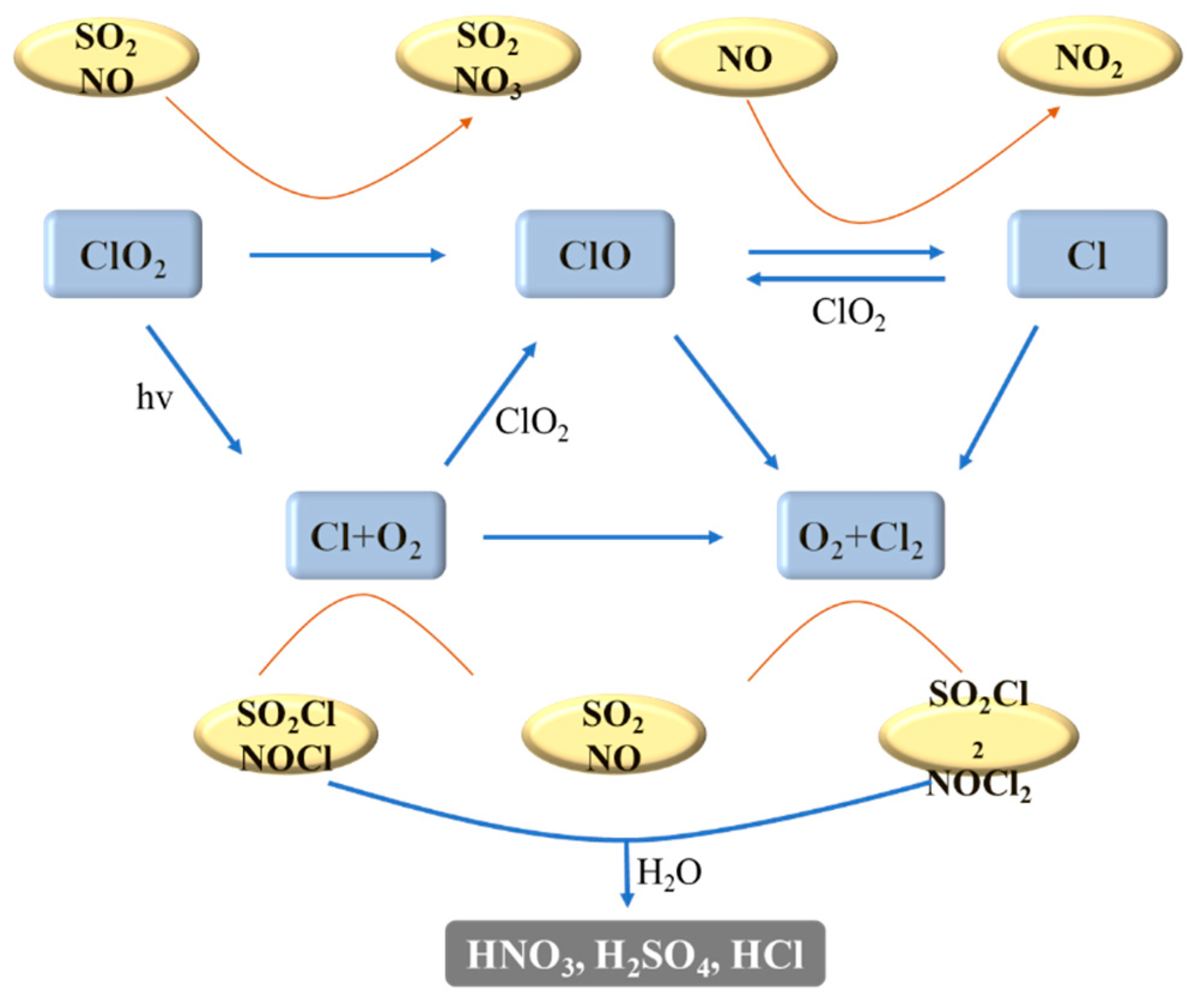

4.3.4. UV/Chlorine Advanced Oxidation Technology

In the UV/chlorine treatment involving active chlorine solution, the effective components of active chlorine, HOCl and OCl−, generate several free radicals via photolysis reactions, including hydroxyl (·OH) and chlorine (Cl·) radicals (Figure 15). Due to the strong and non-selective oxidation properties of these free radicals, it has been reported that UV/chlorine can oxidize NO from flue gas through a wet scrubbing process. The denitrification efficiency of effective chlorine in electrolyzed seawater is extremely low in the absence of light [136]. A significant synergistic effect on NO absorption was attained by integrating UV with electrolyzed seawater. At a pH of 6, NO was primarily removed by the HOCl present in the electrolyzed seawater.

NO(g)↔NO(aq)

NO(aq) + HOCl↔NO2 + H + Cl−

3NO2(aq) + H2O↔2H+ + 2NO3− + NO(aq)

2NO2(aq) + H2O↔HNO2 + H+ + NO3−

HNO2↔H+ + NO2−

NO2− + HOCl→NO3− + H + Cl−

Even though SO2 competes with NO for oxidants, the concentrations of UV-induced oxidants in electrolyzed seawater were ample to absorb both NO and SO2 concurrently in the photochemical bubble reactor. As the SO2 concentration rose from 200 to 1000 ppm, the NO absorption rate saw a slight increase from 2.9 × 10−5 to 3.0 × 10−5 mol/(m2·s) [137].

SO2(g)↔SO2(aq)

SO2(aq) + H2O↔HSO3− + H+

HSO3− + HO·↔SO42− + 2H+

HSO3− + HOCl↔SO42− + 2H+ + Cl−

The removal rate of SO2 from the ship’s exhaust gas by the effective chlorine solution can always be 100% when the pH is between 3 and 10. When the pH of the effective chlorine solution was maintained between 4 and 7, it was able to generate free radicals with high activity, which significantly enhanced the denitrification effect [131]. As the power of the UV irradiation UV lamp set increased, the concentration of active free radicals generated by the photolysis of effective chlorine increased, the oxidative property of the solution was enhanced, and the removal rates of NO and NOX increased close to linearly [138]. When practically applied to the purification of ship exhaust, the denitrification efficiency can be improved by implementing a multi-stage treatment strategy.

Figure 15.

Removal process of SO2 and NOX by Cl2 and ClO2 under UV [139].

Figure 15.

Removal process of SO2 and NOX by Cl2 and ClO2 under UV [139].

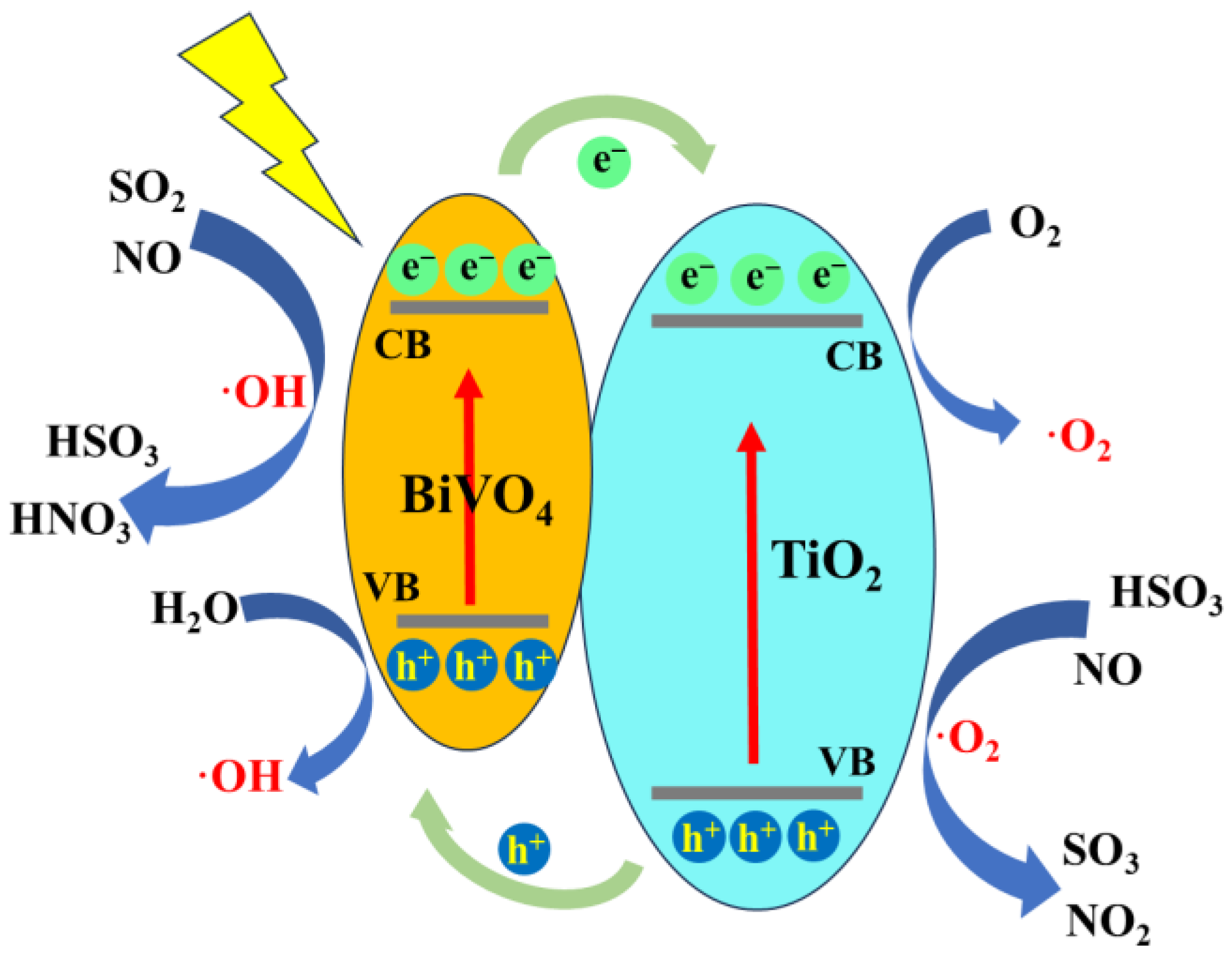

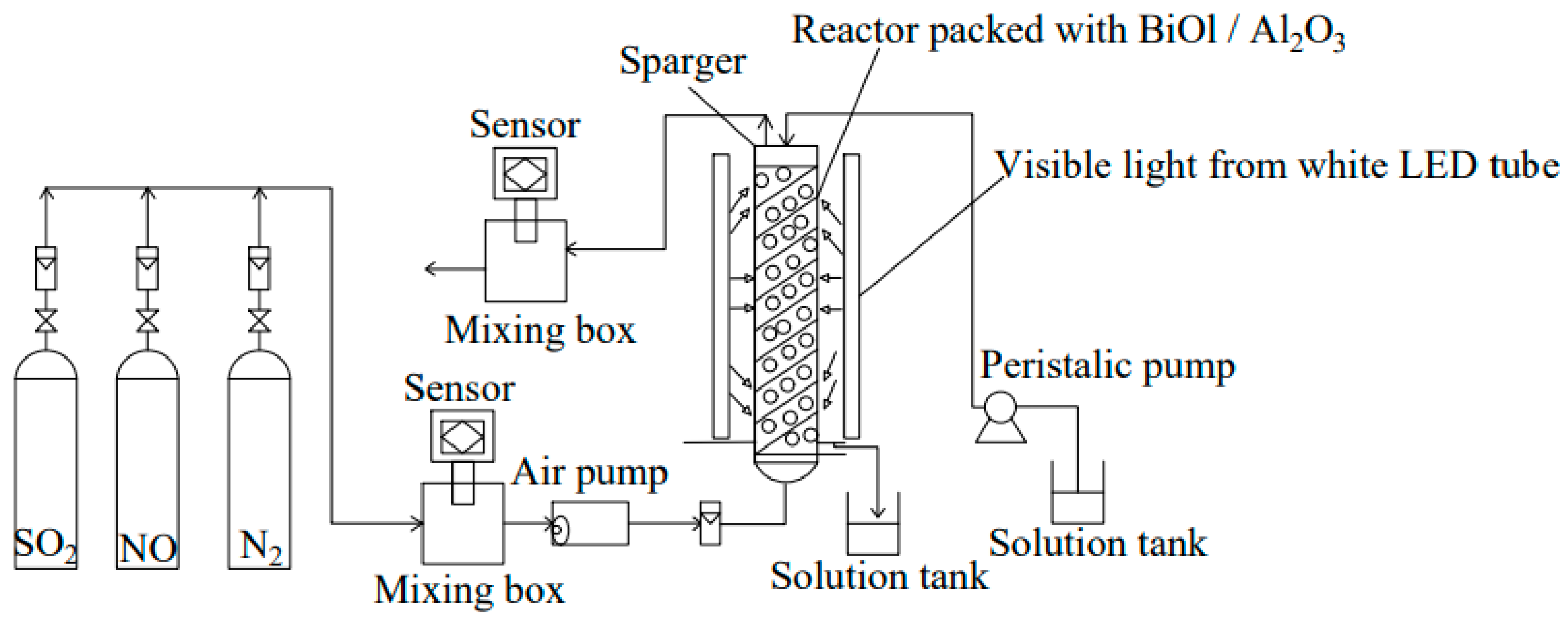

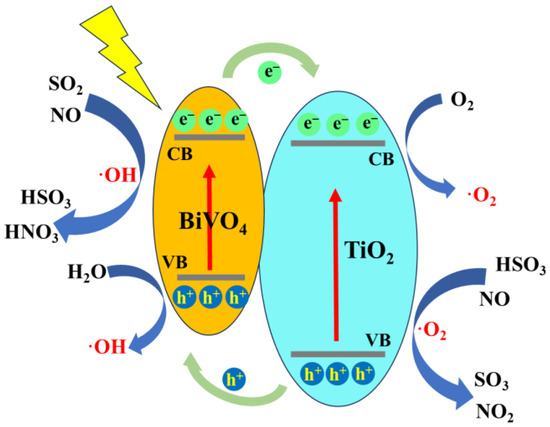

4.3.5. Photocatalysis

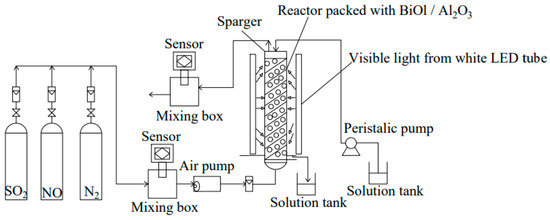

The photocatalytic oxidation approach shows that when a photocatalyst is exposed to light of a specific wavelength, it catalyzes the excitation of surrounding water and oxygen molecules, leading to the formation of reactive ·OH and ·O2 free ion groups (Figure 16). These free ions oxidize gaseous pollutants, which can then be absorbed by a wet scrubber. This process not only oxidizes SO2 to sulfate but also converts NO and NO2 to nitrate, thereby accomplishing both desulfurization and denitrification [140]. Photocatalytic oxidation offers benefits such as a compact design, absence of secondary pollution, and high removal efficiency. TiO2, as a photocatalyst, absorbs light energy and can adsorb SO2 through van der Waals forces present between SO2 and TiO2 molecules. ZnO shares similar advantages with TiO2, including strong photo-oxidizing capabilities, good stability across a broad pH range, and an environmentally friendly profile. Man et al. prepared p-n junction ZnO-CuO/rGO ternary catalysts via the co-precipitation route [141]. The photocatalytic performance of ZnO-CuO/rGO was assessed for concurrent desulfurization and denitrification processes, achieving a desulfurization efficiency of 97% and a denitrification efficiency of 64% over a period of 270 min. When added to a seawater scrubber, ZnO-CuO/rGO facilitated a SO32− conversion rate of 80.72%. The photocatalytic technology is still mainly in the laboratory research stage, but the photocatalytic technology is a very desirable and promising technology for the treatment of ship exhaust. The process flow of photocatalytic desulfurization and denitrification is shown in Figure 17.

Figure 16.

Proposed mechanism of photocatalytic reaction [142].

Figure 17.

Process flow chart of photocatalytic desulfurization and denitrification integration [143].

Currently, the widely respected process in the field of ship exhaust treatment is mainly the integrated technology that integrates the functions of desulfurization and denitrification. The main comparison among the most commonly used desulfurization and denitrification systems is given in Table 2. Compared to separate desulfurization and denitrification processes, integrated desulfurization and denitrification reduce the amount of space taken up by the ship through integrated design and improve space utilization, as well as being able to treat both SOX and NOX at the same time, thereby improving energy efficiency and increasing fuel utilization of the ship.

Table 2.

Process characteristics and removal efficiencies of flue gas desulfurization and denitrification technology.

5. Conclusions and Recommendations

As the global economy and tourism develop rapidly, attention has been paid to the air pollutant problem caused by ship exhaust emissions. Following the introduction of Annex VI of the MARPOL convention in 1997, increasingly strict emission regulations have been put in place to curb emissions from ships. Consequently, numerous emission reduction methods have been explored and developed under various conditions and different devices. This paper is intended to provide a review of the status of emissions and control regulations for ship exhausts in the Lijiang River, and strategies for reducing ship diesel engine emissions. They are summarized as follows:

- (1)

- The Lijiang River has a rich tourist landscape endowed by nature. A large number of tourists have caused a large amount of polluted gas emissions while on the cruise on the Lijiang River. Most ships in the Lijiang River use traditional low-speed diesel engines, with a large number of old ships, and the gas treatment of ships started late, and the equipment was backward. In order to improve air quality, the Guilin Maritime Safety Administration has actively taken measures to solve the problem of ship exhaust pollution in the Lijiang River. In addition to formulating strict emission regulations, the adjustment of ship structure, the promotion of new energy and the construction of a monitoring system are all important measures;

- (2)

- SO2 and PM emissions are largely dependent on the sulfur content of the fuels used by ships. NOX is mainly related to the combustion of nitrogen in the air when the engine is operated at high temperatures. Ships have become a major pollution source in certain inland rivers where shipping lanes are densely populated and ship traffic is high. NOX, SOX, and PM emissions from ships can negatively impact the natural environment and human health along the coastline;

- (3)

- Installing an exhaust aftertreatment system can effectively reduce NOX and SOX emissions, thereby meeting the Tier III standards. The wet flue gas desulfurization system can effectively capture SO2 from flue gas, concentrating it in gypsum and solution. The wet flue gas desulfurization system is applied to large two-stroke marine diesel engines operated with high-sulfur fuel. SCR is the most mature and effective exhaust treatment method for controlling marine diesel engine NOX emission. Most of the exhaust aftertreatment techniques are mature, but they need to be used with appropriate integration and combination to achieve co-reduction in all pollutants and cost-effectiveness. Integrated desulfurization and denitrification treatment technology has its own advantages and disadvantages. The market has not yet found the most ideal solution and still needs to select the appropriate program in accordance with the specific needs of the ship exhaust treatment.

To address the challenges of rising ship emissions and stricter emission standards, the Lijiang River region must urgently adopt advanced exhaust treatment technologies. Current methods are limited by high energy consumption, costs, and spatial requirements. Future developments should focus on creating efficient, compact, and cost-effective solutions. The region should prioritize low-sulfur fuels, LNG, hybrid and electric propulsion systems, and intelligent management to optimize navigation and reduce emissions. New regulations will drive the industry toward cleaner practices, ensuring environmental sustainability and fostering a greener maritime sector.

Author Contributions

Methodology, Y.Z. and S.B.; software, H.L.; validation, P.L.; formal analysis, X.Z.; investigation, P.L. and D.X.; writing—original draft preparation, Y.X.; writing—review and editing, B.X. and D.X.; supervision, M.W. and H.L.; project administration, S.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Natural Science Foundation of Guangxi (2024GXNSFBA010343), Guangxi Key Research and Development Program (Guike AB22080067), National Natural Science Foundation of China (52260024), Guangxi Key Laboratory of Environmental Pollution Control Theory and Technology (Guikeneng 2101Z003).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Acknowledgments

The authors gratefully acknowledge Guangxi Science and Technology Program (Guike AD25069074) and University Engineering Research Center of Watershed Protection and Green Development, Guangxi for providing experimental coordination and safety guarantee.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationship that could have appeared to influence to the work reported in this paper. Mei Wang is employed by Hengsheng Water Environment Treatment Co., Ltd., Guilin 541100, China. Mei Wang declares no conflict of interest.

References

- Lonati, G.; Cernuschi, S.; Sidi, S. Air quality impact assessment of at-berth ship emissions: Case study for the project of a new freight port. Sci. Total Environ. 2010, 409, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.Y.; Peng, L.; Wei, J.L.; Liao, Y.Z. Ammonia coverage ratio control of a novel two-cell SCR-DeNOX system configuration based on IA-ISMC. Chem. Eng. Sci. 2024, 295, 120148–120158. [Google Scholar] [CrossRef]

- IMO. Third IMO Greenhouse Gas Study; International Maritime Organization: London, UK, 2014. [Google Scholar]

- Eyring, V.; Köhler, H.; Lauer, A.; Lemper, B. Emissions from international shipping: 2. Impact of future technologies on scenarios until 2050. J. Geophys. Res. 2005, 110, D17. [Google Scholar] [CrossRef]

- Tavella, R.A.; das Neves, D.F.; Silveira, G.d.O.; Vieira de Azevedo, G.M.G.; Brum, R.d.L.; Bonifácio, A.d.S.; Machado, R.A.; Brum, L.W.; Buffarini, R.; Adamatti, D.F.; et al. The relationship between surface meteorological variables and air pollutants in simulated temperature increase scenarios in a medium-sized industrial city. Atmosphere 2025, 16, 363. [Google Scholar] [CrossRef]

- Tavella, R.A.; Penteado, J.O.; Brum, B.D.L.; Bonifácio, A.D.S.; Martin, M.C.S.; Elizabet, S.S.; Brum, A.N.; Buffarini, R.; Filho, W.L.F.C.; Adamatti, D.F.; et al. An exploratory study on the association between air pollution and health problems (ICD-10) with an emphasis on respiratory diseases. Atmos. Pollut. Res. 2025, 16, 102377. [Google Scholar] [CrossRef]

- Tavella, R.A.; Júnior, F.M.R.D.S.; Santos, M.A.; Miraglia, S.G.E.K.; Filho, R.D.P. A review of air pollution from petroleum refining and petrochemical industrial complexes: Sources, key pollutants, health impacts, and challenges. ChemEngineering 2025, 9, 13. [Google Scholar] [CrossRef]

- Jeevahan, J.; Mageshwaran, G.; Joseph, G.B.; Raj, R.B.D.; Kannan, R.T. Various strategies for reducing NOx emissions of biodiesel fuel used in conventional diesel engines: A review. Chem. Eng. Commun. 2017, 204, 1202–1223. [Google Scholar] [CrossRef]

- Long, Y.X.; Li, G.S.; Zhang, Z.H.; Liang, J.J. Application of reformed exhaust gas recirculation on marine LNG engines for NOx emission control. Fuel 2021, 291, 120114. [Google Scholar] [CrossRef]

- Mao, X.Y.; Meng, J.J.; Wang, Q. Modeling the effects of tourism and land regulation on land-use change in tourist regions: A case study of the Lijiang River Basin in Guilin, China. Land Use Policy 2014, 41, 368–377. [Google Scholar] [CrossRef]

- Lin, C.-Y. Strategies for promoting biodiesel use in marine vessels. Mar. Policy 2013, 40, 84–90. [Google Scholar] [CrossRef]

- Deng, J.J.; Wang, X.C.; Wei, Z.L.; Wang, L.; Wang, C.Y.; Chen, Z.B. A review of NOx and SOx emission reduction technologies for marine diesel engines and the potential evaluation of liquefied natural gas fueled vessels. Sci. Total Environ. 2020, 766, 144319–144324. [Google Scholar] [CrossRef]

- Pham, H.T.; Nguyen, T.M. Solution to reduce air environmental pollution from ships. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2015, 9, 257–261. [Google Scholar]

- Nunes, R.A.O.; Alvim-Ferraz, M.C.M.; Martins, F.G.; Sousa, S.I.V. The activity- based methodology to assess ship emissions—A review. Environ. Pollut. 2017, 231, 87–103. [Google Scholar] [CrossRef]

- Merico, E.; Donateo, A.; Gambaro, A.; Cesari, D.; Gregoris, E.; Barbaro, E.; Dinoi, A.; Giovanelli, G.; Masieri, S.; Contini, D. Influence of in-port ships emissions to gaseous atmospheric pollutants and to particulate matter of different sizes in a Mediterranean harbour in Italy. Atmos. Environ. 2016, 139, 1–10. [Google Scholar] [CrossRef]

- Geng, P.; Tan, Q.M.; Zhang, C.H.; Wei, L.J.; He, X.Z.; Cao, E.M.; Jiang, K. Experimental investigation on NOx and greenhouse gas emissions from a marine auxiliary diesel engine using ultralow sulfur light fuel. Sci. Total Environ. 2016, 572, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Hu, Y.; Zhou, H.Y. Li River Tourism Receives 1.97 Million Tourists in Summer. Guilin Daily, 1 September 2024. [Google Scholar]

- Li, C.L. Considerring of Water Traffie Safety Managementin Li River Travel Sail District; Dalian Maritime University: Dalian, China, 2012. [Google Scholar]

- China New Network. It Is Recommended to Speed Up the Upgrading of the New Energy Tourism Raft Industry. Available online: https://baijiahao.baidu.com/s?id=1792954343862247546&wfr=spider&for=pc (accessed on 1 May 2025).

- Tang, J. Thoughts on ship pollution prevention in Lijiang River Scenic Area in Guilin. Marit. Saf. 2022, 3, 33–36. [Google Scholar]

- DieselNet. IMO Marine Engine Regulations. Available online: https://www.dieselnet.com/standards/inter/imo.php#other (accessed on 17 May 2019).

- Ministry of Transport. Announcement of the Ministry of Transport on Strengthening the Administration of Domestic Waterway Transportation for Imported Ships from Outside China and China-registered International Sailing Ships. Available online: https://www.gov.cn/xinwen/2018-07/04/content_5303394.htm (accessed on 3 May 2025).

- DieselNet. China: Marine Engines. Available online: https://www.dieselnet.com/standards/cn/marine.php (accessed on 1 August 2019).

- Ni, P.Y.; Wang, X.L.; Li, H. A review on regulations, current status, effects and reduction strategies of emissions for marine diesel engines. Fuel 2020, 279, 118477. [Google Scholar] [CrossRef]

- Li, S.J. New Cruise Ship, New Bamboo Raft, New Power, Lijiang River Tour Stepping Into a New Era of Low-Carbon Travel. Guilin Daily, 25 April 2023. [Google Scholar]

- CCTV.com. Lijiang River Launches Pure Electric Power Sightseeing Raft in Guilin. Available online: https://news.cctv.com/2023/04/20/ARTIAvZFPywRADhXTrpYoHsg230420.shtml (accessed on 1 May 2025).

- Guangxi News Network. Guilin Power Supply Bureau Builds a Demonstration Model of Power Supply Service in World-Class Tourist Cities. Available online: https://www.gxnews.com.cn/staticpages/20220425/newgx6266674a-20727577.shtml (accessed on 1 May 2025).

- Mi, J.G.; Huang, Y.T. Keep in mind that Guilin Maritime Bureau should be the “Erlang God” to protect the Lijiang River. China Marit. Aff. 2022, 75–76. [Google Scholar] [CrossRef]

- GB2552-2018; Discharge Standard for Water Pollutants from Ships. China Environmental Science Press: Beijing, China, 2018.

- Guilin Government Network. Notice of Guilin Maritime Safety Administration on Printing and Distributing the Three-year Action Implementation Plan for Pollution Prevention of Ships in Lijiang River. Available online: https://www.guilin.gov.cn/zfxxgk/fdzdgknr/jcxxgk/bmwj/glhsj/202110/t20211014_2141776.shtml (accessed on 3 May 2025).

- Qi, Z.Y.; Peng, S.T.; Hu, J.B.; Deng, M.T.; Zhao, H.X.; Zhu, G.X.; Yu, X.; Su, N. Surveillance practice and automatic data algorithm of sniffing telemetry for SO2 emissions from ship exhaust in Tianjin Port. J. Clean. Prod. 2023, 409, 137225. [Google Scholar] [CrossRef]

- He, L.; Wang, J.J.; Liu, Y.M.; Zhang, Y.; He, C.; Yu, Q.; Ma, W.C. Selection of onshore sites based on monitoring possibility evaluation of exhausts from individual ships for Yantian Port, China. Atmos. Environ. 2021, 247, 118187. [Google Scholar] [CrossRef]

- Peng, X.; Li, T.W.; Wu, L.C.; Huang, L.; Wen, Y.Q.; Zhou, C.H.; Zhang, F.; Han, T.X.; Li, J. Optimal site selection for the remote-monitoring sulfur content of ship fuels in ports. Ocean Coast. Manag. 2022, 225, 106211. [Google Scholar] [CrossRef]

- Paik, B.-G.; Cho, S.-R.; Park, B.-J.; Lee, D.; Bae, B.-D. Development of real-time monitoring system using wired and wireless networks in a full-scale ship. Int. J. Nav. Archit. Ocean Eng. 2010, 2, 132–138. [Google Scholar]

- Sina Finance. Guilin Maritime Safety Administration Introduced UAV Telemetry Equipment for the First Time to Monitor the Tail Gas of Lijiang River Ships. Available online: https://finance.sina.com.cn/jjxw/2021-12-10/doc-ikyamrmy8022940.shtml (accessed on 2 May 2025).

- Zhao, J.; Wei, Q.; Wang, S.; Ren, X.L. Progress of ship exhaust gas control technology. Sci. Total Environ. 2021, 799, 149437–149461. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.L.; Wang, X.; Yin, C.Q.; Xu, W.W.; Shi, W.; Qian, G.R.; Xun, Z.M. Inland Vessels Emission Inventory and the emission characteristics of the Beijing-Hangzhou Grand Canal in Jiangsu province. Process Saf. Environ. Prot. 2018, 113, 498–506. [Google Scholar] [CrossRef]

- Russo, M.A.; Leitão, J.; Gama, C.; Ferreira, J.; Monteiro, A. Shipping emissions over Europe: A state-of-the-art and comparative analysis. Atmos. Environ. 2018, 177, 187–194. [Google Scholar] [CrossRef]

- Han, Z.; Zou, T.; Wang, J.; Dong, J.M.; Deng, Y.B.; Pan, X.X. A novel method for simultaneous removal of NO and SO2 from marine exhaust gas via in-site combination of ozone oxidation and wet scrubbing absorption. J. Mar. Sci. Eng. 2020, 8, 943. [Google Scholar] [CrossRef]

- Lu, Q.; Zheng, J.; Ye, S.; Shen, X.Q.; Yuan, Z.B.; Yin, S.S. Emission trends and source characteristics of SO2, NOx, PM10 and VOCs in the Pearl River Delta region from 2000 to 2009. Atmos. Environ. 2013, 76, 11–20. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, Y.; Ma, W.; Ma, H.X.; Feng, J.L.; Yu, Q.; Yang, X.; Simon, K.W.N.; Fu, Q.Y.; Chen, L.M. Spatial and seasonal dynamics of ship emissions over the Yangtze River Delta and east China sea and their potential environmental influence. Environ. Sci. Technol. 2016, 50, 1322–1329. [Google Scholar] [CrossRef]

- Song, Y.N. Research of Emission Inventory and Emission Character of Inland and Offshore Ships; Beijing Institute of Technology: Beijing, China, 2015. [Google Scholar]

- Gan, L.X.; Che, W.Y.; Zhou, M.G.; Zhou, C.H.; Zheng, Y.Z.; Zhang, L.; Rangel-Buitrago, N.; Song, L. Ship exhaust emission estimation and analysis using automatic identification system data: The west area of Shenzhen port, China, as a case study. Ocean Coast. Manag. 2022, 226, 106245. [Google Scholar] [CrossRef]

- Shu, Y.Q.; Hu, A.Y.; Zheng, Y.Z.; Gan, L.X.; Xiao, G.N.; Zhou, C.H.; Song, L. Evaluation of ship emission intensity and the inaccuracy of exhaust emission estimation model. Ocean. Eng. 2023, 287, 115723. [Google Scholar] [CrossRef]

- Ke, S.Z.; Zhou, Z.J. On the Existing Conditions and Problems with the Prevention and Control of Air Pollution from Ships in China; China Maritime Safety: Beijing, China, 2019; pp. 18–21.

- Fu, Q.Y.; Shen, Y.; Zhang, J. On the ship pollutant emission inventory in Shanghai port. J. Saf. Environ. 2012, 12, 57–64. [Google Scholar]

- Schroeder, C.; Schroeder, W.; Yang, S.; Shi, H.T.; Nystrom, A.; Subramanian, S.; Li, S.J.; Gundersen, M.A.; Cronin, S.B. Plasma-enhanced SO2 remediation in a humidified gas matrix: A potential strategy for the continued burning of high sulfur bunker fuel. Fuel 2020, 274, 117810–117813. [Google Scholar] [CrossRef]

- Wang, X.N.; Shen, Y.; Lin, Y.F.; Pan, J.; Zhang, Y.; Louie, P.K.K.; Li, M.; Fu, Q.Y. Atmospheric pollution from ships and its impact on local air quality at a port site in Shanghai. Atmos. Chem. Phys. 2019, 19, 6315–6330. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Ma, Q.X.; Zhang, P.; Chen, T.Z.; Wang, Y.H.; Chu, B.W.; Li, H.; Li, J.K.; Chen, C.C.; Zhao, J.C.; et al. A light -driven acidic positive feedback mechanism of sulfate formation. Atmos. Environ. 2024, 331, 120606–120613. [Google Scholar] [CrossRef]

- Brynolf, S.; Magnusson, M.; Fridell, E.; Andersson, K. Compliance possibilities for the future ECA regulations through the use of abatement technologies or change of fuels. Transp. Res. Part D Transp. Environ. 2014, 28, 6–18. [Google Scholar] [CrossRef]

- Chen, P. Effect of wet scrubbing oxidation denitration technology combined with ultraviolet online irradiation on the efficiency of desulfurization and denitrification of ship exhaust gas. IOP Conf. Ser. Earth Environ. Sci. 2020, 450, 012101–012110. [Google Scholar] [CrossRef]

- Chen, J.; Fu, X.; Wang, X.F.; Dong, S.W.; Chen, T.S.; Xue, L.K.; Zhou, Y.; Sheng, L.F.; Wang, W.X. Unveiling the overlooked direct emissions of particulate organic nitrates from ship. Environ. Int. 2024, 185, 108487–108493. [Google Scholar] [CrossRef] [PubMed]

- Saxe, H.; Larsen, T. Air pollution from ships in three danish ports. Atmos. Environ. 2004, 38, 4057–4067. [Google Scholar] [CrossRef]

- Liu, M.W.; Zhang, H.; Li, J.; Qi, X.C.; Wang, Y.F.; Pang, J.D. Recent progress and future prospects of metal-organic frameworks for adsorption, separation and catalytic removal of NOx and N2O. ChemCatChem 2024, 6, 922–934. [Google Scholar] [CrossRef]

- Chin, T.; Tam, I.C.K.; Yin, C.-Y. Comparison of various chemical compounds for the removal of SO2 and NOx with wet scrubbing for marine diesel engines. Environ. Sci. Pollut. Res. 2022, 29, 8873–8891. [Google Scholar] [CrossRef]

- Lee, Y.W.; Sung, J.H.; Han, B.W.; Kim, Y.J.; Kim, H.J. Minimizing the consumption of reducing agents for NOx removal in a wet scrubber without H2S formation. Sep. Purif. Technol. 2022, 282, 120101–120112. [Google Scholar] [CrossRef]

- Zetterdahl, M.; Moldanová, J.; Pei, X.Y.; Pathak, R.K.; Demirdjian, B. Impact of the 0.1% fuel sulfur content limit in SECA on particle and gaseous emissions from marine vessels. Atmos. Environ. 2016, 145, 338–345. [Google Scholar] [CrossRef]

- Zhu, Y.Q.; Wan, Q.Q.; Hou, Q.C.; Feng, Y.M.; Yu, J.; Shi, J.; Xia, C. Analysis of diffusion characteristics and influencing factors of particulate matter in ship exhaust plume in arctic environment based on CFD. Atmosphere 2024, 15, 580. [Google Scholar] [CrossRef]

- Zhang, Y.; Eastham, S.D.; Lau, A.K.; Fung, J.C.H.; Selin, N.E. Global air quality and health impacts of domestic and international shipping. Environ. Res. Lett. 2021, 16, 84055–84069. [Google Scholar] [CrossRef]

- Aakko-Saksa, P.; Koponen, P.; Roslund, P.; Laurikko, J.; Nylund, N.-O.N.-O.; Karjalainen, P.; Rönkkö, T.; Timonen, H. Comprehensive emission characterisation of exhaust from alternative fueled cars. Atmos. Environ. 2020, 236, 117643–117644. [Google Scholar] [CrossRef]

- Corbett, J.; Winebrake, E.; Green, P.; Kasibhatla, P.; Eyring, V.; Lauer, A. Mortality from ship emissions: A global assessment. Environ. Sci. Technol. 2007, 41, 8512–8518. [Google Scholar] [CrossRef]

- Mao, X. Present situation and trends of desulfurization and denitrification of flue gas. Shandong Ind. Technol. 2015, 19, 3–6. [Google Scholar]

- Liu, X.W. Progress of desulfurization and denitration technology of flue gas in China. IOP Conf. Ser. Earth Environ. Sci. 2019, 242, 42010–42017. [Google Scholar]

- Zhao, X.; Gao, J.; Wu, S.H.; Qin, Y.K. Development of dry and semi-dry (CalciumBase) flue gas desulfurization technology. Chem. Eng. 2003, 31, 64–67. [Google Scholar]

- Osaka, Y.G.; Kito, T.; Kobayashi, N.; Kurahara, S.; Huang, H.Y.; Yuan, H.R.; He, Z.H. Removal of sulfur dioxide from diesel exhaust gases by using dry desulfurization MnO2 filter. Sep. Purif. Technol. 2015, 150, 80–85. [Google Scholar] [CrossRef]

- Du, C.C.; Yi, H.H.; Tang, X.L.; Zhao, S.Z.; Gao, F.Y.; Yu, Q.J.; Yang, Z.Y.; Yang, K.; Xie, X.Z.; Ma, Y.Q. Desulfurization and denitrification experiments in SDA system: A new high efficient semi-dry process by NaClO2. Separation and Purification Technology 2020, 230, 115873–115881. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zhang, M.C.; Wang, D.F.; Wang, L. Study on a novel semidry flue gas desulfurization with multi fluid alkaline spray generator. Ind. Eng. Chem. Res. 2005, 44, 8830–8836. [Google Scholar] [CrossRef]

- Wang, W.Z. Study on Gas-Liquid Mass Transfer and Reaction Characteristic of Absorption Process in Sodium Alkali FGD; Tianjin University: Tianjin, China, 2007. [Google Scholar]

- Song, H.; Li, X.F.; Jin, H.; Liang, X.Q.; Kang, R.L. Research on the technology of flue gas desulfurization by spray dryer absorber (SDA). China Environ. Prot. Ind. 2021, 4, 50–53. [Google Scholar]

- Peng, G.Y. Discussion on energy saving technology and methods of surrounding structure wall of high-rise building. Shanxi Archit. 2018, 44, 195–197. [Google Scholar]

- Xiang, Y.; Lv, W.H.; Yang, G.H.; Lv, G.; Gou, Y.B. Design and analysis of marine exhaust gas treatment system based on wet desulfurization process. Sichuan Environ. 2020, 39, 97–103. [Google Scholar]

- Zhao, Y.; Ma, S.; Wang, X.; Zhang, Q. Experimental and mechanism studies on seawater flue gas desulfurization. J. Environ. Sci. 2003, 15, 123–128. [Google Scholar]

- Shi, N.; Zhang, X.; Lei, L. Sulfite oxidation in seawater flue gas desulfurization by a pulsed corona discharge process. Sep. Purif. Technol. 2009, 70, 212–218. [Google Scholar] [CrossRef]

- Zhao, J.X.; Yang, Y.; Liu, H.R.; Xu, S.C.; Wei, Q.F.; Ren, X.L. The application of two-phase composite absorbent systems consisting of BAD and seawater resources in the wet treatment of ship exhaust gas. iScience 2023, 26, 106472–106490. [Google Scholar] [CrossRef]

- Bian, J.J.; Zhang, S.; Zhang, J.W.; Min, X.; Li, C.H. Supported manganese dioxide catalyst for seawater flue gas desulfurization application. Chem. Eng. J. 2012, 189–190, 57–61. [Google Scholar] [CrossRef]

- Flagiello, D.; Natale, F.D.; Erto, A.; Lancia, A. Wet oxidation scrubbing (WOS) for flue-gas desulphurization using sodium chlorite seawater solutions. Fuel 2020, 277, 118055. [Google Scholar] [CrossRef]

- Jiang, Q.; He, Y.M.; Wu, Y.L.; Jin, Y.J.; Dian, B.; Li, T.G.; Guo, J.F.; Jiang, M. Research progress of seawater flue gas desulfurization technology. J. Salt Sci. Chem. Ind. 2022, 51, 9–12. [Google Scholar]

- Qi, C.B. Comparison between magnesium oxide and limestone-gypsum wet flue gas desulfurization technology. Silicon Val. 2010, 9, 056–057. [Google Scholar]

- Luo, Z.; Peng, J.J.; Wang, D.H.; Yang, J. Recovery of phosphate from piggery biogas slurry by ultrasonication, aeration and addition of MgO desulfurization waste residue. J. Clean. Prod. 2019, 211, 865–873. [Google Scholar] [CrossRef]

- Tian, H.J.; Wan, D.H.; Che, Y.X.; Chang, J.; Zhao, J.; Hu, X.D.; Guo, Q.J.; Wang, Z.W.; Wang, L.Y. Simultaneous magnesia regeneration and sulfur dioxide generation in magnesium-based flue gas desulfurization process. J. Clean. Prod. 2020, 284, 124720–124734. [Google Scholar] [CrossRef]

- Li, X.; Chen, L.T.; Osaka, Y.; He, Z.H.; Deng, L.S.; Huang, H.Y. Preparation and desulfurization performance of various MnOx materials for ship exhaust emissions control. Sep. Purif. Technol. 2020, 253, 117182–117189. [Google Scholar] [CrossRef]

- Fang, D.A.; Zhang, X.F.; Dong, M.G.; Xue, X.X. A novel method to remove chromium, vanadium and ammonium from vanadium industrial wastewater using a byproduct of magnesium based wet flue gas desulfurization. J. Hazard. Mater. 2017, 336, 8–20. [Google Scholar] [CrossRef]

- Cho, K.J.; Keener, T.C.; Khang, S.-J. A study on the conversion of trona to sodium bicarbonate. Powder Technol. 2008, 184, 58–63. [Google Scholar] [CrossRef]

- Ning, H.Y.; Tang, R.J.; Li, C.M.; Gu, X.L.; Gong, Z.J.; Zhu, C.Q.; Li, J.L.; Wang, K.J.; Yu, J. Recent advances in process and materials for dry desulfurization of industrial flue gas: An overview. Sep. Purif. Technol. 2025, 353, 128425–128443. [Google Scholar] [CrossRef]

- Shu, S.; Huang, Y.; Zou, L.; Zhang, X.; Li, J. Mechanism of synergistic removal of NO and SO2 by sodium bicarbonate. RSC Adv. 2023, 13, 32589–32595. [Google Scholar] [CrossRef]

- Kong, C.J. Research on the Characteristics of Alkaline Combined Desulfurization and Decarbonization for Ocean-Going Ships; Chongqing Jiao Tong University: Chongqing, China, 2024. [Google Scholar]

- Liang, E.S. The role of sodium-alkali waste gas washing and desulfurization technology in the exhaust gas treatment of marine diesel engines. IOP Conf. Ser. Earth Environ. Sci. 2020, 514, 032036–032044. [Google Scholar] [CrossRef]

- Kumar, L.; Dhakad, V.K.; Jana, S.K. Recycling of marble waste for desulfurization of flue gas accompanied by synthesis of gypsum and PoP. Chem. Eng. Res. Des. 2022, 184, 577–591. [Google Scholar] [CrossRef]

- Pan, D.P.; Zhang, D.P.; Zhang, W.D. Investigation on removal characteristics of SO3 acid mist during limestone-gypsum desulfurization Process. Energy Fuels 2018, 32, 12949–12954. [Google Scholar] [CrossRef]

- Yang, D. Experimental Study on Absorber Resistance Characteristic of WFGD. China Environ. Prot. Ind. 2018, 31–36. [Google Scholar]

- Ye, C.W.; Lv, L.; Liu, B.S. Experimental study on the simultaneous desulfurization and denitrification by using urea treatment. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2018, 42, 478–482. [Google Scholar]