Effects of Brush-Type Ionizer Materials on Virus Inactivation

Abstract

1. Introduction

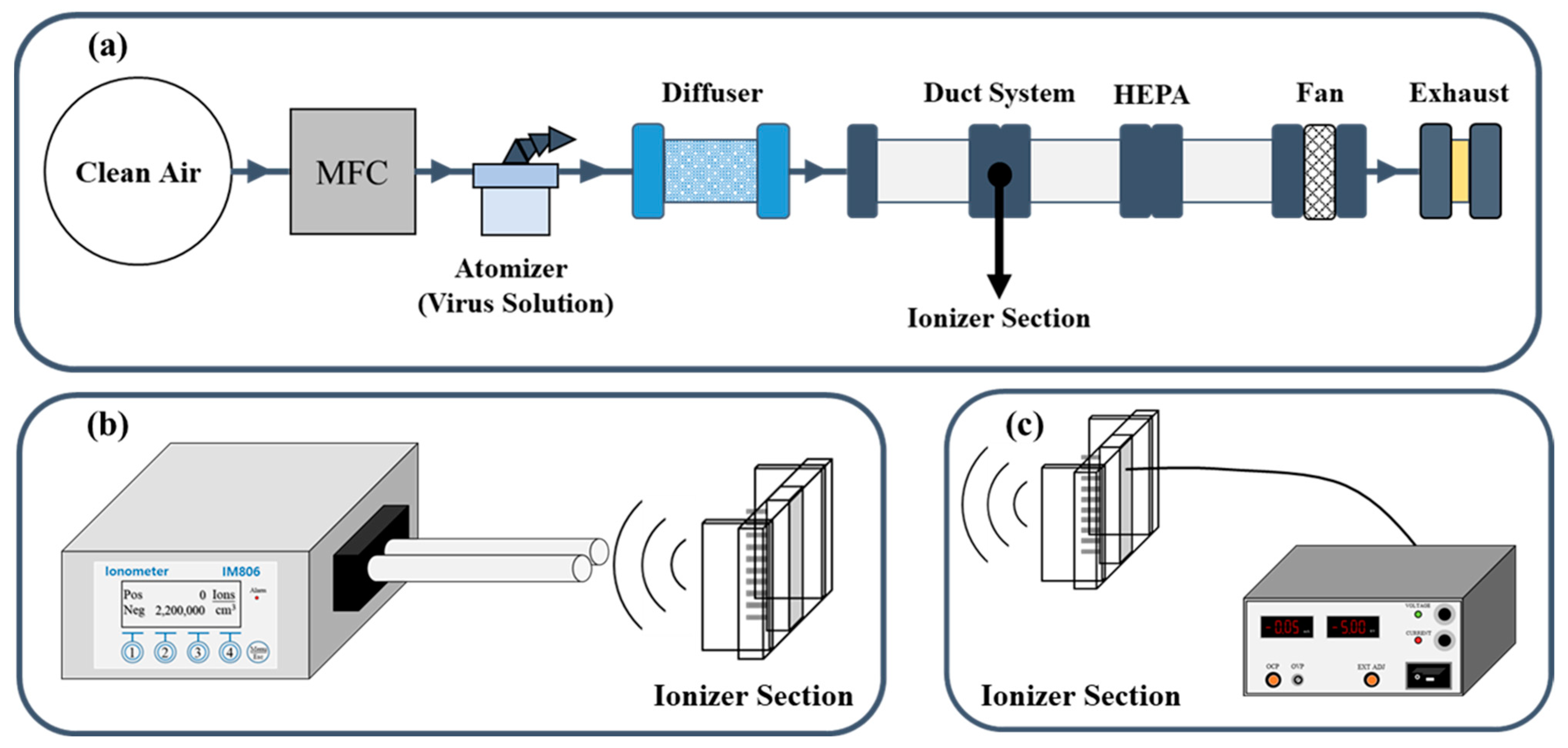

2. Materials and Methods

2.1. Materials and Ion Measurement Experiments

2.2. Virus and Host Preparation

2.3. Spray Aerosolized MS2 Bacteriophage

2.4. Virus Inactivation According to Voltage

2.5. Virus Inactivation According to Flow Velocity

2.6. Calculation of Inactivation Efficiency

3. Results and Discussion

3.1. Experimental Results of the Ion Measurement under Each Condition of Voltage and Material

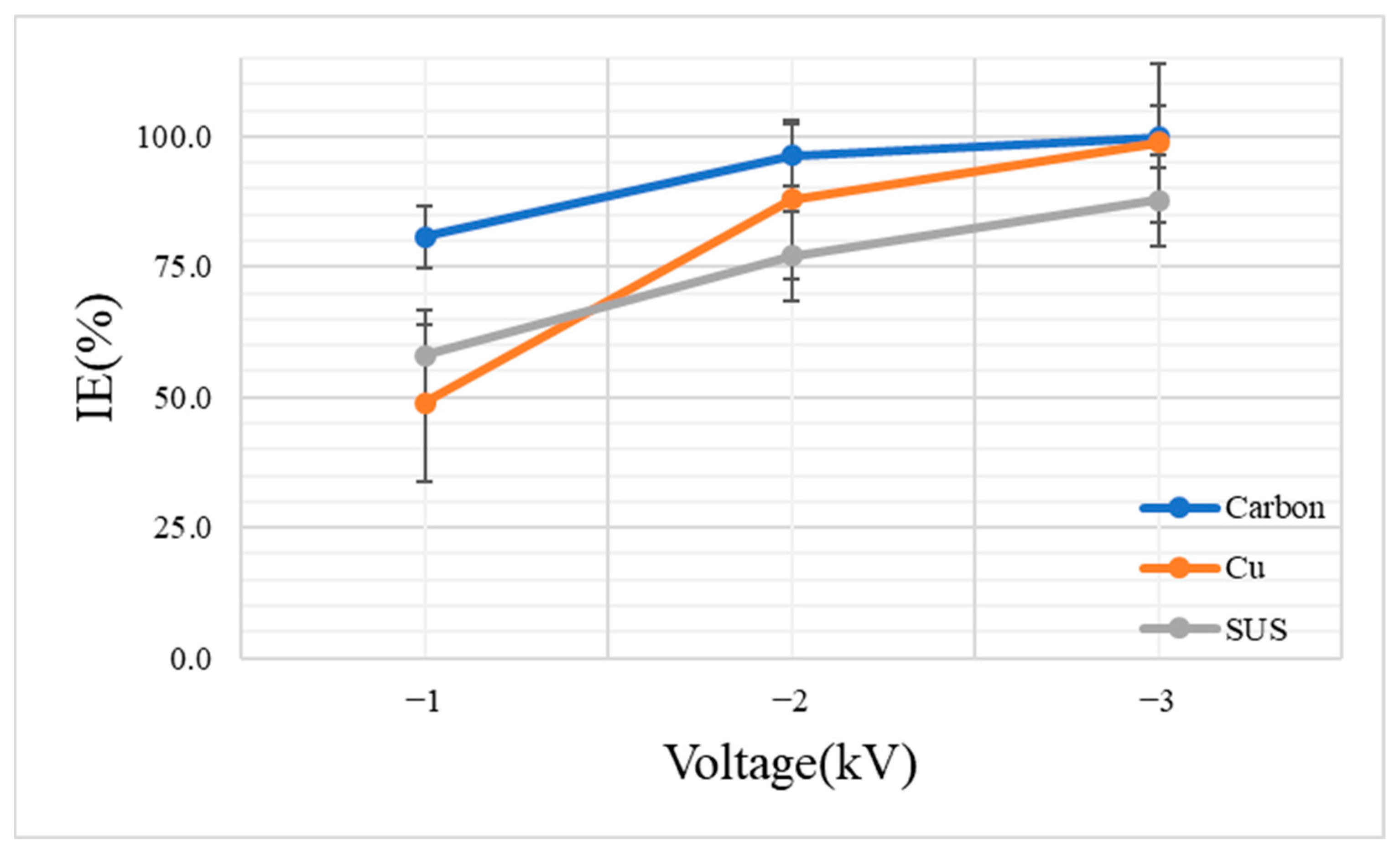

3.2. Experimental Results of the Virus Inactivation According to Voltage

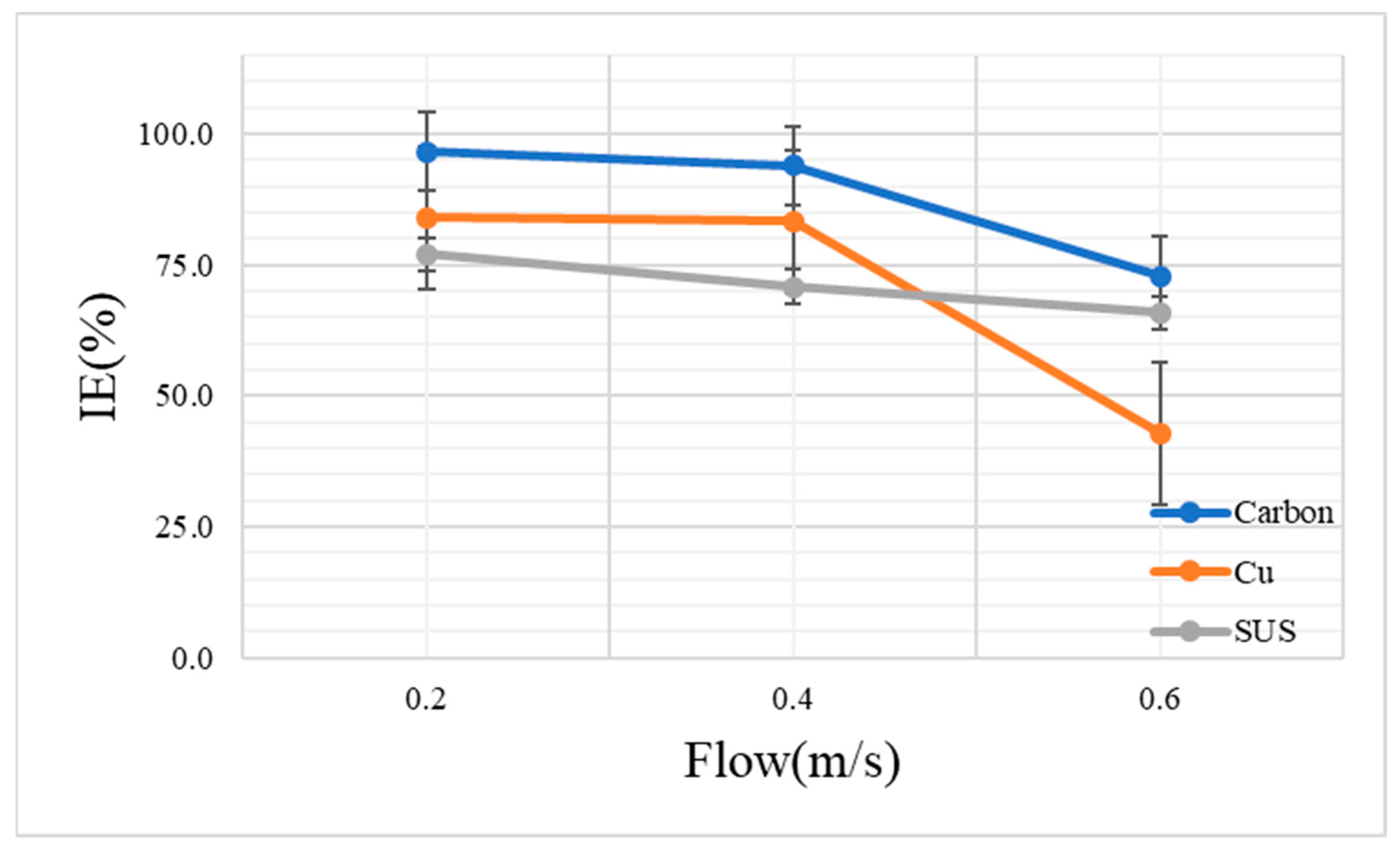

3.3. Experimental Results of the Virus Inactivation According to Flow Velocity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pastuszka, J.S.; Paw, U.K.T.; Lis, D.O.; Wlazło, A.; Ulfig, K. Bacterial and fungal aerosol in indoor environment in Upper Silesia, Poland. Atmos. Environ. 2000, 34, 3833–3842. [Google Scholar] [CrossRef]

- Hyun, J.; Lee, S.-G.; Hwang, J. Application of corona discharge-generated air ions for filtration of aerosolized virus and inactivation of filtered virus. J. Aerosol Sci. 2017, 107, 31–40. [Google Scholar] [CrossRef] [PubMed]

- Law, A.K.; Chau, C.K.; Chan, G.Y. Characteristics of bioaerosol profile in office buildings in Hong Kong. Build. Environ. 2001, 36, 527–541. [Google Scholar] [CrossRef]

- World Health Organization. Coronavirus Disease 2019 (COVID-19): Situation Report, 51; WHO: Geneva, Switzerland, 2020. [Google Scholar]

- Versoza, M.; Jung, W.; Barabad, M.L.; Lee, Y.; Choi, K.; Park, D. Inactivation of filter bound aerosolized MS2 bacteriophages using a non-conductive ultrasound transducer. J. Virol. Methods 2018, 255, 76–81. [Google Scholar] [CrossRef]

- Hinds, W.C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Marr, L.C.; Tang, J.W.; Van Mullekom, J.; Lakdawala, S.S. Mechanistic insights into the effect of humidity on airborne influenza virus survival, transmission and incidence. J. R. Soc. Interface 2019, 16, 20180298. [Google Scholar] [CrossRef]

- Versoza, M.; Heo, J.; Ko, S.; Kim, M.; Park, D. Solid oxygen-purifying (SOP) filters: A self-disinfecting filters to inactivate aerosolized viruses. Int. J. Environ. Res. Public Health 2020, 17, 7858. [Google Scholar] [CrossRef]

- Hwang, J.-H. Nano/bio aerosol particle measurement and reduction technology to improve indoor air quality. J. KSME 2012, 52, 46–50. [Google Scholar]

- Verdenelli, M.C.; Cecchini, C.; Orpianesi, C.; Dadea, G.M.; Cresci, A. Efficacy of antimicrobial filter treatments on microbial colonization of air panel filters. J. Appl. Microbiol. 2003, 94, 9–15. [Google Scholar] [CrossRef]

- Sim, K.M.; Park, H.S.; Bae, G.N.; Jung, J.H. Antimicrobial nanoparticle-coated electrostatic air filter with high filtration efficiency and low pressure drop. Sci. Total Environ. 2015, 533, 266–274. [Google Scholar] [CrossRef]

- Heo, J.; Jang, Y.; Versoza, M.; Kim, G.; Park, D. A New Method of Removing Fine Particulates Using an Electrostatic Force. Int. J. Environ. Res. Public Health 2021, 18, 6199. [Google Scholar] [CrossRef]

- White, H.J.; Cole, W.H. Design and performance characteristics of high-velocity, high-efficiency air cleaning precipitators. J. Air Pollut. Control. Assoc. 1960, 10, 239–245. [Google Scholar] [CrossRef]

- Kim, H.H.; Tsunoda, K.; Katsura, S.; Mizuno, A. Indoor air cleaning using a pulsed discharge plasma. IEEE Trans. Ind. Appl. 1999, 35, 1284–1288. [Google Scholar]

- Castle, G.P.; Inculet, I.I.; Burgess, K.I. Ozone generation in positive corona electrostatic precipitators. IEEE Trans. Ind. Gen. Appl. 1969, IGA-5, 489–496. [Google Scholar] [CrossRef]

- Boelter, K.J.; Davidson, J.H. Ozone generation by indoor, electrostatic air cleaners. Aerosol Sci. Technol. 1997, 27, 689–708. [Google Scholar] [CrossRef]

- Chen, J.; Davidson, J.H. Ozone production in the positive DC corona discharge: Model and comparison to experiments. Plasma Chem. Plasma Process. 2002, 22, 495–522. [Google Scholar] [CrossRef]

- Lee, H.; Sung, J.H.; Kim, M.; Kim, Y.S.; Lee, Y.; Kim, Y.J.; Han, B.; Kim, H.J. Development of Electrostatic-Precipitator-Type Air Conditioner for Reduction of Fine Particulate Matter in Subway. IEEE Trans. Ind. Appl. 2022, 58, 3992–3998. [Google Scholar] [CrossRef]

- Jung, J.-S.; Moon, J.-D. Corona discharge and ozone generation characteristics of a wire-plate discharge system with a glass-fiber layer. J. Electrost. 2008, 66, 335–341. [Google Scholar] [CrossRef]

- Han, B.; Kim, H.J.; Kim, Y.J.; Sioutas, C. Unipolar charging of fine and ultra-fine particles using carbon fiber ionizers. Aerosol Sci. Technol. 2008, 42, 793–800. [Google Scholar] [CrossRef]

- Daniels, S.L. Applications of air ionization for control of VOCs and PMx. In Proceedings of the 94th Air and Waste Management Association Annual Conference, Orlando, FL, USA, 24–28 June 2001. [Google Scholar]

- Grinshpun, S.A.; Mainelis, G.; Trunov, M.; Adhikari, A.; Reponen, T.; Willeke, K. Evaluation of ionic air purifiers for reducing aerosol exposure in confined indoor spaces. Indoor Air 2005, 15, 235–245. [Google Scholar] [CrossRef]

- Daniels, S.L. “On the ionization of air for removal of noxious effluvia” (Air ionization of indoor environments for control of volatile and particulate contaminants with nonthermal plasmas generated by dielectric-barrier discharge). IEEE Trans. Plasma Sci. 2002, 30, 1471–1481. [Google Scholar] [CrossRef]

- Kondrashove, M.N.; Grigorenko, E.V.; Tikhonov, A.V.; Sirota, T.V.; Temnov, A.V.; Stavrovskaja, I.G.; Kosyakova, N.I.; Lange, N.V.; Tikhonov, V.P. The primary physico-chemical mechanism for the beneficial biological/medical effects of negative air ions. IEEE Trans. Plasma Sci. 2000, 28, 230–237. [Google Scholar] [CrossRef]

- Copper, C.; Alley, F. Air Pollution Control: A Design Approach; Waveland Press: Long Grove, IL, USA, 1994. [Google Scholar]

- Havelaar, A.; van Olphen, M.; Drost, Y. F-specific RNA bacteriophages are adequate model organisms for enteric viruses in fresh water. Appl. Environ. Microbiol. 1993, 59, 2956–2962. [Google Scholar] [CrossRef] [PubMed]

- Shields, P.A.; Farrah, S.R. Characterization of virus adsorption by using DEAE-sepharose and octyl-sepharose. Appl. Environ. Microbiol. 2002, 68, 3965–3968. [Google Scholar] [CrossRef] [PubMed]

- Dreier, J.; Stormer, M.; Kleesiek, K. Use of bacteriophage MS2 as an internal control in viral reverse transcription-PCR assays. J. Clin. Microbiol. 2005, 43, 4551–4557. [Google Scholar] [CrossRef] [PubMed]

- Versoza, M.; Jung, W.; Barabad, M.L.; Ko, S.; Kim, M.; Park, D. Reduction of Escherichia coli using metal plates with the influenced of applied low current and physical barrier of filter layers. Int. J. Environ. Res. Public Health 2019, 16, 3887. [Google Scholar] [CrossRef] [PubMed]

- Mittal, H.; Parks, S.R.; Pottage, T.; Walker, J.T.; Bennett, A.M. Survival of microorganisms on HEPA filters. Appl. Biosaf. 2011, 16, 163–166. [Google Scholar] [CrossRef]

- Shin, D.H.; Woo, C.G.; Kim, H.J.; Kim, Y.J.; Han, B. Comparison of discharging electrodes for the electrostatic precipitator as an air filtration system in air handling units. Part. Aerosol Res. 2017, 13, 11–16. [Google Scholar] [CrossRef]

- Hunt, N.K.; Mariñas, B.J. Inactivation of Escherichia coli with ozone: Chemical and inactivation kinetics. Water Res. 1999, 33, 2633–2641. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, J.H.; Hwang, J. Inactivation and Filtration of Bioaerosols Using Carbon Fiber Ionizer Assisted Activated Carbon Fiber Filter. Part. Aerosol Res. 2010, 6, 185–192. [Google Scholar]

- Nunayon, S.S.; Zhang, H.H.; Jin, X.; Lai, A.C. Experimental evaluation of positive and negative air ions disinfection efficacy under different ventilation duct conditions. Build. Environ. 2019, 158, 295–301. [Google Scholar] [CrossRef]

| −1 kV | −2 kV | −3 kV | |

|---|---|---|---|

| Carbon | 1,934,381 ± 1.4 × 105 | 2,274,782 ± 0.3 × 105 | 2,289,422 ± 0.3 × 105 |

| Copper | 37 ± 20 | 1,893,961 ± 1.3 × 105 | 2,276,150 ± 0.3 × 105 |

| Stainless steel | 213 ± 21 | 1,428,998 ± 7.5 × 105 | 2,413,693 ± 0.4 × 105 |

| Material | Voltage (kV) | IE (%) | Diff (Log 10 PFU/mL) |

|---|---|---|---|

| Carbon | −1 | 80.8 ± 8.4% | 0.72 |

| −2 | 96.4 ± 0.5% | 1.44 | |

| −3 | 99.9 ± 0.2% | 2.93 | |

| Copper | −1 | 48.9 ± 16.2% | 0.29 |

| −2 | 87.9 ± 6.2% | 0.92 | |

| −3 | 98.8 ± 0.6% | 1.93 | |

| Stainless steel | −1 | 58.0 ± 2.3% | 0.38 |

| −2 | 77.0 ± 3.4% | 0.64 | |

| −3 | 87.7 ± 2.3% | 0.91 |

| Voltage (kV) | Material | Flow Velocity (m/s) | IE (%) | Diff (Log 10 PFU/mL) |

|---|---|---|---|---|

| −2 | Carbon | 0.2 | 96.6 ± 3.1% | 1.47 |

| 0.4 | 94.1 ± 1.5% | 1.23 | ||

| 0.6 | 72.9 ± 22.1% | 0.57 | ||

| Copper | 0.2 | 84.1 ± 7.4% | 0.80 | |

| 0.4 | 83.4 ± 5.0% | 0.78 | ||

| 0.6 | 42.9 ± 29.1% | 0.24 | ||

| Stainless steel | 0.2 | 77.0 ± 3.4% | 0.64 | |

| 0.4 | 70.8 ± 2.2% | 0.53 | ||

| 0.6 | 65.8 ± 3.2% | 0.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heo, J.; Lee, J.; Park, D. Effects of Brush-Type Ionizer Materials on Virus Inactivation. Toxics 2022, 10, 611. https://doi.org/10.3390/toxics10100611

Heo J, Lee J, Park D. Effects of Brush-Type Ionizer Materials on Virus Inactivation. Toxics. 2022; 10(10):611. https://doi.org/10.3390/toxics10100611

Chicago/Turabian StyleHeo, Jaeseok, Jooyeon Lee, and Duckshin Park. 2022. "Effects of Brush-Type Ionizer Materials on Virus Inactivation" Toxics 10, no. 10: 611. https://doi.org/10.3390/toxics10100611

APA StyleHeo, J., Lee, J., & Park, D. (2022). Effects of Brush-Type Ionizer Materials on Virus Inactivation. Toxics, 10(10), 611. https://doi.org/10.3390/toxics10100611