Study on the Ventilation Method to Maintain the PM10 Concentration in a Subway Cabin below 35 μg/m3

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

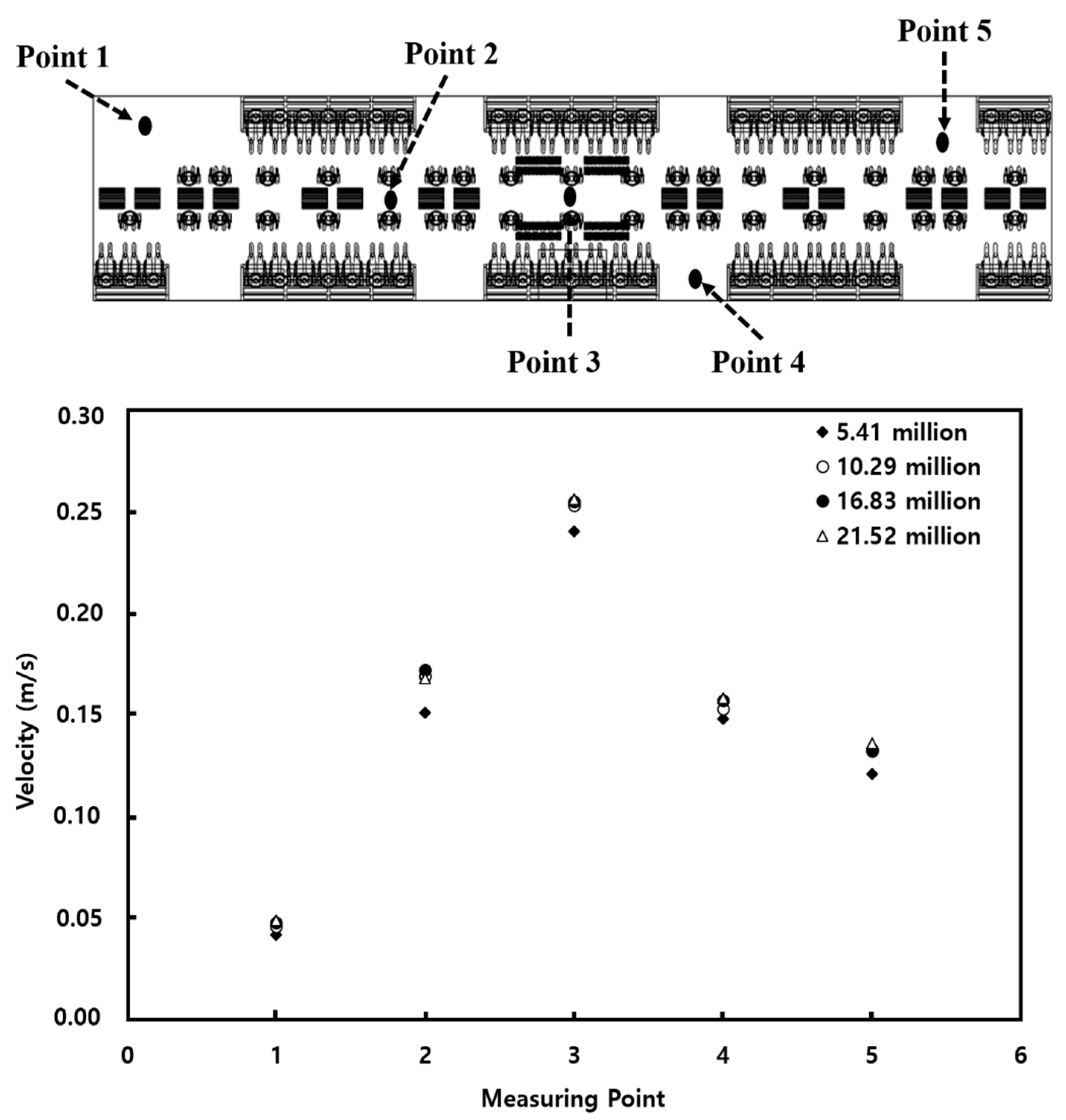

3.1. Model Validation

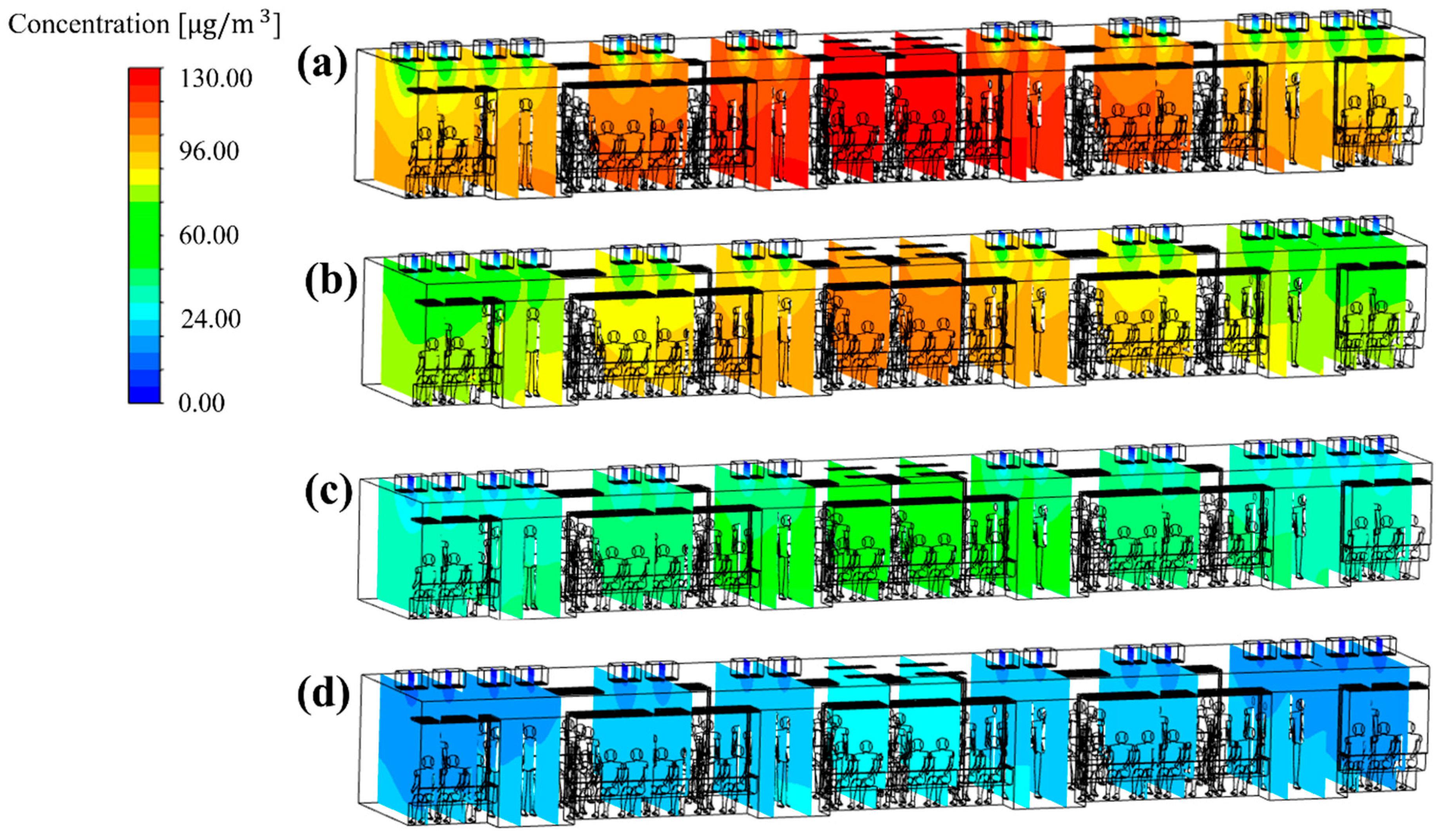

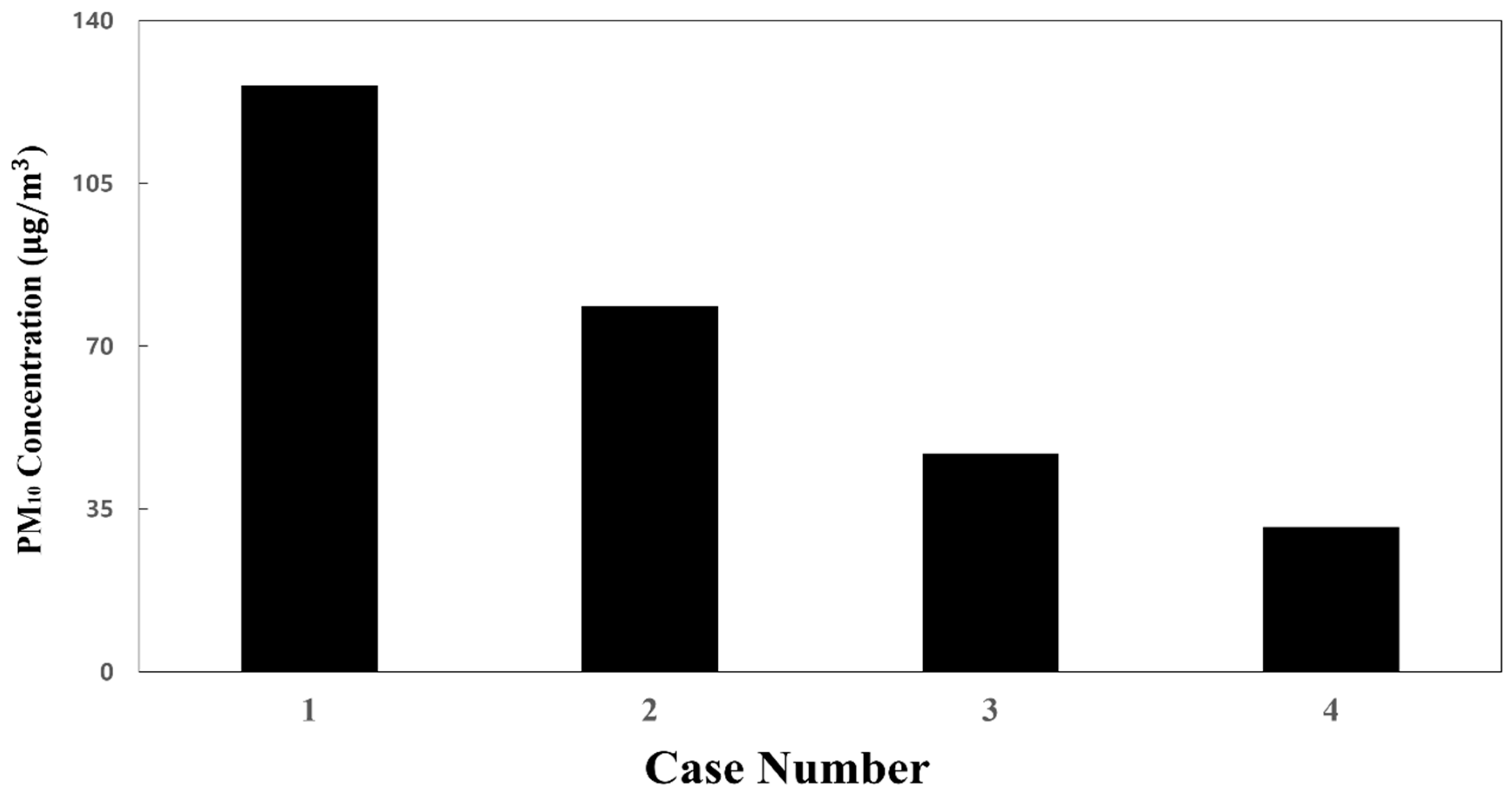

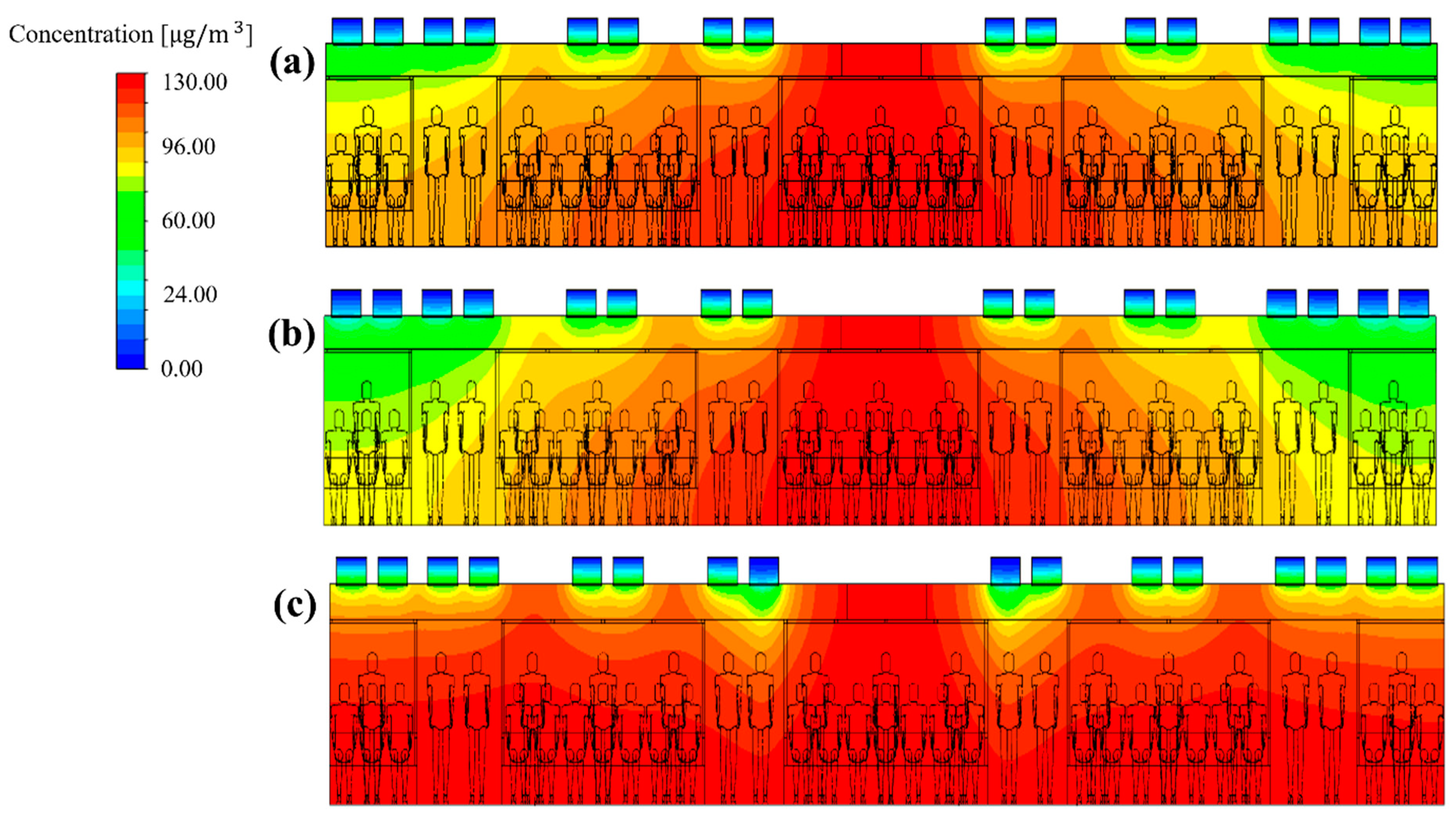

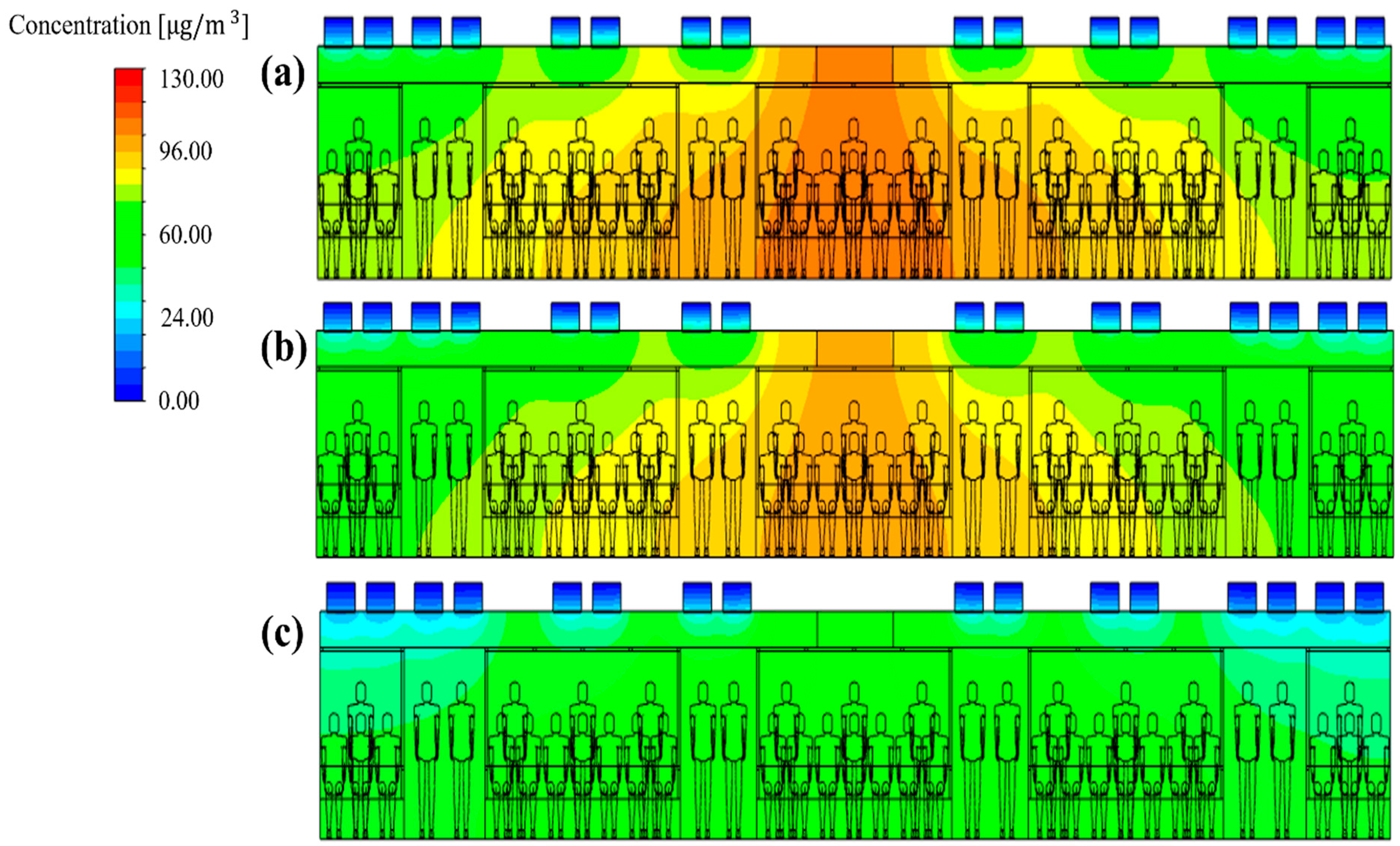

3.2. Effect of the Filter Efficiency on the PM10 Concentration Distribution (Total Flow Rate: 500 CMH)

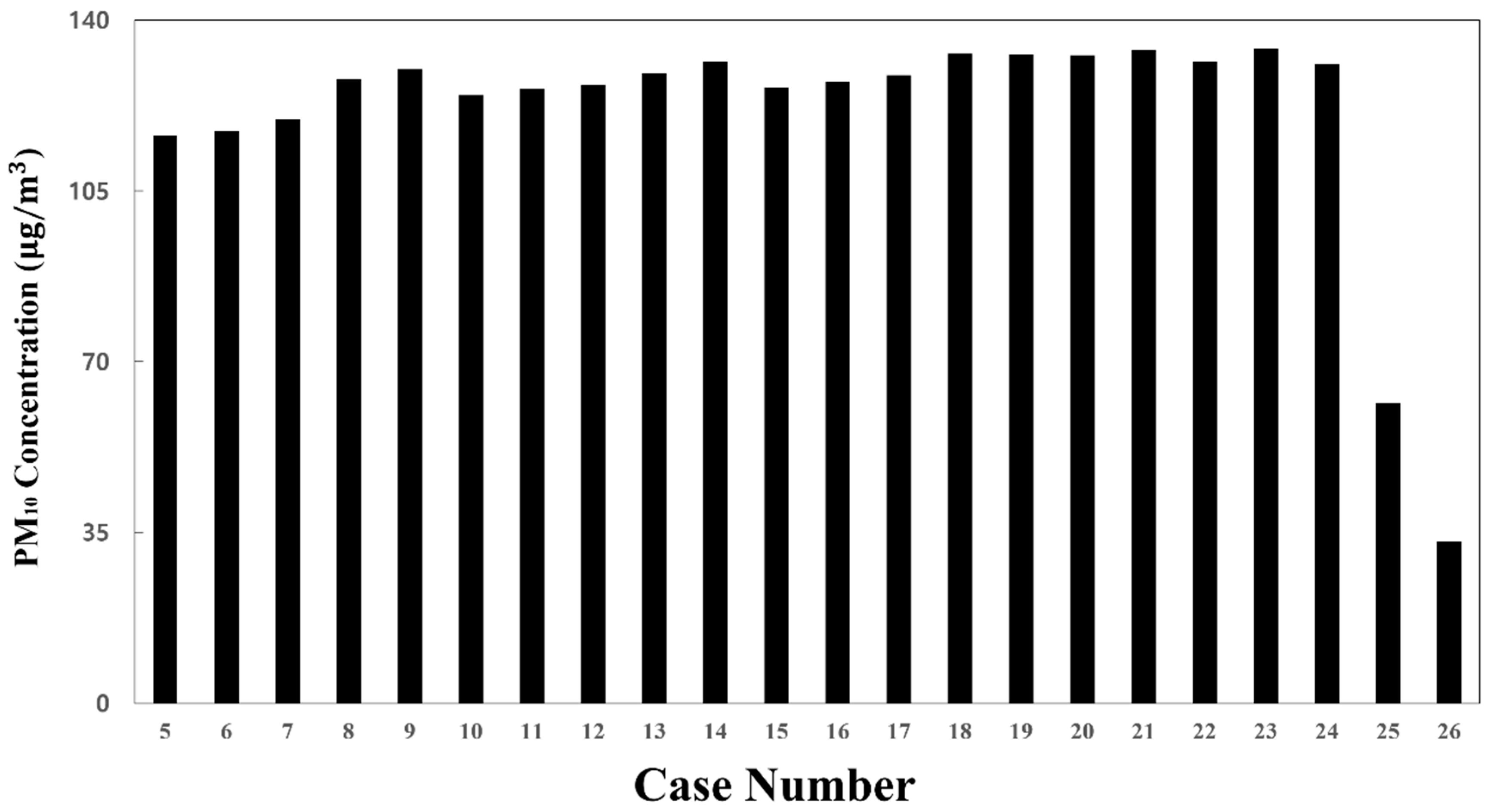

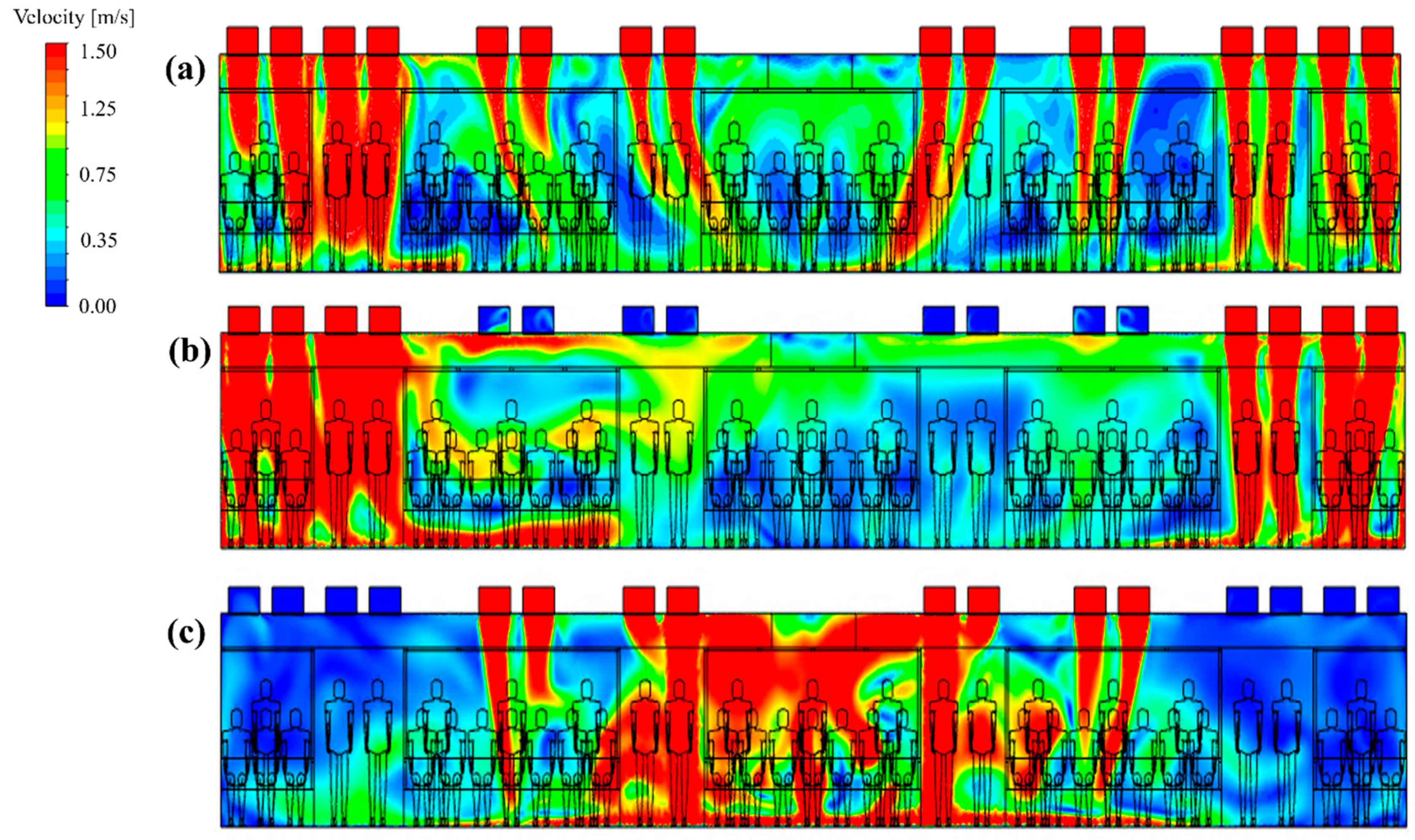

3.3. Effect of the Flow Rate Ratio on the PM10 Concentration Distribution (Total Flow Rate: 500 CMH)

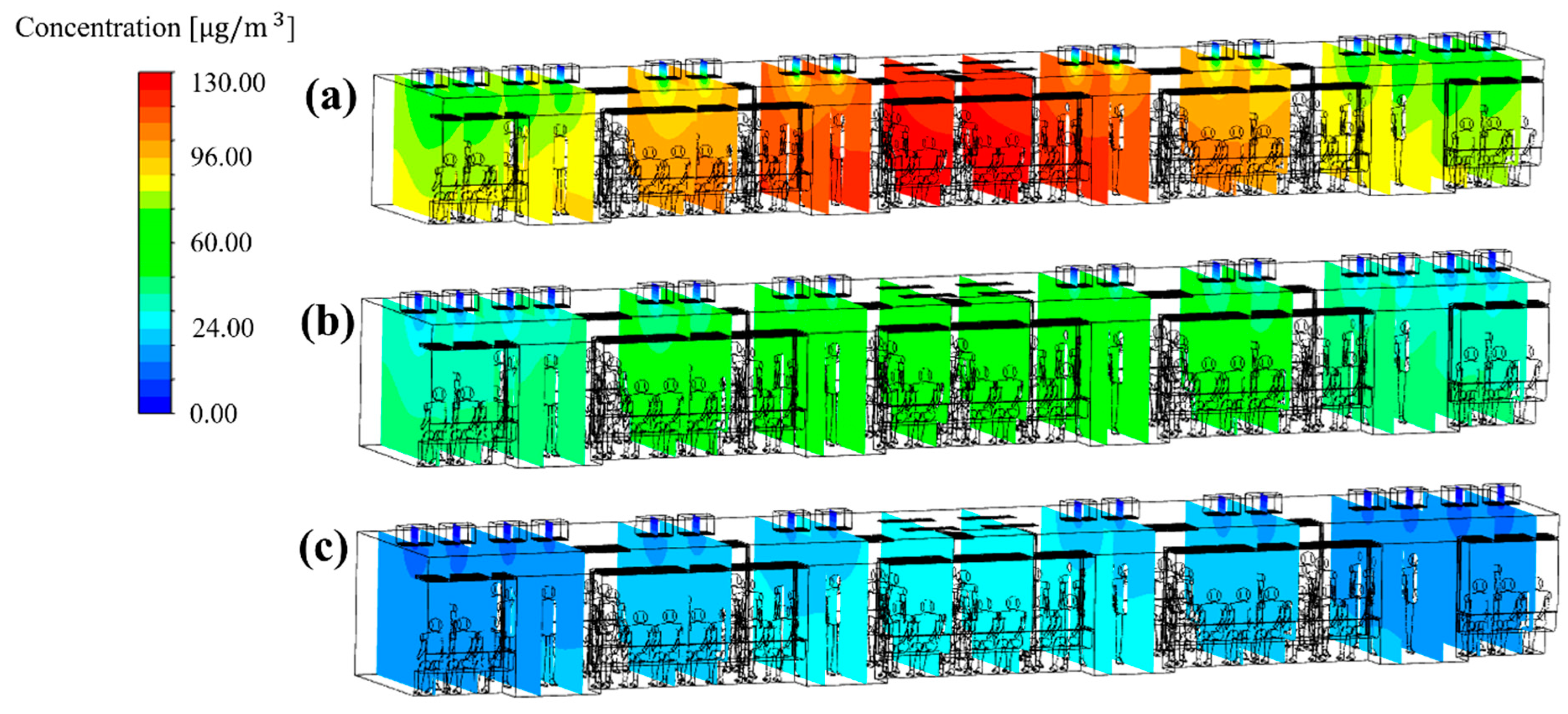

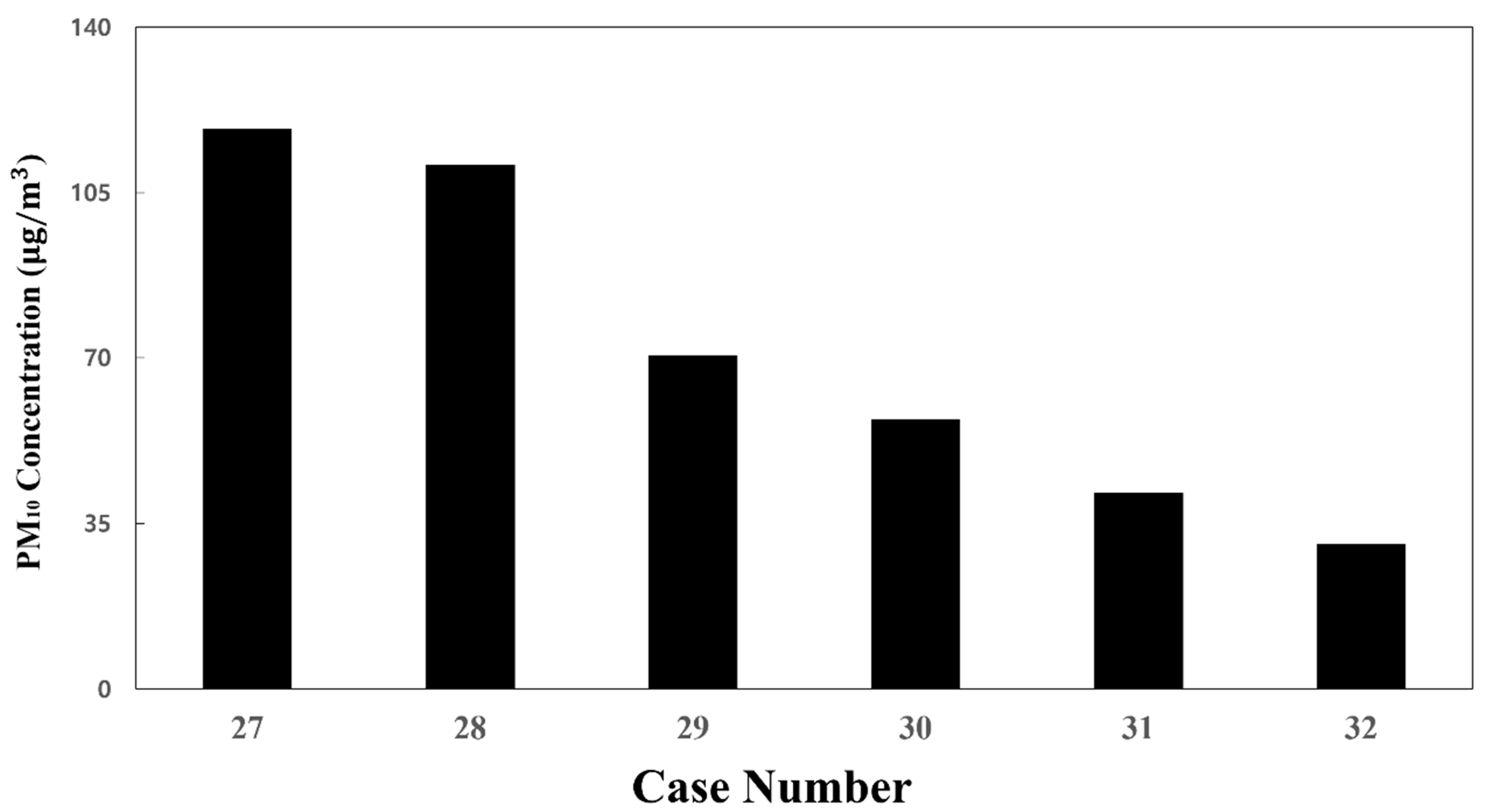

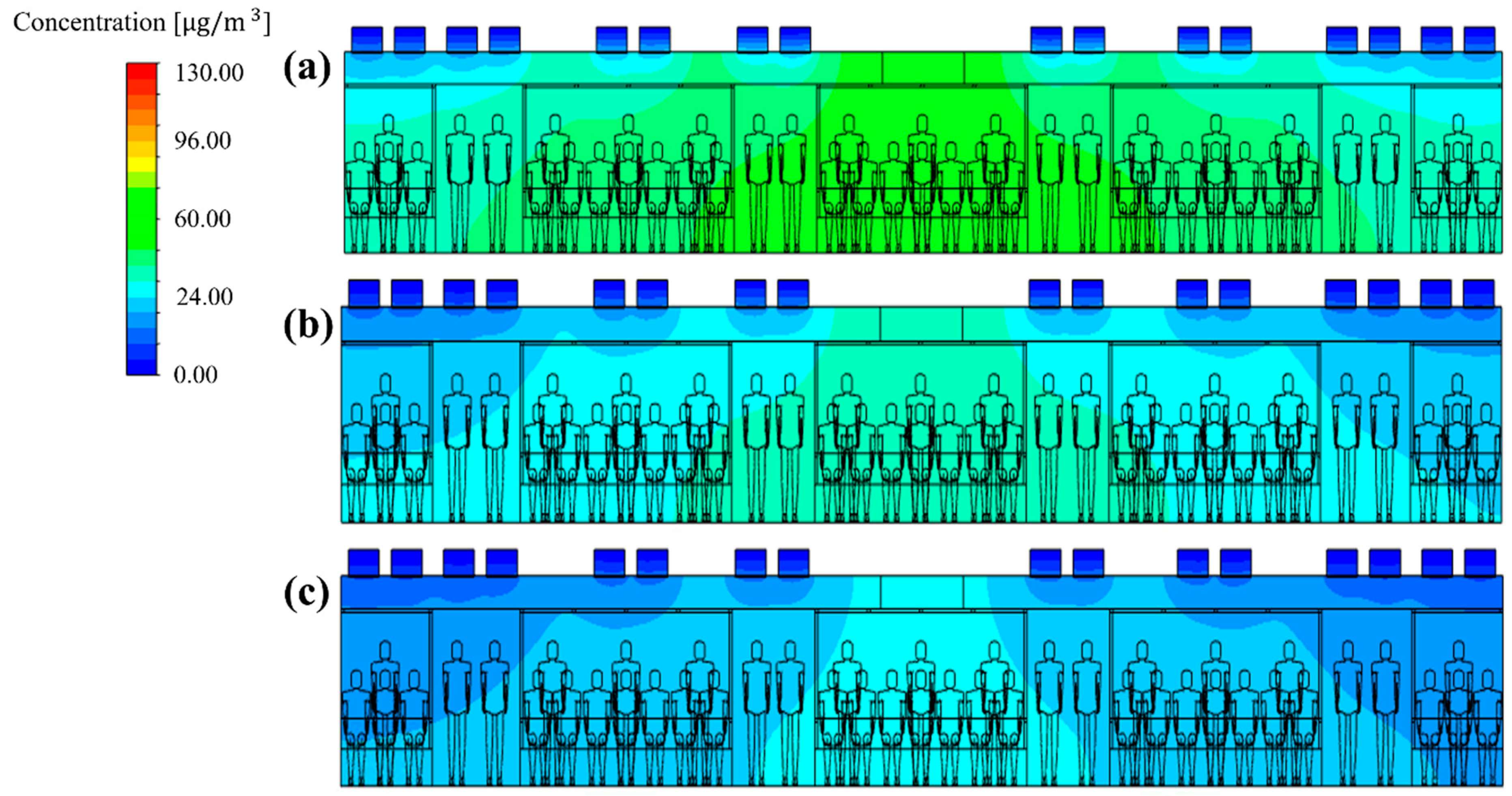

3.4. Effect of the Total Ventilation Flow Rate on the PM10 Concentration Distribution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Katsouyanni, K. Ambient air pollution and health. Br. Med. Bull. 2003, 68, 143–156. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.S.; Lee, T.J.; Park, M.B.; Park, D.S.; Kim, D.S. Characteristics of particulate matter concentration and classification of contamination patterns in the Seoul metropolitan subway tunnels. J. Korean Soc. Atmos. Environ. 2017, 33, 593–604. [Google Scholar] [CrossRef]

- Kim, J.B.; Woo, S.H.; Hwang, M.S.; Yoon, H.H.; Jung, J.S.; Bae, G.N. Change in PM10 concentration by train operation in a single tunnel section. J. Korean Soc. Urban Railw. 2017, 5, 743–751. [Google Scholar] [CrossRef]

- Mao, P.; Li, J.; Xiong, L.; Wang, R.; Wang, X.; Tan, Y.; Li, H. Characterization of urban subway microenvironment exposure—A case of Nanjing in China. Int. J. Environ. Res. Public Health 2019, 16, 625. [Google Scholar] [CrossRef] [PubMed]

- Baudet, A.; Baurès, E.; Blanchard, O.; Le Cann, P.; Gangneux, J.P.; Florentin, A. Indoor carbon dioxide, fine particulate matter and total volatile organic compounds in private healthcare and elderly care facilities. Toxics 2022, 10, 136. [Google Scholar] [CrossRef] [PubMed]

- Cournane, S.; Conway, R.; Byrne, D.; O’Riordan, D.; Silke, B. Air quality and hospital outcomes in emergency medical admissions with respiratory disease. Toxics 2016, 4, 15. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.B.; Kim, S.; Lee, G.J.; Bae, G.N.; Cho, Y.; Park, D.; Lee, D.H.; Kwon, S.B. Status of PM in Seoul metropolitan subway cabins and effectiveness of subway cabin air purifier (SCAP). Clean Technol. Environ. Policy 2014, 16, 1193–1200. [Google Scholar] [CrossRef]

- Park, S.; Kim, M.; Namgung, H.G.; Kwon, S.B. A study on HVAC performance improvement through fine dust blocking device. IJAR 2017, 5, 381–386. [Google Scholar]

- Son, Y.S.; Oh, Y.H.; Choi, I.Y.; Dinh, T.V.; Chung, S.G.; Lee, J.H.; Park, D.; Kim, J.C. Development of a magnetic hybrid filter to reduce PM10 in a subway platform. J. Hazard. Mater. 2019, 368, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Kim, W.; Jo, Y. Field application of a double filtration process to control fine dust in a metro subway station. J. Korean Soc. Atmos. Environ. 2013, 29, 625–633. [Google Scholar] [CrossRef]

- Kwon, S.B.; Song, J.H.; Ryu, J.H.; Jo, S.W.; Oh, T.S.; Bae, S.J.; Kim, H.G. A study on the improvement of the air exhaust system at the PSD installed subway station. J. Korean Tunn. Undergr. Space Assoc. 2015, 17, 353–362. [Google Scholar] [CrossRef]

- Kwon, S.B.; Park, D.S.; Cho, Y.; Kim, J.B.; Kim, T. Mechanical ventilation strategy for subway cabins using numerical simulations. J. Civ. Eng. Archit. 2012, 6, 1070. [Google Scholar]

- Zhao, L.; Zhou, H.; Jin, Y.; Li, Z. Experimental and numerical investigation of TVOC concentrations and ventilation dilution in enclosed train cabin. In Building Simulation; Tsinghua University Press: Beijing, China, 2022; Volume 15, pp. 831–844. [Google Scholar]

- Kwon, S.B.; Park, D.S.; Cho, Y.M.; Kim, J.B.; Cho, G.H.; Nam, G.S.; Lee, J.Y.; Kim, T.S. Removal efficiency of PM10 & CO2 in subway mock-up cabin. In Proceedings of the Korean Society for Railway Conference, Hoengseong-gun, Gangwon-do, Korea, 26–28 May 2011; pp. 613–618. [Google Scholar]

- Kim, J.B.; Kwon, S.B.; Park, D.S.; Cho, Y.; Namgoong, S.; Han, T.W.; Cho, K.; Kim, T. Efficiency of dust removal device in subway cabin. In Proceedings of the 7th Asian Aerosol Conference, Xi’an, China, 17–20 August 2011; p. 1116. [Google Scholar]

- Chang, Z.; Yi, K.; Liu, W. A new ventilation mode of air conditioning in subway vehicles and its air distribution performance. Energy Built Environ. 2021, 2, 94–104. [Google Scholar] [CrossRef]

- Nazari, A.; Hong, J.; Taghizadeh-Hesary, F.; Taghizadeh-Hesary, F. Reducing Virus Transmission from Heating, Ventilation, and Air Conditioning Systems of Urban Subways. 2021. Available online: https://www.researchsquare.com/article/rs-1164057/v1 (accessed on 4 August 2022).

- Jeong, W.; Lee, Y.; Choi, K.; Park, D. Particulate matters levels in subway tunnels and cabins. Int. J. Environ. Monit. Anal. 2016, 4, 89–93. [Google Scholar] [CrossRef]

- Chang, T.B.; Sheu, J.J.; Huang, J.W.; Lin, Y.S.; Chang, C.C. Development of a CFD model for simulating vehicle cabin indoor air quality. Transp. Res. D: Transp. Environ. 2018, 62, 433–440. [Google Scholar] [CrossRef]

- Bolourchi, A.; Atabi, F.; Moattar, F.; Ehyaei, M.A. Experimental and numerical analyses of particulate matter concentrations in underground subway station. Int. J. Environ. Sci. Technol. 2018, 15, 2569–2580. [Google Scholar] [CrossRef]

- ANSYS FLUENT Theory Guide, Release 15.0, November 2013. Available online: http://www.pmt.usp.br/academic/martoran/notasmodelosgrad/ANSYS%20Fluent%20Theory%20Guide%2015.pdf (accessed on 10 September 2022).

- Cao, Q.; Liu, M.; Li, X.; Lin, C.H.; Wei, D.; Ji, S.; Zhang, T.; Chen, Q. Influencing factors in the simulation of airflow and particle transportation in aircraft cabins by CFD. Build. Environ. 2022, 207, 108413. [Google Scholar] [CrossRef]

- Li, M.; Yan, Y.; Zhao, B.; Tu, J.; Liu, J.; Li, F.; Wang, C. Assessment of turbulence models and air supply opening models for CFD modelling of airflow and gaseous contaminant distributions in aircraft cabins. Indoor Built Environ. 2018, 27, 606–621. [Google Scholar] [CrossRef]

- Lin, Z.; Chow, T.T.; Tsang, C.F.; Fong, K.F.; Chan, L.S. CFD study on effect of the air supply location on the performance of the displacement ventilation system. Build. Environ. 2005, 40, 1051–1067. [Google Scholar] [CrossRef]

- Posner, J.D.; Buchanan, C.R.; Dunn-Rankin, D. Measurement and prediction of indoor air flow in a model room. Energy Build. 2003, 35, 515–526. [Google Scholar] [CrossRef]

| Location | PM10 Concentration (μg/m3) | |

|---|---|---|

| Subway cabin | Avg. | 93.1 |

| Max. | 138.4 | |

| Min. | 68.0 | |

| Subway tunnel | Avg. | 161.1 |

| Max. | 226.8 | |

| Min. | 114.1 | |

| Case Number | Total Ventilation Flow Rate (CMH) | Filter efficiency (%) | Flow Rate Ratio (%) | ||

|---|---|---|---|---|---|

| Supply Inlet 1 | Supply Inlet 2 | Supply Inlet 3 | |||

| Case 1 | 500 | 70 | 20 | 20 | 60 |

| Case 2 | 500 | 80 | 20 | 20 | 60 |

| Case 3 | 500 | 85 | 20 | 20 | 60 |

| Case 4 | 500 | 90 | 20 | 20 | 60 |

| Case 5 | 500 | 70 | 0 | 0 | 100 |

| Case 6 | 500 | 70 | 0 | 20 | 80 |

| Case 7 | 500 | 70 | 0 | 40 | 60 |

| Case 8 | 500 | 70 | 0 | 60 | 40 |

| Case 9 | 500 | 70 | 0 | 80 | 20 |

| Case 10 | 500 | 70 | 0 | 100 | 0 |

| Case 11 | 500 | 70 | 20 | 0 | 80 |

| Case 12 | 500 | 70 | 20 | 40 | 40 |

| Case 13 | 500 | 70 | 20 | 60 | 20 |

| Case 14 | 500 | 70 | 20 | 80 | 0 |

| Case 15 | 500 | 70 | 40 | 0 | 60 |

| Case 16 | 500 | 70 | 40 | 20 | 40 |

| Case 17 | 500 | 70 | 40 | 40 | 20 |

| Case 18 | 500 | 70 | 40 | 60 | 0 |

| Case 19 | 500 | 70 | 60 | 0 | 40 |

| Case 20 | 500 | 70 | 60 | 20 | 20 |

| Case 21 | 500 | 70 | 60 | 40 | 0 |

| Case 22 | 500 | 70 | 80 | 0 | 20 |

| Case 23 | 500 | 70 | 80 | 20 | 0 |

| Case 24 | 500 | 70 | 100 | 0 | 0 |

| Case 25 | 500 | 80 | 0 | 0 | 100 |

| Case 26 | 500 | 85 | 0 | 0 | 100 |

| Case 27 | 600 | 70 | 20 | 20 | 60 |

| Case 28 | 700 | 70 | 20 | 20 | 60 |

| Case 29 | 600 | 80 | 20 | 20 | 60 |

| Case 30 | 700 | 80 | 20 | 20 | 60 |

| Case 31 | 600 | 85 | 20 | 20 | 60 |

| Case 32 | 700 | 85 | 20 | 20 | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, E.-S.; Yook, S.-J.; Kim, M.; Park, D. Study on the Ventilation Method to Maintain the PM10 Concentration in a Subway Cabin below 35 μg/m3. Toxics 2022, 10, 560. https://doi.org/10.3390/toxics10100560

Choi E-S, Yook S-J, Kim M, Park D. Study on the Ventilation Method to Maintain the PM10 Concentration in a Subway Cabin below 35 μg/m3. Toxics. 2022; 10(10):560. https://doi.org/10.3390/toxics10100560

Chicago/Turabian StyleChoi, Eun-Seo, Se-Jin Yook, Minjeong Kim, and Duckshin Park. 2022. "Study on the Ventilation Method to Maintain the PM10 Concentration in a Subway Cabin below 35 μg/m3" Toxics 10, no. 10: 560. https://doi.org/10.3390/toxics10100560

APA StyleChoi, E.-S., Yook, S.-J., Kim, M., & Park, D. (2022). Study on the Ventilation Method to Maintain the PM10 Concentration in a Subway Cabin below 35 μg/m3. Toxics, 10(10), 560. https://doi.org/10.3390/toxics10100560