Abstract

Background: Industry 4.0 signifies a profound global transformation in production and service activities through its novel organizational principles, including digital connectivity, information transparency, technical assistance, and decentralized decision making. This transformation poses significant challenges for businesses, particularly small- and medium-sized enterprises (SMEs). In response, maturity models have been developed and adapted to facilitate a transparent and supportive entry into this transformative domain. Method/Aim: This study is dedicated to the comprehensive analysis of Industry 4.0 maturity models through a systematic literature review to identify and evaluate previously published recommendations for the adoption and utilization of Industry 4.0. The aim is to provide valuable insights in this context, with a particular focus on easing entry into this domain for SMEs. Results: Quantitative findings reveal a growing demand for fundamental support when entering this domain, with maturity models capable of meeting the demand for structured guidance. However, these models are currently under-validated, lacking transparency, and are often unsuitable for SMEs. Qualitative results categorize numerous insights and recommendations into ten distinct categories related to Industry 4.0. Conclusions: This paper provides a structured summary to support newcomers, research institutions, and businesses in effectively initiating and optimizing their Industrsy 4.0 activities.

1. Introduction

Introduced at the Hannover Fair in 2011, the term “Industry 4.0” continues to command the attention of both researchers and businesses seeking to delve into its intricate dimensions [1,2,3,4]. It is far from being a mere buzzword, as illustrated by a growing body of research that both praises its benefits and potential and underscores the complex challenges associated with it [5,6]. However, the concept of “Industry 4.0” remains somewhat elusive, particularly for small- and medium-sized enterprises (SMEs), who are left grappling with uncertainties. This can be attributed to the absence of validated, application-oriented perspectives, a matter of significant concern, as Industry 4.0 is not a one-size-fits-all solution [7].

Entering the world of Industry 4.0 is predominantly achieved through assessment models (e.g., maturity models and readiness models). In this process, companies assess their existing capabilities against predefined criteria and then derive a customized roadmap to achieve their desired target level. These assessment models draw inspiration from the capability maturity model (CMM) of the 1980s, having since undergone multiple adaptations and refinements [8]. A multitude of such models have emerged within the context of Industry 4.0. However, their diverse nature and limited universality stem from the incorporation of subjective assumptions and a partial focus on specific facets of Industry 4.0 applications. As a result, the landscape of Industry 4.0 assessment models remains intricate and multifaceted. For example, Leyh et al. [9] proposed an assessment model emphasizing technological aspects in evaluating Industry 4.0 capabilities, though they acknowledged the importance of a comprehensive ecosystem. In contrast, Asdecker and Felch [10] adopted a distinctive approach, utilizing the design science research model (DSR) to evaluate supply chain processes against Industry 4.0 criteria. Their analysis incorporated a variety of comprehensive maturity models. Taking a different angle, Yue et al. [11] developed a maturity model from a socio-technical perspective, recognizing that a company’s performance and benefits depend not only on technology but also on the enablement of individual tasks. Furthermore, Rauch et al. [12] expanded their evaluation framework for Industry 4.0 implementation in SMEs. They integrated socio-cultural elements alongside technological, functional, and organizational dimensions. Their approach was grounded in deriving standard procedures from a norm matrix, enabling structured prioritization. These diverse methodologies highlight the multifaceted nature of Industry 4.0 assessment.

Recent efforts have aimed to address the deficiency in lucidity, the moderately tangible nature, and the ongoing need for model validation through diverse meta-approaches to maturity models, considered from both a research and practical standpoint. These efforts include a comprehensive examination of validated Industry 4.0 maturity models, as described by Flamini and Naldi [13], through participant cohorts of up to 2000 participants. Furthermore, there is an exploration of the adaptability of Industry 4.0 maturity models for SMEs within the production and logistics sector, as elucidated by Elhusseiny and Crispim [14]. Additionally, da Silva et al. [15] explored the practical application of Industry 4.0 technologies in SMEs, examining challenges and performance outcomes. Lastly, Chavez et al. [16] focused on digitization levels in SME deviation management. These studies collectively advance our understanding and application of Industry 4.0.

To date, no comprehensive research has synthesized and evaluated existing insights on Industry 4.0 implementation and application in SMEs. Our work provides a foundational framework for those interested in delving into the complexities of Industry 4.0. Given the pivotal role of SMEs in many economies, job creation, and value addition, our research group strives to educate SMEs on Industry 4.0, enhance their change readiness, and offer an impartial approach. This empowers SMEs to continue their vital contributions and embark successfully on the Industry 4.0 journey. This follows Ghobakhloo [17] (p. 910): “Industry 4.0 is no longer a hype and manufacturers need to get on board sooner rather than later”. Embedded in this context, this article addresses the following research question:

“What findings and recommendations are known to date regarding the implementation and maturity of Industry 4.0 in SMEs?”

Similar to meta-approaches to the study of maturity models, we used a systematic literature review (SLR) as a conceptual framework to explore the research field. However, in the analysis, we emphasize the main focus on the qualitative aspects to identify, explore, categorize, and discuss recommendations.

This study is structured in five sections. Section 1 presents the introduction. Section 2 deals with the relevant basics of the study, followed by the methodological approach in Section 3. Section 4 is dedicated to the structured analysis of the results and their discussion, while Section 5 gives an outlook on further research developments and limitations.

2. Theoretical Background

To put the initiative of this research project in a supportive light, the accompanying terminologies have to be described. This is less a matter of providing a complete account of the content and more a matter of setting the context of the study.

2.1. Industry 4.0

In 2011, the guiding principles of Industry 4.0 emerged through the collaborative efforts of the “Working Group Industry 4.0” and the “Platform Industry 4.0”, debuting at the Hannover Fair. Nevertheless, these principles offer more of a visionary perspective and outline only a few rudimentary technologies, lacking a precise definition [18]. The term Industry 4.0 is expected to evolve progressively, encompassing a refined lexicon, novel developments, and experiential insights. Here, we briefly outline the ongoing pursuits in this domain.

Forecasts suggest a future where companies will establish global networks, interlinking machines, storage systems, and production facilities with cyber-physical systems (CPS). These CPS will engender autonomous information exchange, action initiation, and self-regulation, enhancing industrial processes within smart factories. These factories produce intelligent products, complete with comprehensive documentation of their creation, offering clear identification and traceability throughout the entire production cycle [19].

The primary objective of this fourth industrial revolution is to enhance product and process quality while simultaneously aligning with global market demands and customer expectations [20]. To address this ambitious attempt, this research endeavors to establish a sustainable maturity model that interconnects the four primary goals with their respective sub-objectives and inter-relationships. In contrast, Schuh et al. [2] focused on the internal dynamics of companies, identifying the principal economic potential of Industry 4.0 in expediting corporate decision-making and adaptability processes. Lichtblau et al. [21] supplemented this perspective, emphasizing the paramount potential of optimizing production systems by enhancing flexibility, adherence to delivery schedules, and reducing lead times. Presently, the term “Industry 4.0” remains devoid of a definitive and universally accepted definition, leaving both researchers and companies with a degree of uncertainty.

Networking of all components is a fundamental element within Industry 4.0, serving as the cornerstone for both vertical and horizontal integration throughout the value chain [21]. This integration, however, inevitably leads to a considerable rise in system complexity. According to Issa et al. [7], this heightened complexity introduces delays in the successful implementation of Industry 4.0 systems when aligning various organizational aspects and levels.

Nonetheless, the development of Industry 4.0 systems is not an end in itself; its success hinges on realizing viable business models or generating added value for customers, compelling them to invest. This underscores the fact that the tangible benefits, as opposed to strategic projections, drive the adoption.

Maturity models have emerged as a proven method for assessing a company’s Industry 4.0 maturity. Originally devised for software engineering, these models bring structure and systematization to the domain. As a methodical approach, they aid organizations in evaluating the current maturity level of a specific area based on predefined criteria and in devising an improvement-focused roadmap toward the desired target level [8,22]. Progress along this roadmap signifies a consistent enhancement in the performance or quality of the criteria in question, with the maturity model serving as the scale for evaluation [8].

2.2. Small- and Medium-Sized Enterprises

SMEs hold a position of paramount global significance. With estimates of 400 million SMEs worldwide, these companies represent not only the economic backbone of many economies but also the source of approximately two-thirds of the total workforce [23]. These enterprises are integral to the lives of many individuals. In the European Union, for instance, SMEs account for 65% of all job opportunities and constitute 99% of all businesses [24]. In the context of Germany, SMEs comprise over 99% of all establishments, contributing to more than 50% of the economic output and supplying nearly 60% of the workforce [25]. Regionally, SMEs often serve as crucial employers, generating positions that carry social insurance benefits. Furthermore, they play a pivotal role in providing in-company training and serve as the entry point into the labor market for young people [25]. The EU Commission [26] categorizes SMEs based on employee count and sales/balance sheet total as shown in Table 1.

Table 1.

SME Definition.

SMEs exhibit distinct characteristics, notably an extensive regional network, remarkable flexibility, adaptability in responding to customer demands, and noteworthy innovation [25]. Typically, these enterprises are owner-managed and maintain an organic growth structure, which is often accompanied by a conservative investment approach due to limited financial and human resources. Consequently, decisions regarding acquisitions are subject to meticulous evaluation. A strong emphasis on the company’s intrinsic strengths and traditions is prevalent, leading to incremental changes rather than disruptive or revolutionary ones. In the context of Industry 4.0, SMEs encounter a multitude of challenges as they seek an implementable approach to achieve the elusive triad of cost, time, and quality. Furthermore, as indicated by Ingaldi and Ulewicz [27] and Türkes et al. [28], SMEs grapple with additional difficulties, including:

- narrow product portfolio → Difficulty in the application of automated, autonomous production systems;

- lack of expertise, culture, and standards;

- lack of knowledge about Industry 4.0;

- limited strategic and operational experience.

All these challenges could have a paralyzing effect on SMEs and withhold them from implementation of Industry 4.0. Therefore, it is worthwhile to consider leveraging the inherent characteristics of SMEs and adopting a sequential approach to attain the objectives instead of pursuing them simultaneously. Several fundamental criteria inherent to SMEs can be harnessed as advantages in this endeavor:

- Mostly manufacturers of special products and services.

- Regional grounded.

- Close ties to customer and supplier with direct contact.

- Limited to one (in exceptional cases, a few) plant with appropriate machinery.

- Core focus is on product manufacturing and the creation of customer value.

- Few hierarchical organizational levels (organizational structure) and simple process organization.

3. Data and Methodology

The research framework outlined in the introduction offers a suitable foundation for the comprehensive exploration of the research field using an SLR, as the focus is already set sufficiently concretely. The methodology used is that of Moher et al. [29]: the Preferred Reporting Items for SLRs and Meta-Analysis (PRISMA). PRISMA, an evidence-based reporting standard, facilitates rigorous critical assessment [30]. The SLR methodology is particularly helpful as it meticulously summarizes the available research in response to research questions [31].

The primary objective of the SLR is to identify existing Industry 4.0 maturity models and relevant scientific publications on the implementation of Industry 4.0, using maturity models to answer the research question. The search criteria defined in Table 2 were used for this purpose.

Table 2.

Database research restrictions.

Employing the application’s automated transfer function, the .ris files retrieved from Scopus (308 results) and Web of Science (37 results) were seamlessly integrated into EndNote. To eliminate redundancy, duplicate entries were meticulously identified and eliminated. Subsequently, employing a snowballing technique, an additional 48 publications were identified following a comprehensive full-text assessment. During the screening phase, the publications underwent scrutiny and were systematically categorized based on their relevance to addressing the research question, with a focus on elements such as abstracts, titles, and chapter headings. The categorization process adhered to the criteria delineated in Table 3.

Table 3.

Categorization of results.

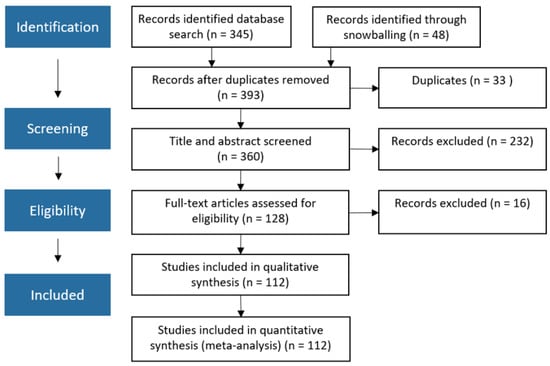

Subsequently, outcomes designated as “significant” underwent a methodical cascading screening process within a thorough analysis. The sequential steps of this PRISMA methodology are depicted in Figure 1, where n indicates the respective number of publications considered.

Figure 1.

Systematic literature review (PRISMA flowchart).

4. Results: Analysis and Discussion

The analysis of the identified publications comprised both quantitative and qualitative aspects. Considering the research aim and question, emphasis was placed on the qualitative facets, resulting in a section-specific discussion within each segment. This allowed for direct inferences with practical relevance and the evaluation of the strengths and weaknesses of the recommendations.

4.1. Quantitative Analysis

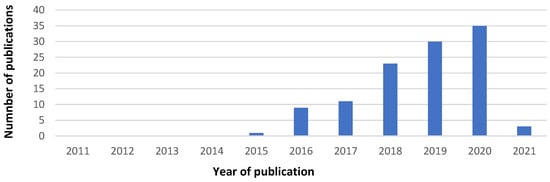

Figure 2 displays the temporal gap between the first identified publication in 2015 and the launch of Industry 4.0 in 2011. This analysis was rooted in the aggregation of keywords, including variations within the keyword string. At this point, the extensive incorporation and clarification of Industry 4.0, supported by evaluation models, commenced. Since that time, this trend has persistently advanced, indicative of the sustained interest in both the methodology and the subject matter.

Figure 2.

Publications over the research period.

In this context, the term ‘maturity model’ specifically underscores researchers’ underlying reservations, skepticism, and foreignness towards the subject. The prevalence and extensive utilization of technical transfer models and CMMI-based models in various applications reveal a lack of clear comprehension concerning Industry 4.0 and its implementation in corporate settings. This points to an overall cautious approach towards the terminology and efficacy of Industry 4.0, as well as its operationalization in this context. The results presented for 2021 were obtained through a snowballing approach, which, unlike the initial search, was not temporally constrained.

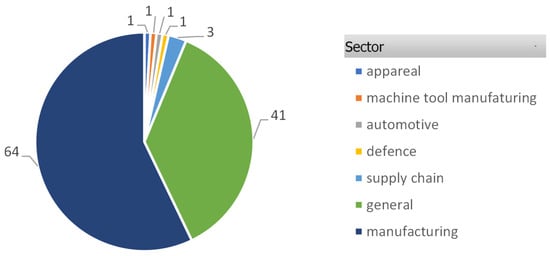

A content-focused analysis about the research sector unveiled additional insights. A significant majority of the scrutinized documents were primarily affiliated with the manufacturing sector (64 out of 112 ≙ 57%) or had a general or unspecified orientation (41 out of 112 ≙ 37%). Only a few publications confined their sectoral focus, as outlined in Figure 3. Notably, the emphasis on the manufacturing sector provides insight into where the potential of Industry 4.0 is believed to reside and where research investments have been channeled.

Figure 3.

Publications per sector.

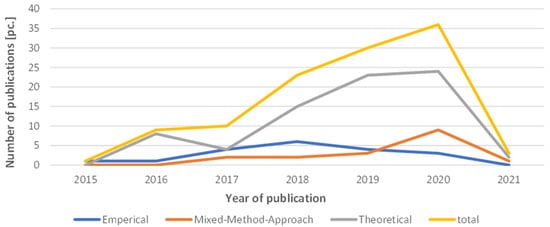

Figure 4 illustrates the chosen scientific approaches among the 112 publications, reflecting the degree of theoretical or practical advancement within the field. The majority of studies (76 out of 112) adopted a theoretical research approach, with a relatively balanced distribution among literature reviews (22), conceptual work (24), and modeling studies (30).

Figure 4.

Publication methods over the research period.

In contrast, empirical research approaches (19 out of 112) consisted of 53% case studies, 26% surveys, and 21% action research. Mixed-method approaches (17 out of 112) primarily combine case studies, literature reviews, and surveys.

The limited number of empirical and mixed-method studies can be attributed to the prevailing theoretical nature of the topic and the restricted implementation in industry, which hinders practical and qualitative analysis. The findings for 2021 do not indicate waning research interest; instead, they reflect the reduced number of publications identified through snowballing. The original SLR encompassed the period 2010–2020 and revealed a consistent upward trajectory in research interest.

4.2. Qualitative Analysis

The comprehensive examination of the publications involved the extraction, tabulation (comprising 360 entries), and categorization of all the identified findings by context, as displayed in Table 4. The categorization framework, originally developed by Schumacher et al. [3], served as the foundational structure, albeit subject to modifications. Various maturity models and analyses of such models, as evidenced in references [32,33,34] were also integrated. The numerical values denote the frequency of citations among the 360 entries. Detailed listings of the publications categorized can be found in Appendix A.

Table 4.

Categories for finding/recommendation analysis.

4.2.1. Strategy and Leadership

According to Facchini et al. [35], Industry 4.0 represents a necessary path for companies “if they intend to survive in rapidly and constantly evolving markets”. This dynamic is clarified by Santos and Martinho [36] (p. 4), with the realization that “the faster a company adapts and anticipates an event that can impact the business, the bigger are the benefits of this adaption”. However, there is still a lack of a comprehensible and clear description of the opportunities, benefits, and barriers of Industry 4.0 that companies have to overcome [37].

The introduction of Industry 4.0 is therefore a strategic project and requires integration into the overall corporate strategy to increase acceptance [38,39]. Only when a high level of readiness and commitment to Industry 4.0 has been achieved in the management circle and a clear vision has been developed, can the entire company also achieve a high level of readiness [40,41,42]. This vision must also be clearly described [43,44] to achieve a common understanding within the company and set up the roadmap for implementation. An Industry 4.0 roadmap is important [17,37] because it offers orientation on foreign terrain and concrete and practical recommendations for action [45].

A comprehensive understanding of Industry 4.0 methodology is a necessary management skill to be able to achieve the goal for the company through effective investments [41,46]. Management as a decision-making authority is also needed as an important contact person for the workforce [47], especially in SMEs, as they are often single-tier [48].

The introduction of Industry 4.0 represents a multifaceted and strategic initiative situated within the realm of corporate management. It is within this sphere that a comprehensive and integrative approach can be effectively harmonized with the overarching strategic objectives of the organization. Particularly in SMEs, the management must recognize that the oversight of this initiative cannot be delegated; rather, it necessitates active engagement and committed leadership to bridge the strategic dimensions with tactical and operational planning. To accomplish this, the management must possess not only a deep understanding of Industry 4.0 but also the requisite leadership resources. Only when a well-defined long-term implementation roadmap is established, proficient planning and execution teams are assembled, meaningful key performance indicators (KPIs) are implemented, and a foundational comprehension of Industry 4.0 permeates the entire organization, can the leadership assume a more relaxed stance. In this endeavor, existing management techniques, such as Hoshin Kanri or Toyota Kata, can provide valuable guidance and orientation.

4.2.2. Customer and Product

Industry 4.0 era is challenging almost all paradigms that were anchored in the Industry 3.0 era, especially customer relationships, business models, and product utility. According to Santos and Martinho [36], the adaptation of business models and the development of new products and services are part of the holistic approach to implementing Industry 4.0. SMEs can play to their strengths here since customer proximity and orientation are among their trademarks and have a positive influence on Industry 4.0 implementation [49]. Exner et al. [50] therefore recommend that companies transform themselves even more from product-oriented to solution-oriented providers.

Companies should fundamentally change their product and service offerings due to digitalization and utilization of sensors, RFID tags, actuators, etc. [51]. The creation of smart products [52], remote monitoring, predictive maintenance [53], smart products, and servitization [54] are becoming an inherent part of the Industry 4.0 chain and are of fundamental importance for digital transformation and design of a digital supply chain of the future [51]. For manufacturing companies, however, this also requires an agile and flexible production structure, which can be reconfigured rapidly for new products [55].

The successful implementation of Industry 4.0 is poised to yield a substantial upsurge in data volume, stemming from sensors embedded in production, as well as from products, services, customers, and suppliers. This is precisely the juncture where SMEs can leverage their inherent advantages, characterized by their direct and intimate engagement with customers and suppliers. However, these efforts require a delicate balancing act. This entails the deployment of requisite technologies and processes, coupled with the development of employee competencies to meaningfully process these data. The ultimate objective is to align products and services more precisely with the fulfillment of customer needs. Additionally, the ability to respond swiftly, coupled with regional accessibility, assumes a pivotal role in terms of speed.

4.2.3. Operations/Processes

The introduction of Industry 4.0 requires broad support in companies as it changes the strategic direction and entire production environment, using new technologies [11].

As Santos and Martinho [36] stated, it is utopian to expect the transformation to happen at the push of a button. Companies that have already implemented elements of lean production (LP) enjoy a small advantage here, regardless of company size [56], as LP and Industry 4.0 are compatible and based on similar goals to increase overall flexibility and productivity [39]. De Carolis et al. [57] recommend that manufacturing companies should first have completed Industry 3.0 before turning to Industry 4.0.

A major challenge has been to break down the rigid corporate culture with the involvement of employees to create space for new technologies and agile processes that enable continuous improvement in the face of changing demands [44].

According to Weyer et al. [55], agile, flexible, modular, scalable, and automated production lines are the declared goals. Especially in terms of technologies, SMEs are mostly inferior to multinational enterprises (MNEs) as they lack the latest technologies, use standard processes, and are less flexible overall [58]. This also refers to the largely still manual, and thus inefficient, input of data in the production field []. Wank et al. [59], therefore, call for a rethinking and the introduction of CPS technologies on the shop floor, including digital communication between systems like the Internet of Things (IoT) and Big Data, so that media disruptions are avoided. The fact that complete digitalization is also moving in with this is a big, but necessary, step [60]. The complete integration of data and processes, and departmental and interdisciplinary cooperation [61], especially in production and the surrounding business areas, is the main key for the development of Industry 4.0 competence as well as data and information management [53].

According to Asdecker and Felch [10], an increase in predictive capability also goes hand in hand with lower inventories and shorter cycle and lead times, resulting in an end-to-end supply chain that follows the mantra “less storage, more flow” [10] (p. 851).

While LP is traditionally associated with Industry 3.0, it serves as an ideal intermediary for bridging the gap between a conventionally positioned SME and Industry 4.0. As a preliminary step toward Industry 4.0 adoption, a company already employing LP gains insights into its broad positive impacts, thereby fostering greater acceptance of workforce changes. Furthermore, it is advisable to instill and embody agility, flexibility, modularity, and scalability as new guiding principles for service provisioning (both in production and services) and process enhancements in the journey towards implementing Industry 4.0. This transformative process unlocks the potential inherent in Industry 4.0. However, it is important to recognize that this evolution requires a substantial amount of time to fully materialize.

4.2.4. Culture/Organization

Industry 4.0 transformation of a company is a mammoth task. It is necessary to build a new culture from different beliefs, principles, norms, and assumptions of individuals which creates a shared commitment, provides orientation, and creates a collective identity [62]. However, according to Ziaei Nafchi [63], an innovative culture, based on the assumptions of the Organizational Culture Index by Wallach [64], is to strive for, as it shows the best results about the readiness to implement Industry 4.0. This form of organization relies on cooperation, is relationship-oriented, supportive, friendly, and allows for personal freedom, as well as fairness, safety, and trust in employees. In addition, Facchini et al. [35] and Gamache et al. [65] show that an internal cultural change has a significantly positive influence on digital performance. However, the fact that people find this difficult is due to their nature, resistance to change and, especially, fear of rapid change [42,66]. But change can be mastered. Talent, management support, training, knowledge, and a high degree of personal responsibility promote adaptation to new challenges [67,68]. In SMEs, the necessary change requires above all a strong management that counteracts the missing culture of innovation and inflexible organizational culture with a long-term and holistic transformation plan [61]. This cultural change is one of the goals that is targeted by management with a long-term roadmap for Industry 4.0 implementation [35,61].

The motivations for instigating a cultural shift are multifaceted, ranging from a yearning for novelty to the compulsion to adapt due to competitive pressures or apprehensions. Facilitating the transformation towards Industry 4.0 necessitates the cultivation and advocacy of an innovative culture. This organizational culture places a premium on cooperation and mutual support, serving as an effective antidote to the vulnerabilities of SMEs outlined in Section 2.2. Nonetheless, this cultural shift mandates comprehensive and enduring endorsement from top management to proactively address apprehensions and concerns, thereby preventing their emergence.

4.2.5. People/Qualification

To date, the evidence on Industry 4.0 about people and qualifications shows that there is a significant shortage of skilled workers with the right skills and attitude for Industry 4.0, and this is a significant barrier to adoption [60,69,70]. It even shows that the availability of experts and skills seems to be more important than the available technology [71].

About Industry 4.0, combinations of professional (especially production process and systemic knowledge) and IT competencies (mainly data analysis, IT security, and protection) with social (including cooperation, communication abilities) and personal (like lifelong and self-regulated learning, analytical ability, interdisciplinary thinking, problem-solving) skills are needed [42,72]. “Cultivate digital people to drive smart factory implementation during and after the transformation”, is the demand of Sjödin et al. [44] (p. 25). It is also important to align the transformation with technologies and knowledge to overcome organizational inertia.

SMEs are again particularly challenged in terms of employees, as there is a lack of diverse employee qualifications, mentoring, targeted individual training, and supervision [61]. Through business transformation models, however, it is possible to win employees for the change and to learn new competencies accordingly Sjödin et al. [44].

People will continue to hold a central role within Industry 4.0 companies. However, the technological components appear to evolve at a pace that outstrips the ability of employees to acquire corresponding competencies. Consequently, there is a growing shortage of skilled workers, and this challenge disproportionately affects SMEs in comparison to MNEs. To prevent employees within SMEs from becoming bottlenecks in this context, it proves advantageous to establish a target competence profile and a comprehensive personnel development plan. In a broader context, companies must invest in their workforce, either by nurturing multidimensional professionals with proficiency in technical and IT domains, as well as social and personal skills, or by actively fostering their ongoing development. It is equally imperative to address the apprehensions and concerns of employees regarding the incessant changes associated with Industry 4.0. This can be achieved through measures such as effective management or changing management strategies.

4.2.6. Governance

A study in Indonesia shows that the government can provide incentives for companies to introduce Industry 4.0 by offering tax benefits and focusing on innovation centers [70]. A study by Da Silva et al. [47] determined sustainable conditions for companies and that the government should provide basic policy as well as technical and infrastructural regulations, as a lack of which hinders the adoption of Industry 4.0. Research also shows that funding for Industry 4.0 projects in Germany tends to come from the private sector, while government funding is common in China [49]. This, and the fact that there are fewer limiting structures in China, promotes the introduction of Industry 4.0 according to Stich et al. [73].

The notion that the introduction of Industry 4.0 will be inherently regulated by the market appears to be illusory. In today’s interconnected global landscape, competition encompasses political dimensions, and shaping the future necessitates governance. In the context of Industry 4.0 implementation, it is imperative for governments to proactively assess the requisite strategic, tactical, and operational mechanisms. This approach is essential to ensure that both SMEs and MNEs are not placed at a competitive disadvantage.

4.2.7. Technology

As much as technology is given attention in most Industry 4.0 maturity models [30], implying that high technology readiness is crucial for success, SMEs struggle with this. In contrast to MNEs, SMEs lack new, high-value technologies: so-called advanced manufacturing technologies (AMT). They have to do with standard processes and make a virtue of the note and operate with a low technology level and standard machines [58,74].

According to Tortorella and Fettermann [56], an optimal technological infrastructure consists of a digital network, machines, and more complex technologies that are modular and can thus be adapted according to the products to be created [44]. Following the value stream, internet technologies (CPS, IoT, sensors, actuators, beacons, RFIDs, etc.) ensure continuous networking [54,75] with a focus on information connectivity [76]. Isolated technological solutions are not to be preferred [39], nor is the approach of always acquiring the latest and best technology [77].

It is important that the technology meets the needs of the organization and is suitable, fully supported, and compatible [54,67]. This is the only way to increase resource utilization. According to Yue et al. [11], it is not the technology itself that influences performance or benefits, but the optimal interaction of technology, task, and the individual that brings the desired success. This is reinforced by the findings of Palčič et al. [78], “that companies have less and less time to learn how to use new technologies, and have to exploit their potential very quickly”. Gradual introduction is therefore the order of the day. It takes into account the socio-technical aspects that, according to Yue et al. [46], directly influence the degree of maturity; they increase acceptance and minimize excessive demands while the foundations and infrastructure are being built [44]. This also enables continuous innovation [44].

While Industry 4.0 undoubtedly derives a significant portion of its potential from emerging technologies, the realization of this potential and its efficient functionality are contingent upon achieving a harmonious equilibrium with evolving tasks and user demands. This holds particularly true for SMEs, emphasizing the need to avoid indiscriminate investments in AMTs, CPS, IoT, sensor technology, and the like, merely based on their novelty, sophistication, or cost. Instead, SMEs should embark on a strategic trajectory that aligns with their organizational needs and facilitates optimal utilization. In some cases, upgrading conventional machinery within SMEs may prove to be a judicious approach, as inundating users with unfamiliar applications can impede the acceptance of Industry 4.0, resulting in diminished productivity, quality, and potential profitability. Moreover, SMEs should prioritize the modularity and interoperability of technologies to harness future synergy effects effectively.

4.2.8. Investment/Resources

The availability of funding is one of the biggest barriers to the adoption of Industry 4.0 for SMEs, as noted by Kumar et al. [69] and Blatz et al. [41]. It therefore counts toward identifying the possibilities of using limited available capital effectively and efficiently.

According to Yue et al. [46], this starts primarily with the management. The cost-effective investment requires a complete understanding of the methodology, the status quo of the company, and the goals. The selection of the appropriate maturity model can also help. Such an assessment tool cannot only help with contextualization but also enable the identification of the required investments [53], which, according to Liebrecht et al. [79], should be based on ROI and be in line with the overall corporate strategy.

The fact that this is currently still like running the gauntlet is because Industry 4.0 is still in the discovery phase as well as, a lack of standardization, according to Hoyer et al. [39], meaning that not every technology is viable in the long term and therefore represents a financial risk which is not clear when the benefit comes around [44]. However, minimizing this risk is important for SMEs. Therefore Jodlbauer and Schagerl [80] recommend prioritizing the implementation of Industry 4.0 towards processes with a high degree of value creation (rapid ROI) and, secondly, on necessary investments instead of maximum investments for “best-in-class products”.

SMEs typically operate with budget constraints that demand prudent financial management. In the context of a sustainable integration of Industry 4.0, it is paramount to conduct a pragmatic appraisal of investment opportunities. One potential pivotal performance metric for achieving effectiveness and efficiency is the ROI. Low ROIs, for instance, imply a restricted timeframe for achieving returns. This underscores the importance of initially prioritizing products and services with substantial contribution margins.

4.2.9. Network/Supply Chain/Data

Seamlessly functioning supply chains are a core element of Industry 4.0 and, according to Fatorachian and Kazemi [75], the coordinated use of technologies such as CPS, IoT, Big Data Analysis and Cloud Computing has a significantly positive impact on internal supply chains. Fatorachian and Kazemi [75] and Qin et al. [81] recommend creating an integrated supra-supply chain system and linked networks through suppliers, wholesalers, and retailers that provides manufacturing companies with information and optimizes the intra-supply chain.

The exchange of information represents one of the most important insights into Industry 4.0. It is no longer a “one against all” approach. The creation of strategic alliances [67] and the sharing of best practices and knowledge [77,82,83] are sufficiently presented as the results of studies.

End-to-end data exchange is crucial! According to [42], the connection of individual departments is necessary to enable data-based decision making. Data quality also plays an essential role in this, Leyh et al. [9] examined, adding that the implementation and safeguarding of master data management is essential.

According to Kolla et al. [61] SMEs in particular often lack strong interdepartmental and external collaboration networks. Furthermore, Pirola et al. [53] suggest “that the main problems for SMEs are mainly related to data and information management inside and outside these companies”. To achieve a higher Industry 4.0 level, the consistent development of a digital network is recommended [20,42,65].

The reliability of the data and information provided must also be considered with the use of data, as Basl and Doucek [84] and Leyh et al. [9] have determined, because unreliable data could otherwise lead to considerable problems with AI, which is why Leyh et al. [9] considers the implementation of adequate master data and quality management to be necessary.

Kumar et al. [69], Rezqianita and Ardi [70] and Rauch et al. [12] found that protecting data from unauthorized access is one of the biggest challenges and needs top priority. Numerous cases prove that hacking is a reality and can have serious consequences (e.g., hack of the Swiss arms manufacturer RUAG in 2011, hack of the US fuel pipeline operator COLONIAL in 2021). Despite the risks, it can be stated that data are the gold of the future.

Industry 4.0 thrives on collaboration and can only achieve limited success in an isolated environment. Consequently, the establishment of continuous technological value chains to facilitate the exchange of data, information, products, and services is imperative, contingent upon a collective willingness to utilize them, characterized by interoperability and awareness. This necessitates the creation and maintenance of channels, especially within SMEs, both internally and externally. The leaner and more efficient this exchange becomes, the higher the level of Industry 4.0 maturity. Furthermore, master data management is fundamental as it serves as the bedrock for data-driven decision making. SMEs, in particular, bear a significant responsibility in this regard. The stability of the digital-analog network structure also holds paramount importance. As the number of nodes increases, so do both complexity and risk. Consequently, a phased introduction is recommended, with security, particularly against unauthorized external access, occupying a position of utmost priority.

4.2.10. Project Management

Using a maturity model is a good starting point for Industry 4.0 transformation. However, if companies are looking forward to receiving an actionable roadmap or action plan after the self-assessment, they will be disappointed. According to De Carolis et al. [57], no available online tool for self-determination of readiness for digital transformation provides an enterprise-specific roadmap or provides any concrete, practical, and easy-to-implement recommendations for action [45]. It is pointed out by various parties that a lack of a clear and specific roadmap or an action plan is one of the most frequently cited barriers to the introduction of Industry 4.0 [37,38,42,53].

To overcome this dilemma, Mittal et al. [74] suggest the installation of a strategy department or a dedicated Industry 4.0 group for SMEs that can work with the input provided by the maturity model. Stepwise/incremental transformation subsequently leads to success [36,85]. However, the “interdimensional interrelationship” of the dimensions must be considered [41] and managed using an iterative review of the maturity level [80,86]. In coordination with management, an Industry 4.0 project team must identify the individual optimum (KPIs) for the company and even adapt the roadmap if necessary [51]. For SMEs in particular, Mittal et al. [42] recommend the inclusion of costs in the KPIs as SME managers/owners mostly use financial data for decision making.

Cotrino et al. [48] propagate that the implementation of Industry 4.0 in SMEs must be simple and not resource-intensive, and that the roadmap should be task-oriented and not team-oriented due to missing team structure in SMEs.

Of particular value, Mittal et al. [42] recommend that the project team organize workshops, seminars, and training involving academics and researchers to share positive stories of successful companies related to Industry 4.0. However, due to the innovative nature of Industry 4.0, the number of existing role models and use cases is still limited [39].

For Lin [67], suitable project guidance tools and a systematic approach according to the “condition monitoring” methodology [59] are therefore recommended for support. For structured implementation, the adaptation of priority strategies according to a multi-criteria decision-making approach (MCDM) according to Kumar et al. [37] can help to achieve this goal step by step and efficiently.

The adoption of Industry 4.0 presents formidable challenges for SMEs, marked by the prospect of encountering hurdles at each interface. Therefore, when an SME elects to embark on this transformative journey, it is essential to approach the endeavor with careful preparation and ample resources. This includes the formation of a dedicated team vested with the requisite competencies, authority, and resources to actualize the specific goals derived from the optimal Industry 4.0 ambitions for the company. In combination with the selection of an appropriate maturity model to facilitate the formulation of a roadmap, in subsequently transitioning it into a project planning and management tool, there arises the need for well-defined and meaningful KPIs. Additionally, a high degree of change management skills is essential, coupled with consistent support from the management (often the owner) and the committed engagement of all stakeholders within the company. The examined publications also underscore the value of a stepwise planning approach, a willingness to learn from errors, sustained investment in staff competence development, and the power of positive storytelling.

5. Conclusions, Limitations, and Next Steps

This work is dedicated to supporting SMEs in the implementation of Industry 4.0 by providing a comprehensive overview. Utilizing an SLR, was possible to identify the contributions regarding the adoption of Industry 4.0 in manufacturing SMEs. The chapter on “analysis and discussion” systematically addresses the initial research question. The article does not present a one-size-fits-all master plan, as individual company-specific nuances are crucial. Nevertheless, the reviewed publications underscore that Industry 4.0 is not an end unto itself but harbors significant potential. Enterprises that cleverly navigate this transformation can enhance their value creation, product and service quality, and flexibility, and also concurrently reduce production resources. The main implication of the in-depth analysis and discussion is that it may serve as a foundational reference for governments and SMEs for calibrating the prerequisites, contextual factors, and expectations surrounding the implementation of Industry 4.0 and operationalizing this transition. Given the complex nature of Industry 4.0, marked by multifaceted technological, organizational, and cultural interactions, it is advisable to adopt a systemic and multidisciplinary approach alongside this categorization.

A noteworthy progression is observed in the research landscape, initially concentrating on MNEs and subsequently extending its scope to include SMEs. This evolution signifies the centrality and broad acceptance of the Industry 4.0 paradigm within the business sphere. This study distinguishes itself by presenting a structured and concise compendium of prior findings and recommendations on Industry 4.0 from an SME perspective. Limitations of this study are rooted in the SLR methodology and the specific constraints imposed, leading to inherent biases in publication selection. The intent is to spread and publish the identified research findings concerning maturity models and readiness models. Furthermore, the gathered maturity models will undergo extensive examination, culminating in the development of a comprehensive, SME-centric maturity model.

Author Contributions

Conceptualization, K.H., C.P. and L.T.; methodology, K.H.; validation C.P. and L.T.; formal analysis, K.H.; writing—original draft preparation, K.H.; writing—review and editing, K.H., C.P. and L.T.; supervision, C.P. and L.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

This work was supported by Algoritmi Research Unit (UIDB/00319/2020), by the research unit on Governance, Competitiveness and Public Policy (UIDB/04058/2020), and by the Institute of Electronics and Informatics Engineering of Aveiro (IEETA)/LASI (UIDB/00127/2020), supported by Portuguese funds through the FCT—Foundation for Science and Technology.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Publications by categories.

Table A1.

Publications by categories.

| Category | Authors |

|---|---|

| Strategy and Leadership | [17,35,36,37,38,39,40,41,42,43,44,45,46,47,48] |

| Customer and Product | [36,49,50,51,52,53,54,55] |

| Operations/Processes | [10,11,36,39,44,53,55,56,57,58,59,60,61] |

| Culture/Organization | [35,42,61,62,63,64,65,66,67,68] |

| People/Qualification | [42,44,60,61,69,70,71,72] |

| Governance | [47,49,70,73] |

| Technology | [11,30,39,42,44,46,54,56,58,67,74,75,76,77,78] |

| Investments | [39,41,44,46,53,69,79,80] |

| Network, Supply Chain, Data | [9,12,20,42,53,61,65,67,69,70,75,77,81,82,83,84] |

| Project Management | [36,37,38,39,41,42,45,48,51,53,57,59,67,74,80,85,86] |

References

- Ganzarain, J.; Errasti, N. Three stage maturity model in SME’s toward industry 4.0. J. Ind. Eng. Manag. 2016, 9, 1119. [Google Scholar] [CrossRef]

- Schuh, G.; Anderl, R.; Gausemeier, J.; Ten Hompel, M.; Wahlster, W. Industrie 4.0 Maturity Index. In Managing the Digital Transformation of Companies; Herbert Utz Verlag: Munich, Germany, 2017; pp. 1–60. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity approach for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Soomro, M.A.; Hizam-Hanafiah, M.; Abdullah, N.L. Abdullah, Digital readiness models: A systematic literature review. Compusoft 2020, 9, 3596–3605. [Google Scholar]

- Dikhanbayeva, D.; Shaikholla, S.; Suleiman, Z.; Turkyilmaz, A. Assessment of Industry 4.0 Maturity Models by Design Principles. Sustainability 2020, 12, 9927. [Google Scholar] [CrossRef]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards industrial digitalization based on an Industry 4.0 maturity model for manufacturing enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- Issa, A.; Hatiboglu, B.; Bildstein, A.; Bauernhansl, T. Industrie 4.0 roadmap: Framework for digital transformation based on the concepts of capability maturity and alignment. Procedia CIRP 2018, 72, 973–978. [Google Scholar] [CrossRef]

- Becker, J.; Knackstedt, R.; Pöppelbuß, J. Entwicklung von Reifegradmodellen für das IT-Management. Wirtschaftsinformatik 2009, 51, 249–260. [Google Scholar] [CrossRef]

- Leyh, C.; Schäffer, T.; Bley, K.; Forstenhäusler, S. SIMMI 4.0—A Maturity Model for Classifying the Enterprise-Wide it and Software Landscape Focusing on Industry 4.0; Institute of Electrical and Electronics Engineers Inc.: Gdansk, Poland, 2016. [Google Scholar]

- Asdecker, B.; Felch, V. Development of an Industry 4.0 maturity model for the delivery process in supply chains. J. Model. Manag. 2018, 13, 840–883. [Google Scholar] [CrossRef]

- Yue, L.; Wang, Z.; Fang, Y.; Han, Z. Implementation of Smart Manufacturing Maturity Assessment Framework: A Socio-Technical Perspective. E3S Web Conf. 2020, 179, 02023. [Google Scholar] [CrossRef]

- Rauch, E.; Unterhofer, M.; Rojas, R.A.; Gualtieri, L.; Woschank, M.; Matt, D.T. A Maturity Level-Based Assessment Tool to Enhance the Implementation of Industry 4.0 in Small and Medium-Sized Enterprises. Sustainability 2020, 12, 3559. [Google Scholar] [CrossRef]

- Flamini, M.; Naldi, M. Maturity of Industry 4.0: A Systematic Literature Review of Assessment Campaigns. J. Open Innov. Technol. Mark. Complex. 2022, 8, 51. [Google Scholar] [CrossRef]

- Elhusseiny, H.M.; Crispim, J. A Review of Industry 4.0 Maturity Models: Adoption of SMEs in The Manufacturing and Logistics Sectors. Procedia Comput. Sci. 2023, 219, 236–243. [Google Scholar] [CrossRef]

- da Silva, N.A.; Abreu, J.L.; Klingenberg, C.O.; Junior, J.A.V.A.; Lacerda, D.P. Industry 4.0 and micro and small enterprises: Systematic literature review and analysis. Prod. Manuf. Res. 2022, 10, 696–726. [Google Scholar] [CrossRef]

- Chavez, Z.; Hauge, J.B.; Bellgran, M. Industry 4.0, transition or addition in SMEs? A systematic literature review on digitalization for deviation management. Int. J. Adv. Manuf. Technol. 2022, 119, 57–76. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef]

- BMWi. 2021. Available online: https://www.plattform-i40.de/PI40/Navigation/DE/Home/home.html (accessed on 27 June 2021).

- Odważny, F.; Wojtkowiak, D.; Cyplik, P.; Adamczak, M. Concept for measuring organizational maturity supporting sustainable development goals. Logforum 2019, 15, 237–247. [Google Scholar] [CrossRef]

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millak, A.; Schmitt, K.; Schmitz, E.; Schröter, M. IMPULSE—Industrie 4.0 Readiness; VDMA e.V.: Frankfurt, Germany, 2015; pp. 1–75. [Google Scholar]

- De Bruin, T.; Rosemann, M.; Freeze, R.; Kaulkarni, U. Understanding the Main Phases of Developing a Maturity Assessment Model. In Proceedings of the Australasian Conference on Information Systems, Brisbane, Australia, 4–6 July 2005. [Google Scholar]

- United Nations. Small & Medium-Sized Enterprises. 2019. Available online: https://globalnaps.org/issue/small-medium-enterprises-smes/ (accessed on 11 September 2021).

- European Commission. Annual Report on European SMEs 2020/2021. In SME Performance Review 2020/2021; European Commission: Brussels, Belgium, 2021. Available online: https://ec.europa.eu/docsroom/documents/46062 (accessed on 10 November 2021).

- Bundesministerium für Wirtschaft und Energie. 2021. Available online: https://www.bmwi.de/Redaktion/DE/Dossier/politik-fuer-den-mittelstand.html (accessed on 30 June 2021).

- European Commission. EU Recommendation 2003/361—SME Definition. 2021. European Commission: Brussels, Belgium. 2021. Available online: https://ec.europa.eu/growth/smes/sme-definition_en (accessed on 26 June 2021).

- Ingaldi, M.; Ulewicz, R. Problems with the Implementation of Industry 4.0 in Enterprises from the SME Sector. Sustainability 2020, 12, 217. [Google Scholar] [CrossRef]

- Türkeș, M.C.; Oncioiu, I.; Aslam, H.D.; Marin-Pantelescu, A.; Topor, D.I.; Căpușneanu, S. Drivers and Barriers in Using Industry 4.0: A Perspective of SMEs in Romania. Processes 2019, 7, 153. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, M.; Tetzlaff, J.; Altman, D.G.; PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Hizam-Hanafiah, M.; Soomro, M.A.; Abdullah, N.L. Industry 4.0 Readiness Models: A Systematic Literature Review of Model Dimensions. Information 2020, 11, 364. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Nausch, M.; Schumacher, A.; Sihn, W. Assessment of Organizational Capability for Data Utilization—A Readiness Model in the Context of Industry 4.0; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2020; pp. 243–252. [Google Scholar] [CrossRef]

- Mrugalska, B.; Stasiuk-Piekarska, A. Readiness and Maturity of Manufacturing Enterprises for Industry 4.0. In AHFE Virtual Conference on Production Management and Process Control, Human Aspects of Advanced Manufacturing and the Additive Manufacturing, Modeling Systems and 3D Prototyping; Springer: Berlin/Heidelberg, Germany, 2020; pp. 263–270. [Google Scholar] [CrossRef]

- Schmitt, P.; Schmitt, J.; Engelmann, B. Evaluation of proceedings for SMEs to conduct I4.0 projects. Procedia CIRP 2019, 86, 257–263. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2019, 12, 86. [Google Scholar] [CrossRef]

- Santos, R.C.; Martinho, J.L. An Industry 4.0 maturity model proposal. J. Manuf. Technol. Manag. 2019, 31, 1023–1043. [Google Scholar] [CrossRef]

- Kumar, V.; Vrat, P.; Shankar, R. Prioritization of strategies to overcome the barriers in Industry 4.0: A hybrid MCDM approach. Opsearch 2021, 58, 711–750. [Google Scholar] [CrossRef]

- Pessl, E.; Sorko, S.R.; Mayer, B. Roadmap Industry 4.0—Implementation Guideline for Enterprises. Int. J. Sci. Technol. Soc. 2017, 5, 193–202. [Google Scholar] [CrossRef]

- Hoyer, C.; Gunawan, I.; Reaiche, C.H. The Implementation of Industry 4.0—A Systematic Literature Review of the Key Factors. Syst. Res. Behav. Sci. 2020, 37, 557–578. [Google Scholar] [CrossRef]

- Moica, S.; Ganzarain, J.; Ibarra, D.; Ferencz, P. Change Made in Shop Floor Management to Transform a Conventional Production System into an ’Industry 4.0’: Case Studies in SME Automotive Production Manufacturing; Institute of Electrical and Electronics Engineers Inc.: Oxford, UK, 2018. [Google Scholar] [CrossRef]

- Blatz, F.; Bulander, R.; Dietel, M. Maturity Model of Digitization for SMEs; Institute of Electrical and Electronics Engineers Inc.: Stuttgard, Germany, 2018. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Purohit, J.K.; Menon, K.; Romero, D.; Wuest, T. A smart manufacturing adoption framework for SMEs. Int. J. Prod. Res. 2020, 58, 1555–1573. [Google Scholar] [CrossRef]

- Amaral, A.; Jorge, D.; Peças, P. Small medium enterprises and industry 4.0: Current models’ ineptitude and the proposal of a methodology to successfully implement industry 4.0 in small medium enterprises. Procedia Manuf. 2019, 41, 1103–1110. [Google Scholar] [CrossRef]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation: A Preliminary Maturity Model for Leveraging Digitalization in ManufacturingMoving to smart factories presents specific challenges that can be addressed through a structured approach focused on people, processes, and technologies. Res. Manag. 2018, 61, 22–31. [Google Scholar] [CrossRef]

- Rauch, E.; Stecher, T.; Unterhofer, M.; Dallasega, P.; Matt, D.T. Suitability of Industry 4.0 Concepts for Small and Medium Sized Enterprises: Comparison between an Expert Survey and a User Survey; IEOM Society: Bangkok, Thailand, 2019. [Google Scholar]

- Yue, L.; Niu, P.; Fang, Y.; Han, Z. Towards a Smart Manufacturing Maturity Assessment Framework: A Socio-Technical Perspective. J. Phys. Conf. Ser. 2019, 1345, 042063. [Google Scholar] [CrossRef]

- Da Silva, V.L.; Kovaleski, J.L.; Pagani, R.N.; Silva, J.D.M.; Corsi, A. Implementation of Industry 4.0 concept in companies: Empirical evidences. Int. J. Comput. Integr. Manuf. 2020, 33, 325–342. [Google Scholar] [CrossRef]

- Cotrino, A.; Sebastián, M.A.; González-Gaya, C. Industry 4.0 Roadmap: Implementation for Small and Medium-Sized Enterprises. Appl. Sci. 2020, 10, 8566. [Google Scholar] [CrossRef]

- Puchan, J.; Zeifang, A.; Leu, J.-D. Industry 4.0 in Practice-Identification of Industry 4.0 Success Patterns; IEEE Computer Society: Bangkok, Thailand, 2019. [Google Scholar] [CrossRef]

- Exner, K.; Zimpfer, R.; Stark, R. Maturity Model and Action Recommendation: A PSS Capability Self-Assessment Tool for Companies. Procedia CIRP 2017, 64, 175–180. [Google Scholar] [CrossRef]

- Klötzer, C.; Pflaum, A. Toward the Development of a Maturity Model for Digitalization within the Manufacturing Industry’s Supply Chain. In Proceedings of the 50th Hawaii International Conference on System Sciences; University of Hawaii at Manoa: Honolulu, HI, USA, 2017. [Google Scholar]

- Zapata, M.L.; Berrah, L.; Tabourot, L. Is a digital transformation framework enough for manufacturing smart products? The case of Small and Medium Enterprises. Procedia Manuf. 2020, 42, 70–75. [Google Scholar] [CrossRef]

- Pirola, F.; Cimini, C.; Pinto, R. Digital readiness assessment of Italian SMEs: A case-study research. J. Manuf. Technol. Manag. 2019, 31, 1045–1083. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Key ingredients for evaluating Industry 4.0 readiness for organizations: A literature review. Benchmarking Int. J. 2019, 27, 2213–2232. [Google Scholar] [CrossRef]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0—Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-PapersOnLine 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D.C. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- De Carolis, A.; Macchi, M.; Negri, E.; Terzi, S. Guiding manufacturing companies towards digitalization a methodology for supporting manufacturing companies in defining their digitalization roadmap. In Proceedings of the 23rd International Conference on Engineering, Technology and Innovation, ICE/ITMC, Madeira Island, Portugal, 27–29 June 2017; pp. 487–495. [Google Scholar] [CrossRef]

- Lin, T.-C.; Wang, K.J.; Sheng, M.L. To assess smart manufacturing readiness by maturity model: A case study on Taiwan enterprises. Int. J. Comput. Integr. Manuf. 2020, 33, 102–115. [Google Scholar] [CrossRef]

- Wank, A.; Adolph, S.; Anokhin, O.; Arndt, A.; Anderl, R.; Metternich, J. Using a Learning Factory Approach to Transfer Industrie 4.0 Approaches to Small- and Medium-sized Enterprises. Procedia CIRP 2016, 54, 89–94. [Google Scholar] [CrossRef]

- Wiesner, S.; Gaiardelli, P.; Gritti, N.; Oberti, G. Maturity Models for Digitalization in Manufacturing—Applicability for SMEs; von Cieminski, G., Kiritsis, D., Lee, G.M., Moo, I., Park, J., Eds.; Springer New York LLC: New York, NY, USA, 2018; pp. 81–88. [Google Scholar] [CrossRef]

- Kolla, S.; Minufekr, M.; Plapper, P. Deriving essential components of lean and industry 4.0 assessment model for manufacturing SMEs. Procedia CIRP 2019, 81, 753–758. [Google Scholar] [CrossRef]

- Nafchi, M.Z.; Mohelská, H. Influence of the type of organizations on their readiness for implementing industry 4.0. In 4th International Symposium, SETE 2019; Popescu, E., Hao, T., Hsu, T.C., Xie, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 76–82. [Google Scholar] [CrossRef]

- Nafchi, M.Z.; Mohelská, H. Organizational Culture as an Indication of Readiness to Implement Industry 4.0. Information 2020, 11, 174. [Google Scholar] [CrossRef]

- Wallach, E.J. Individuals and organizations: The cultural match. Train. Dev. 1983, 37, 29–36. [Google Scholar]

- Gamache, S.; Abdul-Nour, G.; Baril, C. Development of a Digital Performance Assessment Model for Quebec Manufacturing SMEs. Procedia Manuf. 2019, 38, 1085–1094. [Google Scholar] [CrossRef]

- Ramos, L.F.P.; Loures, E.d.F.R.; Deschamps, F. An Analysis of Maturity Models and Current State Assessment of Organizations for Industry 4.0 Implementation. Procedia Manuf. 2020, 51, 1098–1105. [Google Scholar] [CrossRef]

- Lin, T.-C.; Sheng, M.L.; Wang, K.J. Dynamic capabilities for smart manufacturing transformation by manufacturing enterprises. Asian J. Technol. Innov. 2020, 28, 403–426. [Google Scholar] [CrossRef]

- Zeller, V.; Hocken, C.; Stich, V. Acatech Industrie 4.0 Maturity Index—A Multidimensional Maturity Model; von Cieminski, G., Kiritsis, D., Lee, G.M., Moo, I., Park, J., Eds.; Springer New York LLC: New York, NY, USA, 2018; pp. 105–113. [Google Scholar] [CrossRef]

- Kumar, N.V.; Karadgi, S.; Kotturshettar, B.B. Review of research issues and challenges of maturity models concerning industry 4.0. IOP Conf. Ser. Mater. Sci. Eng. 2020, 872, 012006. [Google Scholar] [CrossRef]

- Rezqianita, B.L.; Ardi, R. Drivers and Barriers of Industry 4.0 Adoption in Indonesian Manufacturing Industry. In Proceedings of the 3rd Asia Pacific Conference on Research in Industrial and Systems Engineering, Depok, Indonesia, 16–17 June 2020; Association for Computing Machinery: Depok, Indonesia, 2020. [Google Scholar]

- Simetinger, F.; Zhang, Z. Deriving secondary traits of industry 4.0: A comparative analysis of significant maturity models. Syst. Res. Behav. Sci. 2020, 37, 663–678. [Google Scholar] [CrossRef]

- Kravcik, M.; Wang, X.; Ullrich, C.; Igel, C. Towards Competence Development for Industry 4.0; Luckin, R., Porayska-Pomsta, K., du Boulay, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 442–446. [Google Scholar] [CrossRef]

- Stich, V.; Gudergan, G.; Zeller, V. Need and Solution to Transform the Manufacturing Industry in the Age of Industry 4.0—A Capability Maturity Index Approach; Afsarmanesh, H., Rezgui, Y., Camarinha-Matos, L.M., Eds.; Springer New York LLC: New York, NY, USA, 2018; pp. 33–42. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on supply chain performance. Prod. Plan. Control. 2021, 32, 63–81. [Google Scholar] [CrossRef]

- Jung, K.; Kulvatunyou, B.; Choi, S.; Brundage, M.P. An Overview of a Smart Manufacturing System Readiness Assessment. In Proceedings of the IFIP WG 5.7 International Conference on APMS, Iguassu Fally, Brazil, 3–7 September 2016. [Google Scholar] [CrossRef]

- Wagire, A.A.; Joshi, R.; Rathore, A.P.S.; Jain, R. Development of maturity model for assessing the implementation of Industry 4.0: Learning from theory and practice. Prod. Plan. Control. 2020, 32, 603–622. [Google Scholar] [CrossRef]

- Palčič, I.; Klančnik, S.; Lerher, T.; Ficko, M. The Use of Digital Factory Technologies in Slovenian Manufacturing Companies. In International Conference on New Technologies, Development and Application, NT 2020; Karabegovic, I., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 227–237. [Google Scholar]

- Liebrecht, C.; Kandler, M.; Lang, M.; Schaumann, S.; Stricker, N.; Wuest, T.; Lanza, G. Decision support for the implementation of Industry 4.0 methods: Toolbox, Assessment and Implementation Sequences for Industry 4.0. J. Manuf. Syst. 2021, 58, 412–430. [Google Scholar] [CrossRef]

- Jodlbauer, H.; Schagerl, M. Maturity Model Industry 4.0—A Process Model for the Identification of Industry 4.0 Potentials. In Proceedings of the 46th Annual Meeting of German Informatics Society (GI), Klagenfurt, Austria, 26 September 2016. [Google Scholar]

- Qin, J.; Liu, Y.; Grosvenor, R. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP 2016, 52, 173–178. [Google Scholar] [CrossRef]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels—Case of the defence sector. Prod. Plan. Control. 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Pereira, S.C.F.; Telles, R.; Machado, M.C. Industry 4.0 and digital supply chain capabilities: A framework for understanding digitalisation challenges and opportunities. Benchmarking Int. J. 2019, 28, 1761–1782. [Google Scholar] [CrossRef]

- Basl, J.; Doucek, P. A Metamodel for Evaluating Enterprise Readiness in the Context of Industry 4.0. Information 2019, 10, 89. [Google Scholar] [CrossRef]

- Gökalp, E.; Şener, U.; Eren, P.E. Development of an ASSESSMENT Model for Industry 4.0: Industry 4.0-MM; O’Connor, R.V., Mas, A., Rout, T., Mesquida, A., Dorling, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 128–142. [Google Scholar] [CrossRef]

- De Carolis, A.; Macchi, M.; Kulvatunyou, B.; Brundage, M.P.; Terzi, S. Maturity Models and tools for enabling smart manufacturing systems: Comparison and reflections for future developments. In IFIP Advances in Information and Communication Technology; Springer New York LLC: New York, NY, USA, 2017; Volume 517, pp. 23–35. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).