Abstract

Background: Road transport companies utilize transport capacities as fixed compositions of tractors and semi-trailers, while the possibility of exchanging semi-trailers is considered ad hoc, after some unforeseen circumstances emerge on the route. Such an approach is a limiting factor in achieving optimal utilization of transport capacities, and consequently affects profitability. We proposed a new concept of vehicle fleet management where semi-trailers would not be permanently assigned to the tractors, but could be dynamically reassigned, to utilize optimally the vehicle fleet, on considering the planned itinerary, the driver’s working hours, and traffic conditions. Methods: We set the key performance indicators and developed a prototype application based on the concept of dynamic semi-trailer allocation. We simulated the use of the prototype application on the historical data collected in the case study on one of the leading transport companies in the cold chain, and evaluated the benefits that may be achieved thereof. Results: Simulation showed that implementing the proposed concept enabled the reduction of the vehicle workdays spent on-the-route, the reduction of the number of vehicle compositions needed to handle the transport demand, and improved the quality of service. Conclusions: The proposed concept is beneficial for transport companies that operate large vehicle fleets on long-haul routes, with several transport orders per route. The prototype application may be the basis for developing a fully functional application that can be integrated into the fleet management system.

1. Introduction

Effective management of transport capacities is the basic premise of profitable and sustainable operation of a transport company, which implies the synergy of contracting transport services, vehicle fleet disposition, and technical support for the vehicle fleet. The sensitivity of the transport substrate to temperature deviations puts additional demands on the management of transport capacities in the cold chain. The risk analysis in the cold chain determined that the largest number of non-conformities in the distribution of temperature-sensitive goods occur during loading, unloading, and transport, and therefore, cold chain transport should be carried out by highly reliable means of transport, by the shortest route, and within the shortest transit time.

Urban population growth is driving up the consumption of cold chain products, necessitating faster and more efficient distribution models. Successful and efficient distribution requires optimal utilization of transportation capacities while balancing the interests of transport companies, customers, and government agencies that oversee environmental protection. Scientists and professionals have provided various approaches and algorithms for optimizing vehicle routes against different criteria, to improve fleet management models in terms of effectivity and efficiency, customer satisfaction, and environmental protection. Such solutions have shown significant benefits in the performance of transport processes, however certain challenges remain due to specific conditions and service requirements in the cold chain.

This research is focused on optimization of transport routes, with the aim of better utilization of transport capacities and achieving a greater transport effect, while complying with the planned itinerary. It would improve existing fleet management models, primarily in the segment of utilization of the transport capacities, and consequently raise the profitability of the transport operations, along with the quality level and the safety of the transport substrate.

Road transport companies utilize their transport capacities as fixed combinations of tractors and semi-trailers and consider them as such when constructing routes and offering transport services on the market. The possibility of switching tractor/semi-trailer compositions is considered ad hoc, after some unforeseen events or circumstances emerge on the route (such as vehicle malfunction, traffic jam, or traffic accident) but not proactively, nor continuously. Furthermore, if a switching tractor/semi-trailer composition is to be considered, it is done manually by the dispatchers. Such an approach presents a limiting factor in achieving optimal utilization of transport capacities, and consequently affects the profitability and sustainability of the business. For this reason, it is necessary to investigate the possibility of introducing a different concept of transport capacity management, whereby semi-trailers would not be permanently assigned to the same tractor, but would dynamically join the tractors, to optimize the route with regard to the stipulated time and locations of pick-up and delivery, the driver’s working hours, and road traffic regulation, taking into account the real-time spatiotemporal positions of the vehicles and the traffic conditions. It would open additional space for increasing the utilization of transport capacities and for achieving greater transport performance, thus expanding the cost-revenue framework of the vehicle fleet utilization.

With reference to that, we conducted a case study on one of the leading European transport companies that provide road transport services in the cold chain, to collect and analyze information and historical data on realized transport routes, as well as criteria, priorities, and restrictions for vehicle disposition and construction of routes. Based on the results of the analysis, we designed a conceptual model of transport capacity management with a greater degree of freedom, by considering the dynamic allocation of semi-trailers. We developed a prototype application out of this conceptual model, with sufficient functionalities for testing purposes, and applied it to the historical data collected in the case study, to quantify the improvements that may be achieved. The conceptual model and the prototype application are also a productive foundation for the development of a commercial application that could be integrated into the existing FMS (fleet management system).

The aim of this paper was to present the proposed concept of dynamic semi-trailer allocation and to outline its applicability and benefits that may be achieved by introducing this concept into the fleet management system. Furthermore, we received positive feedback from the IT experts regarding the feasibility of producing a fully functional commercial application based on the prototype that we developed. Such application would continuously monitor the entire vehicle fleet, predict deviations and possibilities of vehicle workday savings, automatically suggesting semi-trailer exchange to the dispatchers.

Unlike the usual way of operating vehicle compositions where exchanging semi-trailers is performed as a reaction to the emerging problem on the route, the algorithm we developed works proactively; it predicts deviations from the planned itinerary, finds a suitable semi-trailer exchange point, and redirects the vehicles. It is important to note that pick-up and delivery time-windows may be relatively extensive and that certain delays may not be considered a major problem by the clients. However, each additional vehicle workday is a fixed cost that not only decreases the margin of the transport route, but also seizes the transport capacity that would otherwise be available.

The structure of the paper consists of six sections. After this introductory section, Section 2 provides a systematic review of the recent literature sources, by segmentation against the dominant optimization criteria. Section 3 dwells on the methodology of the research which involves collecting input data and information within the case study on the transport company, designing the conceptual model of dynamic semi-trailer allocation, developing the prototype application, and testing the model by simulated use of the prototype application on the historical data obtained from the case study. Section 4 presents the results of the analysis of the transport operations performed in the sampled period and the results of the simulation. Section 5 discusses the benefits of introducing the concept of dynamic semi-trailer allocation into the fleet management system, as well as limitations and disadvantages encountered during development and testing of the prototype application. Finally, Section 6 presents the main findings and limitations of this research, while suggesting possible directions for future research.

2. Literature Review

To provide the most recent review of the current state of the research field, we carried out the search for scientific papers on the WoS (Web of Science) platform by keywords: optimization, vehicle fleet, cold chain, for the period of the last five years (from 1 January 2018 to 31 December 2022.). The search resulted in a sample of 107 scientific papers in total (published in scientific journals or in proceedings of scientific conferences). When analyzing the sample, 77 scientific papers were filtered out, which primarily fell into the field of interest of this research. The other 30 scientific papers were excluded from further consideration because they were marginal or out of the field of this research.

On reviewing the papers, we identified the most common optimization criteria that were applied in determining the optimization problem, i.e., the primary goal to be achieved by the optimization. With reference to that, taking care not to depart from the scope of this paper, we carried out the segmentation of the research sample against the following four dominant optimization criteria.

- Transport cost, is considered as one of the criteria in papers [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65], and as a single optimization criterion in papers [46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65]. Optimizing transportation routes with the goal of minimizing costs involves defining the most efficient route that vehicles can take to reduce the variable costs (such as fuel, tolls, etc.) and fixed costs (such as vehicle workday costs, salaries of the drivers, maintenance, etc.), while complying with the planned itinerary. The shortest or the fastest route is not necessarily the most cost effective. The goal is to find the best combination of transport orders, in-the-route movements and travel time that would result in a reduction of total transport costs.

- Quality and safety are not considered as a single optimization criterion in any of the papers but are present as one of the criteria in papers [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,66,67,68,69,70,71,72]. Optimizing transport routes with the aim of meeting the quality standards such as ISO9001, HACCP (hazard analysis critical control point), GDP Pharma (good distribution practice) and safety of the substrate is about finding the best way to deliver the product with minimal risk of contamination or damage. Consolidating different kinds of products that can be transported without cross-contamination would result in better utilization of the transport capacities, which is in line with this criterion.

- Environmental impact is not considered as a single optimization criterion in any of the papers but is present as one of the criteria in papers [1,2,3,4,5,6,7,8,9,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,66,73,74,75,76]. Greenhouse gasses such as carbon dioxide, methane, and nitrous oxide are responsible for the warming of the Earth’s atmosphere, leading to climate change. Climate change affects our environment, lifestyle, and food production. Optimizing vehicle routes with the goal of protecting the environment is about finding the best route for vehicles to travel that would reduce harmful gas emissions, fuel consumption, and environmental impact.

- Customer satisfaction, as a single optimization criterion is present in paper [77], and as one of the criteria in papers [1,22,23,24,25,26,27,28,29,42,43,44,45,73]. Route optimization for customer satisfaction is about defining an itinerary that would enable timeliness in pick-up and delivery, minimizing delays, and the problems thereof. Consequently, the products are delivered on time, without compromising product quality, resulting in higher customer satisfaction and sustainability of cooperation in the future.

The segmentation is outlined in Table 1. where scientific papers are grouped by the optimization criteria presented in the respective paper.

Table 1.

Review of the scientific papers by optimization criterion.

There are different content analyses as well, such as [78] where the authors provided an overview of research articles on data processing, sharing, and utilizing data for decision making in the cold chain logistics. However, we applied this approach to the literature review as it is closely related to the main research issue, while the data and technology that are primarily important for this research refer to FMS.

In the context of fleet management, the optimization issue is a multi-criteria problem. Depending on priorities in a particular case, one can determine answers to different criteria and to select and combine several criteria to achieve the optimal solution. Nevertheless, giving priority to a particular criterion may have a negative impact on the results if evaluated against some other criteria; however, such considerations are not in the focus of this research.

The optimization criteria considered in this research are transport costs, and indirectly customer satisfaction, as well as quality and safety of road transport in the cold chain. The transport costs that are addressed in the research are the fixed costs of the vehicle fleet, which are correlated to the number of days the vehicles spend in realization of the transport routes. Adopting such optimization criterion, the algorithm we developed predicts a deviation from the planned itinerary, finds a suitable semi-trailer exchange point, and redirects the vehicles. This way, not only vehicle workdays are saved but pick-up and delivery delays are avoided, which improves the service quality and raises customer satisfaction and the safety of the product.

Additional areas of recent research could also be considered, such as the issue of logistics customer service quality metrics [79,80], or the quality changes of specific products associated with temperature fluctuations during transport in the cold chain [81]; however, it would go beyond the scope of this paper.

3. Materials and Methods

The materials and methodology of the research consist of three stages. In the first stage, we conducted a case study of one of the leading European road transport companies in the cold chain. The main purpose of the case study was to obtain information and data needed to carry out the subsequent stages of the research. It involved the following tasks.

- Collecting data on the actual transport operation and relevant features of the transport infrastructure within the time frame of the first three quarters of 2023. on the territory of the European Union.

- Analysis of the criteria, priorities, and limitations in construction of transport routes, with reference to the transport demand (desired itinerary) and the restrictions set by the road transport regulations (driving time, driver’s rest).

- Analysis of the realized transport routes according to the KPIs (key performance indicators) that are commonly applied by the transport company (such as the number of transport orders, the number of vehicle workdays, direct costs, timeliness of pick-up and delivery, profitability of the route).

The term vehicle workday cost refers to the fixed costs of the transport company generated by operating one vehicle composition (tractor/semi-trailer) one day, namely, the depreciation of the vehicle composition, maintenance, registration, administrative overhead, and office utilities. For each transport order, in addition to direct transport costs (fuel, tolls, drivers per diems, and travel costs), the cost of vehicle workdays is also calculated, to be multiplied by the number of days on the road, required to execute the transport order from pick-up to delivery.

It is important to note that the cost of vehicle workdays is also generated when the vehicle is not used and when it runs without cargo (empty kilometers). In contrast to that, if the vehicle is unloaded and loaded with a new transport order on the same day, the cost of vehicle workdays is split to two different customers. Generally, it is acceptable to unload the cargo on the first day and load another cargo on the second day, while the situation where the vehicle stands a day or more between the day of delivery and the day of the next pick-up represents a lost vehicle workday, which generates unplanned costs for the transport company. It applies directly to the driver and the tractor, while the semi-trailer can be reassigned and used with different tractors.

For the sake of triangulation with other sources of information, we also considered the vehicle fleet operation of other comparable transport companies, as well as the professional opinion of experts from one of the leading Croatian IT companies that provide telematic software and equipment.

In the second stage of the research, we designed a conceptual model for managing transport capacities in the cold chain, based on dynamic allocation of semi-trailers to tractors. We defined the optimization criteria and the model parameters, input data format, technical solution for obtaining the required data in due time (predefined data and real-time data), and processing logic in the form of a programming task for designing a prototype application with sufficient functionalities for testing purpose. Basically, the algorithm of the prototype application operates in the following manner.

- Initially, it generates vehicle routes based on a given itinerary and draws the planned routes on the road map.

- Next, it looks for the possibilities of reallocating semi-trailers to tractors among the planned routes (switching tractor/semi-trailer compositions) on an hourly basis.

- It simulates the real data arriving from GPS (global positioning system) every hour, updates planned routes, and checks for the possibility of switching tractor/semi-trailer compositions.

- If a switching possibility is found within the maximum deviation from the route (set as parameter), the routes are selected, and the switching point is indicated.

- Next, the new feasible routes are planned, considering that the vehicle compositions must meet each other in the given space and time, while the semi-trailers must follow their itinerary that was originally set.

- Finally, it evaluates the new routes in terms of a savings in the total travel time, and if there is a saving, the routes are displayed on the road map (if there are more possibilities, the best one is indicated).

The third stage refers to testing of the conceptual model of transport capacity management by simulated use of the prototype application on historical data on the vehicle fleet operation, collected in the case study, and comparing the values of the selected KPIs achieved thereof to the respective values realized by the road transport company, in the testing period. We determined the following KPIs to evaluate the transport operations performed in the sampled period and to quantify the improvements that may be achieved by implementing the concept of dynamic semi-trailer allocation.

- Pick-up delay as the difference between the stipulated date of pick-up and the realized date of pick-up, expressed in vehicle workdays, given by Equation (1):where

- PD = total pick-up delay

- DPri = realized date of i-th pick-up

- DPsi = stipulated date of i-th pick-up

- n = total number of events where the stipulated date of pick-up is different from the realized date of pick-up.

- Delivery delay as the difference between the stipulated date of delivery and the realized date of delivery, expressed in vehicle workdays, given by Equation (2):where

- DD = total delivery delay

- DDri = realized date of i-th delivery

- DDsi = stipulated date of i-th delivery

- n = total number of events where the stipulated date delivery is different than the realized date of delivery

- Potential saving is the discrepancy between the planned and the actual number of vehicle workdays spent in realization of the transport routes. Considering pick-up delay a triggering event for the transport route optimization that cannot therefore be retroactively influenced, but necessarily causes future delivery delay, the potential saving of vehicle workdays can be obtained as the total delivery delay decreased by the total pick-up delay, expressed in vehicle workdays, as given by Equation (3):where

- S = potential savings

- DD = total delivery delay

- PD = total pick-up delay.

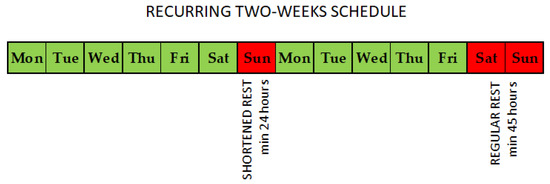

- Potentially released vehicle compositions refer to the number of vehicle compositions that would have been available for performing additional transport operations if potential savings had been achieved. It means that the same volume of transport operations could have been handled by less vehicle compositions, which would enable the transport company to acquire more transport orders, i.e., to perform more transport operations with the same vehicle fleet. Considering the prescribed working hours of the driver (cf., Figure 1), a vehicle composition can be used a maximum of 24 days a month.

Figure 1. Working time of the mobile workers in the road transport.

Figure 1. Working time of the mobile workers in the road transport. - With reference to the above, the number of vehicle compositions that may be released and used to perform additional transport operations is given by Equation (4):where

- R = number of released vehicles

- S = potential saving (vehicle workdays)

The simulation outlines functionalities of the prototype application developed using appropriate software support to simulate real-time data. It involves the use of ready-made services for calculating the shortest path in the network, based on given geographic coordinates and the corresponding geocoding. Based on the historical data from the case study, the application creates the initial vehicle routes, and by applying spatiotemporal discretization, predicts possible switching of tractor/semi-trailer compositions, i.e., reallocates semi-trailers to tractors, to minimize the optimization criterion defined in the previous phase of the research. At the same time, at prediction of the possible points in space and time, in addition to the itinerary and respective vehicle route, the driving time and the driver’s rest intervals must be complied with, as prescribed by the road traffic regulations. To obtain a representative output, the planned routes and potential switching points must be updated in real time, considering the accurate position of the vehicles in time and space. Finally, in cooperation with the external experts, the achieved results and the possibilities of practical application were discussed.

There were two main reasons for which we decided to follow this three-stage methodology. First, we wanted to evaluate the concept of dynamic allocation of semi-trailers in terms of effectivity and applicability, as no such concept has been used before by road transport companies. We chose to perform the case study on road transport in the cold chain due to specific requirements of the controlled temperature regime, that make route planning more demanding than in transport of conventional goods. From the technical perspective, switching refrigerated semi-trailers is not more demanding nor costly, as they comply with the same standards as regular semi-trailers and each one has an autonomous power supply for the refrigerator (a reservoir of 200 L diesel and a plug-in possibility). What makes the route planning more demanding are the strict time-windows that must be complied with due to the quality standards in the cold chain. For this reason, a delay that may not be a problem in the transport of regular goods, would be a significant problem in the cold chain.

The second reason refers to the way in which the potential for raising profitability needed to be presented to the stakeholders of the road transport company. Due to the use of FMS software and telematic equipment in the route planning and relatively extensive time-windows (most of the clients approve one to three working days period for the truck to arrive for pick-up or delivery), the desired itineraries are mostly met from the perspective of the clients. However, it does not necessarily mean that the transport company should be satisfied as well, since each vehicle workday that was spent waiting instead of driving decreases the margin of the transport route. To bring this issue to the attention of the transport company stakeholders, we needed to demonstrate, in a transparent way, that both the transport capacities utilization and the transport operations profitability could be raised with existing resources, by abandoning the fixed truck/semi-trailer composition paradigm and adopting our concept of dynamic semi-trailer allocation. The most convenient way to do so was to simulate the use of the prototype application on the transport company historical data and to quantify savings in terms of the vehicle workdays.

4. Results

The results are obtained from the case study on the transport company and by simulating the use of the prototype application on the historical data collected in the case study.

4.1. The Case Study

The transport company’s fleet consists of 140 tractor/semi-trailer compositions, of which 130 semi-trailers are refrigerated, ensuring the transport of temperature sensitive goods along the cold chain, while the other 10 are classic semitrailers with tarpaulin. The company employs an average of 160 drivers, while the actual number of drivers depends on the seasonality of transport demand during the year.

The target assigned to the transport operations department (dispatchers) is to ensure that each vehicle composition is loaded with a new cargo the same or the next day after the delivery is completed. If a vehicle is not used and stands without cargo for one or more days, while the driver has no need to make a rest, it is considered poor management of the transport capacities.

The data on contracted transports (transport orders) and realized transport routes in the period of the first three quarters of 2023. are given in Table 2.

Table 2.

Realized transport operations in the first three quarters of 2023.

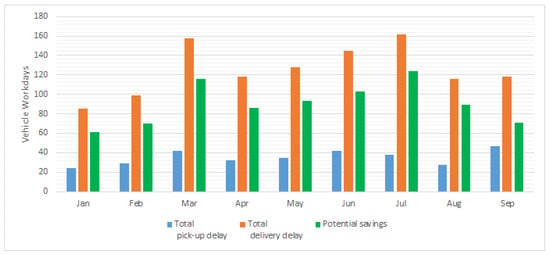

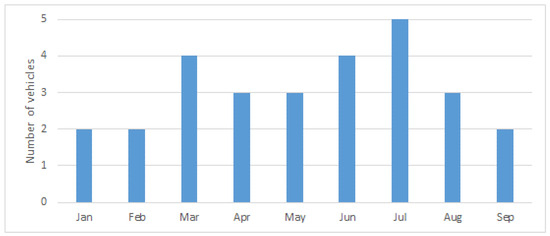

We obtained the data from the transport company’s FMS system and by cross-checking against the vehicle worksheets and invoicing records. The values of the KPIs on a monthly basis achieved in the sampled period, as well as the improvements that may be achieved by implementing the concept of dynamic semi-trailer allocation are outlined by graphs in Figure 2. and in Figure 3.

Figure 2.

Deviations from the planned itinerary and potential savings.

Figure 3.

The number of potentially released vehicle compositions.

Figure 2 depicts the total pick-up and delivery delays recorded monthly for the entire vehicle fleet of 140 vehicle compositions, as well as potential savings that could be achieved by implementing the proposed concept of dynamic semi-trailer allocation.

Figure 3 depicts the number of vehicle compositions that could be released monthly, in the case where the savings depicted in Figure 2. are achieved, i.e., the total number of vehicle compositions in the existing vehicle fleet that could be made available for performing additional transport operations.

4.2. Simulation Using the Prototype Application

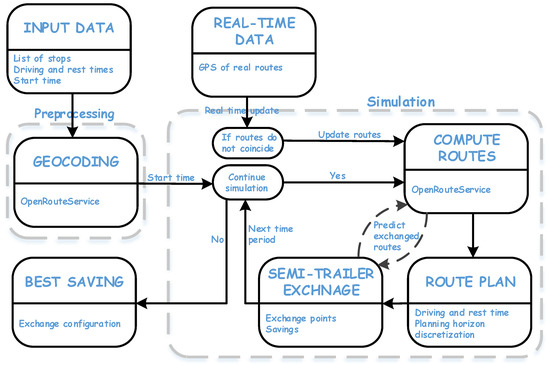

The diagram of the conducted simulation to assess the possible exchange of semi-trailers is presented in Figure 4. The first step is the preprocessing of the used input data for simulation. Then, in each simulation period, the shortest routes between stop points for each semi-trailer are computed. Further on, based on the determined routes, the route plan is fixed, which includes driving and rest time, as well as planning horizon discretization. Next, possible current and future exchange points are evaluated and stored in the list. Lastly, the predicted routes are updated (if needed) based on the revealed real-time information, which then calls for route plan and exchange recomputation. The best exchange point, according to the biggest saving in time duration, is selected from a list of all possible exchange points.

Figure 4.

Simulation diagram.

4.2.1. Input Data for the Simulation

For the purpose of simulation, we used the historical data for semi-trailers of two vehicle compositions (further on referred as ST1 and ST2), selected from the sample: list of labeled stops (Excel files), global positioning system (GPS) positions of real driven routes (Excel files), and working time in the previous 7 and 14 days (text files). Tables for the list of labeled stops contained the following attributes: start time, end time, duration, total distance (km), distance traveled to stop (km), and location name in Croatian. There were in total 6 stops for ST1, and 16 stops for ST2. These stops are crucial elements to simulate the order of visits along semi-trailer routes. To use these stops in the routing simulation environment, first the labeled locations had to be geocoded. To geocode the locations, we used the application programming interface (API) from OpenRouteService (ORS) and additionally manually checked and corrected the geocoded locations as most of them were in Croatian. Tables of GPS positions of actual driven routes contained the following attributes: time stamp, longitude and latitude, height, speed, heading, and status (active or not). These real GPS data were used to update the predicted route at specific discrete decision time points. The sampling time of GPS points is on average 19.07 s for an active vehicle (driving mode) and 192.62 s for an inactive vehicle (stationary mode). In total there are 2633 samples for ST1 (active 81.12%) and 7376 samples for ST2 (active 77.30%). The previous driving time for ST1 is set to 545 min for today and the last 14 days, while for ST12 it is set to 2820 min for the last 14 days and 0 for today.

4.2.2. Computation of Predicted Routes

To be able to detect the possible spatiotemporal exchange of semi-trailers, we had to determine the routes between the geocoded stops that needed to be visited. As we needed routing across the whole European continent, we used the free Directions API within the ORS. To obtain the route between two consecutive points within the program, we constructed programmatically a query string that computes the shortest path between the designated coordinates. For example, query parameters are start-location: 6.52038840496516, 52.7113227718456, end-location: 9.66173095026495, 50.7118518657053, and geometry: true. Parameter geometry is set true to get the complete route geometry per segments. For authorization we used an API key that we obtained when registering on the ORS. The service responds in the JavaScript object notation (JSON) format, which is deserialized into the Route object. The Route object has the following attributes: list of all geographical coordinates in the route, traveled distance [m], duration [s], and list of Steps about real road-segments used when traversing the route (i.e., routing plan). Each Step contains the following attributes: distance [m], duration [s], instruction (i.e., head north), road-segment name, and road-segment type. The sum of all steps of duration and distance corresponds to the total route duration and distance. To compute the shortest path on such a large road-network the ORS uses contraction hierarchies and customizable alternative algorithms, implemented based on the idea presented in [82].

4.2.3. Determination of Routing Plan

After loading the routes, next we predict the complete route duration, including the rest-time periods. The driving time and rest periods for Europe are determined by Regulation (EC) No 516/2006 [83].

These regulations notably specify the following.

- The maximum daily driving period is 9 h, with an exception allowing it to be extended to 10 h twice a week.

- The total weekly driving time cannot surpass 56 h, and the total fortnightly driving time must not exceed 90 h.

- A daily rest period of at least 11 h is required, with the possibility of reducing it to 9 h up to three times a week. This daily rest can be split into two parts: 3 h followed by 9 h, resulting in a total of 12 h of rest.

- Breaks of at least 45 min, which can be divided into 15 min followed by 30 min, must be taken after driving for a maximum of 4½ hours.

- A weekly rest period should last for 45 continuous hours but can be reduced to 24 h every second week, subject to compensation arrangements. This weekly rest must be taken after six consecutive working days, except for drivers engaged in occasional international passenger transport, who may postpone their weekly rest period for up to 12 days to accommodate holidays.

- In exceptional situations, daily and/or weekly driving times may be exceeded by up to one hour to allow the driver to reach their place of residence or the employer’s operational center to take a weekly rest period.

Using the rules specified above and a list of Steps for each semi-trailer, we determined the whole route planning horizon which includes both driving-time and rest-time. Additionally, we discretized the whole route horizon into 10 min time buckets, to be able to efficiently find possible spatiotemporal exchange points between semi-trailers. Large steps, in terms of duration and distance, are uniformly discretized into time buckets of equal duration length of 10 min.

4.2.4. Check for Semi-Trailer Exchange

The procedure for evaluating all possible semi-trailer exchanges for the current routing plan is given by Algorithm 1. Starting from the current time bucket, first we check whether the semi-trailers are spatially close. We used a threshold of 100 km in aerial distance to narrow the search space and reduce the execution time. The threshold of 100 km was recommended by an expert from our industrial partner. It enables us to identify potential locations for trailer exchange without incurring significant losses in driving time. If the spatial threshold is met, we conduct the evaluation of possible semi-trailer exchange. As an exchange point, we first look in the list of not visited stops for each semi-trailer and select the closest within the spatial threshold (if any). If there is no stop within the spatial threshold, we assume the drivers or dispatcher will be able to determine the exchange point within 100 km, and we approximate the exchange point at the middle between the semi-trailers. Next, we compute the new route planning horizons for each semi-trailer. Using the ORS, first we compute the shortest routes from current semi-trailer positions to the exchange point. As at the exchange points, the drivers exchange the trailers, we recompute the rest of the routes with new (exchanged) stops in the route. After the route recomputation, we determine the new route planning horizons to include both driving and rest times. Lastly, we evaluate the end times of both semi-trailers and compute the duration savings compared to the no-exchange scenario. If savings can be achieved, we store them in a list of possible savings. The whole evaluation is then repeated for all 10 min time buckets in the planned horizons, and as a result if any, we list the possible semi-trailer exchanges that produce the highest total duration savings.

| Algorithm 1: Evaluate possible exchanges for current routing plan |

| 1. Initialize an empty list to store possible savings 2. For each time bucket in planned horizons: 3. Get the positions of semi-trailers at the current time bucket 4. If semi-trailers are spatially close: 5. Find the closest not visited stop within the threshold for each semi-trailer 6. Compute the exchange point or approximate it as the midpoint 7. Compute new routes from current positions to the exchange points 8. Recompute the rest of the routes with exchanged stops 9. Determine new route planning horizons including driving and rest times 10. Compute end times for semi-trailers 11. Compute the duration savings compared to the no-exchange scenario 12. If savings are possible: 13. Store the pair and the duration savings in the list of possible savings 14. If possible savings is not empty: 15. Identify the pair with the highest total duration savings 16. Store the best exchange in the result |

4.2.5. Real-Time Update

As it was noted during the development, the drivers tend to change their routing plan either due to their own route preferences, unpredictable incidents on the road, or by dispatcher change in visits. Also, in some cases the exact driving-times and rest-times are unknown. To overcome this, we used the real driven GPS data, as an update on the real time position. After the determination of the initial route plan and exchange point (if any) for the set starting time, within the developed framework, we allowed real positions to be revealed every 60 min. After revealing the real positions, if the predicted time and distance coincide with the real revealed time and distance computed from the GPS points, the routing plan is not updated. Otherwise, the routing plan is completely updated to match the current real-time state:

- Start time is the current real revealed time

- New predicted routes are computed

- New routing plan is determined

- New exchange points are computed.

The driving time is updated to match the actual driving time from GPS samples labeled as active, while the real-time rest times are computed from GPS samples labeled as inactive.

4.2.6. Simulation

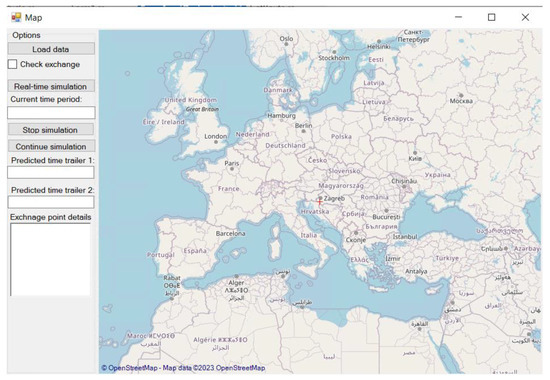

The simulation is conducted through a Windows Form application implemented in the C# programming language. Simulations were performed on a machine with an Intel E5 processor and 32 GB of RAM. The graphical user interface (GUI), presented in Figure 5, includes the left side bar with options setup and text boxes for results, and on the right side, the map container. To represent the map, we used the free OpenStreetMap (OSM) form GMap.NET.WinForms package. All methods were implemented in C# programming language with a total of 1834 lines of source code. For implementation details, the complete source code without confidential data is publicly available on GitHub (https://github.com/terdelic/TrailerExchangeSimGitHub, accessed on 6 November 2023).

Figure 5.

Simulation graphical user interface (GUI).

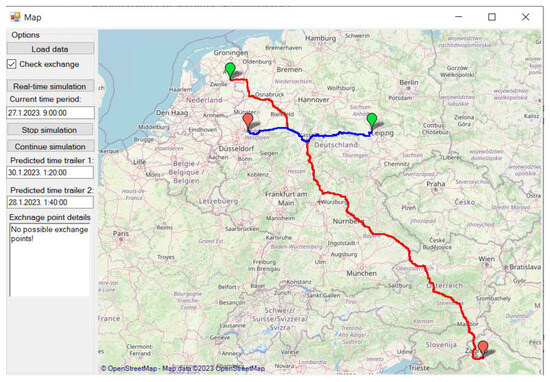

After pressing the Load data button, the complete routing plan for two semi-trailers is determined, as presented in Figure 6. At this point the complete routing plan is determined together with discretization of exchange point checks for the current time period: 27.1.2023. 9:00:00 (start time). Predicted transport route for ST1, represented with blue line, starts in Halle (Germany) and ends in Herne (Germany), while the predicted transport route for ST2, represented with red line, starts in Hoogeveen (Netherlands) and ends in Rugvica (Croatia). Start points are represented with green pins, while end points are represented with red pins. The predicted end time for ST1 is 28.1.2023. 1:40:00, while for ST2 it is 30.1.2023. 1:20:00. In the current routing plan, there are no possible predicted exchanges of semi-trailers that could lead to savings in time.

Figure 6.

Predicted routing plan—First time period.

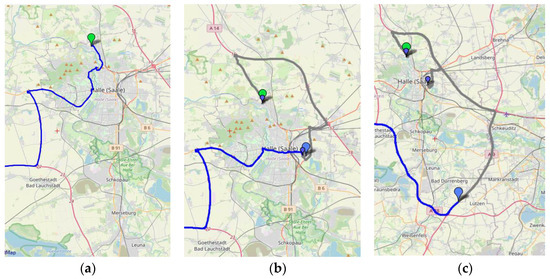

By pressing the button Real-time simulation, the actual information is used to update the routing plan. The example of real time progression per one hour time period is depicted in Figure 7. Predicted routes for ST1 in three consecutive time periods are presented, where the gray colored lines indicate the really revealed parts of the GPS data, while the blue colored lines indicate the predicted parts of the routes. Green pins indicate starting points, big blue pins indicate current positions and small blue pins indicate already visited locations. It can be seen that routes are adapted according to the real data, as well as that drivers tend to make unplanned stops along the way.

Figure 7.

Simulation of routes in consecutive time periods: (a) first time period; (b) second time period; (c) third time period.

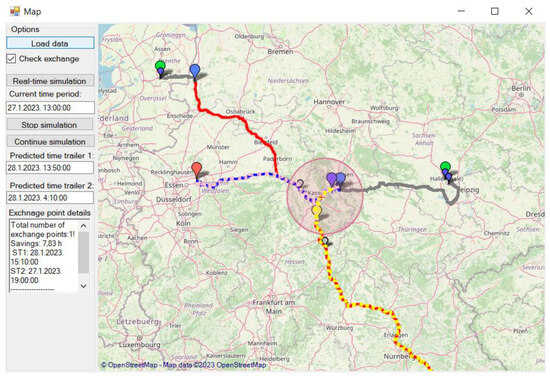

An example of a possible exchange point with savings is presented in Figure 8. The time period is 27 January 2023. 13:00:00, at which the semi-trailers are in positions marked with light blue pins. Predicted transport route for ST1 is indicated by blue line and predicted transport route for ST2 is indicated by red line. The pink circle overlay represents the geographical area in which the vehicle will be spatiotemporally close, and there is a possibility to compute the exchange point. In the left sidebar, the summary of exchange points is presented. At the current time period, only one exchange point was found, with an approximated reduction of the total duration for both vehicles by 7.83 h. The determined exchange point is represented with a purple pin. Yellow pins represent the predicted location of ST1 (not visible as it is at the same place as the purple pin) and ST2, at a future time period when they start rerouting to the exchange point. The algorithm predicted that the ST1 will take its rest period at the position of the purple pin parking station Hackelberg. Yellow and pink dashed lines represent the rerouting taken to arrive at the exchange point as well as the exchanged parts of the routes between the semi-trailers. In the current example, only ST2 is rerouted as it travels to the exchange point, while ST1 waits there. At the exchange point, the vehicle compositions exchange semi-trailers, and a new routing plan is determined (yellow and pink dashed lines).

Figure 8.

Exchange of semi-trailers.

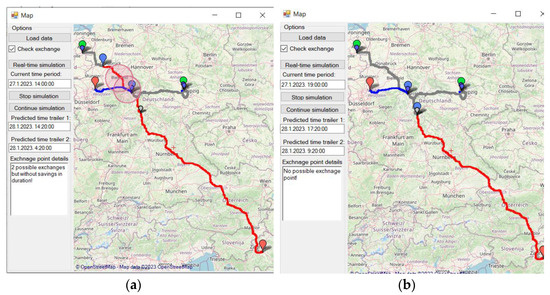

In some cases, the vehicle compositions are spatiotemporally close but there are no savings achieved when conducting the exchange of trailers, as shown in Figure 9a, where two exchange points are found, but no reduction in total duration is predicted. Figure 9b shows an example where no exchange point is found as semi-trailers are not spatiotemporally close. The marking in Figure 9a,b follows the same pattern: blue lines indicate predicted sections of transport routes for ST1, red lines indicate predicted parts of transport routes for ST2, while gray lines indicate already driven parts of the routes. Green pins indicate starting points, red pins indicate endpoints, small blue pins indicate already visited locations and pink circles represent the exchange area. In total, eight possible exchange points are found, but only one produced the possible savings, presented in Figure 8.

Figure 9.

Examples of no exchange: (a) Spatiotemporally close; (b) not spatiotemporally close.

To validate the results, we checked that the actual routes (itinerary and duration of the routes) recorded by the transport company (historical data collected in the case study) correspond with the simulated routes and compared the initial duration of the routes (vehicle workdays) with the duration of the routes after the semi-trailers are exchanged as the algorithm suggested. We shared the findings regarding the best-suggested exchange point with the dispatchers from the transport company. The consensus reached was that while the results appear promising, the practical implementation of such exchanges may be uncertain in some cases. This uncertainty stems from the fact that the drivers must be willing to accept suggested changes and locate suitable space for the physical exchange of semi-trailers. Therefore, the feasibility of achieving improved results across the board may be limited. Generally, it should not be an issue as the drivers need only to follow the instructions provided by the dispatchers.

4.2.7. Sensitivity Analysis

The implemented model is highly sensitive to the accuracy of its parameters related to the time spent driving in the recent day, recent seven days, and recent two weeks, as well as the rest time taken during those time periods. These values significantly impact the spatiotemporal proximity of semi-trailers, directly affecting the prediction of exchange points. For instance, using zero values for all driving and rest-related variables results in detecting nine exchange points earlier in the spatiotemporal flow, but neither of them leads to a reduction in the total duration. To ensure high-quality predictions, it is crucial to obtain accurate real-time data.

In terms of the designated stops, the model is quite sensitive to the accuracy of these values. Using incorrect information stemming from geocoding errors in location names (often due to language discrepancies) or inaccurate input data, or making real-time stops that were not predicted, can lead to erroneous route predictions and travel time estimates, ultimately affecting the accuracy of exchange point predictions. Additionally, road traffic conditions play a significant role in predicting travel times for routes. This issue is partially addressed through real-time information updates and route corrections to enhance the accuracy of exchange point predictions.

5. Discussion

Within the time frame of the first three quarters of 2023. (sampled period) the transport company dispatchers handled a total of 16.102 transport orders (average of 1.789 on monthly basis) by constructing a total of 4.433 transport routes (average of 493 on monthly basis). In performing those routes, the fleet of 140 vehicle compositions spent a total of 37.682 vehicle workdays.

By analyzing transport operations performed in the sampled period, we found the potential of saving a total of 813 vehicle workdays and releasing an average of three vehicle compositions monthly, in the case where the concept of dynamic allocation of semi-trailers that we developed would have been applied in addition to the existing FMS.

With regard to the above, introducing the concept of dynamic allocation of semi-trailers would provide the following benefits:

- (a)

- Reducing the number of vehicle workdays spent performing transport operations (2.16% in this case), which would increase the profitability of transport operations and improve safety of the products being transported.

- (b)

- Reducing the number of vehicle compositions needed to handle the transport demand (2.34% in this case, taking into account average operational availability of the vehicle fleet), which enables the transport company to acquire more transport orders while operating the existing vehicle fleet (increased volume of transport operations).

- (c)

- Improving the quality of the transport service (meeting quality standards) and raising the level of customer satisfaction, by reducing delivery delays.

- (d)

- Better coordination of the transport operations department, that enables dispatchers to handle more transport orders (increased productivity).

Obstacles, limitations and disadvantages we encountered during development and testing the prototype application may be summarized as follows:

- Although in electronic form, transport orders contain location names that require a geocoding service to extract the GPS locations. In addition to departure and destination that are indicated in the transport order, there are other stops on the route that the driver made for some reason, for which the GPS data also need to be retrieved.

- Prior to planning the transport route, accurate information on the driver’s working time in the previous 30 days must be available. This information is essential for route planning, as it is a constraint that defines the approximate locations of stopping points and duration of stays along the route. It has a direct impact on the results of searching the feasible switching points of tractor/semi-trailer compositions on different routes in space and time.

- The planned route and the route driven do not match completely (only after several real-time updates does the match increase) because the drivers may make a detour for some reason.

- In route planning, we were using the free version of the ORS API, which is limited to 40 calls per minute, and 2000 calls per day. In the example outlined in Section 4, it took three minutes to evaluate all the planned routes, as the new updated routes are planned on an hourly basis, when the real-time data is retrieved. Also, when checking the exchange points, the application algorithm needs to define the most suitable deviations from the selected routes to enable vehicles to reach the same location in space and time. Additionally, the rest of the route from the exchange point to the end of the route also needs to be determined. For larger problems, the paid version of some routing service needs to be used.

- The evaluation of switching possibility is carried out if the vehicles are less than 100 km apart in the space-time flow. We set this value as a parameter, which could possibly be increased, as the hourly spatiotemporal discretization of the simulation is rather coarse. We had to do so, in order not to plan routes too frequently and not to overload the ORS server.

- Searching for switching possibilities makes sense if there is a sufficient number of tractor/semi-trailer compositions (the road transport company from the case study operates 140 tractor/semi-trailer compositions). In the conducted case study, we investigated the possible exchange for only two semi-trailers, and not the subset combination from all 140 semi-trailers. There were in total 211 checks for exchange points, and only eight within the 100 km threshold at a specific time. The evaluation of the whole fleet of 140 semi-trailers would significantly increase the search space and execution time, as there are in total possible permutations of a subset of two semi-trailers from the whole 140 semi-trailers in the fleet. Also considering the substantial use of the shortest path algorithm, the final system should definitely use some faster decision algorithms, use a lower discretization period (a couple of hours), or use some form of parallelization.

The issues addressed above could be overcome by adapting formats of the input data, certain technical improvements of the prototype application, which could be integrated into existing FMS software, as a separate module.

6. Conclusions

Road transport companies utilize their transport capacities as fixed combinations of tractors and semi-trailers, while the possibility of switching tractor/semi-trailer compositions is considered ad hoc, after some unforeseen events or circumstances emerge on the route (such as vehicle malfunction, traffic jams, or traffic accidents) but not proactively, nor continuously. Furthermore, if a switching tractor/semi-trailer composition is to be considered, it is done manually by the dispatchers. It is also important to note that pick-up and delivery time-windows may be relatively extensive and that certain delays may not be considered a major problem by the clients; however, each additional vehicle workday is a fixed cost that not only decreases the margin of the transport route, but also seizes the transport capacity that would otherwise be available.

Such an approach is a limiting factor in achieving optimal utilization of transport capacities, and consequently affects the profitability and sustainability of the transport operations. We investigated the possibility of introducing a different concept of transport capacity management, whereby semi-trailers would not be permanently assigned to the same tractors, but would dynamically join the tractors, to optimize the route regarding the stipulated time and locations of pick-up and delivery, the driver’s working hours, and road traffic regulations. Unlike the usual way of operating vehicle compositions where exchanging semi-trailers is performed as a reaction to the emerging problem on the route, the algorithm we developed works proactively; it predicts deviations from the planned itinerary, finds a suitable semi-trailer exchange point, and redirects the vehicles. Applied continuously for the entire vehicle fleet, it also improves the productivity of the dispatchers, enabling the transport company to handle more transport orders.

Adopting the concept of dynamic semi-trailer allocation would improve the transport performance by better utilization of transport capacities, enable the continuous meeting of quality standards and product safety (critical issue in the cold chain), ultimately resulting in a higher level of customer satisfaction. Although the case study was carried out on the transport operations in the cold chain, which are more demanding due to specific quality standards, other transport companies could benefit from implementing the concept of dynamic allocation of semi-trailers as well, especially those that operate a considerable vehicle fleet (50 or more tractor/semi-trailer compositions).

We evaluated applicability and benefits of this concept by developing a prototype application and simulating its use on the sample of historical data collected in the case study. We compared the KPI achieved in the simulation with the respective KPI achieved by the transport company and quantified the improvement thereof. The results were also verified by professionals from the transport company that provided the historical data.

The prototype application has sufficient functionalities for testing purposes, yet certain technical improvements are still needed for commercial use. However, it can be a basis for developing a fully functional application, which could be integrated into existing FMS software, as confirmed by the external experts from the IT company that produces telematic software and equipment.

The research is limited to road transport operations that involve long haul transport routes, with several transport orders per route. Also, the vehicle fleet management must be supported by telematic software and hardware that enable the location of vehicles and exchange of information in real-time.

Further research could be directed towards improving the algorithm we developed with prediction of on-going transport route margin falls below the threshold set by the transport company, checking for semi-trailer exchange options, and automatically suggesting a solution to the dispatchers. In addition to that, extra criteria and their priorities could be considered, such as customer satisfaction and customer service level, quality changes of specific products associated with temperature fluctuations during transport in the cold chain, or the impact on the environment.

Since a larger number of vehicle compositions yields a greater potential for dynamic semi-trailer allocation, it would also be useful to explore the possibilities of including subcontractors in addition to the vehicles belonging to the transport company.

Author Contributions

Conceptualization, R.S., T.P. and T.E.; Data curation, T.P.; Formal analysis, T.E.; Funding acquisition, R.S.; Investigation, T.P.; Methodology, R.S.; Project administration, R.S.; Resources, R.S.; Software, T.E.; Supervision, R.S.; Validation, R.S., T.P. and T.E.; Visualization, R.S. and T.E.; Writing—original draft, R.S., T.P. and T.E.; Writing—review & editing, R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the University of Zagreb, grant number 210260. The APC is funded by the University of Zagreb.

Data Availability Statement

Restrictions apply to the availability of these data.

Conflicts of Interest

Author T.P. is employed by the company Ralu logistika d.d. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Khan, A.S.; AlArjani, A. A Cold Chain Vehicle Routing Problem Embedded with Manufacturing, Re-Manufacturing and Product Quality under Multiple Constraints. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management, IEEM, Singapore, 13–16 December 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 68–72. [Google Scholar] [CrossRef]

- Cui, J.; Wu, D.; Mansour, R.F. Research on EVRP of Cold Chain Logistics Distribution Based on Improved Ant Colony Algorithm; Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); LNCS:537–48; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2022; Volume 13338. [Google Scholar]

- Fu, M.; Wang, D. Research on Optimization of Cold Chain Logistics Distribution Path of Fresh Products Based on Hybrid Genetic Algorithm. Proc. IOP Conf. Ser. Earth Environ. Sci. 2020, 585, 012131. [Google Scholar] [CrossRef]

- Ji, Y.; Du, J.; Wu, X.; Wu, Z.; Qu, D.; Yang, D. Robust Optimization Approach to Two-Echelon Agricultural Cold Chain Logistics Considering Carbon Emission and Stochastic Demand. Environ. Dev. Sustain. 2021, 23, 13731–13754. [Google Scholar] [CrossRef]

- Jia, X. Research on the Optimization of Cold Chain Logistics Distribution Path of Agricultural Products E-Commerce in Urban Ecosystem from the Perspective of Carbon Neutrality. Front. Ecol. Evol. 2022, 10, 966111. [Google Scholar] [CrossRef]

- Wu, D.; Cui, J.; Li, D.; Mansour, R.F. A New Route Optimization Approach of Fresh Agricultural Logistics Distribution. Intell. Autom. Soft Comput. 2022, 34, 1553–1569. [Google Scholar] [CrossRef]

- Wu, L.J.; Chen, Z.G.; Chen, C.H.; Li, Y.; Jeon, S.W.; Zhang, J.; Zhan, Z.H. Real Environment-Aware Multisource Data-Associated Cold Chain Logistics Scheduling: A Multiple Population-Based Multiobjective Ant Colony System Approach. IEEE Trans. Intell. Transp. Syst. 2022, 23, 23613–23627. [Google Scholar] [CrossRef]

- Wu, X.; Hu, D.; Liu, C. Optimization of Vehicle Routing Problem in Cold Chain Logistics under Low Carbon Economy. In Proceedings of the 19th COTA International Conference of Transportation Professionals, Nanjing, China, 6–8 July 2019; pp. 4551–4563. [Google Scholar]

- Yao, Q.; Zhu, S.; Li, Y. Green Vehicle-Routing Problem of Fresh Agricultural Products Considering Carbon Emission. Int. J. Environ. Res. Public Health 2022, 19, 8675. [Google Scholar] [CrossRef] [PubMed]

- Amaruchkul, K.; Pongsathornwiwat, A.; Bantadtiang, P. Constrained Joint Replenishment Problem with Refrigerated Vehicles. Eng. J. 2022, 26, 75–91. [Google Scholar] [CrossRef]

- Golestani, M.; Moosavirad, S.H.; Asadi, Y.; Biglari, S. A Multi-Objective Green Hub Location Problem with Multi Item-Multi Temperature Joint Distribution for Perishable Products in Cold Supply Chain. Sustain. Prod. Consum. 2021, 27, 1183–1194. [Google Scholar] [CrossRef]

- Rahman, H.; Rahman, F.; Tseng, T.L. Estimation of Fuel Consumption and Selection of the Most Carbon-Efficient Route for Cold-Chain Logistics. Int. J. Syst. Sci. Oper. Logist. 2022, 10, 2075043. [Google Scholar] [CrossRef]

- Huai, C.-X.; Sun, G.-H.; Ran-ran, Q.; Gao, Z.; Zhabg, Z.-H. Vehicle Routing Problem with Multi-Type Vehicles in the Cold Chain Logistics System. In Proceedings of the 16th International Conference on Service Systems and Service Management (ICSSSM2019), Shenzhen, China, 13–15 July 2019. [Google Scholar]

- Qi, C.; Hu, L. Optimization of Vehicle Routing Problem for Emergency Cold Chain Logistics Based on Minimum Loss. Phys. Commun. 2020, 40, 101085. [Google Scholar] [CrossRef]

- Song, M.X.; Li, J.Q.; Han, Y.Q.; Han, Y.Y.; Liu, L.L.; Sun, Q. Metaheuristics for Solving the Vehicle Routing Problem with the Time Windows and Energy Consumption in Cold Chain Logistics. Appl. Soft Comput. 2020, 95, 106561. [Google Scholar] [CrossRef]

- Al Theeb, N.; Smadi, H.J.; Al-Hawari, T.H.; Aljarrah, M.H. Optimization of Vehicle Routing with Inventory Allocation Problems in Cold Supply Chain Logistics. Comput. Ind. Eng. 2020, 142, 106341. [Google Scholar] [CrossRef]

- Wang, Z.; Wen, P. Optimization of a Low-Carbon Two-Echelon Heterogeneous-Fleet Vehicle Routing for Cold Chain Logistics under Mixed Time Window. Sustainability 2020, 12, 1967. [Google Scholar] [CrossRef]

- Zhang, Y.; Hua, G.; Cheng, T.C.E.; Zhang, J. Cold Chain Distribution: How to Deal with Node and Arc Time Windows? Ann. Oper. Res. 2020, 291, 1127–1151. [Google Scholar] [CrossRef]

- Zhao, B.; Gui, H.; Li, H.; Xue, J. Cold Chain Logistics Path Optimization via Improved Multi-Objective Ant Colony Algorithm. IEEE Access 2020, 8, 142977–142995. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, X.; Zhou, X. Distribution Route Optimization for Electric Vehicles in Urban Cold Chain Logistics for Fresh Products under Time-Varying Traffic Conditions. Math. Probl. Eng. 2020, 2020, 9864935. [Google Scholar] [CrossRef]

- Zhu, S.; Fu, H.; Li, Y. Optimization Research on Vehicle Routing for Fresh Agricultural Products Based on the Investment of Freshness-Keeping Cost in the Distribution Process. Sustainability 2021, 13, 8110. [Google Scholar] [CrossRef]

- Jiao, X.; Xu, W.; Duan, L. Study on Cold Chain Transportation Model of Fruit and Vegetable Fresh-Keeping in Low-Temperature Cold Storage Environment. Discret. Dyn. Nat. Soc. 2021, 2021, 8445028. [Google Scholar] [CrossRef]

- Li, F.; Ai, W.; Ju, T. Cold Chain Logistics Distribution Path Planning of Fresh Products in Beijing Subcenter. Sustainability 2022, 14, 10622. [Google Scholar] [CrossRef]

- Lim, M.K.; Li, Y.; Song, X. Exploring Customer Satisfaction in Cold Chain Logistics Using a Text Mining Approach. Ind. Manag. Data Syst. 2021, 121, 2426–2449. [Google Scholar] [CrossRef]

- Rahbari, M.; Hajiagha, S.H.R.; Mahdiraji, H.A.; Dorcheh, F.R.; Garza-Reyes, J.A. Internal A Novel Location-Inventory-Routing Problem in a Two-Stage Red Meat Supply Chain with Logistic Decisions: Evidence from an Emerging Economy A Novel Location-Inventory-Routing Problem in a Two-Stage Red Meat Supply Chain with Logistic Decisions: Evidence from an Emerging Economy. Kybernetes 2022, 51, 1498–1531. [Google Scholar]

- Wang, M.; Wang, Y.; Liu, W.; Ma, Y.; Xiang, L.; Yang, Y.; Li, X. How to Achieve a Win–Win Scenario between Cost and Customer Satisfaction for Cold Chain Logistics? Phys. A Stat. Mech. Its Appl. 2021, 566, 125637. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, Z.; Hu, D.; Mansour, R.F. Optimizing Fresh Logistics Distribution Route Based on Improved Ant Colony Algorithm. Comput. Mater. Contin. 2022, 73, 2079–2095. [Google Scholar] [CrossRef]

- Yang, Y.; Zang, Y.; Qi, M. Robust Network Design and Last-Mile Delivery in Cold Chain Logistics System. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management, IEEE 2021, Singapore, 13–16 December 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 765–772. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Q.; Li, F.; Jin, C. Research on Green Technology Path of Cold-Chain Distribution of Fresh Products Based on Sustainable Development Goals. Sustainability 2022, 14, 16659. [Google Scholar] [CrossRef]

- Bai, Q.; Yin, X.; Lim, M.K.; Dong, C. Low-Carbon VRP for Cold Chain Logistics Considering Real-Time Traffic Conditions in the Road Network. Ind. Manag. Data Syst. 2022, 122, 521–543. [Google Scholar] [CrossRef]

- Chen, Y.; Lan, H.; Wang, C.; Jia, X. Integrated Online Order Picking and Vehicle Routing of Food Cold Chain with Demand Surge. Math. Probl. Eng. 2022, 2022, 4485376. [Google Scholar] [CrossRef]

- Dávila, S.; Alfaro, M.; Fuertes, G.; Vargas, M.; Camargo, M. Vehicle Routing Problem with Deadline and Stochastic Service Times: Case of the Ice Cream Industry in Santiago City of Chile. Mathematics 2021, 9, 2750. [Google Scholar] [CrossRef]

- Fu, Z.; Dong, P.; Ju, Y. An Intelligent Green Vehicle Management System for Urban Food Re-liably Delivery: A Case Study of Shanghai, China. Energy 2022, 257, 124642. [Google Scholar] [CrossRef]

- Hu, L.; Xiang, C.; Qi, C. Optimization of VRR for Cold Chain with Minimum Loss Based on Actual Traffic Conditions. Wirel. Commun. Mob. Comput. 2021, 2021, 2930366. [Google Scholar] [CrossRef]

- Leng, L.; Zhang, C.; Zhao, Y.; Wang, W.; Zhang, J.; Li, G. Biobjective Low-Carbon Location-Routing Problem for Cold Chain Logistics: Formulation and Heuristic Approaches. J. Clean. Prod. 2020, 273, 122801. [Google Scholar] [CrossRef]

- Leng, L.; Zhang, J.; Zhang, C.; Zhao, Y.; Wang, W.; Li, G. A Novel Bi-Objective Model of Cold Chain Logistics Considering Location-Routing Decision and Environmental Effects. PLoS ONE 2020, 15, e0230867. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Cao, Q.; Zuo, M.; Xu, F. Optimization of Green Fresh Food Logistics with Heterogeneous Fleet Vehicle Route Problem by Improved Genetic Algorithm. Sustainability 2020, 12, 1946. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Z.; Su, X.; Qin, H. A Hybrid Algorithm for the Vehicle Routing Problem with Compatibility Constraints. In Proceedings of the ICNSC 2018—15th IEEE International Conference on Networking, Sensing and Control, Zhuhai, China, 27–29 March 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Shi, Y.; Lin, Y.; Lim, M.K.; Tseng, M.-L.; Tan, C.; Li, Y. An Intelligent Green Scheduling System for Sustainable Cold Chain Logistics. Expert Syst. Appl. 2022, 209, 118378. [Google Scholar] [CrossRef]

- Wang, H.; Li, W.; Li, M.; Yang, X.; Wang, Z.; Zhao, Z.; Wang, L. Intelligent Selection of Delivery Parties for Fresh Agricultural Product Based on Third-Party Logistics in Smart City. Sustain. Energy Technol. Assess. 2022, 52, 102151. [Google Scholar] [CrossRef]

- Yu, L. A route optimization model based on cold chain logistics distribution for fresh agricultural products from a low-carbon perspective. Fresenius Environ. Bull. 2021, 30, 1112–1124. [Google Scholar]

- Khan, A.S.; Salah, B.; Zimon, D.; Ikram, M.; Khan, R.; Pruncu, C.I. A Sustainable Distribution Design for Multi-Quality Multiple-Cold-Chain Products: An Integrated Inspection Strategies Approach. Energies 2020, 13, 6612. [Google Scholar] [CrossRef]

- Maiorino, A.; Petruzziello, F.; Aprea, C. Refrigerated Transport: State of the Art, Technical Issues, Innovations and Challenges for Sustainability. Energies 2021, 14, 7237. [Google Scholar] [CrossRef]

- Suraraksa, J.; Shin, K.S. Urban Transportation Network Design for Fresh Fruit and Vegetables Using Gis–the Case of Bangkok. Appl. Sci. 2019, 9, 5048. [Google Scholar] [CrossRef]

- Yan, L.; Grifoll, M.; Zheng, P. Model and Algorithm of Two-Stage Distribution Location Routing with Hard Time Window for City Cold-Chain Logistics. Appl. Sci. 2020, 10, 2564. [Google Scholar] [CrossRef]

- Ba, Y.; Feng, C.; Jia, W.; Liu, X.; Ren, J. A Multi-Scenario Optimization Model for Emergency Cold Chain Logistics Distribution. Math. Probl. Eng. 2021, 2021, 1628162. [Google Scholar] [CrossRef]

- Chen, J.; Liao, W.; Yu, C. Route optimization for Cold Chain Logistics of Front Warehouses Based on Traffic Congestion and Carbon Emission. Comput. Ind. Eng. 2021, 161, 107663. [Google Scholar] [CrossRef]

- Chen, J.; Gui, P.; Ding, T.; Na, S.; Zhou, Y. Optimization of Transportation Routing Problem for Fresh Food by Improved Ant Colony Algorithm Based on Tabu Search. Sustainability 2019, 11, 6584. [Google Scholar] [CrossRef]

- Chen, Y.; Lan, H.; Wang, C.; Jia, X. An integrated distribution scheduling and route planning of food cold chain with demand surge. Complex Intell. Syst. 2023, 9, 475–491. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Qian, B.; Na, J.; Hu, R.; Mao, J.-L. A Three-Dimensional Ant Colony Optimization Algorithm for Multi-Compartment Vehicle Routing Problem Considering Carbon Emissions. Appl. Soft Comput. 2022, 127, 109326. [Google Scholar] [CrossRef]

- Lian, J. An Optimization Model of Cross-Docking Scheduling of Cold Chain Logistics Based on Fuzzy Time Window. J. Intell. Fuzzy Syst. 2021, 41, 1901–1915. [Google Scholar] [CrossRef]

- Liu, G.; Hu, J.; Yang, Y.; Xia, S.; Lim, M.K. Vehicle Routing Problem in Cold Chain Logistics: A Joint Distribution Model with Carbon Trading Mechanisms. Resour. Conserv. Recycl. 2020, 156, 104715. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, C. Optimization of Urban Cold Chain Transport Routes under Time-Varying Network Conditions. J. Adv. Transp. 2021, 2021, 8817991. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, C. Optimization of Cold Chain Distribution Route with Mixed Time Window Considering Customer Priority. Comput. Intell. Neurosci. 2022, 2022, 2953205. [Google Scholar] [CrossRef]

- Qiao, J. Research on Optimizing the Distribution Route of Food Cold Chain Logistics Based on Modern Biotechnology. AIP Conf. Proc. 2019, 2110, 020070. [Google Scholar] [CrossRef]

- Qin, G.; Tao, F.; Li, L. A Vehicle Routing Optimization Problem for Cold Chain Logistics Considering Customer Satisfaction and Carbon Emissions. Int. J. Environ. Res. Public Health 2019, 16, 576. [Google Scholar] [CrossRef]

- Ren, X.Y. Path Optimization of Cold Chain Distribution with Multiple Distribution Centers Considering Carbon Emissions. Appl. Ecol. Environ. Res. 2019, 17, 9437–9453. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.S.; Lam, H.Y.; Tang, V. An Intelligent Model for Assuring Food Quality in Managing a Multi-Temperature Food Distribution Centre. Food Control 2018, 90, 81–97. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, C.; Hou, H. Risk Management in Perishable Food Distribution Operations. Ind. Manag. Data Syst. 2020, 120, 291–311. [Google Scholar] [CrossRef]

- Wu, L.-J.; Shi, L.; Zhan, Z.-H.; Lai, K.-K.; Zhang, J. A Buffer-Based Ant Colony System Approach for Dynamic Cold Chain Logistics Scheduling. IEEE Trans. Emerg. Top. Comput. Intell. 2022, 6, 1438–1452. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y. Optimizing Method of Cold Link Path for Agricultural Products Transportation Facing Environmental Protection. Ekoloji 2019, 28, 2083–2095. [Google Scholar]

- Xiong, H. Research on Cold Chain Logistics Distribution Route Based on Ant Colony Optimization Algorithm. Discret. Dyn. Nat. Soc. 2021, 2021, 6623563. [Google Scholar] [CrossRef]

- Yu, H. Research on Fresh Product Logistics Transportation Scheduling Based on Deep Reinforcement Learning. Sci. Program. 2022, 2022, 8750580. [Google Scholar] [CrossRef]

- Zhang, B. The Optimization of Distribution Path of Fresh Cold Chain Logistics Based on Genetic Algorithm. Comput. Intell. Neurosci. 2022, 2022, 4667010. [Google Scholar] [CrossRef]

- Zulvia, F.E.; Kuo, R.; Nugroho, D.Y. A Many-Objective Gradient Evolution Algorithm for Solving a Green Vehicle Routing Problem with Time Windows and Time Dependency for Perishable Products. J. Clean. Prod. 2020, 242, 118428. [Google Scholar] [CrossRef]

- Fu, Q.; Li, J.; Chen, H. Resource Scheduling Method for Optimizing the Distribution Path of Fresh Agricultural Products under Low-Carbon Environmental Constraints. Sci. Program. 2022, 2022, 7692135. [Google Scholar] [CrossRef]

- Li, N.; Li, G. Hybrid Partheno-Genetic Algorithm for Multi-Depot Perishable Food Delivery Problem with Mixed Time Windows. Ann. Oper. Res. 2022, 312, 1–32. [Google Scholar] [CrossRef]

- Lim, M.K.; Li, Y.; Wang, C.; Tseng, M.-L. Prediction of Cold Chain Logistics Temperature Using a Novel Hybrid Model Based on the Mayfly Algorithm and Extreme Learning Machine. Ind. Manag. Data Syst. 2022, 122, 819–840. [Google Scholar] [CrossRef]

- Qiang, X.; Appiah, M.Y.; Boateng, K.; Appiah, F.V. Route Optimization Cold Chain Logistic Distribution Using Greedy Search Method. Opsearch 2020, 57, 1115–1130. [Google Scholar] [CrossRef]

- Utama, D.M.; Widodo, D.S.; Ibrahim, M.F.; Dewi, S.K. A New Hybrid Butterfly Optimization Algorithm for Green Vehicle Routing Problem. J. Adv. Transp. 2020, 2020, 8834502. [Google Scholar] [CrossRef]

- Yan, L.; Zheng, P. Study on Vehicle Routing Optimization of Cold Chain Logistics with Soft Time Window under Stochastic Demand. UPB Sci. Bull. 2020, 82. [Google Scholar]

- Huiling, Z.; Dinglan, W.; Changgui, L.; Yanchun, W. Research on Optimization of Pasteurized Milk Cold Chain Logistics Distribution Network. In Proceedings of the 2018 15th International Conference on Service Systems and Service Management, ICSSSM 2018, Hangzhou, China, 21–22 July 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, X.; Zhou, X. Optimization of Transportation Routing Problem for Fresh Food in Time-Varying Road Network: Considering Both Food Safety Reliability and Temperature Control. PLoS ONE 2020, 15, e0235950. [Google Scholar] [CrossRef] [PubMed]

- Ivan, D.W.; Vanany, I.; Siswanto, N. An Optimization Model for Fresh-Food Electronic Commerce Supply Chain with Carbon Emissions and Food Waste. J. Ind. Prod. Eng. 2022, 40, 1–21. [Google Scholar]

- Ning, T.; An, L.; Duan, X. Optimization of Cold Chain Distribution Path of Fresh Agricultural Products under Carbon Tax Mechanism: A Case Study in China. J. Intell. Fuzzy Syst. 2021, 40, 10549–10558. [Google Scholar] [CrossRef]

- Shui, W.; Li, M. Integrated Pricing and Distribution Planning for Community Group Purchase of Fresh Agricultural Products. Sci. Program. 2020, 2020, 8839398. [Google Scholar] [CrossRef]

- Li, Y.; Lim, M.K.; Tseng, M.-L. A Green Vehicle Routing Model Based on Modified Particle Swarm Optimization for Cold Chain Logistics. Ind. Manag. Data Syst. 2019, 119, 473–494. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Dukovska-Popovska, I.; Subramanian, N.; Chan, H.K.; Bai, R. Decision-making in cold chain logistics using data analytics: A literature review. Int. J. Logist. Manag. 2018, 29, 839–861. [Google Scholar] [CrossRef]

- Kadlubek, M. Completeness Meter in Logistics Service Quality Management of Transport Companies. Int. J. Qual. Res. 2020, 14, 1223–1234. [Google Scholar] [CrossRef]

- Kadłubek, M.; Jereb, B. Measurement of the Logistic Customer Service Level in Commercial Cargo Motor Transport Companies. Logist. Sustain. Transp. 2014, 5, 8–15. [Google Scholar] [CrossRef]

- Yue, J.; Liu, L.; Li, Z.; Li, D.; Fu, Z. Improved Quality Analytical Models for Aquatic Products at the Transportation in the Cold Chain. Math. Comput. Model. 2013, 58, 474–479. [Google Scholar] [CrossRef]

- Bauer, R.; Delling, D.; Sanders, P.; Schieferdecker, D.; Schultes, D.; Wagner, D. Combining hierarchical and goal-directed speed-up techniques for dijkstra’s algorithm. ACM J. Exp. Algorithmics 2010, 15, 2.1–2.31. [Google Scholar] [CrossRef]

- European Commisson. Mobility and Transport—Driving Time and Rest Periods. Available online: https://transport.ec.europa.eu/transport-modes/road/social-provisions/driving-time-and-rest-periods_en (accessed on 28 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).