The Influence of Technologies in Increasing Transparency in Textile Supply Chains

Abstract

:1. Introduction

- Which technologies are being used in the textile industry to increase transparency along supply chains?

- To which extent does the use of the respective technologies influence the increase in transparency along the supply chains of the textile industry?

2. Materials and Methods

- Textile and apparel companies that see themselves as sustainable and are responsible for the production itself and the possible implementation of technologies;

- NGOs working for occupational safety and environmental protection in the textile industry. NGOs were chosen that advocate for workers and environmental conditions in the industry by publishing reports or campaigning, among other things. The advocacy group’s point of view is particularly interesting, as they have direct channels to the workers, the companies as well as the government;

- Service companies that help trading companies trace their supply chains;

- Textile factories, as actors at the beginning of the supply chain, can assess the impact of technologies.

- (i)

- General questions about the organization’s activities in the textile industry and especially in sustainability and transparency;

- (ii)

- Transparency in the supply chain, where the interviewees were asked about their understanding of transparency as well as the main challenges in the textile industry concerning transparency and its importance;

- (iii)

- Technologies for transparency, where the interviewees were asked about the relevance of the technologies for the industry, their role in generating transparency and the risks and challenges in their implementation.

3. Results

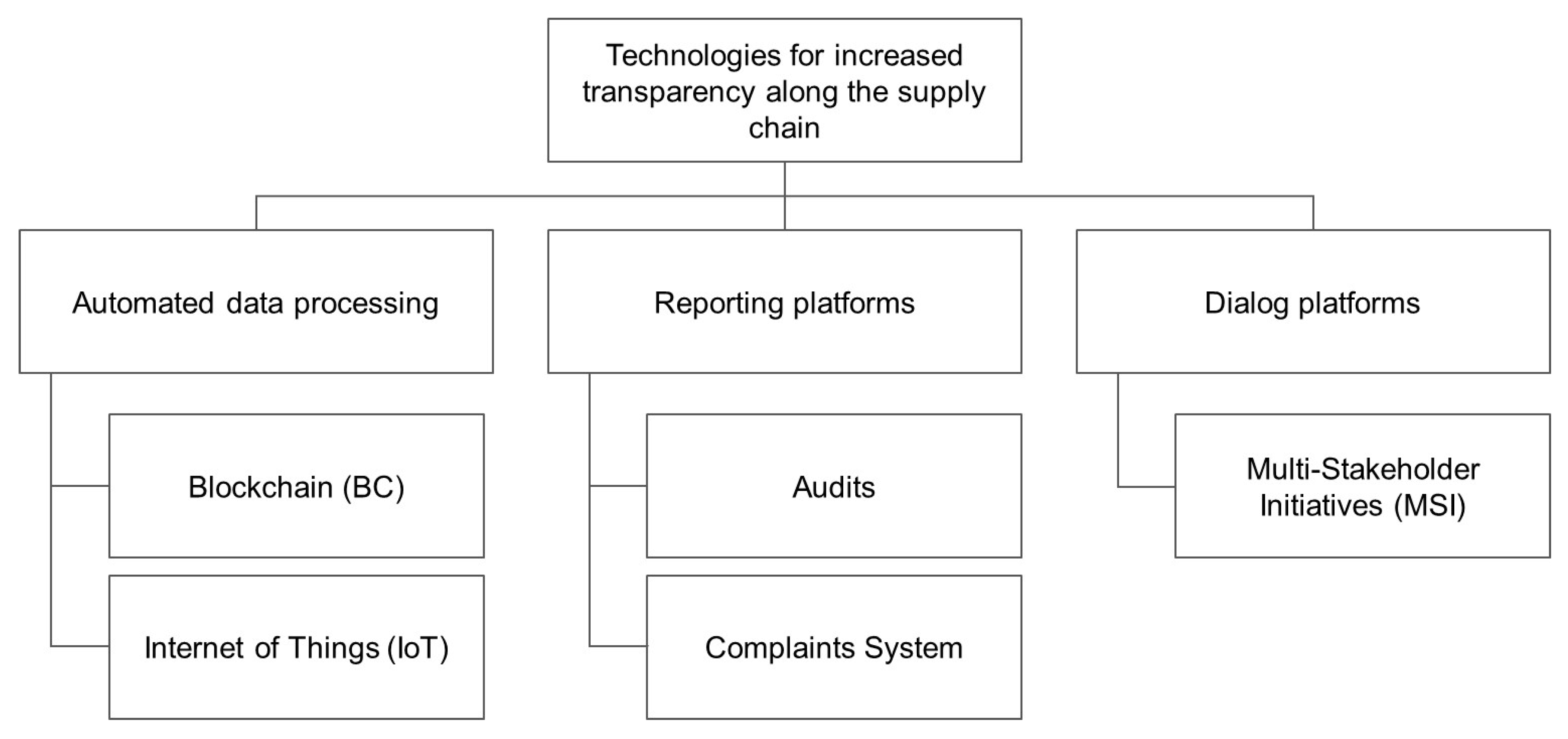

3.1. Automated Data Processing

3.1.1. Internet of Things (IoT)

3.1.2. Blockchain (BC)

3.2. Platforms for Reporting

3.2.1. Audits

3.2.2. Complaint Systems

3.3. Dialog Platforms

3.4. Other Technologies

3.4.1. DNA and Fine Dust Analysis

3.4.2. Sustainability Management Platform

3.5. Transparency as Means to an End

3.6. The Schallmauer Effect

4. Discussion

4.1. Impact of Technologies on Traceability

4.2. Influence of Technologies on the Information on Sustainability

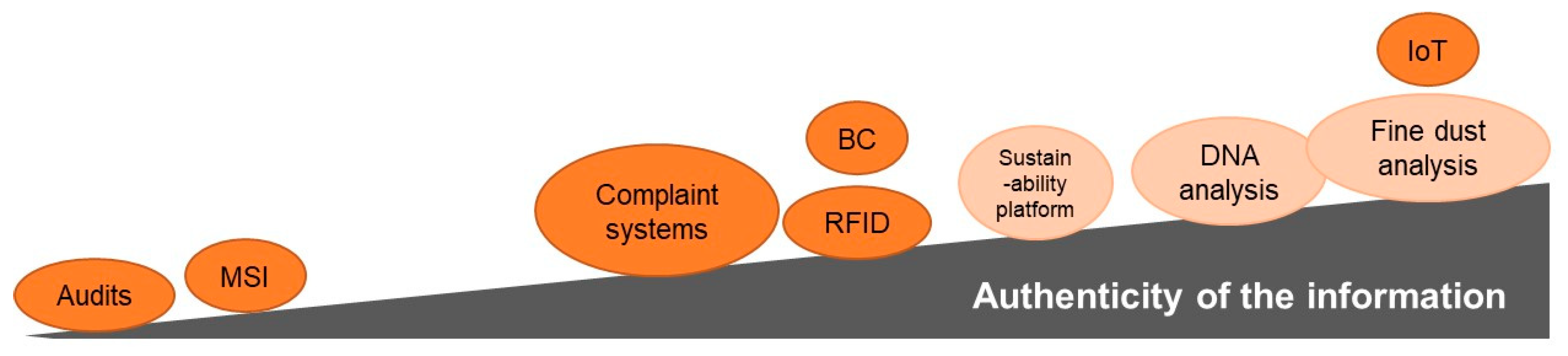

4.3. Authenticity of Information for Transparency

4.4. Implementation of Technologies in the Textile Industry

5. Conclusions

5.1. Limitations

5.2. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stamm, A.; Altenburg, T.; Müngersdorff, M.; Stoffel, T.; Vrolijk, K. Soziale und Ökologische Herausforderungen der Globalen Textilwirtschaft: Lösungsbeiträge der Deutschen Entwicklungszusammenarbeit; German Development Institute/Deutsches Institut für Entwicklungspolitik (DIE): Bonn, Germany, 2019. [Google Scholar]

- Dohmen, C. Lieferketten: Risiken globaler Arbeitsteilung für Mensch und Natur; Verlag Klaus Wagenbach: Berlin, Germany, 2021; ISBN 3803137063. [Google Scholar]

- Tewari, M. Can place-based network contracting foster decent work in informal segments of global garment chains? Lessons from Mewat, India 1. In Labor, Global Supply Chains, and the Garment Industry in South Asia; Saxena, S.B., Ed.; Routledge: Oxfordshire, UK; New York, NY, USA, 2019; pp. 173–191. ISBN 9780429430039. [Google Scholar]

- Shih, W.C.; Agrafiotis, K. Detoxifying the Supply Chains: Production Networks of Slow Garment Factories in South-Eastern Europe. In Detox Fashion; Muthu, S.S., Ed.; Springer: Singapore, 2018; pp. 1–27. ISBN 978-981-10-4782-4. [Google Scholar]

- Egels-Zandén, N.; Hansson, N. Supply Chain Transparency as a Consumer or Corporate Tool: The Case of Nudie Jeans Co. J. Consum. Policy 2016, 39, 377–395. [Google Scholar] [CrossRef]

- Saxena, S.B.; Baumann-Pauly, D. Off the radar: Subcontracting in Bangladesh’s RMG industry. In Labor, Global Supply Chains, and the Garment Industry in South Asia: Bangladesh after Rana Plaza; Saxena, S.B., Ed.; Routledge Taylor & Francis Group: London, UK; New York, NY, USA, 2020; pp. 45–61. ISBN 9781138366800. [Google Scholar]

- Straube, F.; Wutke, S.; Doch, S. Nachhaltigkeit in der Logistik: Messbarkeit ökologischer und sozialer Faktoren und die Einbindung von Supply Chain Partnern. In Industrie Management, 5/2013; GITO mbH Verlag: Berlin, Germany, 2013; pp. 7–10. ISSN 1434-1980. [Google Scholar]

- Ahmad, S.; Miskon, S.; Alabdan, R.; Tlili, I. Towards Sustainable Textile and Apparel Industry: Exploring the Role of Business Intelligence Systems in the Era of Industry 4.0. Sustainability 2020, 12, 2632. [Google Scholar] [CrossRef]

- McGrath, P.; McCarthy, L.; Marshall, D.; Rehme, J. Tools and Technologies of Transparency in Sustainable Global Supply Chains. Calif. Manag. Rev. 2021, 64, 67–89. [Google Scholar] [CrossRef]

- Zelbst, P.J.; Green, K.W.; Sower, V.E.; Bond, P.L. The impact of RFID, IIoT, and Blockchain technologies on supply chain transparency. J. Manuf. Technol. Manag. 2020, 31, 441–457. [Google Scholar] [CrossRef]

- Gardner, T.A.; Benzie, M.; Börner, J.; Dawkins, E.; Fick, S.; Garrett, R.; Godar, J.; Grimard, A.; Lake, S.; Larsen, R.K.; et al. Transparency and sustainability in global commodity supply chains. World Dev. 2019, 121, 163–177. [Google Scholar] [CrossRef] [PubMed]

- Müller, M.; Siakala, S. Nachhaltiges Lieferkettenmanagement: Von der Strategie zur Umsetzung; De Gruyter: Berlin, Germany, 2019; ISBN 9783110652628. [Google Scholar]

- UN Global Compact. A Guide to Traceability: A Practical Approach to Advance Sustainability in Global Supply Chains; United Nations Global Compact Office: New York, NY, USA, 2014. [Google Scholar]

- Garcia-Torres, S.; Albareda, L.; Rey-Garcia, M.; Seuring, S. Traceability for sustainability—literature review and conceptual framework. Supply Chain. Manag. Int. J. 2019, 24, 85–106. [Google Scholar] [CrossRef]

- Garcia-Torres, S.; Rey-Garcia, M.; Sáenz, J.; Seuring, S. Traceability and transparency for sustainable fashion-apparel supply chains. J. Fash. Mark. Manag. Int. J. 2022, 26, 344–364. [Google Scholar] [CrossRef]

- Saxena, S.B. (Ed.) Labor, Global Supply Chains, and the Garment Industry in South Asia: Bangladesh after Rana Plaza; Routledge Taylor & Francis Group: London, UK; New York, NY, USA, 2020; ISBN 9781138366800. [Google Scholar]

- Egels-Zandén, N.; Hulthén, K.; Wulff, G. Trade-offs in supply chain transparency: The case of Nudie Jeans Co. J. Clean. Prod. 2015, 107, 95–104. [Google Scholar] [CrossRef]

- Gill, K.; Khanna, A. Emerging solutions to the global transparency problem. In Labor, Global Supply Chains, and the Garment Industry in South Asia: Bangladesh after Rana Plaza; Saxena, S.B., Ed.; Routledge Taylor & Francis Group: London, UK; New York, NY, USA, 2020; pp. 192–205. ISBN 9781138366800. [Google Scholar]

- Linich, D. The Path to Supply Chain Transparency: A Practical Guide to Defining, Understanding, and Building Supply Chain Transparency in a Global Economy; Deloitte University Press: London, UK, 2014. [Google Scholar]

- Sunny, J.; Undralla, N.; Madhusudanan Pillai, V. Supply chain transparency through blockchain-based traceability: An overview with demonstration. Comput. Ind. Eng. 2020, 150, 106895. [Google Scholar] [CrossRef]

- Ellebrecht, A. Chain of Custody and Transparency in Global Supply Chains. In Sustainable Global Value Chains; Schmidt, M., Giovannucci, D., Palekhov, D., Hansmann, B., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 227–238. ISBN 978-3-319-14876-2. [Google Scholar]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4.0. Resour. Conserv. Recycl. 2020, 163, 105064. [Google Scholar] [CrossRef]

- Straube, F.; Verhoeven, P.; Nitsche, B. Potenzielle Anwendungsgebiete der Blockchain-Technologie in der Logistik; GITO mbH Verlag: Berlin, Germany, 2021; Volume 17. [Google Scholar]

- Nayak, R.; Singh, A.; Padhye, R.; Wang, L. RFID in textile and clothing manufacturing: Technology and challenges. Fash. Text. 2015, 2, 9. [Google Scholar] [CrossRef]

- Terwindt, C.; Saage-Maass, M. Liability of Social Auditors in the Textile Industry; Friedrich-Ebert-Stiftung: Berlin, Germany; Available online: https://www.ecchr.eu/fileadmin/Publikationen/Policy_Paper_Liability_of_Social_Auditors_in_the_Textile_Industry_FES_ECCHR_2016.pdf (accessed on 4 June 2023).

- Terwindt, C.; Burckhardt, G. Sozialaudits in Der Textilbranche: Wie Kann Man Kontrolleure Kontrollieren? Available online: https://www.business-humanrights.org/de/blog/sozialaudits-in-der-textilbranche-wie-kann-man-kontrolleure-kontrollieren/ (accessed on 1 June 2022).

- Lamnek, S.; Krell, C. Qualitative Sozialforschung: Mit Online-Material, 6; überarbeitete Auflage; Beltz Verlag: Weinheim, Germany; Basel, Switzerland, 2016; ISBN 978-3-621-28269-7. [Google Scholar]

- Mayring, P. Qualitative Inhaltsanalyse: Grundlagen und Techniken, 12; überarbeitete Auflage; Beltz Verlag: Weinheim, Germany; Basel, Switzerland, 2015; ISBN 978-3-407-25730-7. [Google Scholar]

- Markschläger, F. Schritt Für Schritt Zu Mehr Transparenz in Der Lieferkette; Deutsche Gesellschaft Für Internationale Zusammenarbeit (GIZ) Gmbh: Bonn, Germany; Available online: https://www.textilbuendnis.com/download/schritt-fuer-schritt-zu-mehr-transparenz-in-der-lieferkette-2020/ (accessed on 4 June 2023).

- Müller-Hoff, C.; Leifker, M.; Paasch, A.; Keller, A.; Bause, M.; Sodji, L. Menschenrechtsfitness von Audits und Zertifizierern?—Eine sektorübergreifende Analyse der aktuellen Herausforderungen und möglicher Antworten; European Center for Constitutional and Human Rights e.V. (ECCHR), Brot für die Welt, Bischöfliches Hilfswerk MISEREOR e.V.: Berlin, Germany; Aachen, German, 2021; Available online: https://www.ecchr.eu/fileadmin/Fachartikel/ECCHR_AUDITS_DS_WEB.pdf (accessed on 4 June 2023).

- Marx, S. Sozialaudits: Wie sie Unternehmen Schützen und Arbeiter*innen im Stich Lassen; Kampagne für Saubere Kleidung, FEMNET e.V.: Berlin, Germany; Available online: https://saubere-kleidung.de/2019/11/sozialaudits-lassen-arbeiterinnen-im-stich/ (accessed on 4 June 2023).

- Linares Barbero, M. Trazabilidad con Blockchain. Actas Del Congr. Int. De Ing. De Sist. 2019, 99–106. [Google Scholar] [CrossRef]

- Grünrock-Kern, U. Die Sache mit dem Hype—Schein und Sein der Blockchain: BVL Dossiers. Available online: https://www.bvl.de/dossiers/blockchain (accessed on 4 June 2023).

- Burckhardt, G.; Marx, S. Fact Sheet Transparenz und Audits: Wer passt auf, dass Unternehmen Verantwortung Übernehmen? Available online: https://saubere-kleidung.de/wp-content/uploads/2018/01/FEMNET-factsheet_transparenz.pdf (accessed on 4 June 2023).

- Wimberger, C.; Fincke, J.; Rodríguez, E.Y. Vertrauen Ist Gut, Kontrolle Ist Besser! Überprüfung von Arbeitsrechten Durch die Öffentliche Hand am Beispiel Einer Textilfabrik in Vietnam; Münster, Germany. 2016. Available online: https://www.ci-romero.de/wp-content/uploads/2018/06/CIR-Studie-WfkmS_Vietnam-1.pdf (accessed on 4 June 2023).

| Person ID | Role within the Institution | Actor in the Supply Chain | Institution ID |

|---|---|---|---|

| P1 | CEO/Founder | Blockchain as a service (BaaS) and sustainability platform provider for textile companies | NP1 |

| P2 | Consultant for sustainable supply chains and clothing | NGO | NGO2 |

| P3 | CSR Manager | Textile company | TBU3 |

| P4 | Auditor | Certification company | ZU4 |

| P5 | Sustainability Advocate & Consultant; former CSR Manager | Freelance; former textile company | TBU5 |

| P6 | Founder of the German NGO6; reg. coordinator | NGO | NGO6 |

| P7 | Technical coordinator | NGO | NGO6 |

| Person. | IoT | BC | Audits | Complaint Systems | Dialog Platforms | Others |

|---|---|---|---|---|---|---|

| P1 | x | x | x | Sustainability Management Platform | ||

| P2 | x | x | ||||

| P3 | x | x | x | x | ||

| P4 | x | x | ||||

| P5 | x | x | x | x | ||

| P6 | x | x | x | x | Unions | |

| P7 | x | x | x | x | x | DNA-Analysis. Fine dust analysis |

| IoT | BC | Audits | Complaint System | MSI | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T | IoS | T | IoS | T | IoS | T | IoS | T | IoS | |

| P1 | Reference to sustainability platform | Cooperation | ||||||||

| P2 | ||||||||||

| P3 | Cooperation | |||||||||

| P4 | ||||||||||

| P5 | Cooperation | |||||||||

| P6 | MSI | |||||||||

| P7 | MSI | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hauschild, C.; Coll, A. The Influence of Technologies in Increasing Transparency in Textile Supply Chains. Logistics 2023, 7, 55. https://doi.org/10.3390/logistics7030055

Hauschild C, Coll A. The Influence of Technologies in Increasing Transparency in Textile Supply Chains. Logistics. 2023; 7(3):55. https://doi.org/10.3390/logistics7030055

Chicago/Turabian StyleHauschild, Caterina, and Angelica Coll. 2023. "The Influence of Technologies in Increasing Transparency in Textile Supply Chains" Logistics 7, no. 3: 55. https://doi.org/10.3390/logistics7030055

APA StyleHauschild, C., & Coll, A. (2023). The Influence of Technologies in Increasing Transparency in Textile Supply Chains. Logistics, 7(3), 55. https://doi.org/10.3390/logistics7030055