Abstract

Background: With the continuing growth of warehouses globally, there is an increasing need for sustainable logistics solutions in warehousing, but research linking warehouse management systems (WMS) and sustainability is lacking. Methods: A systematic literature review and bibliometric analysis were conducted in Scopus and Web of Science databases from 2006 to 2022 to investigate academic knowledge of WMS contributing to warehouses’ social and environmental sustainability. Results: Findings revealed only 12 topic-relevant articles from 2013 to 2022, primarily published recently. More recent articles have received more citations than earlier published works. The articles were from multiple research fields, such as business economics, engineering, computer science, and social sciences, with only one article on environmentally sustainable technologies. The top keywords were “warehouse management system”, “internet of things”, “industry 4.0” and “supply chain”. Only six articles had environmental sustainability terms in the keywords. Findings show more discussions about social rather than environmental sustainability. Most studies suggest integrating WMS with other systems to support sustainability efforts in warehousing. Conclusions: The study addressed a gap in academic literature regarding WMS and sustainability. Research findings added knowledge of practical activities to achieve warehouse operations and performance sustainability and proactively reduce warehouse operations’ environmental and social impacts.

1. Introduction

The need for environmentally friendly logistics solutions is growing as circumstances dictate large-scale actions to reduce global emissions, natural resource consumption, and waste generation. Global greenhouse gas (GHG) emissions keep scaling up, despite the most significant CO2 emission drop (8.8%) in history [1] because of the COVID-19 pandemic. As the pandemic compelled people to stay home from work and education and restricted access to shops, the volume of materials in supply chains (SCs) has significantly increased. Simultaneously, companies are transitioning from asset producers to service solutions and digitalization experts, reducing physical asset output [2]. Several countries have already pledged to achieve carbon neutrality in the near future, reducing GHG emissions and combating global warming [3,4]. In the target of reducing global emissions, any wide-scale improvements, performance enhancement [5], and application of green management practices [6] on the sustainability front inside SC and logistics can directly affect the global reduction of CO2 emissions [7]. According to ref. [8], SCs are often responsible for over 75% of GHG emissions. Half of global GHG is from the top eight global SCs in fast-moving consumer goods, food, fashion, electronics, professional services, construction, automotive, and freight [9]. Research by the World Economic Forum and Boston Consulting Group found that SC decarbonization offers a game-changing opportunity for companies to fight against climate change [9]. Technology is the most popular tool business companies use to improve sustainability performance [10]. Moreover, rapid technological progress presents a chance to harness the power of digitalization and technologization to tackle sustainability challenges [11] and actively pursue a transition toward sustainability [12].

The positive intersection of Industry 4.0 technologies and sustainable warehousing is a topic of research interest [13] to contribute to achieving the Sustainable Development Goals (SDGs) set by the United Nations (UN) [14]. A warehouse, being an indispensable part of the SC and playing a vital strategic role in logistics, generates significant sustainability impacts by consuming energy and resources [15]. Logistics buildings alone account for approximately 10% of total CO2 emissions in the logistics and transport sectors (2800 CO2 megatons) [16]. To reduce carbon intensity, ref. [17] addresses the development of GHG assessment and allocation methods in a logistics facility in the form of environmental performance indicators. The International Warehouse Logistics Association, together with the Sustainable Supply Chain Foundation, introduces sustainable initiatives and standards development for the warehousing industry to enhance real SC sustainability [18]. Ref. [19] research a warehouse’s more profoundly environmental performance indicators and assign them to primary warehouse operations (receiving/shipping, put-away/storage/picking, cross-docking/sorting, and others) and provide examples of such CO2 emissions. Analyzing warehouse emission scenarios, ref. [20] points out that the research in warehousing pays only scarce attention to the environmental impact of warehousing operations. Ref. [13] also concludes that both warehouse equipment technologies, together with the usage of greener energy sources, can reduce or even prevent the increase in CO2. Ref. [21] shows how inner transportation in a warehouse can optimize sustainability to decrease nearly 60% of warehouse waste (such as redundant forklift driving and operations). Ref. [22] design and weigh the importance of 30 sustainable warehouse key performance indicators (KPIs) in economic, environmental, and social dimensions for sustainable warehousing. One of the technologies that can decarbonize warehouse activities is a warehouse management system (WMS) [23].

A warehouse management system (WMS) is an IT software solution for handling and optimizing warehouse logistics activities and supporting warehouse process automation. According to VDI guideline 3601, published by The Association of German Engineers [24], WMS is: “management, control, and optimization of storage and distribution using a software system (including storage and storage management, as well as the management and administration of the equipment), with extensive methods and means for checking the system conditions and with a selection of operational and optimization strategies to manage and optimize in-house storage and transport systems”. Drawing a simple analogy, WMS does the same for warehousing as ERP does for a company in operations and asset management. Thus, WMS plays a significant role in the planning and operations of warehouse logistics [25]. Furthermore, as an information system, WMS supports specific warehouse management operations [26]. Even though the concept of sustainability in warehousing has shown signs of increasing academic attention, the actual role of WMS as a tool to bring sustainability to warehouse activities is still not a well-studied field. Ref. [27] defined KPIs for a sustainable WMS by mapping indicators of warehouse management according to the triple-bottom-line approach.

This research offers a structured and comprehensive overview of area-specific research and warehouse sustainability in the academic literature to understand and map the current status of research. As a limitation, the financial benefits of WMS for warehouse operators, WMS definition, environmentally friendly materials for warehouse building construction, and renewable energy utilization in warehouses lie beyond the scope of this research. Our findings help researchers and practitioners identify research gaps in WMS and sustainability and reveal ways academic research has shown directions to utilize WMS for positive sustainability contributions.

This research addresses the following research questions based on the literature.

- RQ1: What are current academic research directions and focus areas on WMS and sustainability?

- RQ2: What is the current state of the art in WMS and sustainability-related literature?

The research data collection and analysis undertaken in the study are based on a mixed methodology of systematic literature review (SLR) and bibliometric analysis. These research methods are used to cover the research gap by conducting SLR with biometric analysis concerning the research area of WMS and sustainability. SLR helps to answer the first RQ, while bibliometric analysis is conducted to answer the second RQ.

2. Research Design

To answer the set RQ, the choice of SLR over a formal literature review was based on a need to remove potential biases caused by the author’s subjectivity and guarantee good baseline work for further research replications [28]. According to [29], SLR helps to identify, evaluate, and interpret all available literature related to the research topic, being at the top of the hierarchy of research evidence [30,31,32]. Providing a rigorous process of theoretical synthesis of already published literature on the topic, SLR can advance both academic and practitioner communities in pragmatic management research [33]. To ensure transparency and repetitiveness of the research, the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) was applied [34].

Following the SLR guidance by [35], the first step of defining the research purpose and research-specific questions was covered in the introduction and research methodology sections. In the second stage, the research implementation states inclusion and exclusion criteria. Ref. [33] also emphasizes the importance of a review protocol to provide a transparent and high-quality research process. This study focused purely on peer-reviewed academic journal articles written in English. A preference was expressed for peer-reviewed articles because of their high-quality contributions and rigorous research validation practices. This decision was supported by [28,36], who strongly recommend focusing on peer-reviewed articles in SLRs to avoid the use of gray literature sources (such as some working papers, conference proceedings, books, etc.).

For the timeframe, articles from 2006 to 2023 were included. Even though the oft-quoted “sustainable development” terminology was already introduced in the 1980s [37], there are reasons for setting timeframes. For example, ref. [38] proposes a 22-criteria concept model to assess warehouse sustainability based on the analyzed literature on sustainable warehouses dating from the earliest study in 2008. In an in-depth analysis of the literature on green warehousing, ref. [39] emphasizes the trend to publish studies on this topic in 2006. Thus, for this research, literature was gathered by searching the databases at set time points until the 8th of May 2023 to withdraw all possible recent mentions of WMS bringing sustainability. So, the publication timespan for this research was set from 2006 to June 2022.

The third step addressed database selection and defining/building keyword groups. In this research, the Web of Science (Core Collection) and Scopus (Elsevier) were used as online electronic databases to extract academic literature. According to ref. [40], these databases are recognized as academic search systems for systematic reviews, allowing evidence synthesis. Besides, these two databases were chosen for the search because of their multidisciplinary nature and essential common measures supporting the comparison of the academic results. Their data extraction features allow a proper bibliometric analysis [36]. Additionally, the Web of Science database has the most extensive systematic history of citation indexes. In contrast, the Scopus index has the most significant number of journals in all the different fields [41]. The results data was exported in CSV format files from databases and tabulated in Microsoft Excel for further data analysis, pairing, interpretation, and graph and figure visualizations.

Following the academic guidance for SLR, the focus was turned to determining keywords to collect the literature from the databases. With a proper selection of keywords, it is possible to include studies strongly contributing to the search results [33,42]. We started the keyword selection based on area-specific research to get a wide starting point. After an overview of WMS and warehousing-related publications, previous SLR studies on similar topics were briefly reviewed. Their keywords for collecting the literature were used to build our search baseline. The keywords were prioritized and grouped in a manner supporting a collection of research-specific relevant literature for future analysis steps.

Following the previous publications and the set of research questions, two main groups of keywords were developed: Group A (“warehouse management system”—1 keyword) and Group B (sustainability-related—33 keywords).

Table 1 presents the utilized keywords. The following parts of this publication explain a comprehensive description of the steps that resulted in this set of keywords. By combining keywords from Group A and B, all word combinations were considered to match them in databases for studies’ titles, abstracts, or publications keywords. When possible, an asterisk (*) was applied to words to give more variations and scope in the literature-gathering phase.

Table 1.

Group A (“warehouse management system”), Group B (words related to sustainability).

To map the current academic literature on WMS and sustainability, WMS is a core keyword component of the keywords set. In trial searches, it was found that using just the abbreviation “WMS” alone, without any explication connected to warehousing, tended to include a considerable number of non-related publications. The three-letter acronym “WMS” is widely used in academic literature and has multiple meanings, such as waste/water/workload management system, or wildlife/weather monitoring system, etc. For consistent and warehousing-connected results, we included only “warehouse management system” as a keyword in the main Group A to use in a follow-up search. To comprise sustainability keywords in Group B, we built keywords from a recent study by [39] on systematic analyses of green warehousing as comprehensive research and a summary of key knowledge of the green warehousing theme in literature. Plus, to enrich sustainability keyword selection and ensure complete coverage of sustainability terms, we extracted keywords from the study [43] on the classification of sustainability-oriented principles, approaches, and sub-systems to characterize sustainable development. More illustrations of the logic of building the 33 sustainability-related keywords from different academic works for Group B can be found in Appendix A. Appendix B presents the final keyword set combination used to collect literature from Scopus (Elsevier) and Web of Science (Core Collection) as a full-fledged query into the databases with field tags (searching matches in titles, abstracts, and keywords) and Booleans operators. After running selected keyword-based searches and filtering all results, we retrieved 133 and 73 journal articles written in English that were published in the period from the start of 2006 until the 8th of May 2023 in Scopus and Web of Science, respectively. These results were merged, leading to 206 studies without the removal of duplicates (Table 2).

Table 2.

Publications search process in Scopus and Web of Science.

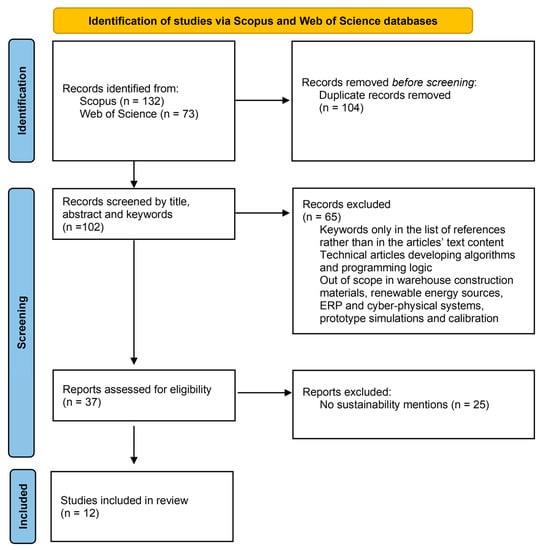

After exporting results from Scopus and Web of Science databases, the PRISMA flow diagram was used to record further article analysis for review (Figure 1).

Figure 1.

PRISMA 2020 flow diagram, adapted from [34].

Following the literature collection, the articles’ relevance was determined by their titles and abstracts. If an article was not excluded based on its title, its abstract was analyzed to verify its WMS-specific contribution. Some articles were excluded because they appeared in the search results, having defined keywords only in the list of references rather than in the body of the article. This way, articles about ERP systems, information systems, cyber-physical systems, network optimization, prototype calibration, and dynamic simulations were excluded due to a lack of relevance. The same was true of too technical articles discussing, e.g., fuzzy analysis, data quality problems, integer programming, and generic algorithms. After passing all these review rounds, the remaining articles were comprehensively studied as the final phase of the article selection process. We verified that the article’s content matched the set goals and research questions, which could help build a connection between WMS and sustainability. During this check, more than half of the articles had to be excluded from the final article list due to the absence of any exact sustainability mentions. Some articles discuss close topics to warehousing sustainability, for example, perishable products’ shelf life and labor capacity, but only from the perspective of economic and operational efficiency. Thus, a working sample of 12 articles was obtained for descriptive content analysis.

3. Results

This section is divided into the descriptive and content analysis of 12 found articles shedding light on the topic of WMS and social and environmental sustainability. The descriptive analysis allows for describing the found dataset in a measurable form, while the content analysis synthesizes literature findings.

3.1. Descriptive Results

Table 3 shows main articles’ details (authors, titles, published years) as well as reference citation numbers. Articles are sorted in the table in alphabetical order according to authors’ names. Additionally, articles were assigned Roman index numbers from I to XII to ease the representation of a reference to one of the 12 articles in the follow-up tables and figures illustrations. Appendix C gathers the entire article’s information.

Table 3.

Brief 12 articles information and index numbers.

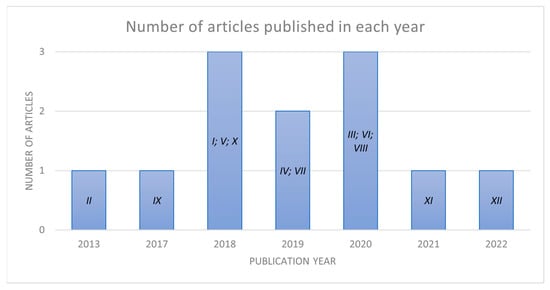

3.1.1. Analysis of Publishing Years

Even though the publications’ timespan covered studies from 2006, the first relevant paper found was from 2013 (Figure 2), followed by a few years of publishing gaps. However, 2017 and the next three years received numerous research contributions. There was only one publication in 2021 and the first half of 2022. Given the standard lengthy academic publishing processes, it would be expected to see more contributions later in 2023. In short, most found publications were from 2018 to 2020, indicating the topic’s freshness.

Figure 2.

The number of publications discussing WMS and sustainability topics per year.

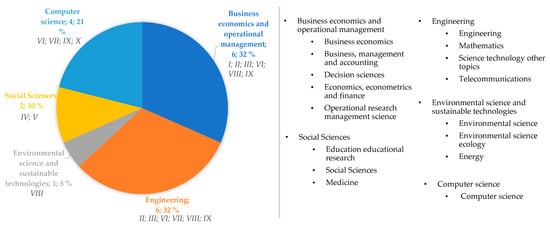

3.1.2. Research Areas and Subjects

Using the data tools from both Scopus and Web of Science, we were able to get ready-made base classification lists for the selected publications’ research and subject areas. Figure 3 illustrates a pie chart of general research areas covered in 12 articles extracted from both databases indexing subjects. In addition, the pie chart provides indicators of what articles and how many were identified in a particular research category. One article could be identified in multiple research fields. Among the most significant shares came from the business economics and management field (seven articles).

Figure 3.

Selected articles research areas in the form of the pie chart (left) and precise research categorization (right).

Similarly, seven articles discussed engineering solutions for warehouse operations. Five articles focused on computer science. In a few articles in this research context, social science aspects were not yet touched on too much. Only one article was found to discuss environmentally sustainable technologies.

3.1.3. Research Methods Classification

To open up articles’ material and identify what research methods best reflect their content, we identified and summarized research methodologies. Table 4 shows the research methods in each selected article based on five research methodologies (Table 5).

Table 4.

Description of research methods adapted from [55,56,57].

Table 5.

Research methods classification of 12 articles adapted from [55,56,57].

An article could be classified into multiple methodology categories depending on its characteristics. For example, the article [27] comprised only a theory review and model development. All articles had a literature review of their research topic. Five articles verified that their conceptual model developed in a real-life context. Likewise, studies tested their research hypothesis or theory by conducting interviews; half of the articles described software simulations, and seven included mathematical calculations.

3.1.4. Publication Channels

As an inclusion criterion, only articles published in journals were considered. Table 6 gathers journals’ titles and the number of published articles in particular journals. There was no single published journal touching on both WMS and sustainability in more than one article. All journals were equal in the number of published articles (one per each). Based on the titles’ scope, these journals generally focus on industrial engineering and management, sustainability, and social and computer sciences. Remarkably, there were no journals on the list with an emphasis on warehousing logistics, or WMS. Besides, most of the journals had a technical and business management focus.

Table 6.

The list of journals and articles number published on the topic.

3.1.5. Authorship Collaboration

In total, 41 authors contributed to the found publications set. Table 7 presents the list of these authors and the number of co-authorized publications. Only seven authors (grey-colored cells) contributed to two different articles. Other authors published/co-authored only one article.

Table 7.

The full list of authors and numbers of co-authored publications.

Table 8 reports the number of authors per article and shows that most papers (33%) were written by two authors, followed by a collaboration of three and four authors (17% each). For the rest of the papers, there was no notable similarity in the number of co-authorships. None of the articles were written by a single author. The collaborations of more authors might be motivated by the increased number of researchers interested in the sustainability of warehousing operations using information management technologies such as WMSs.

Table 8.

Authorship per publication.

3.1.6. Countries of Faculties Where Authors Did the Contributing Research

Table 9 presents the list of 11 separate countries, including all academic faculties to which the authors contributed. Only five countries seemed to be more than a bit productive in this research direction. The United States is the first on the list, which can be just the correlative reality of the fact that the USA has more than a few of the largest warehouses in the world [58].

Table 9.

The list of countries interested in WMS and sustainability topic search.

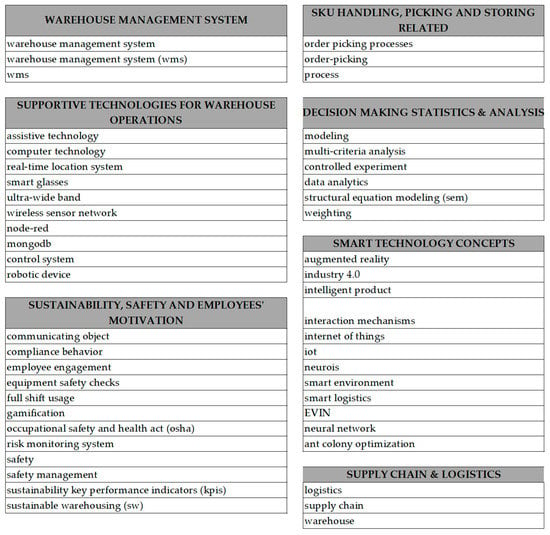

3.1.7. Keywords Analysis

The keywords are expected to capture the main focus of the study [59]. The number of accepted keywords might be defined by the journals too. Table 10 reports the number of keywords per article. Nearly half of the articles had five keywords, one-fourth of the articles had four keywords, and an equal number of articles had seven keywords and six keywords, respectively.

Table 10.

Keywords count among articles.

The frequency of the keywords was accounted for to see the most commonly used keywords. Table 11 depicts the list of 49 unique keywords and their occurrences. There were three top keywords, “warehouse management system”, “internet of things”, “industry 4.0 and “supply chain”, heading the list. Thus, WMS words and technologies were at the top, and others were used only once.

Table 11.

The list of authors’ keywords and their occurrence among articles’ keywords.

Analyzing keywords’ semantics, we divided all the keywords into seven most prominent content-related groups (Figure 4). The number of keywords in groups varied from three to 12. The main focus group was on WMS-related keywords (WMS abbreviation and warehouse management system). The most prominent groups contained sustainability-related terminology keywords (sustainable warehousing and performance indexes, safety management) and employees’ motivation (gamification and engagement). Another keyword group was about technologies simplifying storage and assisting in picking (smart glasses, wristbands, and other location systems). The technologies-related group contained smart technologies and similar concepts (industry 4.0, smart, and intelligent storage). The other two small groups include supply chain, logistic, and warehouse process terms. Interestingly, three articles did not mention “warehouse management system” or “wms” in their list of keywords. Similarly, only half of the articles had environmental sustainability terms in the keywords (Appendix C).

Figure 4.

Grouping selected articles’ keywords in themantic areas.

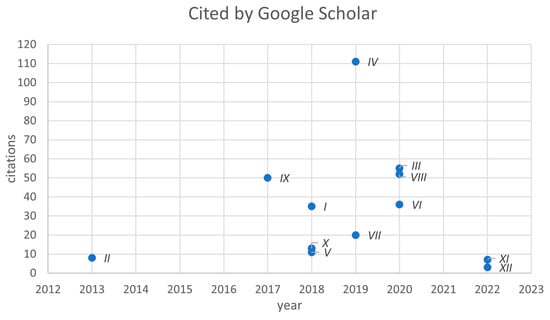

3.1.8. Citation Analysis

From the 12 articles retrieved from Scopus and Web of Science, only a few were available in both databases. All articles’ citation counts collected from Scopus and Web of Science were presented in Appendix C. The Google Scholar index was utilized to study the global interest in citing these studies. Figure 5 depicts articles by publishing year (horizontal axis) and citation count (vertical axis). Blue dots with Roman numerals indicate the articles. As an interesting note, the more recent articles have received more citations than the earlier published works, except XI and XII, which were published in 2022. However, it was expected that older articles would collect more citations. Noticeably, IV has been cited much more than other articles.

Figure 5.

Articles’ publication years and a number of Google Scholar citations.

3.2. Content Analysis

To access WMS and sustainability connection, all 12 articles were read, and their content was analyzed to understand their research aims (Table 12).

Table 12.

The research aims of 12 articles.

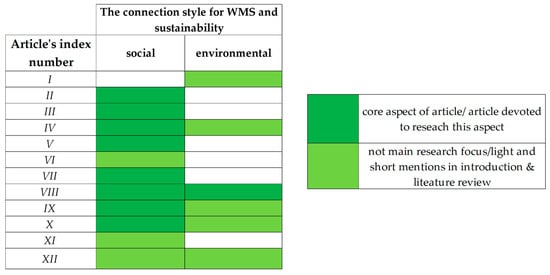

Figure 6 shows an overview of articles’ focus on adding value to the environmental and social sustainability sides of WMS. We marked with green colors if an article discussed WMS and sustainability from both social and environmental sides or only one. In addition, the darker green indicates that a certain aspect is one of the article’s core aspects. In contrast, aspects marked with the light green are not a primary focus of the paper and are partly discussed and slightly mentioned, e.g., in theory, as can be seen from the table, 10 out of 12 articles built some social sustainability connections with WMS. In comparison, only five articles contributed to WMS and environmental content. Nearly half of the articles (four) covered social and environmental sustainability associated with WMS usage and implementation.

Figure 6.

The colored connection style for WMS and social and environmental sustainability in the 12 articles with color identification description.

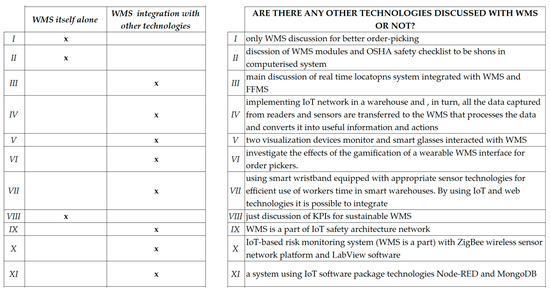

Together with the social or environmental sustainability focus in articles, all articles were assessed based on the technology interface with WMS. The evaluation was completed, as WMS integration into other systems had the technological capability to add a new level of sustainability to warehouse operations. Figure 7 gathers two tables about the assessment of technologies discussed in 12 selected articles. The left table identifies whether WMS alone or any additional technologies used with WMS contribute to environmental or social sustainability, where matches are marked with “X”. At the same time, the right table has a detailed description of any other technologies used with WMS. In most papers (nine out of 12), assistive technology was integrated with WMS to work in tandem.

Figure 7.

Mentioned technologies working with WMS in 12 selected studies, the left table—identification of technologies used or not with WMS in a warehouse, the right table—a description of technologies in a warehouse.

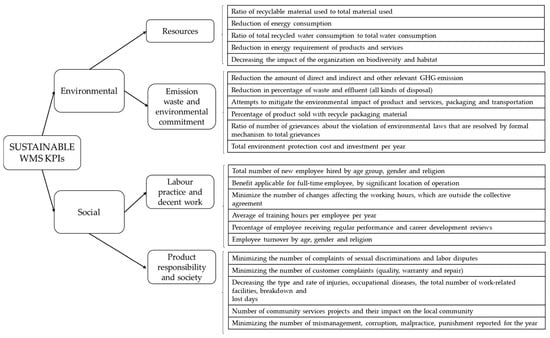

Analyzing the found publications from a sustainability point of view, the article with the strongest contribution, connecting both social and environmental sustainability with WMS was written by ref. [27]. The authors devised 33 KPIs for WMS in all three sustainability pillars (economic, environmental, and social) derived from sustainability reporting guidance and literature and interviews with Malaysian automotive warehouse managers in 2004 (Figure 8). This study was also the only one discussing the sustainability performance of WMS. However, since the authors did not disclose the exact interview question list, it was hard to judge on the questions asked: were these questions related to warehouse performance, WMS functions, or the dashboard of WMS. Nevertheless, this research has made a good step towards researching and stating such metrics for policymakers and the government to push sustainability through warehousing operations to make them more sustainable. Developing sustainability indicators, ref. [27] did not say how WMS could contribute to reaching them or how these indicators affect warehousing operations. For the model’s environmental group of indicators, the authors defined warehouse resources (consumption of recyclable materials, energy, water, impact on biodiversity and habitat), emission waste, and environmental commitment (emission and waste reduction, environmental laws violations, green investing). The authors identified labor practice, decent work, product responsibility, and society as social indicator groups. Besides, after analyzing interviews, the authors concluded that some indicators have a higher contribution among their own group indicators and sustainable warehousing. For example, the percentage of products sold with recyclable packaging material had the highest weight to form sustainable warehousing using WMS, and the total number of new employees hired by age, gender, and religion had the highest contribution to sustainable warehousing.

Figure 8.

Environmental and sustainable KPIs of sustainable WMS adapted from [27].

The research of ref. [27] indicated a lack of theory in the field of KPIs for sustainable warehousing with WMS. This article was also the closest to the current core research connecting WMS to sustainability matters. The authors validated these KPIs with industry experts but did not align the defined KPIs with the actual scope of WMS activities, keeping the discussion at a general level. Thus, these KPIs cover general warehousing activities rather than activities that lie within the scope of WMS. Another group of three articles [47,51,52] with similar contribution weights to environmental and social sustainability and WMS discussed more social issues than environmental warehouse issues. Ref. [47] strongly emphasized the role of IoT implementation in warehousing. Namely, WMS received all the data captured from readers attached to gates, forklifts, products’ tags, and shelves’ sensors (product’s location, product type, expiry date, storage, and picking confirmation) and converted this data into useful information and a set of actions providing real-time visibility of inventory levels and preventing stock-outs. Plus, the HVAC system got the data required to optimize energy consumption and assure product quality and warehouse safety. Controlled and reported actions in order picking helped to update the inventory level automatically, make immediate order fulfillment more efficient, easier, and accurate, and prevent counterfeiting. The authors’ proposed IoT framework decreased human interventions and consequently led to more safety for warehouse workers and products, reduced accidents, decreased counterfeiting and fraud, and decreased theft. The other two articles shared the same research idea of bringing up social (mainly) and environmental sustainability in developing warehouse operations [51] and implementing [52] an IoT-controlled Safe Area. Ref. [51] implemented an IoT-controlled safety area to ensure safety control of all warehouse operations related to hazardous products, shelves, forklifts, and human labor. This study used WMS with highly autonomous components supporting a communicating object concept, RFID readers, and tags. In the paper of ref. [51], WMS and an IoT-architecture reference model generated safety-based scenarios with an IoT-controlled Safe Area improving warehousing operations of hazardous products by using safety mechanisms for detecting and pretending all potential conflictual and risky situations, environmental disturbances, and disasters (e.g., the absence of a product due to a theft or a human error in storing, the existence of an empty or damaged product, the lack of warehouse workers’ safety protection equipment). Ref. [52] added safety to a WMS with the help of a smart product IoT-based risk monitoring system (ZigBee wireless sensor network platform and LabView software) to safely manage goods and people in a warehouse with hazardous chemical products (warehousing operations control, intelligence, and decision-making support, control sensors for storing products in different temperate sections, detection of environmental disturbances, and risky and conflictual situations). Furthermore, this article discussed warehouse safety issues (harmful forklift accidents, storage and transportation of dangerous goods, etc.) as a part of the literature review. Both papers revealed the importance of warehousing safety, overcoming safety problems in a warehouse, and investigating a lack of automated safety control during WMS operations with the smart product concept.

Even though an article by [44] was not about sustainability, there is a description of WMS facilitating sustainability in a warehouse by reducing paperwork/paper consumption and decreasing CO2 emissions level and energy consumption with optimized utilization of transportation equipment (the last is mentioned in the literature review only). The primary article focused on the importance of implementing a WMS for improving the order-picking process as a warehouse activity.

Another article that concentrated more on developing control system algorithms for robot path optimization in the order-picking process than on social and environmental sustainability aspects belongs to [54]. In this article, the authors minimized the number of robots needed for order-picking, optimized their travel paths, and reduced the risks of robot collisions, which, in turn, resulted in increased control, safety, and energy consumption in a warehouse using WMS.

In the recently published article [53], the primary focus was not strongly on social sustainability. The article primarily demonstrates IoT benefits for SC if software such as Node-RED and MongoDB can enhance a WMS. However, the authors summed up the positive impacts of integrating this software with WMS to gain more control of warehouse operations with IoT, decrease fraud, theft, and counterweighting, and avoid warehouse accidents because of more accurate online data, analysis, and reporting.

Discussing the social sustainability of warehouse operations, Ref. [45] only brought up the issue of reducing forklift accidents in a warehouse by using an equipment safe module in WMS for vehicle checks (visual inspection and operational equipment checks like wheels, forks, battery, seat, etc.). This article compared a computerized system against a simple paper instruction check. Another article lighting the social sustainability of warehousing operations belongs to [48]. These authors reported studying augmented reality devices such as visualization device monitors and smart glasses integrated with a WMS. In the following way, they analyzed health-oriented aspects as well as the task completion time and the error frequency for an entire shift of eight hours of usage of smart glasses in order picking processes. One of the negative consequences of such long glass shifts is that participants experience headaches, pain in or around the eyeball, and difficulty focusing. Summing up, the pickers’ opinions about the full-shift usage of smart glasses in combination with a ProGlove as an interaction device are quite different. Some employees enjoyed working with the glasses. Most of them liked the user interface and the colors, especially the series of numbers, with which they had a better overview. Providing for error feedback is appreciated and leads to nearly error-free picking’. The higher working speed is viewed as advantageous because it is caused by visualization in their field of view and the avoidance of head- and body movements. Wireless working without a power bank prevented entanglement. One picker described the tasks as robot work, where a worker only performed the work without thinking. Some other negative aspects were the weight of the glasses, the inflexible and narrow temples, and left imprints left by the nose clips. The headache at the back of the head was caused by the design of the temples. Another challenge was to refocus from objects to visualization in the glasses and the limited field of view. Few pickers perceived the display as blinding. This experiment resulted in a decrease in the mean task completion time. While the sub-values of ‘mental demand’, ‘performance’, and ‘frustration’ were higher after using smart glasses as visualization devices, the sub-values of physical demand’, ‘temporal demand’, and ‘effort’ were higher using the monitor.

In addition to the warehouse safety topic, ref. [46] discussed social sustainability in a warehouse, in literature and case studies. The authors investigated primarily the introduction of real-time location technology (RTLS) integrated with WMS to enhance safety and operational efficiency. The RTLS uses actual data obtained from WMS and the forklift fleet management system to optimize driving routing and identify unsafe driving behaviors like overspeeding or harshness in braking. As a result, the zones with safety concerns can be visualized with the help of warehouse performance heat maps concerning speed, braking, impacts, and routing policy compliance. An algorithm utilizing both WMS and RTLS was developed to mitigate the noise issue. Thus, data-driven decision support systems could assist in accurate and efficient vehicle management.

For social sustainability in warehousing, Ref. [50] suggested increasing the quality of the working lives of people with disabilities in a warehouse with the help of assistive technologies integrated with WMS. The wireless sensor network and cloud computing technology are used in the Industry 4.0 concept. The authors suggest using smart wristbands with sensor technologies for efficient workers’ usage. In the following manner, all relevant data from logistic processes can be integrated into WMS with the help of IoT and web technologies. Ref. [49] presents an interesting study where wearable devices are used with a WMS interface to motivate warehouse workers’ pathways using gamification that positively affects workers’ engagement and performance.

4. Discussion

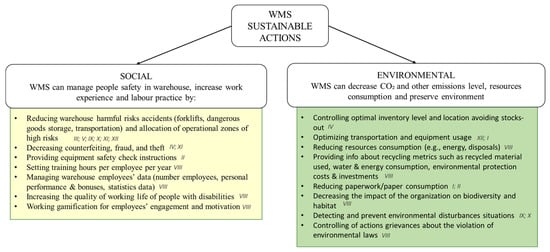

This study has collected the current literature on WMS and sustainability-related research together. Primarily, this study has searched for evidence of WMS contributing to social and environmental sustainability. Based on the found literature, this is the first SLR to address WMS and sustainability together. Additionally, as part of the goal to seek an answer to what the current state of the art and scale on topic-specific academic research, we were able to show this research topic is still in its early phases and quite narrow in scale. Figure 9 gathers a synthesis of findings with references to the articles in Roman numbers and presents the list of actions WMS can take to bring social and environmental sustainability into warehouse operations.

Figure 9.

The list of WMS’s social and environmental sustainability activities was gathered from literature findings.

Only 12 articles described the effect of WMS on sustainability in warehousing. From the found literature, the study most focused explicitly on this matter belongs to [27], who defined KPIs for a sustainable WMS. However, this study misses instructions on how exactly WMS could contribute to reaching these KPIs. The research on achieving social and/or environmental sustainability with WMS functions or through utilizing WMS as a part of operations management is missing from the current literature, indicating a clear research gap. Based on this finding, we suggest additional research on warehouse information systems utilization, social sustainability, and operations continuous improvement context. One should fit continuous improvement and employees’ participation levels properly with the level of centralization of authority [60]. The fitment is essential for WMS utilization level studies and experiments when, e.g., action research and employee engagement-based development activities are studied.

Additionally, even though the sustainability goals achievement studies with WMS connected manner are lacking, there is increasing research attention to studies of reducing GHG in warehousing. Ref. [17] addressed the development of the assessment and allocation method of GHG in a logistics facility, as well as [19], which developed environmental performance indicators for main warehouse activities. Furthermore, ref. [39] indicated a growing research interest in sustainable warehousing in general. Moreover, companies need to achieve shorter delivery times, increase the speed of deliveries, and find ways to win the tight competition in warehousing performance levels worldwide [61]. In the same way, as WMS increases inventory visibility and traces inventory [62], WMS might calculate GHG emissions based on resources consumed in a warehouse, like in the model [19], and collaborate with SC partners to allocate CO2 [63].

Considering the found publications’ focus areas, most generally discussed warehouse operations and focused on social sustainability in a warehousing context, especially workers’ safety. This finding aligns well with the view that humans are the key players in both warehouses’ physical and non-physical activities [64]. Additionally, from the point of view of business productivity and operations side cost, carelessness on the topic of employee safety has been shown to negatively impact business quality and performance [65], give companies bad publicity, and damage companies’ brands.

Considering WMS as a sustainability-enhancing tool, the academic world is still missing the research line addressing the topic of utilizing WMS for warehouse personnel and sustainability management efforts, even though it is known that a WMS can manage warehouse resources (such as inventory, storage, orders, and workforce). However, for the system, this should not be a difficult task; for example, ref. [66] introduced the sustainable warehouse management approach through workforce scheduling for better usage of the workforce, resources, and equipment.

Another significant finding was sustainability, which the literature mainly focused on. The studies were more steered towards social sustainability aspects than environmental sustainability aspects, indicating a research gap on the side of environmental sustainability that could be achieved with WMS. As with any other logistics activity, warehousing sustainability is a part of SC sustainability research. For example, the SLR of the transport sector studies by [67] with a little focus on sustainability topics gave the opposite result of more environmental rather than social sustainability studies. Additionally, the literature analysis on sustainability interactions between SC actors revealed the domination of environmental over social practices in studies and the increasing gap between these two dimensions in the last decade [68]. A study [69] also emphasizes a predominant focus on environmental concerns in designing sustainability methods and tools. Our findings show that the sustainability discussion is ongoing and supports research in the warehousing literature. However, the sustainability focus on warehousing is different from that in logistics sectors. Especially, research on warehouse operations management software like the WMS and their possible contribution towards environmental sustainability is lacking. These systems are top operations management tools in all medium- and large-scale warehouses nowadays, all around the globe.

In most of the analyzed articles on the topic of WMS and social and environmental sustainability, WMS was interfaced with other supporting technologies. Generally speaking, the found literature emphasizes IT utilization’s role in warehousing. This issue can be connected with the value of IT-based systems for sustainable SC business activities [70]. For WMS, integration with other systems is always beneficial for efficient and smooth operations [61]. In the list of world trends in warehousing logistics, there are robotization, big data, RFID, EDI, drones, IoT, additive technology, cross-docking, and multi-story warehouses [71]. This correlates with the findings of [72], who conclude that warehousing research after 2011 has evolved to be focused more on highly automated and integrated warehousing systems to boost operations efficiency and effectiveness. Technologies can help identify unsustainable behavior, e.g., forklift over-speeding [46]. The rising interest in pro-environmental behavior will increase the adoption of sustainability norms [73]. Ref. [18] noted that more automation deployed in a warehouse led to higher energy expenditure. In contrast, ref. [74] proposed a model of controllable energy consumption for environmental conservation (reduced pollution and emissions) and increased profit. Several studies have already been dedicated to extending our understanding of how automation technologies can enhance operational energy efficiency [75,76]. The recent SLR validated a similar positive linkage between sustainable warehousing and industry 4.0 technologies [13]. Such an increasing dependence on information technology systems may result in negative consequences from technology disruptions, as discovered in the study of ref. [77] on the link between sustainability and resilience.

Moreover, due to more automation deployed in a warehouse, it is estimated that the warehousing industry will not experience a dramatic loss of jobs—technologies can lower the skill level required for the job and reduce monotonous or highly physical energy-consuming activities [78]. Considering the supply of safety-related publications, issues like gender equality, the UN SDG, the high cost of a talented workforce, and replacing qualified personnel in case of an accident, the present spread of COVID-19 might have pushed research in this particular direction.

It is also surprising that warehouse waste reduction in a warehouse is not brought up in found articles, except for being mentioned by ref. [27] without any further description in one of the tables about WMS KPIs. From 12 articles, ref. [53] also mentioned a waste problem in a warehouse, but in the meaning of impropriate utilization of a warehouse space without any reference to sustainability. Ref. [79] found that pollution prevention and waste management practices positively affected GHG emission reduction. In recent years, sustainability, circularity, and waste reduction have gotten more attention in research communities [80,81]. There can be a circular economy and a sustainable stream of WMS studies in the near future. The social distancing restrictions due to COVID-19 limited warehouse work (rising labor costs because of working restrictions, the need to increase stock levels because of quickly increased demand, and the need to store large inventory volumes because of interrupted SCs) [71]. All of the above can hinder the sustainability research development speed as corporations are forced to focus on the survival of their organizations as their priority.

5. Conclusions

The global markets and social development have put the companies under a pressing need for more sustainable SCs. Meanwhile, turning a widely known paradigm [82] of a SC to be as strong as its weakest link towards sustainability, it can be said that every chain (stop/intermediate/connection point) of a SC should also be sustainable to ensure the overall sustainability of the SC. Maintaining the same sustainability perception, using the PRISMA model, the present research paper was designed to gather evidence from WMS and sustainability discussion from Scopus and Web of Science databases. The current academic literature on this topic appears to be somewhat limited in terms of research. As a result, 12 academic articles within the range from 2013 to 2023 were extracted. The research topic was first discussed in the article published in 2013, then had a few years of publishing gaps, was raised again in 2017, and had two peaks in 2018 and 2020. Next year, the research topic received numerous research contributions.

Regarding the geographical enlargement of research, of the 11 countries, only five countries were more active in their contributions to the research direction. The United States is the most popular, followed by Egypt, Malaysia, France, and Tunisia. From the citation count, surprisingly, recent articles have received more citations than earlier published articles. Based on findings in most cases, WMS is currently integrated with other warehouse sub-systems to bring up the social and environmental sustainability results of warehousing. Interestingly, most articles observe social sustainability and WMS as dominant over environmental sustainability focus. Furthermore, nearly half of the articles contributed to WMS’s social and environmental knowledge. Synthesizing knowledge from these 12 articles, we listed activities that WMS could do to foster warehousing operations’ social and environmental sustainability.

6. Theoretical Applications

The current research findings have a number of theoretical implications for WMS and social and environmental sustainability research that can be significant in several ways. This research is an addition to the body of knowledge on WMS and sustainability. Another theoretical implication is the potential to enhance understanding of the interplay between technology and sustainable warehousing. Investigating how WMS can contribute to social and environmental sustainability can become a starting point for designing and developing technologies to promote sustainable practices in a warehouse. The research can help to balance social and environmentally sustainable warehousing operations with the economic efficiency of warehousing operations. Moreover, the current research can positively impact the development of a more sustainable supply chain that cares about people and the environment.

7. Managerial Applications

By gaining more knowledge about and control over warehousing operations, companies could reduce the environmental impact of warehousing operations and move closer to achieving the UN SDG [83]. Ban Ki-moon, the Secretary-General of the UN, acknowledged the crucial role of business companies in maximizing efforts toward the SDGs by integrating sustainability across all SC functions [84]. Defining relevant sustainable SCM practices, ref. [85] placed green warehousing into the sustainable practice of the downstream SC. In decarbonizing SC activities, ref. [86] indicated a significant role of third-party logistics in freight transportation and warehousing in implementing a low-carbon strategy. To reach the concept of sustainable warehousing, ref. [87] introduced sustainable warehouse system modeling, and ref. [38] developed criteria for the assessment of warehouse sustainability mentioning the role of warehouse systems and automatization. Ref. [88] reviewed the development of warehousing systems and technologies to contribute to sustainable warehousing. Refs. [89,90] demonstrated a scarcity of research in the WMS context and sustainability-supporting aspects of third-party logistics. As content analysis has shown, the topics of WMS and sustainability are truly missing practical implications.

Companies could reduce the environmental and social impact of their warehousing operations with added knowledge for practical implementation activities to achieve sustainability KPIs and control warehousing operations with respect to sustainability. All this will allow companies to push the surrounding society closer to achieving the set UN Sustainable Development Goals Research 2030 Agenda [91].

8. Future Research Suggestions

We would recommend academics and business owners research more about the topic and collaborate in this direction. The combination of our findings supports the need for further research on utilizing WMS for sustainability activities. WMS are the key systems in warehousing, controlling what happens where and why in a warehouse.

In this context, further research is needed to support companies’ proactive approaches to sustainability matters. In this case, if the high demand for sustainable warehousing comes from the government, policymakers, producers, or even end customers, warehousing companies should be prepared and know what to do, why, and when. One potential higher-level integration of automatization optimization in the WMS context could be self-operating autonomous vehicles [92] in the restricted parts of warehouses and their surrounding yards to be controlled by the WMS. In the long term, WMS could be developed to handle larger-scale fleets [93,94], and improve their optimization capabilities in warehouse environments.

To further understand the potential of WMS to achieve and set sustainability goals, studies on utilizing WMS alone for sustainability would be beneficial. This would add to understanding what can be achieved in warehouses with different available resources and tools. For example, in further studies, WMS functional characteristics for sustainability should be considered when discovering purely WMS-based capabilities for sustainability, including sustainability report functions, separated waste streams quantity generation forecasting, mapping and classification of different processes based on their CO2, and waste production per handled ton. This, in turn, will also lead to incorporating more quantitative and qualitative techniques to investigate this research direction further.

When there is a bigger picture of how WMS can be both socially and environmentally sustainable, it would be important to also be able to identify WMS sustainability contributing development possibilities according to the triple bottom line approach to cover all three pillars of sustainability [95] and overlapping sustainability elements in the same way as completed by ref. [96]. The same call for building WMS and sustainability knowledge came from the 3PL area specialist interviews by ref. [97]. Here, we would suggest also considering the sustainability trade-offs with WMS in warehousing, which is completed by refs. [98,99] in the SC contexts.

9. Limitations

The most important limitation of this research lies in the fact that only 12 studies contributed to the understanding of the environmental and social sustainability of WMS. The current academic literature on the researched WMS and sustainability topic is a bit narrow in availability, so it could not produce wider insights into WMS utilization in the sustainability connection. What makes the generalizability of these results subject to certain limitations.

As only Web of Science (Core Collection) and Scopus (Elsevier) were used as two databases to extract literature for the bibliometric and content analysis, this choice may lead to omitting findings from other databases.

For example, researchers can consider mapping the available knowledge from gray literature sources. It is also crucial to approach the study findings with understanding, as only English-published academic literature was analyzed.

Other limitations come from the main focus of the research on WMS actions towards sustainability rather than, e.g., using eco-friendly materials in warehouse construction or utilizing renewable energy in warehouses. For the same reasons, technical-related studies, e.g., programming and developing algorithms, were not reviewed. The current research has identified ways to utilize WMS for positive social and environmental sustainability contributions.

Despite the abovementioned limitations, we see our work as contributing to a better understanding of the current literature on WMS and sustainability for new in-depth research gap fulfillment efforts.

Author Contributions

Conceptualization, D.M. and A.H.; methodology, D.M.; software, D.M.; validation, D.M. and A.H.; formal analysis, D.M.; investigation, D.M.; resources, D.M.; data curation, D.M.; writing—original draft preparation, D.M.; writing—review and editing, D.M. and A.H.; visualization, D.M.; supervision, A.H.; project administration, A.H.; funding acquisition, A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported and funded by the European Neighborhood instrument Cross-border Cooperation (ENI CBC) funded AWARE project under Grant KS1913.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Keywords Based on [39,43].

Table A1.

Keywords Based on [39,43].

| Selected Sustainability Keywords | Bartolini—Environmental Sustainability Terms | Glavič & Lukma—Sustainability Principles, Approaches & Sub-Systems |

|---|---|---|

| carbon | “carbon” | - |

| CO2 | “CO2” | - |

| control* | - | “pollution control”, “integrated pollution prevention and control” |

| clean* | - | “cleaner production” |

| degrad* | degradation | |

| eco | “eco” | “eco-design”, “eco-efficiency” |

| emission | “emission” | - |

| energ* | “energy” | - |

| environment* | “environment*” | “environmental engineering”, “environmental technology”, “environmental accounting”, “environmental legalisation”, “environmental management strategy”, “voluntary environmental agreement” |

| ethic* | - | “ethical investment” |

| green | “green” | “green chemistry” |

| health* | - | “safety and health” |

| “life cycle” | “life cycle” | “life cycle assessment” |

| renewabl* | - | “renewable resources” |

| repair* | - | repair |

| reus* | - | reuse |

| recover* | - | recovery |

| recycl* | - | recycling |

| reduc* | - | “source reduction” |

| regenerat* | - | regeneration |

| remanufactur* | - | remanufacturing |

| report* | - | reporting |

Appendix B

Table A2.

Combination of Keywords Used in Database Searches.

Table A2.

Combination of Keywords Used in Database Searches.

| Database | Keywords Combination |

|---|---|

| Scopus (Elsevier) | TITLE-ABS-KEY(“warehouse management system*”) AND TITLE-ABS-KEY(carbon OR CO2 OR control* OR clean* OR degrad* OR eco OR emission OR energ* OR environment* OR ethic* OR green OR health* OR “life cycle” OR renewabl* OR repair* OR reus* OR recover* OR recycl* OR reduc* OR revers* OR regenerat* OR remanufactur* OR report* OR resourc* OR responsib* OR pollut* OR prevent* OR minimis* OR minimiz* OR safe* OR social* OR sustain* OR waste*) |

| Web of Science (Core Collection) | TS = (“warehouse management system*”) AND TS = (carbon OR CO2 OR control* OR clean* OR degrad* OR eco OR emission OR energ* OR environment* OR ethic* OR green OR health* OR “life cycle” OR renewabl* OR repair* OR reus* OR recover* OR recycl* OR reduc* OR revers* OR regenerat* OR remanufactur* OR report* OR resourc* OR responsib* OR pollut* OR prevent* OR minimis* OR minimiz* OR safe* OR social* OR sustain* OR waste*) |

Appendix C

Table A3.

Full Details of Found 12 Articles on the Research Topic.

Table A3.

Full Details of Found 12 Articles on the Research Topic.

| Index Number | Authors | Title | Year | Journal Title | Publisher | Volume | Issue | Art. No. | Page Start | Page End |

| I | Andelkovic A.; Radosavljevic M. | Improving Order-picking Process Through Implementation of Warehouse Management System | 2018 | Strategic Management | University of Novi Sad, Faculty of Economics, Subotica | 23 | 1 | - | 3 | 10 |

| II | Goomas D.T.; Yeow P.H.P. | IT-assisted equipment safety checks system to improve compliance: A case study at a distribution center | 2013 | Safety Science | Elsevier | 60 | Dec. 2013 | - | 77 | 86 |

| III | Halawa F.; Dauod H.; Lee I.G.; Li Y.; Yoon S.W.; Chung S.H. | Introduction of a real time location system to enhance the warehouse safety and operational efficiency | 2020 | International Journal of Production Economics | Elsevier | 224 | - | 107541 | 1 | 21 |

| IV | Mostafa N.; Hamdy W.; Alawady H. | Impacts of internet of things on supply chains: A framework for warehousing | 2019 | Social Sciences | MDPI AG | 8 | 3 | 84 | 1 | 10 |

| V | Murauer N.; Pflanz N. | A full shift field study to evaluate user-and process-oriented aspects of smart glasses in automotive order picking processes | 2018 | Interaction Design and Architectures | Interaction Design & Architectures | - | 38 | - | 64 | 82 |

| VI | Passalacqua M.; Léger P.-M.; Nacke L.E.;Fredette M.; Labonté-Lemoyne É.; Lin X.; Caprioli T.; Sénécal S. | Playing in the backstore: interface gamification increases warehousing workforce engagement | 2020 | Industrial Management and Data Systems | Emerald Group Publishing Ltd. | 120 | 7 | - | 1309 | 1330 |

| VII | Periša M.; Kuljanić T.M.; Cvitić I.; Kolarovszki P. | Conceptual model for informing user with innovative smart wearable device in industry 4.0 | 2019 | Wireless Networks | Springer New York LLC | - | - | 1 | 12 | |

| VIII | Torabizadeh M.; Yusof N.M.; Ma’aram A.; Shaharoun A.M. | Identifying sustainable warehouse management system indicators and proposing new weighting method | 2020 | Journal of Cleaner Production | Elsevier | 248 | - | 119190 | 1 | 11 |

| IX | Trab S.; Bajic E.; Zouinkhi A.; Thomas A.; Abdelkrim M.N.; Chekir H.; Ltaief R.H. | A communicating object’s approach for smart logistics and safety issues in warehouses | 2017 | Concurrent Engineering Research and Applications | SAGE Publications Ltd | 25 | 1 | - | 53 | 67 |

| X | Trab S.; Zouinkhi A.; Bajic E.; Abdelkrim M.N.; Chekir H. | IoT-based risk monitoring system for safety management in warehouses | 2018 | International Journal of Information and Communication Technology | Inderscience Publishers | 13 | 4 | - | 424 | 438 |

| XI | Hamdy, W.; Al-Awamry, A.; Mostafa, N. | Warehousing 4.0: A proposed system of using node-red for applying internet of things in warehousing | 2022 | Sustainable Futures | Elsevier | - | 4 | 100069 | ||

| XII | Likhouzova, T., Demianova, Y. | Robot path optimization in warehouse management system | 2022 | Evolutionary Intelligence | - | - | - | - | ||

| Index number | DOI | Authors’ keywords | ISSN | Journal impact factor (Clarivate 2019) | Cited by Scopus | Cited by WoS | Cited by Google Scholar | Country/Territory | ||

| I | 10.5937/StraMan1801003A | Warehouse, process, warehouse management system, order-picking | 1821-3448 | - | - | 10 | 35 | Serbia | ||

| II | 10.1016/j.ssci.2013.07.002 | Compliance behavior, Computer technology, Equipment safety checks, Occupational Safety and Health Act (OSHA), Warehouse management system | - | 4.105 | 5 | 3 | 8 | United States, Malaysia | ||

| III | 10.1016/j.ijpe.2019.107541 | Data analytics, Industry 4.0, Real-time location system, Ultra-wide band, Warehouse management system | - | 5.134 | 38 | 32 | 55 | United States | ||

| IV | 10.3390/socsci8030084 | Industry 4.0, Internet of Things, Supply chain, Warehouse management system | 2076-0760 | - | 58 | 42 | 111 | Egypt | ||

| V | - | Augmented Reality, smart glasses, order picking processes, logistics, full shift usage | - | - | 9 | 6 | 11 | Germany | ||

| VI | 10.1108/IMDS-08-2019-0458 | Controlled experiment, Employee engagement, Gamification, NeuroIS, Warehouse management system (WMS) | - | 3.329 | 22 | 16 | 36 | United States, Canada | ||

| VII | 10.1007/s11276-019-02057-9 | Assistive technology, Internet of things, Smart environment, Wireless sensor network | - | 2.659 | 16 | 9 | 20 | Croatia, Slovakia | ||

| VIII | 10.1016/j.jclepro.2019.119190 | Multi-criteria analysis, Structural equation modeling (SEM), Sustainability key performance indicators (KPIs), Sustainable warehousing (SW), Weighting | - | 7.246 | 27 | 21 | 52 | Malaysia, Saudi Arabia | ||

| IX | 10.1177/1063293X16672508 | communicating object, interaction mechanisms, Internet of Things, modeling, safety, smart logistics, warehouse management system | 1063-293X | - | 31 | 25 | 50 | France, Tunisia | ||

| X | 10.1504/IJICT.2018.095032 | Intelligent product, Internet of things, IoT, Risk monitoring system, Safety management, Warehouse management system, WMS | - | - | 9 | - | 13 | France, Tunisia | ||

| XI | 10.1016/j.sftr.2022.100069 | Industry 4.0, Internet of things, Warehouse management system, Supply chain, Node-RED, MongoDB | - | - | 3 | 2 | 7 | Egypt | ||

| XII | 10.1007/s12065-021-00614-w | EVIN, Neural network, Ant colony optimization, Warehouse management system, Control system, Robotic device | 18645909 | - | 1 | 1 | 3 | Ukraine | ||

References

- Liu, Z.; Ciais, P.; Deng, Z.; Lei, R.; Davis, S.J.; Feng, S.; Zheng, B.; Cui, D.; Dou, X.; Zhu, B.; et al. Near-real-time monitoring of global CO2 emissions reveals the effects of the COVID-19 pandemic. Nat. Commun. 2020, 11, 5172. [Google Scholar] [CrossRef]

- Kortelainen, H.; Happonen, A.; Hanski, J. From Asset Provider to Knowledge Company—Transformation in the Digital Era. Asset Intelligence through Integration and Interoperability and Contemporary Vibration Engineering Technologies. In Lecture Notes in Mechanical Engineering; Mathew, J., Lim, C., Ma, L., Sands, D., Cholette, M., Borghesani, P., Eds.; Springer: Cham, Switzerland, 2019; pp. 333–341. [Google Scholar] [CrossRef]

- Fan, R.; Zhang, X.; Bizimana, A.; Zhou, T.; Liu, J.S.; Meng, X.Z. Achieving China’s carbon neutrality: Predicting driving factors of CO2 emission by artificial neural network. J. Clean. Prod. 2022, 362, 132331. [Google Scholar] [CrossRef]

- Wei, Y.-M.; Chen, K.; Kang, J.-N.; Chen, W.; Wang, X.-Y.; Zhang, X. Policy and Management of Carbon Peaking and Carbon Neutrality: A Literature Review. Engineering 2022, 14, 52–63. [Google Scholar] [CrossRef]

- Oubrahim, I.; Sefiani, N.; Happonen, A. Supply Chain Performance Evaluation Models: A Literature Review. Acta Logist. 2022, 9, 207–221. [Google Scholar] [CrossRef]

- Alcaraz, J.L.G.; Reza, J.R.D.; Soto, K.C.A.; Escobedo, G.H.; Happonen, A.; Puig I Vidal, R.; Macías, E.J. Effect of Green Supply Chain Management Practices on Environmental Performance: Case of Mexican Manufacturing Companies. Mathematics 2022, 10, 1877. [Google Scholar] [CrossRef]

- Ramaa, A.; Subramanya, K.N.; Rangaswamy, T.M. Impact of Warehouse Management System in a Supply Chain. Int. J. Comput. Appl. 2012, 54, 14–20. [Google Scholar] [CrossRef]

- EPA. Emerging Trends in Supply Chain Emissions Engagement. 2018. Available online: https://www.epa.gov/sites/production/files/2018-06/documents/emerging_trends_in_supply_chain_emissions_engagement.pdf (accessed on 30 May 2023).

- Bataille, C.; Waisman, H.; Briand, Y.; Svensson, J.; Vogt-Schilb, A.; Jaramillo, M.; Delgado, R.; Arguello, R.; Clarke, L.; Wild, T.; et al. Net-zero deep decarbonization pathways in Latin America: Challenges and opportunities. Energy Strat. Rev. 2020, 30, 100510. [Google Scholar] [CrossRef]

- Kordestani, A.; Peighambari, K.; Foster, T. Emerging trends in sustainability research: A look back as we begin to look forward. Int. J. Environ. Sustain. Dev. 2015, 14, 154. [Google Scholar] [CrossRef]

- Brenner, B.; Hartl, B. The perceived relationship between digitalization and ecological, economic, and social sustainability. J. Clean. Prod. 2021, 315, 128128. [Google Scholar] [CrossRef]

- Giganti, P.; Falcone, P.M. Strategic Niche Management for Sustainability: A Systematic Literature Review. Sustainability 2022, 14, 1680. [Google Scholar] [CrossRef]

- Ali, I.; Phan, H.M. Industry 4.0 technologies and sustainable warehousing: A systematic literature review and future research agenda. Int. J. Logist. Manag. 2022, 33, 644–662. [Google Scholar] [CrossRef]

- Aravindaraj, K.; Chinna, P.R. A systematic literature review of integration of industry 4.0 and warehouse management to achieve Sustainable Development Goals (SDGs). Clean. Logist. Supply Chain 2022, 5, 100072. [Google Scholar] [CrossRef]

- Freis, J.; Vohlidka, P.; Günthner, W.A. Low-Carbon Warehousing: Examining Impacts of Building and Intra-Logistics Design Options on Energy Demand and the CO2 Emissions of Logistics Centers. Sustainability 2016, 8, 448. [Google Scholar] [CrossRef]

- Doherty, S.; Hoyle, S. Supply Chain Decarbonization: Role of Transport and Logistics in Reducing Supply Chain Carbon Emissions, World Economic Forum Report. 2009. Available online: http://www3.weforum.org/docs/WEF_LT_SupplyChainDecarbonization_Report_2009.pdf (accessed on 30 May 2023).

- Rüdiger, D.; Schön, A.; Dobers, K. Managing Greenhouse Gas Emissions from Warehousing and Transshipment with Environmental Performance Indicators. Transp. Res. Procedia 2016, 14, 886–895. [Google Scholar] [CrossRef]

- Bank, R.; Murphy, R. Warehousing sustainability standards development. In IFIPAICT; Springer: Berlin/Heidelberg, Germany, 2013; Volume 414, pp. 294–301. [Google Scholar] [CrossRef]

- Perotti, S.; Prataviera, L.B.; Melacini, M. Assessing the environmental impact of logistics sites through CO2eq footprint computation. Bus. Strat. Environ. 2022, 31, 1679–1694. [Google Scholar] [CrossRef]

- Ries, J.M.; Grosse, E.H.; Fichtinger, J. Environmental impact of warehousing: A scenario analysis for the United States. Int. J. Prod. Res. 2017, 55, 6485–6499. [Google Scholar] [CrossRef]

- Burinskiene, A.; Lorenc, A.; Lerher, T. A Simulation Study for the Sustainability and Reduction of Waste in Warehouse Logistics. Int. J. Simul. Model. 2018, 17, 485–497. [Google Scholar] [CrossRef]

- Kusrini, E.; Ahmad, A.; Murniati, W. Design Key Performance Indicator for Sustainable Warehouse: A Case Study in a Leather Manufacturer. IOP Conf. Ser. Mater. Sci. Eng. 2019, 598, 012042. [Google Scholar] [CrossRef]

- Minashkina, D.; Happonen, A. Decarbonizing warehousing activities through digitalization and automatization with WMS integration for sustainability supporting operations. E3S Web Conf. 2020, 158, 03002. [Google Scholar] [CrossRef]

- VDI-Fachbereich Technische Logisti, 2015. VDI-Standard: VDI 3601. Available online: https://www.vdi.eu/nc/guidelines/vdi_3601-warehouse_management_systeme/ (accessed on 30 May 2023).

- Minashkina, D.; Happonen, A. Systematic literature review and research gap issues on third party logistics operators selecting WMS for efficient operations for customers. Int. J. Supply Chain Inventory Manag. 2020, 3, 142. [Google Scholar] [CrossRef]

- Faber, N.; de Koster, M.; Smidts, A. Organizing warehouse management. Int. J. Oper. Prod. Manag. 2013, 33, 1230–1256. [Google Scholar] [CrossRef]

- Torabizadeh, M.; Yusof, N.M.; Ma’aram, A.; Shaharoun, A.M. Identifying sustainable warehouse management system indicators and proposing new weighting method. J. Clean. Prod. 2019, 248, 119190. [Google Scholar] [CrossRef]

- Kraus, S.; Breier, M.; Dasí-Rodríguez, S. The art of crafting a systematic literature review in entrepreneurship research. Int. Entrep. Manag. J. 2020, 16, 1023–1042. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University: Keele, UK, 2004; Volume 33, pp. 1–26. [Google Scholar]

- Ganeshkumar, P.; Gopalakrishnan, S. Systematic reviews and meta-analysis: Understanding the best evidence in primary healthcare. J. Fam. Med. Prim. Care 2013, 2, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Glasziou, P.; Vandenbroucke, J.; Chalmers, I. Assessing the quality of research. BMJ 2004, 328, 39–41. [Google Scholar] [CrossRef]

- Siddaway, A. What Is a Systematic Literature Review and How Do I Do One; University of Stirling: Stirling, UK, 2014; Volume 1, pp. 1–13. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Durach, C.F.; Kembro, J.; Wieland, A. A New Paradigm for Systematic Literature Reviews in Supply Chain Management. J. Supply Chain Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- de Oliveira, O.J.; da Silva, F.F.; Juliani, F.; Barbosa, L.C.F.M.; Nunhes, T.V. Bibliometric method for mapping the state-of-the-art and identifying research gaps and trends in literature: An essential instrument to support the development of scientific projects. In Scientometrics Recent Advances; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- United Nations General Assembly. Report of the World Commission on Environment and Development: Our Common Future; United Nations General Assembly, Development and International Co-operation: Oslo, Norway, 1987. [Google Scholar]

- Malinowska, M.; Rzeczycki, A.; Sowa, M. Roadmap to sustainable warehouse. In SHS Web of Conferences; EDP Sciences: Les Ulis, France, 2018; p. 01028. [Google Scholar] [CrossRef]

- Bartolini, M.; Bottani, E.; Grosse, E.H. Green warehousing: Systematic literature review and bibliometric analysis. J. Clean. Prod. 2019, 226, 242–258. [Google Scholar] [CrossRef]

- Gusenbauer, M.; Haddaway, N.R. Which academic search systems are suitable for systematic reviews or meta-analyses? Evaluating retrieval qualities of Google Scholar, PubMed, and 26 other resources. Res. Synth. Methods 2020, 11, 181–217. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Burnham, J.F.; Lemley, T.; Britton, R.M. Citation analysis: Comparison of Web of Science, Scopus, SciFinder, and Google Scholar. J. Electron. Resour. Med. Libr. 2010, 7, 196–217. [Google Scholar] [CrossRef]

- Čablová, L.; Pates, R.; Miovský, M.; Noel, J. How to write a systematic review article and meta-analysis. In Addiction Science: A Guide for the Perplexed; Ubiquity Press: London, UK, 2017; pp. 173–189. [Google Scholar] [CrossRef]

- Glavič, P.; Lukman, R. Review of sustainability terms and their definitions. J. Clean. Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Anđelković, A.; Radosavljević, M. Improving order-picking process through implementation of warehouse management system. Strat. Manag. 2018, 23, 3–10. [Google Scholar] [CrossRef]

- Goomas, D.T.; Yeow, P.H. IT-assisted equipment safety checks system to improve compliance: A case study at a distribution center. Saf. Sci. 2013, 60, 77–86. [Google Scholar] [CrossRef]

- Halawa, F.; Dauod, H.; Lee, I.G.; Li, Y.; Yoon, S.W.; Chung, S.H. Introduction of a real time location system to enhance the warehouse safety and operational efficiency. Int. J. Prod. Econ. 2020, 224, 107541. [Google Scholar] [CrossRef]

- Mostafa, N.; Hamdy, W.; Alawady, H. Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Soc. Sci. 2019, 8, 84. [Google Scholar] [CrossRef]

- Murauer, N.; Pflanz, N. A full shift field study to evaluate user- and process-oriented aspects of smart glasses in automotive order picking processes. Interact. Des. Arch. 2018, 38, 64–82. [Google Scholar] [CrossRef]

- Passalacqua, M.; Léger, P.-M.; Nacke, L.E.; Fredette, M.; Labonté-Lemoyne, É.; Lin, X.; Caprioli, T.; Sénécal, S. Playing in the backstore: Interface gamification increases warehousing workforce engagement. Ind. Manag. Data Syst. 2020, 120, 1309–1330. [Google Scholar] [CrossRef]

- Periša, M.; Kuljanić, T.M.; Cvitić, I.; Kolarovszki, P. Conceptual model for informing user with innovative smart wearable device in industry 4.0. Wirel. Netw. 2021, 27, 1615–1626. [Google Scholar] [CrossRef]

- Trab, S.; Bajic, E.; Zouinkhi, A.; Thomas, A.; Abdelkrim, M.N.; Chekir, H.; Ltaief, R.H. A communicating object’s approach for smart logistics and safety issues in warehouses. Concurr. Eng. 2016, 25, 53–67. [Google Scholar] [CrossRef]

- Trab, S.; Zouinkhi, A.; Bajic, E.; Abdelkrim, M.N.; Chekir, H. IoT-based risk monitoring system for safety management in warehouses. Int. J. Inf. Commun. Technol. 2018, 13, 424–438. [Google Scholar] [CrossRef]

- Hamdy, W.; Al-Awamry, A.; Mostafa, N. Warehousing 4.0: A proposed system of using node-red for applying internet of things in warehousing. Sustain. Futur. 2022, 4, 100069. [Google Scholar] [CrossRef]

- Likhouzova, T.; Demianova, Y. Robot path optimization in warehouse management system. Evol. Intell. 2022, 15, 2589–2595. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Staudt, F.H.; Alpan, G.; Di Mascolo, M.; Rodriguez, C.M.T. Warehouse performance measurement: A literature review. Int. J. Prod. Res. 2015, 53, 5524–5544. [Google Scholar] [CrossRef]

- Glock, C.; Lange, A.; Grosse, E.H.; Das, A. Celebrating the 10th volume of IJISM: A bibliographic review and outlook. Int. J. Integr. Supply Manag. 2017, 11, 332. [Google Scholar] [CrossRef]

- Spacer Marketing Team. Largest Warehouses in the World. 2021. Available online: https://www.spacer.com.au/blog/largest-warehouses-in-the-world (accessed on 30 May 2023).

- Babaii, E.; Taase, Y. Author-assigned keywords in research articles: Where do they come from. Iran. J. Appl. Linguist. 2013, 16, 1–19. [Google Scholar]

- Galeazzo, A.; Furlan, A.; Vinelli, A. The role of employees’ participation and managers’ authority on continuous improvement and performance. Int. J. Oper. Prod. Manag. 2021, 41, 34–64. [Google Scholar] [CrossRef]

- Richards, G. Warehouse Management: A Complete Guide to Improving Efficiency and Minimizing Costs in the Modern Warehouse, 3rd ed.; Kogan Page Publishers: London, UK, 2017; p. 528. Available online: https://www.koganpage.com/product/warehouse-management-9780749479770 (accessed on 30 May 2023).

- Andiyappillai, N. Digital Transformation in Warehouse Management Systems (WMS) Implementations. Int. J. Comput. Appl. 2020, 177, 34–37. [Google Scholar] [CrossRef]