Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform

Abstract

:1. Introduction

2. Theoretical Background

2.1. Biomass Energy: Characteristics and Challenges in SC Management

2.2. Lean Philosophy, Lean Tools, LIM, and BPMN

2.3. The Information Systems and the Supply Chain

3. Materials and Methods

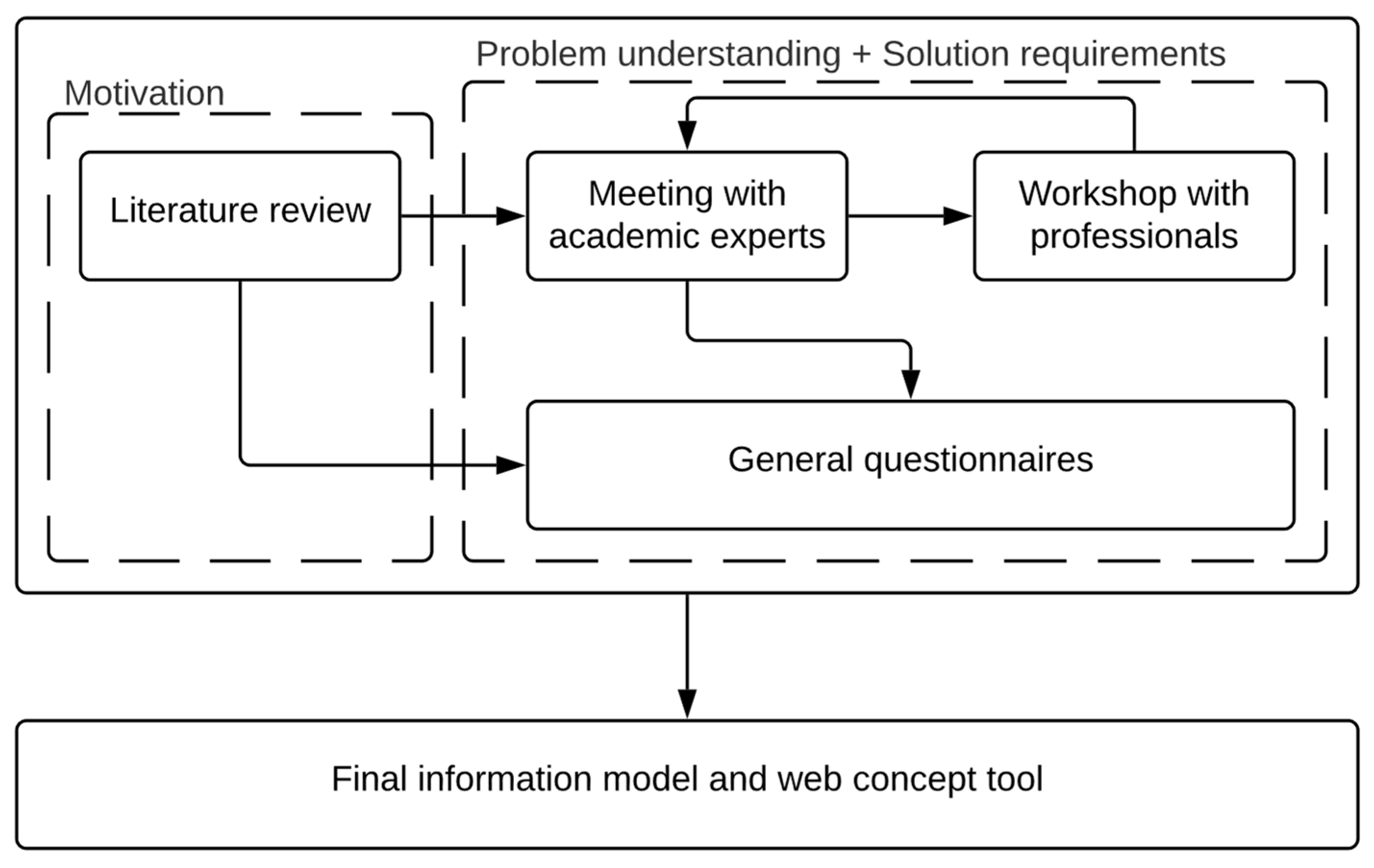

3.1. Methodological Approach

3.2. Data Collection and Data Analysis

4. Practical Vision (The Workshop Notes and Questionnaire Conclusions)

4.1. The Workshop Notes

4.1.1. Supply Perspective

4.1.2. Demand Perspective

4.2. Questionnaire Insights

5. Results

5.1. Actual Scenario of the Residual Biomass Supply Chain

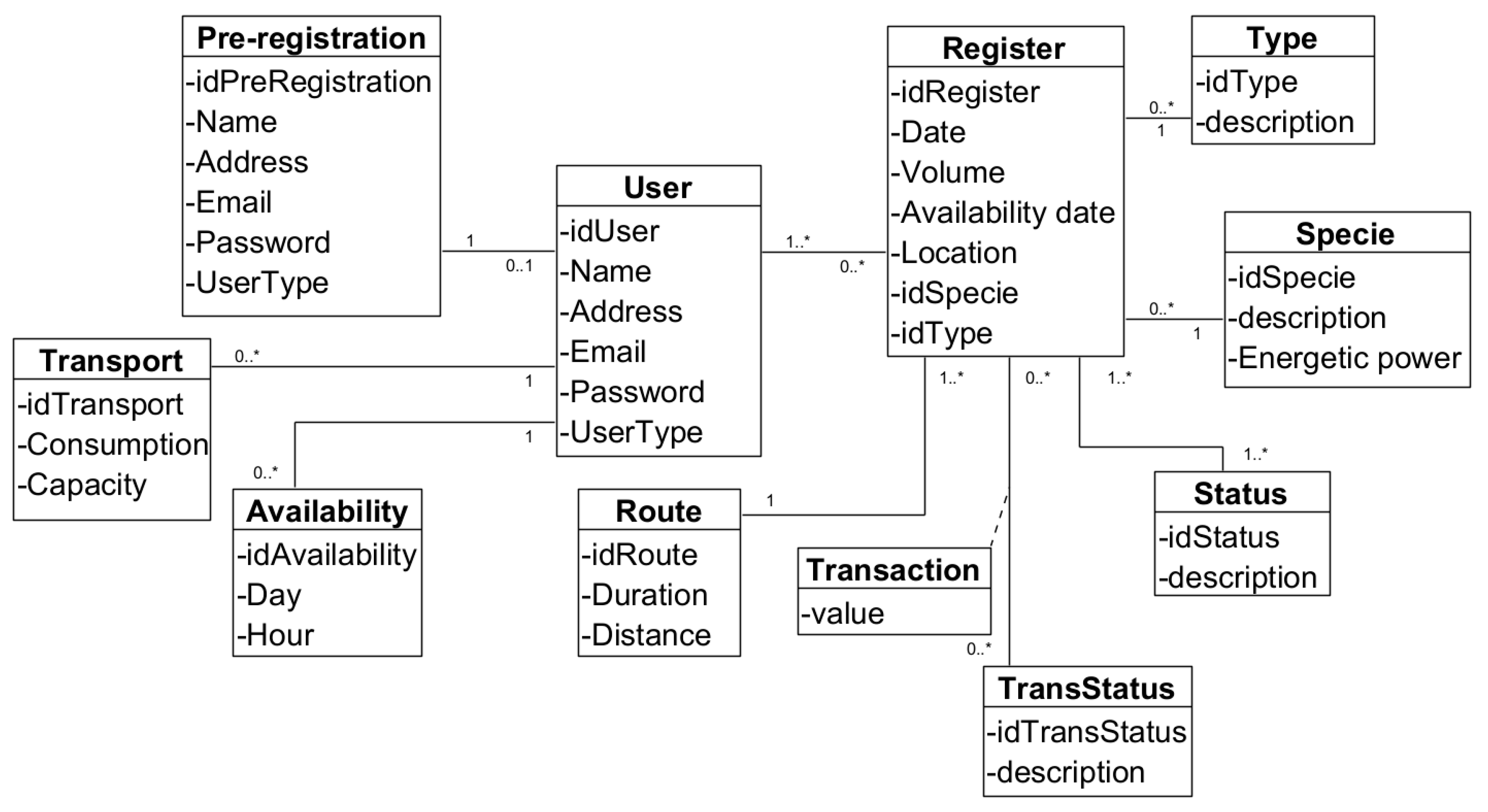

5.2. Conceptual Model of the Proposed Solution

5.3. The Information Process Flow—To-Be Model

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Azarpour, A.; Mohammadzadeh, O.; Rezaei, N.; Zendehboudi, S. Current status and future prospects of renewable and sustainable energy in North America: Progress and challenges. Energy Convers. Manag. 2022, 269, 115945. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Chai, Y.H.; Yusup, S. Biomass energy in Malaysia: Current scenario, policies, and implementation challenges. Bioenergy Res. 2022, 15, 1371–1386. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Raza, S.A.; Adebayo, T.S.; Yi, S.; Shah, M.I. The roles of hydro, nuclear and biomass energy towards carbon neutrality target in China: A policy-based analysis. Energy 2023, 262, 125303. [Google Scholar] [CrossRef]

- Umar, M.; Ji, X.; Kirikkaleli, D.; Alola, A.A. The imperativeness of environmental quality in the United States transportation sector amidst biomass-fossil energy consumption and growth. J. Clean. Prod. 2021, 285, 124863. [Google Scholar] [CrossRef]

- Philipp, R. Blockchain for LBG maritime energy contracting and value chain management: A green shipping business model for seaports. Rigas Teh. Univ. Zinat. Raksti 2020, 24, 329–349. [Google Scholar] [CrossRef]

- Tehrani, M.M.; Akhtari, M.; Kasaeian, A.; Rad, M.A.V.; Toopshekan, A.; Motlagh, M.S. Techno-economic investigation of a hybrid biomass renewable energy system to achieve the goals of SDG-17 in deprived areas of Iran. Energy Convers. Manag. 2023, 291, 117319. [Google Scholar] [CrossRef]

- Pocha, C.K.R.; Chia, W.Y.; Kurniawan, T.A.; Khoo, K.S.; Chew, K.W. Thermochemical conversion of different biomass feedstocks into hydrogen for power plant electricity generation. Fuel 2023, 340, 127472. [Google Scholar] [CrossRef]

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Lu, H.; Yadav, V.; Bilal, M.; Iqbal, H.M. Bioprospecting microbial hosts to valorize lignocellulose biomass—Environmental perspectives and value-added bioproducts. Chemosphere 2022, 288, 132574. [Google Scholar] [CrossRef]

- M’Arimi, M.; Mecha, C.; Kiprop, A.; Ramkat, R. Recent trends in applications of advanced oxidation processes (AOPs) in bioenergy production. Renew. Sustain. Energy Rev. 2020, 121, 109669. [Google Scholar] [CrossRef]

- Bullock, R.C.; Zurba, M.; Parkins, J.R.; Skudra, M. Open for bioenergy business? Perspectives from Indigenous business leaders on biomass development potential in Canada. Energy Res. Soc. Sci. 2020, 64, 101446. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Mofijur, M.; Chowdhury, S.N.; Nahrin, M.; Rafa, N.; Chowdhury, A.T.; Nuzhat, S.; Ong, H.C. Pathways of lignocellulosic biomass deconstruction for biofuel and value-added products production. Fuel 2022, 318, 123618. [Google Scholar] [CrossRef]

- San Martin, D.; Orive, M.; Martinez, E.; Inarra, B.; Ramos, S.; Gonzalez, N.; Guinea de Salas, A.; Vázquez, L.A.; Zufia, J. Multi-criteria assessment of the viability of valorising vegetable by-products from the distribution as secondary raw material for animal feed. Environ. Sci. Pollut. Res. 2021, 28, 15716–15730. [Google Scholar] [CrossRef] [PubMed]

- Kramarz, M.; Kmiecik, M. Quality of Forecasts as the Factor Determining the Coordination of Logistics Processes by Logistic Operator. Sustainability 2022, 14, 1013. [Google Scholar] [CrossRef]

- Escobar, N.; Laibach, N. Sustainability check for bio-based technologies: A review of process-based and life cycle approaches. Renew. Sustain. Energy Rev. 2021, 135, 110213. [Google Scholar] [CrossRef]

- Gebeyehu, S.G.; Abebe, M.; Gochel, A. Production lead time improvement through lean manufacturing. Cogent Eng. 2022, 9, 2034255. [Google Scholar] [CrossRef]

- Redeker, G.A.; Kessler, G.Z.; Kipper, L.M. Lean information for lean communication: Analysis of concepts, tools, references, and terms. Int. J. Inf. Manag. 2019, 47, 31–43. [Google Scholar] [CrossRef]

- Klimecka-Tatar, D.; Ingaldi, M. How to indicate the areas for improvement in service process-the Knowledge Management and Value Stream Mapping as the crucial elements of the business approach. Rev. Gestão Tecnol. 2020, 20, 52–74. [Google Scholar] [CrossRef]

- Holechek, J.L.; Geli, H.M.; Sawalhah, M.N.; Valdez, R. A global assessment: Can renewable energy replace fossil fuels by 2050? Sustainability 2022, 14, 4792. [Google Scholar] [CrossRef]

- Hoang, A.T.; Huang, Z.; Nižetić, S.; Pandey, A.; Nguyen, X.P.; Luque, R.; Ong, H.C.; Said, Z.; Le, T.H. Characteristics of hydrogen production from steam gasification of plant-originated lignocellulosic biomass and its prospects in Vietnam. Int. J. Hydrogen Energy 2022, 47, 4394–4425. [Google Scholar] [CrossRef]

- Chung, M.J.; Wang, S.Y. Physical and mechanical properties of composites made from bamboo and woody wastes in Taiwan. J. Wood Sci. 2019, 65, 1–10. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, W. China’s energy transition pathway in a carbon neutral vision. Engineering 2022, 14, 64–76. [Google Scholar] [CrossRef]

- Diez, M.A.; Centeno, T.A.; Amado-Fierro, Á. Coal use for iron and steel production in low-carbon transition scenarios. In The Coal Handbook; Elsevier: Amsterdam, The Netherlands, 2023; pp. 493–546. [Google Scholar]

- Durmaz, Y.G.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Gupta, J.; Kumari, M.; Mishra, A.; Akram, M.; Thakur, I.S. Agro-forestry waste management-A review. Chemosphere 2022, 287, 132321. [Google Scholar] [CrossRef] [PubMed]

- Kaniapan, S.; Hassan, S.; Ya, H.; Patma Nesan, K.; Azeem, M. The utilisation of palm oil and oil palm residues and the related challenges as a sustainable alternative in biofuel, bioenergy, and transportation sector: A review. Sustainability 2021, 13, 3110. [Google Scholar] [CrossRef]

- Osman, A.I.; Chen, L.; Yang, M.; Msigwa, G.; Farghali, M.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Cost, environmental impact, and resilience of renewable energy under a changing climate: A review. Environ. Chem. Lett. 2023, 21, 741–764. [Google Scholar] [CrossRef]

- Rossi, A.H.G.; Marcondes, G.B.; Pontes, J.; Leitão, P.; Treinta, F.T.; De Resende, L.M.M.; Mosconi, E.; Yoshino, R.T. Lean tools in the context of industry 4.0: Literature review, implementation and trends. Sustainability 2022, 14, 12295. [Google Scholar] [CrossRef]

- Vlachos, I.P.; Pascazzi, R.M.; Zobolas, G.; Repoussis, P.; Giannakis, M. Lean manufacturing systems in the area of Industry 4.0: A lean automation plan of AGVs/IoT integration. Prod. Plan. Control. 2023, 34, 345–358. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhang, D.; Huang, C.; Zhang, H.; Dai, N.; Song, Y.; Chen, H. Artificial intelligence in sustainable energy industry: Status Quo, challenges and opportunities. J. Clean. Prod. 2021, 289, 125834. [Google Scholar] [CrossRef]

- Al Robaaiy, M.S.D.; Rahima, M.A.; Alghazali, M.H. Application the Kanban Cards and the Value Stream Map (Vsm) to Rationalize Inventory Costs and to Improve The Company’s Performance and Oversight Applied Research in Electrical Cables Factory/Ur State Company For Electrical Industries. Int. J. Prof. Bus. Rev. Int. J. Prof. Bus. Rev. 2023, 8, 20. [Google Scholar] [CrossRef]

- de Paula Ferreira, W.; Armellini, F.; de Santa-Eulalia, L.A.; Thomasset-Laperrière, V. Extending the lean value stream mapping to the context of Industry 4.0: An agent-based technology approach. J. Manuf. Syst. 2022, 63, 1–14. [Google Scholar] [CrossRef]

- Becher, M.; Herr, D.; Müller, C.; Kurzhals, K.; Reina, G.; Wagner, L.; Ertl, T.; Weiskopf, D. Situated visual analysis and live monitoring for manufacturing. IEEE Comput. Graph. Appl. 2022, 42, 33–44. [Google Scholar] [CrossRef] [PubMed]

- Elattar, S.; Mohamed, H.G.; Hussien, S.A. A Multi-Objective Optimization of Secure Pull Manufacturing Systems. Appl. Sci. 2022, 12, 5937. [Google Scholar] [CrossRef]

- Medne, A.; Lapina, I. Sustainability and continuous improvement of organization: Review of process-oriented performance indicators. J. Open Innov. Technol. Mark. Complex. 2019, 5, 49. [Google Scholar] [CrossRef]

- Klein, L.L.; Tonetto, M.S.; Avila, L.V.; Moreira, R. Management of lean waste in a public higher education institution. J. Clean. Prod. 2021, 286, 125386. [Google Scholar] [CrossRef]

- Aravindh, M.D.; Nakkeeran, G.; Krishnaraj, L.; Arivusudar, N. Evaluation and optimization of lean waste in construction industry. Asian J. Civ. Eng. 2022, 23, 741–752. [Google Scholar] [CrossRef]

- Mulyana, I.J.; Singgih, M.L.; Partiwi, S.G.; Hermanto, Y.B. Identification and Prioritization of Lean Waste in Higher Education Institutions (HEI): A Proposed Framework. Educ. Sci. 2023, 13, 137. [Google Scholar] [CrossRef]

- Mahdi, O.R.; Nassar, I.A. The business model of sustainable competitive advantage through strategic leadership capabilities and knowledge management processes to overcome COVID-19 pandemic. Sustainability 2021, 13, 9891. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Fosso Wamba, S.; Machado, M.C.; Telles, R. Smart production systems drivers for business process management improvement: An integrative framework. Bus. Process Manag. J. 2020, 26, 1075–1092. [Google Scholar] [CrossRef]

- Gaborov, M.; Ivetić, D. The importance of integrating Thinking Design, User Experience and Agile methodologies to increase profitability. J. Appl. Tech. Educ. Sci. 2022, 12, 1–17. [Google Scholar]

- Durán, F.; Rocha, C.; Salaün, G. Resource provisioning strategies for BPMN processes: Specification and analysis using Maude. J. Log. Algebr. Methods Program. 2021, 123, 100711. [Google Scholar] [CrossRef]

- Hikmah, D. Media for language teaching and learning in digital era. Int. J. Engl. Educ. Linguist. (IJoEEL) 2019, 1, 36–41. [Google Scholar] [CrossRef]

- Alowad, A.; Samaranayake, P.; Ahsan, K.; Alidrisi, H.; Karim, A. Enhancing patient flow in emergency department (ED) using lean strategies–an integrated voice of customer and voice of process perspective. Bus. Process Manag. J. 2021, 27, 75–105. [Google Scholar] [CrossRef]

- Yücenur, G.N.; Şenol, K. Sequential SWARA and fuzzy VIKOR methods in elimination of waste and creation of lean construction processes. J. Build. Eng. 2021, 44, 103196. [Google Scholar] [CrossRef]

- Remko, V.H. Research opportunities for a more resilient post-COVID-19 supply chain–closing the gap between research findings and industry practice. Int. J. Oper. Prod. Manag. 2020, 40, 341–355. [Google Scholar] [CrossRef]

- Omar, I.A.; Jayaraman, R.; Debe, M.S.; Hasan, H.R.; Salah, K.; Omar, M. Supply chain inventory sharing using ethereum blockchain and smart contracts. IEEE Access 2021, 10, 2345–2356. [Google Scholar] [CrossRef]

- Kumar, B.; Sharma, A. Managing the supply chain during disruptions: Developing a framework for decision-making. Ind. Mark. Manag. 2021, 97, 159–172. [Google Scholar] [CrossRef]

- Pangaribuan, G.P.; Nender, R.; Fitrina, R.; Sugiyanto, S. The Analysis of the Effectiveness of Delivery Order (DO) Online on Import Activities at Terminal 3 International PT. IPC TPK. Adv. Transp. Logist. Res. 2021, 4, 935–947. [Google Scholar]

- Gorgan, C.; Chersan, I.-C.; Dragomir, V.D.; Dumitru, M. Food waste prevention solutions in the annual reports of European companies. Amfiteatru Econ. 2022, 24, 309–329. [Google Scholar] [CrossRef]

- Choi, T.M.; Kumar, S.; Yue, X.; Chan, H.L. Disruptive technologies and operations management in the Industry 4.0 era and beyond. Prod. Oper. Manag. 2022, 31, 9–31. [Google Scholar] [CrossRef]

- Horstink, L.; Wittmayer, J.M.; Ng, K.; Luz, G.P.; Marín-González, E.; Gährs, S.; Campos, I.; Holstenkamp, L.; Oxenaar, S.; Brown, D. Collective renewable energy prosumers and the promises of the energy union: Taking stock. Energies 2020, 13, 421. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Kang, K.; Klinghoffer, N.B.; ElGhamrawy, I.; Berruti, F. Thermochemical conversion of agroforestry biomass and solid waste using decentralized and mobile systems for renewable energy and products. Renew. Sustain. Energy Rev. 2021, 149, 111372. [Google Scholar] [CrossRef]

- Budiman, I. The complexity of barriers to biogas digester dissemination in Indonesia: Challenges for agriculture waste management. J. Mater. Cycles Waste Manag. 2021, 23, 1918–1929. [Google Scholar] [CrossRef]

- Ngwira, S.; Watanabe, T. An analysis of the causes of deforestation in Malawi: A case of Mwazisi. Land 2019, 8, 48. [Google Scholar] [CrossRef]

- Ouro Salim, O.; Guarnieri, P. Circular economy of food waste: A literature review. Environ. Qual. Manag. 2022, 32, 225–242. [Google Scholar] [CrossRef]

- Chen, M.; Chen, J.; Zhou, W.; Han, X.; Yao, Y.; Wong, C.P. Realizing an all-round hydrogel electrolyte toward environmentally adaptive dendrite-free aqueous Zn-MnO2 batteries. Adv. Mater. 2021, 33, 2007559. [Google Scholar] [CrossRef] [PubMed]

- Budholiya, K.; Shrivastava, S.K.; Sharma, V. An optimized XGBoost based diagnostic system for effective prediction of heart disease. J. King Saud Univ. Comput. Inf. Sci. 2022, 34, 4514–4523. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R.; Khan, S. Exploring relationships between Lean 4.0 and manufacturing industry. Ind. Robot. Int. J. Robot. Res. Appl. 2022, 49, 402–414. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital twin for supply chain coordination in modular construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Upadhyay, A.; Mukhuty, S.; Kumari, S.; Garza-Reyes, J.A.; Shukla, V. A review of lean and agile management in humanitarian supply chains: Analysing the pre-disaster and post-disaster phases and future directions. Prod. Plan. Control. 2022, 33, 641–654. [Google Scholar] [CrossRef]

- Yuik, C.J.; Puvanasvaran, P. Development of lean manufacturing implementation framework in machinery and equipment SMEs. Int. J. Ind. Eng. Manag. 2020, 11, 157. [Google Scholar] [CrossRef]

- Gross, S.; Stelzl, K.; Grisold, T.; Mendling, J.; Röglinger, M.; vom Brocke, J. The Business Process Design Space for exploring process redesign alternatives. Bus. Process Manag. J. 2021, 27, 25–56. [Google Scholar] [CrossRef]

| (a) | What do you consider to be your level of motivation to contribute to the valorization/reuse of agroforestry leftovers? |

| (b) | Please indicate the degree of importance you give to the valorization of agroforestry leftovers. |

| (c) | Please indicate the degree of importance you give to the implementation of a project with the characteristics of this one in your municipality. |

| Requirements for producer: | |

| (d) | Enter the characteristics of agroforestry leftovers from his/her properties (e.g., species, type of leftovers, and quantity). |

| (e) | Enter the data that characterizes the way his/her agroforestry leftovers is available (e.g., place and date). |

| (f) | Request cleaning services for my land/forest. |

| (g) | Visualize on a map the location of the consumption centers of this type of waste. |

| Requirements for transporter/consumer/receiver: | |

| (h) | Visualize the collection points and availability of agroforestry leftovers (e.g., google maps). |

| (i) | View the characteristics of the leftovers available for collection. |

| (j) | Enter on the platform the receipt of the agroforestry leftovers when it was delivered to him. |

| (k) | Having an agile communication channel with the producers of agroforestry leftovers |

| Requirements for member of political authority: | |

| (l) | Knowing the state of cleanliness of the properties in your municipality. |

| (m) | Contribute to the management of the platform by registering users of the platform. |

| (n) | View indicators on the agroforestry/biomass supply chain. |

| (o) | Have an agile channel to communicate with the owners of potential sources of agroforestry leftovers. |

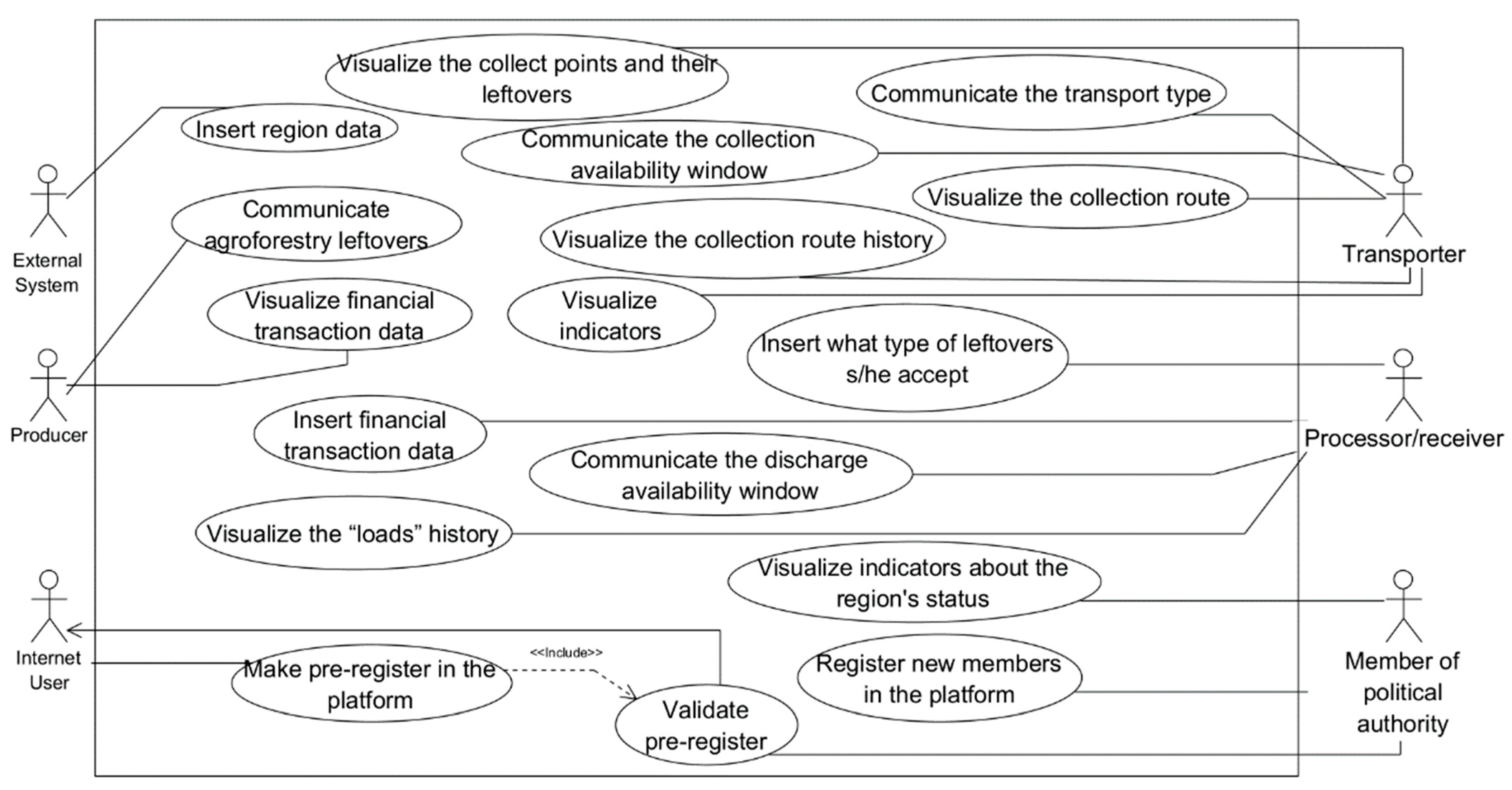

| Stakeholder | Requirements |

|---|---|

| Internet user | Make pre-registration in the platform |

| Producer | Communicate agroforestry leftovers Visualize financial transaction data |

| Transporter | Visualize the collection route Visualize the collection route history Visualize indicators Communicate the collection availability window Communicate the transport type (capacity, fuel usage…) Visualize the collection points and their leftovers |

| Processor/receiver | Insert what type of leftovers are accepted Communicate the discharge availability window Visualize the “loads” history Insert financial transaction data |

| Member of political authority | Visualize indicators about the region’s status Register new members in the platform Validate pre-registration made by possible users |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastos, T.; Teixeira, L.C.; Matias, J.C.O.; Nunes, L.J.R. Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform. Logistics 2023, 7, 56. https://doi.org/10.3390/logistics7030056

Bastos T, Teixeira LC, Matias JCO, Nunes LJR. Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform. Logistics. 2023; 7(3):56. https://doi.org/10.3390/logistics7030056

Chicago/Turabian StyleBastos, Tiago, Leonor C. Teixeira, João C. O. Matias, and Leonel J. R. Nunes. 2023. "Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform" Logistics 7, no. 3: 56. https://doi.org/10.3390/logistics7030056

APA StyleBastos, T., Teixeira, L. C., Matias, J. C. O., & Nunes, L. J. R. (2023). Agroforestry Biomass Recovery Supply Chain Management: A More Efficient Information Flow Model Based on a Web Platform. Logistics, 7(3), 56. https://doi.org/10.3390/logistics7030056