Analyzing the Implementation of Digital Twins in the Agri-Food Supply Chain

Abstract

1. Introduction

2. Theoretical Background

2.1. Challenges in the Agri-Food Supply Chain

2.2. Supply Chain DTs

3. Methodology

3.1. Data Sources and Keywords Definition

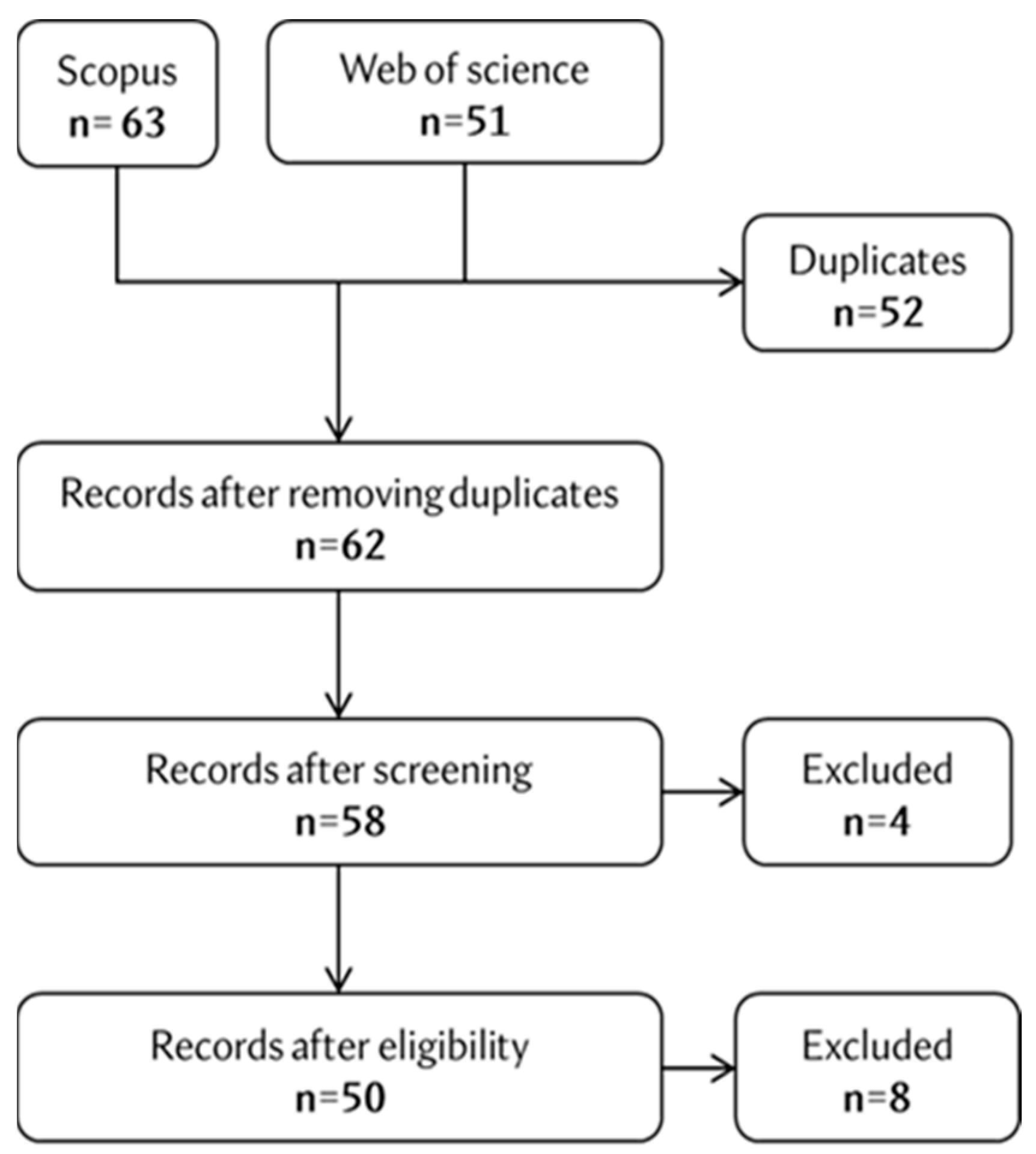

3.2. Screening and Eligibility Check

- SEC1—Is it a peer-reviewed journal article, a book chapter, a review, or a conference paper?

- SEC2—Does the document illustrate the use of DTs in the agri-food supply chain?

- EEC1—Is the full document available for reading?

- EEC2—Does the paper discuss digital models, digital shadows, or DTs in the agri-food supply chain?

- EEC3—Does the paper answer at least one of the research questions that have already been set?

4. Analysis and Discussion

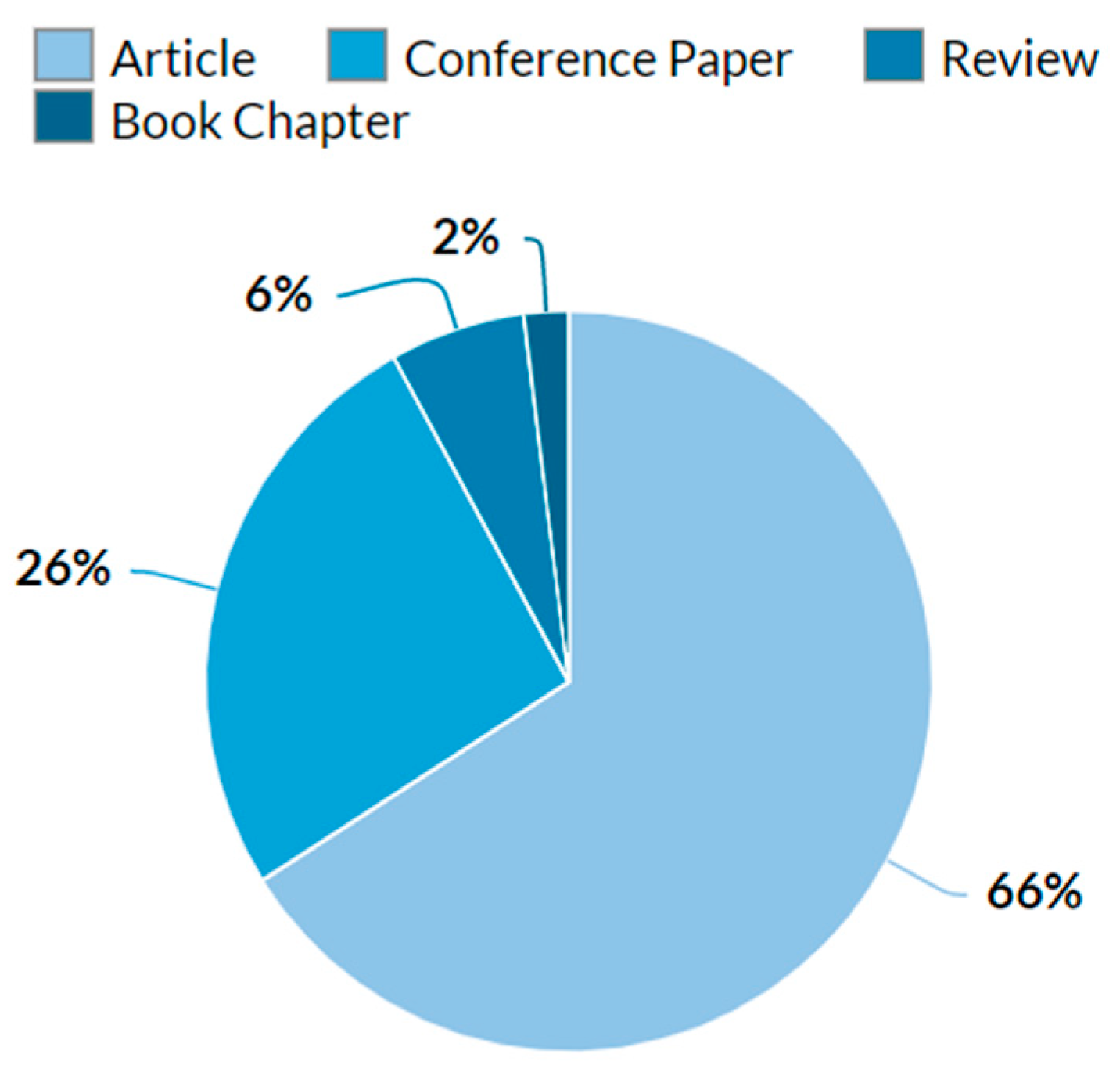

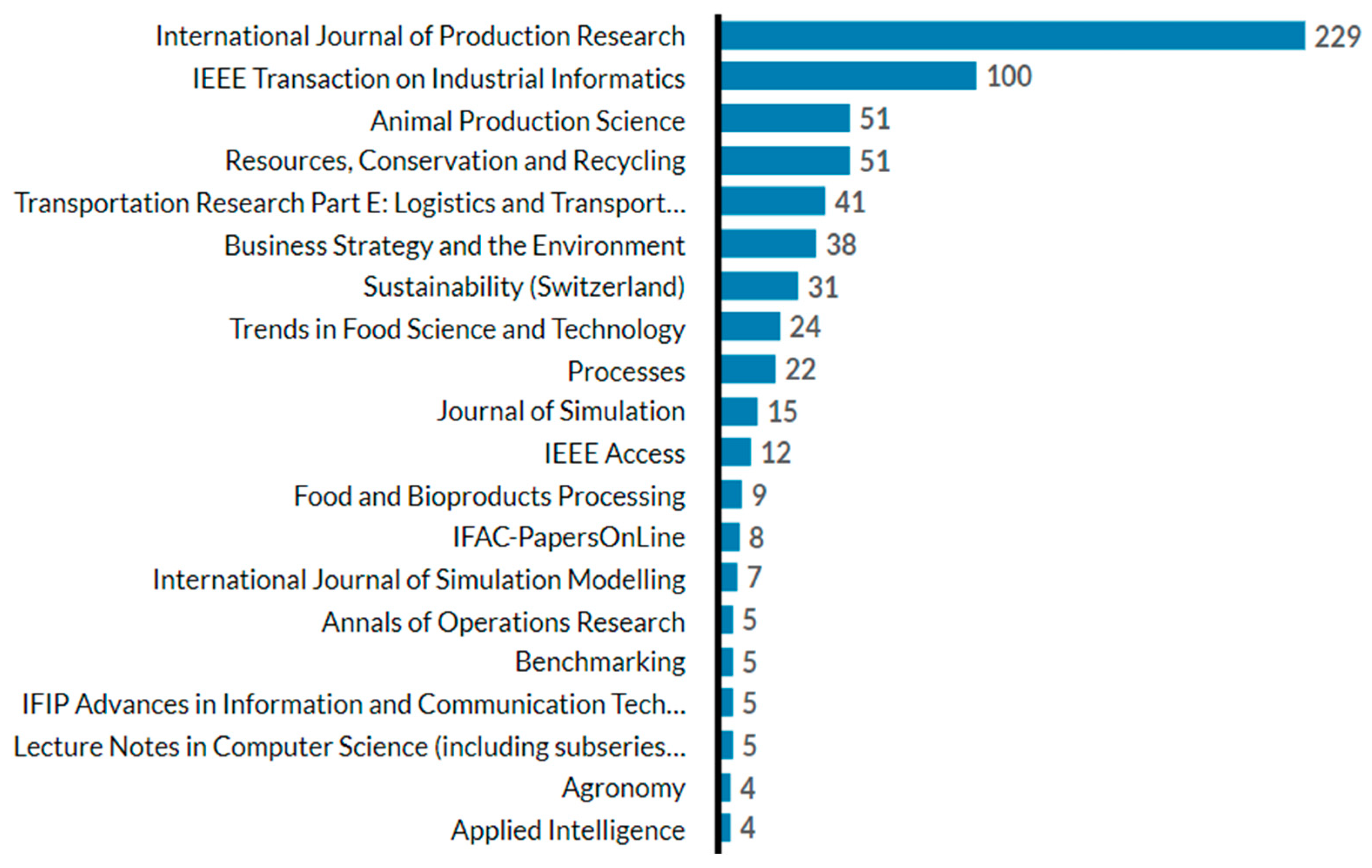

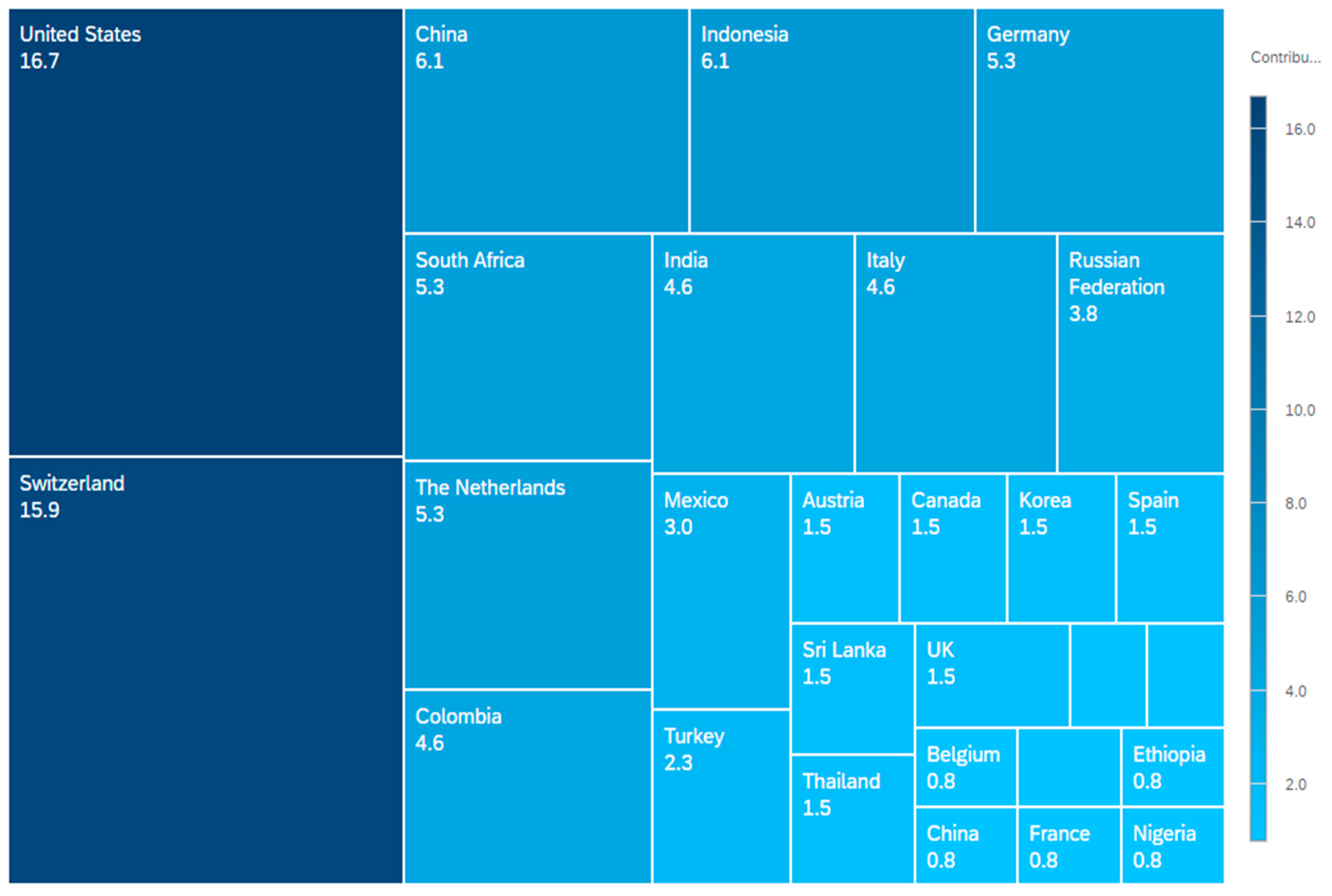

4.1. Descriptive Analysis of Selected Studies

4.2. Discussion of Results with Respect to the Research Questions

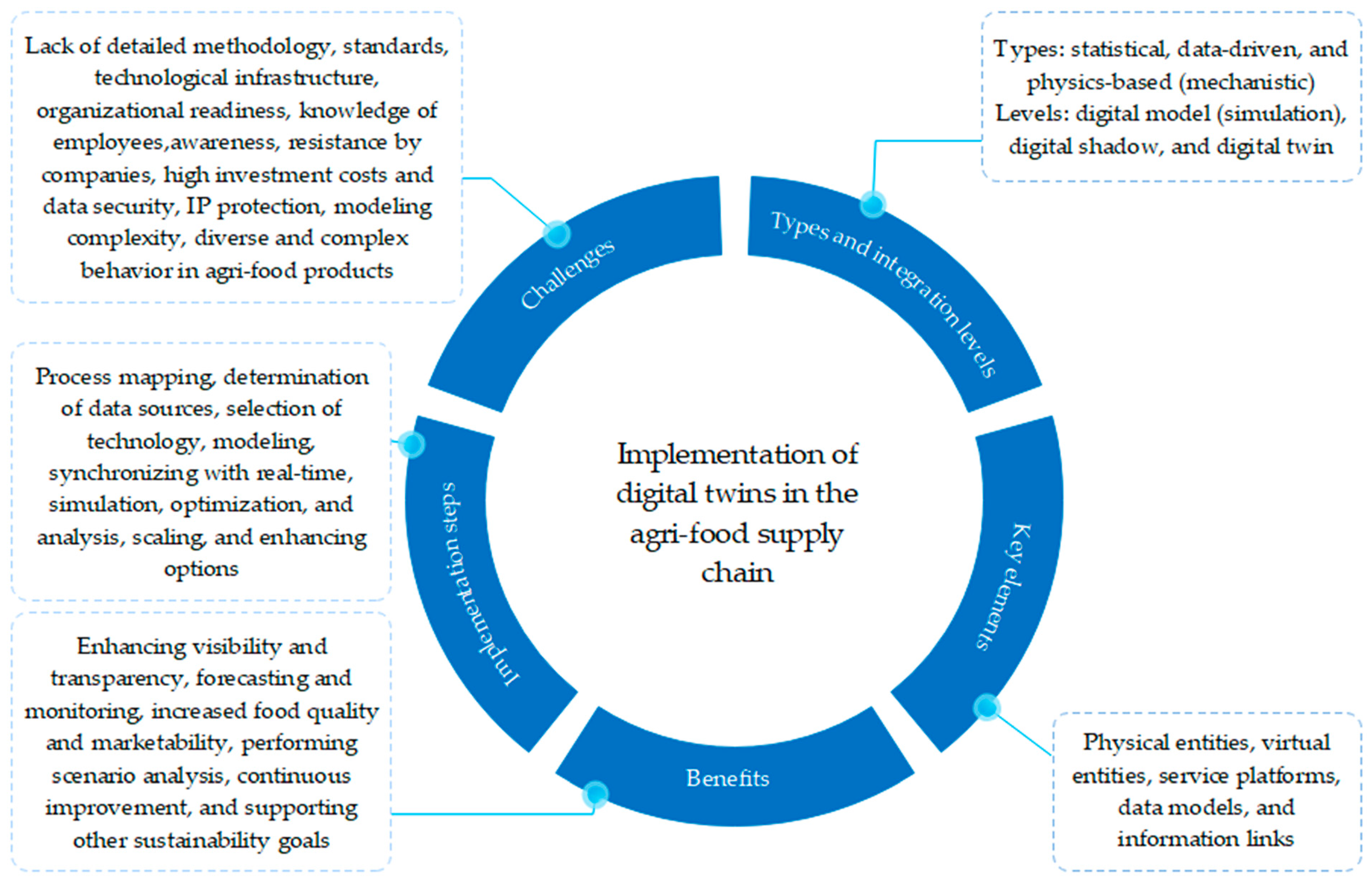

4.2.1. Contributions of DTs to the Agri-Food Supply Chain (RQ1)

4.2.2. Key Elements in DT Implementation (RQ2)

4.2.3. Types and Levels of DT Integration (RQ3)

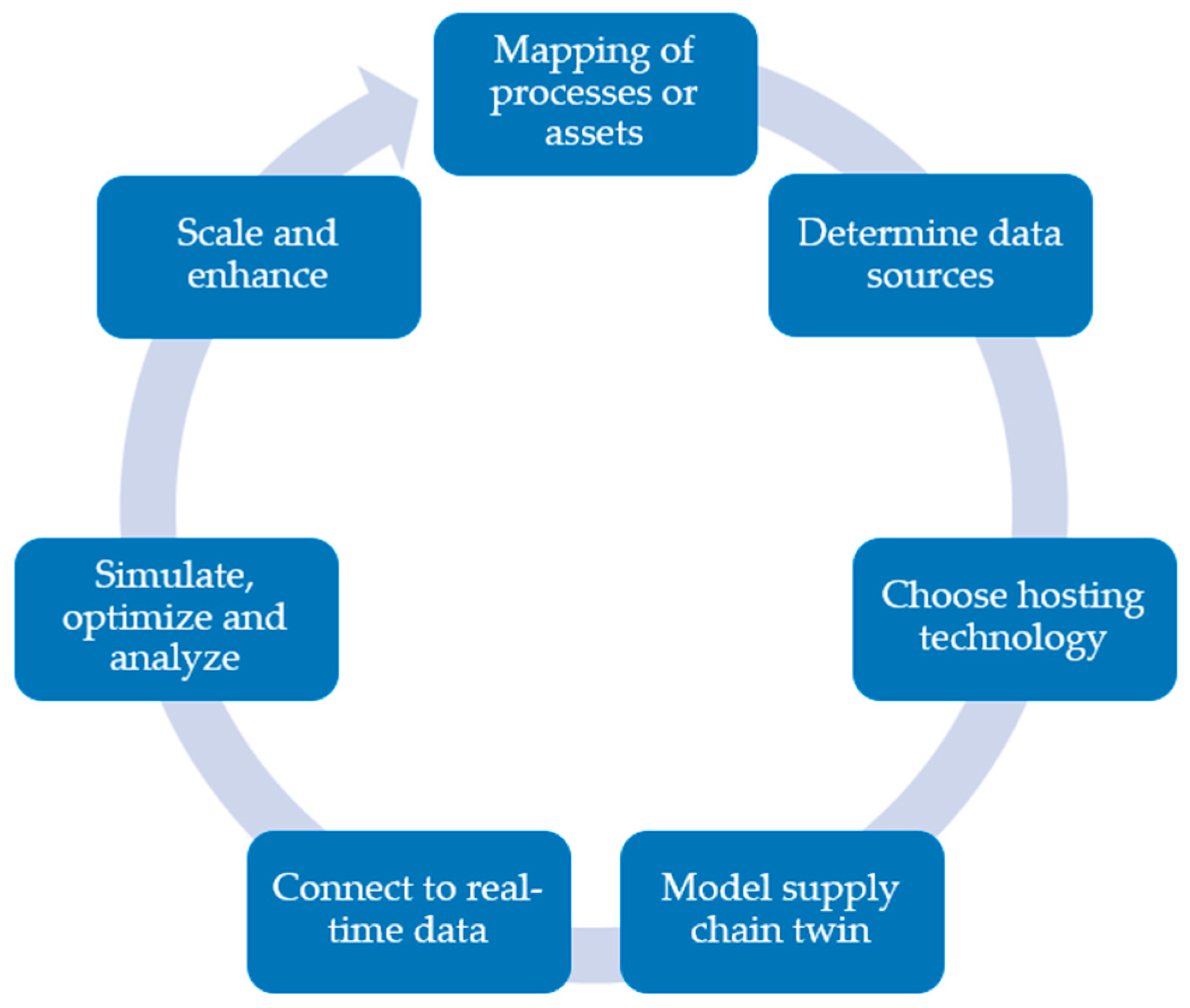

4.2.4. Implementation Steps (RQ4)

4.2.5. Challenges for the DT Implementation (RQ5)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van der Burg, S.; Kloppenburg, S.; Kok, E.J.; van der Voort, M. Digital Twins in Agri-Food: Societal and Ethical Themes and Questions for Further Research. NJAS Impact Agric. Life Sci. 2021, 93, 98–125. [Google Scholar] [CrossRef]

- Neethirajan, S.; Kemp, B. Digital Twins in Livestock Farming. Animals 2021, 11, 1008. [Google Scholar] [CrossRef] [PubMed]

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Digital Twin Models in Industrial Operations: State-of-the-Art and Future Research Directions. IET Collab. Intell. Manuf. 2021, 3, 37–47. [Google Scholar] [CrossRef]

- Koulouris, A.; Misailidis, N.; Petrides, D. Applications of Process and Digital Twin Models for Production Simulation and Scheduling in the Manufacturing of Food Ingredients and Products. Food Bioprod. Process. 2021, 126, 317–333. [Google Scholar] [CrossRef]

- Eppinger, T.; Longwell, G.; Mas, P.; Goodheart, K. Increase Food Production Efficiency Using the Executable Digital Twin (XDT). Chem. Eng. Trans. 2021, 87, 37–42. [Google Scholar] [CrossRef]

- Supply Chain Digital Twins: Definition, the Problems They Solve, and How to Develop Them. Available online: https://www.anylogistix.com/features/supply-chain-digital-twins/ (accessed on 27 December 2022).

- Busse, A.; Gerlach, B.; Lengeling, J.C.; Poschmann, P.; Werner, J.; Zarnitz, S. Towards Digital Twins of Multimodal Supply Chains. Logistics 2021, 5, 25. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Liu, A. Digital Twin-Driven Supply Chain Planning. Procedia CIRP 2020, 93, 198–203. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Stecken, J.; Ebel, M.; Bartelt, M.; Poeppelbuss, J.; Kuhlenkötter, B. Digital Shadow Platform as an Innovative Business Model. Procedia CIRP 2019, 83, 204–209. [Google Scholar] [CrossRef]

- Tseng, G.W.G.; Chen, C.Q.G.; Erkorkmaz, K.; Engin, S. Digital Shadow Identification from Feed Drive Structures for Virtual Process Planning. CIRP J. Manuf. Sci. Technol. 2019, 24, 55–65. [Google Scholar] [CrossRef]

- Vogt, A.; Schmidt, P.H.; Mayer, S.; Stark, R. Production in the Loop-the Interoperability of Digital Twins of the Product and the Production System. Procedia CIRP 2021, 99, 561–566. [Google Scholar] [CrossRef]

- Bamunuarachchi, D.; Georgakopoulos, D.; Banerjee, A.; Jayaraman, P.P. Digital Twins Supporting Efficient Digital Industrial Transformation. Sensors 2021, 21, 6829. [Google Scholar] [CrossRef]

- Kalaboukas, K.; Rožanec, J.; Košmerlj, A.; Kiritsis, D.; Arampatzis, G. Implementation of Cognitive Digital Twins in Connected and Agile Supply Networks-an Operational Model. Appl. Sci. 2021, 11, 4103. [Google Scholar] [CrossRef]

- Defraeye, T.; Shrivastava, C.; Berry, T.; Verboven, P.; Onwude, D.; Schudel, S.; Bühlmann, A.; Cronje, P.; Rossi, R.M. Digital Twins Are Coming: Will We Need Them in Supply Chains of Fresh Horticultural Produce? Trends Food Sci. Technol. 2021, 109, 245–258. [Google Scholar] [CrossRef]

- Henrichs, E.; Noack, T.; Krupitzer, C.; María, A.; Piedrahita, P.; Salem, M.A.; Stolz, J. Can a Byte Improve Our Bite? An Analysis of Digital Twins in the Food Industry. Sensors 2021, 22, 115. [Google Scholar] [CrossRef] [PubMed]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing Digital Twins to Agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Verboven, P.; Defraeye, T.; Datta, A.K.; Nicolai, B. Digital Twins of Food Process Operations: The next Step for Food Process Models? Curr. Opin. Food Sci. 2020, 35, 79–87. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Sorooshian, S.; Okfalisa, O. Digital Twins Driven Supply Chain Visibility within Logistics: A New Paradigm for Future Logistics. Appl. Syst. Innov. 2021, 4, 29. [Google Scholar] [CrossRef]

- Lezoche, M.; Panetto, H.; Kacprzyk, J.; Hernandez, J.E.; Alemany Díaz, M.M.E. Agri-Food 4.0: A Survey of the Supply Chains and Technologies for the Future Agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Zarnitz, S.; Straube, F.; Nitsche, B. Digital Supply Chain Twins for Sustainable Planning of a Logistics System; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; ISBN 9783031288395. [Google Scholar]

- Burgos, D.; Ivanov, D. Food Retail Supply Chain Resilience and the COVID-19 Pandemic: A Digital Twin-Based Impact Analysis and Improvement Directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 152, 102412. [Google Scholar] [CrossRef]

- Violi, A.; De Maio, A.; Fattoruso, G.; Olivieri, M.G. An Age-Based Dynamic Approach for Distribution of Perishable Commodities with Stochastic Demands. Soft Comput. 2023, 27, 7039–7050. [Google Scholar] [CrossRef]

- Gerlach, B.; Zarnitz, S.; Nitsche, B.; Straube, F. Digital supply chain Twins—Conceptual clarification, use cases and benefits. Logistics 2021, 5, 86. [Google Scholar] [CrossRef]

- Perez, H.D.; Amaran, S.; Erisen, E.; Wassick, J.M.; Grossmann, I.E. A Digital Twin Framework for Business Transactional Processes in Supply Chains. Comput. Aided Chem. Eng. 2021, 50, 1755–1760. [Google Scholar]

- Melesse, T.Y.; Bollo, M.; Di Pasquale, V.; Riemma, S. Digital Twin for Inventory Planning of Fresh Produce. IFAC-Pap. 2022, 55, 2743–2748. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, Use Cases, Challenges, and Opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.J.M.; Rialland, A. Virtualization of Food Supply Chains with the Internet of Things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef]

- Agrawal, T.K.; Kalaiarasan, R.; Olhager, J.; Wiktorsson, M. Understanding Supply Chain Visibility Through Experts’ Perspective: A Delphi Based Approach. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems, Proceedings of the IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, 5–9 September 2021; Springer: Cham, Switzerland, 2021; Volume 633, ISBN 9783030859091. [Google Scholar]

- Dyck, G.; Hawley, E.; Hildebrand, K.; Paliwal, J. Digital Twins: A Novel Traceability Concept for Post-Harvest Handling. Smart Agric. Technol. 2023, 3, 100079. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Bollo, M.; Di Pasquale, V.; Centro, F.; Riemma, S. Machine Learning-Based Digital Twin for Monitoring Fruit Quality Evolution. Procedia Comput. Sci. 2022, 200, 13–20. [Google Scholar] [CrossRef]

- Zou, Z.; Chen, Q.; Uysal, I.; Zheng, L. Radio Frequency Identification Enabled Wireless Sensing for Intelligent Food Logistics. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130313. [Google Scholar] [CrossRef] [PubMed]

- Jedermann, R.; Nicometo, M.; Uysal, I.; Lang, W. Reducing Food Losses by Intelligent Food Logistics. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130302. [Google Scholar] [CrossRef]

- Chergui, N.; Kechadi, M.T.; McDonnell, M. The Impact of Data Analytics in Digital Agriculture: A Review. In Proceedings of the International Multi-Conference on Organization of Knowledge and Advanced Technologies, OCTA 2020, Tunis, Tunisia, 6–8 February 2020. [Google Scholar] [CrossRef]

- Jo, S.K.; Park, D.H.; Park, H.; Kim, S.H. Smart Livestock Farms Using Digital Twin: Feasibility Study. In Proceedings of the 2018 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Republic of Korea, 17–19 October 2018; pp. 1461–1463. [Google Scholar] [CrossRef]

- Mishra, S.; Sharma, S.K. Advanced Contribution of IoT in Agricultural Production for the Development of Smart Livestock Environments. Internet Things 2023, 22, 100724. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital Twins in Smart Farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Purcell, W.; Neubauer, T. Digital Twins in Agriculture: A State-of-the-Art Review. Smart Agric. Technol. 2023, 3, 100094. [Google Scholar] [CrossRef]

- Ariesen-Verschuur, N.; Verdouw, C.; Tekinerdogan, B. Digital Twins in Greenhouse Horticulture: A Review. Comput. Electron. Agric. 2022, 199, 107183. [Google Scholar] [CrossRef]

- Torres-Sánchez, R.; Martínez-Zafra, M.T.; Castillejo, N.; Guillamón-Frutos, A.; Artés-Hernández, F. Real-Time Monitoring System for Shelf Life Estimation of Fruit and Vegetables. Sensors 2020, 20, 1860. [Google Scholar] [CrossRef]

- Haji, M.; Kerbache, L.; Muhammad, M.; Al-Ansari, T. Roles of Technology in Improving Perishable Food Supply Chains. Logistics 2020, 4, 33. [Google Scholar] [CrossRef]

- Ghandar, A.; Ahmed, A.; Zulfiqar, S.; Hua, Z.; Hanai, M.; Theodoropoulos, G. A Decision Support System for Urban Agriculture Using Digital Twin: A Case Study with Aquaponics. IEEE Access 2021, 9, 35691–35708. [Google Scholar] [CrossRef]

- Thomé, A.M.T.; Scavarda, L.F.; Scavarda, A.J. Conducting Systematic Literature Review in Operations Management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Shrivastava, C.; Berry, T.; Cronje, P.; Schudel, S.; Defraeye, T. Digital Twins Enable the Quantification of the Trade-Offs in Maintaining Citrus Quality and Marketability in the Refrigerated Supply Chain. Nat. Food 2022, 3, 413–427. [Google Scholar] [CrossRef]

- Shoji, K.; Schudel, S.; Onwude, D.; Shrivastava, C.; Defraeye, T. Mapping the Postharvest Life of Imported Fruits from Packhouse to Retail Stores Using Physics-Based Digital Twins. Resour. Conserv. Recycl. 2022, 176, 105914. [Google Scholar] [CrossRef]

- Tagliavini, G.; Defraeye, T.; Carmeliet, J. Multiphysics Modeling of Convective Cooling of Non-Spherical, Multi-Material Fruit to Unveil Its Quality Evolution throughout the Cold Chain. Food Bioprod. Process. 2019, 117, 310–320. [Google Scholar] [CrossRef]

- Krupitzer, C.; Noack, T.; Borsum, C. Digital Food Twins Combining Data Science and Food Science: System Model, Applications, and Challenges. Processes 2022, 10, 1781. [Google Scholar] [CrossRef]

- Defraeye, T.; Tagliavini, G.; Wu, W.; Prawiranto, K.; Schudel, S.; Assefa, M.; Verboven, P.; Bühlmann, A.; Assefa Kerisima, M.; Verboven, P.; et al. Digital Twins Probe into Food Cooling and Biochemical Quality Changes for Reducing Losses in Refrigerated Supply Chains. Resour. Conserv. Recycl. 2019, 149, 778–794. [Google Scholar] [CrossRef]

- Vallejo, M.E.; Larios, V.M.; Magallanes, V.G.; Cobian, C.; De La Luz Guzman Castaneda, M.; Tellez, G.B. Creating Resilience for Climate Change in Smart Cities Based on the Local Food Supply Chain. In Proceedings of the 2021 IEEE International Smart Cities Conference (ISC2), Online, 7–10 September 2021. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Zhou, Q. Established Digital Model of Fruit Body Growth of Agrocybe Cylindracea Based on Network Programming. Discret. Dyn. Nat. Soc. 2021, 2021, 6643273. [Google Scholar] [CrossRef]

- Keates, O. The Design and Validation of a Process Data Analytics Methodology for Improving Meat and Livestock Value Chains. In Proceedings of the 17th International Conference on Business Process Management (BPM 2019), Vienna, Austria, 1–6 September 2019; Volume 2420. [Google Scholar]

- Sung, Y.M.; Kim, T. Smart Farm Realization Based on Digital Twin. ICIC Express Lett. Part B Appl. 2022, 13, 421–427. [Google Scholar] [CrossRef]

- Bottani, E.; Vignali, G.; Carlo Tancredi, G.P. A Digital Twin Model of a Pasteurization System for Food Beverages: Tools and Architecture. In Proceedings of the IEEE International Conference on Engineering, Technology, and Innovation, ICE/ITMC 2020, Virtual Conference, 15–17 June 2020; pp. 1–3. [Google Scholar] [CrossRef]

- Vignali, G.; Bottani, E. A Tube-in-Tube Food Pasteurizer Modelling for a Digital Twin Application. In Proceedings of the 6th International Food Operations and Processing Simulation Workshop (FoodOPS 2020), Online, 16–18 September 2020; pp. 30–36. [Google Scholar] [CrossRef]

- Shoji, K.; Schudel, S.; Shrivastava, C.; Onwude, D.; Defraeye, T. Optimizing the Postharvest Supply Chain of Imported Fresh Produce with Physics-Based Digital Twins. J. Food Eng. 2022, 329, 111077. [Google Scholar] [CrossRef]

- Leithner, M.; Fikar, C. A Simulation Model to Investigate Impacts of Facilitating Quality Data within Organic Fresh Food Supply Chains. Ann. Oper. Res. 2019, 314, 529–550. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Hensel, O. Toward the Next Generation of Digitalization in Agriculture Based on Digital Twin Paradigm. Sensors 2022, 22, 498. [Google Scholar] [CrossRef] [PubMed]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C.C. Enabling Technologies and Tools for Digital Twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Abideen, A.Z.; Sundram, V.P.K.; Pyeman, J.; Othman, A.K.; Sorooshian, S. Digital Twin Integrated Reinforced Learning in Supply Chain and Logistics. Logistics 2021, 5, 84. [Google Scholar] [CrossRef]

- Onwude, D.I.; Chen, G.; Eke-Emezie, N.; Kabutey, A.; Khaled, A.Y.; Sturm, B. Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes 2020, 8, 1431. [Google Scholar] [CrossRef]

- Sanchez-Londono, D.; Barbieri, G.; Fumagalli, L. Smart Retrofitting in Maintenance: A Systematic Literature Review. J. Intell. Manuf. 2022, 34, 1–19. [Google Scholar] [CrossRef]

- Marquardt, T.; Cleophas, C.; Morgan, L. Indolence Is Fatal: Research Opportunities in Designing Digital Shadows and Twins for Decision Support. In Proceedings of the 2021 Winter Simulation Conference, Brussels, Belgium, 10–13 December 2021. [Google Scholar] [CrossRef]

- Jayalath, M.M.; Perera, H.N. Mapping Post-Harvest Waste in Perishable Supply Chains through System Dynamics: A Sri Lankan Case Study. J. Agric. Sci.-Sri Lanka 2021, 16, 526–543. [Google Scholar] [CrossRef]

- Veerakachen, W.; Raksapatcharawong, M. RiceSAP: An Efficient Satellite-Based AquaCrop Platform for Rice Crop Monitoring and Yield Prediction on a Farm—To Regional-Scale. Agronomy 2020, 10, 858. [Google Scholar] [CrossRef]

- Zou, G.; Tang, J.; Yilmaz, L.; Kong, X. Online Food Ordering Delivery Strategies Based on Deep Reinforcement Learning. Appl. Intell. 2022, 52, 6853–6865. [Google Scholar] [CrossRef]

- Sarjoughian, H.S. DEVS-scripting: A black-box test frame for DEVS models. In Proceedings of the 2020 Winter Simulation Conference, Orlando, FL, USA, 14–18 December 2020. [Google Scholar]

- Cai, X.; Zhang, H.; Li, Q. Analysis and Design of Smart Cold Chain Logistics Simulation Model Based on Internet of Things Technology. In Proceedings of the 2022 IEEE Asia-Pacific Conference on Image Processing, Electronics and Computers (IPEC2022), Dalian, China, 14–16 April 2022; pp. 1352–1356. [Google Scholar] [CrossRef]

- Tebaldi, L.; Vignali, G.; Bottani, E. Digital Twin in the Agri-Food Supply Chain: A Literature Review. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems, Proceedings of the IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, 5–9 September 2021; Springer International Publishing: Cham, Switzerland, 2021; Volume 633, ISBN 9783030859091. [Google Scholar]

- Sharma, A.; Zanotti, P.; Musunur, L.P. Drive through Robotics: Robotic Automation for Last Mile Distribution of Food and Essentials during Pandemics. IEEE Access 2020, 8, 127190–127219. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A Digital Supply Chain Twin for Managing the Disruption Risks and Resilience in the Era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Rahman, M.M.; Nguyen, R.; Lu, L. Multi-Level Impacts of Climate Change and Supply Disruption Events on a Potato Supply Chain: An Agent-Based Modeling Approach. Agric. Syst. 2022, 201, 103469. [Google Scholar] [CrossRef]

- Perdana, T.; Chaerani, D.; Achmad, A.L.H. Supporting Data for the Integrated Agent-Based Modelling and Robust Optimization on Food Supply Network Design in COVID-19 Pandemic. Data Br. 2022, 40, 107809. [Google Scholar] [CrossRef] [PubMed]

- Kazancoglu, Y.; Ekinci, E.; Mangla, S.K.; Sezer, M.D.; Kayikci, Y. Performance Evaluation of Reverse Logistics in Food Supply Chains in a Circular Economy Using System Dynamics. Bus. Strateg. Environ. 2021, 30, 71–91. [Google Scholar] [CrossRef]

- Hernández, J.M.; Pedroza-Gutiérrez, C. Estimating the Influence of the Network Topology on the Agility of Food Supply Chains. PLoS ONE 2019, 14, e0218958. [Google Scholar] [CrossRef]

- Herrera, M.M.; Orjuela-Castro, J. An Appraisal of Traceability Systems for Food Supply Chains in Colombia. Int. J. Food Syst. Dyn. 2021, 12, 37–50. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, R.; Panchal, R.; Tiwari, M.K. Impact of COVID-19 on Logistics Systems and Disruptions in Food Supply Chain. Int. J. Prod. Res. 2021, 59, 1993–2008. [Google Scholar] [CrossRef]

- Suryani, E.; Hendrawan, R.A.; Muhandhis, I.; Indraswari, R. A Simulation Model to Improve the Value of Rice Supply Chain (A Case Study in East Java–Indonesia). J. Simul. 2022, 16, 392–414. [Google Scholar] [CrossRef]

- Zhu, Q.; Krikke, H. Managing a Sustainable and Resilient Perishable Food Supply Chain (PFSC) after an Outbreak. Sustainability 2020, 12, 5004. [Google Scholar] [CrossRef]

- Yuan, Y.; Viet, N.; Behdani, B. The Impact of Information Sharing on the Performance of Horizontal Logistics Collaboration: A Simulation Study in an Agri-Food Supply Chain. IFAC-Pap. 2019, 52, 2722–2727. [Google Scholar] [CrossRef]

- Ambekar, S.; Kapoor, R. Optimization of Inventory Policies of Food Grain Distribution Stage in Public Distribution System. Benchmarking 2019, 26, 692–713. [Google Scholar] [CrossRef]

- Mittal, A.; Krejci, C.C. A Hybrid Simulation Modeling Framework for Regional Food Hubs. J. Simul. 2019, 13, 28–43. [Google Scholar] [CrossRef]

- Almeder, C.; Preusser, M. A Hybrid Simulation Optimization Approach for Supply Chains. Congr. Model. Simul. 2007, 2007, 9–13. [Google Scholar]

- Ortúzar, J.E.; Dogan, O.B.; Sotomayor, G.; Jiménez, C.; Clarke, J.; Flores, R.A.; Gray, G.M.; Rupnow, J.H.; Wang, B. Quantitative Assessment of Microbial Quality and Safety Risk: A Preliminary Case Study of Strengthening Raspberry Supply System in Chile. Food Control 2020, 113, 107166. [Google Scholar] [CrossRef]

- Feng, J.; Zeng, L.; He, L. Apple Fruit Recognition Algorithm Based on Multi-Spectral Dynamic Image Analysis. Sensors 2019, 19, 949. [Google Scholar] [CrossRef] [PubMed]

- Gurupatham, S.; Fahad, F.; Hudlow, A. Improving Shelf-Life of Fruits Using Thermography; Kennesaw State University: Kennesaw, GA, USA, 2018; pp. 1–6. [Google Scholar]

- Manickavasagan, A.; White, N.D.G. Applications of Thermal Imaging in Agriculture—A Review. Can. Soc. Eng. Agric. Food Biol. Syst. 2005, 1–11. [Google Scholar]

- Ferreira, D.S. Thermal Imaging as a Tool in Food Analysis. J. Spectr. Imaging 2020, 9, a7. [Google Scholar] [CrossRef]

- Jiao, L.Z.; Wu, W.B.; Zheng, W.G.; Dong, D.M. The Infrared Thermal Image-Based Monitoring Process of Peach Decay under Uncontrolled Temperature Conditions. J. Anim. Plant Sci. 2015, 25, 202–207. [Google Scholar]

- Smith, M.J. Getting Value from Artificial Intelligence in Agriculture. Anim. Prod. Sci. 2019, 60, 46–54. [Google Scholar] [CrossRef]

- Pal, A.; Kant, K. Smart Sensing, Communication, and Control in Perishable Food Supply Chain. ACM Trans. Sens. Netw. 2020, 16, 1–41. [Google Scholar] [CrossRef]

- Rehman, A.; Saba, T.; Kashif, M.; Fati, S.M.; Bahaj, S.A.; Chaudhry, H. A Revisit of Internet of Things Technologies for Monitoring and Control Strategies in Smart Agriculture. Agronomy 2022, 12, 127. [Google Scholar] [CrossRef]

- Purcell, W.; Neubauer, T.; Mallinger, K. Digital Twins in Agriculture: Challenges and Opportunities for Environmental Sustainability. Curr. Opin. Environ. Sustain. 2023, 61, 101252. [Google Scholar] [CrossRef]

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.K.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.I.; Warrian, P.J. Digital Twin for the Oil and Gas Industry: Overview, Research Trends, Opportunities, and Challenges. IEEE Access 2020, 8, 104175–104197. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the Digital Twin for Design and Production Engineering. CIRP Ann.-Manuf. Technol. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Tzachor, A.; Richards, C.E.; Jeen, S. Transforming Agrifood Production Systems and Supply Chains with Digital Twins. Npj Sci. Food 2022, 6, 47. [Google Scholar] [CrossRef] [PubMed]

- Lohtander, M.; Garcia, E.; Lanz, M.; Volotinen, J.; Ratava, J.; Kaakkunen, J. Micro Manufacturing Unit—Creating Digital Twin Objects with Common Engineering Software. Procedia Manuf. 2018, 17, 468–475. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital Twin for Sustainable Manufacturing Supply Chains: Current Trends, Future Perspectives, and an Implementation Framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

| Application Area | Implementation Purpose of DT | References |

|---|---|---|

| Transportation and storage of fruit | To provide insights regarding the thermophysical behavior of fruit | [48] |

| Food retail supply chains | To enhance end-to-end visibility and resilient management of demand, inventory, and capacity | [22] |

| Postharvest supply chains | To provide insight with actionable data and aid in detecting and predicting supply chain issues | [15] |

| Refrigerated transport and cold storage | To optimize the cooling process for a variety of fruits and vegetables with complex shapes and compositions | [46] |

| Cold chain | For cold chain optimizations in the design process | [45] |

| Food industry | To enhance food quality and traceability, and design personalized foods | [16] |

| Refrigerated supply chain | For monitoring food quality and marketability | [44] |

| Fruit retail | For monitoring the quality of fruit during storage | [31] |

| Food supply chain | To replicate the dynamic evolution of a system over time | [49] |

| Agriculture | To collect and analyze fruiting body growth in farming | [50] |

| Meat and livestock | To replicate the value chain | [51] |

| Smart farm | To enhance farm management | [52] |

| Food processing plant | To enhance pasteurization and predict processing conditions in beverage processing | [53,54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melesse, T.Y.; Franciosi, C.; Di Pasquale, V.; Riemma, S. Analyzing the Implementation of Digital Twins in the Agri-Food Supply Chain. Logistics 2023, 7, 33. https://doi.org/10.3390/logistics7020033

Melesse TY, Franciosi C, Di Pasquale V, Riemma S. Analyzing the Implementation of Digital Twins in the Agri-Food Supply Chain. Logistics. 2023; 7(2):33. https://doi.org/10.3390/logistics7020033

Chicago/Turabian StyleMelesse, Tsega Y., Chiara Franciosi, Valentina Di Pasquale, and Stefano Riemma. 2023. "Analyzing the Implementation of Digital Twins in the Agri-Food Supply Chain" Logistics 7, no. 2: 33. https://doi.org/10.3390/logistics7020033

APA StyleMelesse, T. Y., Franciosi, C., Di Pasquale, V., & Riemma, S. (2023). Analyzing the Implementation of Digital Twins in the Agri-Food Supply Chain. Logistics, 7(2), 33. https://doi.org/10.3390/logistics7020033