The proposed method discussed further on was developed using MATLAB software and Microsoft Excel. For the purposes of this study, a sample of 5842 SKUs was examined. After defining the new types of slots needed, a layout redesign and storage assignment method was proposed and implemented in the case study facility, with the aim of enhancing OP performance by mitigating workers’ physical fatigue through an innovative OP difficulty ranking system.

4.1. Selection of Slot Sizes

In the initial layout, products were assigned to slots based on their unit dimensions, so that the required picking storage space was minimized. However, this strategy overloaded the system with frequent replenishment demands. Therefore, the company decided to determine the slot size selection based on the demanded unit quantities of each SKU, with the aim of achieving sufficient inventory levels for seven days, with no replenishment needs in the meantime. Based on the average daily demand and number of items included in one unit, the number of boxes needed was estimated for each product. In this direction, an algorithm was developed, exploring the six degrees of freedom of a rigid body in a three-dimensional space. In such a manner, the optimal placement orientation or combination of orientations was defined for each SKU, targeting the storage of all the demanded units per product while minimizing the dead volume in the selected slot. Nevertheless, this algorithm is out of scope for the current study, and will be presented in authors’ future work.

Although all slots have the same depth and height because of the fixed rack structure, their length varies according to their size. Assuming S is the length of the medium-sized slot, S2 would be the length of the small-sized slot, equal to half the length of S, and 2S the length of the large-sized slot, equal to double the length of S.

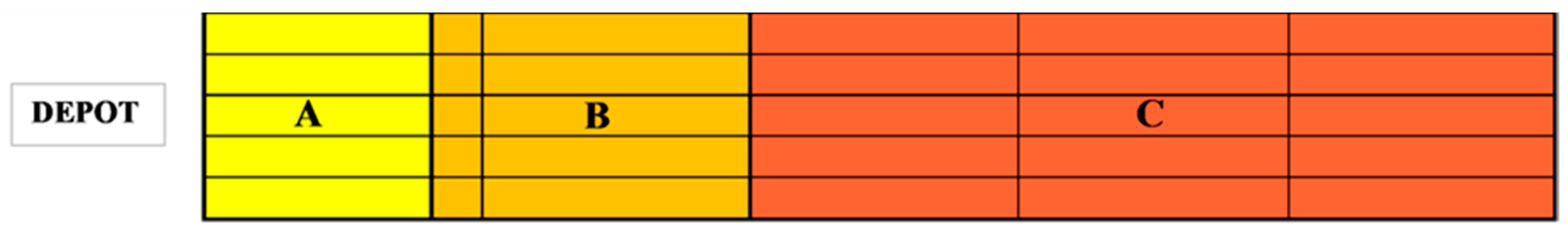

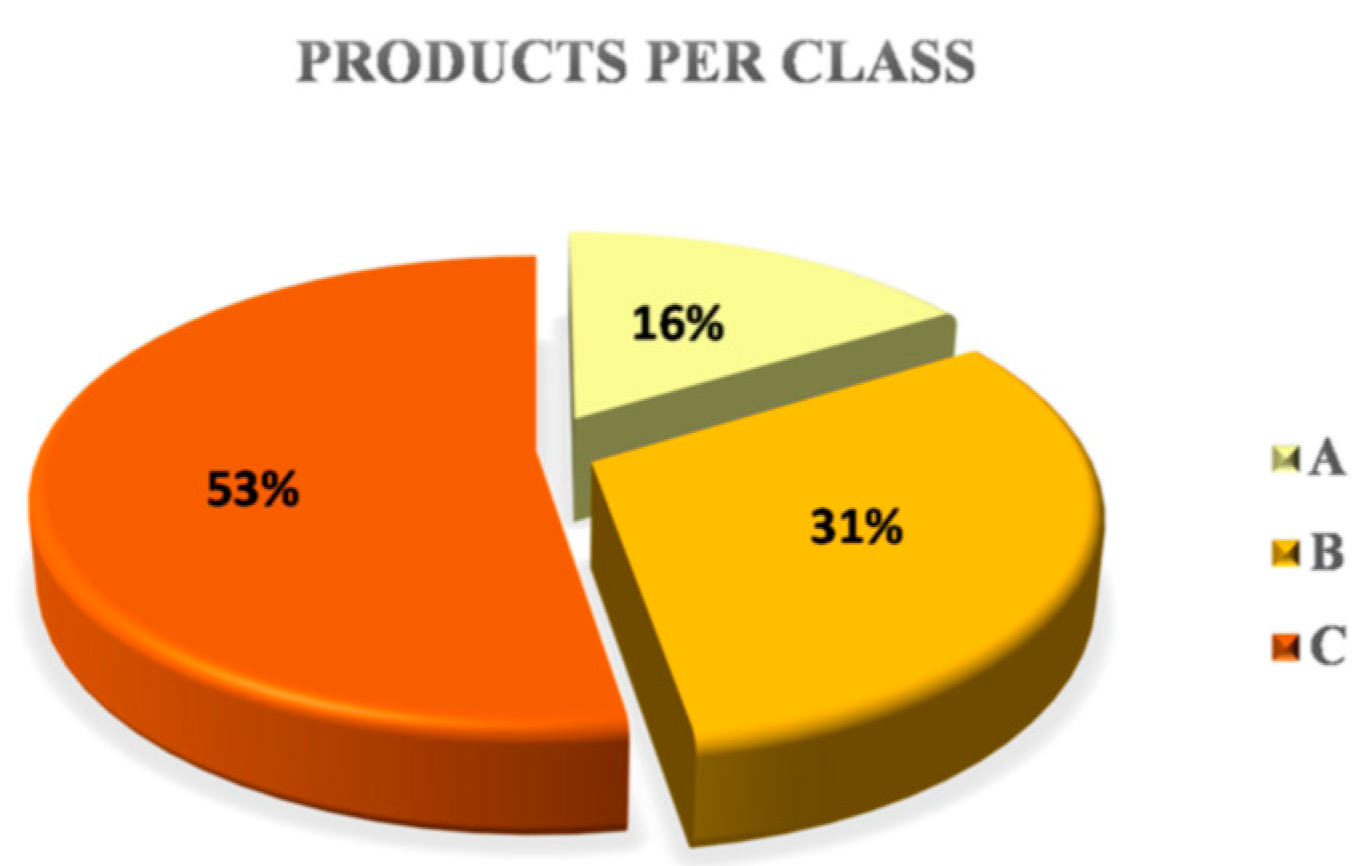

4.2. Classification of SKUs Using ABC Analysis

In order to decrease picking time and effort, it is imperative that a popularity analysis be conducted based on products’ turnover rates, which is defined as the daily number of times a picker needs to travel to a specific location and retrieve a demanded quantity of an SKU. By applying Pareto’s principle, products were classified into three categories. SKUs with more than five transfer orders per day were classified as “A” products, i.e., the most fast-moving ones. SKUs with less than five but more than one transfer order fell into class “B”, while the rest into class “C”. Every SKU is characterized by two factors; its popularity class and the minimum slot size in which it can fit. Thus, by having three turnover classes and three slot sizes, nine different combinations emerge; in other words, nine different slot types. The new slot types are notated as XY, with the first symbol designating the class, i.e., A, B, or C, and the second the slot size, i.e., S2, S, or 2S.

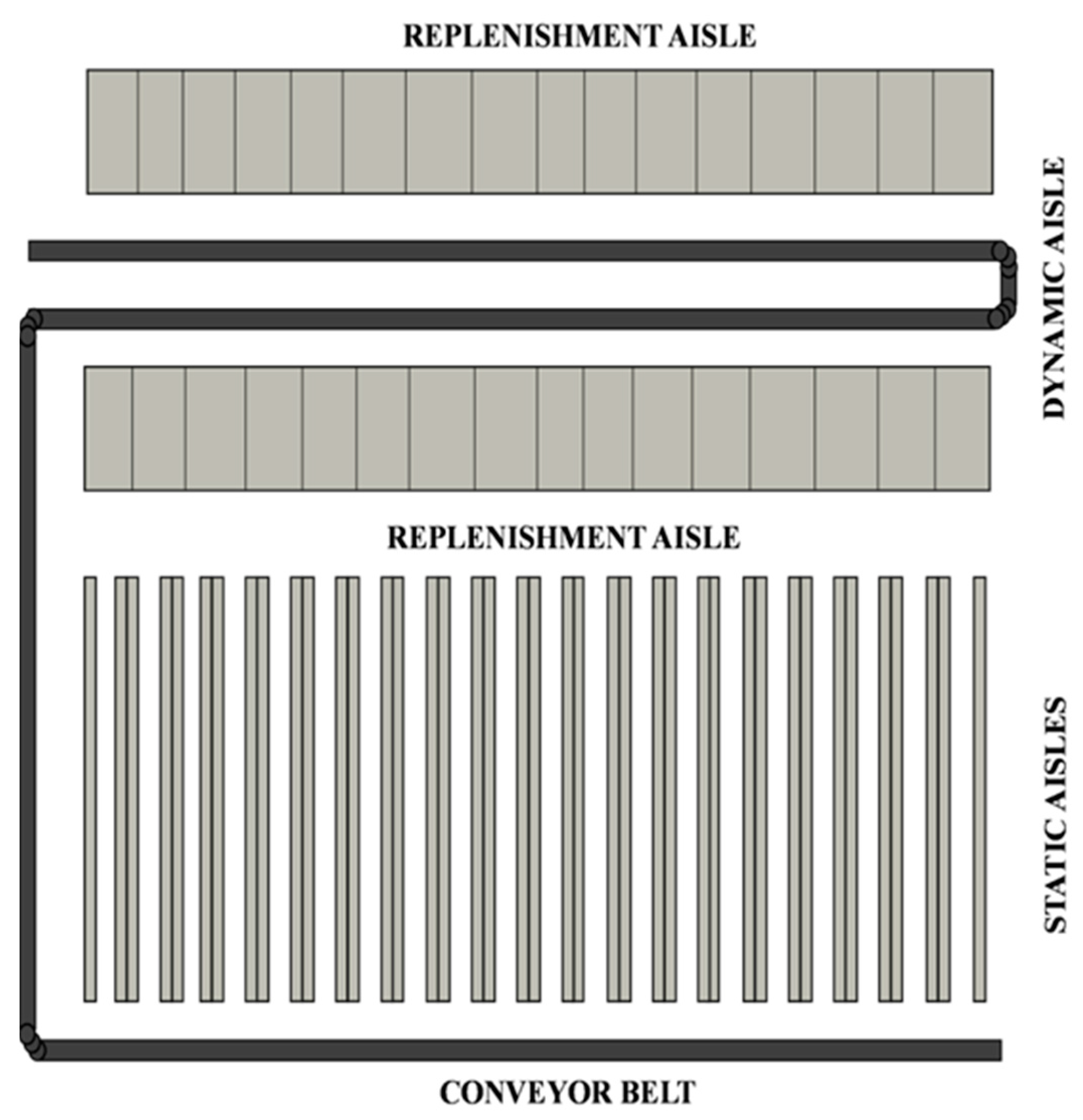

4.3. Number of Slot Types per Aisle

The main goal of the proposed method is to design an “ideal aisle” which meets the system’s needs and can be reproduced across the picking area, assuming equal travel distance from the depot to the starting point of each aisle. First, it is important to specify the exact number of slots which can fit in a rack, i.e., the space between two consecutive columns separating bays from one another.

Nine small-sized slots (S2)

Four medium-sized (S) plus one small-sized slot (S2)

Two large-sized (2S) plus one medium-sized (S) or two small-sized slots (S2)

As it can be easily inferred, there can be diverse combinations, given that every length type is a multiple of the others. The steps for estimating the number of slots per aisle are detailed below.

Calculation of the number of products classified in each category of the nine slots developed above, according to their characteristics and corresponding percentages.

Assuming that each aisle can accommodate 100 products in total, the percentages found in Step 1 are converted in S length according to Equation (1).

The total length per aisle of XY slots needed for 100 products is calculated in S length.

Since each rack can accommodate four S-sized slots and one S2-sized slot, the total rack length equals to 4.5 S. Therefore, for an aisle consisting of 50 racks, the total slot length equals to 225 S.

Knowing the length of each slot type per aisle in S level, the total rack length required for 100 products, and the total rack length per aisle, the number of each slot type per aisle is calculated according to Equation (2).

After applying the above described methodology, the total length of the estimated number of slots resulting from the ROUND function was adjusted accordingly, so as to approach as much as possible the maximum rack length per aisle, i.e., 225 S.

4.4. Ergonomic Constraints

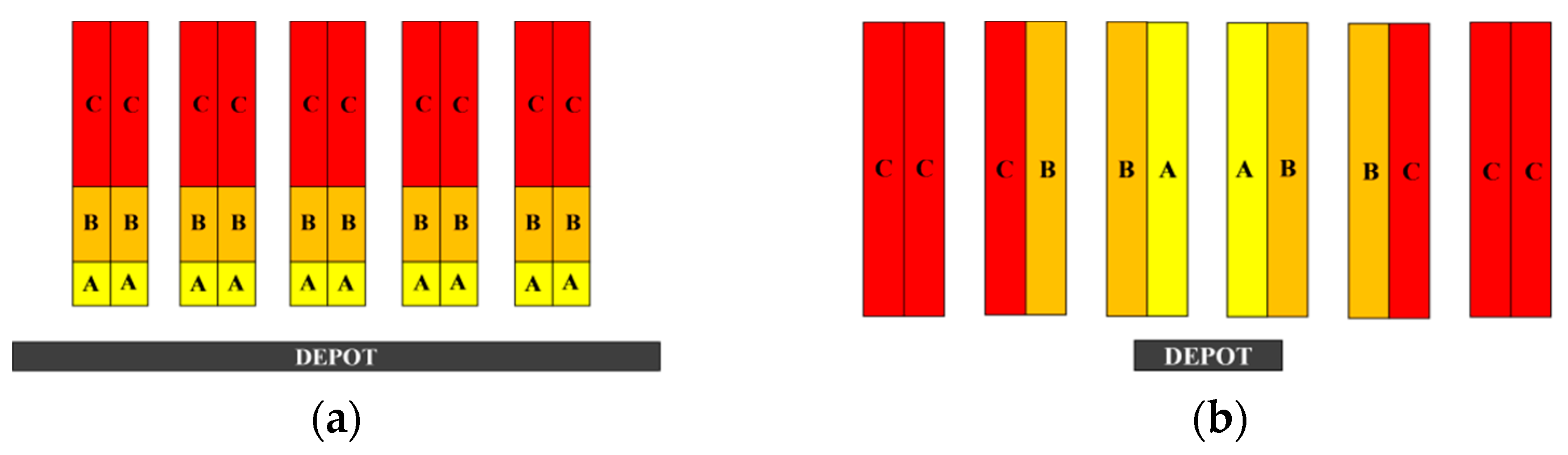

As previously mentioned, the conveyor crosses all aisles from their front side. According to literature, the classification of slots preferred in such a layout structure is the “across-aisle”, based on which a vertical separation of classes can be observed, such as the one shown in

Figure 5, with “A” products occupying the bays closest to the depot, followed by “B” and “C” ones at the back.

Although the aforementioned classification has considerable merit, the approach taken in this paper differs in that it introduces several ergonomic criteria, which refer not only to the travel distance but also the ergonomics of the height at which each slot is located. Considering that walking is the least intense physical activity in a warehouse, this study proposes that “A” products, which would be expected to be placed in slots close to the conveyor, should occupy positions in distant bays with one essential limitation: rack ergonomics.

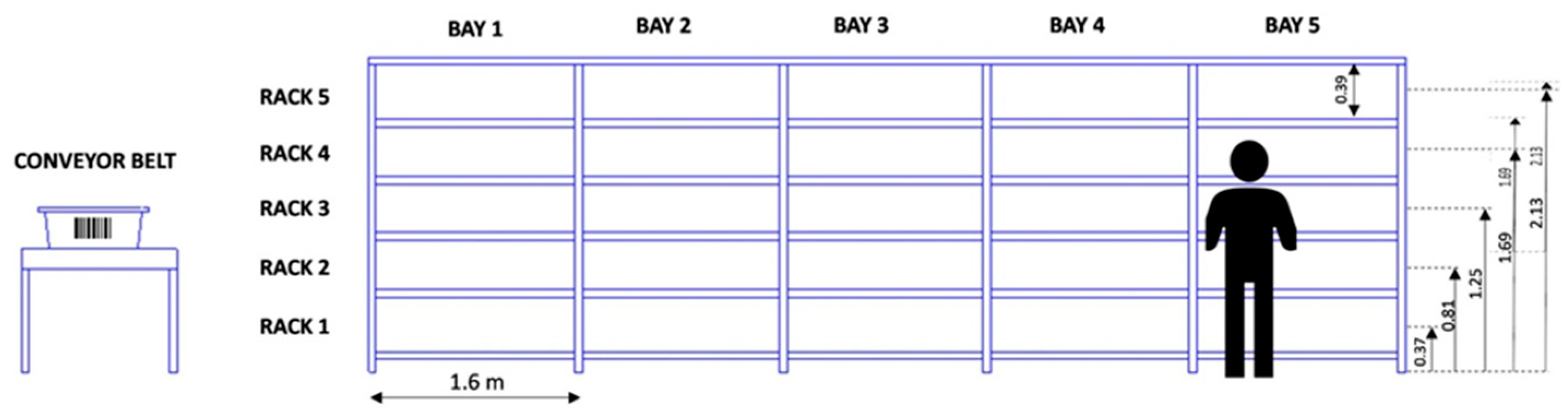

According to the concept of “Golden zone” picking, in our case the most ergonomic rack is the 3rd one, as its middle point is approximately 1.2 m from the ground, which is higher than a picker’s waist but lower than his/her shoulders (

Figure 3), taking into consideration that the average picker height is around 1.73 m. The 2nd and the 4th rack are almost equally ergonomic, placed in second and third rank respectively, since their height levels are not far away from the golden zone yet they require more intense movements compared to the 3rd rack. The 4th rack, at 1.69 m, forces pickers to resort to constant arm raising, thus leading to shoulder straining and pain, while the 2nd one requires slight bending for reaching items at 0.8 m. The 1st rack, placed at the ground level, is a quite inefficient picking height since it compels workers to bend over or kneel repeatedly, thus hurting their back, waist, and knees in the long run. The 5th rack, situated at a height of 2.13 m, is indisputably the least ergonomic one since it requires the use of a step stool enabling pickers to reach for the products and endangers them of getting hit by a falling object, which can cause severe blunt force trauma and leave them out of work for a long period of time, or render them incapable of returning to work. This is why placing bulky and heavy products on high racks should be prohibited.

It goes without saying that decreasing human workload will yield substantial results in terms of performance improvement. In the short-term basis, workers will be more efficient and faster in their day-to-day OP tasks, while in the foreseeable future physical pain will substantially diminish. Thus, by investing in ergonomics and ameliorating working conditions inside their distribution centers, companies will manage to extend the productive lifespan of workers. Based on the above,

Table 1,

Table 2 and

Table 3 present the bay and rack constraints based on each slot class and size.

It is worth underlining that the bays’ identification numbers, i.e., 1 to 5, represent the sequence of bays at each side of an aisle, starting from Bay 1 at the front side next to the depot, culminating in Bay 5 at the back. So, the bigger the identification number of the bay is, the longer the travel distance. It is worth mentioning that A-class slots may be located at more distant bays as long as they are placed in ergonomic racks. On the contrary, “C” slots can be situated at bays right next to the depot on condition that they are placed at the least ergonomic heights. Also, with regard to size, 2S slots, i.e., the large sized ones, are not allowed to be placed in racks above the 3rd one, as they are more likely to accommodate heavy and bulky products.

4.5. Layout Algorithm

An aisle is visualized as a four-dimensional matrix, notated as

The first dimension of the matrix (r) can take the values 1 or 2, and represents the left or right side of an aisle, as perceived by a picker looking at the aisle from the conveyor side.

The second dimension (x) represents the bay number and increases as the picker progresses along the aisle. Since each side of the aisle has a total of five bays, x takes values from 1 (closest to the depot) to 5 (farthest from the depot).

The third dimension (y) represents the rack number in each bay and can take values from 1 (lowest rack) to 5 (highest rack).

The fourth dimension (s) represents the ascending number of slots on each rack, starting from the point closest to the depot. Each rack can accommodate from three (two 2S and one S2) to nine (S2) slots.

The required number of slots per aisle will be equally divided between its two sides. However, because the number of some slot types per aisle is not even, the storage assignment on the two sides will be different.

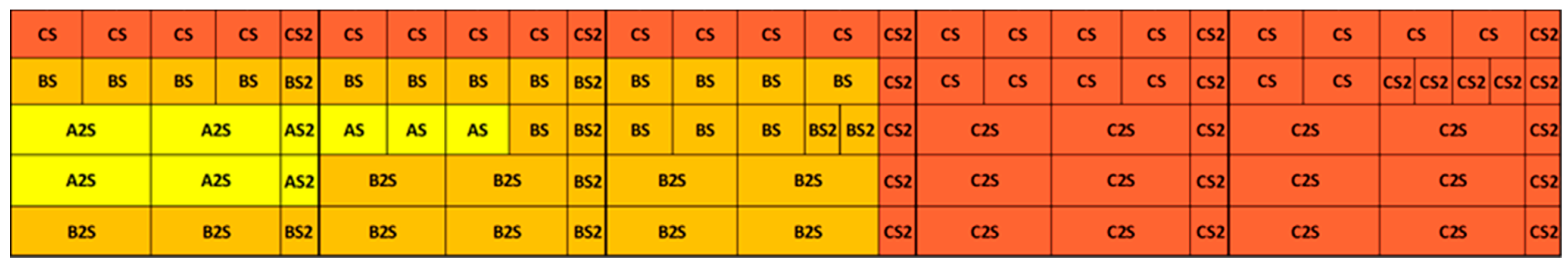

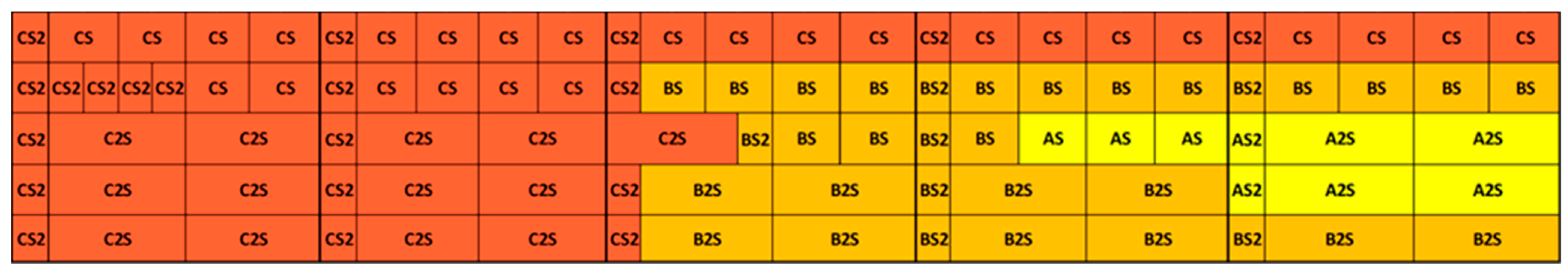

Table 4 summarizes the location constraints for each slot type for variables x and y in the SL matrix, i.e., bay and rack, based on the above-analyzed ergonomic factors.

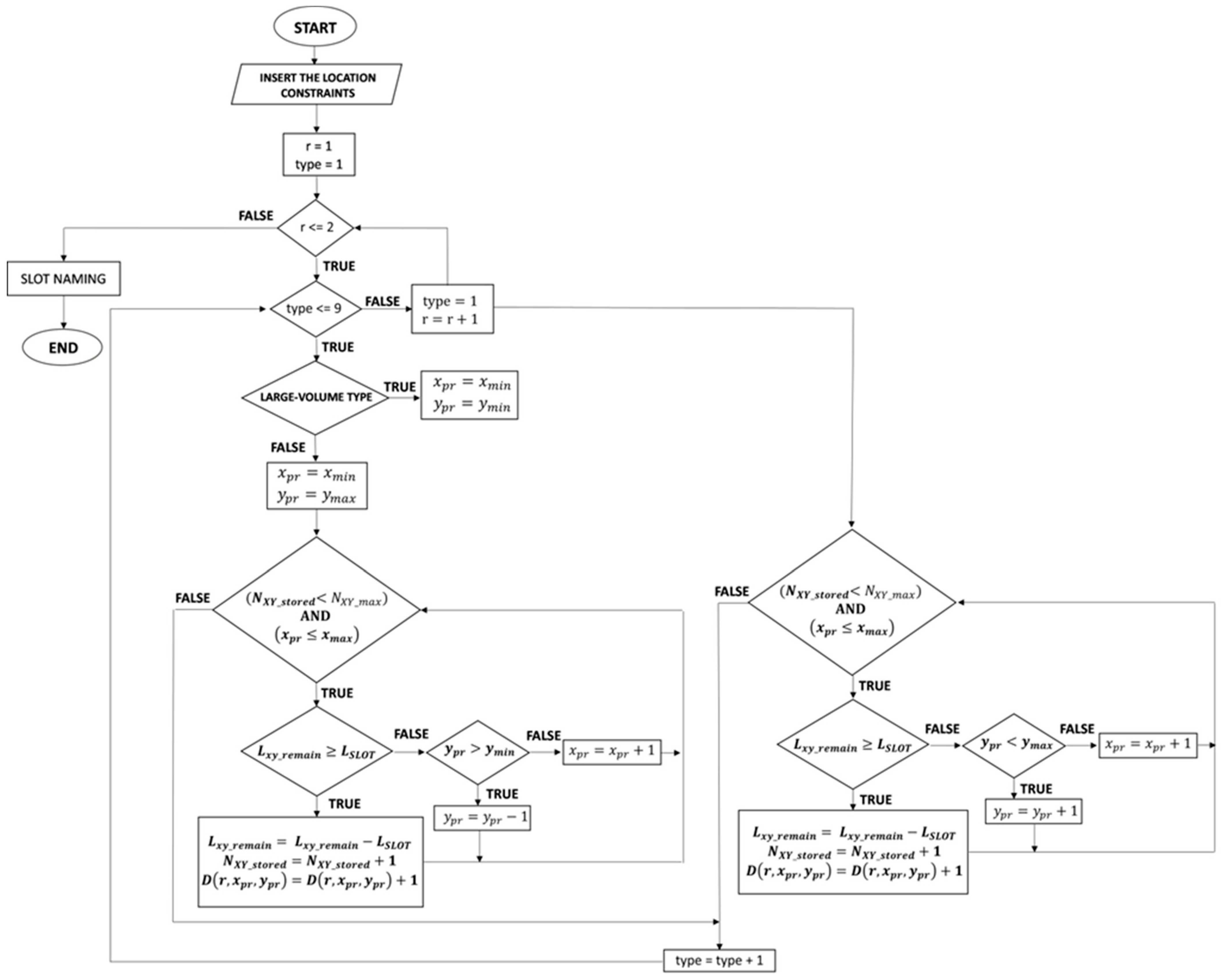

The algorithm receives as input the needed number of each slot type per aisle and the ergonomic constraints specified above. The process begins with placing the slots on the left (r = 1) and then on the right side (r = 2) of the aisle.

The order in which slots will be placed is in accordance with

Table 4 and, thus, class “A” will be first, “B” second, and “C” third, since assignment starts from Bay 1. As far as the slot sizes within each class are concerned, large slots, i.e., 2S slots, will be placed first followed by S, and finally S2 slots. Large sized slots have a height restriction and, thus, must be placed before the smaller ones. Also, small sized slots can be placed in the space left by large- and medium- sized slots.

For each type considered, in order to achieve as much uniformity as possible between the two sides of the aisle, the condition to be checked for an even number of slots is

while, for an odd number of slots, the condition to be checked is

where

Conditions (3) and (4) specify that for even numbers, half slots will be stored on the right and half on the left side. For odd numbers, half slots plus one will be stored on the left side for as many types as they can fit. As for the rest, one additional slot will be placed on the right side. The final number of slots per aisle side is presented in

Table 5.

For each slot type, following the order above, the algorithm starts by filling all empty slots starting from the bay closest to the depot, i.e., xmin with respect to the bay and rack limitations. Then, it moves on to the next bay until it reaches the farthest bay allowed, i.e., xmax, or until all slots of the specific type, for the particular side of the aisle are placed.

As far as the racks are concerned, the placement does not necessarily start from the lowest to the highest rack. As for the large sized slots, which need to be located in low level racks, the process will be initiated from the lowest (ymin) to the highest rack (ymax). On the contrary, medium- and small-sized slots are progressively assigned from the highest to the lowest rack with regard to their respective ergonomic constraints. For this reason, variables xpr and ypr are used, indicating the bay and rack from which the placement will start.

Starting from the left side of the aisle (r = 1) for the first slot type, the starting point (x

pr, y

pr) is assessed. The algorithm examines if there is available length (L

xy_remain) for the slot under consideration (L

SLOT) to be placed in. If there is not, the rack examined is increased or decreased by one, according to the slot type and the same condition is checked again.

In case the available length of a particular rack is sufficient, the slot is assigned there. The length of the slot at hand is then subtracted from the available length of the rack. Note that the initial available length for all racks is 1.6 m.

The number of XY slots stored (N

XY_stored) is increased by one.

Finally, the total number of slots available on the specific rack is increased by one. This step is very important for slot naming which will be conducted after the placement. The number above is fed in a matrix as

which represents variable

s in the matrix

SL(

r,

x,

y,

s).

Consequently, conditions (3) or (4) are checked again for the left side of the aisle. In case the logical condition is true, the process is repeated. However, if the available length of the initial rack is not adequate, the algorithm proceeds to examine the next rack in order. If no rack of the bay under examination fulfills this condition, the next bay in sequence is assessed, starting again from the initial rack. The loop is completed either when all the slots of a particular type, for the left side, have been placed in a rack, i.e., conditions (3) or (4) have turned false, or when there is no more space left for the specific slot type, so until condition (5) turns false for all racks. In such case, the same steps are followed again for the next slot type in order. Once all nine slot types have been examined, the algorithm continues with the right side of the aisle (r = 2), initializing the available rack length and repeating the whole process for the remaining slots. This way, an “ideal aisle” is created, which can be reproduced across the picking area.

The same layout design policy was also applied for dynamic slots, where the only ergonomic factor examined is the rack height since walking is negligible in this case, as stated in

Section 3. However, that configuration is out of scope for this study and is only mentioned to support the final findings that incorporate products stored in that area.

Next, new names have to be assigned to the altered slot layout. To that end, an 8-number code is used, notated as

The first two numbers represent the number of the aisle, while the second two define the number of the bay. Note that the value

BB can take values between 1 and 10, since there are 10 bays per aisle and the sequence is diagonal, with Bay 1 being the first bay on the left side of the aisle, Bay 2 the first bay on the right side, Bay 3 the second bay on the left side and so on.

CC represents the number of the rack, starting from the ground floor, and can receive values between 1 and 5. Finally,

DD is a counter of the consecutive slots in each rack, starting from the point closest to the depot. The layout algorithm is demonstrated in the flowchart presented in

Figure 6.

4.6. Optimal Storage Location Assignment

Following the layout redesign, products have to be assigned to their optimal locations in order to minimize OP time, improve resource allocation, and mitigate the intensity of physical workload. However, several factors require further examination, as explained below:

The slot type, which is defined by product popularity class and the size required to accommodate them.

The weight of storage units, which is an extremely important factor, since products with unit weight above 10 kg should not be assigned to racks higher than the 3rd one.

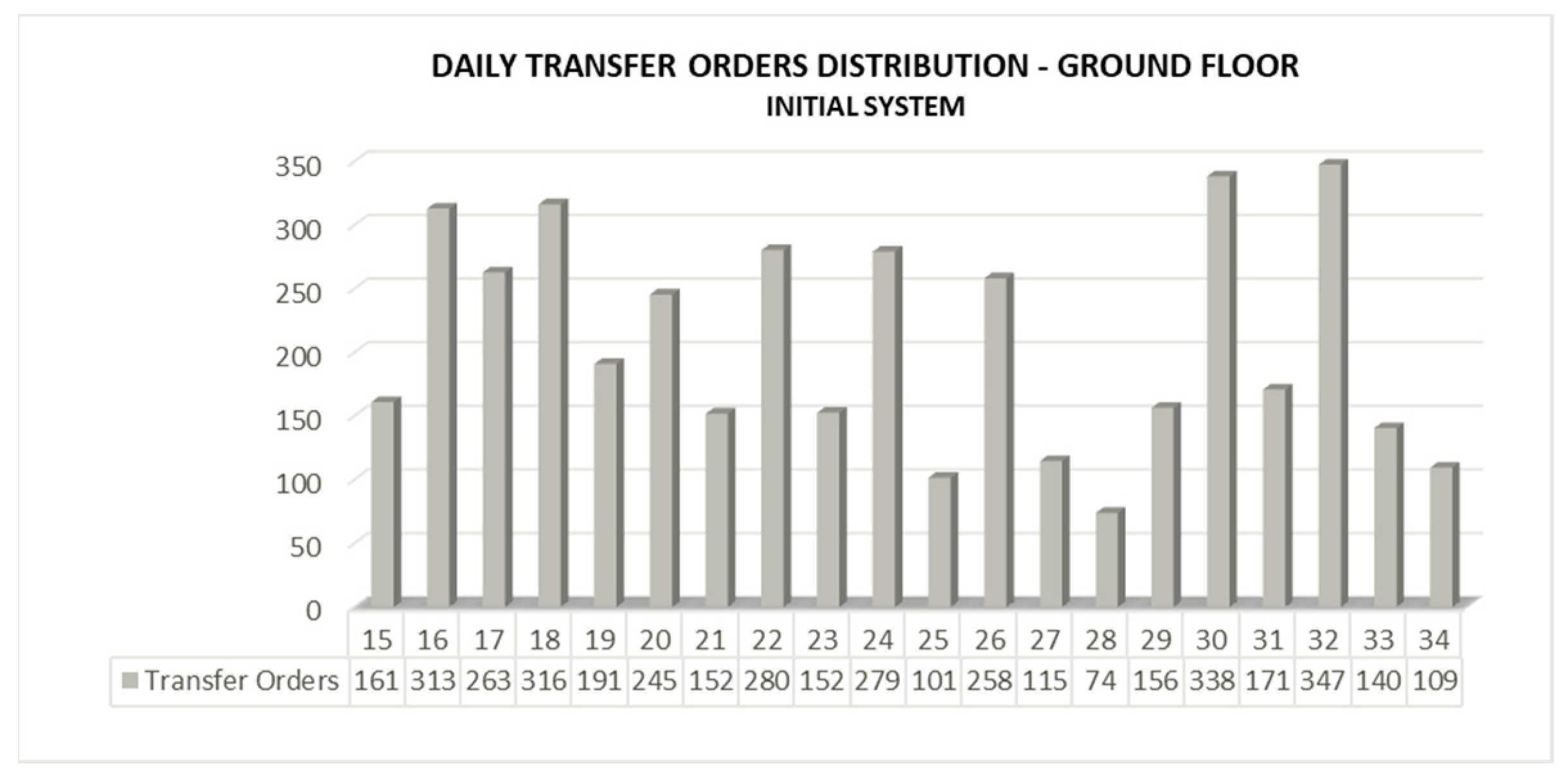

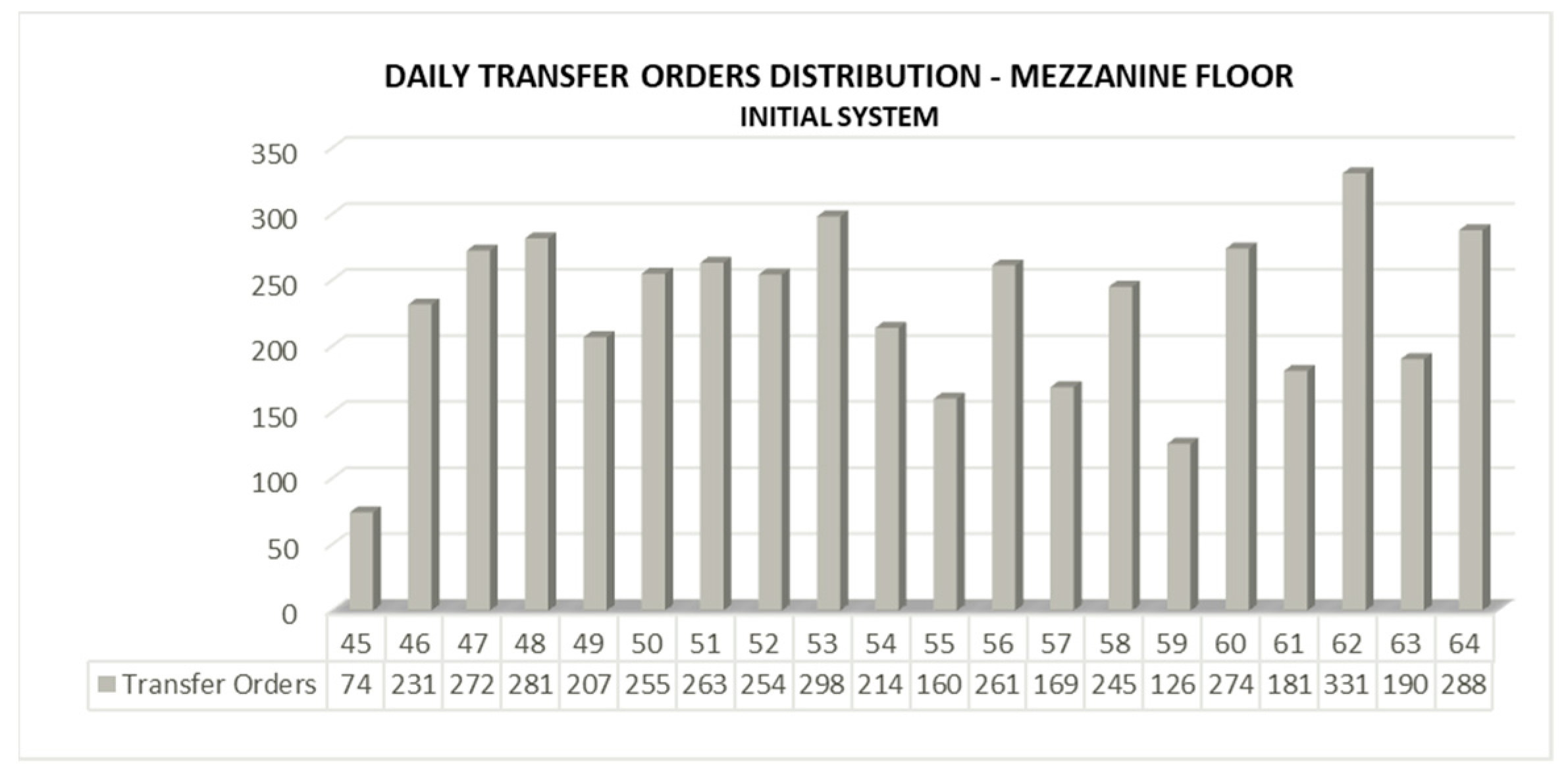

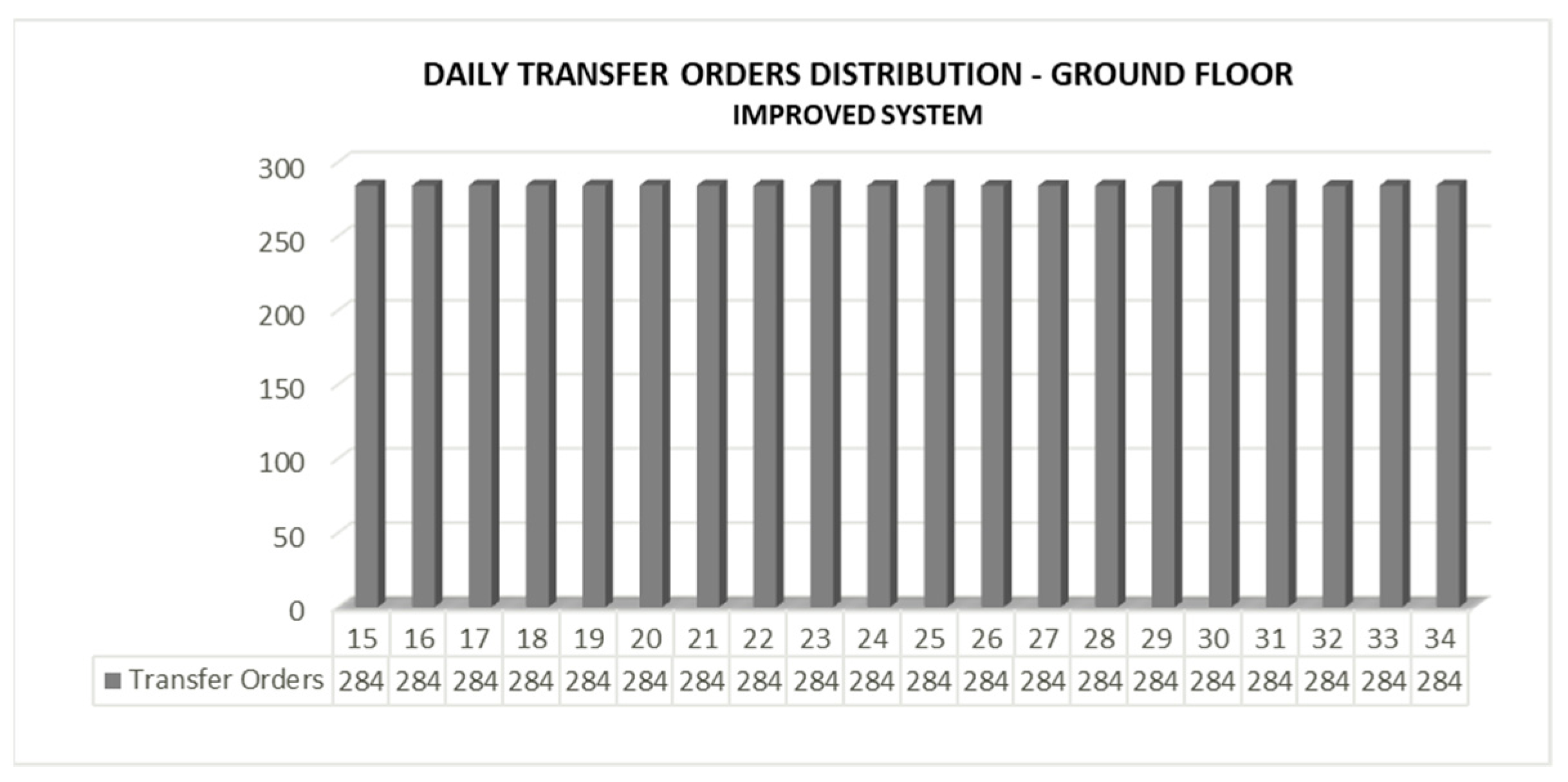

Equal allocation of workload and transfer orders among aisles, with to the aim of preventing picker collision.

The initial storage aisle of each product is the first to be examined, so that the time and movements needed for transferring the products to their new locations are limited to the bare minimum.

Knowing the daily turnover value of 5842 SKUs, the total daily orders can be easily calculated and divided equally among the 40 aisles, considering a maximum margin of error of 1.26%, found after trials. The maximum transfer orders per aisle are therefore defined according to the following equation:

Applying a random order of the given SKUs, the slot type required for the first product in line, its initial aisle, and its daily turnover are provided as inputs in the algorithm. Subsequently, the availability of the demanded slot type is examined for the initial aisle, followed by checking whether the total transfer orders of the aisle, including the turnover of the product to be assigned there, exceed the maximum limit or not. After examining these conditions, all slots are sequentially examined, starting from the first slot of Rack 1 in Bay 1, until an empty slot of the demanded type is found whereupon the product is assigned and the available number of its slot type in this specific aisle is reduced by one and registered as “full” in the system. This way, double entries are prevented and only empty slots are checked.

However, if the transfer orders of an aisle exceed the maximum limit (Equation (9)) or there is no empty slot of the demanded type, then the next or previous closest aisle of the same mezzanine floor is examined. This process continues until the product is successfully assigned to a location. After completing the loop, the next SKU in line is examined.

4.7. OP Difficulty Ranking System

Considering that ergonomics is hard to quantify, the authors suggest that in order to compare the initial and improved layout with respect to this metric, the difficulty of OP should be measured. In this vein, an innovative OP difficulty ranking system was proposed, according to which, the difficulty of handling each product is rated based on its daily transfer orders, rack, bay and weight (

Table 6), as follows.

According to Equation (10), there are several factors impacting the difficulty in product handling. First, a “Bay Difficulty Rate” ranking system is defined (

Table 7, since the location of bays in a picking area determines how difficult it will be for a picker to walk to a slot and back to the depot, while carrying the average number of units of product

i retrieved per transfer order. Likewise, a “Rack Difficulty Rate” ranking system is defined (

Table 8), taking into consideration the effort required to retrieve a product from a particular rack based on its storage box weight. Box handling might include replenishing, shifting, opening of cartons, moving to reach, and count products etc. Daily transfer orders of the product under examination are also included in this equation. This is essential, because the more repetitive a task is, the more difficult it becomes. Thus, the bigger the turnover, the more times a picker has to handle a particular SKU and as a consequence, the greater his/her physical fatigue will be.

As depicted, the racks have been rated according to the ergonomic constraints presented in

Section 4.4, starting from a minimum value of 1 for the 3rd rack to a maximum of 5 for the 5th one. As far as the bay difficulty rating values go, it was decided by the authors for them to be exactly half of the respective rack difficulty rating values, since according to the existing literature on this topic [

58], walking is the least intense activity a picker is required to perform. Hence, the closer the bay is to the deposition point, the lower the difficulty rate, starting from 0.5 for the 1st bay and reaching up to 2.5 for the 5th one.

For the SKUs stored in dynamic slots, a different formula was developed based on the same variables and rating system as Equation (10). Again, for the reasons mentioned above, only the ergonomics pertinent to racks are considered. Thus, Equation (10) is transformed into

Considering Equations (10) and (12), the “Total Difficulty Rate” is defined as