Improving Manufacturing Supply Chain by Integrating SMED and Production Scheduling

Abstract

1. Introduction

2. Literature Review

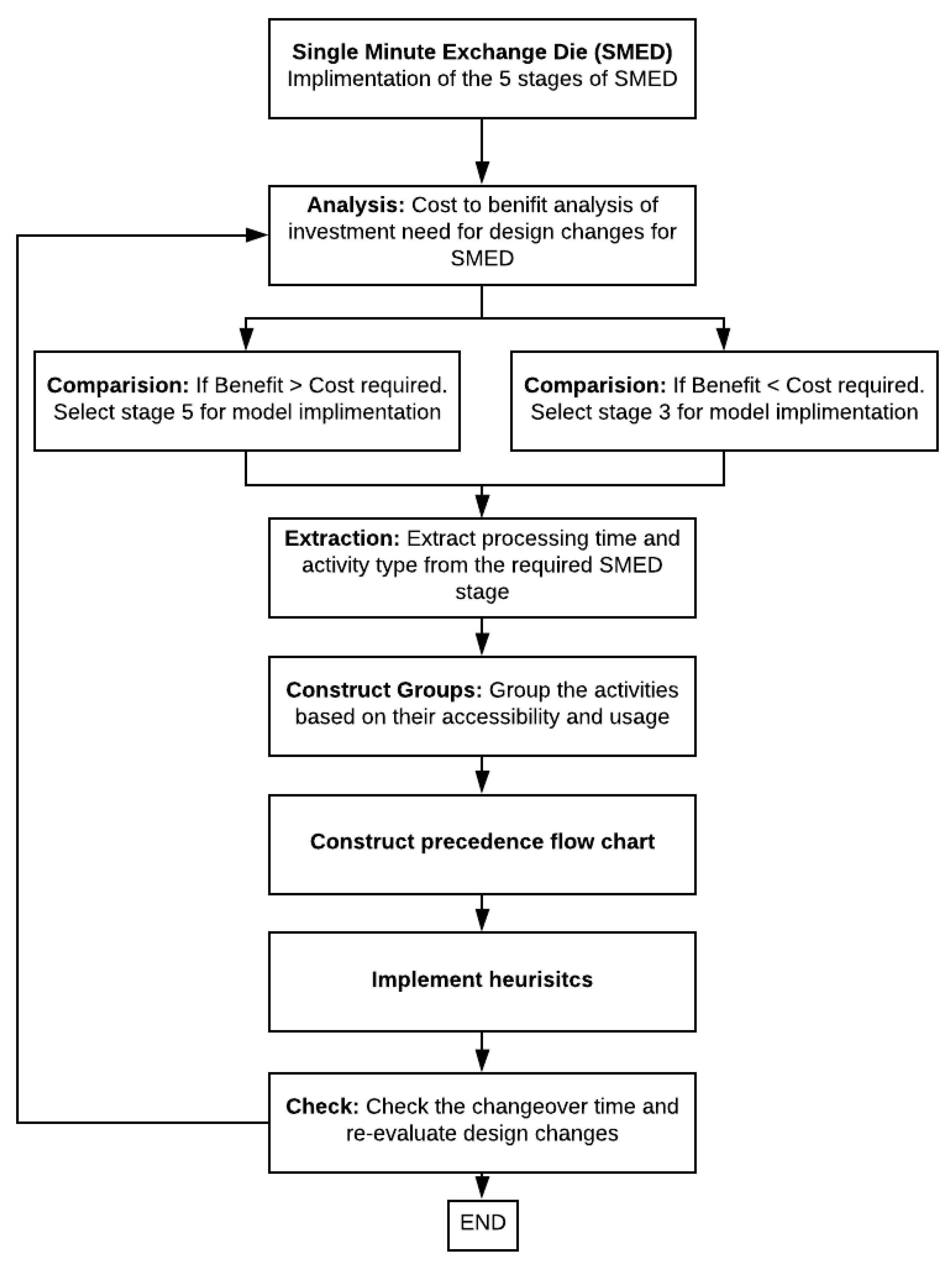

3. Materials and Methods

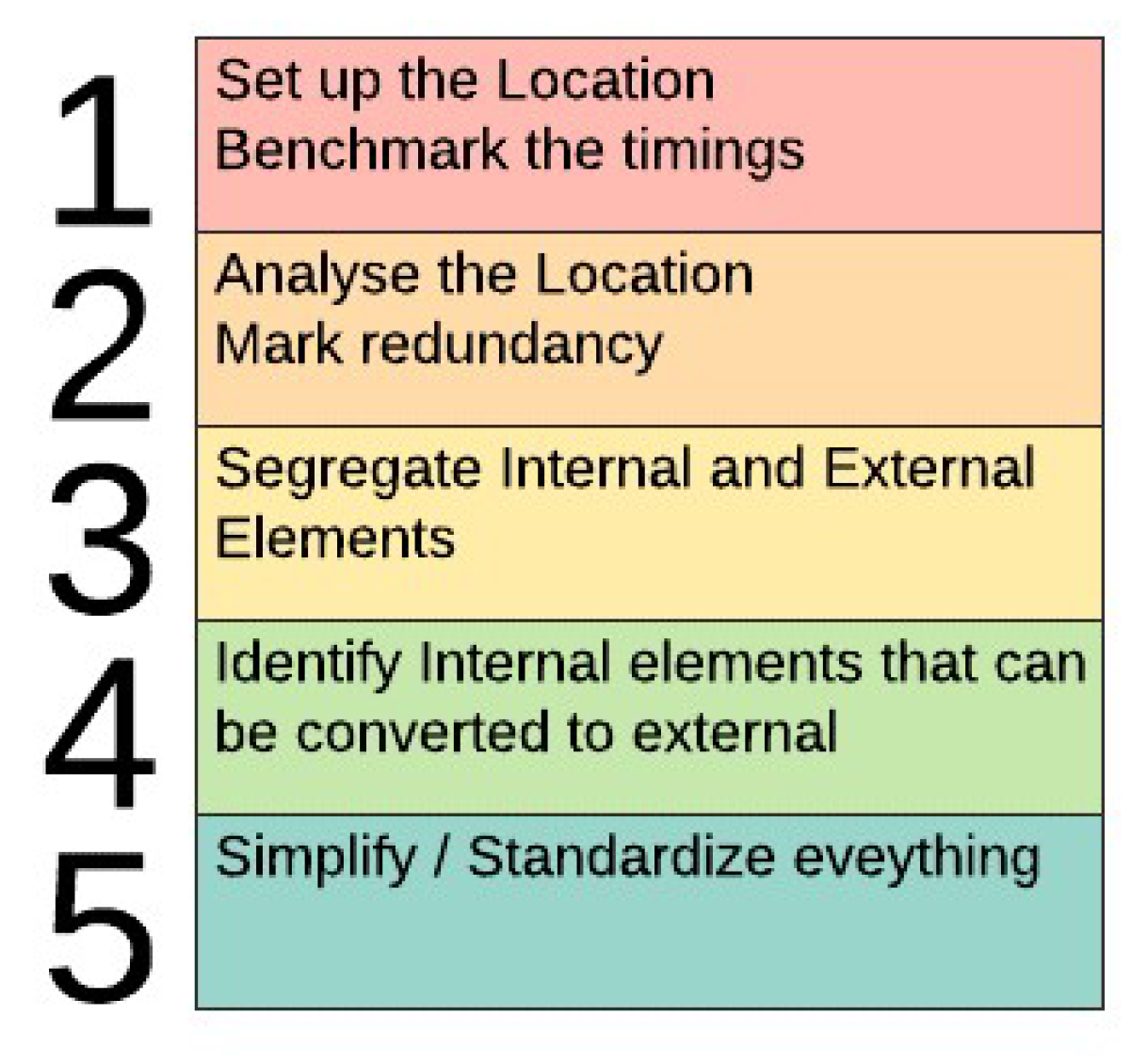

3.1. SMED Implementation Stages

3.2. Proposed Scheduling Model

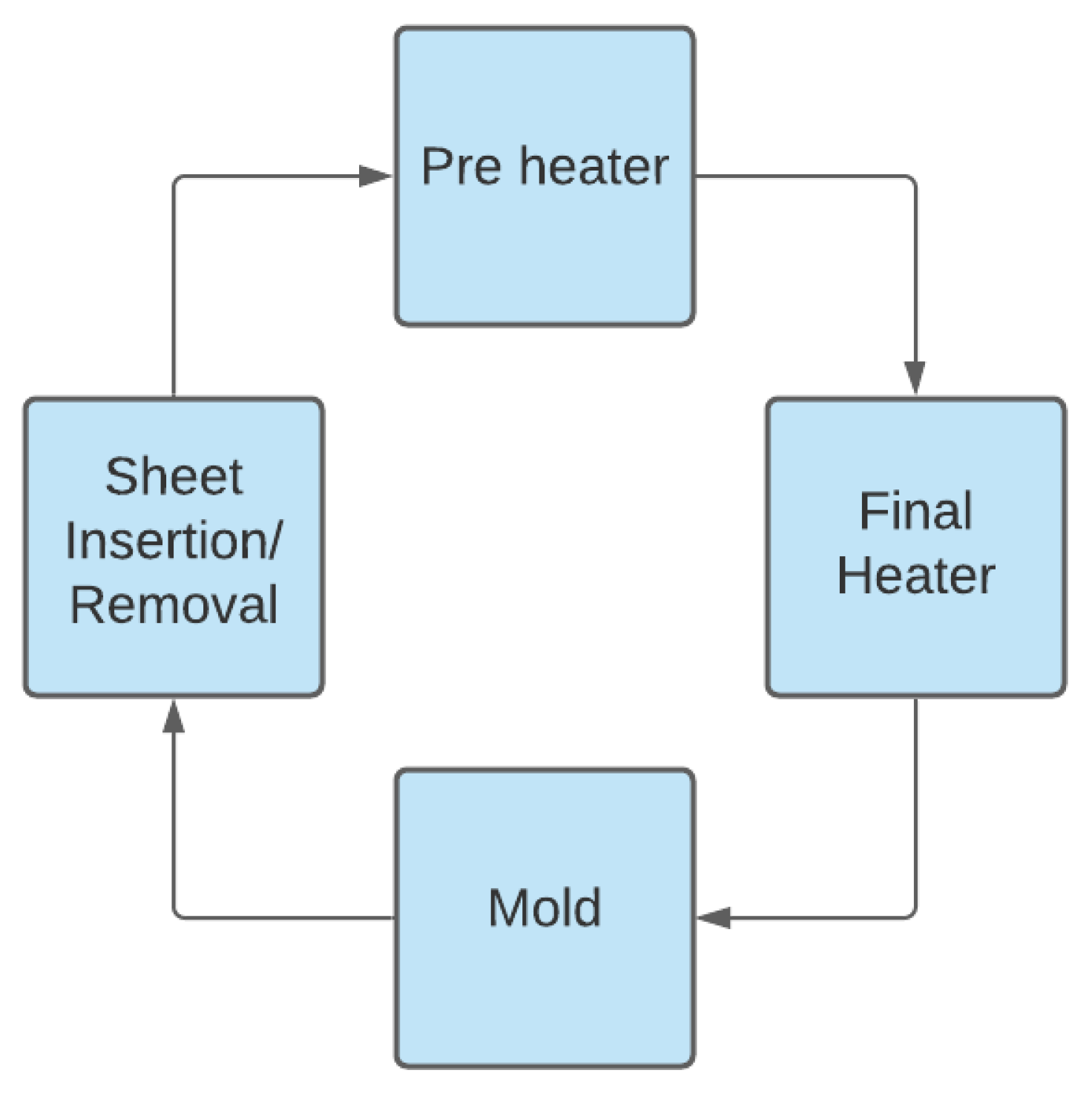

4. Case Study

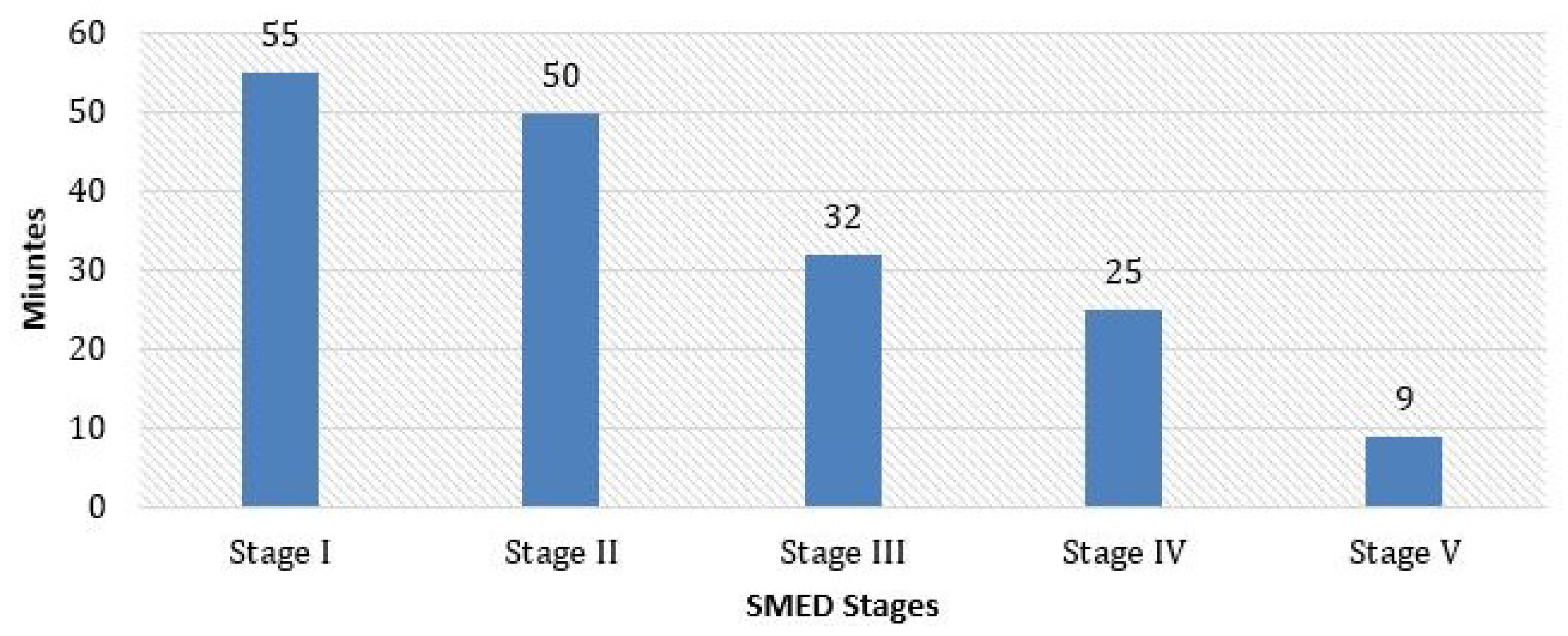

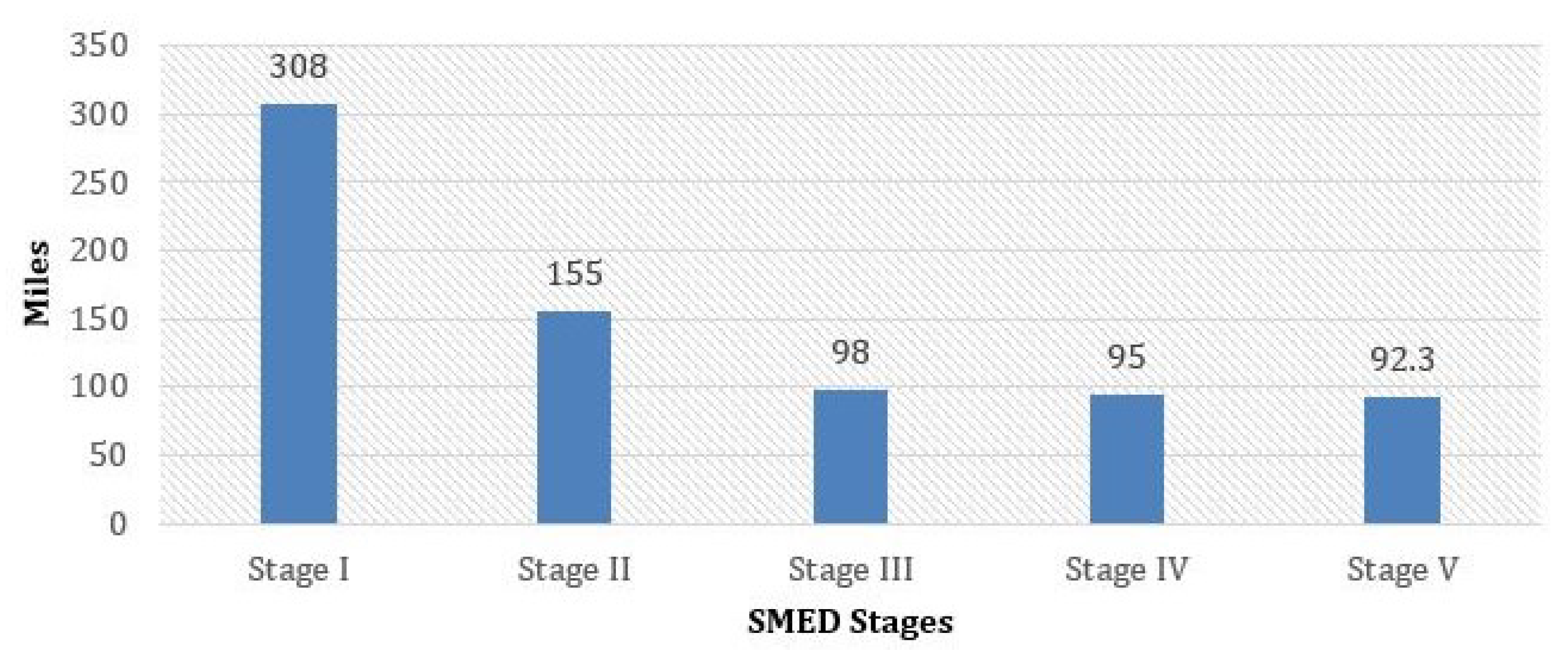

4.1. SMED Implementation

4.2. Model Implementation

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gungor, Z.E.; Evans, S. Understanding the hidden cost and identifying the root causes of changeover impacts. J. Clean. Prod. 2017, 167, 1138–1147. [Google Scholar] [CrossRef]

- Boran, S.; Ekincioğlu, C. A novel integrated SMED approach for reducing setup time. Int. J. Adv. Manuf. Technol. 2017, 92, 3941–3951. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Ciocanel, A.B.; Pavelescu, F.M. Innovation and Competitiveness in European Context. Procedia Econ. Financ. 2015, 32, 728–737. [Google Scholar] [CrossRef]

- Kumar, S.V.; Mani, V.; Devraj, N. Production Planning and Process Improvement in an Impeller Manufacturing Using Scheduling and OEE Techniques. Procedia Mater. Sci. 2014, 5, 1710–1715. [Google Scholar] [CrossRef][Green Version]

- Lozano, J.; Saenz-Díez, J.; Martínez, E.; Jiménez, E.; Blanco, J. Methodology to improve machine changeover performance on food industry based on SMED. Int. J. Adv. Manuf. Technol. 2017, 90, 3607–3618. [Google Scholar] [CrossRef]

- Cottyn, J.; Van Landeghem, H.; Stockman, K.; Derammelaere, S. A method to align a manufacturing execution system with Lean objectives. Int. J. Prod. Res. 2011, 49, 4397. [Google Scholar] [CrossRef]

- Ismail, A.; Ghani, J.A.; Ab Rahman, M.N.; Md Deros, B.; Che Haron, C.H. Application of Lean Six Sigma Tools for Cycle Time Reduction in Manufacturing: Case Study in Biopharmaceutical Industry. Arab. J. Sci. Eng. 2013, 39, 1449–1463. [Google Scholar] [CrossRef]

- Wierschem, D.C.; Jimenez, J.A.; Méndez Mediavilla, F.A. A motion capture system for the study of human manufacturing repetitive motions. Int. J. Adv. Manuf. Technol. 2020, 110, 813–827. [Google Scholar] [CrossRef]

- Wang, S.S.; Chiou, C.C.; Luong, H.T. Application of SMED Methodology and Scheduling in High-Mix Low Volume Production Model to Reduce Setup Time: A Case of S Company. IOP Conf. Ser. Mater. Sci. Eng. 2019, 598, 012058. [Google Scholar] [CrossRef]

- Saryanto, S.; Purba, H.; Trimarjoko, A. Improve Quality Remanufacturing Welding and Machining Process in Indonesia Using Six Sigma Methods. J. Eur. SystèMes Autom. 2020, 53, 377–384. [Google Scholar] [CrossRef]

- Jit Singh, B.; Khanduja, D. SMED: For quick changeovers in foundry SMEs. Int. J. Product. Perform. Manag. 2009, 59, 98–116. [Google Scholar] [CrossRef]

- Shingo, S. A Revolution in Manufacturing: The SMED System/Shigeo Shingo; Translated by Andrew P. Dillon; With a Preface by Norman Bodek; Productivity Press: Norwalk, CT, USA, 1985. [Google Scholar]

- Kholil, M.; Alfa, B.N.; Supriyanto. Optimization of Production Process Time with Network/PERT Analysis Technique and SMED Method. IOP Conf. Ser. Mater. Sci. Eng. 2018, 453, 012050. [Google Scholar] [CrossRef]

- Braglia, M.; Frosolini, M.; Gallo, M. SMED enhanced with 5-Whys Analysis to improve set-upreduction programs: The SWAN approach. Int. J. Adv. Manuf. Technol. 2016, 90, 1845–1855. [Google Scholar] [CrossRef]

- Stadnicka, D. Setup Analysis: Combining SMED with Other Tools. Manag. Prod. Eng. Rev. 2015, 6, 36–50. [Google Scholar] [CrossRef]

- Kiran, D. Chapter 21—Resistance to change. In Work Organization and Methods Engineering for Productivity; Kiran, D., Ed.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 279–290. [Google Scholar] [CrossRef]

- Mihok, J.; Kádárová, J.; Demečko, M.; Ružinský, M. The Use of SMED in Engineering Manufacturing. Appl. Mech. Mater. 2015, 816, 568–573. [Google Scholar] [CrossRef]

- Nee, L.S.; Yee, S.H.; Razalli, S.; Hou, C.S.; Kamaruddin, S. External Setup in SMED Improvement in an Injection Molding Manufacturing Company. Appl. Mech. Mater. 2012, 229–231, 2551–2555. [Google Scholar] [CrossRef]

- Díaz-Reza, J.; García-Alcaraz, J.; Martínez-Loya, V.; Blanco-Fernández, J.; Jiménez-Macías, E.; Avelar-Sosa, L. The Effect of SMED on Benefits Gained in Maquiladora Industry. Sustainability 2016, 8, 1237. [Google Scholar] [CrossRef]

- Ahmad, R.; Ahmad, R.; Soberi, M.S.F.; Soberi, M.S.F. Changeover process improvement based on modified SMED method and other process improvement tools application: An improvement project of 5-axis CNC machine operation in advanced composite manufacturing industry. Int. J. Adv. Manuf. Technol. 2018, 94, 433–450. [Google Scholar] [CrossRef]

- Bachman, A.; Janiak, A. Scheduling Jobs with Position-Dependent Processing Times. J. Oper. Res. Soc. 2004, 55, 257–264. [Google Scholar] [CrossRef]

- Branke, J.; Nguyen, S.; Pickardt, C.W.; Zhang, M. Automated Design of Production Scheduling Heuristics: A Review. IEEE Trans. Evol. Comput. 2016, 20, 110–124. [Google Scholar] [CrossRef]

- Ruiz, R.; Vázquez-Rodríguez, J.A. The hybrid flow shop scheduling problem. Eur. J. Oper. Res. 2010, 205, 1–18. [Google Scholar] [CrossRef]

- Godinho Filho, M.; de Andrade Guimarães, A.; Oprime, P.C. Guiding improvement programs towards lead time reduction in a single-machine environment. Int. J. Adv. Manuf. Technol. 2012, 66, 1987–1998. [Google Scholar] [CrossRef]

- Basri, A.Q.; Mohamed, N.M.Z.N.; Yasir, K.A.S.H.M.; Fazi, H.M.; Fudzin, A.F. The validation of productivity on the changeover activity at the automotive stamping press line by comparing the embedded SMED frame-work versus SMED approach: A witness simulation case study. IOP Conf. Ser. Mater. Sci. Eng. 2019, 469, 12005. [Google Scholar] [CrossRef]

- Stankovic, A.; Petrovic, G.; Zarko Cojbasic, D.M. An application of metaheuristic optimization algorithms for solving flexible job-shop scheduling problem. Oper. Res. Eng. Sci. Theory Appl. 2020, 53, 13–28. [Google Scholar] [CrossRef]

- Huang, R.H. Multi-objective job-shop scheduling with lot-splitting production. Int. J. Prod. Econ. 2010, 124, 206–213. [Google Scholar] [CrossRef]

- Cavalcante, V.F.; Cardonha, C.H.; Herrmann, R.G. A Resource Constrained Project Scheduling Problem with Bounded Multitasking. IFAC Proc. Vol. 2013, 46, 433–437. [Google Scholar] [CrossRef]

- Cakmakci, M. Process improvement: Performance analysis of the setup time reduction-SMED in the automobile industry. Int. J. Adv. Manuf. Technol. 2008, 41, 168–179. [Google Scholar] [CrossRef]

- Pinedo, M.L. Planning and Scheduling in Manufacturing and Services, 2nd ed.; Springer: New York, NY, USA, 2009. [Google Scholar]

- Karasu, M.K.; Salum, L. FIS-SMED: A fuzzy inference system application for plastic injection mold changeover. Int. J. Adv. Manuf. Technol. 2018, 94, 545–559. [Google Scholar] [CrossRef]

- Antosz, K.; Pacana, A. Comparative Analysis of the Implementation of the SMED Method on Selected Production Stands. Teh. Vjesn. 2018, 25, 276–282. [Google Scholar]

| Internal Activities Converted to External | Time Saved (Seconds) |

|---|---|

| Documenting the production | 37 |

| Bringing the lockbox to the machine | 30 |

| Getting and placing the hard hat near control panel | 14 |

| Bringing new form near the machine | 85 |

| Cleaning the new form | 145 |

| Jobs | Processing Time pj (s) |

|---|---|

| A | 38 |

| B | 109 |

| C | 35 |

| D | 33 |

| E | 44 |

| F | 40 |

| G | 14 |

| H | 12 |

| I | 103 |

| J | 92 |

| K | 41 |

| Jobs | Earliest Start Time (s) | Latest Finish Time (s) | Slack (s) |

|---|---|---|---|

| A | 0 | 38 | 0 |

| B | 38 | 147 | 0 |

| C | 38 | 73 | 183 |

| D | 147 | 180 | 11 |

| E | 147 | 191 | 0 |

| F | 191 | 231 | 0 |

| G | 231 | 245 | 0 |

| H | 231 | 243 | 2 |

| I | 245 | 348 | 0 |

| J | 73 | 165 | 183 |

| K | 348 | 389 | 0 |

| Jobs | Earliest Start Time (s) | Latest Finish Time (s) | Slack (s) |

|---|---|---|---|

| A | 0 | 38 | 0 |

| B | 38 | 93 | 0 |

| C | 38 | 128 | 74 |

| D | 93 | 126 | 11 |

| E | 93 | 137 | 0 |

| F | 137 | 177 | 0 |

| G | 177 | 191 | 0 |

| H | 177 | 189 | 2 |

| I | 191 | 294 | 0 |

| J | 128 | 220 | 74 |

| K | 294 | 335 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parwani, V.; Hu, G. Improving Manufacturing Supply Chain by Integrating SMED and Production Scheduling. Logistics 2021, 5, 4. https://doi.org/10.3390/logistics5010004

Parwani V, Hu G. Improving Manufacturing Supply Chain by Integrating SMED and Production Scheduling. Logistics. 2021; 5(1):4. https://doi.org/10.3390/logistics5010004

Chicago/Turabian StyleParwani, Viren, and Guiping Hu. 2021. "Improving Manufacturing Supply Chain by Integrating SMED and Production Scheduling" Logistics 5, no. 1: 4. https://doi.org/10.3390/logistics5010004

APA StyleParwani, V., & Hu, G. (2021). Improving Manufacturing Supply Chain by Integrating SMED and Production Scheduling. Logistics, 5(1), 4. https://doi.org/10.3390/logistics5010004