Micro-Foundations of Supply Chain Integration: An Activity-Based Analysis

Abstract

1. Introduction

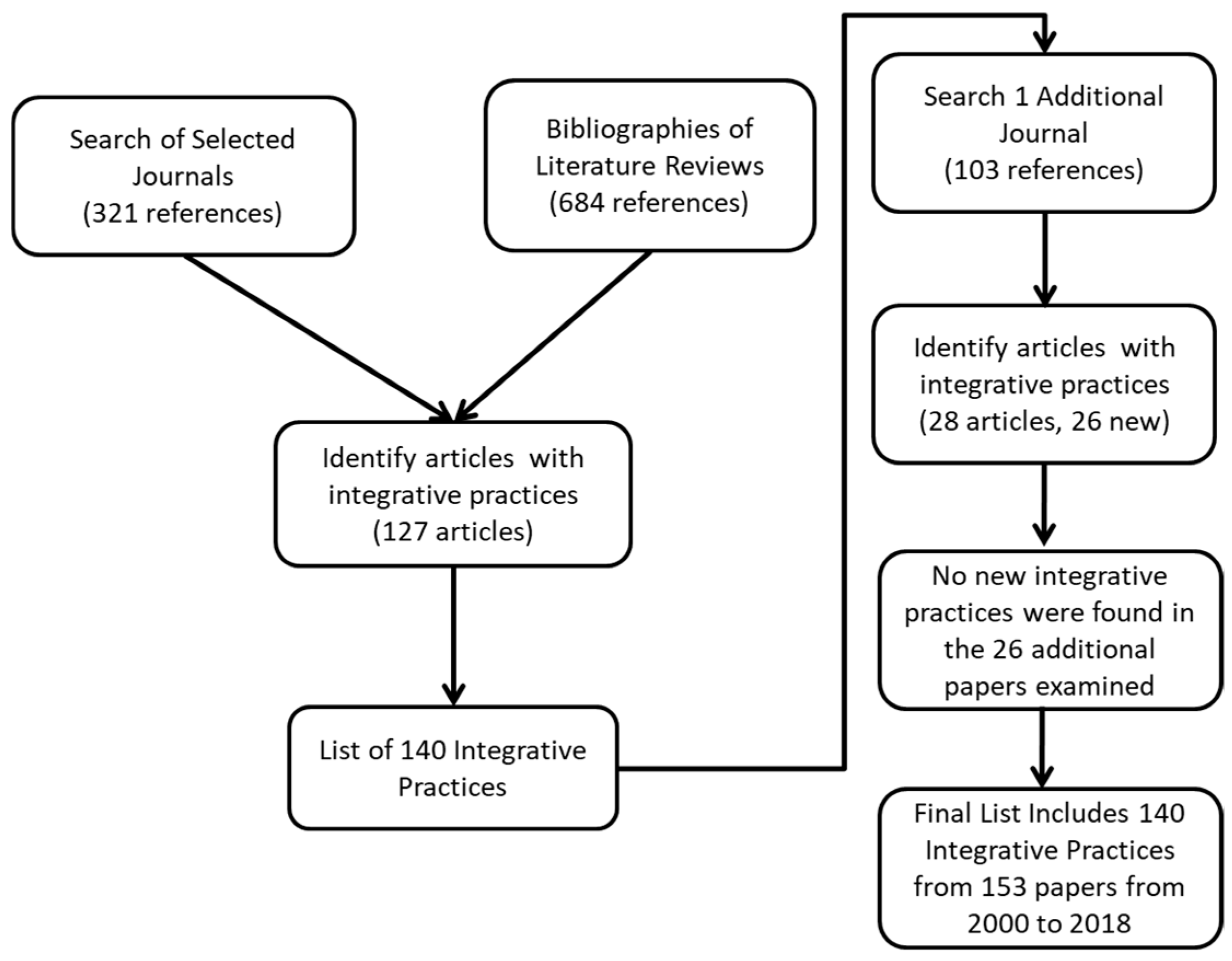

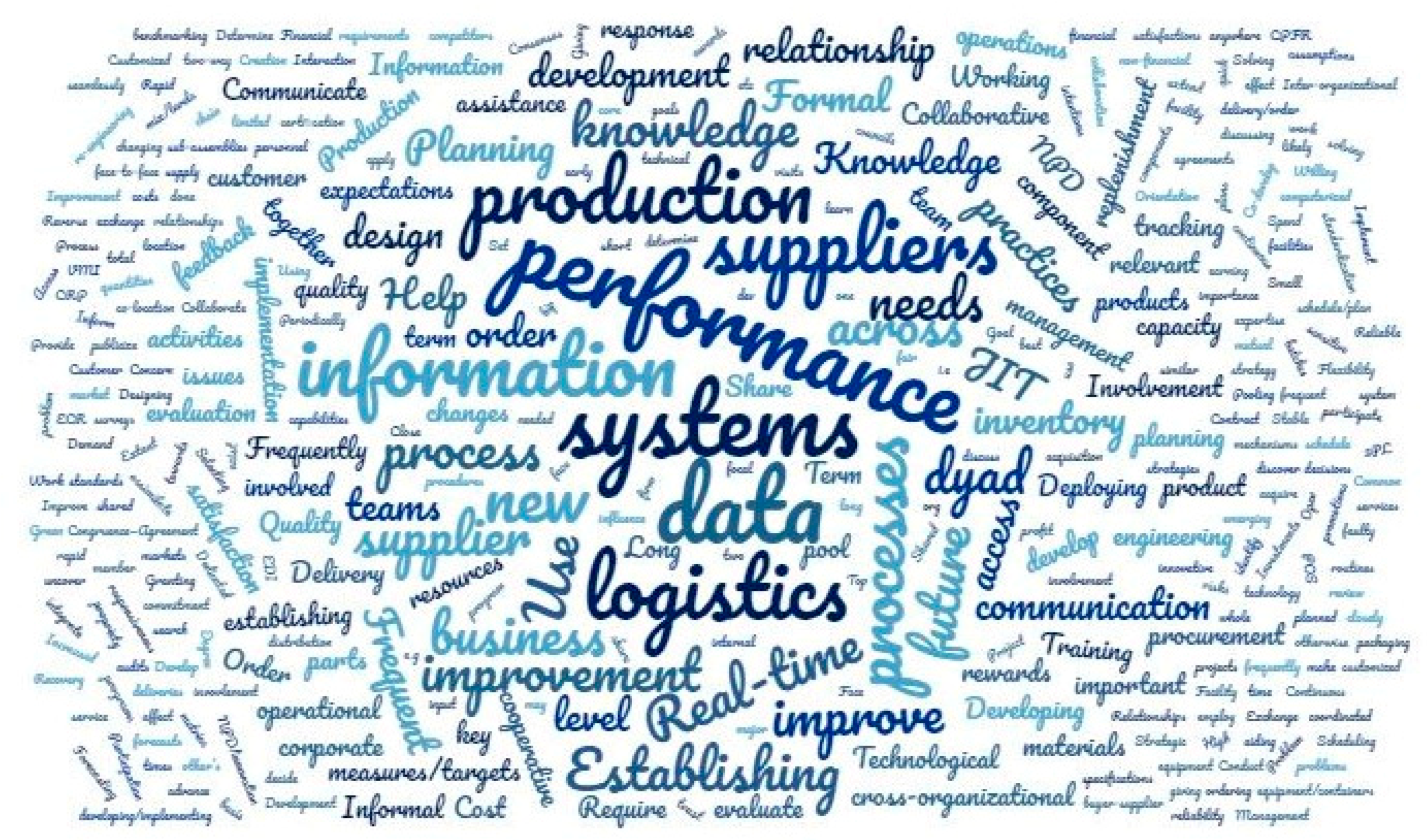

2. Identifying Integrative Practices

3. Theoretical Development

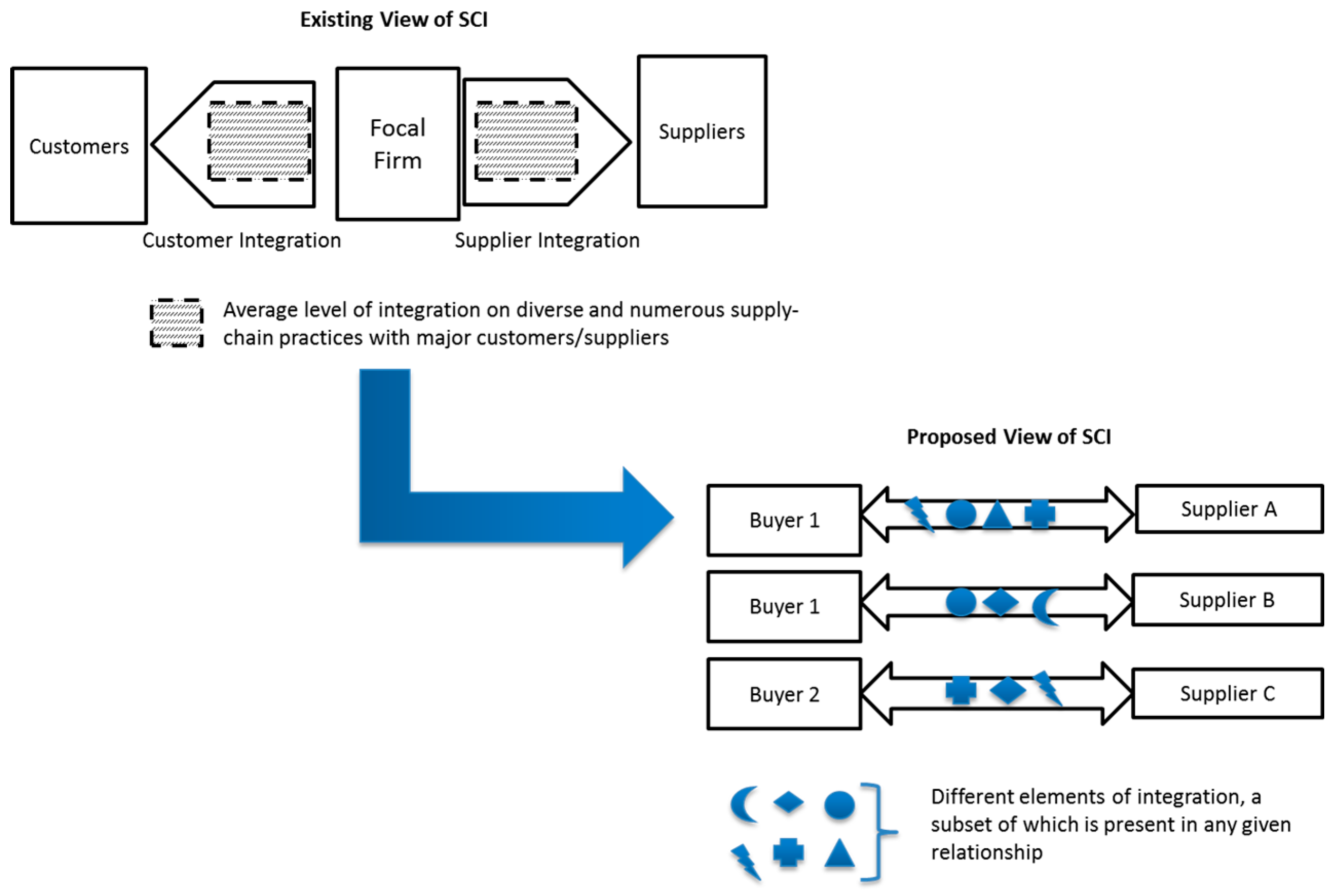

3.1. Defining Inter-Firm Supply Chain Integration

- A supply-chain integrative practice is a shared activity between a buyer firm and a supplier firm, with the aim of creating greater value for both firms than what could be achieved without such joint action.

- A shared activity is one in which each supply chain partner has to do some share of the tasks. A recurring activity is also called a process.

- A buyer-supplier dyad’s level of integration can be determined based on the use of supply-chain integrative practices.

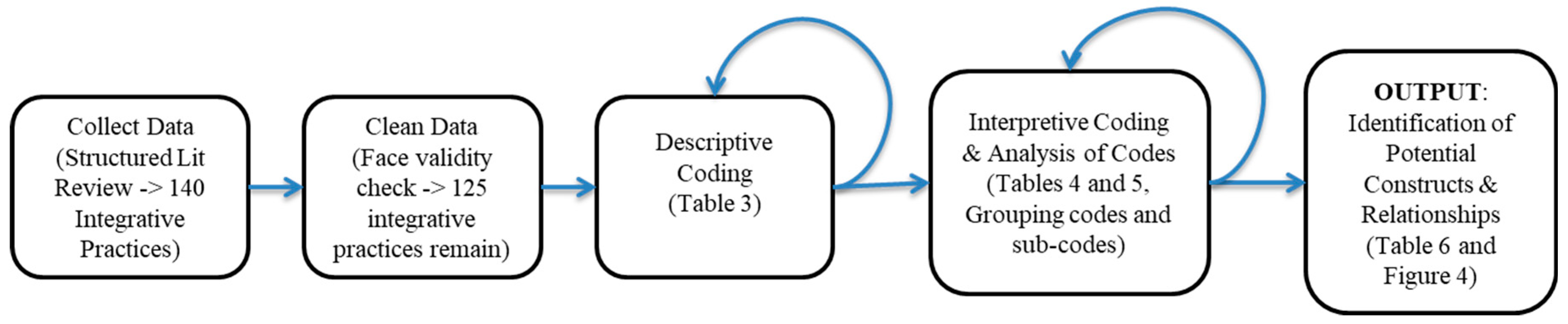

3.2. Qualitative Analysis for the Integrative Practices

3.2.1. Identifying Constructs from Codes

3.2.2. Detailed Steps for Basic Communication

3.3. Constructs Identified through Qualitative Analysis

4. Theoretical Contributions

5. Limitations

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Soosay, C.A.; Hyland, P. A decade of supply chain collaboration and directions for future research. Supply Chain Manag. Int. J. 2015, 20, 613–630. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Impact of supply chain risk on agility performance: Mediating role of supply chain integration. Int. J. Prod. Econ. 2018, 205, 118–138. [Google Scholar] [CrossRef]

- Yu, W.; Jacobs, M.A.; Salisbury, W.D.; Enns, H. The effects of supply chain integration on customer satisfaction and financial performance: An organizational learning perspective. Int. J. Prod. Econ. 2013, 146, 346–358. [Google Scholar] [CrossRef]

- Min, S.; Mentzer, J.T. Developing and measuring supply chain management concepts. J. Bus. Logist. 2004, 25, 63–99. [Google Scholar] [CrossRef]

- Narasimhan, R.; Jayaram, J. Causal Linkages in Supply Chain Management: An Exploratory Study of North American Manufacturing Firms. Decis. Sci. 1998, 29, 579–605. [Google Scholar] [CrossRef]

- Terpend, R.; Tyler, B.B.; Krause, D.R.; Handfield, R.B. Buyer-Supplier Relationships: Dervied Value Over Two Decades. J. Supply Chain Manag. 2008, 44, 28–55. [Google Scholar] [CrossRef]

- Ho, D.C.K.; Au, K.F.; Newton, E. Empirical research on supply chain management: A critical review and recommendations. Int. J. Prod. Res. 2002, 40, 4415–4430. [Google Scholar] [CrossRef]

- Van der Vaart, T.; van Donk, D.P. A critical review of survey-based research in supply chain integration. Int. J. Prod. Econ. 2008, 111, 42–55. [Google Scholar] [CrossRef]

- Johnson, G.; Melin, L.; Whittington, R. Micro strategy and strategizing: Towards an activity-based view. J. Manag. Stud. 2003, 40, 3–22. [Google Scholar] [CrossRef]

- Ray, G.; Barney, J.B.; Muhanna, W.A. Capabilities, business processes, and competitive advantage: Choosing the dependent variable in empirical tests of the resource-based view. Strateg. Manag. J. 2004, 25, 23–37. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Huo, B.; Qi, Y.; Wang, Z.; Zhao, X. The impact of supply chain integration on firm performance: The moderating role of competitive strategy. Supply Chain Manag. Int. J. 2014, 19, 369–384. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Understanding supply chain management: Critical research and a theoretical framework. Int. J. Prod. Res. 2004, 42, 131–163. [Google Scholar] [CrossRef]

- Lee, H.L. Creating value through supply chain integration. Supply Chain Manag. Rev. 2000, 4, 30–36. [Google Scholar]

- Simatupang, T.M.; Sridharan, R. Design for supply chain collaboration. Bus. Process Manag. J. 2008, 14, 401–418. [Google Scholar] [CrossRef]

- Burgess, K.; Singh, P.J.; Koroglu, R. Supply chain management: A structured literature review and implications for future research. Int. J. Oper. Prod. Manag. 2006, 26, 703–729. [Google Scholar] [CrossRef]

- Goffin, K.; Lemke, F.; Szwejczewski, M. An exploratory study of ‘close’ supplier–manufacturer relationships. J. Oper. Manag. 2006, 24, 189–209. [Google Scholar] [CrossRef]

- Soni, G.; Kodali, R. A critical analysis of supply chain management content in empirical research. Bus. Process Manag. J. 2011, 17, 238–266. [Google Scholar] [CrossRef]

- Ahmed, M.U.; Kristal, M.M.; Pagell, M.; Gattiker, T.F. Towards a classification of supply chain relationships: A routine based perspective. Supply Chain Manag. Int. J. 2017, 22, 341–374. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Croom, S.; Romano, P.; Giannakis, M. Supply chain management: An analytical framework for critical literature review. Eur. J. Purch. Supply Manag. 2000, 6, 67–83. [Google Scholar] [CrossRef]

- Menor, L.J.; Roth, A.V. New service development competence in retail banking: Construct development and measurement validation. J. Oper. Manag. 2007, 25, 825–846. [Google Scholar] [CrossRef]

- Parmigiani, A.; Rivera-Santos, M. Clearing a path through the forest: A meta-review of interorganizational relationships. J. Manag. 2011, 37, 1108–1136. [Google Scholar] [CrossRef]

- Carter, C.R.; Ellram, L.M. Thirty-Rve Years of the Journal of Supply Chain Management: Where Have We Been and Where are We Going? J. Supply Chain Manag. 2003, 39, 27–39. [Google Scholar] [CrossRef]

- Fabbe-Costes, N.; Jahre, M. Supply chain integration and performance: A review of the evidence. Int. J. Logist. Manag. 2008, 19, 130–154. [Google Scholar] [CrossRef]

- Giannakis, M.; Croom, S.R. Toward the Development of a Supply Chain Management Paradigm: A Conceptual Framework. J. Supply Chain Manag. 2004, 40, 27–37. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Joseph-Matthews, S.; Yoon, T.E.; Brudvig, S. A Decade of SCM Literature: Past, Present and Future Implications. J. Supply Chain Manag. 2008, 44, 66–86. [Google Scholar] [CrossRef]

- Ketchen, D.J., Jr.; Giunipero, L.C. The intersection of strategic management and supply chain management. Ind. Mark. Manag. 2004, 33, 51. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- McAdam, R.; McCormack, D. Integrating business processes for global alignment and supply chain management. Bus. Process Manag. J. 2001, 7, 113–130. [Google Scholar] [CrossRef]

- Gimenez, C.; Ventura, E. Logistics-production, logistics-marketing and external integration: Their impact on performance. Int. J. Oper. Prod. Manag. 2005, 25, 20–38. [Google Scholar] [CrossRef]

- Peteraf, M.A.; Barney, J.B. Unraveling the Resource-Based Tangle. Manag. Decis. Econ. 2003, 24, 309–323. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M. Qualitative Data Analysis: An Expanded Sourcebook; Sage: Thousand Oaks, CA, USA, 1994; ISBN 0-8039-2274-4. [Google Scholar]

- Strauss, A.; Corbin, J.M. Basics of Qualitative research: Grounded Theory Procedures and Techniques; Sage: Thousand Oaks, CA, USA, 1990. [Google Scholar]

- Galbraith, J.R. Organization design: An information processing view. Interfaces 1974, 4, 28–36. [Google Scholar] [CrossRef]

- Lavie, D. The competitive advantage of interconnected firms: An extension of the resource-based view. Acad. Manag. Rev. 2006, 31, 638–658. [Google Scholar] [CrossRef]

- Swink, M.; Narasimhan, R.; Wang, C. Managing beyond the factory walls: Effects of four types of strategic integration on manufacturing plant performance. J. Oper. Manag. 2007, 25, 148. [Google Scholar] [CrossRef]

- Dyer, J.H.; Singh, H. The relational view: Cooperative strategy and sources of interorganizational competitive advantage. Acad. Manag. Acad. Manag. Rev. 1998, 23, 660. [Google Scholar] [CrossRef]

- Das, A.; Narasimhan, R.; Talluri, S. Supplier integration—Finding an optimal configuration. J. Oper. Manag. 2006, 24, 563–582. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Ketchen, D.J.; Cavusgil, S.T.; Calantone, R.J. Knowledge as a strategic resource in supply chains. J. Oper. Manag. 2006, 24, 458–475. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Hsuan, J.; Kotzab, H. Complementary theories to supply chain management revisited–from borrowing theories to theorizing. Supply Chain Manag. Int. J. 2015, 20, 574–586. [Google Scholar] [CrossRef]

- Chen, F.; Drezner, Z.; Ryan, J.K.; Simchi-Levi, D. Quantifying the bullwhip effect in a simple supply chain: The impact of forecasting, lead times, and information. Manag. Sci. 2000, 46, 436–443. [Google Scholar] [CrossRef]

- Lee, H.L.; Padmanabhan, V.; Whang, S. Information distortion in a supply chain: The bullwhip effect. Manag. Sci. 1997, 43, 546–558. [Google Scholar] [CrossRef]

- Liu, H.; Wei, S.; Ke, W.; Wei, K.K.; Hua, Z. The configuration between supply chain integration and information technology competency: A resource orchestration perspective. J. Oper. Manag. 2016, 44, 13–29. [Google Scholar] [CrossRef]

- Grant, R.M. Toward a Knowledge-Based Theory of the Firm. Strateg. Manag. J. 1996, 17, 109. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Ketchen, D.J., Jr.; Slater, S.F. Information Processing, Knowledge Development, and Strategic Supply Chain Performance. Acad. Manag. J. 2004, 47, 241–253. [Google Scholar]

- Koufteros, X.A.; Vonderembse, M.; Jayaram, J. Internal and External Integration for Product Development: The Contingency Effects of Uncertainty, Equivocality, and Platform Strategy. Decis. Sci. 2005, 36, 97–133. [Google Scholar] [CrossRef]

- Ring, P.S.; Van De Ven, A.H. Developmental Processes of Cooperative Interorganizational Relationships. Acad. Manag. Rev. 1994, 19, 90–118. [Google Scholar] [CrossRef]

- Ireland, R.D.; Webb, J.W. A multi-theoretic perspective on trust and power in strategic supply chains. J. Oper. Manag. 2007, 25, 482–497. [Google Scholar] [CrossRef]

- Das, T.K.; Teng, B.-S. Between trust and control: Developing confidence in partner cooperation in alliances. Acad. Manag. Rev. 1998, 23, 491–512. [Google Scholar] [CrossRef]

- Qi, Y.; Huo, B.; Wang, Z.; Yeung, H.Y.J. The impact of operations and supply chain strategies on integration and performance. Int. J. Prod. Econ. 2017, 185, 162–174. [Google Scholar] [CrossRef]

- Fisher, M.L. What Is the Right Supply Chain for Your Product? Harv. Bus. Rev. 1997, 75, 105–116. [Google Scholar]

- Attaran, M.; Attaran, S. Collaborative supply chain management: The most promising practice for building efficient and sustainable supply chains. Bus. Process Manag. J. 2007, 13, 390–404. [Google Scholar] [CrossRef]

- Power, D. Supply chain management integration and implementation: A literature review. Supply Chain Manag. Int. J. 2005, 10, 252–263. [Google Scholar] [CrossRef]

- Lawrence, P.R.; Lorsch, J.W. Organization and Environment: Managing Differentiation and Integration; Harvard Business School Press: Boston, MA, USA, 1967. [Google Scholar]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J. The impact of internal integration and relationship commitment on external integration. J. Oper. Manag. 2011, 29, 17. [Google Scholar] [CrossRef]

| Journal Name | Count |

|---|---|

| Journal of Operations Management | 49 |

| International Journal of Production Economics | 31 |

| Journal of Supply Chain Management | 16 |

| International Journal of Operations & Production Management | 11 |

| Decision Sciences | 7 |

| Industrial Marketing Management | 7 |

| Journal of Business Logistics | 6 |

| International Journal of Production Research | 3 |

| Journal of Business Research | 3 |

| Others | 20 |

| Total | 153 |

| Codes (High Level) | Description | Number of Practices Coded |

|---|---|---|

| COMM-HOW | Communication How: Communication is broad term that captures sharing intangible resources. How refers to modes of communication, for example EDI, and face to face meetings. | 25 |

| COMM-WHAT | Communication What: Communication is broad term that captures sharing intangible resources. What refers to what type of information and knowledge is shared. | 65 |

| RES-SHARE | Sharing Tangible Resources: Captures sharing and pooling together physical resources. | 12 |

| BUS-PRATICES | Business Practices: Various business practices that involve of buyer and supplier firms working together. | 68 |

| LT-ORIENT | Long-Term Orientation: Long-term collaborative arrangements or types of collaboration that suggest long-time horizon | 15 |

| Code | Description | Number of Practices |

|---|---|---|

| COMM-HOW | Communication How | |

| F2F | High Level Face to Face Communication, such meetings, facility visits | 13 |

| CompMed | Computer Mediated Communication: use of emails, IT systems, EDI, and electronic information sharing | 9 |

| CommFreq | Communication Frequency: ensuring frequent and timely communication | 6 |

| Teams | Using Inter-organizational Teams | 9 |

| COMM-WHAT | Communication What | |

| PerfFeedback | Sharing performance assessments and providing feedback | 24 |

| OpsComm | Operational (day-to-day) communication to coordinate material flows and manage production and logistics related processes | 34 |

| KnowComm | Sharing knowledge | 11 |

| NPDComm | Communication related to new product development (NPD) | 2 |

| StratComm | Long-term sensitive and strategic communication | 26 |

| RES-SHARE | Sharing tangible resources | |

| Fin&Tech | Providing financial and technological support | 6 |

| LogRes | Sharing logistics related resources, such as shipping containers. | 6 |

| BUS-PRACTICES | Business practices | |

| P and C | Planning and control of logistics, material flows, and manufacturing related activities | 26 |

| JIT-Lean | JIT and lean related practices that involve supply-chain partners | 6 |

| Quality-CI | Quality and continuous improvement activities that involve supply-chain partners | 22 |

| NPD | Jointly conducting new product development (NPD) | 8 |

| Teams-P and C | Use of teams for planning and control | 7 |

| Teams-NPD | Use of Teams for new product development | 5 |

| Teams-OpsImp | Use of Teams for operational improvement | 11 |

| LT-ORIENT | Long-term orientation | |

| CollabOrient | Maintaining and strengthening collaborative orientation and a long-term relationship perspective | 9 |

| StratPlan | Strategic planning with supply-chain partners | 8 |

| Theoretical Perspective | Integrative Practices | Explanation |

|---|---|---|

| System Dynamics | COMM-WHAT: OpsComm BUS-PRACTICES: P and C BUS-PRACTICES: JIT-Lean, Quality-CI | Integrative practices that reduce oscillations in flow of materials and inventory in the supply chain, and create efficient flows |

| Relational/Extended RBV | COMM-WHAT: PerfFeedback RES-SHARE: Fin&Tech, LogRes BUS-PRACTICES: JIT-Lean, Quality-CI | Integrative practices that allow greater value to be produced from the configuration, coordination and use of resources and capabilities in the buyer and supplier firms |

| TCE | RES-SHARE: Fin&Tech, LogRes LT-ORIENT: CollabOrient, StratPlan COMM-WHAT: PerfFeedback | Integrative practices that reduce opportunism in various ways, such as through generating goodwill, developing shared strategies and creating shared resources that increase the cost of opportunism |

| KBV | COMM-WHAT: KnowComm, NPDComm BUS-PRACTICES: JIT-Lean, Quality-CI BUS-PRACTICES: NPD | Integrative practices that lead to sharing and development of knowledge, such as by generating new products and developing better processes |

| Electronic (IT Mediated) Communication | Face to Face Communication | |

|---|---|---|

| Contractual Trust: confidence in partner behavior due to control (governance through contracts and contract enforceability) | COMM-WHAT: PerfFeedback, OpsComm BUS-PRACTICES: P and C | RES-SHARE: Fin&Tech COMM-WHAT: PerfFeedback |

| Goodwill Trust: confidence based on knowledge of partner’s intentions, relationship strength, and past history | RES-SHARE: LogRes | COMM-WHAT: KnowComm, NPDComm, StratComm BUS-PRACTICES: JIT-Lean, Quality-CI, NPD LT-ORIENT: CollabOrient, StratPlan |

| Construct | Definition |

|---|---|

| Operational Communication | Operational communication refers to sharing routine data between the buyer and supplier firms that is used in day to day decision making, like inventory levels, sales forecasts, delivery and order information, logistics data, capacity and production related data. |

| Performance Related Communication | Performance Related communication refers to sharing of performance metrics, performance score-cards and similar feedback between the supply chain dyad members. |

| Operational Planning and Control | Operational planning and control refers to buyer and supplier firms jointly planning and synchronizing recurring tasks and activities and systematically reacting to environmental signals related to production and flow of goods and services. |

| Collaborative Improvement | Collaborative improvement refers to the buyer-supplier dyad jointly establishing continuous improvement programs and quality practices. |

| Sharing Logistics Resources | Sharing logistics resources refers to combining transportation, storage and distribution resources to improve efficiency of logistics operations. |

| New Product Development | New product development refers to collaboration by the buyer and supplier firms to research, design and commercialize products that are new for the supply chain dyad. |

| General Knowledge Generation | General knowledge generation refers to collaboration by buyer and supplier firms to generate new relevant knowledge outside of new product development efforts such as acquiring or developing new capabilities and technologies. |

| Financial and Technological Support | Providing financial and technological support refers to combining financial assets and/or technological capabilities usually for strategic and long-term gains. |

| Strategic Partnership | Strategic partnership refers to a buyer and supplier dyad developing and implementing business strategy together such that their fate (success or failure) is intimately tied. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.U.; Pagell, M.; Kristal, M.M.; Gattiker, T.F. Micro-Foundations of Supply Chain Integration: An Activity-Based Analysis. Logistics 2019, 3, 12. https://doi.org/10.3390/logistics3020012

Ahmed MU, Pagell M, Kristal MM, Gattiker TF. Micro-Foundations of Supply Chain Integration: An Activity-Based Analysis. Logistics. 2019; 3(2):12. https://doi.org/10.3390/logistics3020012

Chicago/Turabian StyleAhmed, Muhammad Usman, Mark Pagell, Mehmet Murat Kristal, and Thomas F. Gattiker. 2019. "Micro-Foundations of Supply Chain Integration: An Activity-Based Analysis" Logistics 3, no. 2: 12. https://doi.org/10.3390/logistics3020012

APA StyleAhmed, M. U., Pagell, M., Kristal, M. M., & Gattiker, T. F. (2019). Micro-Foundations of Supply Chain Integration: An Activity-Based Analysis. Logistics, 3(2), 12. https://doi.org/10.3390/logistics3020012