Additive Manufacturing: A Game Changer in Supply Chain Design

Abstract

:1. Introduction

2. Contemporary Developments in SC Design

3. Methodology

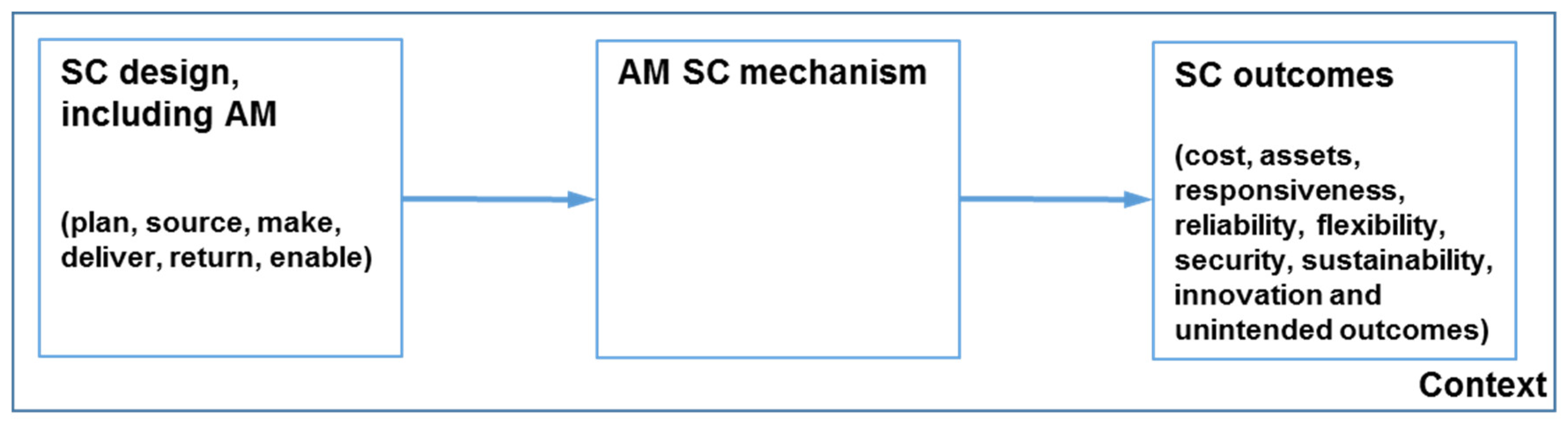

3.1. Initial Theoretical Framework and Question Formulation

“An AM SC mechanism links the SC design elements (including AM) with the SC outcomes in a given context”

- In which contexts are AM supply chains used, how are they designed, and how do they perform?

- What AM SC mechanisms for manufacturing applications can be constructed and what are the conceptual relationships between intervention (I) and outcomes (O) in various contexts (C)?

- What are the disrupting effects of using AM supply chains for the SC actors?

- How are AM SC mechanisms related to ‘traditional’ SC mechanisms?

3.2. Identifying the Characteristics of the Studies

3.3. Retrieving Samples of Potentially Relevant Literature

3.4. Synthesizing Samples

3.5. Analyzing and Synthesizing the Results

3.6. Reporting the Results

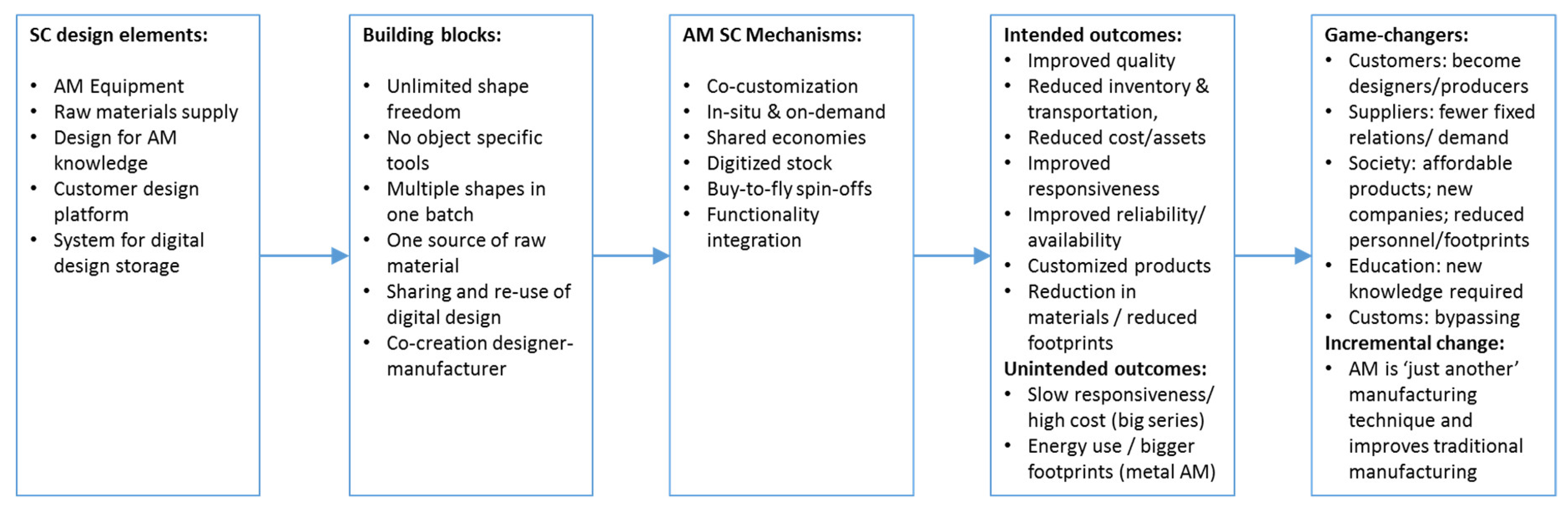

4. Results

4.1. Descriptive Results

- AM equipment, including decisions about the positioning of machine(s) in the SC; AM allows unlimited freedom of (shape) design in the manufacturing of light-weight products with integrated functions, requiring no object specific tools (to be amortized over long series). It also allows production of different shaped products in the same production run;

- Supply of raw materials products are produced from the same source material (e.g., powder). Material is (relatively) easily transported to (local) AM production;

- Design for AM knowledge are required to realize the full potential of specific digital designs;

- Customer platforms enabling ordering and/or co-creation between designer/customer and manufacturers;

- System for the storage of designs enabling design reuse and/or adaption.

4.2. Constructing AM SC Mechanisms

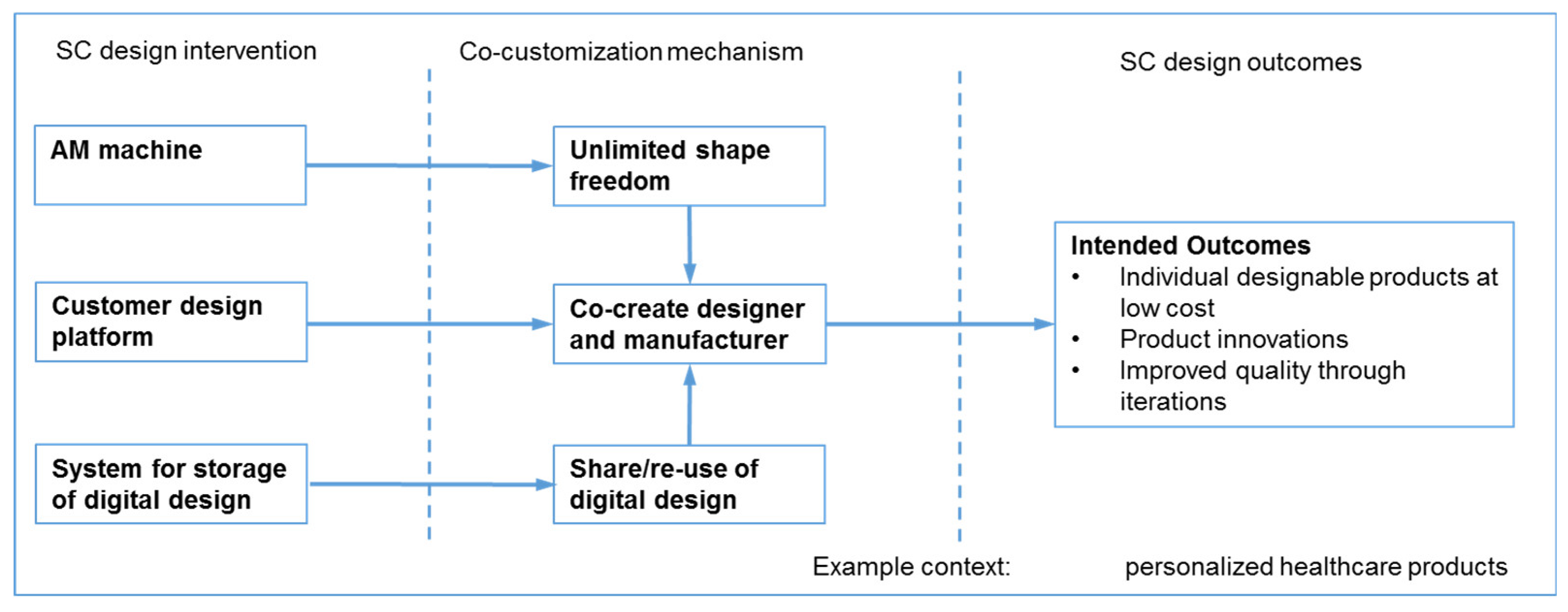

4.2.1. Co-Customization Mechanism

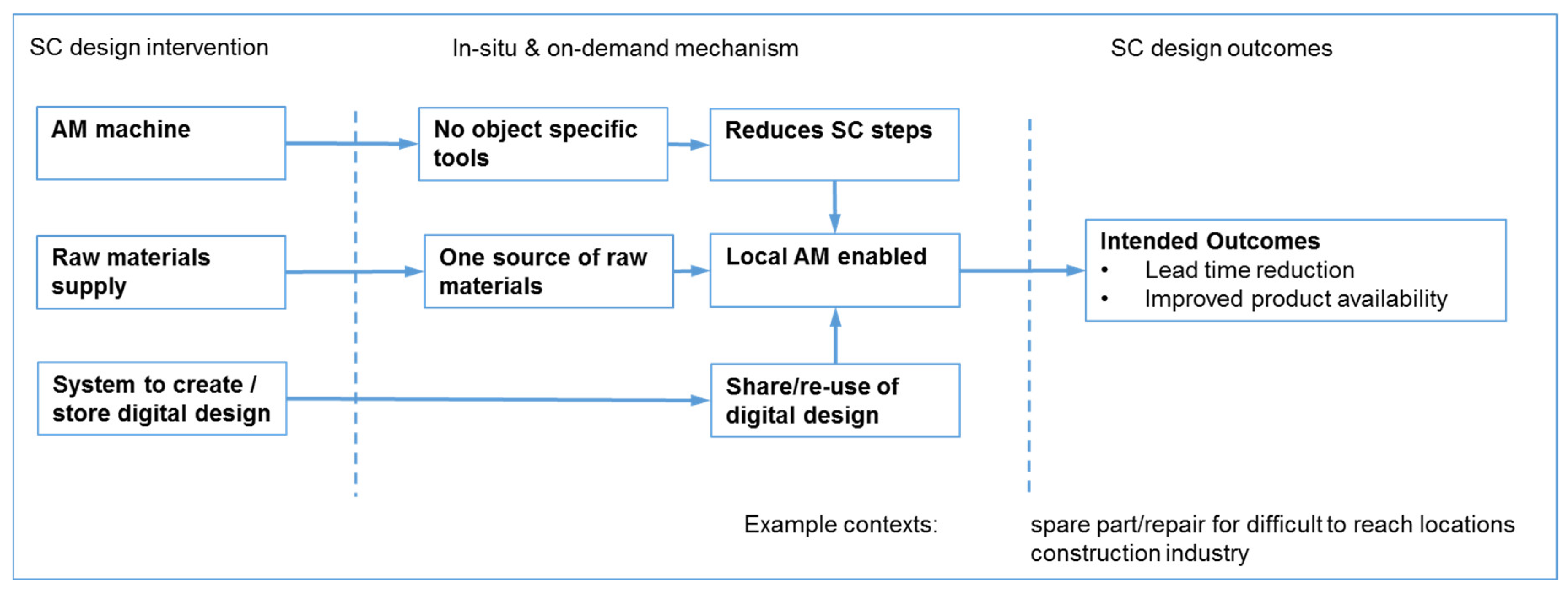

4.2.2. In-Situ & on-Demand Mechanism

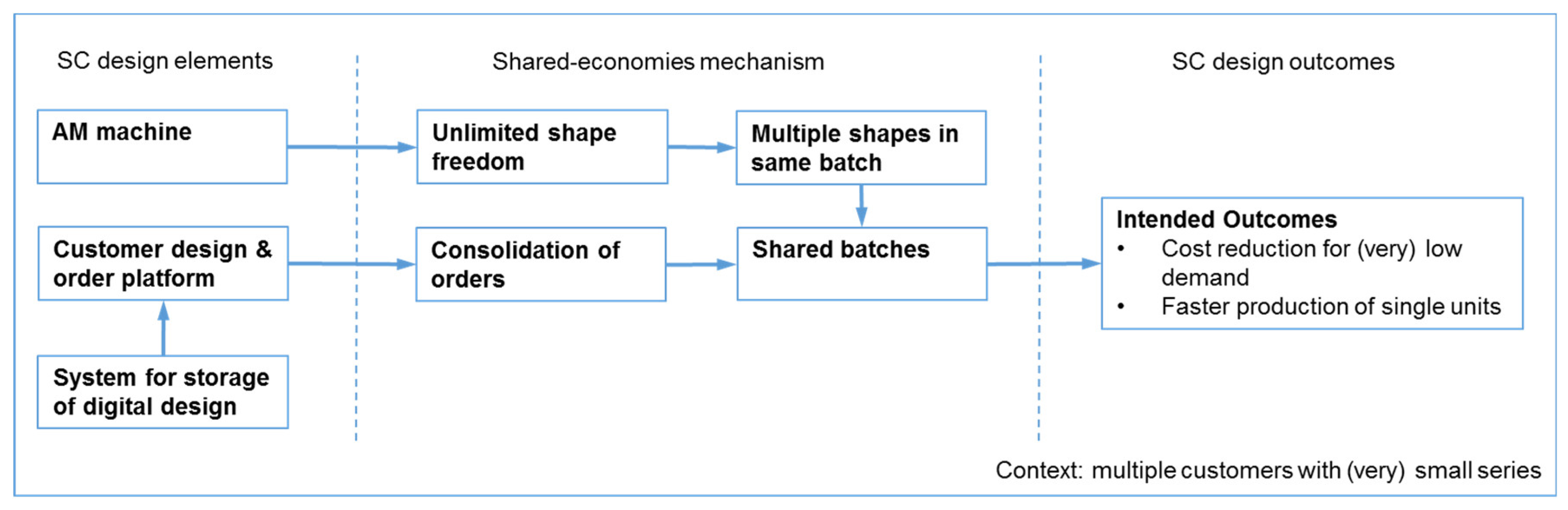

4.2.3. Shared-Economies Mechanism

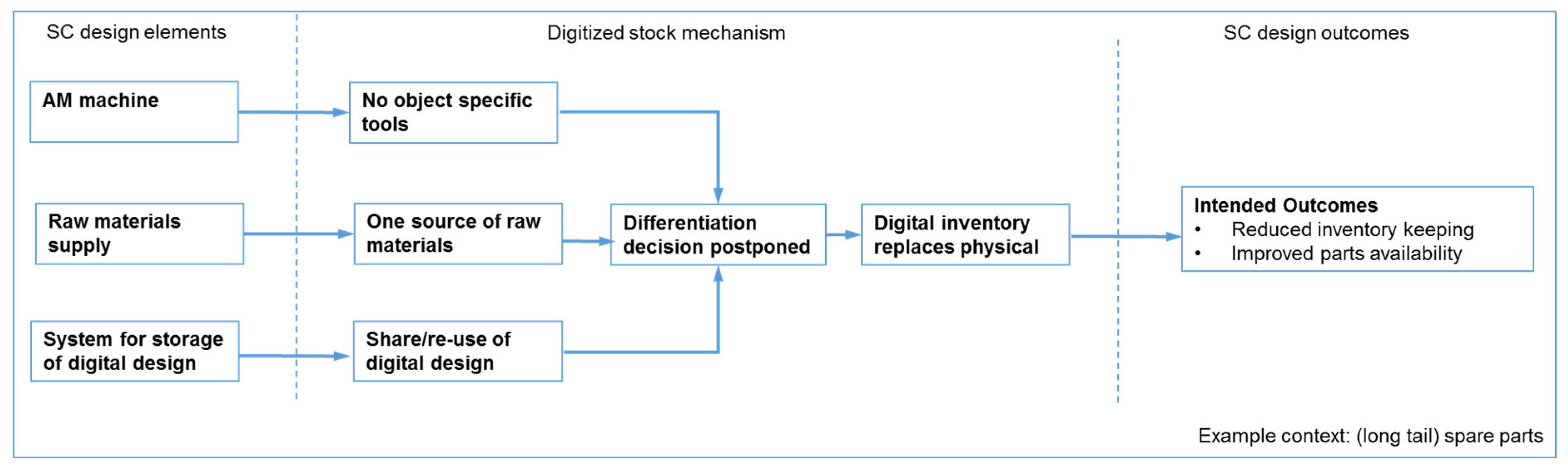

4.2.4. Digitized Stock Mechanism

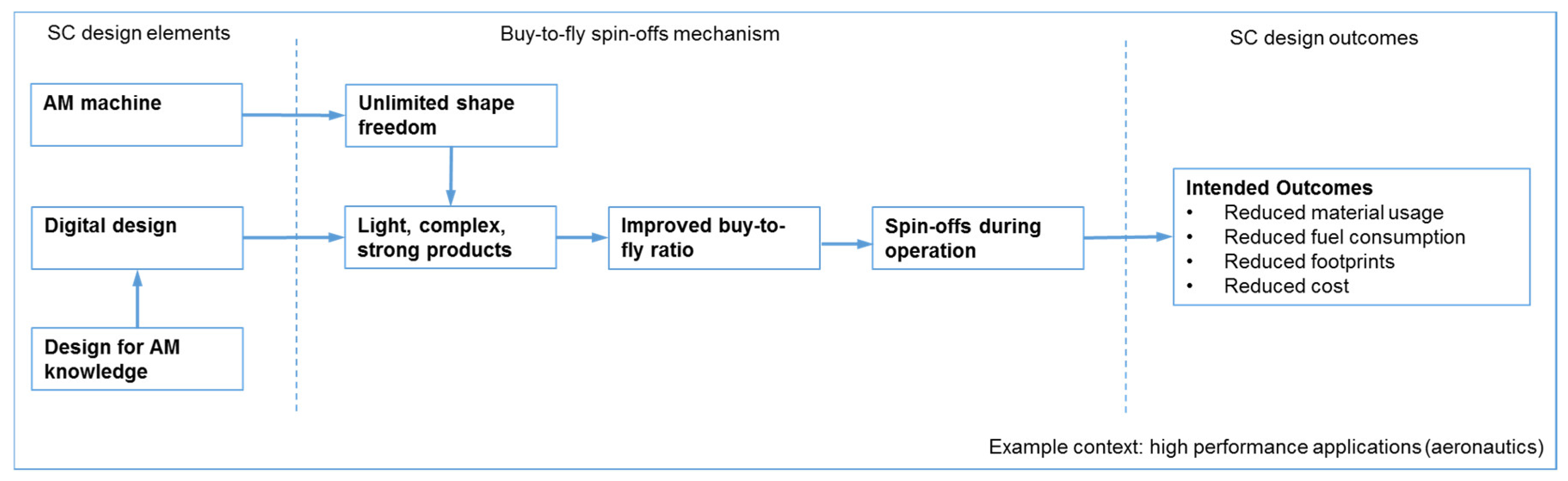

4.2.5. Buy-to-Fly Spin-offs Mechanism

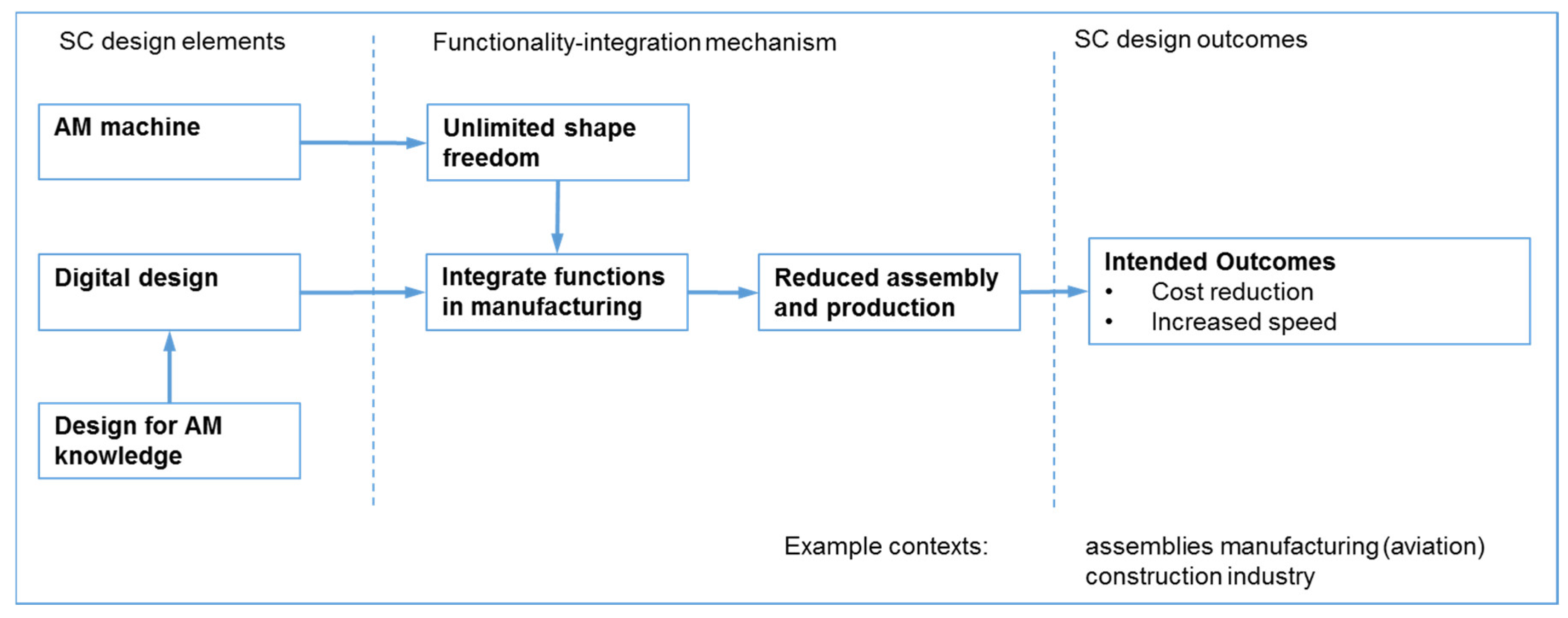

4.2.6. Functionality-Integration Mechanism

4.3. The Game-Changing Effects of AM SC Design

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| AM SC Context | Authors | |

| Industry | Aeronautics | [14,62,66,75,80,84,92,93] |

| AM Service Providers | [8,87] | |

| Construction | [66,67,69] | |

| Utilities (energy, mining, oil) | [62,66] | |

| Food | [94] | |

| Healthcare | [8,18,19,20,62,63,64,68,88] | |

| Humanitarian aid | [21] | |

| Manufacturing | [66,78,79,82,86,95,96,97,98,99,100,101,102,103,104] | |

| Retail | [60] | |

| Products | Components & assemblies | [62,66,67,78,82,84,86,92,98,100,101,104] |

| Consumer products | [8,60,94,95,97,102,105] | |

| Houses | [67] | |

| Medical devices | [8,18,19,20,62,63,64,68] | |

| Spare parts | [13,14,16,21,22,62,66,79,80,81,93] | |

| Tools | [8,66,99,101] | |

| Sales channel | Business-to-business | [6,13,14,18,19,20,21,22,60,61,62,63,64,66,68,72,75,76,77,78,80,81,82,83,84,86,89,93,96,97,98,99,100,101] |

| Business-to-consumer | [67,73,76,94,95,102,105,106] | |

| Customer-to-customer | [60,61] | |

| Product life-cycle phase | Development (prototyping) | [8,16,17,19,60,61,63,72,73,75,76,88,92,97,98,100,104] |

| Both development and production | [6,20,62,67,68,72,78,81,87,94,101,102] | |

| Production | [6,8,13,16,18,19,60,61,62,64,66,67,72,73,74,75,76,77,78,79,81,82,84,86,87,88,95,96,97,99,101,107,108] | |

| Operation/use | [8,19,66,83,84] | |

| End-of-life (repair) | [14,21,22,62,66,80,93] | |

| Demand | Low (or very low) demand/single units | [13,14,16,22,61,62,66,67,72,73,76,81,82,86,88,92,93,95,96,99,109] |

| High demand fluctuations | [93,95] | |

| Immediate availability (not) required | [13,18] | |

| Systems difficult to access | [14,21,22,62] | |

| Product unavailability, shortage | [14,81] | |

| Barriers | Product, (surface) quality, accuracy, durability, strength | [15,57,60,66,67,68,72,75,78,95,103,105,106] |

| Material availability | [57,68,84] | |

| Material characteristics | [67,73,75,105] | |

| Material cost | [17,57,72,103] | |

| Lack of process automation | [66,67] | |

| Low production speed | [75,78,84,103] | |

| Reliability, stability of print process | [57,67] | |

| High machine cost, limited build sizes | [57,69] | |

| Limited process parameter control | [109] | |

| AM and AM design knowledge required | [20,57,61,73] | |

| Awareness and acceptance of employees, management and customers | [57,104] | |

| Lack of government support; cost calculation knowledge, vendor trust; management support; designers attitude; workers resistance | [103] | |

| IP unclear | [6,13,60,61,72,73,75,81,87,103,106] | |

| Missing legislation and regulations | [15,57,61,64,68,87] | |

| Liability and warranty unclear | [6,61,66] | |

| QA, testing and inspection missing | [13,61,66,67,73,75] | |

| SC Design Intervention | Authors | |

| Plan | Range of SKU’s replaced by one process | [14,22,62,72,76,77,78] |

| Regular SC re-alignment required with increasing AM maturity | [110] | |

| Design-build-deliver paradigm shift | [73] | |

| Improved economies of scope in mass-production | [82] | |

| SC shorter and simpler | [6,22,67,68,76,79,81,84,107] | |

| Source | Network of partners and cooperation with SC partners required | [20,21,73,75,87,111] |

| Licencing agreements with OEMs | [87] | |

| Local supply of raw materials | [66,73,77,101,102] | |

| Shift from component supply to raw material supply; Reduced dependency on component suppliers; Reduced supply of raw materials | [66,67,72,83,101] | |

| Outsourcing of AM to service providers/capacity pooling | [13,72,75,81] | |

| Powerful raw material suppliers | [109] | |

| Reduced partners in the supply chain | [67] | |

| Make | Engineer-To-Order/Make-To-Order | [6,13,14,16,18,19,20,21,22,60,61,62,64,66,68,72,76,79,81,87,94,95,101,102,107,108] |

| Make-To-Stock | [13,18,80,93] | |

| Central AM configuration | [13,18,60,79,80,93,94,101,106,109] | |

| Distributed AM configuration | [6,8,13,14,21,22,57,60,61,62,66,68,73,74,75,76,77,80,87,88,102,105,112,113] | |

| Distributed manufacturing, central coordination | [60] | |

| Distributed manufacturing, central design | [20] | |

| Distributed scanning, central manufacturing | [87] | |

| Mobile AM | [69] | |

| Personal manufacturing (at site of consumer) | [8,69] | |

| AM production next to TM production line | [101] | |

| Reduced production steps and machines, assembly, facilities | [61,62,66,76,78,80,81] | |

| Versatile machine with standardized interface | [62] | |

| Deliver | Reduced need for—and adaptions to—material handling equipment and distribution centers | [61,64,73,75,77,81,84,88,105] |

| Reduced stock-keeping and shift to raw material stock-keeping | [6,13,17,60,64,66,68,72,76,79,81,82,83,88,93,96,102] | |

| Reduced transportation | [17,60,64,68,75,76,79,81,83,87,88,102] | |

| Change to digital file distribution | [13,21,66] | |

| Distribution of raw materials only | [66,67] | |

| Local distribution | [61] | |

| Production in-transit (mobile AM) | [69] | |

| At home printing as means of product distribution | [8] | |

| Transportation modalities require adaptions (e.g., bulk to fine) | [73,77,105] | |

| Return | Enables extension of assets’ lifecycle | [66] |

| Enables internal recycling | [66] | |

| Enables use of recycled materials | [76] | |

| Reduced disassembly efforts | [78] | |

| Reduced waste material | [64] | |

| Reduced polution, landfill | [20,67,72,78] | |

| Enable | Digital catalogue/database required for sharing and retaining of digital images | [13,19,66,73,74,87,101] |

| Secure infrastructure required | [87] | |

| Combination with other electronic services | [14,107,108] | |

| Digital file co-creation by engineer and customer, design and customer integration through online platform | [60,61,66,73,88,101,102,113] | |

| Shift from conventional inventory management, using Bill Of Material, to individual tracking | [6,61] | |

| Online platform required | [60,84] | |

| Distinction between roles disappears; redistribution of tasks in the SC | [8,67,73,76] | |

| Reduced manual intervention; Reduced knowledge and skills required; Reduced need for personnel and overheads | [18,61,62,76,80] | |

| Production done by customer | [8,60,102,105] | |

| SC Outcomes | Authors | |

| Cost | Reduced inventory cost (includes finished goods, raw materials, work-in-process, safety stock, obsolescence) | [6,13,17,18,60,61,64,66,67,72,73,75,76,79,81,82,86,88,93,95,96,101,102,109] |

| Increased production cost (per piece); inefficient capacity utilization | [8,13,19,74,79,98] | |

| Reduced production cost (assembly, energy, set-up, efficiency) | [6,62,78,84,86,92,97,99,101] | |

| Products customized at no additional cost | [8,62,88] | |

| Increased transportation cost | [13,80] | |

| Decreased transportation cost | [17,60,64,66,67,75,76,79,83,87,102] | |

| Reduced final product cost (low volumes or complex products) | [15,88,105] | |

| Reduced lifecycle cost (includes operating, logistics, opportunity, warehouse, SC, material handling, warehouse cost) | [19,21,22,61,64,66,75,79,80,81,84,87,88,95,102] | |

| Assets | Extended lifecycle | [66,88] |

| Reduced parts for specific equipment (machines, facilities, tools) | [6,8,60,61,62,66,69,72,74,75,76,80,86,96,97,98,101,105] | |

| Responsiveness | Increased time for production, assembly or repair | [80,95] |

| Decreased production time (small series), assembly time; Decreased product development, (re) design, time to market | [6,8,13,14,15,16,18,19,20,21,22,57,60,62,66,67,68,69,72,73,75,76,78,80,82,86,88,92,96,97,98,99,100,101,113] | |

| Reliability | Improved availability of products/services | [14,21] |

| Improved product quality, reliability | [16,19,63,64,66,67,86,101] | |

| Improved consent and trust | [19] | |

| Improved replicability | [20] | |

| Improved reliability of delivery dates | [6] | |

| Flexibility | Improved management of demand swings; Manufacturing volume and product flexibility; High customization, individual design | [8,14,15,22,62,67,69,72,76,79,80,95,96,101,113] |

| Security | Increased risk e.g., for knowledge leak | [66,87,102] |

| Reduced dependency on component suppliers | [6,13] | |

| Improved product safety; Reduced risk for infection | [19,64] | |

| Reduced risk for law suits | [96] | |

| Sustainability | Reduced (carbon) footprint, energy, emissions, pollution, waste, materials | [20,64,66,67,75,79,84,101] |

| Extended lifecycle of assets | [66] | |

| Social: labor shift when manufacturing near consumption | [88] | |

| Innovation | Improved design, highly complex, highly customized, integrated functions | [15,20,61,62,67,75,81,88] |

| Enables co-creation | [17,19,57,60,66,73,76,94,101,102] | |

| Encourages innovation; Incremental product improvement/introduce new technologies to products in use | [22,88] |

References

- Swab, K. The Fourth Industrial Revolution; Penguin Random House: New York, NY, USA, 2017. [Google Scholar]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Christopher, M. Logistics and Supply Chain Management: Strategies for Reducing Cost and Improving Service (Second Edition). Int. J. Logist. Res. Appl. 1999, 2, 103–104. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management Strategy, Planning, and Operation, Global Edition, 5th ed.; Pearson Education: London, UK, 2013. [Google Scholar]

- Melnyk, S.; Davis, E.; Spekman, R.; Sandor, J. Outcome-Driven Supply Chains. Sloan Manag. Rev. 2010, 33–38. [Google Scholar]

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- ISO/ASTM. ISO/ASTM 52900: 2015 (ASTM F2792) Additive Manufacturing—General Principles—Terminology; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef]

- Manners-Bell, J. The Implications of 3D Printing for the Global Logistics Industry; Transport Intelligence Ltd: Bath, UK, 2012. [Google Scholar]

- Janssen, R.; Blankers, I.; Moolenburgh, E.; Posthumus, B. TNO: The Impact of 3-D Printing on Supply Chain Management; TNO: Delft, The Netherlands, 2014. [Google Scholar]

- Accenture. 3D Printing’s Disruptive Potential; Accenture Technology: Silicon Valley, CA, USA, 2014. [Google Scholar]

- Cohen, D.; Sargeant, M.; Somers, K. McKinsey Quarterly: 3-D Printing Takes Shape; Mc Kinsey & Company: New York, NY, USA, 2014. [Google Scholar]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain: Alternative approaches to capacity deployment. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Pérès, F.; Noyes, D. Envisioning e-logistics developments: Making spare parts in situ and on demand: State of the art and guidelines for future developments. Comput. Ind. 2006, 57, 490–503. [Google Scholar] [CrossRef]

- Steenhuis, H.-J.; Pretorius, L. The additive manufacturing innovation: A range of implications. J. Manuf. Technol. Manag. 2017, 28, 122. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Waller, M.A. Supply Chain Game Changers—Mega, Nano, and Virtual Trends—And Forces That Impede Supply Chain Design (i.e., Building a Winning Team). J. Bus. Logist. 2014, 35, 157–164. [Google Scholar] [CrossRef]

- Waller, M.A.; Fawcett, S.E. Click Here to Print a Maker Movement Supply Chain: How Invention and Entrepreneurship Will Disrupt Supply Chain Design. J. Bus. Logist. 2014, 35, 99–102. [Google Scholar] [CrossRef]

- Emelogu, A.; Marufuzzaman, M.; Thompson, S.M.; Shamsaei, N.; Bian, L. Additive manufacturing of biomedical implants: A feasibility assessment via supply-chain cost analysis. Addit. Manuf. 2016, 11, 97–113. [Google Scholar] [CrossRef]

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2009, 40, 116–127. [Google Scholar] [CrossRef]

- Oettmeier, K.; Hofmann, E. Impact of additive manufacturing technology adoption on supply chain management processes and components. J. Manuf. Technol. Manag. 2016, 27, 944–968. [Google Scholar] [CrossRef]

- De la Torre, N.; Espinosa, M.M.; Domínguez, M. Rapid Prototyping in Humanitarian Aid To Manufacture Last Mile Vehicles Spare Parts: An Implementation Plan. Hum. Factors Ergon. Manuf. Serv. Ind. 2016, 26, 533–540. [Google Scholar] [CrossRef]

- Meisel, N.A.; Williams, C.B.; Ellis, K.P.; Taylor, D. Decision support for additive manufacturing deployment in remote or austere environments. J. Manuf. Technol. Manag. 2016, 27, 898–914. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D.; van Aken, J. Developing design propositions through research synthesis. Organ. Stud. 2008, 29, 393–413. [Google Scholar] [CrossRef]

- Van Aken, J.; Chandrasekaran, A.; Halman, J. Conducting and publishing design science research. J. Oper. Manag. 2016. [Google Scholar] [CrossRef]

- APICS. Supply Chain Operating Reference (SCOR) Model. Available online: http://www.apics.org/apics-for-business/frameworks/scor (accessed on 2 July 2018).

- Mills, J.F.; Camek, V. The risks, threats and opportunities of disintermediation: A distributor’s view. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 714–727. [Google Scholar] [CrossRef]

- Vendrell-Herrero, F.; Bustinza, O.F.; Parry, G.; Georgantzis, N. Servitization, digitization and supply chain interdependency. Ind. Mark. Manag. 2017, 60, 69–81. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Vermeulen, B.; Kesselhut, J.; Pyka, A.; Saviotti, P.P. The Impact of Automation on Employment: Just the Usual Structural Change? Sustainability 2018, 10, 1661. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Telles, R.; Bonilla, S.H. Blockchain and supply chain management integration: A systematic review of the literature. Supply Chain Manag. Int. J. 2019. [Google Scholar] [CrossRef]

- Gawer, A. Bridging differing perspectives on technological platforms: Toward an integrative framework. Res. Policy 2014, 43, 1239–1249. [Google Scholar] [CrossRef]

- Fogliatto, F.S.; da Silveira, G.J.C.; Borenstein, D. The mass customization decade: An updated review of the literature. Int. J. Prod. Econ. 2012, 138, 14–25. [Google Scholar] [CrossRef]

- Hsuan Mikkola, J.; Skjøtt-Larsen, T. Supply-chain integration: Implications for mass customization, modularization and postponement strategies. Prod. Plan. Control 2004, 15, 352–361. [Google Scholar] [CrossRef]

- Van Hoek, R.I. The rediscovery of postponement a literature review and directions for research. J. Oper. Manag. 2001, 19, 161–184. [Google Scholar] [CrossRef]

- Shingo, S. A Revolution in Manufacturing: The SMED System; Productivity Press: Cambridge, MA, USA, 1985. [Google Scholar]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Krikke, H.; Hofenk, D.; Wang, Y. Revealing an invisible giant: A comprehensive survey into return practices within original (closed-loop) supply chains. Resour. Conserv. Recycl. 2013, 73, 239–250. [Google Scholar] [CrossRef]

- Bals, L.; Tate, W.L. Sustainable Supply Chain Design in Social Businesses: Advancing the Theory of Supply Chain. J. Bus. Logist. 2018, 39, 57–79. [Google Scholar] [CrossRef]

- Booth, A.; Sutton, A.; Papaioannou, D. Systematic Approaches to a Successful Literature Review, 2nd ed.; SAGE Publications Ltd.: London, UK, 2016. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Pawson, R. Evidence-based Policy: The Promise of Realist Synthesis. Evaluation 2002, 8, 340–358. [Google Scholar] [CrossRef]

- Durach, C.F.; Kembro, J.; Wieland, A. A New Paradigm for Systematic Literature Reviews in Supply Chain Management. J. Supply Chain Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Mulder, N. Value-Based Project Management: Een Aanpak Voor Chaordische Projecten Vanuit het Perspectief van het Complexiteitsdenken. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2012. [Google Scholar]

- Tanskanen, K.; Ahola, T.; Aminoff, A.; Bragge, B.; Kaipia, R. Towards evidence-based management of external resources: Developing design propositions and future research avenues through research synthesis. Res. Policy 2017, 46, 1087–1105. [Google Scholar] [CrossRef]

- Van Aken, J.; Andriessen, D. Handboek Ontwerpgericht Wetenschappelijk Onderzoek; Boom Lemma Uitgevers: Den Haag, The Netherlands, 2011; p. 414. [Google Scholar]

- Pawson, R.; Tilley, N. What Works in Evaluation Research? Br. J. Criminol. 1994, 34, 291–306. [Google Scholar] [CrossRef]

- Plsek, P.; Bibby, J.; Whitby, E. Practical Methods for Extracting Explicit Design Rules Grounded in the Experience of Organizational Managers. J. Appl. Behav. Sci. 2007, 43, 153–170. [Google Scholar] [CrossRef]

- Romme, A.G.L.; Endenburg, G. Construction Principles and Design Rules in the Case of Circular Design. Organ. Sci. 2006, 17, 287–297. [Google Scholar] [CrossRef]

- Fronia, P.; Wriggers, F.S.; Nyhuis, P. A Framework for Supply Chain Design. In Proceedings of the EngOpt 2008—International Conference on Engineering Optimization, Rio de Janeiro, Brazil, 1–5 June 2008. [Google Scholar]

- Holmström, J.; Ketokivi, M.; Hameri, A.P. Bridging Practice and Theory: A Design Science Approach. Decis. Sci. 2009, 40, 65–87. [Google Scholar] [CrossRef]

- Cooper, H.; Hedges, L.V. Research Synthesis as a Scientific Enterprise; Russel Sage Foundation: New York, NY, USA, 1994. [Google Scholar]

- NAICS. North American Industry Classification System. United States Census Bureau; Executive Office of the President: Washington, DC, USA, 2017. [Google Scholar]

- Gummesson, E.; Polese, F.; Stockholms, u.; Samhällsvetenskapliga, f. B2B is not an island. J. Bus. Ind. Mark. 2009, 24, 337–350. [Google Scholar] [CrossRef]

- Levitt, T. Exploit the product life cycle. Harv. Bus. Rev. 1965, 43, 81–94. [Google Scholar]

- Sundin, E.; Bras, B. Making functional sales environmentally and economically beneficial through product remanufacturing. J. Clean. Prod. 2005, 13, 913–925. [Google Scholar] [CrossRef]

- Mangiaracina, R.; Song, G.; Perego, A. Distribution network design: A literature review and a research agenda. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 506–531. [Google Scholar] [CrossRef]

- Durach, C.F.; Kurpjuweit, S.; Wagner, S.M. The impact of additive manufacturing on supply chains. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 954–971. [Google Scholar] [CrossRef]

- Olhager, J. Strategic positioning of the order penetration point. Int. J. Prod. Econ. 2003, 85, 319–329. [Google Scholar] [CrossRef]

- Olhager, J. The role of the customer order decoupling point in production and supply chain management. Comput. Ind. 2010, 61, 863–868. [Google Scholar] [CrossRef]

- Eyers, D.R.; Potter, A.T. E-commerce channels for additive manufacturing: An exploratory study. J. Manuf. Technol. Manag. 2015, 26, 390–411. [Google Scholar] [CrossRef]

- Thiesse, F.; Wirth, M.; Kemper, H.G.; Moisa, M.; Morar, D.; Lasi, H.; Piller, F.; Buxmann, P.; Mortara, L.; Ford, S.; et al. Economic Implications of Additive Manufacturing and the Contribution of MIS. Bus. Inf. Syst. Eng. 2015, 57, 139–148. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- He, Y.; Ye, M.; Wang, C. A method in the design and fabrication of exact-fit customized implant based on sectional medical images and rapid prototyping technology. Int. J. Adv. Manuf. Technol. 2006, 28, 504–508. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Srai, J.S.; Kumar, M.; Graham, G.; Phillips, W.; Tooze, J.; Ford, S.; Beecher, P.; Raj, B.; Gregory, M.; Tiwari, M.K.; et al. Distributed manufacturing: Scope, challenges and opportunities. Int. J. Prod. Res. 2016, 54, 6917–6935. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Kothman, I.; Faber, N. How 3D printing technology changes the rules of the game: Insights from the construction sector. J. Manuf. Technol. Manag. 2016, 27, 932–943. [Google Scholar] [CrossRef]

- Moore, S.S.; O’Sullivan, K.J.; Verdecchia, F. Shrinking the Supply Chain for Implantable Coronary Stent Devices. Ann. Biomed. Eng. 2016, 44, 497–507. [Google Scholar] [CrossRef] [PubMed]

- Ryan, M.J.; Eyers, D.R.; Potter, A.T.; Purvis, L.; Gosling, J. 3D printing the future: Scenarios for supply chains reviewed. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 992–1014. [Google Scholar] [CrossRef]

- Hill, T. Process choice. In Manufacturing Strategy: Text and Cases; Macmillan Education UK: London, UK, 1995; pp. 131–171. [Google Scholar] [CrossRef]

- Hayes, R.; Wheelwright, S. Link Manufacturing Process and Product Life Cycles. Harv. Bus. Rev. 1979, 57, 133. [Google Scholar]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D Printing Disrupts Manufacturing. Res. Technol. Manag. 2013, 56, 12. [Google Scholar] [CrossRef]

- Waller, M.A.; Fawcett, S.E. Click Here for a Data Scientist: Big Data, Predictive Analytics, and Theory Development in the Era of a Maker Movement Supply Chain. J. Bus. Logist. 2013, 34, 249–252. [Google Scholar] [CrossRef]

- Wagner, S.M.; Walton, R.O. Additive manufacturing’s impact and future in the aviation industry. Prod. Plan. Control 2016, 27, 1124–1130. [Google Scholar] [CrossRef]

- Mohr, S.; Khan, O. 3D Printing and Its Disruptive Impacts on Supply Chains of the Future. Technol. Innov. Manag. Rev. 2015, 5, 20–25. [Google Scholar] [CrossRef]

- Chen, Z. Research on the Impact of 3D Printing on the International Supply Chain. Adv. Mater. Sci. Eng. 2016, 2016, 1–16. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: A critical review. Int. J. Adv. Manuf. Technol. 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Li, Y.; Jia, G.; Cheng, Y.; Hu, Y. Additive manufacturing technology in spare parts supply chain: A comparative study. Int. J. Prod. Res. 2017, 55, 1498–1515. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmstrom, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J. Digital manufacturing-driven transformations of service supply chains for complex products. Supply Chain Manag. Int. J. 2014, 19, 421–430. [Google Scholar] [CrossRef]

- Sasson, A.; Johnson, J.C. The 3D printing order: Variability, supercenters and supply chain reconfigurations. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 82–94. [Google Scholar] [CrossRef]

- Barz, A.; Buer, T.; Haasis, H.-D. Quantifying the effects of additive manufacturing on supply networks by means of a facility location-allocation model. Logist. Res. 2016, 9, 1–14. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Glasschroeder, J.; Prager, E.; Zaeh, M.F. Powder-bed-based 3D-printing of function integrated parts. Rapid Prototyp. J. 2015, 21, 207–215. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Rogers, H.; Baricz, N.; Pawar, K.S. 3D printing services: Classification, supply chain implications and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 886–907. [Google Scholar] [CrossRef]

- Holmström, J.; Liotta, G.; Chaudhuri, A. Sustainability outcomes through direct digital manufacturing-based operational practices: A design theory approach. J. Clean. Prod. 2017, 167, 951–961. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Rosamond, E.; Hague, R. Transparency Built-in Energy Consumption and Cost Estimation for Additive Manufacturing. J. Ind. Ecol. 2013, 17, 418–431. [Google Scholar] [CrossRef]

- Moore, G.A. Crossing the Chasm: Marketing and Selling Disruptive Products to Mainstream Customers; Harperbusiness: New York, NY, USA, 2014. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations; Free Press of Glencoe: New York, NY, USA, 1962; p. 367. [Google Scholar]

- Raja, V.; Zhang, S.; Garside, J.; Ryall, C.; Wimpenny, D. Rapid and cost-effective manufacturing of high-integrity aerospace components. Int. J. Adv. Manuf. Technol. 2006, 27, 759–773. [Google Scholar] [CrossRef]

- Liu, P.; Huang, S.H.; Mokasdar, A.; Zhou, H.; Hou, L. The impact of additive manufacturing in the aircraft spare parts supply chain: Supply chain operation reference (scor) model based analysis. Prod. Plan. Control 2014, 25, 1169–1181. [Google Scholar] [CrossRef]

- Jia, F.; Wang, X.F.; Mustafee, N.; Hao, L. Investigating the feasibility of supply chain-centric business models in 3D chocolate printing: A simulation study. Technol. Forecast. Soc. Chang. 2016, 102, 202–213. [Google Scholar] [CrossRef]

- Chiu, M.C.; Lin, Y.H. Simulation based method considering design for additive manufacturing and supply chain An empirical study of lamp industry. Ind. Manag. Data Syst. 2016, 116, 322–348. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmstrom, J.; Tuomi, J. Risk reduction in new product launch: A hybrid approach combining direct digital and tool-based manufacturing. Comput. Ind. 2015, 74, 29–42. [Google Scholar] [CrossRef]

- Chin, K.-S. Implementation of rapid Prototyping technology—A Hong Kong manufacturing industry’s perspective. Int. J. Adv. Manuf. Technol. 1998, 14, 570–579. [Google Scholar] [CrossRef]

- Chua, C.K.; Lee, C.W.; Hong, K.H. Rapid prototyping in the development of optical pickup unit. Int. J. Adv. Manuf. Technol. 2005, 25, 484–492. [Google Scholar] [CrossRef]

- Chua, C.K.; Hong, K.H.; Ho, S.L. Rapid tooling technology. Part 2. A case study using arc spray metal tooling. Int. J. Adv. Manuf. Technol. 1999, 15, 609–614. [Google Scholar] [CrossRef]

- Vinodh, S.; Devadasan, S.R.; Maheshkumar, S.; Aravindakshan, M.; Arumugam, M.; Balakrishnan, K. Agile product development through CAD and rapid prototyping technologies: An examination in a traditional pump-manufacturing company. Int. J. Adv. Manuf. Technol. 2010, 46, 663–679. [Google Scholar] [CrossRef]

- Rylands, B.; Böhme, T.; Gorkin, R.; Fan, J.; Birtchnell, T. The adoption process and impact of additive manufacturing on manufacturing systems. J. Manuf. Technol. Manag. 2016, 27, 969–989. [Google Scholar] [CrossRef]

- Bogers, M.; Hadar, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technol. Forecast. Soc. Chang. 2016, 102, 225–239. [Google Scholar] [CrossRef]

- Dwivedi, G.; Srivastava, S.K.; Srivastava, R.K. Analysis of barriers to implement additive manufacturing technology in the Indian automotive sector. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 972–991. [Google Scholar] [CrossRef]

- Vinodh, S.; Sundararaj, G.; Devadasan, S.R.; Kuttalingam, D.; Rajanayagam, D. Agility through rapid prototyping technology in a manufacturing environment using a 3D printer. J. Manuf. Technol. Manag. 2009, 20, 1023–1041. [Google Scholar] [CrossRef]

- Steenhuis, H.-J.; Pretorius, L. Consumer additive manufacturing or 3D printing adoption: An exploratory study. J. Manuf. Technol. Manag. 2016, 27, 990–1012. [Google Scholar] [CrossRef]

- Neely, E.L. The Risks of Revolution: Ethical Dilemmas in 3D Printing from a US Perspective. Sci. Eng. Ethics 2016, 22, 1285–1297. [Google Scholar] [CrossRef] [PubMed]

- Tien, J.M. The Next Industrial Revolution: Integrated Services and Goods. J. Syst. Sci. Syst. Eng. 2012, 21, 257–296. [Google Scholar] [CrossRef]

- Tien, J.M. Internet of Connected Servgoods: Considerations, Consequences and Concerns. J. Syst. Sci. Syst. Eng. 2015, 24, 130–167. [Google Scholar] [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Rogers, H.; Braziotis, C.; Pawar, K.S. Special issue on 3D printing: Opportunities and applications for supply chain management. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 950–953. [Google Scholar] [CrossRef]

- Ortt, R. Guest editorial. J. Manuf. Technol. Manag. 2016, 27, 890–897. [Google Scholar] [CrossRef]

- Durão, L.F.C.S.; Christ, A.; Zancul, E.; Anderl, R.; Schützer, K. Additive manufacturing scenarios for distributed production of spare parts. Int. J. Adv. Manuf. Technol. 2017, 93, 869–880. [Google Scholar] [CrossRef]

- Oettmeier, K.; Hofmann, E. Additive manufacturing technology adoption: An empirical analysis of general and supply chain-related determinants. J. Bus. Econ. 2017, 87, 97–124. [Google Scholar] [CrossRef]

| Supply Chain Design | Additive Manufacturing |

|---|---|

| Supply Chain OR Supply Network OR Logistic OR Value Chain OR Network Design | Additive Manufacturing (AM) OR 3D Printing OR 3 Dimensional Printing (3DP) OR Rapid Manufacturing OR Rapid Prototyping OR Stereo Lithography OR DDM OR Digital Manufacturing OR Solid Free-form OR Layer Manufacturing OR Rapid Casting (RC) OR Rapid Tooling (RT) OR Material Deposit Manufacturing OR Material Addition Manufacturing OR Additive Layer Manufacturing |

| Journal Categories | Number of Articles |

|---|---|

| Manufacturing/Production/Technology | 27 |

| SC/Logistics/Operations Management | 12 |

| Information Systems | 5 |

| Business/Economics | 5 |

| Social/Ethics | 4 |

| Ecology/Energy | 4 |

| Materials/Engineering | 2 |

| Unknown | 2 |

| Total | 61 |

| Context | SC Intervention | Mechanism | Desired SC Outcomes | Disruptive Effect on Stakeholders | |

|---|---|---|---|---|---|

| I |

|

|

|

|

|

| II |

|

|

|

|

|

| III |

|

|

|

|

|

| IV |

|

|

|

|

|

| V |

|

|

|

|

|

| VI |

|

|

|

|

|

| Traditional SC mechanisms | → | AM SC mechanisms |

|---|---|---|

| Mass-customization | → | Co-customization |

| Postponement | → | In-situ & on-demand |

| → | Digitized stock | |

| Economies-of-scale/batches for identical products | → | Shared-economies |

| Buy-to-fly | → | Buy-to-fly spin-offs |

| Disintermediation | → | Functionality-integration |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verboeket, V.; Krikke, H. Additive Manufacturing: A Game Changer in Supply Chain Design. Logistics 2019, 3, 13. https://doi.org/10.3390/logistics3020013

Verboeket V, Krikke H. Additive Manufacturing: A Game Changer in Supply Chain Design. Logistics. 2019; 3(2):13. https://doi.org/10.3390/logistics3020013

Chicago/Turabian StyleVerboeket, Victor, and Harold Krikke. 2019. "Additive Manufacturing: A Game Changer in Supply Chain Design" Logistics 3, no. 2: 13. https://doi.org/10.3390/logistics3020013

APA StyleVerboeket, V., & Krikke, H. (2019). Additive Manufacturing: A Game Changer in Supply Chain Design. Logistics, 3(2), 13. https://doi.org/10.3390/logistics3020013