Accelerated Benders’ Decomposition for Integrated Forward/Reverse Logistics Network Design under Uncertainty

Abstract

:1. Introduction

2. Literature Review

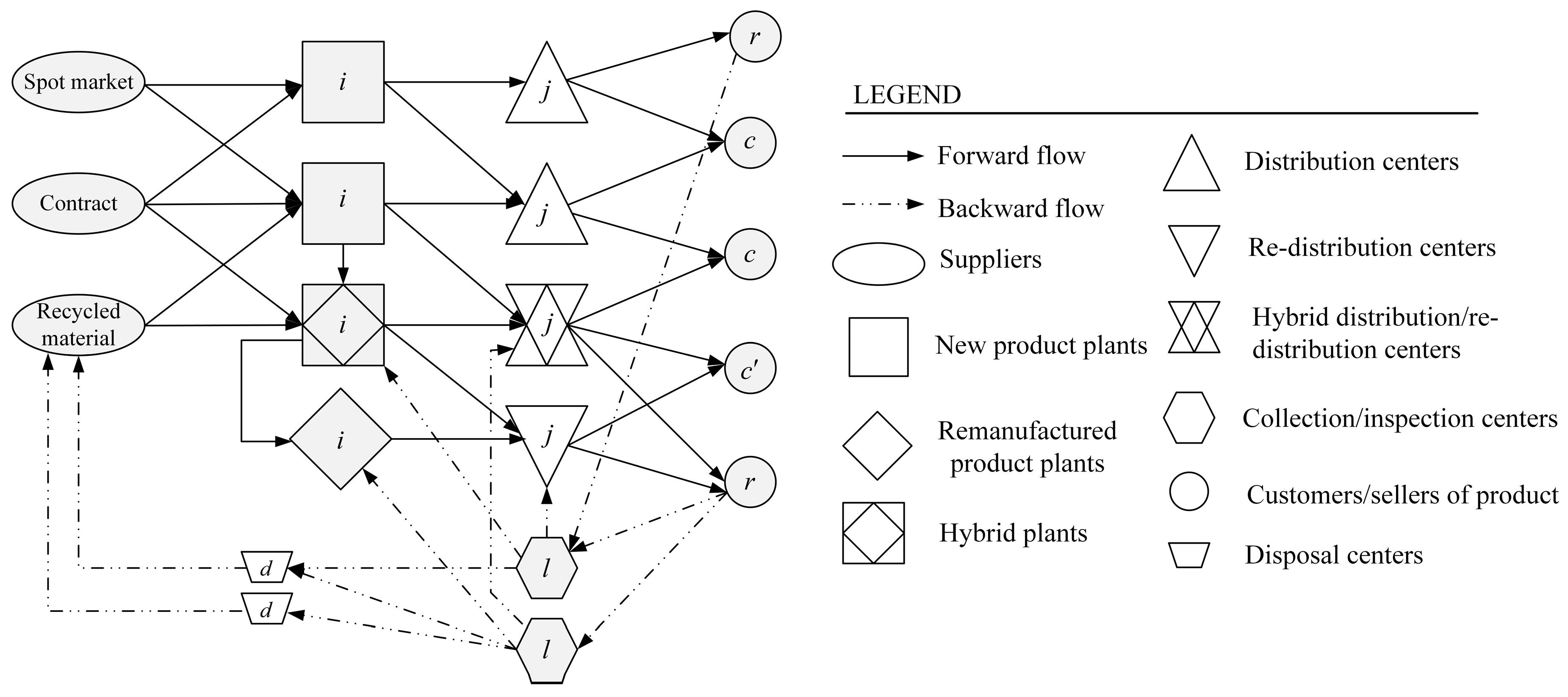

3. Problem Definition

3.1. Model Description

- The periodic review policy is used for the distribution centers and manufacturers, in which the inventory levels are reviewed at certain intervals and the appropriate orders are placed after each review. The inventory level of raw material should meet a specific amount in each period. The production and shipment from the manufacturers to the distribution centers takes place, to raise the inventory level of distribution centers to the base-stock level (S) at the beginning of each period. This concept is referred to as the push strategy in the related literature. On the other hand, customer demands are met with the inventory kept by the distribution centers. The customers only place orders to the distribution centers. This system is known as a pull-based system.

- A hybrid concept for production plants is considered. Due to the fact that locating manufacture and remanufacture plants in the same potential place will reduce fixed costs, we are interested in locating hybrid plants.

- In distribution centers, a risk pooling strategy is considered, where both new and remanufactured products are held simultaneously. The “risk-pooling” strategy is an efficient way of managing demand uncertainty, for which inventory needs to be centralized at distribution centers (DC’s) arriving at a convenient service level. Each DC uses a base stock level inventory policy to satisfy demands from retailers, as well as safety stock to cope with the variability of customer demand at retailers, to achieve “risk-pooling” benefits.

- As mentioned above, the inventory level of a raw material should meet a specific amount in each period. To this aim, raw material is provided through wholesale contracts, spot markets and recycled materials. A wholesale contract is a long term agreement with suppliers to convey a certain proportion of raw materials in the beginning of each period. If the amount of provided raw material from a wholesale contract and recycled material do not meet the base stock level in each period, the shortage of raw material is compensated for by buying from spot markets, but at a higher price.

- A single-product, multi-stage, multi-period supply chain network is given.

- We assume a finite set of facilities (i.e., manufacturers and distribution centers) should be opened.

- There is no limitation on the capacity of the material flow through the network.

- We are faced with uncertainty for the demand of the customers to the distribution centers and return of used products to collection centers.

- Transportation costs are linearly dependent on the distance between stages.

- Distribution centers and raw material stock at manufactures incur inventory holding costs at the end of each period.

- All of the returned products must be collected, but a shortage is allowed, to satisfy the demands of second market customers.

- Customers’ locations are known and fixed.

3.2. Model Formulation

| Sets: | |

| Set of potential manufacturer locations | |

| Set of potential distribution center locations | |

| Set of periods in planning horizon | |

| Set of customers for new product | |

| Set of customers for used product | |

| Set of potential collection center locations | |

| Set of disposal locations | |

| Set of seller products | |

| Set of scenarios | |

| Parameters, constants, and coefficients: | |

| Fixed costs: | |

| Fixed cost of locating manufacturer at location i | |

| Fixed cost of locating remanufacturer at location i | |

| Fixed cost of locating distribution center for new product at location j | |

| Fixed cost of locating distribution center for used product at location j | |

| Fixed cost of locating collection center at location l | |

| Capacity costs and saving costs: | |

| Saving cost of locating a hybrid manufacture/ remanufacture facility at location i | |

| Saving cost of locating a hybrid distribution center facility at location j | |

| Cost for capacity of manufacturer i per unit of product | |

| Cost for capacity of remanufacturer i per unit of product | |

| Cost for capacity of distribution center j per unit of new product | |

| Cost for capacity of distribution center j per unit of used product | |

| Cost for capacity of collection center l per unit of returned product | |

| Capacity of facilities: | |

| Maximum available capacity of manufacturing at location i | |

| Maximum available capacity of remanufacturing at location i | |

| Maximum available capacity for new products at distribution center j | |

| Maximum available capacity for second hand products at distribution center j | |

| Maximum available capacity of collection center at location l | |

| Maximum available capacity for production facilities at location i | |

| Maximum available capacity for distributing center facilities at location j | |

| Transportation costs: | |

| Cost of transporting, per unit of product, between manufacturer p and distribution center j | |

| Cost of transporting, per unit of new product, between distribution center j and customer c | |

| Cost of transporting, per unit of used product, between distribution center j and customer | |

| Cost of transporting, per unit of product, between seller r and collection center l | |

| Cost of transporting, per unit of product, between collection center l and disposal d | |

| Cost of transporting, per unit of recycled product, between disposal d and manufacturer i | |

| Cost of transporting, per unit of product, between collection center l and distribution center j | |

| Cost of transporting, per unit of product, between collection center l and manufacturer i | |

| Cost of transporting, per unit of product, between manufacturer i and remanufacturer | |

| Inventory costs: | |

| Cost of holding, per unit of inventory, in distribution center j | |

| Cost of holding, per unit of inventory, in manufacturer i | |

| Demand and return: | |

| Product demand of customer c in scenario s at period t | |

| Product returns of seller r in scenario s at period t | |

| Other parameters: | |

| Probability of scenario s | |

| The quantity of raw material needed for one unit of a product | |

| Cost of buying raw material from spot market | |

| Coefficients and ratios: | |

| Rate of raw material shipping from disposal center to raw material stock | |

| Rate of new product shipping from manufacture centers to distribution centers | |

| Rate of product shipping from collection centers to distribution centers | |

| Rate of product shipping from collection centers to disposal centers | |

| A large number | |

| Number of periods | |

| Decision variables: | |

| Binary variables (relating to opening and locating facilities): | |

| Binary variable equals 1 if a manufacturer is located at location i, 0 otherwise | |

| Binary variable equals 1 if a remanufacturer is located at location i, 0 otherwise | |

| Binary variable equals 1 if a distribution center for a new product is located at location j, 0 otherwise | |

| Binary variable equals 1 if a distribution center for a used product is located at location j, 0 otherwise | |

| Binary variable equals 1 if a manufacturer and remanufacturer are located at location i, 0 otherwise | |

| Binary variable equals 1 if a new product distribution center and used product distribution center are located at location j, 0 otherwise | |

| Binary variable equals 1 if a collection center is located at location l, 0 otherwise | |

| Continuous variables (relating to production and raw material acquisition): | |

| Quantity committed in wholesale contract | |

| Quantity committed in contract to manufacturer i at period t | |

| Quantity bought from a spot market for manufacturer i in scenario s at period t | |

| Quantity of production from manufacturer i in scenario s at period t | |

| Continuous variables (relating to capacity of facilities): | |

| Capacity of manufacturer i | |

| Capacity of remanufacturer i | |

| Capacity of distribution center j for new product | |

| Capacity of distribution center j for used product | |

| Capacity of collection center l | |

| Continuous variables (relating to inventory decisions): | |

| Base-stock level of distribution center j at the beginning of each period | |

| Base-stock level of manufacturer i at the beginning of each period | |

| Inventory level of manufacturer i at the end of period t in scenario s | |

| Inventory level of distribution center j for new products at the end of period t in scenario s | |

| Inventory level of distribution center j for second market products at the end of period t in scenario s | |

| Continuous variables (relating to flows on network): | |

| Flow of production from manufacturer i transported to distribution center j at period t in scenario s | |

| Flow of material from disposal d transported to manufacturer i at period t in scenario s | |

| Flow of remanufactured product from remanufacturer i transported to distribution center j in scenario s at period t | |

| Flow of production from manufacturer i transported to remanufacturer in scenario s at period t | |

| Flow of returned product from collection center l transported to remanufacturer i in scenario s at period t | |

| Flow of returned product from collection center l transported to distribution center j at period t in scenario s | |

| Flow of returned product from collection center l transported to disposal d at period t in scenario s | |

| Flow of new product from distribution center j transported to customer c at period t in scenario s | |

| Flow of used product from distribution center l transported to customer at period t in scenario s | |

| Flow of returned product from seller r transported to collection center l at period t in scenario s | |

4. A Benders’ Decomposition-Based Solution Algorithm

| Benders’ Decomposition Algorithm |

| Step 0. Initialization |

| i. |

| ii. |

| iii. k = 0. |

| iv. Solve the initial master problem to obtain |

| While () |

| Step 1. Solving the sub-problems |

| For each s ∈ S |

| Solve the sub-problems by determined |

| End for |

| Step 2. Updating the lower and upper bounds |

| i. |

| ii. |

| Step 3. Solving the master problem |

| i. Add optimality cuts to the master problem for each scenario. |

| ii. k = k + 1. |

| iii. Solve the master problem to obtain . |

| End while |

Valid Inequalities

5. Computational Results

Data Generation for Parameters and Settings

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Simchi-Levi, D.; Simchi-Levi, E.; Kaminsky, P. Designing and Managing the Supply Chain: Concepts, Strategies, and Cases; McGraw-Hill: New York, NY, USA, 1999. [Google Scholar]

- Amiri, A. Designing a distribution network in a supply chain system: Formulation and efficient solution procedure. Eur. J. Oper. Res. 2006, 171, 567–576. [Google Scholar] [CrossRef]

- Tozanli, O.; Duman, G.M.; Kongar, E.; Gupta, S.M. Environmentally Concerned Logistics Operations in Fuzzy Environment: A Literature Survey. Logistics 2017, 1, 4. [Google Scholar] [CrossRef]

- Ayvaz, B.; Bolat, B.; Aydın, N. Stochastic reverse logistics network design for waste of electrical and electronic equipment. Res. Conserv. Recycl. 2015, 104, 391–404. [Google Scholar] [CrossRef]

- Kasarda, J.D. Logistics Is about Competitiveness and More. Logistics 2017, 1, 1. [Google Scholar] [CrossRef]

- Wieland, A.; Handfield, R.B.; Durach, C.F. Mapping the landscape of future research themes in supply chain management. J. Bus. Logist. 2016, 37, 205–212. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Dekker, R.; Fleischmann, M.; Inderfurth, K.; van Wassenhove, L.N. (Eds.) Reverse Logistics: Quantitative Models for Closed-Loop Supply Chains; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Larsson, F.; Creutz, M. Reverse Logistics: Case Study Comparison between an Electronic and a Fashion Organization. Master’s Thesis, Jönköping International Business School, Jönköping University, Jönköping, Sweden, 2012. [Google Scholar]

- Norek, C.D. Returns management: Making order out of chaos. Supply Chain Manag. Rev. 2002, 6, 34–42. [Google Scholar]

- Li, X.; Olorunniwo, F. An exploration of reverse logistics practices in three companies. Suppl. Chain Manag. Inter. J. 2008, 13, 381–386. [Google Scholar] [CrossRef]

- Fattahi, M.; Mahootchi, M.; Husseini, S.M. Integrated strategic and tactical supply chain planning with price-sensitive demands. Ann. Oper. Res. 2016, 242, 423–456. [Google Scholar] [CrossRef]

- Biehl, M.; Prater, E.; Realff, M.J. Assessing performance and uncertainty in developing carpet reverse logistics systems. Comput. Oper. Res. 2007, 34, 443–463. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; Van der Laan, E.; Van Nunen, J.A.; Van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Tibben-Lembke, R.S.; Rogers, D.S. Differences between forward and reverse logistics in a retail environment. Suppl. Chain Manag. Inter. J. 2002, 7, 271–282. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.K.; Setoputro, R. Reverse logistics in e-business: Optimal price and return policy. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 70–89. [Google Scholar] [CrossRef]

- Batarfi, R.; Jaber, M.Y.; Aljazzar, S.M. A profit maximization for a reverse logistics dual-channel supply chain with a return policy. Comput. Ind. Eng. 2017, 106, 58–82. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, G.; Sha, J. Optimal production and pricing policy for a closed loop system. Res. Conserv. Recycl. 2011, 55, 639–647. [Google Scholar] [CrossRef]

- Soleimani, H.; Govindan, K. Reverse logistics network design and planning utilizing conditional value at risk. Eur. J. Oper. Res. 2014, 237, 487–497. [Google Scholar] [CrossRef]

- Keyvanshokooh, E.; Fattahi, M.; Seyed-Hosseini, S.M.; Tavakkoli-Moghaddam, R. A dynamic pricing approach for returned products in integrated forward/reverse logistics network design. Appl. Math. Model. 2013, 37, 10182–10202. [Google Scholar] [CrossRef]

- Kim, H.; Kang, J.G.; Kim, W. An application of capacitated vehicle routing problem to reverse logistics of disposed food waste. Inter. J. Ind. Eng. 2014, 21, 46–52. [Google Scholar]

- Ferri, G.L.; Chaves, G.L.D.; Ribeiro, G.M. Reverse logistics network for municipal solid waste management: The inclusion of waste pickers as a Brazilian legal requirement. Waste Manag. 2015, 40, 173–191. [Google Scholar] [CrossRef] [PubMed]

- Dowlatshahi, S. Developing a theory of reverse logistics. Interfaces 2000, 30, 143–155. [Google Scholar] [CrossRef]

- Erol, I.; Nurtaniş Velioğlu, M.; Sivrikaya Şerifoğlu, F.; Büyüközkan, G.; Aras, N.; Demircan Çakar, N.; Korugan, A. Exploring reverse supply chain management practices in Turkey. Suppl. Chain Manag. Inter. J. 2010, 15, 43–54. [Google Scholar] [CrossRef]

- Ahluwalia, P.K.; Nema, A.K. Multi-objective reverse logistics model for integrated computer waste management. Waste Manag. Res. 2006, 24, 514–527. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Putnam, V. Cradle to cradle: Reverse logistics strategies and opportunities across three industry sectors. Inter. J. Prod. Econ. 2008, 115, 305–315. [Google Scholar] [CrossRef]

- De Brito, M.P.; Dekker, R.; Flapper, S.D.P. Reverse Logistics: A Review of Case Studies. In Distribution Logist; Springer: Berlin, Germany, 2005; pp. 243–281. [Google Scholar]

- Guide, V.D.R.; van Wassenhove, L.N. The Evolution of Closed-Loop Supply Chain Research. Oper. Res. 2009, 57, 10–18. [Google Scholar] [CrossRef]

- Pokharel, S.; Mutha, A. Perspectives in reverse logistics: A review. Resour. Conserv. Recycl. 2009, 53, 175–182. [Google Scholar] [CrossRef]

- Klibi, W.; Martel, A.; Guitouni, A. The design of robust value-creating supply chain networks: A critical review. Eur. J. Oper. Res. 2010, 203, 283–293. [Google Scholar] [CrossRef]

- Prodhon, C.; Prins, C. A survey of recent research on location-routing problems. Eur. J. Oper. Res. 2014, 238, 1–17. [Google Scholar] [CrossRef]

- Govindan, K.; Fattahi, M.; Keyvanshokooh, E. Supply chain network design under uncertainty: A comprehensive review and future research directions. Eur. J. Oper. Res. 2017, 263, 108–141. [Google Scholar] [CrossRef]

- Torabi, S.A.; Namdar, J.; Hatefi, S.M.; Jolai, F. An enhanced possibilistic programming approach for reliable closed-loop supply chain network design. Int. J. Prod. Res. 2016, 54, 1358–1387. [Google Scholar] [CrossRef]

- Snyder, L.V.; Atan, Z.; Peng, P.; Rong, Y.; Schmitt, A.J.; Sinsoysal, B. OR/MS models for supply chain disruptions: A review. IIE Trans. 2016, 48, 89–109. [Google Scholar] [CrossRef]

- Sadghiani, N.S.; Torabi, S.; Sahebjamnia, N. Retail supply chain network design under operational and disruption risks. Transp. Res. Part E Logist. Transp. Rev. 2015, 75, 95–114. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef] [Green Version]

- Akçalı, E.; Çetinkaya, S.; Üster, H. Network design for reverse and closed-loop supply chains: An annotated bibliography of models and solution approaches. Networks 2009, 53, 231–248. [Google Scholar] [CrossRef]

- Chanintrakul, P.; Coronado Mondragon, A.E.; Lalwani, C.; Wong, C.Y. Reverse logistics network design: A state-of-the-art literature review. Inter. J. Bus. Perform. Suppl. Chain Model. 2009, 1, 61–81. [Google Scholar] [CrossRef]

- Lieckens, K.; Vandaele, N. Multi-level reverse logistics network design under uncertainty. Inter. J. Prod. Res. 2012, 50, 23–40. [Google Scholar] [CrossRef]

- Alumur, S.A.; Nickel, S.; Saldanha-da-Gama, F.; Verter, V. Multi-period reverse logistics network design. Eur. J. Oper. Res. 2012, 220, 67–78. [Google Scholar] [CrossRef]

- Liao, C.-L.; Jiang, M.-Y. Reverse Logistics Network Design with Recovery Rate Taken into Account. Ind. Eng. J. Gongye Gongcheng 2011, 14, 47–51. [Google Scholar]

- Fattahi, M.; Govindan, K.; Keyvanshokooh, E. Responsive and resilient supply chain network design under operational and disruption risks with delivery lead-time sensitive customers. Transp. Res. Part E Logist. Transp. Rev. 2017, 101, 176–200. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K. Integrated forward/reverse logistics network design under uncertainty with pricing for collection of used products. Ann. Oper. Res. 2017, 253, 193–225. [Google Scholar] [CrossRef]

- Van Landeghem, H.; Vanmaele, H. Robust planning: A new paradigm for demand chain planning. J. Oper. Manag. 2002, 20, 769–783. [Google Scholar] [CrossRef]

- Yu, C.-S.; Li, H.-L. A robust optimization model for stochastic logistic problems. Int. J. Prod. Econ. 2000, 64, 385–397. [Google Scholar] [CrossRef]

- Owen, S.H.; Daskin, M.S. Strategic facility location: A review. Eur. J. Oper. Res. 1998, 111, 423–447. [Google Scholar] [CrossRef]

- Listeş, O.; Dekker, R. A stochastic approach to a case study for product recovery network design. Eur. J. Oper. Res. 2005, 160, 268–287. [Google Scholar] [CrossRef]

- Salema, M.I.G.; Barbosa-Povoa, A.P.; Novais, A.Q. An optimization model for the design of a capacitated multi-product reverse logistics network with uncertainty. Eur. J. Oper. Res. 2007, 179, 1063–1077. [Google Scholar] [CrossRef]

- Listes, O.L. A Decomposition Approach to a Stochastic Model for Supply-and-Return Network Design; Econometric Institute Reports EI 2002-43; Econometric Institute, Erasmus School of Economics, The Erasmus University Rotterdam: Rotterdam, The Netherlands, 2002. [Google Scholar]

- Realff, M.J.; Ammons, J.C.; Newton, D.J. Robust reverse production system design for carpet recycling. IIE Trans. 2004, 36, 767–776. [Google Scholar] [CrossRef]

- Fleischmann, M.; Beullens, P.; BloemhoF-Ruwaard, J.M.; Wassenhove, L.N. The impact of product recovery on logistics network design. Prod. Oper. Manag. 2001, 10, 156–173. [Google Scholar] [CrossRef]

- Chouinard, M.; D’Amours, S.; Aït-Kadi, D. A stochastic programming approach for designing supply loops. Int. J. Prod. Econ. 2008, 113, 657–677. [Google Scholar] [CrossRef]

- Fonseca, M.C.; García-Sánchez, Á.; Ortega-Mier, M.; Saldanha-da-Gama, F. A stochastic bi-objective location model for strategic reverse logistics. Top 2010, 18, 158–184. [Google Scholar] [CrossRef]

- Kara, S.S.; Onut, S. A two-stage stochastic and robust programming approach to strategic planning of a reverse supply network: The case of paper recycling. Exp. Syst. Appl. 2010, 37, 6129–6137. [Google Scholar] [CrossRef]

- Kara, S.S.; Onut, S. A stochastic optimization approach for paper recycling reverse logistics network design under uncertainty. Int. J. Environ. Sci. Technol. 2010, 7, 717–730. [Google Scholar] [CrossRef]

- Lee, D.-H.; Dong, M.; Bian, W. The design of sustainable logistics network under uncertainty. Inter. J. Prod. Econ. 2010, 128, 159–166. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Jolai, F.; Razmi, J. A stochastic optimization model for integrated forward/reverse logistics network design. J. Manuf. Syst. 2009, 28, 107–114. [Google Scholar] [CrossRef]

- Lee, D.-H.; Dong, M. Dynamic network design for reverse logistics operations under uncertainty. Transp. Res. Part E Logist. Transp. Rev. 2009, 45, 61–71. [Google Scholar] [CrossRef]

- Lieckens, K.; Vandaele, N. Reverse logistics network design with stochastic lead times. Comput. Oper. Res. 2007, 34, 395–416. [Google Scholar] [CrossRef]

- El-Sayed, M.; Afia, N.; El-Kharbotly, A. A stochastic model for forward–reverse logistics network design under risk. Comput. Ind. Eng. 2010, 58, 423–431. [Google Scholar] [CrossRef]

- Listeş, O. A generic stochastic model for supply-and-return network design. Comput. Oper. Res. 2007, 34, 417–442. [Google Scholar] [CrossRef]

- Ramezani, M.; Bashiri, M.; Tavakkoli-Moghaddam, R. A new multi-objective stochastic model for a forward/reverse logistic network design with responsiveness and quality level. Appl. Math. Model. 2013, 37, 328–344. [Google Scholar] [CrossRef]

- Hatefi, S.; Jolai, F. Robust and reliable forward—Reverse logistics network design under demand uncertainty and facility disruptions. Appl. Math. Model. 2014, 38, 2630–2647. [Google Scholar] [CrossRef]

- Keyvanshokooh, E.; Ryan, S.M.; Kabir, E. Hybrid robust and stochastic optimization for closed-loop supply chain network design using accelerated Benders decomposition. Eur. J. Oper. Res. 2016, 249, 76–92. [Google Scholar] [CrossRef]

- Birge, J.R.; Louveaux, F. Introduction to Stochastic Programming; Springer Science & Business Media: Berlin, Germany, 2011. [Google Scholar]

- Benders, J.F. Partitioning procedures for solving mixed-variables programming problems. Numer. Math. 1962, 4, 238–252. [Google Scholar] [CrossRef]

- Santoso, T.; Ahmed, S.; Goetschalckx, M.; Shapiro, A. A stochastic programming approach for supply chain network design under uncertainty. Eur. J. Oper. Res. 2005, 167, 96–115. [Google Scholar] [CrossRef]

- MirHassani, S.A.; Lucas, C.; Mitra, G.; Messina, E.; Poojari, C.A. Computational solution of capacity planning models under uncertainty. Parallel Comput. 2000, 26, 511–538. [Google Scholar] [CrossRef]

- Üster, H.; Easwaran, G.; Akçali, E.; Çetinkaya, S. Benders decomposition with alternative multiple cuts for a multi-product closed-loop supply chain network design model. Nav. Res. Logist. 2007, 54, 890–907. [Google Scholar] [CrossRef]

- Birge, J.R.; Louveaux, F.V. A multicut algorithm for two-stage stochastic linear programs. Eur. J. Oper. Res. 1988, 34, 384–392. [Google Scholar] [CrossRef]

- Rei, W.; Cordeau, J.F.; Gendreau, M.; Soriano, P. Accelerating Benders decomposition by local branching. Inf. J. Comput. 2009, 21, 333–345. [Google Scholar] [CrossRef]

- Sherali, H.D.; Fraticelli, B.M. A modification of Benders’ decomposition algorithm for discrete subproblems: An approach for stochastic programs with integer recourse. J. Glob. Optim. 2002, 22, 319–342. [Google Scholar] [CrossRef]

- Saharidis, G.K.; Boile, M.; Theofanis, S. Initialization of the Benders master problem using valid inequalities applied to fixed-charge network problems. Expert Syst. Appl. 2011, 38, 6627–6636. [Google Scholar] [CrossRef]

- Magnanti, T.L.; Wong, R.T. Accelerating Benders decomposition: Algorithmic enhancement and model selection criteria. Oper. Res. 1981, 29, 464–484. [Google Scholar] [CrossRef]

- Poojari, C.A.; Beasley, J.E. Improving benders decomposition using a genetic algorithm. Eur. J. Oper. Res. 2009, 199, 89–97. [Google Scholar] [CrossRef]

- Bussieck, M.R.; Meeraus, A. General algebraic modeling system (GAMS). Appl. Optim. 2004, 88, 137–158. [Google Scholar]

| Category | Detail | Code | Category | Detail | Code |

|---|---|---|---|---|---|

| Model objectives | Cost minimization | CM | Features of model | Period | |

| Profit maximization | PM | Single-period | S | ||

| Responsiveness | R | Multi-period | M | ||

| Quality | Q | Facility capacity | |||

| Other | OT | Un-capacitated | U | ||

| Features of model | Stochastic parameters | Capacitated | C | ||

| Quantity of demand | D | Capacity expansion | CE | ||

| Quantity of returns | R | Single sourcing | SS | ||

| Quality of returns | RQ | Model | Mixed Integer Linear Programming | MILP | |

| Recovery rate | RR | ||||

| Recovery cost | RC | Mixed Integer Non-Linear Programming | MINLP | ||

| Transportation cost | TC | ||||

| Lead time | LT | Decision variables of model | Inventory decisions | I | |

| Income | In | Facility capacity | Fc | ||

| Other | OT | Demand satisfaction | D | ||

| Product commodity | Transportation values | TV | |||

| Single-commodity | S | Location/allocation | LA | ||

| Multi-commodity | M | Transportation mode selection | TM | ||

| Solution methodology | Technology selection | TS | |||

| Exact solution method | EX | ||||

| Heuristic solution method | HE |

| Ref. | Model Obj. | Stoch. Param. | Product Com. | Period | Facility Cap. | Model | D.V. | Sol. Method | Solution Approach |

|---|---|---|---|---|---|---|---|---|---|

| [50] | PM | R | S | S | C | MILP | TV, LA | EX | B&C |

| [51] | PM | D | M | M | C | MILP | TV, LA, Fc, TM | -- a | AIMMS |

| [48] | PM | R, In | M | S | C | MILP | TV, LA | -- a | CPLEX |

| [62] | PM | D, R | S | S | C | MILP | TV, LA, SS | EX | Integer L-Shape Method |

| [49] | CM | TC, D, R | M | S | C | MILP | TV, LA, D | -- a | CPLEX |

| [60] | PM | LT | S | S | C | MINLP | TV, LA, Fc, I | HE | Differential Evaluation (DE) |

| [59] | CM | D, R | M | M | C | MILP | TV, LA | HE | SAA with SA |

| [54] | CM, OT | TC, R, OT | M | S | C | MILP | TV, LA, TS | -- a | CPLEX10 |

| [58] | CM | TC, D, R, RQ | S | S | C | MILP | TV, LA | -- a | LINGO |

| [55] | PM | D, R | S | S | C | MILP | TV, LA | -- a | CPLEX |

| [57] | CM | D, R | M | S | C | MILP | TV, LA | EX | SAA with CPLEX |

| [53] | CM | RQ | S | S | MILP | LA | EX | SAA | |

| [63] | CM, R, Q | D, R, RC, OT | M | S | C, SS | MILP | TV, LA, Fc | -- a | Commercial Solver |

| [56] | CM | D, R | S | S | C | MILP | TV, LA | -- a | CPLEX |

| [61] | PM | D, R | S | M | C | MILP | TV, LA, I | -- a | XpressSp |

| [20] | PM | OT | M | S | C | MILP | TV, LA | -- a | CPLEX |

| [64] | CM | D, R, RQ | S | S | C | MILP | TV, LA | -- a | CPLEX/GAMS |

| [4] | PM | R, RQ | P | S | C | MILP | TV, LA | EX | SAA |

| [65] | PM | D, R, TC | S | M | C | MILP | TV, LA | EX | Accelerated BD |

| Our paper | CM | D, R | S | M | C | MILP | TV, LA, I | EX | Accelerated BD |

| Parameter | Range | Parameter | Range |

|---|---|---|---|

| ~Uniform (1,000,000, 4,000,000) | ~ Uniform (10, 25) | ||

| ~Uniform (500,000, 1,500,000) | ~ Uniform (10, 20) | ||

| ~Uniform (500,000, 2,500,000) | ~ Uniform (20, 25) | ||

| ~Uniform (400,000, 600,000) | ~ Uniform (30, 40) | ||

| ~Uniform (300,000, 900,000) | |||

| ~Uniform (1000, 1800) | α ~ Uniform (20, 40) | ||

| ~Uniform(2000,2800) | ~ Uniform (0.15, 0.2) | ||

| ~Uniform (1500, 3000) | ~ N(0, Uniform (20, 35)) | ||

| ~Uniform (900, 1500) | ~ Uniform (30, 50) | ||

| ~Uniform (7000, 15,000) | |||

| ~Uniform (1000, 2000) | α ~ Uniform (10, 20) | ||

| ~Uniform (1000, 5000) | ~ Uniform (0.15, 0.2) | ||

| ~Uniform (10, 30) | ~ N(0, Uniform (10, 25)) | ||

| ~Uniform (15, 30) | ~ Uniform (20, 30) | ||

| ~Uniform (10, 30) | 60 | ||

| ~Uniform (20, 35) | 0.7 | ||

| ~Uniform (10, 30) | 0.95 | ||

| ~Uniform (15, 30) | 0.4 | ||

| ~Uniform (10, 20) | 0.4 |

| Size of Test Problems | ID | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Small | 1 | 4 | 8 | 8 | 10 | 15 | 10 | 2 | 20 | 12 |

| 2 | 4 | 8 | 8 | 10 | 15 | 10 | 2 | 40 | 12 | |

| 3 | 5 | 10 | 10 | 12 | 15 | 12 | 2 | 20 | 12 | |

| 4 | 5 | 10 | 10 | 12 | 15 | 12 | 2 | 40 | 12 | |

| Medium | 5 | 8 | 18 | 12 | 18 | 15 | 15 | 2 | 20 | 12 |

| 6 | 8 | 18 | 12 | 18 | 15 | 15 | 2 | 40 | 12 | |

| 7 | 10 | 20 | 12 | 20 | 15 | 15 | 2 | 20 | 12 | |

| 8 | 10 | 20 | 12 | 20 | 15 | 15 | 2 | 40 | 12 | |

| Large | 9 | 15 | 40 | 30 | 40 | 15 | 20 | 2 | 20 | 12 |

| 10 | 15 | 40 | 30 | 40 | 15 | 20 | 2 | 40 | 12 | |

| 11 | 20 | 60 | 40 | 60 | 15 | 20 | 2 | 20 | 12 | |

| 12 | 20 | 60 | 40 | 60 | 15 | 20 | 2 | 40 | 12 |

| ID | Number of Variables | No. of Constraints | No. of Scenarios | |

|---|---|---|---|---|

| Binary | Continuous | |||

| 1 | 44 | 117,213 | 35,116 | 20 |

| 2 | 44 | 234,333 | 70,156 | 40 |

| 3 | 55 | 169,316 | 43,532 | 20 |

| 4 | 55 | 338,516 | 86,972 | 40 |

| 5 | 90 | 358,747 | 67,586 | 20 |

| 6 | 90 | 717,307 | 135,026 | 40 |

| 7 | 102 | 433,183 | 75,682 | 20 |

| 8 | 102 | 866,143 | 151,364 | 40 |

| 9 | 195 | 1,439,176 | 143,584 | 20 |

| 10 | 195 | 2,877,976 | 287,167 | 40 |

| 11 | 280 | 2,750,921 | 202,516 | 20 |

| 12 | 280 | 5,501,321 | 405,032 | 40 |

| CPLEX | Classic BD | Accelerated BD | ||||

|---|---|---|---|---|---|---|

| ID | Optimality Gap (%) | CPU (s) | Optimality Gap (%) | CPU (s) | Optimality Gap (%) | CPU (s) |

| 1 | 0 | 210 | 4.231 | 330.12 | 0.8197 | 320.64 |

| 2 | 0 | 721.18 | 7.3141 | 645.56 | 0.4826 | 642.61 |

| 3 | 0 | 400.5 | 11.8911 | 400.5 | 0.5528 | 393.76 |

| 4 | -- b | >3 h | 15.0164 | 779.74 | 0.8998 | 780.02 |

| 5 | 0 | 2751.16 | 11.4512 | 1312.51 | 1.3446 | 1268.44 |

| 6 | -- b | >5 h | 14.7121 | 2669.98 | 1.5875 | 2618.37 |

| 7 | -- b | >5 h | 15.1241 | 1591.56 | 2.6123 | 1540.67 |

| 8 | -- b | >5 h | 16.0195 | 3090.12 | 3.4303 | 3089.33 |

| 9 | -- b | >10 h | 15.9184 | 5093.42 | 4.9106 | 5009.21 |

| 10 | -- b | >10 h | 17.412 | 10,274.84 | 7.2837 | 10,121.71 |

| 11 | -- b | >10 h | 18.1027 | 7421.12 | 6.2287 | 7021.13 |

| 12 | -- b | >10 h | 19.8193 | 14,573.69 | 8.585 | 14,011.87 |

| ABD-I | ABD-1 | ABD-2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Lower Bound | Gap (%) | CPU (s) | Lower Bound | Gap (%) | CPU (s) | Lower bound | Gap (%) | CPU (s) |

| 1 | 127,007,212 | 0.81 | 320.64 | 126,982,020 | 0.83 | 327.21 | 126,994,615 | 0.82 | 325.16 |

| 2 | 129,448,338 | 0.48 | 642.61 | 129,422,577 | 0.50 | 643.28 | 129,448,338 | 0.48 | 643.12 |

| 3 | 151,583,859 | 0.55 | 393.76 | 151,312,985 | 0.73 | 396.30 | 151,508,519 | 0.6 | 396.74 |

| 4 | 137,039,534 | 0.89 | 780.02 | 136,998,797 | 0.92 | 780.53 | 137,012,373 | 0.91 | 781.46 |

| 5 | 210,742,541 | 1.34 | 1268.44 | 210,368,884 | 1.52 | 1296.98 | 210,700,958 | 1.36 | 1270.14 |

| 6 | 215,373,195 | 1.58 | 2618.37 | 215,140,222 | 1.69 | 2660.02 | 215,288,419 | 1.62 | 2622.63 |

| 7 | 230,643,712 | 2.61 | 1540.67 | 229,859,667 | 2.96 | 1573.89 | 229,881,994 | 2.95 | 1576.68 |

| 8 | 215,260,805 | 3.43 | 3089.33 | 213,485,714 | 4.29 | 3090.01 | 215,219,189 | 3.45 | 3090.81 |

| 9 | 418,327,768 | 4.91 | 5009.21 | 416,027,739 | 5.49 | 5064.46 | 418,287,897 | 4.92 | 5060.58 |

| 10 | 444,456,828 | 7.28 | 10,121.71 | 440,514,861 | 8.24 | 10,245.74 | 442,888,060 | 7.66 | 10,199.11 |

| 11 | 617,187,359 | 6.22 | 7021.13 | 615,680,328 | 6.48 | 7142.71 | 616,085,342 | 6.41 | 7130.65 |

| 12 | 644,450,944 | 8.58 | 14,011.87 | 636,073,843 | 10.01 | 14,315.41 | 642,026,640 | 8.99 | 14,149.29 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vahdat, V.; Vahdatzad, M.A. Accelerated Benders’ Decomposition for Integrated Forward/Reverse Logistics Network Design under Uncertainty. Logistics 2017, 1, 11. https://doi.org/10.3390/logistics1020011

Vahdat V, Vahdatzad MA. Accelerated Benders’ Decomposition for Integrated Forward/Reverse Logistics Network Design under Uncertainty. Logistics. 2017; 1(2):11. https://doi.org/10.3390/logistics1020011

Chicago/Turabian StyleVahdat, Vahab, and Mohammad Ali Vahdatzad. 2017. "Accelerated Benders’ Decomposition for Integrated Forward/Reverse Logistics Network Design under Uncertainty" Logistics 1, no. 2: 11. https://doi.org/10.3390/logistics1020011

APA StyleVahdat, V., & Vahdatzad, M. A. (2017). Accelerated Benders’ Decomposition for Integrated Forward/Reverse Logistics Network Design under Uncertainty. Logistics, 1(2), 11. https://doi.org/10.3390/logistics1020011