Influence of Processing Conditions on the Flavor Profiles of Mulberry (Morus alba Linn) Fruits Using Instrumental Flavor Analysis and Descriptive Sensory Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Flavor Extraction Using Distillation under Reduced Pressure

2.3. Concentration of Volatile Components

2.4. Volatile Compound Analysis

2.5. Descriptive Sensory Analysis of Mulberry Fruits

2.6. Statistical Analysis

3. Results and Discussion

3.1. Instrumental Analysis of Volatile Flavor Compounds in Mulberry Fruit

3.2. Descriptive Sensory Analysis Results

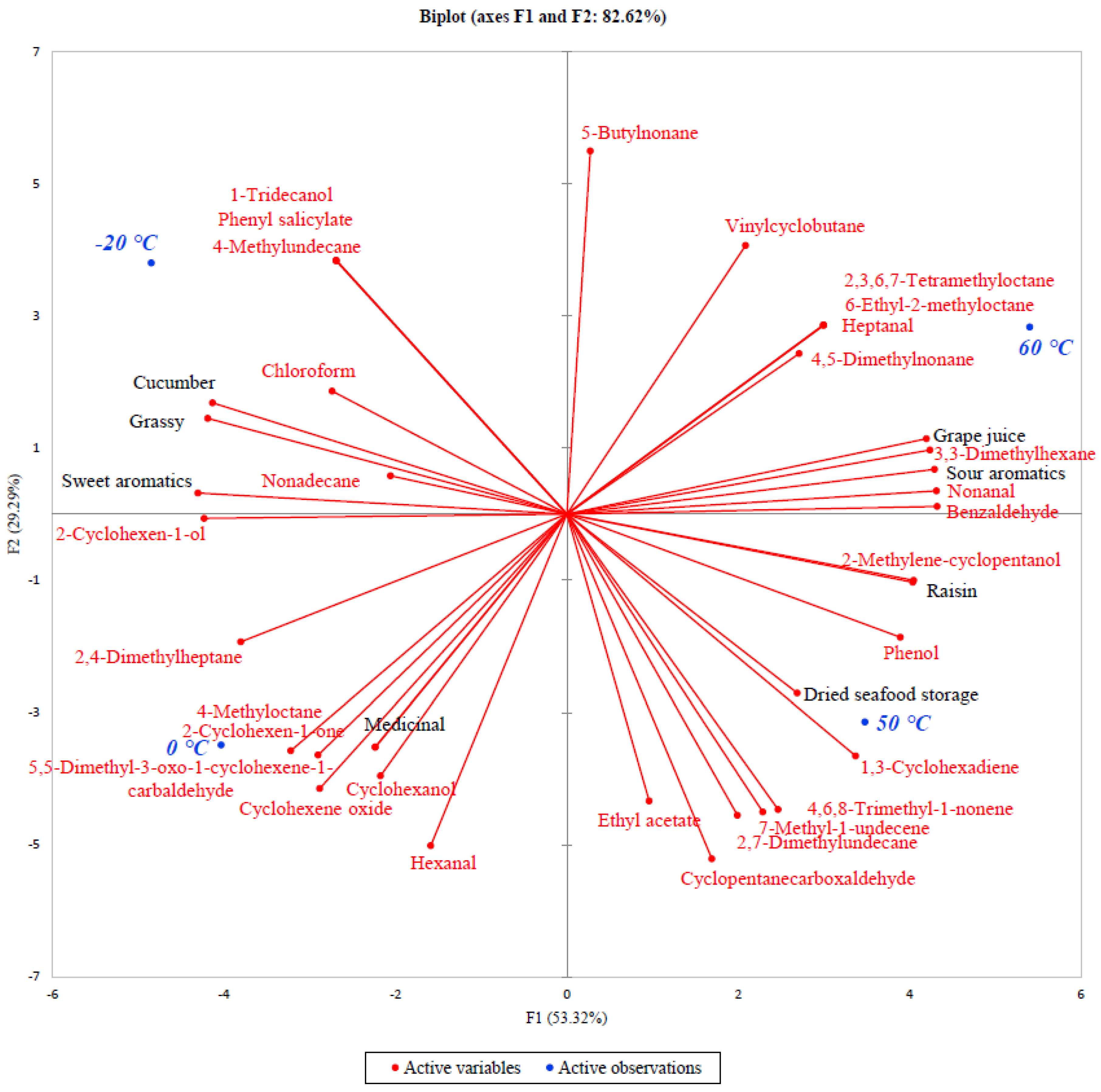

3.3. PCA of Mulberry Fruits Treated at Different Temperatures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Seo, K.-H.; Lee, D.-Y.; Jeong, R.-H.; Lee, D.-S.; Kim, Y.-E.; Hong, E.-K.; Kim, Y.-C.; Baek, N.-I. Neuroprotective effect of prenylated arylbenzofuran and flavonoids from Morus alba fruits on glutamate-induced oxidative injury in HT22 hippocampal cells. J. Med. Food 2015, 18, 403–408. [Google Scholar] [CrossRef] [PubMed]

- Ercisli, S.; Orhan, E. Chemical composition of white (Morus alba), red (Morus rubra) and black (Morus nigra) mulberry fruits. Food Chem. 2007, 103, 1380–1384. [Google Scholar] [CrossRef]

- Kang, T.H.; Hur, J.Y.; Kim, H.B.; Ryu, J.H.; Kim, S.Y. Neuroprotective effects of the cyanidin-3-O-beta-d-glucopyranoside isolated from mulberry fruit against cerebral ischemia. Neurosci. Lett. 2006, 391, 122–126. [Google Scholar] [CrossRef]

- Yang, X.; Yang, L.; Zheng, H. Hypolipidemic and antioxidant effects of mulberry (Morus alba L.) fruit in hyperlipidaemia rats. Food Chem. Toxicol. 2010, 48, 2374–2379. [Google Scholar] [CrossRef]

- Kim, M.K.; Lee, Y.J.; Kwak, H.S.; Kang, M.w. Identification of sensory attributes that drive consumer liking of commercial orange juice products in Korea. J. Food Sci. 2013, 78, S1451–S1458. [Google Scholar] [CrossRef]

- Desai, N.T.; Shepard, L.; Drake, M.A. Sensory properties and drivers of liking for Greek yogurts. J. Dairy Sci. 2013, 96, 7454–7466. [Google Scholar] [CrossRef]

- Drake, S.; Gerard, P.; Drake, M. Consumer preferences for mild Cheddar cheese flavors. J. Food Sci. 2008, 73, S449–S455. [Google Scholar] [CrossRef]

- Ouyang, X.; Zhu, B.; Liu, R.; Gao, Q.; Lin, G.; Wu, J.; Hu, Z.; Zhang, B. Comparison of volatile composition and color attributes of mulberry wine fermented by different commercial yeasts. J. Food Process. Preserv. 2018, 42, e13432. [Google Scholar] [CrossRef]

- Kwaw, E.; Ma, Y.; Tchabo, W.; Apaliya, M.T.; Xiao, L.; Wu, M. Effect of lactic acid fermentation on the phytochemical, volatile profile and sensory attributes of mulberry juice. J. Food Nutr. Res. 2017, 56, 305–317. [Google Scholar]

- Kim, M.K.; Choi, S.H. Volatile flavor components of commercial mulberry leaf tea. J. Korean Tea Soc. 2011, 17, 89–94. [Google Scholar]

- Elmacı, Y.; Altuğ, T. Flavour evaluation of three black mulberry (Morus nigra) cultivars using GC/MS, chemical and sensory data. J. Sci. Food Agric. 2002, 82, 632–635. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X.; Jin, Q.; Yang, L.; Li, J.; Chen, F. Free and bound volatile chemicals in mulberry (Morus atropurpurea Roxb.). J. Food Sci. 2015, 80, C975–C982. [Google Scholar] [CrossRef]

- Kim, M.K.; Lee, Y.-Y.; Lee, K.-g.; Jang, H.W. Instrumental volatile flavor analysis of omija (Schisandra chinesis Baillon) using headspace stir-bar sorptive extraction-gas chromatography-mass spectrometry and its relationship to human sensory perceptions. Food Res. Int. 2019, 120, 650–655. [Google Scholar] [CrossRef] [PubMed]

- Meilgaard, M.C.; Carr, B.T.; Civille, G.V. Sensory Evaluation Techniques; CRC Press: New York, NY, USA, 1999. [Google Scholar]

- Santos, J.P.; Arroyo, T.; Aleixandre, M.; Lozano, J.; Sayago, I.; Garcı́a, M.; Fernández, M.J.; Arés, L.; Gutiérrez, J.; Cabellos, J.M.; et al. A comparative study of sensor array and GC–MS: Application to Madrid wines characterization. Sens. Actuators B Chem. 2004, 102, 299–307. [Google Scholar] [CrossRef]

- Northrop, B.H.; Houk, K. Vinylcyclobutane−cyclohexene rearrangement: Theoretical exploration of mechanism and relationship to the Diels−Alder potential surface. J. Org. Chem. 2006, 71, 3–13. [Google Scholar] [CrossRef]

- Baek, H.; Cadwallader, K.R. Aroma volatiles in cooked alligator meat. J. Food Sci. 1997, 62, 321–325. [Google Scholar] [CrossRef]

- Kamiguchi, S.; Nishida, S.; Kodomari, M.; Chihara, T. Catalytic hydrodehydration of cyclohexanone, hydrogenation of 2-cyclohexen-1-one, and dehydrogenation of cyclohexene over a Mo chloride cluster with an octahedral metal framework. J. Clust. Sci. 2005, 16, 77–91. [Google Scholar] [CrossRef]

- Ross, C.F.; Rosales, M.U.; Fernandez-Plotka, V.C. Aroma profile of Niagara grape juice contaminated with multicoloured Asian lady beetle taint using gas chromatography/mass spectrometry/olfactometry. Int. J. Food Sci. Technol. 2010, 45, 789–793. [Google Scholar] [CrossRef]

- Cho, I.H.; Namgung, H.J.; Choi, H.K.; Kim, Y.S. Volatiles and key odorants in the pileus and stipe of pine-mushroom (Tricholoma matsutake Sing.). Food Chem. 2008, 106, 71–76. [Google Scholar] [CrossRef]

- Kiritsakis, A. Flavor components of olive oil—A review. J. Am. Oil Chem. Soc. 1998, 75, 673–681. [Google Scholar] [CrossRef]

- Xie, J.-C.; Sun, B.-G.; Wang, S.-B. Aromatic constituents from Chinese traditional smoke-cured bacon of Mini-pig. Food Sci. Technol. Int. 2008, 14, 329–340. [Google Scholar] [CrossRef]

- Jo, D.; Kim, G.-R.; Yeo, S.-H.; Jeong, Y.-J.; Noh, B.S.; Kwon, J.-H. Analysis of aroma compounds of commercial cider vinegars with different acidities using SPME/GC-MS, electronic nose, and sensory evaluation. Food Sci. Biotechnol. 2013, 22, 1559–1565. [Google Scholar] [CrossRef]

- Alejandro Vazquez-Cruz, M.; Jimenez-Garcia, S.N.; Torres-Pacheco, I.; Horacio Guzman-Maldonado, S.; Guevara-Gonzalez, R.G.; Miranda-Lopez, R. Effect of maturity stage and storage on flavor compounds and sensory description of berrycactus (Myrtillocactus geometrizans). J. Food Sci. 2012, 77, C366–C373. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Friend, C.M. Selective oxidation of cyclohexanol and 2-cyclohexen-1-ol on O/Au (111): The effect of molecular structure. Langmuir 2010, 26, 16552–16557. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Mula, H.M.; Marín, A.; Jordán, M.J.; Gil, M.I. Off-odor compounds responsible for quality loss of minimally processed baby spinach stored under MA of low O2 and high CO2 using GC–MS and olfactometry techniques. Postharvest. Biol. Technol. 2017, 129, 129–135. [Google Scholar] [CrossRef]

- Friedrich, J.E.; Acree, T.E. Gas chromatography olfactometry (GC/O) of dairy products. Int. Dairy J. 1998, 8, 235–241. [Google Scholar] [CrossRef]

- Villière, A.; Arvisenet, G.; Lethuaut, L.; Prost, C.; Sérot, T. Selection of a representative extraction method for the analysis of odourant volatile composition of French cider by GC–MS–O and GC × GC–TOF-MS. Food Chem. 2012, 131, 1561–1568. [Google Scholar] [CrossRef]

- Palassarou, M.; Melliou, E.; Liouni, M.; Michaelakis, A.; Balayiannis, G.; Magiatis, P. Volatile profile of Greek dried white figs (Ficus carica L.) and investigation of the role of β-damascenone in aroma formation in fig liquors. J. Sci. Food Agric. 2017, 97, 5254–5270. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Martínez-Nicolás, J.J.; Munera-Picazo, S.; Carbonell-Barrachina, Á.A.; Legua, P.; Hernández, F. Bioactive compounds and sensory quality of black and white mulberries grown in Spain. Plant Foods Hum. Nutr. 2013, 68, 370–377. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, L.; Xiao, Z.; Niu, Y. Characterization of the key aroma compounds in mulberry fruits by application of gas chromatography–olfactometry (GC-O), odor activity value (OAV), gas chromatography-mass spectrometry (GC–MS) and flame photometric detection (FPD). Food Chem. 2018, 245, 775–785. [Google Scholar] [CrossRef]

- Lignou, S.; Parker, J.K.; Baxter, C.; Mottram, D.S. Sensory and instrumental analysis of medium and long shelf-life Charentais cantaloupe melons (Cucumis melo L.) harvested at different maturities. Food Chem. 2014, 148, 218–229. [Google Scholar] [CrossRef]

- Hongsoongnern, P.; Chambers IV, E. A lexicon for green odor or flavor and characteristics of chemicals associated with green. J. Sens. Stud. 2008, 23, 205–221. [Google Scholar] [CrossRef]

- Chambers, E.; Sanchez, K.; Phan, U.X.T.; Miller, R.; Civille, G.V.; Di Donfrancesco, B. Development of a “living” lexicon for descriptive sensory analysis of brewed coffee. J. Sens. Stud. 2016, 31, 465–480. [Google Scholar] [CrossRef]

- Koppel, K.; Anderson, E.L.; Chambers IV, E. Influence of processing on pomegranate (Punica granatum L.) juice flavor and aroma. J. Sci. Food Agric. 2015, 95, 1066–1071. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.K.; Jang, H.W.; Lee, K.G. Sensory and instrumental volatile flavor analysis of commercial orange juices prepared by different processing methods. Food Chem. 2018, 267, 217–222. [Google Scholar] [CrossRef]

- Sakakibara, H.; Ide, J.; Yanai, T.; Yajima, I.; Hayashi, K. Volatile flavor compounds of some kinds of dried and smoked fish. Agric. Biol. Chem. 1990, 54, 9–16. [Google Scholar] [CrossRef]

| NO. | Compound Names | Odor Description | RT | ID | PAR | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | Sample 4 | ||||||

| 1 | Ethyl acetate | Fruity | 6.005 | RI, MS | 0.619 c | 0.990 b | 1.509 a | 0.589 c | [15] |

| 2 | Chloroform | Floral | 6.311 | RI, MS | 0.855 | 1.115 | 0.703 | 0.864 | [26] |

| 3 | 1,3-Cyclohexadiene | - | 7.059 | RI, MS | 1.823 | 2.542 | 2.545 | 2.246 | - |

| 4 | Vinylcyclobutane | - | 7.196 | RI, MS | 51.694 | 63.581 | 58.327 | 62.499 | - |

| 5 | 2,4-Dimethylheptane | - | 10.459 | RI, MS | 1.266 b | 1.853 a | 1.342 b | 1.198 b | - |

| 6 | Hexanal | Green-like, apple-like | 10.839 | RI, MS | - | 1.010 a | 0.361 b | - | [21] |

| 7 | 4-Methyloctane | - | 11.423 | RI, MS | 0.997 b | 1.494 a | 1.188 ab | 1.007 b | - |

| 8 | Cyclopentanecarboxaldehyde | - | 11.955 | RI, MS | 0.654 | 0.911 | 0.900 | 0.753 | - |

| 9 | Cyclohexene oxide | - | 12.142 | RI, MS | 2.108 b | 3.128 a | 2.600 ab | 2.197 b | - |

| 10 | Cyclohexanol | Camphor-like | 13.061 | RI, MS | 0.230 b | 0.379 a | 0.403 a | - | [23] |

| 11 | Heptanal | Green, sweet | 13.172 | RI, MS | - | - | - | 0.453 a | [27] |

| 12 | 2-Methylene-cyclopentanol | - | 13.177 | RI, MS | - | - | 2.641 a | 1.820 b | - |

| 13 | 2-Cyclohexen-1-ol | Caramelized, phenolic, floral | 13.182 | RI, MS | 2.047 b | 3.025 a | - | - | [24] |

| 14 | 2-Cyclohexen-1-one | Fresh air, sweet | 14.419 | RI, MS | 4.792 ab | 6.622 a | 6.042 ab | 4.341 b | [17] |

| 15 | Benzaldehyde | Almond-like | 14.832 | RI, MS | 0.262 c | 0.432 b | 1.106 a | 1.222 a | [20] |

| 16 | 2,7-Dimethylundecane | - | 15.538 | RI, MS | - | 5.136 a | 4.299 ab | 3.431 b | - |

| 17 | 7-Methyl-1-undecene | - | 15.964 | RI, MS | - | 0.533 a | 0.499 a | 0.384 b | - |

| 18 | Phenol | Phenolic | 16.106 | RI, MS | 1.537 b | 2.084 ab | 2.399 a | 2.049 ab | [28] |

| 19 | 6-Ethyl-2-methyloctane | - | 16.169 | RI, MS | - | - | - | 0.609 a | - |

| 20 | 4,5-Dimethylnonane | - | 16.310 | RI, MS | 4.813 a | - | 7.071 a | 5.506 a | - |

| 21 | 4-Methylundecane | - | 16.364 | RI, MS | 0.785 a | - | - | - | - |

| 22 | Nonanal | Fatty, green, sweet | 17.055 | RI, MS | - | - | 0.362 a | 0.425 a | [22] |

| 23 | Nonadecane | - | 19.582 | RI, MS | 3.055 | 3.311 | 3.738 | 2.522 | - |

| 24 | 1-Tridecanol | Musty | 19.766 | RI, MS | 0.506 a | - | - | - | [29] |

| 25 | 5-Butylnonane | - | 19.911 | RI, MS | 1.770 b | 0.731 c | - | 2.775 a | - |

| 26 | 4,6,8-Trimethyl-1-nonene | - | 20.115 | RI, MS | - | 0.565 a | 0.575 a | 0.425 b | - |

| 27 | 3,3-Dimethylhexane | - | 20.242 | RI, MS | - | - | 1.067 b | 2.377 a | - |

| 28 | 2,3,6,7-Tetramethyloctane | - | 20.420 | RI, MS | - | - | - | 0.308 a | - |

| 29 | 5,5-Dimethyl-3-oxo-1-cyclohexene-1-carbaldehyde | - | 20.963 | RI, MS | - | 0.558 a | - | - | - |

| 30 | Phenyl salicylate | - | 23.952 | RI, MS | 0.599 a | - | - | - | - |

| Lexicon | Definition/Reference | Sample 1 | Sample 2 | Sample 3 | Sample 4 |

|---|---|---|---|---|---|

| Cucumber | Aromatics associated with cucumber (Ref. Freshly cut cucumber) | 2.50 a | 1.55 b | 0.00 c | 0.00 c |

| Green/grassy | Aromatics associated with grass (Ref. The rind of a watermelon) | 0.87 a | 0.59 b | 0.00 c | 0.00 c |

| Sweet aromatics | Aromatics associated with syrup (Ref: Oligosaccharides, CJ Cheiljedang, Seoul, Republic of Korea) | 0.87 a | 0.80 a | 0.07 b | 0.00 b |

| Raisin | Aromatics associated with raisin (Ref. Raisins, Sunview, CA, USA) | 0.00 c | 0.00 c | 2.00 a | 1.48 b |

| Sour aromatics | Aromatics associated with citric acid (Ref. Citric acid, Sigma-Aldrich, MO, USA) | 0.00 b | 0.00 b | 0.47 a | 0.68 a |

| Grape juice | Aromatics associated with grape juice (Ref. Jabez grape juice, Yeongdong Jabez Community, Yeongdong, Republic of Korea) | 0.00 c | 0.00 c | 0.55 b | 1.00 a |

| Dried seafood storage | Aromatics associated with Dried seafood storage (Ref. Woorim stock pack, Gijangfood, Busan, Republic of Korea) | 0.00 b | 0.00 b | 0.70 a | 0.15 b |

| Medicinal | Aromatics associated with hospital (Ref: Band-aid, Johnson-Johnson® Korea, Seoul, Republic of Korea) | 0.00 b | 0.87 a | 0.00 b | 0.00 b |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, I.-S.; Kim, M.K. Influence of Processing Conditions on the Flavor Profiles of Mulberry (Morus alba Linn) Fruits Using Instrumental Flavor Analysis and Descriptive Sensory Analysis. Foods 2020, 9, 581. https://doi.org/10.3390/foods9050581

Hwang I-S, Kim MK. Influence of Processing Conditions on the Flavor Profiles of Mulberry (Morus alba Linn) Fruits Using Instrumental Flavor Analysis and Descriptive Sensory Analysis. Foods. 2020; 9(5):581. https://doi.org/10.3390/foods9050581

Chicago/Turabian StyleHwang, In-Seo, and Mina K. Kim. 2020. "Influence of Processing Conditions on the Flavor Profiles of Mulberry (Morus alba Linn) Fruits Using Instrumental Flavor Analysis and Descriptive Sensory Analysis" Foods 9, no. 5: 581. https://doi.org/10.3390/foods9050581

APA StyleHwang, I.-S., & Kim, M. K. (2020). Influence of Processing Conditions on the Flavor Profiles of Mulberry (Morus alba Linn) Fruits Using Instrumental Flavor Analysis and Descriptive Sensory Analysis. Foods, 9(5), 581. https://doi.org/10.3390/foods9050581