Formulations of Rancid and Winey-Vinegary Artificial Olfactory Reference Materials (AORMs) for Virgin Olive Oil Sensory Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Samples

2.3. Determination of Volatile Compounds

2.4. Sensory Analysis and Optimization of RM Formulations

3. Results and Discussion

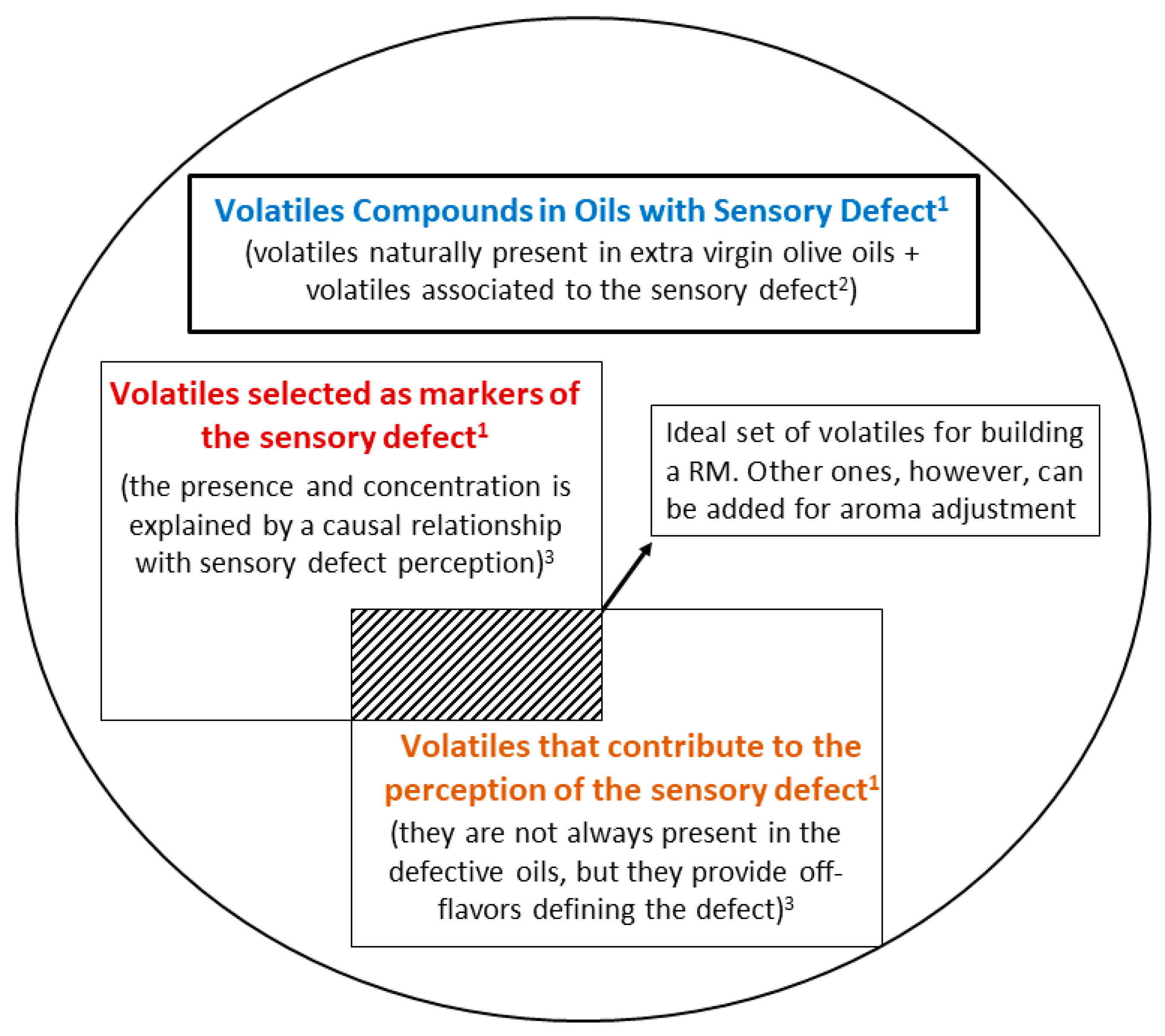

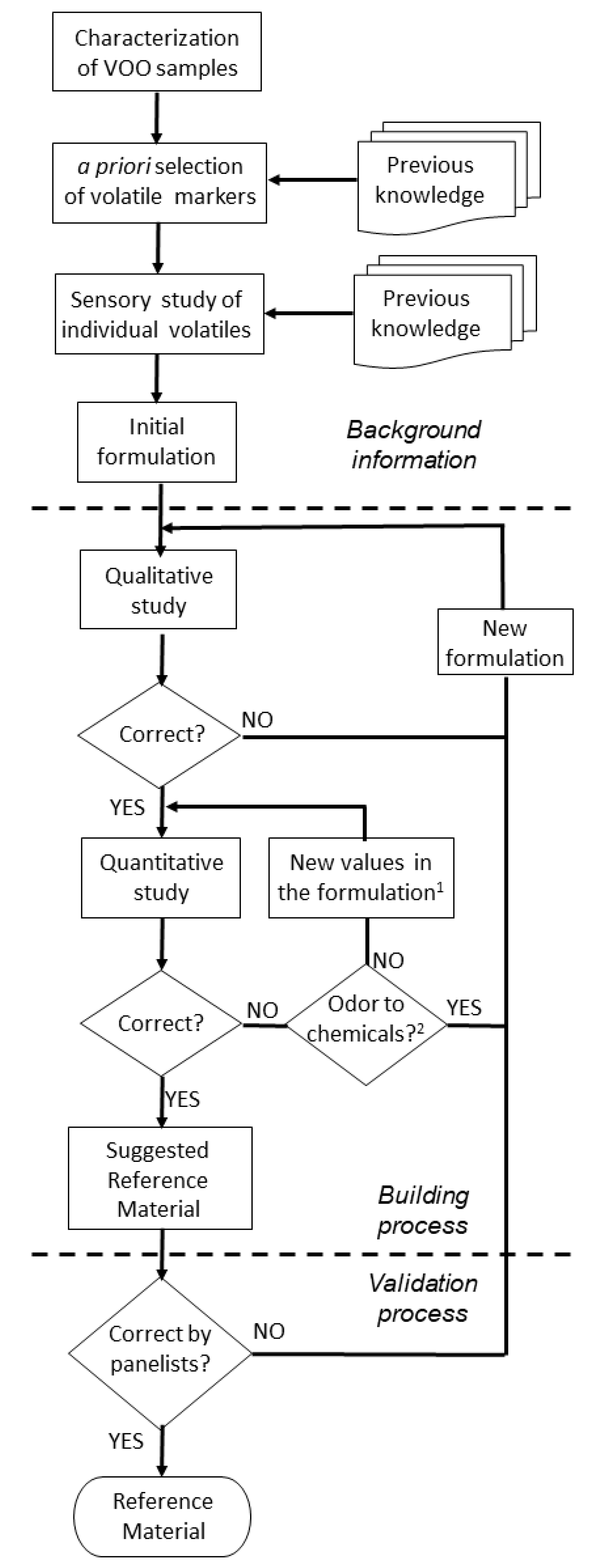

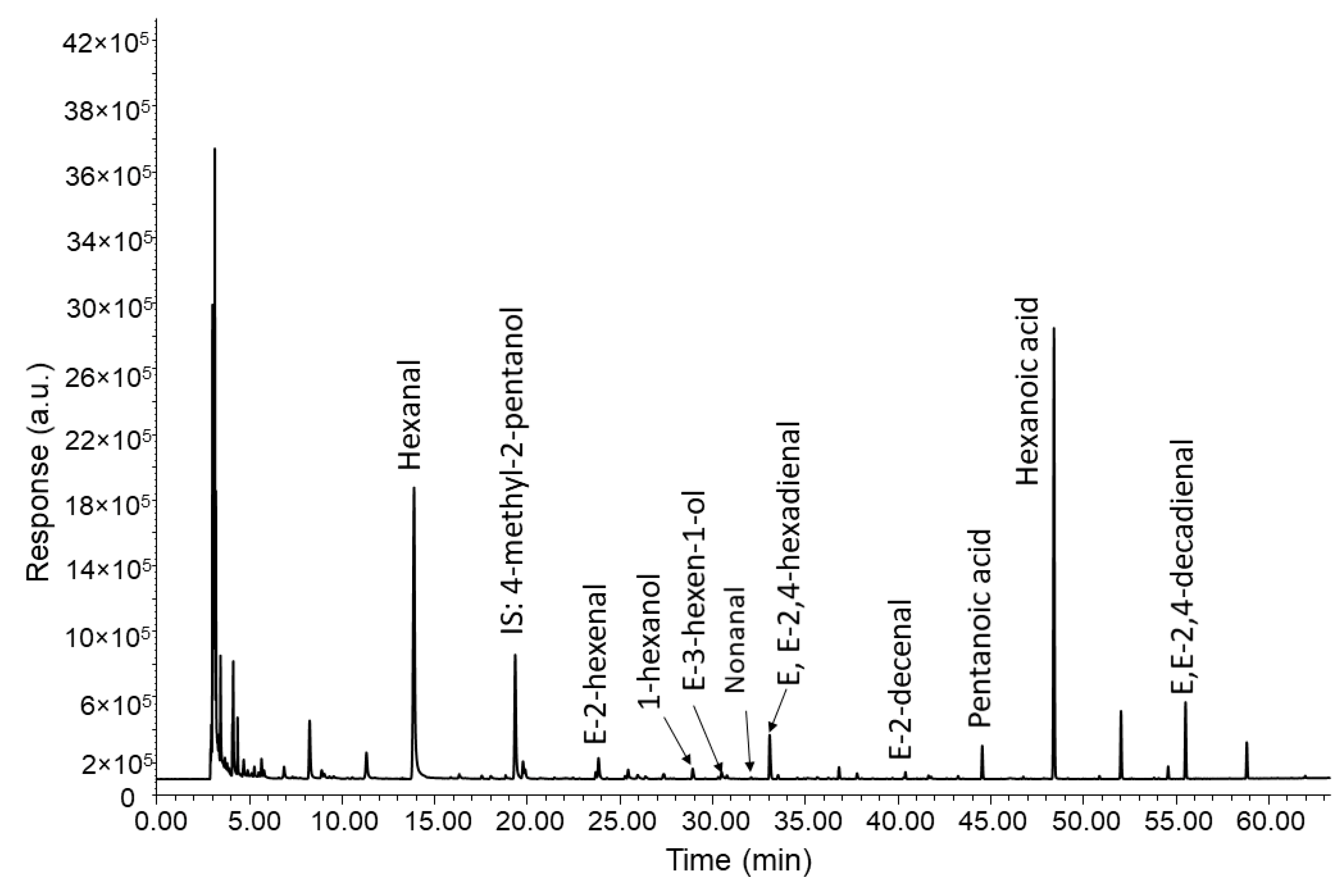

3.1. Planning and Selection of Volatile Markers Suitable for Formulations

3.2. Building a Formulation as RM for the Winey-Vinegary Defect

3.3. Building a Formulation as RM for the Rancid Defect

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Compañó Beltrán, R.; Ríos Castro, A. Referencias Analíticas. In Garantía de la Calidad en los Laboratorios Analíticos; Compañó Beltrán, R., Ríos Castro, A., Eds.; Editorial Síntesis: Madrid, Spain, 2002; pp. 153–174. ISBN 84-9756-024-8. [Google Scholar]

- Papadakis, I. (Certified) reference materials. In Quality Assurance in Analytical Chemistry: Training and Teaching, 2nd ed.; Wenclawiak, B.W., Koch, M., Hadjicostas, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- ISO. International Organization for Standardization (1992) ISO Guide 30—Terms and Definitions Used in Connection with Reference Materials, 2nd ed.; ISO: Geneva, Switzerland, 1992. [Google Scholar]

- ISO. International Organization for Standardization (2000) ISO Guide 34—General Requirements for the Competence of Reference Material Producers, 2nd ed.; ISO: Geneva, Switzerland, 2000. [Google Scholar]

- Emons, H.; Fajgelj, A.; van der Veen, A.M.H.; Watters, R. New definitions on reference materials. Accredit. Qual. Assur. 2006, 10, 576–578. [Google Scholar] [CrossRef]

- García-González, D.L.; Tena, N.; Romero, I.; Aparicio-Ruiz, R.; Morales, M.T.; Aparicio-Ruíz, R. A study of the differences between trade standards inside and outside Europe. Grasas Aceites 2017, 68, 210. [Google Scholar] [CrossRef]

- Angerosa, F.; Campestre, C. Sensory quality: Methodologies and applications. In Handbook of Olive Oil: Analysis and Properties, 2nd ed.; Aparicio, R., Harwood, J., Eds.; Springer: New York, NY, USA, 2013; pp. 523–560. ISBN 978-1-4614-7776-1. [Google Scholar] [CrossRef]

- European Union (EU). Commission Delegated Regulation (EU) 2016/2095 amending Regulation (EEC) No. 2568/91 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis. Off. J. Eur. Union 2016, L326, 1–6. [Google Scholar]

- International Olive Council (IOC). Trade Standard Applying to Olive Oils and Olive Pomace Oils; COI/T.15/NC No. 3/Rev.; International Olive Council: Madrid, Spain, 2018. [Google Scholar]

- Conte, L.; Bendini, A.; Valli, E.; Lucci, P.; Moret, S.; Maquet, A.; Lacoste, F.; Brereton, P.; García-González, D.L.; Moreda, W.; et al. Olive oil quality and authenticity: A review of current EU legislation, standards, relevant methods of analyses, their drawbacks and recommendations for the future. Trends Food Sci. Technol. 2020, 105, 483–493. [Google Scholar] [CrossRef]

- International Olive Council (IOC). Guidelines for the Accomplishment of Requirements of Standard ISO 17025 of Sensory Testing Laboratories with Particular Reference to Virgin Olive Oil; COI/T.28/Doc. No. 1/Rev. 3, 2018; International Olive Council: Madrid, Spain, 2018. [Google Scholar]

- International Olive Council (IOC). Sensory Analysis of Olive Oil. Method for the Organoleptic Assessment of Virgin Olive Oil; COI/T.20/Doc. No 15/Rev. 10, 2018; International Olive Council: Madrid, Spain, 2018. [Google Scholar]

- Langstaff, S. Sensory Quality Control. In Olive Oil Sensory Science; Monteleone, E., Langstaff, S., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2014; pp. 81–108. ISBN 978-1-118-33252-8. [Google Scholar] [CrossRef]

- European Union (EU). Regulation (EEC) No. 2568/91 of 11 July 1991 on the Characteristics of Olive Oil and Olive-Residue Oil and on the Relevant Methods of Analysis. Off. J. Eur. Communities 1991, L248, 1–83. [Google Scholar]

- Aparicio-Ruiz, R.; Morales, M.T.; Aparicio, R. Does authenticity of virgin olive oil sensory quality require input from Chemistry? Eur. J. Lipid Sci. Technol. 2019, 121, 1900202. [Google Scholar] [CrossRef]

- Barbieri, S.; Brkić Bubola, K.; Bendini, A.; Bučar-Miklavčič, M.; Lacoste, F.; Tibet, U.; Winkelmann, O.; García-González, D.L.; Gallina Toschi, T. Alignment and proficiency of virgin olive oil sensory panels: The OLEUM approach. Foods 2020, 9, 355. [Google Scholar] [CrossRef]

- Circi, S.; Capitani, D.; Randazzo, A.; Ingallina, C.; Mannina, L.; Sobolev, A.P. Panel Test and Chemical Analyses of Commercial Olive Oils: A Comparative Study. Chem. Biol. Technol. Agric. 2017, 4, 18. [Google Scholar] [CrossRef]

- Morales, M.T.; Aparicio-Ruiz, R.; Aparicio-Ruíz, R. Chromatographic methodologies: Compounds for olive oil odor Issues. In Handbook of Olive Oil: Analysis and Properties, 2nd ed.; Aparicio, R., Harwood, J., Eds.; Springer: New York, NY, USA, 2013; pp. 261–309. ISBN 978-1-4614-7776-1. [Google Scholar] [CrossRef]

- Lukić, I.; Horvat, I.; Godena, S.; Krapac, M.; Lukić, M.; Vrhovsek, U.; Brkić Bubola, K. Towards Understanding the Varietal Typicity of Virgin Olive Oil by Correlating Sensory and Compositional Analysis Data: A Case Study. Food Res. Int. 2018, 112, 78–89. [Google Scholar] [CrossRef]

- Campestre, C.; Angelini, G.; Gasbarri, C.; Angerosa, F. The Compounds Responsible for the Sensory Profile in Monovarietal Virgin Olive Oils. Molecules 2017, 22, 1833. [Google Scholar] [CrossRef] [PubMed]

- Angerosa, F.; Servili, M.; Selvaggini, R.; Taticchi, A.; Esposto, S.; Montedoro, G. Volatile compounds in virgin olive oil: Occurrence and their relationship with the quality. J. Chromatogr. A 2004, 1054, 17–31. [Google Scholar] [CrossRef]

- Morales, M.T.; Luna, G.; Aparicio, R. Comparative study of virgin olive oil sensory defects. Food Chem. 2005, 91, 293–301. [Google Scholar] [CrossRef]

- Langstaff, S. The Defects Wheel for Olive Oil. 2011. Available online: http://www.appliedsensory.com/olive-oil-sensory.html (accessed on 14 November 2020).

- Aparicio-Ruiz, R.; García-González, D.L.; Morales, M.T.; Lobo-Prieto, A.; Romero, I. Comparison of two analytical methods validated for the determination of volatile compounds in virgin olive oil: GC-FID vs GC-MS. Talanta 2018, 187, 133–141. [Google Scholar] [CrossRef] [PubMed]

- Valli, E.; Panni, F.; Casadei, E.; Barbieri, S.; Cevoli, C.; Bendini, A.; García-González, D.L.; Gallina Toschi, T. An HS-GC-IMS method for the quality classification of virgin olive oils as screening support for the panel test. Foods 2020, 9, 657. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Pozo, C.; Aparicio-Ruiz, R.; Romero, I.; García-González, D.L. Analysis of volatile markers for virgin olive oil aroma defects by SPME-GC/FID: Possible sources of incorrect data. J. Agric. Food Chem. 2015, 63, 10477–10483. [Google Scholar] [CrossRef]

- Oliver-Pozo, C.; Trypidis, D.; Aparicio, R.; García-González, D.L.; Aparicio-Ruiz, R. Implementing dynamic headspace With SPME sampling of virgin olive oil volatiles: Optimization, quality analytical study, and performance testing. J. Agric. Food Chem. 2019, 67, 2086–2097. [Google Scholar] [CrossRef]

- Tena, N.; Wang, S.C.; Aparicio-Ruiz, R.; García-González, D.L.; Aparicio, R. In-depth assessment of analytical methods for olive oil purity, safety, and quality characterization. J. Agric. Food Chem. 2015, 63, 4509–4526. [Google Scholar] [CrossRef]

- Ryan, P.B.; Barr, R.L.; Todd, H.D. Simplex techniques for nonlinear optimization. Anal. Chem. 1980, 52, 1460–1467. [Google Scholar] [CrossRef]

- García-González, D.L.; Vivancos, J.; Aparicio, R. Mapping brain activity induced by olfaction of virgin olive oil aroma. J. Agric. Food Chem. 2011, 59, 10200–10210. [Google Scholar] [CrossRef]

- Kalua, C.M.; Allen, M.S.; Bedgood, D.R.; Bishop, A.G.; Prenzler, P.D.; Robards, K. Olive Oil Volatile Compounds, Flavour Development and Quality: A Critical Review. Food Chem. 2007, 100, 273–286. [Google Scholar] [CrossRef]

- Romero, I.; García-González, D.L.; Aparicio-Ruiz, R.; Morales, M.T. Validation of SPME–GCMS method for the analysis of virgin olive oil volatiles responsible for sensory defects. Talanta 2015, 134, 394–401. [Google Scholar] [CrossRef] [PubMed]

- Romero, I.; García-González, D.L.; Aparicio-Ruiz, R.; Morales, M.T. Study of volatile compounds of virgin olive oils with ‘frostbitten olives’ sensory defect. J. Agric. Food Chem. 2017, 65, 4314–4320. [Google Scholar] [CrossRef] [PubMed]

- Nogueira, M.S.; Scolaro, B.; Milne, G.L.; Castro, I.A. Oxidation Products from Omega-3 and Omega-6 Fatty Acids during a Simulated Shelf Life of Edible Oils. LWT 2019, 101, 113–122. [Google Scholar] [CrossRef]

- Frankel, E.N. Foods. In Lipid Oxidation, 2nd ed.; Oily Press Lipid Library Series; Frankelm, E.N., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 299–354. ISBN 9780953194988. [Google Scholar] [CrossRef]

- Aparicio, R.; Morales, M.T.; Alonso, M.V. Relationship between volatile compounds and sensory attributes by statistical sensory wheel. J. Am. Oil Chem. Soc. 1996, 73, 1253–1264. [Google Scholar] [CrossRef]

- Morales, M.T.; Rios, J.J.; Aparicio, R. Changes in the volatile composition of virgin olive oil during oxidation: Flavors and off-flavors. J. Agric. Food Chem. 1997, 45, 2666–2673. [Google Scholar] [CrossRef]

- Taticchi, A.; Esposto, S.; Servili, M. The basis of the sensory properties of virgin olive oil. In Olive Oil Sensory Science; Monteleone, E., Langstaff, S., Eds.; John Wiley and Sons, Ltd.: Chichester, UK, 2014; pp. 33–54. ISBN 978-1-118-33252-8. [Google Scholar] [CrossRef]

- Morales, M.T.; Przybylski, R. Olive oil oxidation. In Handbook of Olive Oil: Analysis and Properties, 2nd ed.; Aparicio, R., Harwood, J., Eds.; Springer: New York, NY, USA, 2013; pp. 479–522. ISBN 978-1-4614-7776-1. [Google Scholar] [CrossRef]

- Morales, M.T.; Luna, G.; Aparicio, R. Sensory and chemical evaluation of winey-vinegary defect in virgin olive oils. Eur. Food Res. Technol. 2000, 211, 222–228. [Google Scholar] [CrossRef]

- Morales, M.T.; Aparicio, R. Optimization by mathematical procedures of two dynamic headspace techniques for quantifying virgin olive oil volatiles. Anal. Chim. Acta 1993, 282, 423–431. [Google Scholar] [CrossRef]

| Sensory Defect | Volatile Marker | Sensory Characteristics | Odor Threshold (mg/kg) |

|---|---|---|---|

| Winey-vinegary | Acetic acid | Vinegary, sour | 0.50 |

| Ethyl acetate | Sticky | 0.94 | |

| Ethanol | Alcohol | 30.00 | |

| 3-Methyl-1-butanol | Whiskey | 0.10 | |

| Rancid | Pentanal | Oily | 0.24 |

| Hexanal | Oily, fatty | 0.08 | |

| Heptanal | Oily, fatty | 0.50 | |

| E-2-Heptenal | Tallowy, oxidized | 0.04 | |

| Octanal | Fatty | 0.32 | |

| Nonanal | Waxy, fatty | 0.15 | |

| E-2-Decenal | Fishy, fatty | 0.01 | |

| Hexanoic acid | Rancid | 0.70 |

| Volatile Compound | Category | N | Mean (Min–Max) | RM IOC |

|---|---|---|---|---|

| Acetic acid | EV | 12 | 0.212 (0.037–1.115) | 8.688 |

| V-L (excluding those with winey-vinegary defect) | 44 | 0.678 (0.045–8.485) | ||

| V-L (winey-vinegary as main defect) | 7 | 1.506 (0.436–2.389) | ||

| Ethanol | EV | 12 | 0.423 (0.111–1.030) | 0.581 |

| V-L (excluding those with winey-vinegary defect) | 44 | 2.770 (0.083–53.688) a | ||

| V-L (winey-vinegary as main defect) | 7 | 4.381 (0.033–19.039) | ||

| Ethyl acetate | EV | 12 | 0.150 (0.021–0.530) | 19.620 |

| V-L (excluding those with winey-vinegary defect) | 44 | 0.345 (0.013–1.519) | ||

| V-L (winey-vinegary as main defect) | 7 | 0.874 (0.236–3.149) | ||

| Hexanal | EV | 12 | 0.731 (0.116–1.497) | 8.396 |

| V-L (excluding those with rancid defect) | 31 | 0.680 (0.069–6.533) | ||

| V-L (rancid as main defect) | 20 | 1.013 (0.065–3.064) b | ||

| Nonanal | EV | 12 | 0.002 (tr–0.004) c | 0.074 |

| V-L (excluding those with rancid defect) | 31 | 0.003 (0.001–0.009) | ||

| V-L (rancid as main defect) | 20 | 0.009 (0.001–0.050) |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | Sensory Descriptors | Code |

|---|---|---|---|---|---|---|---|---|

| 80 | 600 | 40 | - | 20 | - | 40 | Slightly vinegary, sweet, slightly rancid | AV1 |

| 200 | 600 | 600 | 50 | 50 | 50 | 50 | Vinegary, glue, chemicals, wood | AV2 |

| 400 | 1200 | 1200 | 100 | 100 | 100 | 100 | Vinegary, chemicals, glue, rancid, mushrooms | AV3 |

| 200 | 600 | 600 | 10 | 10 | 10 | 10 | Vinegary, glue, no natural, slightly vinegary | AV4 |

| 40 | 5000 | 600 | 10 | 10 | 10 | 10 | Slightly vinegary, vinegary | AV5 |

| - | 5000 | 600 | 1.5 | 1.5 | 1.5 | 1.5 | Less intense to vinegary | AV6 |

| - | 10,000 | 1200 | 3 | 3 | 3 | 3 | Vinegary at high and medium-high intensities | AV7 |

| - | 20,000 | 2000 | 5 | 5 | 5 | 5 | Vinegary, alcohol, artificial vinegary | AV8 |

| - | 32,000 | 4800 | 7.5 | 7.5 | 7.5 | 7.5 | Vinegary, high intensity of acetic acid and alcohol | AV9 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Sensory Descriptors | Code |

|---|---|---|---|---|---|---|---|---|---|

| 600 | 80 | 20 | 40 | - | - | - | - | Green aroma ending with slight rancid sensory notes | R1 |

| 100 | - | 100 | 100 | 100 | 600 | 600 | 600 | Rancid but slightly green as well, a little sweet, undesirable | R2 |

| 50 | - | 50 | 50 | 50 | 600 | 600 | 600 | Rancid but slightly green, rancid but a little sweet | R3 |

| 35 | - | 35 | 35 | 35 | 600 | 600 | 600 | Slight green, slightly rancid, sweet, ripe fruity, rancid nuts, rancid aftertaste | R4 |

| 600 | - | 1.5 | 1.5 | 1.5 | 600 | 600 | 600 | Intensely rancid, nuts | R5 * |

| 600 | - | 1.5 | 1.5 | 1.5 | - | 363 | 420 | Intensely rancid, nuts, seeds | R6 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aparicio-Ruiz, R.; Barbieri, S.; Gallina Toschi, T.; García-González, D.L. Formulations of Rancid and Winey-Vinegary Artificial Olfactory Reference Materials (AORMs) for Virgin Olive Oil Sensory Evaluation. Foods 2020, 9, 1870. https://doi.org/10.3390/foods9121870

Aparicio-Ruiz R, Barbieri S, Gallina Toschi T, García-González DL. Formulations of Rancid and Winey-Vinegary Artificial Olfactory Reference Materials (AORMs) for Virgin Olive Oil Sensory Evaluation. Foods. 2020; 9(12):1870. https://doi.org/10.3390/foods9121870

Chicago/Turabian StyleAparicio-Ruiz, Ramón, Sara Barbieri, Tullia Gallina Toschi, and Diego L. García-González. 2020. "Formulations of Rancid and Winey-Vinegary Artificial Olfactory Reference Materials (AORMs) for Virgin Olive Oil Sensory Evaluation" Foods 9, no. 12: 1870. https://doi.org/10.3390/foods9121870

APA StyleAparicio-Ruiz, R., Barbieri, S., Gallina Toschi, T., & García-González, D. L. (2020). Formulations of Rancid and Winey-Vinegary Artificial Olfactory Reference Materials (AORMs) for Virgin Olive Oil Sensory Evaluation. Foods, 9(12), 1870. https://doi.org/10.3390/foods9121870