What Is the Color of Milk and Dairy Products and How Is It Measured?

Abstract

1. Introduction

2. Materials and Methods

2.1. Inclusion Criteria

2.2. Information Source

2.3. Search Strategy

- Milk color evaluation

- Hunter Lab milk color values

- CIE L*a*b* dairy color values

- Instrumental milk color measurement

- Instrumental dairy products/cheese color assessment

- Physicochemical characteristics of milk and milk products

2.4. Data Extraction and Analysis

- Cheese and analogs;

- Dairy-based desserts (e.g., ice cream, dulce de leche, peda, etc.);

- Fats and oils (including butter, butter oil, anhydrous milkfat, ghee);

- Fermented milk products (including flavored yoghurt);

- Fluid milk and milk products (include all plain and flavored fluid milks based on skim, part-skim, low-fat, and whole milk);

- Milk and cream powder and powder analogs;

- Other products (colostrum, infant formula, cream, milk gel);

- Whey and whey products.

3. Results and Discussion

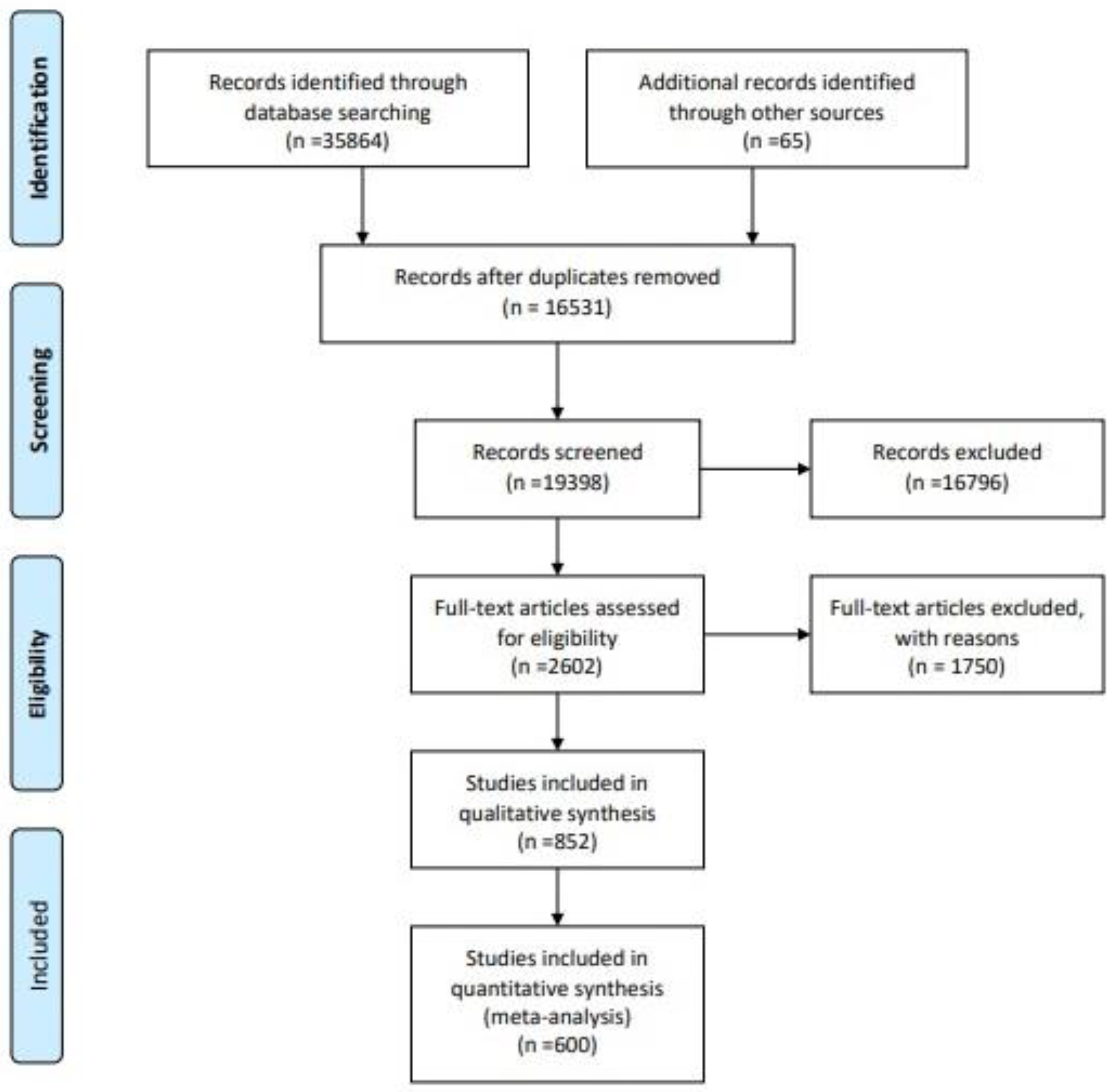

3.1. Search Strategy

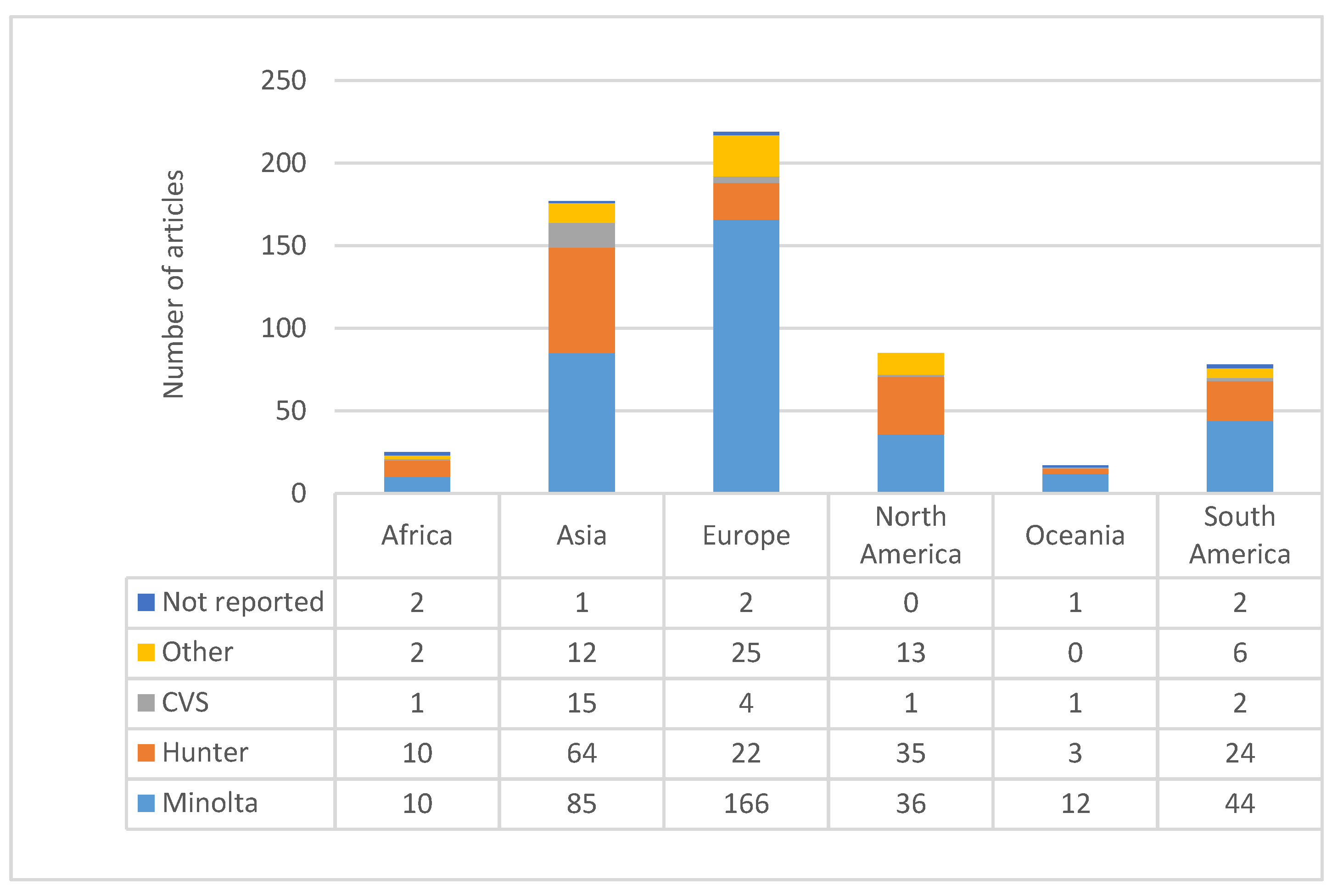

3.2. Type of Products Studied and Origin of Publication

3.3. Instrument Type Used for Color Determination of Milk and Milk Products

3.4. Calibration Procedure

3.5. Light Source (Illuminant) Used for Instrumental Color Determination of Milk Products

3.6. Aperture Size of the Instrumental Device for Color Determination

3.7. Observation Angle

3.8. Technical Replicates (Number of Readings)

3.9. Data for Color Coordinates Tristimulus Methods

3.10. Milk Color Data

3.11. Interaction between Country and Instrument

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Conti-Silva, A.C.; Souza-Borges, P.K. Sensory characteristics, brand and probiotic claim on the overall liking of commercial probiotic fermented milks: Which one is more relevant? Food Res. Int. 2019, 116, 184–189. [Google Scholar] [CrossRef] [PubMed]

- Spence, C.; Velasco, C. On the multiple effects of packaging color on consumer behaviour and product experience in the ‘food and beverage’ and ‘home and personal care’ categories. Food Qual. Prefer. 2018, 68, 226–237. [Google Scholar] [CrossRef]

- Jo, Y.; Benoist, D.M.; Ameerally, A.; Drake, M.A. Sensory and chemical properties of Gouda cheese. J. Dairy Sci. 2018, 101, 1967–1989. [Google Scholar] [CrossRef] [PubMed]

- Ritvanen, T.; Lampolahti, S.; Lilleberg, L.; Tupasela, T.; Isoniemi, M.; Appelbye, U.; Lyytikäinen, T.; Eerola, S.; Uusi-Rauva, E. Sensory evaluation, chemical composition and consumer acceptance of full fat and reduced fat cheeses in the Finnish market. Food Qual. Prefer. 2005, 16, 479–492. [Google Scholar] [CrossRef]

- Costa, M.P.; Monteiro, M.L.G.; Frasao, B.S.; Silva, V.L.M.; Rodrigues, B.L.; Chiappini, C.C.J.; Conte-Junior, C.A. Consumer perception, health information, and instrumental parameters of cupuassu (Theobroma grandiflorum) goat milk yogurts. J. Dairy Sci. 2017, 100, 157–168. [Google Scholar] [CrossRef]

- Krause, A.J.; Lopetcharat, K.; Drake, M.A. Identification of the characteristics that drive consumer liking of butter. J. Dairy Sci. 2007, 90, 2091–2102. [Google Scholar] [CrossRef]

- Cadena, R.S.; Cruz, A.G.; Faria, J.A.F.; Bolini, H.M.A. Reduced fat and sugar vanilla ice creams: Sensory profiling and external preference mapping. J. Dairy Sci. 2012, 95, 4842–4850. [Google Scholar] [CrossRef] [PubMed]

- Shepard, L.; Miracle, R.E.; Leksrisompong, P.; Drake, M.A. Relating sensory and chemical properties of sour cream to consumer acceptance. J. Dairy Sci. 2013, 96, 5435–5454. [Google Scholar] [CrossRef]

- Fernández-Vázquez, R.; Stinco, C.M.; Hernanz Vila, D.; Heredia, F.J.; Chaya, C.; Vicario, I.M. Internal preference mapping of milk–fruit beverages: Influence of color and appearance on its acceptability. Food Sci. Nutr. 2017, 6, 27–35. [Google Scholar] [CrossRef]

- Ryan, J.; Hutchings, S.C.; Fang, Z.; Bandara, N.; Gamlath, S.; Ajlouni, S.; Ranadheera, C.S. Microbial, physico-chemical and sensory characteristics of mango juice-enriched probiotic dairy drinks. Int. J. Dairy Technol. 2020, 73, 182–190. [Google Scholar] [CrossRef]

- Leon, K.; Mery, D.; Pedreschi, F.; Leon, J. Color measurement in L*a*b* units from RGB digital images. Food Res. Int. 2006, 39, 1084–1091. [Google Scholar] [CrossRef]

- Rossel, R.A.V.; Minasny, B.; Roudier, P.; Mcbratney, A.B. Color space models for soil science. Geoderma 2006, 133, 320–337. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Color measurement and analysis in fresh and processed foods: A review. Food Bioproc. Technol. 2012, 6, 36–60. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Codex Alimentarius. General Standard for Food Additives. Available online: http://www.fao.org/gsfaonline/docs/CXS_192e.pdf (accessed on 21 January 2020).

- Cheng, N.; Barbano, D.M.; Drake, M.A. Hunter versus CIE color measurement systems for analysis of milk-based beverages. J. Dairy Sci. 2018, 101, 4891–4905. [Google Scholar] [CrossRef]

- Whetzel, N. Measuring Color Using Hunter L, a, b versus CIE 1976 L* a* b*. Available online: https://support.hunterlab.com/hc/enus/articles/204137825-Measuring-Color-using-Hunter-Lab-versus-CIE-1976-Lab-AN-1005b (accessed on 28 January 2015).

- Phillips, S.D.; Estler, W.T.; Doiron, T.; Eberhardt, K.R.; Levenson, M.S. A careful consideration of the calibration concept. J. Res. Natl. Inst. Stand. Technol. 2001, 106, 371–379. [Google Scholar] [CrossRef]

- Kortei, N.; Akonor, P. Correlation between hue-angle and color lightness of gamma irradiated mushrooms. Ann. Food Sci. Technol. 2015, 16, 98–103. [Google Scholar]

- MacDougall, D.B. Colour measurement of food: Principles and practice. In Colour Measurement Principles, Advances and Industrial Applications; Gulrajani, M.L., Ed.; Woodhead Publishing Limited in association with The Textile Institute Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 312–342. [Google Scholar]

- Tapp, W.; Yancey, J.; Apple, J. How is the instrumental color of meat measured? Meat Sci. 2011, 89, 1–5. [Google Scholar] [CrossRef] [PubMed]

- MacDougall, D.B. Color of meat. In Quality Attributes and Their Measurement in Meat, Poultry and Fish Products; Pearson, A.M., Dutson, T.R., Eds.; Springer: Boston, MA, USA, 1994; Volume 9, pp. 79–93. [Google Scholar]

- AMSA Meat Color Measurement Guidelines. Available online: https://meatscience.org/publications-resources/printed-publications/amsa-meat-color-measurement-guidelines (accessed on 21 December 2012).

- Yancey, J.W.S.; Kropf, D.H. Instrumental reflectance values of fresh pork are dependent on aperture size. Meat Sci. 2008, 79, 734–739. [Google Scholar] [CrossRef]

- Mason, R.L.; Gunst, R.F.; Hess, J.L. Statistical Principles in Experiment Design Statistical Design and Analysis of Experiments; with Application to Engineering and Science, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2003; pp. 107–139. [Google Scholar]

- Honikel, K.O. Reference methods for the assessment of physical characteristics of meat. Meat Sci. 1998, 49, 4. [Google Scholar] [CrossRef]

- Anonymous. Measuring Meat Steaks, Fillets and Patties Using the MiniScan EZ 45/0 LAV. 2012. Available online: www.hunterlab.com (accessed on 30 October 2020).

- Holman, B.; Collins, D.; Kilgannon, A.; Hopkins, D. The effect of technical replicate (repeats) on Nix Pro Color Sensor™ measurement precision for meat: A case-study on aged beef colour stability. Meat Sci. 2017, 135, 42–45. [Google Scholar] [CrossRef]

- Bermúdez-Aguirre, D.; Mawson, R.; Versteeg, K.; Barbosa-Cánovas, G.V. Composition properties, physicochemical characteristics and shelf life of whole milk after thermal and thermo-sonication treatments. J. Food Qual. 2009, 32, 283–302. [Google Scholar] [CrossRef]

- Vargas, M.; Chafer, M.; Albors, A.; Chiralt, A.; Gonzalez-Martinez, M. Physicochemical and sensory characteristics of yoghurt produced from mixtures of cows’ and goats’ milk. Int. J. Dairy Technol. 2008, 18, 1146–1152. [Google Scholar] [CrossRef]

- Solah, V.A.; Staines, V.; Honda, S.; Limley, H.A. Measurement of milk color and composition: Effect of dietary intervention on Western Australian Holstein-Friesian cow’s milk quality. J. Food Sci. 2007, 72, S560–S566. [Google Scholar] [CrossRef]

- Buera, M.; Lozano, R.; Petriella, C. Definition of color in the non-enzymatic browning process. Die Farbe 1986, 32, 318–322. [Google Scholar]

- Erbay, Z.; Koca, N. Effects of whey or maltodextrin addition during production on physical quality of white cheese powder during storage. J. Dairy Sci. 2015, 98, 8391–8404. [Google Scholar] [CrossRef]

- Fernandez-Avila, C.; Gutierrez-Merida, C.; Trujillo, A.J. Physicochemical and sensory characteristics of a UHT milk-based product enriched with conjugated linoleic acid emulsified by Ultra-High-Pressure Homogenization. Innov. Food Sci. Emerg. Technol. 2017, 39, 275–283. [Google Scholar] [CrossRef]

- Quintanilla, P.; Beltran, M.C.; Molina, A.; Escriche, I.; Molina, M.P. Characteristics of ripened Tronchon cheese from raw goat milk containing legally admissible amounts of antibiotics. J. Dairy Sci. 2019, 4, 2941–2953. [Google Scholar] [CrossRef] [PubMed]

- Lucas, A.; Rock, E.; Agabriel, C.; Chilliard, Y.; Coulon, J.B. Relationships between animal species (cow versus goat) and some nutritional constituents in raw milk farmhouse cheeses. Small Rumin. Res. 2008, 74, 243–248. [Google Scholar] [CrossRef]

- Prache, S.; Cornu, A.; Berdagué, J.L.; Priolo, A. Traceability of animal feeding diet in the meat and milk of small ruminants. Small Rumin. Res. 2005, 59, 157–168. [Google Scholar] [CrossRef]

- Nozière, P.; Graulet, B.; Lucas, A.; Martin, B.; Grolier, P.; Doreau, M. Carotenoids for ruminants: From forages to dairy products. Anim. Feed Sci. Technol. 2006, 131. [Google Scholar] [CrossRef]

- Langman, L. Calidad Organolética en Leche Expresada en Su Color y Perfil de Olor. Relación de Estos Parámetros con la Incorporación de Antioxidantes Naturales en la Dieta Implementada en las Vacas. Ph.D. Thesis, La Plata National University, La Plata, Argentina, 2009. [Google Scholar]

- Berry, S.D.; Davis, S.R.; Beattie, E.M.; Thomas, N.L.; Burrett, A.K.; Ward, H.E.; Stanfield, A.M.; Biswas, M.; Ankersmit-Udy, A.E.; Oxley, P.E.; et al. Mutation in bovine β-carotene oxygenase 2 affects milk color. Genetics 2009, 182, 923–926. [Google Scholar] [CrossRef] [PubMed]

- Scarso, S.; McParland, S.; Visentin, G.; Berry, D.P.; McDermott, A.; De Marchi, M. Genetic and nongenetic factors associated with milk color in dairy cows. J. Dairy Sci. 2017, 100, 7345–7361. [Google Scholar] [CrossRef]

- Walker, G.P.; Wijesundera, C.; Dunshea, F.R.; Doyle, P.T. Seasonal and stage of lactation effects on milk fat composition in northern Victoria. Anim. Prod. Sci. 2013, 53, 560–572. [Google Scholar] [CrossRef]

- Viguier, C.; Arora, S.; Gilmartin, N.; Welbeck, K.; O’Kennedy, R. Mastitis detection: Current trends and future perspectives. Trends Biotechnol. 2009, 27, 486–493. [Google Scholar] [CrossRef]

- Popov-Raljić, J.V.; Lakić, N.S.; Laličić-Petronijević, J.G.; Barać, M.B.; Sikimić, V.M. Color changes of UHT milk during storage. Sensors 2008, 8, 5961–5974. [Google Scholar] [CrossRef]

- Hassan, A.; Amjad, I.; Mahmood, S. Microbiological and physicochemical analysis of different UHT milks available in market. Afr. J. Food Sci. 2009, 3, 100–106. [Google Scholar] [CrossRef]

- Grigioni, G.; Biolatto, A.; Langman, L.; Descalzo, A.; Irurueta, M.; Paez, R.; Taverna, M. Color and pigments in milk and dairy. In Practical Food Research, 1st ed.; Rui, M.S., Ed.; Nova Science Publisher: New York, NY, USA, 2010; pp. 283–297. [Google Scholar]

- Park, Y.W. Goat milk-chemistry and nutrition. In Handbook of Milk of Non-Bovine Mammals; Park, Y.W., Haenlein, G.F.W., Eds.; Blackwell Publishers: Ames, IA, USA; Oxford, UK, 2006; pp. 34–58. [Google Scholar]

- Abd El-Salam, M.H.; El-Shibiny, S. A comprehensive review on the composition and properties of buffalo milk. Dairy Sci. Technol. 2011, 91, 663. [Google Scholar] [CrossRef]

- Raynal-Ljutovac, K.; Lagriffoul, G.; Paccard, P.; Guillet, I.; Chilliard, Y. Composition of goat and sheep milk products: An update. Small Rumin. Res. 2008, 79, 57–72. [Google Scholar] [CrossRef]

- Martínez-Rodríguez, Y.; Acosta-Muñiz, C.; Olivas, G.I.; Guerrero-Beltrán, J.; Rodrigo-Aliaga, D.; Sepúlveda, D.R. High hydrostatic pressure processing of cheese. Compr. Rev. Food Sci. Food Saf. 2012, 11, 399–416. [Google Scholar] [CrossRef]

- Koca, N.; Balasubramaniam, V.M.; Harper, W. High-Pressure Effects on the Microstructure, Texture, and Color of White-Brined Cheese. J. Food Sci. 2011, 76, 399–404. [Google Scholar] [CrossRef]

- Chudy, S.; Bilska, A.; Kowalski, R.; Teichert, J. Color of milk and milk products in CIE L*a*b* space. Medycyna Weterynaryjna 2020, 76, 77–81. [Google Scholar] [CrossRef]

- Bermúdez-Aguirre, D.; Barbosa-Cánovas, G.V. Study of butter fat content in milk on the inactivation of Listeria innocua ATCC 51742 by thermo-sonication. Innov. Food Sci. Emerg. Technol. 2008, 9, 176–185. [Google Scholar] [CrossRef]

- Bermúdez-Aguirre, D.; Corradini, M.G.; Mawson, R.; Barbosa-Cánovas, G.V. Modeling the inactivation of Listeria innocua in raw whole milk treated under thermo-sonication. Innov. Food Sci. Emerg. Technol 2009, 10, 172–178. [Google Scholar] [CrossRef]

- Ávila, M.; Garde, S.; Nuñez, M. The influence of some manufacturing and ripening parameters on the color of ewes’ milk cheese. Milchwissenschaft 2008, 63, 160–164. [Google Scholar]

- Diezhandino, I.; Fernández, D.; Sacristán, N.; Combarros-Fuertes, P.; Prieto, B.; Fresno, J.M. Rheological, textural, color and sensory characteristics of a Spanish blue cheese (Valdeón cheese). LWT 2016, 65, 1118–1125. [Google Scholar] [CrossRef]

- Queirós, M.S.; Grimaldi, R.; Gigante, M.L. Addition of olein from milk fat positively affects the firmness of butter. Food Res. Int. 2016, 84, 69–75. [Google Scholar] [CrossRef]

- Kaya, A. Properties and stability of butter oil obtained from milk and yoghurt. Food Nahrung 2000, 44, 126–129. [Google Scholar] [CrossRef]

- Kristensen, D.; Boesen, M.; Jakobsen, U.L.; Månsson, L.; Erichsen, L.; Skibsted, L.H. Oxidative and color stability of salted sour cream dairy spread compared to salted sweet cream dairy spread. Milchwissenschaft 2000, 55, 504–507. [Google Scholar]

- Hettinga, D. Bailey’s Industrial Oil and Fat Products, 6th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Erkaya, T.; Şengül, M.A. Comparative Study on Some Quality Properties and Mineral Contents of Yoghurts Produced from Different Type of Milks. Kafkas Universitesi Veteriner Fakultesi Dergisi 2012, 18, 323–329. [Google Scholar] [CrossRef]

- Mazloomi, S.M.; Shekarforoush, S.S.; Ebrahimnejad, H.; Sajedianfard, J. Effect of adding inulin on microbial and physic-chemical properties of low fat probiotic yogurt. Iran. J. Vet. Res. 2011, 12, 93–98. [Google Scholar] [CrossRef]

- Mani-López, E.; Palou, A.; López-Malo. Probiotic viability and storage stability of yogurts and fermented milks prepared with several mixtures of lactic acid bacteria. J. Dairy Sci. 2014, 97, 2578–2590. [Google Scholar] [CrossRef] [PubMed]

- Hilali, M.; Iñiguez, L.; Knaus, W.; Schreiner, M.; Wurzinger, M.; Mayer, H.K. Dietary supplementation with nonconventional feeds from the Middle East: Assessing the effects on physicochemical and organoleptic properties of Awassi sheep milk and yogurt. J. Dairy Sci. 2011, 94, 5737–5749. [Google Scholar] [CrossRef]

- Meena, G.S.; Singh, A.K.; Arora, S.; Borad, S.; Sharma, R.; Gupta, V.K. Physico-chemical, functional and rheological properties of milk protein concentrate 60 as affected by disodium phosphate addition, diafiltration and homogenization. J. Food Sci. Technol. 2017, 54, 1678–1688. [Google Scholar] [CrossRef]

- Morales, F.J.; van Boekel, M.A. A study on advanced maillard reaction in heated casein/sugar solutions: Color formation. Int. Dairy J. 1998, 8, 907–915. [Google Scholar] [CrossRef]

- Le, T.T.; Holland, J.W.; Bhandari, B.; Alewood, P.F.; Deeth, H.C. Direct evidence for the role of Maillard reaction products in protein cross-linking in milk powder during storage. Int. Dairy J. 2013, 31, 83–91. [Google Scholar] [CrossRef]

- González-Martınez, C.; Becerra, M.; Cháfer, M.; Albors, A.; Carot, J.M.; Chiralt, A. Influence of substituting milk powder for whey powder on yoghurt quality. Trends Food Sci. Technol. 2002, 13, 334–340. [Google Scholar] [CrossRef]

- Carvalho, F.; Prazeres, A.R.; Rivas, J. Cheese whey wastewater: Characterization and treatment. Sci. Total Environ. 2013, 445, 385–396. [Google Scholar] [CrossRef]

- De Castro-Cislaghi, F.P.; Carina Dos Reis, E.S.; Fritzen-Freire, C.B.; Lorenz, J.G.; Sant’Anna, E.S. Bifidobacterium Bb-12 microencapsulated by spray drying with whey: Survival under simulated gastrointestinal conditions, tolerance to NaCl, and viability during storage. J. Food Eng. 2012, 113, 186–193. [Google Scholar] [CrossRef]

- Mohajan, H. Two Criteria for Good Measurements in Research: Validity and Reliability. Ann. Spiru Haret Univ. Econ. Ser. 2017, 17, 59–82. [Google Scholar] [CrossRef]

| Journals | Number of Articles (%) |

|---|---|

| Other 1 | 203 (33.8%) |

| Journal of Dairy Science | 88 (14.7%) |

| International Journal of Dairy Technology | 84 (14.0%) |

| International Dairy Journal | 64 (10.7%) |

| LWT-Food Science and Technology | 59 (9.8%) |

| Food Research International | 22 (3.7%) |

| Food Chemistry | 21 (3.5%) |

| Innovative Food Science and Emerging | 20 (3.3%) |

| Food Hydrocolloids | 14 (2.3%) |

| Dairy Science and Technology | 13 (2.2%) |

| Journal of Food Engineering | 12 (2.0%) |

| Country of research | |

| Europe | 218 (36.3%) |

| Asia | 177 (29.5%) |

| North America | 84 (14.0%) |

| South America | 79 (13.2%) |

| Africa | 25 (4.2%) |

| Oceania | 17 (2.8%) |

| Milk and Milk Products | Number of Articles (%) |

|---|---|

| Cheese | 186 (31.0%) |

| Fermented products | 127 (21.2%) |

| Fluid milk and milk products | 102 (17.0%) |

| Milk and cream powder | 49 (8.2%) |

| Dairy-based desserts | 48 (8.0%) |

| Whey and whey powder | 47 (7.8%) |

| Other 1 | 32 (5.3%) |

| Fats and oils (e.g., butter) | 16 (2.7%) |

| System Used for Color Determination | Number of Articles (%) |

|---|---|

| Minolta | 353 (58.8%) |

| Hunter | 158 (26.3%) |

| Other 1 | 56 (9.0%) |

| CVS (Computer vision system) | 25 (4.8%) |

| Not reported | 8 (1.3%) |

| Illuminant | Number of Articles (%) |

|---|---|

| Not reported | 366 (61.0%) |

| D65 | 177 (29.5%) |

| Other 1 | 32 (5.3%) |

| C | 14 (2.3%) |

| A | 12 (2.0%) |

| Aperture Size | Number of Articles (%) |

|---|---|

| Not reported | 563 (93.8%) |

| 8 mm | 18 (3.0%) |

| 45 mm | 5 (0.8%) |

| More than 50 mm | 5 (0.8%) |

| 10–25 mm | 4 (0.7%) |

| 30–35 mm | 2 (0.3%) |

| 50 mm | 2 (0.3%) |

| 4 mm or less | 1 (0.2%) |

| Observer | Number of Articles (%) |

|---|---|

| Not reported | 440 (73.3%) |

| 10 | 123 (20.5%) |

| 2 | 24 (4.0%) |

| 0 | 6 (1.0%) |

| More than 45 | 4 (0.7%) |

| 3–8 | 2 (0.3%) |

| 45 | 1 (0.2%) |

| Number of Readings | Number of Articles (%) |

|---|---|

| Not reported | 435 (72.5%) |

| 4–6 | 80 (13.3%) |

| 3 | 44 (7.3%) |

| 10–12 | 23 (3.8%) |

| 2 | 8 (1.3%) |

| 7–8 | 7 (1.2%) |

| 15–20 | 2 (0.3%) |

| More than 20 | 1 (0.2%) |

| Source of Milk | Cow’s (n = 41) | Goat’s (n = 1) | Sheep’s (n = 3) | Camel’s (n = 1) | Deer’s (n = 1) | Mare’s (n = 2) | Mixture (n = 23) | |

|---|---|---|---|---|---|---|---|---|

| Milks (n = 72) | L* | 81.0 ± 8.1 | 86.0 ± 0.0 | 79.9 ± 8.9 | 67.8 ± 0.0 | 89.2 ± 0.0 | 73.5 ± 14.3 | 64.8 ± 22.3 |

| a* | −1.5 ± 3.0 | −2.1 ± 0.0 | −2.4 ± 1.3 | −2.0 ± 0.0 | −3.0 ± 0.0 | −2.2 ± 0.2 | 3.1 ± 8.7 | |

| b* | 7.5 ± 4.4 | 5.5 ± 0.0 | 7.5 ± 1.3 | −0.2 ± 0.0 | 8.4 ± 0.0 | −2.3 ± 2.4 | 11.3 ± 9.1 | |

| Source of Milk | Cow’s (n = 93) | Goat’s (n = 20) | Sheep’s (n = 19) | Buffalo’s (n = 5) | Mixture (n = 4) | |

|---|---|---|---|---|---|---|

| Cheeses (n = 141) | L* | 82.6 ± 9.2 | 87.1 ± 14.8 | 83.3 ± 6.4 | 85.2 ± 11.5 | 85.9 ± 5.5 |

| a* | 0.3 ± 9.1 | 0.0 ± 2.8 | −0.7 ± 2.8 | −3.0 ± 3.2 | −4.3 ± 3.6 | |

| b* | 17.4 ± 10.0 | 8.2 ± 4.4 | 15.4 ± 3.8 | 12.3 ± 7.3 | 14.5 ± 4.4 | |

| (n = 6) | (n = 1) | (n = 5) | ||||

| Butter (n = 12) | L* | 84.9 ± 9.9 | 95.0 ± 0.0 | - | - | 40.3 ± 39.2 |

| a* | −1.4 ± 3.1 | −1.4 ± 0.0 | - | - | −1.5 ± 2.2 | |

| b* | 24.3 ± 7.5 | 4.9 ± 0.0 | - | - | 9.7 ± 9.0 | |

| (n = 34) | (n = 8) | (n = 4) | (n = 1) | (n = 15) | ||

| Yoghurt (n = 62) | L* | 86.2 ± 11.0 | 86.6 ± 6.0 | 84.0 ± 17.7 | 84.8 ± 0.0 | 64.6 ± 27.9 |

| a* | −1.1 ± 4.9 | −0.8 ± 2.2 | −18.8 ± 28.3 | −1.1 ± 0.0 | −0.0 ± 6.6 | |

| b* | 9.0 ± 5.3 | 12.1 ± 7.0 | 11.8 ± 7.9 | 8.1 ± 0.0 | 9.7 ± 8.5 | |

| (n = 9) | (n = 4) | |||||

| Fermented milks (n = 13) | L* | 70.5 ± 18.0 | - | - | - | 76.7 ± 28.2 |

| a* | −3.8 ± 1.7 | - | - | - | 2.8 ± 3.0 | |

| b* | 8.9 ± 5.0 | - | - | - | 9.3 ± 10.4 | |

| (n = 8) | ||||||

| Set-type yoghurt (n = 8) | L* | 86.6 ± 8.5 | - | - | - | - |

| a* | −1.8 ± 4.4 | - | - | - | - | |

| b* | 11.2 ± 7.5 | - | - | - | - | |

| (n = 1) | (n = 2) | (n = 1) | ||||

| Kefir (n = 4) | L* | 91.6 ± 0.0 | 66.9 ± 2.2 | - | 93.0 ± 0.0 | - |

| a* | −2.2 ± 0.0 | −1.7 ± 0.1 | - | −1.7 ± 0.0 | - | |

| b* | 6.2 ± 0.0 | 5.1 ± 0.2 | - | 6.5 ± 0.0 | - | |

| (n = 4) | ||||||

| Fruit yoghurt (n = 4) | L* | 69.8 ± 13.7 | - | - | - | - |

| a* | 6.0 ± 6.6 | - | - | - | - | |

| b* | 0.3 ± 7.2 | - | - | - | - | |

| (n = 17) | (n = 3) | (n = 2) | (n = 13) | |||

| Milk powder products (n = 35) | L* | 88.6 ± 10.1 | 89.2 ± 6.0 | - | 87.9 ± 3.6 | 78.7 ± 21.3 |

| a* | 0.2 ± 6.8 | −1.62 ± 0.7 | - | −3.56 ± 0.4 | 1.13 ± 6.5 | |

| b* | 11.8 ± 6.1 | 11.0 ± 2.8 | - | 8.8 ± 6.5 | 13.0 ± 17.0 | |

| (n = 20) | (n = 6) | |||||

| Whey products (n = 26) | L* | 83.0 ± 15.1 | - | - | - | 67.5 ± 25.1 |

| a* | 1.2 ± 6.2 | - | - | - | 2.4 ± 9.5 | |

| b* | 7.9 ± 4.7 | - | - | - | 6.3 ± 6.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milovanovic, B.; Djekic, I.; Miocinovic, J.; Djordjevic, V.; Lorenzo, J.M.; Barba, F.J.; Mörlein, D.; Tomasevic, I. What Is the Color of Milk and Dairy Products and How Is It Measured? Foods 2020, 9, 1629. https://doi.org/10.3390/foods9111629

Milovanovic B, Djekic I, Miocinovic J, Djordjevic V, Lorenzo JM, Barba FJ, Mörlein D, Tomasevic I. What Is the Color of Milk and Dairy Products and How Is It Measured? Foods. 2020; 9(11):1629. https://doi.org/10.3390/foods9111629

Chicago/Turabian StyleMilovanovic, Bojana, Ilija Djekic, Jelena Miocinovic, Vesna Djordjevic, Jose M. Lorenzo, Francisco J. Barba, Daniel Mörlein, and Igor Tomasevic. 2020. "What Is the Color of Milk and Dairy Products and How Is It Measured?" Foods 9, no. 11: 1629. https://doi.org/10.3390/foods9111629

APA StyleMilovanovic, B., Djekic, I., Miocinovic, J., Djordjevic, V., Lorenzo, J. M., Barba, F. J., Mörlein, D., & Tomasevic, I. (2020). What Is the Color of Milk and Dairy Products and How Is It Measured? Foods, 9(11), 1629. https://doi.org/10.3390/foods9111629