Abstract

Innovation in food packaging is mainly represented by the development of active and intelligent packing technologies, which offer to deliver safer and high-quality food products. Active packaging refers to the incorporation of active component into the package with the aim of maintaining or extending the product quality and shelf-life. The intelligent systems are able to monitor the condition of packaged food in order to provide information about the quality of the product during transportation and storage. These packaging technologies can also work synergistically to yield a multipurpose food packaging system. This review is a critical and up-dated analysis of the results reported in the literature about this fascinating and growing field of research. Several aspects are considered and organized going from the definitions and the regulations, to the specific functions and the technological aspects regarding the manufacturing technologies, in order to have a complete overlook on the overall topic.

1. Introduction

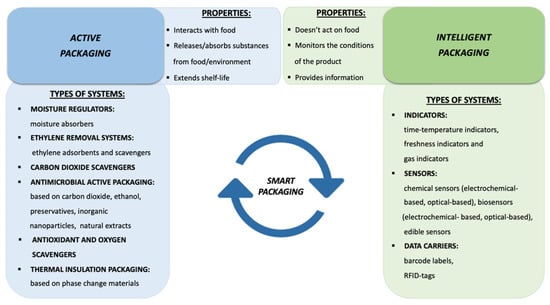

Traditional food packages are passive barriers designed to delay the adverse effects of the environment on the food product []. Modern food packages, instead, besides the passive role of containment, protection, and marketing of the product are characterized by an active function that allows packages to play a dynamic role in food preservation (during processing and storage), retaining the safety and quality of food throughout the distribution chain []. In other terms, the key safety objective for traditional packaging materials coming in contact with food is to be as inert as possible; whereas the innovative packaging systems concepts are based on the useful interaction between packaging and the environment inside, to provide active protection to the food []. Many terms are used to describe innovative packaging technologies such as “active”, “interactive”, “smart”, “clever”, “intelligent”, “indicators”, etc. []. These terms often lack in a clear definition and are interchangeable in some literature. Therefore, it is important to differentiate their meanings []. Intelligent and active packaging are two very different concepts united by the fact of having started a new way of conceiving food packaging. The main difference is that intelligent packaging does not act directly on food with any action other than monitoring the condition of the packaged product, while active packaging acts on the environment surrounding food to increase the shelf-life. Therefore, active packaging is the component that takes some action, while intelligent packaging is the component that senses and shares the information []. Intelligent and active packaging can, almost inevitably, work in synergy to create what is called a “smart” packaging [].

Considering the manufacturing techniques for innovative packaging production, it has to be considered that most of the time the package is produced in the conventional way such as extrusion, injection molding, injection stretch blow molding, casting, blown film, thermoforming, foaming, blending, and compounding. The active component can be directly incorporated in the polymer-based package matrix and/or film otherwise sachets and pads can be inserted in the package. The intelligent component can be instead integrated in the primary or secondary packaging. However, also polymer packaging manufacturing innovations are interesting, in order to follow the progress emerging in packaging composition and structure.

From a market point of view, the position covered by active and intelligent packaging in Europe is far behind foreign markets, in particular Japan, USA and Australia, where these products are widely commercialized []. This lag was often attributed to inadequate and very strict European regulation of food packaging []. To date, the only regulation entirely dedicated to intelligent and active materials for food packaging is Regulation 450/2009 [], which establishes specific requirements on the use and authorization of active and intelligent materials as materials intended to come into contact with foods.

The aim of this review is to present an overview of recent innovations in food packaging with the objective of providing clear definitions and classifications of each kind of active and intelligent packaging, and related manufacturing technologies up to commercial applications. A comprehensive diagram of all the categories of active and intelligent packaging detailed in this work is shown in Figure 1, from which it is also possible to deduce the different function that these two types of packaging perform with respect to packaged foods.

Figure 1.

Active and Intelligent packaging classification and their main properties.

2. Definition and Regulatory Aspects

In Europe, active and intelligent packaging must be in agreement with the Legislation about food-contact materials, which includes the evaluation of the overall migration limits (OMLs), specific migration limits (SMLs) and toxicological properties. In particular, the Regulation 1935/2004/EC [] establishes in art. 3 that any material or article intended to come into contact directly or indirectly with food shall be manufactured in compliance with good manufacturing practice, in such a way that under the normal and foreseeable conditions, their constituents do not migrate toward food in quantities that could represent a risk of human health that could change food composition or that could deteriorate food organoleptic properties. National and International regulations, specific for categories of materials are available, among them Regulations (EU No. 10/2011 [] and Regulation (EU) 2016/1416 [], amending and correcting the former, are of particular interest in the field of packaging. In addition, the Regulation 1935/2004/EC in article 4 regulates the labeling which must indicate that the parts are non-edible and that intelligent materials shall not give information about the condition of the food which could mislead consumers []. The Commission Regulation 450/2009/EC [] specifically deals with active and intelligent materials and articles intended to come into contact with food. In particular, it is emphasized that intelligent packaging systems must not release their components into food. The intelligent component is allowed to be placed on the external side of the package and the contact with food may be avoided by a functional barrier that prevents the migration of substances. The functional barrier allows the use of unauthorized substances, under the respect of defined criteria and of the established migration limits. Furthermore, it is also specified that the risk related to the employment of technologies such as nanoparticles should be analyzed for the specific application until more information is available regarding their use and their possible interactions with food and with human health []. Concerning active packaging, art. 5 indicates that components which may be added to food packaging with active function must be listed in the Community list of authorized substances. On each of the listed substances, the European Food Safety Authority (EFSA) performed a risk and safety assessment including the migration of the active agents, the migration of their reaction products and the evaluation of their toxicological properties. In general, active packaging can be classified into non-migratory and migratory. The former implies that the action of active agent is carried out without intentional migration of non-volatile or volatile compounds from packaging into food. Nevertheless, the active agent in the packaging may deliberately be intended to be released into food. In this case, the overall migration limit of the packaging may be exceeded, so the Regulation implies two exceptions. Indeed, if the active function is not a specific feature of the passive material, the amount of released active agent should not be included in the evaluation of overall migration. In addition, the migration of the released active substances can exceed the specific migration limit if its concentration in food is in compliance with the applicable food law. Furthermore, the active substance intentionally released in food, or that have a technical effect, must comply with the Regulation 1333/2008/EC [], concerning direct food additives. For already approved substances which are incorporated in active materials by means of techniques such as grafting and immobilization, the manufacturer is expected to perform a safety evaluation and to verify the stability of the substances when chemical reactions, degradation or decomposition are expected to occur. Furthermore, the active substances should not mislead the consumer (e.g., masking spoiled food), and they must be indicated in the label associated with the sentence “do not eat” or a symbol to prevent the nonedible part to be erroneously ingested. An extensive overview about regulation aspects of food active packaging in Europe is reported by Restuccia et al. (2010) [].

Considering different jurisdictions, a different approach compared to the European one can be observed. The introduction of active and intelligent packaging into the Japanese market is already consolidated, but specific regulations related to these two categories of packaging are still missing. Indeed, safety of active and intelligent packaging is ensured by the application of the Japanese Food Sanitation Law of 1947, together with the Food Safety Base Law of 2003. Generally, to introduce active and intelligent packaging materials to the Japanese market, risk assessment criteria are adopted including also compliance with foreign regulations, such as the European Union or the United States []. For US regulatory concepts about food-contact materials, toxicological justification is greatly minimized by exposure assessments compared to European legislation. Active and intelligent packagings are considered almost like conventional packaging. Food-contact materials are subjected to regulatory clearance before placing on the market by the United States Food and Drug Administration if they are considered “food additives” under the Federal Food, Drug, and Cosmetic Act, while as long as the material in the active or intelligent packaging is intended neither to add any substance to the food, nor to have a technical effect in the food (so-called “indirect additives”), there are no specific regulations for these components, which are simply regulated like all other food-contact substances []. The Canadian food packaging regulatory system is based on high safety standards and is similar to the one of US. The crucial difference between the two systems concerns migrating food packaging components, which are not considered to be food additives, legally requiring Health Products and Food Branch (HPFB)preclearance [].

3. Active Packaging

Active food packaging represents an improvement in the function ascribed to the classical packaging, aiming to increase product shelf-life by interacting with food or the environment surrounding food. A thorough definition of “active materials and articles” is given by European Regulation 450/2009/EC []. It defines them as “designed to deliberately incorporate components that would release or absorb substances into or from the packaged food or the environment surrounding the food” []. Indeed, conventional food packages are usually intended as passive barriers, which protect food by segregation against environmental contaminations, while active packaging promotes an active action of the packing material providing enhanced food conservation. This active action may be due to particular features that belong to the packaging material or to active agents, which are added to the passive barrier in order to work as absorbers, emitters or releasers of compounds that are able to play a pivotal role in food preservation. Thus, the main target of active packaging is to prevent microbial and chemical contamination, as well as to maintain visual and organoleptic properties of food.

Table 1 shows some examples of commercially available active food packaging for each of the categories which will be discussed in the following paragraphs.

Table 1.

Commercially available food active packaging.

3.1. Moisture Regulators

Moisture absorbers are active non-migratory packaging, working as controllers of excess moisture. High content of water into the package may be provided by several causes, such as trapping during packaging process, release due to temperature fluctuations, respiration of fresh products, low vapor permeability of the package, etc. Excess water reduces food shelf-life, since promotes microbial proliferation inducing undesired changes in food quality, particularly in dry food. In addition, presence of liquid inside the package of raw fish and meat, due to dripping or formation of foggy film in packaging of fresh fruit and vegetables, results into a low appeal for customers [,]. The main purpose of moisture absorbers is the reduction of food water activity by using hygroscopic substrates or substances, providing an environment less suitable for mold, yeast and bacteria growth and spoilage. Some packaging materials used as passive system are inherently moisture scavengers due to their hygroscopicity. According to the Regulation 450/2009/EC [], these kind of materials and articles, which work on the basis of the natural constituents only and are not designed to deliberately absorb substances, cannot be defined as active systems (e.g., pads composed of 100% cellulose). Nevertheless, if they contain components designed for the scope, they fall under the definition of active packaging. Moisture scavengers can be defined as “relative humidity controllers” if they provide a reduction of humidity in the headspace, while “moisture removers” absorb liquids exuded from food and are usually placed on the bottom of fresh products and meat packages []. Examples of moisture absorber commercially available are absorbent pads, sheets, trays and blankets [,,,], as summarized in Table 2. The structure comprehends two layers of microporous non-woven plastic film in polyethylene, polypropylene, etc. containing the active substance, such as superabsorbent polymer, silica gel-based adsorbents, sodium chloride, starch copolymers, etc. [,]. For package design, it is important that the active agent maintains its properties after the package processing and must not interfere with plastic properties.

Table 2.

Main features of commercially available systems working as moisture regulators.

In addition, the polymer containing the desiccant has to be water-permeable []. Nevertheless, for high water content products, moisture absorber should be carefully designed in order to avoid undesired food dehydration []. Sachets containing desiccants as calcium oxide, calcium chloride, molecular sieves, natural clays, and silica gel are usually employed for humidity control in low-level moisture food, for instance in dry food packages []. In addition, moisture absorbing material can be dispersed into the polymeric matrix or between two layers of plastic films constituting the package []. Inorganic compounds used as desiccants include materials such as silica gel, bentonite, calcium sulfate, molecular sieves, which are able to retain increasing amounts of water as the humidity increase, or metal oxides, such as calcium, barium, and magnesium oxides, which irreversibly react with water providing the corresponding oxides []. Organic-based absorbers are also reported such as fructose [], sorbitol and cellulose and modified starch []. Liu et al. [] reported the application of graphene oxide papers as desiccant for food preservation. They studied the moisture adsorption capacity of graphene oxide papers with different conditions of surface functionalization, showing promising results for applications related to food preservation. An extensive review about moisture absorbers was provided by Gaikwad et al. [].

3.2. Ethylene Removal Systems

Ethylene is a pure unsaturated hydrocarbon, odorless and colorless. It is a hormone naturally produced by plants and plays an important role in their growth cycle, respiration rate, somatic embryogenesis, seed germination, root growth and development. On the one hand, its action can lead to an appropriate ripening process that prepares fresh produce to the market (e.g., de-greening of lemons), on the other hand the acceleration of ripening and degradation of chlorophyll can cause a deterioration of the quality and reduce the shelf-life during postharvest storage of fresh products [,]. Climacteric fruit and vegetables produce high amount of ethylene, aldehydes, and other gases during ripening, which further promote the ripening process. The reduction of ethylene in the package atmosphere by active systems can slow undesired effects on these products []. The presence of just 1 ppm of ethylene in the package is sufficient to trigger climacteric fruit ripening []. Conversely, the application of ethylene removal systems is not common in packaging of non-climacteric fruit (cherry, strawberry, pineapple, etc.), since they do not require ethylene gas during ripening []. Ethylene removal can be carried out by ethylene absorbers, which physically absorb and hold its molecules, and scavengers, acting by chemical reactions.

3.2.1. Ethylene Adsorbents

Ethylene adsorbents include silica, zeolite, montmorillonite, cloisite, activated carbon and Japanese Oya clay [,,]. In general, commercial ethylene adsorbents can be provided in sachets or could be incorporated into a plastic film structure, commonly used in fresh produce packaging [,]. Recently, Gaikwad et al. [] studied alkali-treated halloysite nanotubes as ethylene absorber compared to raw halloysite nanotubes. The alkaline treatment provided an increase of the pore size of natural halloysite allowing a larger and faster adsorption capacity of ethylene than raw halloysite nanotubes. A novel work [] provided useful data for the design of new adsorbent based on the interesting properties of Yttrium doped graphene oxide. The adsorption properties of H2O, CO, and C2H4 molecules on the surface of the graphene oxide and Yttrium doped graphene oxide were investigated by the density functional theory calculations. Results showed as the substituted Yttrium atom can affect the electronic properties of graphene oxide molecule, leading to a noticeable increase in the adsorption energies.

3.2.2. Ethylene Scavenger

The most widely used ethylene scavengers is made by potassium permanganate (4–6%) [] supported on inert matrices, such as alumina or silica gel []. This compound is not integrated in surfaces in contact with food because of its toxicity [], so it is embedded in minerals or nanoparticles to enhance its scavenging ability and it is usually enclosed in permeable sachets []. Moreover, KMnO4-based scavengers are also available in the forms of tube filters, blankets, and films []. Mechanism of action involves the conversion of ethylene gas by oxidation into ethylene glycol, carbon dioxide and water []. Due to their high surface activity and reactivity, nanoparticles can be used to oxidize ethylene into water and carbon dioxide by photocatalytic reaction, using silver, titanium dioxide, zinc oxide, copper, and palladium []. Chitosan-titanium dioxide nanocomposite film was developed by Siripatrawan and Kaewklin [], who aimed to reduce the problems related to the spontaneous agglomeration observed for TiO2 nanoparticles, and to produce an active packaging with both ethylene scavenger and antimicrobial properties. Chitosan film containing 1% TiO2 showed suitable water barrier and ethylene degradation properties, as well as antimicrobial activity. Supplementary details about ethylene scavengers can be found elsewhere [,].

3.3. Carbon Dioxide Scavengers

Presence of carbon dioxide into food packages is generally beneficial and this aspect will be discussed in following paragraph. Nevertheless, an excess of carbon dioxide can induce undesirable effects on food and packaging. Excess of carbon dioxide could be due to the metabolism of the product and of microbial contaminant, being CO2 one of the main results of catabolic reactions that occur in biological systems. For instance, packaged non-pasteurized or non-sterilized fermented foods, such as kimchi, yogurt, cheese, and soy paste [], continue the microbial activity during storage and distribution. The microbial activity produces high levels of CO2 inside the package, leading to its potential collapse or to undesirable changes in texture and flavor of food, such as discoloration, off-flavor development, and tissue breakdown. Examples of foods, whose quality can be affected by excess of carbon dioxide are potato, lettuce, onion, cucumber, cauliflower, artichoke, apricot, peach, apple, and carrot []. Also roasted coffee is able to release high amount of carbon dioxide, which may cause the package to burst. Due to the low permeability of some packaging to CO2 and to overcome its accumulation, scavengers placed into the food package in form of sachets were developed. Calcium oxide and hydrating agents such as silica gel enclosed in porous sachets allow the reaction between water and calcium oxide forming calcium hydroxide, which finally reacts with CO2 producing calcium carbonate []. Other absorbers consist of sodium hydroxide, potassium hydroxide [] in form of sachets or granules or physical absorbers (zeolites, activated carbon) in form of beads and powder []. Commercially available solutions and applications of carbon dioxide scavengers are reported by Han et al. and by Verneiren et al. [,] and extensively treated by Lee [].

3.4. Antimicrobial Active Packaging

Food shelf-life is strongly affected by the presence of microorganisms. Contamination could occur at every stage of the supply chain, whenever food is exposed to the environment and its outcomes can range from simple alterations of sensory features to serious health hazards for consumers. Among the technologies developed to hinder this issue, antimicrobial packaging can be an effective tool to improve food safety, extend food shelf-life and reduce food waste and economic losses. Active emitters contained in packaging aim to provide a controlled release of compounds, able to ensure a right level of humidity, inhibition of harmful microorganisms and prevent bacteria spoilage [].

3.4.1. Carbon Dioxide

Carbon dioxide has a well-known antimicrobial effect on several microorganisms and it is used in modified atmosphere packaging to prolong food shelf-life. Nevertheless, since CO2 permeability through some packaging materials is higher than oxygen and it can also dissolve in food, carbon dioxide generators are needed to maintain the CO2 concentration to a desired value and to avoid packaging deformation []. The antimicrobial activity of carbon dioxide is strictly related to its rate of solubility and the amount dissolved in food, which increases as temperature decreases, and in food packaging it is proportional to the gas partial pressure in the headspace []. For fresh products partial pressures of CO2 higher than 0.1 atm are able to inhibit the respiration rate and microbial growth on food surface []. The formation of carbonic acid within the cell, decreasing the intracellular pH and activities, inhibition of decarboxylating enzymes, non-specific inhibition of susceptible non-decarboxylating enzymes, inhibition of membrane functions are all possible mechanisms of CO2 antimicrobial activity []. Sachets or pads with double action of CO2 emitters/O2 scavengers are usually employed. Iron carbonate (II) and metal halide as a catalyst are conventionally used []. Ferrous carbonate, combinations of sodium bicarbonate and citric acids, or ascorbic acid and sodium bicarbonate are commercially solutions to obtain CO2-releasing system [,].

3.4.2. Ethanol

Ethanol is an antimicrobial agent able to inhibit yeast and bacteria growth. It is particularly effective on molds, and its effect in prolonging shelf-life of bakery products by direct spraying was widely demonstrated. Emitting sachets or films containing food grade ethanol provide the exchange of ethanol with water vapor in the package headspace. To mask the odor of ethanol, sometimes flavors are added to the sachets. Examples of commercial ethanol generators are listed in Table 1, while further examples were provided by Vermeiren et al., Suppakul et al., and Sung et al. [,,]. The rate of ethanol release depends on carrier water permeability, amount of ethanol into the sachet, food water activity and ethanol permeability through film material. In the latter case, ethanol imbedded films usually require additional layers to provide a sustained release. Recently, Mu et al. [] proposed an ethanol gel, obtained by gelation reaction between ethanol and sodium stearate, adsorbed on diatomite, in order to enhance the release of ethanol emitter. The main disadvantage of ethanol emitters is its absorption on food, which can be reduced to insignificant values by heating or microwaving the product. Food products consumed without being heated may contain residual ethanol and might cause regulatory problems [,].

3.4.3. Preservatives

Chlorine dioxide and sulfur dioxide enclosed in sachets and pads attached to the internal part of the package are volatile agent with antimicrobial action. Commercial products are reported by Ozdemir et al. and Sung et al. [,]. Non-volatile preservatives with antimicrobial activity include weak acids and their salts such as acetate, sorbate, benzoate, and propionate, which probably exert the antimicrobial activity being transported in the undissociated form into the plasma membrane, where the higher pH provide the dissociations in ions that cannot return through the plasma membrane. The antifungal activity of potassium sorbate in films was reported in several studies [].

3.4.4. Inorganic Nanoparticles

Moreover, inorganic nanoparticles composed of metal ions of silver, copper, gold, platinum, selenium [] and metal oxides such as TiO2, ZnO, MgO, and CuO are used for the production of active packaging, obtained by the incorporation of such materials into adsorbent pads or plastic films. Even if the mechanism of action is still under debate, the antimicrobial activity seems to be due mainly to the release of metal ions and the formation of reactive oxygen species, which provoke deadly damages to the wall and membranes of microbial cells [,]. The small size of nanoparticles implies a high surface-to-volume ratio, resulting in an enhance of metal reactivity as photocatalysts and improving the interactions between metal nanoparticles and microbial membranes []. Recently a review by Basavegowda et al. [] explored the advantages of bimetallic and trimetallic nanoparticles compared to monometallic ones and their potential application in food packaging. They are hybrid nanostructured material showing improved thermal, mechanical and gas barrier properties and higher antimicrobial activity compared to monometallic nanoparticles []. However, the use of such inorganic nanoparticles should be carefully selected, basing on the type of food and the properties of packaging film (barrier properties, transparency) that can be affected. Furthermore, some concerns related to potential toxic effects on human health due to migration to food, dermal contact, and inhalation, are presently increasing [,], and depends on the chemical composition of nanoparticles, size, surface chemistry, solubility, and hydrophobicity [].

3.5. Synthetic Antioxidants and Oxygen Scavengers

Food products are generally sensitive to oxygen, which induces undesired changes to the organoleptic properties, such as color modifications, development of off-flavors, as well as deterioration of nutritional properties, and supports microbial growth [,]. Consequently, great importance is given to strategies aiming to minimize oxygen content in the headspace of food packages. Vacuum and modified atmosphere packaging are two methods that proved to be effective in prolonging shelf-life of some foods. Nevertheless, both of them cannot impede the permeation of oxygen over time from the external environment and are also able to reduce the amount of oxygen in the package up to only 0.5–2 vol.%, while lower values can be achieved by oxygen scavengers [,]. The control of oxygen levels is obtained using synthetic antioxidants and oxygen scavengers.

Oxygen scavengers are used in packaged food products in sachets, bottle crowns, labels, plastic films, and trays []. One of the most used solutions available in the market employs metallic scavengers, which carry out oxygen removal by chemical reactions. For instance, in iron-based scavengers (iron powder, activated iron, ferrous oxide, iron salt) the reduced metal oxidation occurs in presence of moisture or Lewis acids []. The rapid rate of oxidation of iron, can be further increased by using nano-iron particles blended with activated carbon, sodium chloride and calcium chloride []. However, some disadvantages of iron-based scavenging systems are related to potential contamination of food due to accidental breakage, to interferences with inline metal detectors and to the inhibition of heating by microwave ovens []. Other metals employed are platinum and palladium as efficient catalysts for the conversion of hydrogen in water. For this purpose, the atmosphere needs to be modified in order to hold high pressures of molecular hydrogen and the metal catalyst is used to improve the reaction also in presence of small amount of oxygen. Nevertheless, as reported by [], due to the flammability of hydrogen, there is a maximum of oxygen that can be removed (2.5 vol. %) when hydrogen is introduced in the modified atmosphere. An alternative involves hydrogen-evolving compounds, such as calcium hydride or sodium borohydride, which allow a controlled hydrogen release, and which can be easily inserted in the cap of bottles, while more difficulties are met in their incorporation in films []. In addition, films based on oxidizable transition metals such as copper, zinc, magnesium, manganese, aluminum, or titanium, and nanocrystalline titanium particles are also reported []. Commercial solutions and mechanisms of action of the most common oxygen scavengers in food packaging as well as new approaches in this field can be found in the recent reviews published by Dey and Neogi [] and Gaikward et al. [].

The most common synthetic antioxidants comprise phenolic compounds as butylated hydroxytoluene, butylated hydroxyanisole and tert-butylhydroquinone and propyl gallate, which are hydrogen donating free radical scavengers []. They are widely used in food active packaging in order to prevent lipid oxidation, thus they are extensively applied to enhance the shelf-life of fat and fat containing products []. In addition, although they are generally used as antioxidants, they have shown also antimicrobial activity []. However, these compounds are suspected to have potentially toxic and carcinogenic effects, thus the research is more oriented toward the application of natural antioxidants [], which will be discussed in this review in the following paragraphs.

3.6. Agents for Active Packaging from Natural Products

The use of naturally occurring agents for the fabrication of active food packaging is the trend to which the research is currently approaching. Natural antioxidant and antimicrobial agents are perceived as safer than synthetic ones by consumers, thus different natural compounds have been proposed for active packaging purposes and the interest of the scientific community in this field is continuously increasing.

3.6.1. Bacteriocins and Enzymes

Bacteriocins, such as Pediocins, Nisins, Enterocins and Sakacins, are peptides produced by bacteria ribosomal synthesis, which gained strong attention by food industry due to their antimicrobial effect [], even at low concentrations []. The main bacteriocin producers are lactic acid bacteria, so these naturally occurring compounds are present in several fermented food. They are able to inhibit many pathogenic microorganisms, but the mechanism of action is still not completely known. Bacteriocins produced by each strain are active only against their competing bacteria, since the originating bacterial cells possess specific immunity mechanism toward their bacteriocins []. Some hypotheses related to the mechanism of action were evaluated by recent studies and discussed in a recent review by Santos et al. []. Such mechanisms include the disturbance of bacterial metabolism, interaction with intracellular targets, inhibition of the synthesis of nucleic acids and proteins, interferences with the formation of cellular components, in which the cationic characters of the antimicrobial peptides play a crucial role in their adsorption on microbial cell surfaces.

Bacteriocins produced by lactic bacteria show properties that make them attractive for active packaging applications. Indeed, they are substances generally recognized as safe and are inactive and nontoxic on eukaryotic cells and on consumers. In addition, bacteriocins have little influence on consumer’s gut microbiota, being inactivated by digestive protease, while show broad antimicrobial activity against many food-borne pathogenic and spoilage bacteria. Furthermore, they do not provide any alteration of the organoleptic properties of food as they are taste-, odor-, and colorless []. Finally, they are active in wide ranges of pH and temperatures []. The last aspect plays an important role from an industrial point of view, since standard melting blending technological processes are not suitable for thermosensitive compounds []. Nisin is a commercially acceptable food grade bacteriocin, active against Gram-positive bacteria such as Listeria monocytogenes, Clostridium botulinum, Staphylococcus aureus and Bacilli. It is allowed for use in pasteurized cheese and liquid eggs and commercially used in a range of foods including dairy, eggs, vegetables, meat, fish, beverages, and cereal products []. Holcapkova et al. [] found that the antimicrobial activity of nisin against Micrococcus luteus is temperature-resistant, indeed they showed that the polylactic acid (PLA)-based films displayed antimicrobial properties even when they were thermally treated above the melting temperature of PLA, but losing the 25% of their activity under treatment at 160 °C and more than 60% at 180 °C for 5 min. Pediocin was also reported to be a remarkable natural biopreservative to overcome the post-processing contamination of meat products against L. monocytogenes []. According to literature, nisin and other bacteriocins such as pediocin and lacticin are ineffective against molds, yeasts, and Gram-negative bacteria, with the only exception given by a few strains. Incorporating chelating agents such as Ethylenediaminetetraacetic acid (EDTA) was found to increase the effectiveness of bacteriocins in food packaging application []. However, in a recent work, the bacteriocins extracted from standard Pediococcus acidilactici culture and the isolate, Enterococcus faecium, showed antibacterial activity against both Gram-positive and Gram-negative bacteria []. In addition, Woraprayote et al. [] reported that Bacteriocin 7293, a novel bacteriocin from Weissella hellenica BCC 7293, with polylactic acid/sawdust particle (PLA/SP) film provided both Gram-positive (Listeria monocytogenes and Staphylococcus aureus) and Gram-negative bacteria (Pseudomonas aeruginosa, Aeromonas hydrophila, Escherichia coli and Salmonella Typhimurium) inhibition in pangasius fish fillet. In addition, bacteriocins demonstrated additive or synergistic effects when used in a combination with other bacteriocins or with other preservatives or phenolic compounds [].

Enzymes are also currently applied as antimicrobial agents in food packaging. In particular, lysozyme is a naturally occurring enzyme with activity against cellular structure specific to bacteria, since it is able to damage the structural integrity of the cell wall, resulting in the lysis of bacterial cells []. This enzyme exhibits antimicrobial activity against Gram-positive bacteria but not on Gram-negative bacteria, but susceptibility of Gram-negative bacteria could be enhanced by the addition of chelating agents such as EDTA []. Another enzyme that can be used as an active agent is Glucose oxidase, whose reaction products, yielding hydrogen peroxide from glucose and oxygen, show antimicrobial power []. However, the application of this enzyme in packaging is limited by the cost of enzyme and the requirement of glucose, whose amount in many foods in not sufficient []. Both bacteriocins and enzymes were employed as directly incorporated in polymer matrix, as coated onto material’s surface or by immobilization in active packaging. The first method is used with biodegradable polymers such as carbohydrates and proteins, when thermal processing is not used, due to the potential loss of antimicrobial activity. Alternatively, coating by immersing or contacting the film with a peptide solution or by solvent casting can be performed. Immobilization can be achieved by physical or chemical methods [] and, due to the low tolerance of enzymes to high temperatures, immobilization is the option for the application of enzymes to antimicrobial packaging [] and can improve the stability of bacteriocins [,].

3.6.2. Phytochemicals

Among natural food preservatives, essential oils and other extracts from plants, herbs, and spices, deserve particular attention being able to exhibit great antimicrobial and antioxidant potential []. Essential oils are volatile substances because of the high content of low molecular weight aromatic compounds. They are biologically produced by plants as secondary metabolites and exert antimicrobial activity due to the high concentration of phenolic compounds (up to 85%), which provoke damages to bacterial enzyme systems, genetic material, and cell membrane phospholipid bilayers []. The main drawback of the use of essential oils and their components as antimicrobial agents is the high concentration required []. Most of essential oils extracted from plants and spices are classified as Generally Recognized As Safe but, due to their strong flavor potentially changing organoleptic features of food, their incorporation in films can be preferred to their direct use as food additive []. Examples of natural sources of essential oils proposed for active packaging applications are garlic [,], cinnamon [], lemongrass [], oregano [], rosemary [], thyme [] and bergamot []. Antioxidant and antibacterial packaging materials with essential oils can be obtained by direct mixing into packaging material by blending or solvent casting technologies. Alternatively, adsorption or coating the packaging material can be used for the addition of essential oils. In addition, carriers in which essential oils are adsorbed or embedded can be used for the fabrication of small antibacterial bags continuously releasing the active compound in package headspace, or modified atmosphere packaging can be created by filling the entire packaging with essential oils in gaseous form []. The application of essential oils into hydrophilic materials by casting is mainly obtained by emulsification or homogenization techniques, which allow creating fine emulsion and after drying the lipid droplets remain embedded in the polymer matrix []. In addition, biopolymer-stabilized emulsions, also known as Pickering emulsions, are an interesting sustained delivery tool that was used for the same purpose [,,]. They involve the stabilization of oil in water O/W or water in oil W/O emulsions by replacing surfactants with solid particles. A solid layer around the essential oils droplets prevents the contact with the aqueous phase, thus allowing higher coalescence stability, higher loading capacity, a more sustained release of the active agent and its protection from the external environment, particularly from oxidation [,].

Solutions of active packaging with essential oils and examples of applications can be found in recent reviews [,,]. However, an important characteristic that should be taken into account is the interaction between essential oils and the packaging material, due to the alterations that the former can induce on the film. For instance, the addition of thyme essential oil to bio-nanocomposites made of whey protein isolate and cellulose nanofiber provided the decrease of water vapor permeability, the reduction of film transparency and the films obtained with thyme essential oil resulted as less strong and elastic than the control samples []. On the other hand, Mendes et al. [] found that the addition of lemongrass essential oil by emulsification into formulations based on glycerol-plasticized cassava starch improved colorimetric attributes, thermal stability, barrier to moisture, and mechanical properties of film.

Active packaging has been developed using several natural extracts from plants and spices. Pure standards of natural antioxidants were used in several works to produce active films by different techniques. For instance, gallic acid and quercetin were added in polyvinyl alcohol (PVA) for the fabrication of active films by solvent casting [], quercetin-starch-based complex were incorporated in chitosan-gelatin-based films [], quercetin was adsorbed onto maize starch and calcium alginate aerogel through supercritical carbon dioxide adsorption [], while α-tocopherol into polyethylene terephthalate/polypropylene (PET/PP) films was added by supercritical CO2 impregnation [], and Poly(L-lactic acid) (PLLA)/antioxidant mixtures containing tocopherol and resveratrol were compression molded to films []. The antioxidant and antimicrobial properties of natural substances such as phenolic compounds are well-known in the literature [,,]. Many plants, herbs and spices are considered to be potential antioxidant sources due to the rich amount of phenolic acids, carotenoids, and polyphenols in their extracts, which can be added to packaging materials, resulting in an extension of food shelf-life, as reviewed by Valdés et al. []. Free radical scavenging of phenolic compounds is mainly provided by two mechanisms, the former involves an H-atom transfer by the antioxidants, while the second a one-electron transfer, resulting in the formation of a nonreactive phenoxyl radical or a stable radical cation, respectively. The single antioxidant ability to inhibit oxidizing chain reactions depends on the molecular structure, conjugation, and resonance effects [].

Very powerful antioxidants are also carotenoids. As reported by Stahl and Sies [], they are most likely involved in the scavenging of singlet molecular oxygen, peroxyl radicals and they are effective deactivators of electronically excited sensitizer molecules, which are involved in the generation of radicals and singlet oxygen by physical quenching. Antimicrobial activity of phenolic compounds was explained by several mechanisms, such as aggregatory effect on all the bacterial cell, destabilization of cytoplasmic membrane, permeabilization of cell membrane, inhibition of extracellular microbial enzymes, deprivation of substrates required for microbial growth and direct action on microbial metabolism, depending on the subclass considered []. Several studies evaluated carotenoids antimicrobial activity against both Gram-positive and Gram-negative bacteria []. Recently, the antimicrobial activity of fucoxanthin, a carotenoid produced by brown algae and diatoms, was evaluated by Karpiński et al. []. However, some studies highlighted synergistic effects of natural compounds, able to increase both their antioxidant and antimicrobial activity when they are simultaneously present in mixtures or in extracts, compared to the same amounts of a single compounds [,,,]. For this reason, studies on active packaging dealing with the incorporation of natural extracts, rather than a single compound, in polymers for food applications are attracting more and more the attention of the scientific community. In addition, agrifood industry residues, such as spent coffee grounds [], apple skins [], grape seeds and skins [], tomato waste [], olive pomace [], are still rich of antioxidant compounds, which can be recovered for active packaging purposes, allowing a waste valorization.

Examples of recent solution of active food packaging with natural extracts are reported in Table 3.

Table 3.

Examples of packaging with natural extracts as active agents.

3.6.3. Challenges and Solutions

One of the main disadvantages of natural antioxidants is related to their sensitivity to oxygen, heat and light, which can induce a loss of their activity. In particular, their thermo-sensitivity has implications both on their extraction, as well as in the packaging fabrication technique. Thanks to non-conventional processes such as supercritical-assisted extraction, ultrasound-assisted extraction, microwave-assisted extraction, solvent-free microwave-assisted extraction, pressurized liquid extraction, high pressure and temperature extraction, pulsed electric field-assisted extraction, whose efficiency and greener approach in the recovery the aforementioned compounds from natural sources was reviewed [,,], the first problem can find effective solutions. The second issue can be faced performing the encapsulation of the active agent. By the encapsulation process, the active agent is entrapped in a carrier material and protected from external environment and stresses. Several advantages are related to the encapsulation, since solubility of the payload can be modulated, its delivery can be controlled, unpleasant odor and tastes can be masked, and the activity of the bioactive molecules can be extended, by choosing the suitable wall material []. In addition, the encapsulation of compounds for active food packaging can be used to improve the compatibility between the packaging polymer and the active agent, to increase its availability, to reduce changes in food sensorial properties or comply with the legal restriction limits [].

Encapsulation of the active agent can be achieved by several techniques, as reported a recent reviews by Becerril et al. [], Bahrami at al. [] and Brandelli et al. []. For instance, Talón et al. [] developed microparticles of soy lecithin, whey protein isolate, with and without and purified oleic acid, loaded with eugenol by spray drying, which were incorporated in corn starch films obtained by compression moulding. Zein electrospun nanofibers were used for the encapsulation of gallic acid [], curcumin [], rose hip seed oil [], and β-carotene [], while chitosan/PEO nanofibers containing microalgal phenolics were prepared to preserve their antibacterial activity []. Alternatively, zein microparticles were used for the encapsulation of the antioxidant luteolin [], while the use of liposome nanoparticles was widely proved to be an efficient carrier for extract exhibiting antimicrobial and antioxidant activity [,,]. Furthermore, antimicrobial activity of bacteriocins can be enhanced by encapsulation, which can help to reduce activity loss due to inactivation in complex food systems []. One of the most used and promising techniques involves the use of cyclodextrins, a family of cyclic oligomers of α-d-glucopyranose linked by α-1,4 glycosidic bonds, which were used for the preparation of active food packaging [,,]. An upgrade of the encapsulation of active compounds by using cyclodextrins was given by cyclodextrin nanosponges, obtained by cross-linked cyclodextrin polymers nanostructured within a three dimensional network, which are stable in a wide range of pH and temperature, offering new perspectives to active packaging preparation techniques [].

3.7. Phase Change Materials

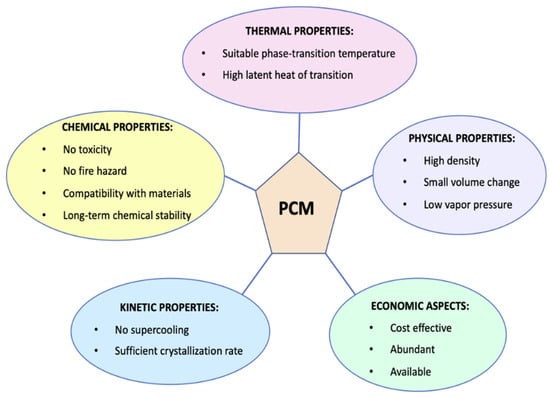

For many products, such as chilled foods, maintaining the cold chain is a crucial aspect to ensure food safety and quality. Traditional packaging materials are usually inadequate to respond to incorrect storage or transport conditions, showing low thermal buffering capacity [,]. Phase change materials (PCM) have aroused great interest as materials to be incorporated directly on the primary packaging, being able to prevent unwanted temperature changes and, therefore, to avoid or postpone consequent microbial, physical, and chemical food alterations []. A PCM is a substance that can undergo a phase transition at a specific temperature, absorbing or releasing latent heat, changing its phase from a solid state into a liquid or vice versa. PCMs have been used for several years, mainly for the storage of thermal energy [], in the construction [] and in the textile fields [], and only recently they approached to the food sector []. Whatever the field of application, phase change materials must have some thermal, physical, kinetic properties and satisfy some economic aspects which are briefly reported in Figure 2 [,].

Figure 2.

Main properties for ideal phase change material (PCM).

In a review by Sharma et al. [] it is possible to find the main properties sought in the PCMs such as the melting point and latent heat of fusion values, as well as the typical measurement techniques of these parameters such as the differential scanning calorimeter (DSC) and differential thermal analysis (DTA). With regard to chemical properties, an interesting and complete work by Chandel et al. [], compared all the categories of PCMs in terms of toxicity, health hazards and environmental effects.

Generally, PCMs can be classified into three groups of organic, inorganic, and eutectic materials []. The former can be further divided into paraffinic and non-paraffinic materials []. The most used paraffinic materials are paraffin waxes, consisting of a mixture of n-alkanes mainly with a linear chain (e.g., n-dodecane, n-tridecane etc.) []. They are chemically inert, non-toxic, non-corrosive, with small volume change and low vapor pressures, moreover they are safe and predictable []. On the other hand, paraffins usually have low thermal conductivity and are flammable in nature []. These problems can be solved by encapsulating the paraffins in an outer shell of a more stable supporting material, such as carbon nanotubes as investigated by Han et al. [] for thermal management systems. Regarding the use of paraffins for applications in food packaging, some researchers have developed and optimized a smart packaging based on the encapsulation of dodecane into a biopolymeric matrix of zein using the uniaxial and coaxial electrospinning technique. The best results were obtained with coaxial configuration by adding a nucleating agent (tetracosane) to decrease the supercooling effect of the encapsulated [].

However, the use of pure alkanes is quite expensive, therefore mixtures of alkanes with different molecular weights are usually used in order to regulate the melting temperature [].

Non-paraffinic materials include fatty acids (myristic acid, capric acid, palmitic acid, lauric acid, stearic acid and their mixtures) [], sugar alcohols (e.g., xylitol, D-sorbitol, D-mannitol) [] and glycols (e.g., polyethylene glycol, triethylene glycol) [,]. In particular, fatty acids are among the most studied compounds for food applications due to the concurrent melting point, lack of supercooling, self-nucleating behavior, low volume change, high latent heat, chemical stability, and non-toxicity. The main problem is their high cost. They are also slightly corrosive in nature and have unpleasant odors []. In the work by Sathishkumar et al. [] for example, the authors have investigated the use of palmitic acid as phase change material for application in food storage containers, obtaining better thermal energy storage than the same system without PCM. As for sugar alcohols, Palomo del Barrio et al. [] have characterized several of these compounds (xylitol, adonitol, L-arabitol, erythritol, D-mannitol) for applications in heat storage, comparing their performance with those of the most used PCMs (paraffin waxes and salt hydrates). This study showed that the energy density provided by sugar alcohols and salt hydrates is much higher than that provided by paraffins and fatty acids.

Inorganic PCMs can be divided mainly into metallics (e.g., gallium, indium, bismuth) [,] and salt hydrates (e.g., potassium hydrogen phosphate hexahydrate, magnesium chloride hexahydrate) []. Materials belonging to this group have a higher phase change enthalpy than organic PCMs, but they show supercooling due to the poor nucleating ability, corrosion, phase segregation and phase separation []. Also in this case, these problems can be solved by encapsulating the inorganic PCMs as reported by Milián et al. []. While the problem of supercooling is treated in detail by Zahir et al. []. In this work, the authors discuss the main techniques to reduce the supercooling effect for the various types of PCMs, such as the addition of nucleating agents (e.g., carbon nanotubes, nonadditives). The authors also discuss the mitigation of phase separation and thermal cycling effects on supercooling. Salt hydrates have been used, for example, to improve the thermal performance of commercial freezers during the opening of the doors or the lack of electricity. The PCM used, a commercial salt hydrate composed of sodium nitrate dissolved in water, was able to keep the internal temperature of the freezer almost constant for 3 h in the absence of electricity, confirming the potential of these compounds in the transport and storage of perishable foods [].

Finally, the eutectics consist of two or more low melting temperature components (e.g., tetradecane + octadecane, lauric + palmitic acid, water + polyacrylamide) []. The main advantage of eutectics respect other types of PCMs is that their melting points can be adjusted by combining different weight percentages of components []. Some researchers have characterized four types of micro/nano capsules composed of paraffins with different molecular weights encapsulated, via emulsion polymerization, using poly (methyl methacrylate) as shell material. The eutectic mixtures thus obtained showed good chemical and thermal stability and good thermal conductivity, resulting as suitable for food storage, as well as in the construction, textile, medical and electronic fields [].

Most PCMs are liquid at room temperature, making difficult their direct incorporation into a package material. To overcome this issue, the encapsulation of PCMs in various polymeric matrices has been carried out, such as polystyrene, poly (butyl methacrylate), melamine-urea-formaldehyde [], but also biodegradable polymers such as polycaprolactone [], alginate [], zein [], gum Arabic and gelatin powder [] have been investigated. In addition to preventing liquid leaks, the encapsulation techniques also serve to control the volume change during the phase transition [], to protect the PCM from the external environment, in order to not compromise the thermal performance, and also to protect the external environment in the case of potentially corrosive PCM []. Moreover, the encapsulation allows obtaining a controlled release of thermal energy and an increase of the efficiency of heat transfer thanks to a larger area of heat transfer []. Generally, encapsulation techniques could be divided into three categories: chemical methodologies that include suspension polymerization [], emulsion polymerization [], in situ and interfacial polymerization [,]; physico-chemical methodologies, as coacervation [], sol-gel encapsulation [], supercritical CO2-assisted []; and physico-mechanical methodologies, like spray drying [], electrospinning [] and vacuum impregnation []. PCMs are a really interesting class of compounds to be integrated into the primary food packaging, but to date the applications in this sense are still few [,,] compared to applications in refrigerated containers [,,,,,] or in the, already mentioned, construction and textile fields.

4. Intelligent Packaging

In the literature there are many definitions of the concept of intelligent packaging. European Commission defines intelligent packaging as “materials and articles that monitor the condition of packaged food or the environment surrounding the food” []. Intelligent packaging has also been defined as science and technology that uses the communication function to facilitate decision making to extend shelf-life, improve safety, guarantee quality, provide information, and warn of any problems by monitoring changes in the internal and external environment of the packages [,]. More in details, intelligent packaging is a packaging system that uses the internal (e.g., metabolites) or external (e.g., temperature) package environment as “information” to monitor the status of product quality, in order to improve not only product safety, but also to track the product for automatic identification and traceability [].

The aim of intelligent packaging lies in its communication ability; the package can be considered the best companion of the product, since they constantly move together along the entire supply chain and therefore the package can, in principle, constantly communicate the conditions of the product [,]. The development of new intelligent packaging capable of continuously providing information on the conditions of both the food product and the packaging integrity, allows for a safer and more efficient supply chain, avoiding unnecessary transports and logistics and reducing food waste [].

Products are regularly subjected to microbiological and chemical tests, which are carried out during production [], but ensuring adequate control after delivery to the supermarket it is often not possible. Intelligent packaging can fill this gap []. Intelligent packaging can also contribute to improving ‘Hazard Analysis and Critical Control Point’ (HACCP) and ‘Quality Analysis and Critical Control Point’ (QACCP) methodologies, used to control, detect, prevent, reduce, and eliminate any possible criticism that could compromise the food product and its final quality [].

The main technologies for intelligent packaging system are three: indicators, sensors, and data carriers []. Indicators and sensors have the main function of providing information relating to product quality, while the class of data carriers is more involved in the management of the supply chain logistics. These systems can be placed on the primary packaging, inside or outside, on the secondary or tertiary packaging [].

4.1. Indicators

The main function of indicators is to transmit to the consumer information related to the presence or absence of a specific substance, to indicate whether a reaction is taking place between two or more components or to monitor the concentration of a certain substance. This information is translated into signals usually in the form of immediate visual changes (e.g., different color intensities or diffusion of a dye along a straight path) [], providing qualitative or semiquantitative information. In most of the cases, the basic requirement of an indicator is that these changes in color or intensity are irreversible []. The indicators represent a very consistent class of intelligent packaging; the most used classification, also for this review, is based on the type of variable controlled, so they can be grouped into three macro categories: time-temperature indicators, freshness indicators, and gas indicators. For a more general classification, the indicators can be classified as external or internal, based on their positioning on the packaging [].

4.1.1. Time-Temperature Indicators

Temperature is a fundamental factor in monitoring and determining the shelf-life of a food product, especially for perishable products. One of the main challenges of the perishable food industry is to ensure the quality of food by protecting it from unwanted temperature fluctuations, a challenge that is not simple at all. Temperature monitoring and control along all the supply chain are essential to maintaining the quality and safety of perishable foods. Incorrect or uncontrolled temperature management can cause a large amount of food waste during production, as well as during the distribution chain. Studies report that poorly managed temperature in perishable food logistics can cause up to 35% loss of products []. To meet these needs, time-temperature indicators (TTI) provide valuable support.

Time-temperature indicators find application majorly for temperature-sensitive foods such as chilled and frozen products []. Furthermore, TTIs have also been applied to control the pasteurization and sterilization process []. The classification of TTI varies slightly from one author to another, the clearest grouping them into two categories: partial or full history indicators. A partial history indicator does not respond unless a certain predetermined threshold temperature is exceeded, and therefore identifies abusive temperature conditions, warning consumers of the potential survival of microorganisms and protein denaturation during, for example, freezing or defrosting [,]. A full history indicator responds continuously to all temperatures along the food supply chain, so as to provide a measure relating to the entire life of the product [,,]. The TTIs currently available on the market, reported in Table 4, have operating mechanisms based on different principle that mainly include physical change or chemical reaction such as polymerization, melting or acid-based reaction, generally expressed through a visible response in the form of mechanical deformation, color development or color movement []. These types are the most common, but there is another class to mention, which is the enzymatic one, based on a biological response. In this case, TTI is sensitive to the change in biological activity of microorganisms, spores or enzymes []. The rate of change is directly proportional to the change in temperature similarly to the reactions responsible for the product deterioration. However, enzymatic TTIs still have limitations in terms of high cost and enzymatic instability. Some authors have developed an immobilized laccase-based TTI by electrospinning zein fiber to increase the stability of the enzyme. Immobilization onto solid carriers is the most used strategy to improve stability and fibrous membranes made by electrospinning have a great potential to be used for enzyme immobilization []. Usually, TTIs are made of small, self-adhesive labels attached onto containers or individual consumer packages, so as to be clearly visible and interpretable. These systems must represent time-temperature dependent changes in an easily measurable manner that can be quickly correlated with the extent of deterioration and the remaining shelf-life of the food [].

Table 4.

Commercially available time-temperature indicators (TTI) indicators.

4.1.2. Freshness Indicators

Freshness indicators are intelligent devices that allow the monitoring of the quality of food products during storage and transport. Freshness decay can be due both to exposure to harmful conditions and to a shelf-life longer than that established. Freshness indicators, unlike temperature indicators, provide direct information on the quality of the product, analyzing the chemical reactions of food deterioration due to target microorganisms [,]. Changes in the concentration of metabolites such as glucose, organic acids, ethanol, carbon dioxide, biogenic amines, volatile nitrogen compounds or sulfur derivatives are indicators of microbial growth and their presence can therefore be exploited in the freshness indicators []. In most cases, freshness indicators are based on the use of dyes sensitive to pH variations caused by the deterioration of the product, which lead to the visible change in the color of the indicator. These indicators find applications in various products including fresh food, fruit, and seafood [], but their marketing is still rare, especially in Europe, primarily for legislative issues related to substances that can be in contact with food. Table 5 reports some examples of freshness indicators present on the market and their main functioning.

Table 5.

Commercially available freshness indicators.

In most cases, various polymeric matrices (e.g., polypropylene, nylon, or cellulose films) are impregnated with pH-sensitive dyes that are typically: bromocresol purple, bromocresol green, bromophenol blue, methyl red, and cresol red. In recent years, the use of natural dyes has also been studied. For instance, curcumin, grape peel, and beetroot extracts have been explored to detect the aging of cod flesh [], or a system based on corn starch, chitosan and red cabbage extract was tested during fish spoilage [].

Freshness indicators for seafood are based on the total volatile basic nitrogen content (TVB-N), as volatile amines, which are formed as the food spoils. Instead, hydrogen sulfide indicators can be used to determine the quality of meat products; in fact, hydrogen sulfide is correlated with the color of myoglobin, which is considered a quality attribute for meat products []. Most of these sensing mechanisms are based on color changing dyes, but penetration of the dyes into the package can affect the organoleptic properties of the packed food. To avoid this issue, some researchers have developed a freshness indicator consisting of a triple layer: a layer in contact with the food in non-woven high-density polyethylene, a layer containing a dye sensitive to pH variations, bromocresol green, immobilized with the binding polymer, and an external layer in low-density polyethylene. This indicator is able to detect chicken spoilage as a function of the change in concentration of volatile basic nitrogen, CO2, and bacterial count, without migration of the dye inside the package, thus offering a safe packaging solution, simple and reliable []. Normally, freshness indicators are printed on the packaging film or are incorporated, in the form of labels, inside the packaging film, reacting with agents produced during the storage []. A common problem with the category of indicators is related to false negatives/positives. In the first case, there would be samples that seem safe but that are not, constituting a danger to the health of the consumer, while in the case of false positives the problem would be connected to the useless food waste induced by samples that seem dangerous or damaged, but which are actually healthy. In this sense, it would be necessary to develop standard protocols to accelerate the development of indicators, in particular those of freshness, also on an industrial scale [].

4.1.3. Gas Indicators

The activity of the food, the nature of the package, and the environmental conditions to which the package is subjected lead to the variation of the gas composition in the headspace of the package [,]. Gas indicators are used to monitor these changes and are also often used to evaluate the effectiveness of active packaging components (e.g., O2 and CO2 scavengers) [] or to detect the occurrence of leaks across the packaging, and therefore to detect package integrity, which is an essential requirement, especially when the food is stored in a modified atmosphere packaging (MAP) []. The most well-known gas indicators are used to control oxygen and carbon dioxide concentrations []. Oxygen is responsible for the microbial and biochemical deterioration of food and is therefore removed from the packaging and replaced with gas such as nitrogen or using oxygen scavenger []. However, during transport and storage, oxygen may be able to penetrate the package due to poor sealing, defects, or damage. For this reason, the use of visible oxygen indicators becomes essential to quickly and easily verify the presence of oxygen inside the package, without using professional equipment or laboratory analysis []. The most commonly used oxygen indicator is a colorimetric indicator based on a redox dye, generally methylene blue and a reducing agent, such as glucose, in an alkaline solution such as sodium or potassium hydroxide [,]. If no oxygen is present, the glucose in the alkaline solution reduces the methylene blue which is, in this case, colorless. If oxygen is present in the monitored environment, the dye is oxidized and intensely colored. The reducing agent is sensitive to oxygen, therefore these indicators must be created and maintained in anaerobic conditions to avoid the rapid exhaustion of the reducing agent, due to the reaction with oxygen, and to the consequent malfunction of the indicator. Furthermore, there may be safety problems due to the contamination of the food product by the synthetic and, often harmful, chemical components used in the indicator []. A solution was proposed by Jang et al. [], who developed an indicator by physically separating the components via a barrier. Activation of the indicator occurs by hand pressing and breaking the barrier, so components can come into contact. The rate of the color change is related to the oxygen concentration. In addition, the same authors have redesigned the indicator using natural organic compounds such as cysteine and laccase [], thus finding a possible solution to the second issue mentioned.

The other predominant class of gas indicators is related to CO2. The microbial growth responsible for the deterioration of food usually begins immediately after packaging, and therefore there is a production of CO2 due to the metabolic activity of microorganisms. The rate of carbon dioxide production depends on the type of food, time, and conditions of storage, and on packaging materials []. Carbon dioxide is also used, in combination with oxygen and nitrogen, in protective atmosphere technology to inhibit microbial metabolism over time []. Again, most of the carbon dioxide indicators are colorimetric labels, whose color changes as a function of the pH of the product. Saliu and Della Pergola [] have, for example, studied the performance of a colorimetric indicator composed of a mixture of lysine, polylysine and anthocyanins extracted from red cabbage, tested on cold-preserved foods such as poultry meat. The reversible reaction of amino group of lysine in presence of CO2, leads to the formation of the corresponding carbamic acid derivative, and to a consequent variation in the pH of the solution, which is shown by a significant variation in the color of the anthocyanin dye. In recent years, anthocyanins have attracted the attention of many researchers who have investigated their behavior as natural dyes, in combination with natural-based polymer matrices, for the production of safe, non-toxic, biodegradable, and suitable colorimetric indicators to be use in the food sector [,,].

Gas indicators, mainly in the form of labels or printed directly on the packaging films, are positioned inside the package to monitor changes in the internal gas composition, thus providing a strategy for monitoring the quality and safety of food products [].

Table 6 reports some examples of gas indicators present on the market.

Table 6.

Commercially available gas indicators.

4.2. Sensors

A sensor is a device that responds to a chemical, biological, or physical property by providing a quantifiable signal proportional to the measurement []. The most popular traditional sensors are designed to measure temperature, humidity, pH, and light exposure []. In addition to these, the need to monitor food quality and packaging integrity has led researchers to place a growing interest in applying disposable and advanced sensors (such as edible sensors) for intelligent packaging. Sensor usually consists of four main components: the first part is a receptor (the sensitive part of the sensor), which generally consists of a selective coating that acts as a sampling area that is able to detect the presence, activity, composition, or the concentration of specific chemical analyte by surface adsorption, with consequent modification of a certain property of the coating []. This change is typically detected by the transducer, which is the second part of the sensor, converting the signal change into an output signal. If the transducer requires external power for measurement, the transducer is called “active”, if not, it is called “passive” [,]. Finally, the sensor is completed by a part of electronics for signal processing and a signal display unit [].

The integration of these disposable into food packaging is not simple or immediate; in fact, there are very few products currently on the market, reported in Table 7. This class of intelligent devices has yet to overcome several obstacles before it can reach large-scale marketing. In particular, extensive research efforts are still needed to study the potentially dangerous effects of the chemical and biological components present in the sensor on foods, to avoid any migration of these components, and also to avoid potential changes in taste and consistency of the food products []. Disposable sensors for food packaging should also satisfy the following requirements: selectivity for the target species; sensitivity to changes in target species concentrations; quick response times; small size (miniaturization); low construction cost []; use inexpensive, sustainable or biodegradable materials; be simple to use; operate without or with an affordable, portable instrument []. Furthermore, the approach to sensors is made difficult by the fact that the terms indicators and sensors are often used indiscriminately. In fact, in the literature, the term sensor is often referred to a device capable of detecting a specific analyte, a definition which includes both sensors and indicators. Actually, they represent two very distinct classes of devices []. An indicator, as reported in the previous chapter, checks a condition, and displays it directly by providing qualitative or semi-quantitative information through a visible change that is easy to interpret. On the contrary, a sensor can provide quantitative results and must send the transduced signal to an electronic or logical module for the interpretation of the information []. Sensors intended for food packaging applications can be classified into two macro categories: chemical sensors and biosensors. Each of these two categories can in turn be divided into subclasses based on the method for signal transduction: electrochemical; optical; mechanical; magnetic; thermometric, and microgravimetric.

Table 7.

Commercially available sensors.

Certainly less interesting for food application, mechanical sensors detect physical changes due to stress: they are mainly used to measure physical quantities, such as force, acceleration, pressure, and flow []. Microgravimetry is used to measure mass changes and offers a possible approach for unlabeled detection of biomolecules []. Thermometric sensing devices transduce temperature change into an electrical signal and include: thermocouples, resistance thermometers, thermistors, and diodes []. Magnetic methods are still rarely used in disposable sensing devices []. Instead, some of the most recent chemical sensors or biosensors for food applications are based exclusively on the electrochemical [,,] and optical transduction methods [,]. Therefore, these two types of devices will be discussed in the following paragraphs, in which examples of applications have been reported in order to try to provide a clear and complete picture of this complex class of devices.

This category of devices is usually positioned inside the packaging, separated from food product. The future developments aim to integrate the sensors into the package itself through printed electronics technology [,], using electrically functional inks on flexible substrates (polyamide, PET, transparent conductive polyester, steel, paper) []. This technology has numerous advantages, including the possibility of having lightweight, thin, foldable, portable, and selective sensors [,]. Moreover, the initial problem of the low performance that these devices had shown is finding a solution in the use of nanomaterials [,].

Finally, due to the trend of recent years, it will be possible to find sensors also in contact with food thanks to the formulation of edible sensors, a very particular category of devices that will be addressed at the end of this chapter.

4.2.1. Chemical Sensors

Chemical sensors are the most suitable devices for the realization of intelligent food packaging thanks to the receptor, which is chemically capable of detecting the presence, activity, composition and concentration of a specific chemical molecule, such as volatile organic compounds (VOCs) and gas molecules (H2, CO, NO2, CO2, H2S, etc.), which are primarily responsible for food spoilage [,], especially for meat, fish, fruit and vegetable products. In fact, the composition of gas within food packaging changes due to the activity of the food products, the gas permeability of the packaging material, and the environmental conditions. These changes are directly related to the shelf life, quality, and safety of packaged food []. For this reason, most of the chemical sensors that are being studied are gas sensors based, as mentioned, on electrochemical or optical signal transduction methods. In general, these sensors could be used to replace traditional analysis performed with fixed or portable instruments, such as gas chromatography mass spectrometer or gas analyzers that require breakage of package, do not allow real time measurements and on-line control, and are available for small-scale use. However, chemical sensors currently on the market, are still too large and rigid to be integrated into the packaging, not sufficiently selective and still require a high power (e.g., high operating temperature) []. Furthermore, their marketing in the food sector has so far been hindered by high development and production costs []. However, interesting works can already be found in the literature [,,,], the number of which is constantly growing, confirming the interest of researchers in this field.

4.2.2. Electrochemical-Based Sensors