Utilization of Fermented Rice Milk as a Novel Coagulant for Development of Paneer (Soft Cheese)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection

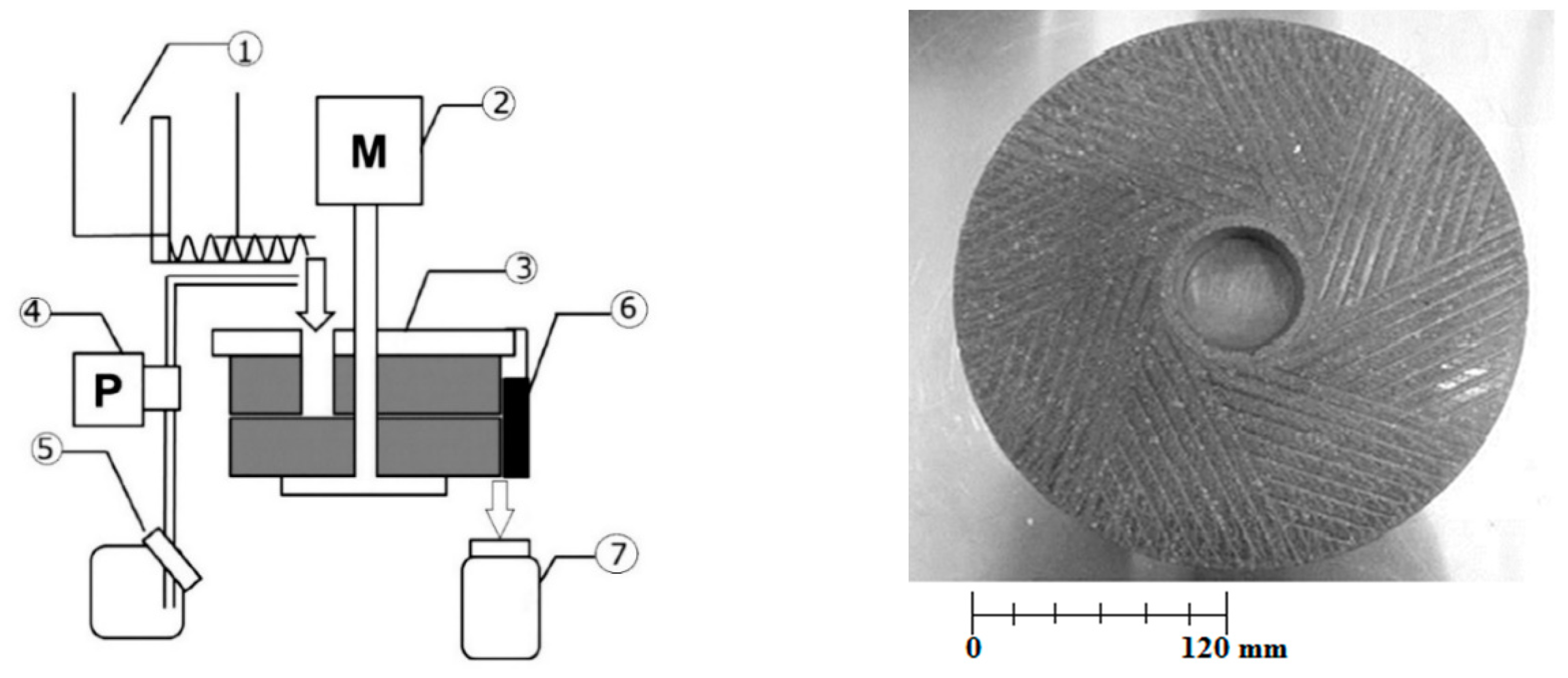

2.2. Production of Rice Milk

2.3. Preparation of Fermented Rice Milk

2.4. Determination of Physical Properties of Rice Milk

2.5. Determination of Total Reducing Sugar, pH, and LA

2.6. Microbial Analysis

2.7. Development of Paneer

2.8. Determination of Moisture Content, Total Yield, and Total Acidity of Paneer

2.9. Color Measurement of Paneer

2.10. Texture Measurement

2.11. Storage Test

2.12. Sensory Evaluation

2.13. Statistical Analysis

3. Results and Discussions

3.1. Physical Properties of Rice Milk

3.2. Properties of Saccharified and Fermented Rice Milk

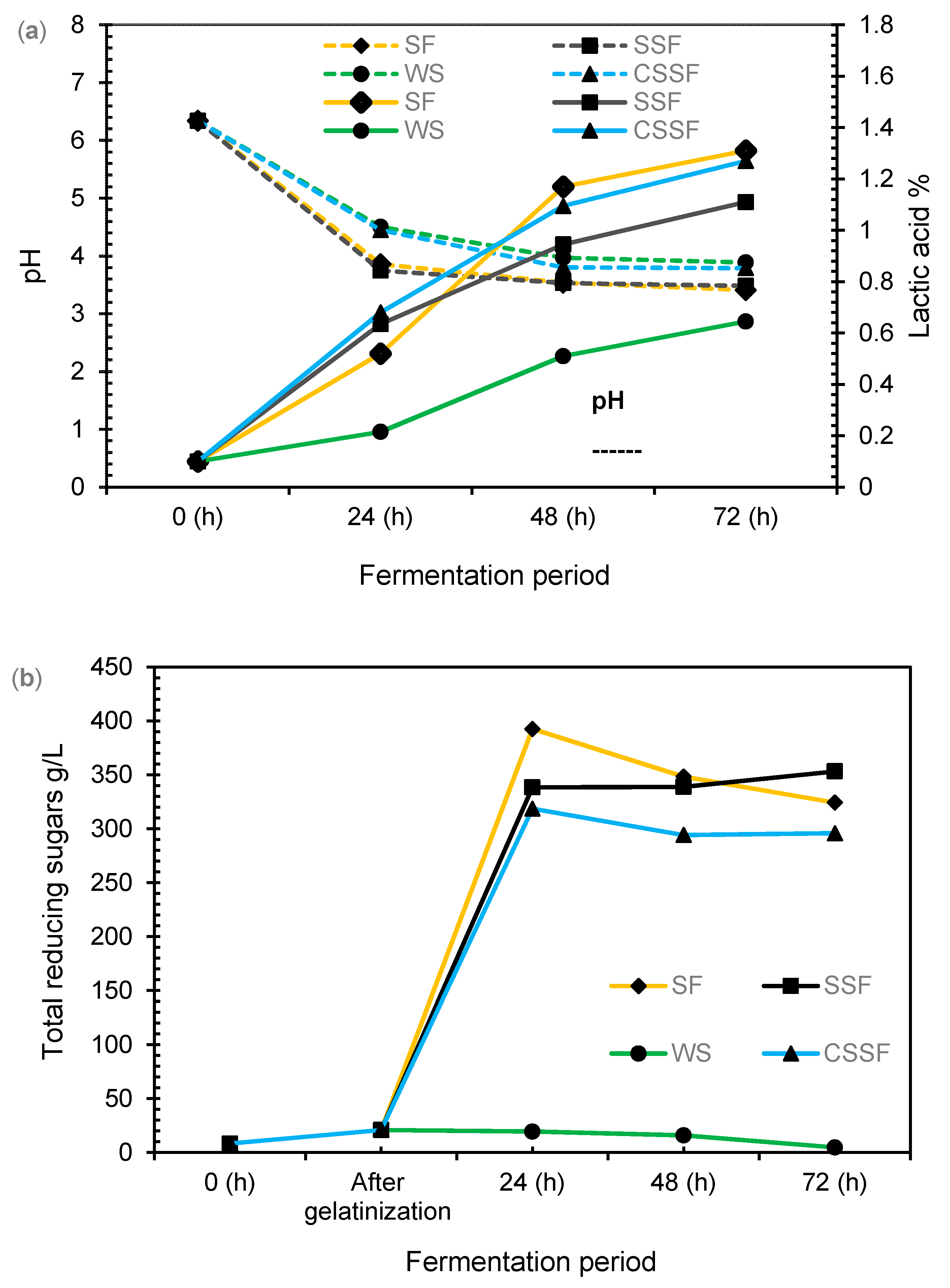

3.2.1. pH and LA Production

3.2.2. Changes in Reducing Sugars

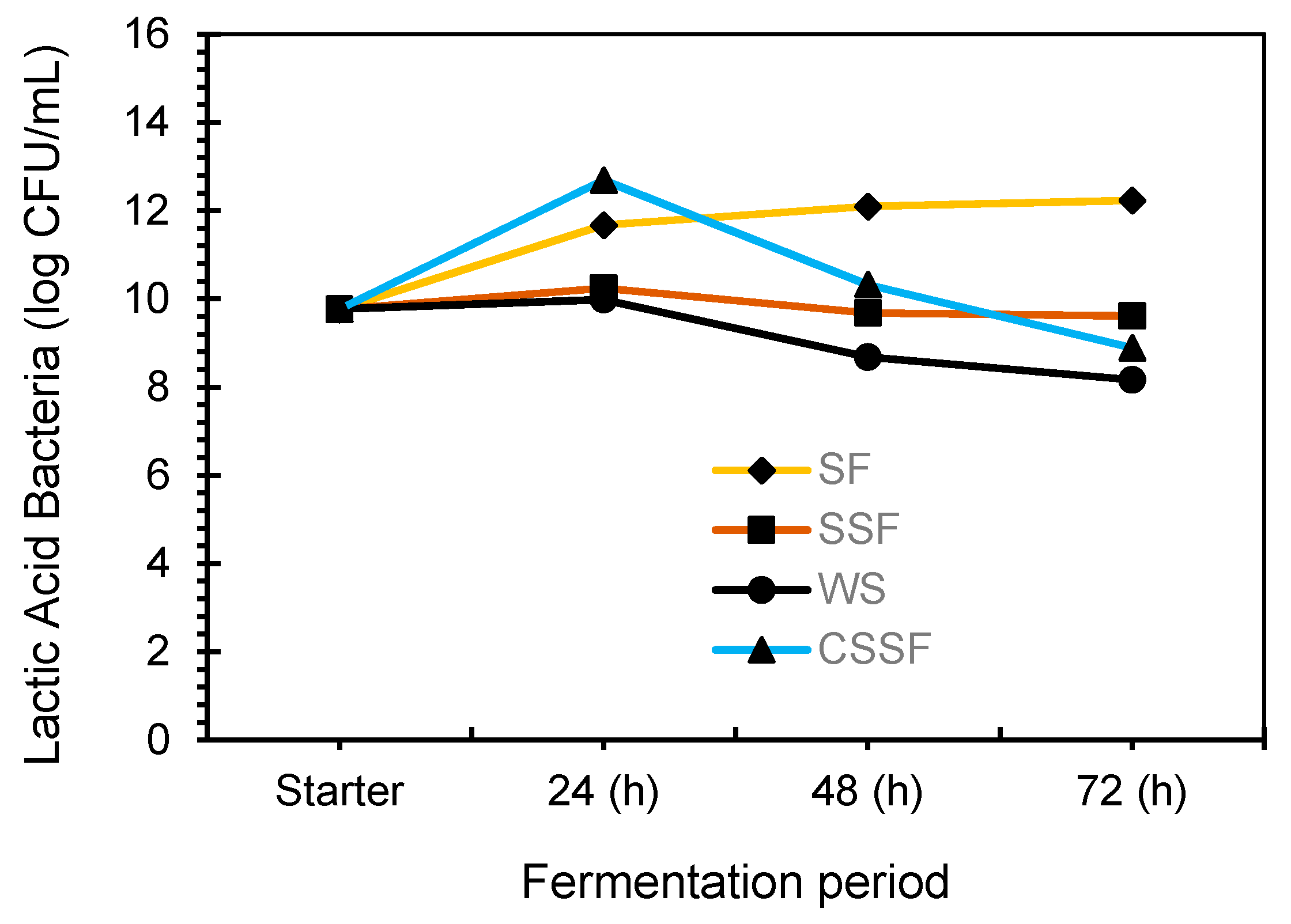

3.2.3. Total Bacterial Count as LAB

3.3. Analysis of Paneer

3.3.1. Ash Content and Total Yield of Paneer

3.3.2. Changes of Moisture during Storage of Paneer

3.3.3. Changes of Total Acidity during Storage of Paneer

3.3.4. Microbial Growth during Storage of Paneer

3.3.5. Texture Analysis during Storage of Paneer

3.3.6. Color Measurements during Storage of Paneer

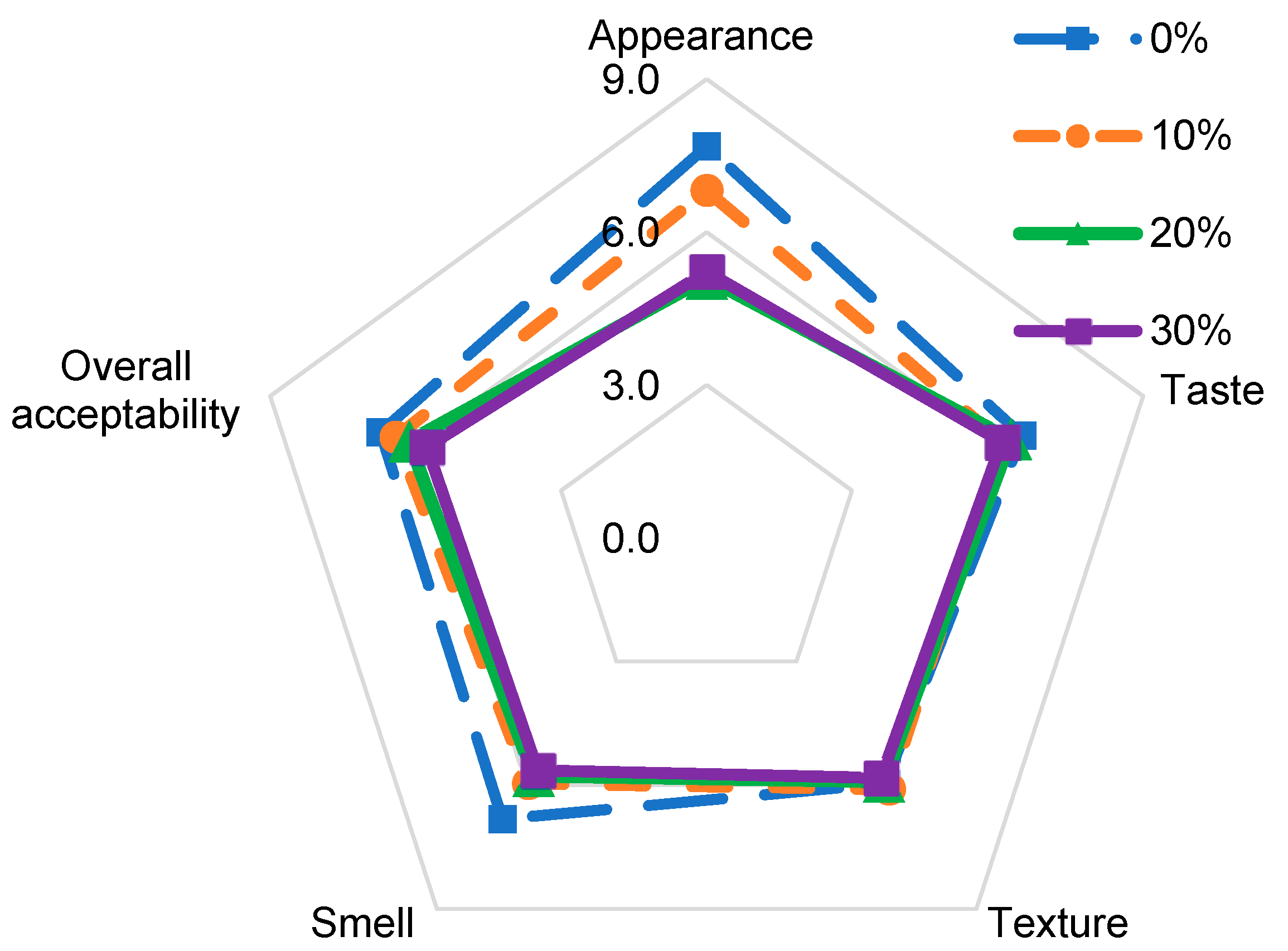

3.3.7. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar, S.; Rai, D.C.; Niranjan, K.; Bhat, Z.F. Paneer—An Indian soft cheese variant: A review. J. Food Sci. Technol. 2014, 51, 821–831. [Google Scholar] [CrossRef] [PubMed]

- Karadbhajne, S.V.; Bhoyarkar, P. Studies on effect of different coagulant on paneer texture prepared from buffalo milk. Int. J. PharmTech Res. 2010, 2, 1916–1923. [Google Scholar]

- Aradhita Ray, A.B.K.; Kaur, A. Studies on Shelf Life Extension of Paneer with the Addition of Plant Essential Oil and Different Packaging Materials. Int. J. Curr. Microbiol. Appl. Sci. 2017, 6, 376–389. [Google Scholar] [CrossRef] [Green Version]

- Thippeswamy, L.; Venkateshaiah, B.V.; Patil, S.B. Effect of modified atmospheric packaging on the shelf stability of paneer prepared by adopting hurdle technology. J. Food Sci. Technol. 2011, 2, 230–235. [Google Scholar] [CrossRef] [PubMed]

- Eresam, E.K.K.; Pinto, S.; Aparnathi, K.D. Concise and informative title: Evaluation of selected spices in extending shelf life of paneer. J. Food Sci. Technol. 2015, 52, 2043–2052. [Google Scholar] [CrossRef] [PubMed]

- Masoodi, F.A. Comparative Study of Soy Paneer Prepared from Soymilk, Blends of Soymilk and Skimmed Milk. J. Food Process. Technol. 2014, 5, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Kandeepan, G.; Sangma, S. Comparison of quality characteristics of full fat and low fat paneer developed from yak milk. Int. J. Dairy Technol. 2011, 64, 117–120. [Google Scholar] [CrossRef]

- Khan, S.U.; Pal, M.A. Effect of different coagulants at varying strengths on the quality of paneer made from reconstituted milk. Assoc. Food Sci. Technol. 2014, 51, 565–570. [Google Scholar] [CrossRef]

- Pawar, D.P.; Das, R.M.; Modi, V.K. Quality characteristics of dehydrated egg yolk paneer and changes during storage. J. Food Sci. Technol. 2012, 49, 475–481. [Google Scholar] [CrossRef]

- Ahmed, A.; Bajwa, U. Composition, texture and microstructure appraisal of paneer coagulated with sour fruit juices. J. Food Sci. Technol. 2019, 56, 253–261. [Google Scholar] [CrossRef]

- Deshmukh, D.S.; Zanjad, P.N.; Pawar, V.D.; MacHewad, G.M. Studies on the use of acidified and cultured whey as coagulant in the manufacture of paneer. Int. J. Dairy Technol. 2009, 62, 174–181. [Google Scholar] [CrossRef]

- Slavin, J.L.; Martini, M.C.; Jacobs, D.R.; Marquart, L. Plausible mechanisms for the protectiveness of whole grains. Am. J. Clin. Nutr. 1999, 70, 459S–463S. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, S.; Chandra, R.; Shukla, S. Process Optimisation and shelf life extension of fiber enriched paneer. Pharma Innov. J. 2016, 5, 77–79. [Google Scholar]

- Koyama, M.; Kitamura, Y. Development of a new rice beverage by improving the physical stability of rice slurry. J. Food Eng. 2014, 131, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Ray, M.; Ghosh, K.; Singh, S.; Chandra Mondal, K. Folk to functional: An explorative overview of rice-based fermented foods and beverages in India. J. Ethn. Foods 2016, 3, 5–18. [Google Scholar] [CrossRef] [Green Version]

- Panesar, R.; Panesar, P.S.; Singh, R.S.; Kennedy, J.F. Hydrolysis of milk lactose in a packed bed reactor system using immobilized yeast cells. J. Chem. Technol. Biotechnol. 2011, 86, 42–46. [Google Scholar] [CrossRef]

- Linko, Y.Y.; Javanainen, P. Simultaneous liquefaction, saccharification, and lactic acid fermentation on barley starch. Enzyme Microb. Technol. 1996, 19, 118–123. [Google Scholar] [CrossRef]

- Maślanka, S.; Kos, A.; Bańczyk, M.; Czopek, I.; Adam, Ł. Study of concentration of lactic acid obtained in the process of lactic fermentation of lactose contained in the spent whey using Lactobacillus. Sci. Tech. 2015, 69, 241–251. [Google Scholar]

- 3MTM PetrifilmTM Interpretation Guide. Available online: https://multimedia.3m.com/mws/media/1251803O/3m-petrifilm-lactic-acid-bacteria-interpretation-guide.pdf (accessed on 26 June 2019).

- Khan, S.U.; Pal, M.A. Paneer production: A review. J. Food Sci. Technol. 2011, 48, 645–660. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- AOAC Official. Official Methods of Analysis of, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1980; Volume 52. [Google Scholar]

- Taghadomi-Saberi, S.; Omid, M.; Emam-Djomeh, Z.; Faraji-Mahyari, K.H. Determination of cherry color parameters during ripening by artificial neural network assisted image processing technique. J. Agric. Sci. Technol. 2015, 17, 589–600. [Google Scholar]

- Jain, S.K.; Mhatre, S.S. The textural properties of soy paneer. Int. J. Dairy Technol. 2009, 62, 584–591. [Google Scholar] [CrossRef]

- Mishra, D.; Rao, K.J.; Bhardwaj, R.; Sutariya, H.; Kavitkar, R.S.; Subhash, W.S. Effect of pH on Sensory, Textural, Microbial Quality and Shelf-life of Paneer. Int. J. Food. Ferment. Technol 2016, 6, 405–414. [Google Scholar] [CrossRef]

- Watanabe, M.; Makino, M.; Kaku, N.; Koyama, M.; Nakamura, K.; Sasano, K. Fermentative l-(+)-lactic acid production from non-sterilized rice washing drainage containing rice bran by a newly isolated lactic acid bacteria without any additions of nutrients. J. Biosci. Bioeng. 2013, 115, 449–452. [Google Scholar] [CrossRef] [PubMed]

- Hassen, Y.; Mukisa, I.M.; Kurabachew, H.; Desalegn, B.B. Evaluation of Yeast and Lactic Acid Bacteria Starter Cultures for the Production of Rice Injera. J. Food Process. Technol. 2018, 9, 1–5. [Google Scholar]

- Wongkhalaung, C.; Boonyaratanakornkit, M. Development of a Yogurt-type Product from Saccharified Rice. Kasetsart J. (Nat. Sci.) 2000, 34, 107–116. [Google Scholar]

- Pleissner, D.; Demichelis, F.; Mariano, S.; Fiore, S.; Navarro Gutiérrez, I.M.; Schneider, R.; Venus, J. Direct production of lactic acid based on simultaneous saccharification and fermentation of mixed restaurant food waste. J. Clean. Prod. 2017, 143, 615–623. [Google Scholar] [CrossRef]

- Khatkar, A.B.; Ray, A.; Kaur, A. Effect of addition of clove essential oil on the storage stability of paneer. Pharma Innov. 2017, 6, 39–44. [Google Scholar]

- Rai, S.; Goyal, G.; Rai, G. Effect of Modified Atmosphere Packaging (MAP) and storage on the chemical quality of paneer. J. Dairying Foods Home Sci. 2008, 27, 33–37. [Google Scholar]

- Agnihotri, M.K.; Pal, U.K. Quality and shelf-life of goat milk Paneer in refrigerated storage. Small Rumin. Res. 1995, 20, 75–81. [Google Scholar] [CrossRef]

- Sonia, S.; Witjaksono, F.; Ridwan, R. Effect of cooling of cooked white rice on resistant starch content and glycemic response. Asia Pac. J. Clin. Nutr. 2015, 24, 620–625. [Google Scholar]

- León, K.; Mery, D.; Pedreschi, F.; León, J. Color measurement in L∗a∗b∗ units from RGB digital images. Food Res. Int. 2006, 39, 1084–1091. [Google Scholar] [CrossRef]

- Maurya, S.B.; Shukla, S.S.; Gour, L. Studies on Physical and Hunter Colour of Gamma Irradiated Tofu (Soy Paneer). Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 2008–2018. [Google Scholar] [CrossRef]

- Punoo, H.A.; Shafi, M.; Baba, W.N. Textural, Physico-chemical, Micro-structural and Antioxidant Properties of Soy Paneer prepared from admixtures of Skim cow milk and Soymilk. Int. J. Adv. Res. Sci. Eng. 2017, 6, 387–400. [Google Scholar]

| Rice Milk (%) | Ash Content (%) | Total Yield (%) |

|---|---|---|

| 0 | 1.19 ± 0.016 c | 21.67 ± 0.24 a |

| 10 | 1.36 ± 0.009 c | 20.02 ± 0.31 b |

| 20 | 1.49 ± 0.002 b | 19.58 ± 0.25 b |

| 30 | 1.78 ± 0.005 a | 19.44 ± 0.99 b |

| Storage Properties | Rice Milk (%) | Storage Period (Days) | ||||

|---|---|---|---|---|---|---|

| 1st | 3rd | 6th | 9th | 12th | ||

| Moisture Content (%) | 0 | 41.51 ± 1.39 a | 40.35 ± 1.52 a | 40.13 ± 1.39 a | 40.04 ± 0.02 a,b | 39.93 ± 0.11 a |

| 10 | 40.39 ± 0.69 a | 40.27 ± 0.28 a | 40.27 ± 0.02 a | 40.07 ± 2.51 a | 39.88 ± 0.23 a | |

| 20 | 41.13 ± 0.61 a | 40.53 ± 0.86 a | 39.47 ± 0.98 a | 39.25 ± 1.28 b | 37.79 ± 1.87 a | |

| 30 | 41.29 ± 0.74 a | 40.79 ± 1.99 a | 39.95 ± 0.55 a | 39.91 ± 0.51 a,b | 37.79 ± 2.27 a | |

| Total Acidity (%) | 0 | 0.161 ± 0.007 a | 0.168 ± 0.007 a | 0.265 ± 0.040 a | 0.342 ± 0.050 a | 0.431 ± 0.070 a |

| 10 | 0.175 ± 0.007 a | 0.155 ± 0.006 b | 0.157 ± 0.007 a,b | 0.165 ± 0.007 b | 0.158 ± 0.020 b | |

| 20 | 0.331 ± 0.004 c | 0.341 ± 0.008 c | 0.356 ± 0.006 b | 0.366 ± 0.017 b | 0.376 ± 0.006 b | |

| 30 | 0.371 ± 0.007 c | 0.378 ± 0.006 c | 0.456 ± 0.009 c | 0.557 ± 0.007 c | 0.657 ± 0.004 c | |

| Microbial growth (log CFU g−1) | 0 | 3.9 ± 0.301 b | 3.7 ± 0.113 b | 3.8 ± 0.030 a | 3.8 ± 0.069 a | 4.1 ± 0.003 a |

| 10 | 4.1 ± 0.088 b | 3.9 ± 0.053 ab | 3.8 ± 0.668 a | 4.1 ± 0.763 a | 4.1 ± 1.398 a | |

| 20 | 4.3 ± 0.140 a,b | 3.9 ± 0.326 a,b | 3.7 ± 0.899 a | 4.1 ± 0.476 a | 4.5 ± 0.498 a | |

| 30 | 4.9 ± 0.041 a | 4.4 ± 0.316 a | 3.7 ± 0.659 a | 4.5 ± 0.667 a | 4.6 ± 1.220 a | |

| Hardness (N) | 0 | 4.56 ± 0.03 a | 4.11 ± 1.05 a | 6.78 ± 0.06 a | 6.23 ± 0.08 a | 5.36 ± 0.53 a |

| 10 | 6.02 ± 0.44 a | 11.30 ± 0.25 a,b | 7.24 ± 0.13 a | 10.54 ± 1.11 a,b | 8.04 ± 0.58 a | |

| 20 | 4.48 ± 0.43 a | 8.16 ± 0.07 b | 7.04 ± 1.18 a | 8.07 ± 1.05 ab | 7.68 ± 0.18 a | |

| 30 | 5.43 ± 0.66 a | 9.38 ± 0.26 c | 7.04 ± 0.47 a | 8.57 ± 1.00 b | 7.49 ± 0.34 b | |

| Rice Milk (%) | Storage Period (Days) | |||||

|---|---|---|---|---|---|---|

| Color Parameter | 1st | 3rd | 6th | 9th | 12th | |

| 0 | L* | 97.910 a | 98.514 a | 97.076 a | 98.912 a | 90.675 a |

| a* | −0.369 a | −0.984 a | −1.252 a | −1.186 a | −1.981 a | |

| b* | 1.373 a | 1.412 a | −0.128 | 3.068 a | 1.193 a | |

| 10 | L* | 98.222 a | 97.117 a | 93.812 a,b | 96.369 a | 92.075 b |

| a* | −1.022 a | −0.945 a | −1.809 a | −1.238 a,b | −0.542 a | |

| b* | 4.284 a,b | 3.059 a | 0.725 a,b | 4.762 a,b | 2.907 a | |

| 20 | L* | 95.712 a | 96.470 a | 97.023 a,b | 95.988 a | 91.404 a,b |

| a* | −1.227 a | −1.218 a,b | −1.281 a | −1.354 a,b | −1.348 a | |

| b* | 7.342 b | 6.653 b | 7.337 b,c | 7.817 b,c | 2.707 b | |

| 30 | L* | 94.380 a | 94.072 a | 93.371 b | 95.848 a | 91.702 a |

| a* | −1.785 a | −1.394 b | −2.060 a | −1.643 b | −0.134 a | |

| b* | 13.858 c | 9.395 c | 9.457 c | 11.455 c | 7.392 a | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amini, R.K.; Islam, M.Z.; Kitamura, Y.; Kokawa, M. Utilization of Fermented Rice Milk as a Novel Coagulant for Development of Paneer (Soft Cheese). Foods 2019, 8, 339. https://doi.org/10.3390/foods8080339

Amini RK, Islam MZ, Kitamura Y, Kokawa M. Utilization of Fermented Rice Milk as a Novel Coagulant for Development of Paneer (Soft Cheese). Foods. 2019; 8(8):339. https://doi.org/10.3390/foods8080339

Chicago/Turabian StyleAmini, Rasool Khan, Md Zohurul Islam, Yutaka Kitamura, and Mito Kokawa. 2019. "Utilization of Fermented Rice Milk as a Novel Coagulant for Development of Paneer (Soft Cheese)" Foods 8, no. 8: 339. https://doi.org/10.3390/foods8080339

APA StyleAmini, R. K., Islam, M. Z., Kitamura, Y., & Kokawa, M. (2019). Utilization of Fermented Rice Milk as a Novel Coagulant for Development of Paneer (Soft Cheese). Foods, 8(8), 339. https://doi.org/10.3390/foods8080339