Nanomaterial Gas Sensors for Online Monitoring System of Fruit Jams

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment Design

2.2. GC–MS SPME Detection

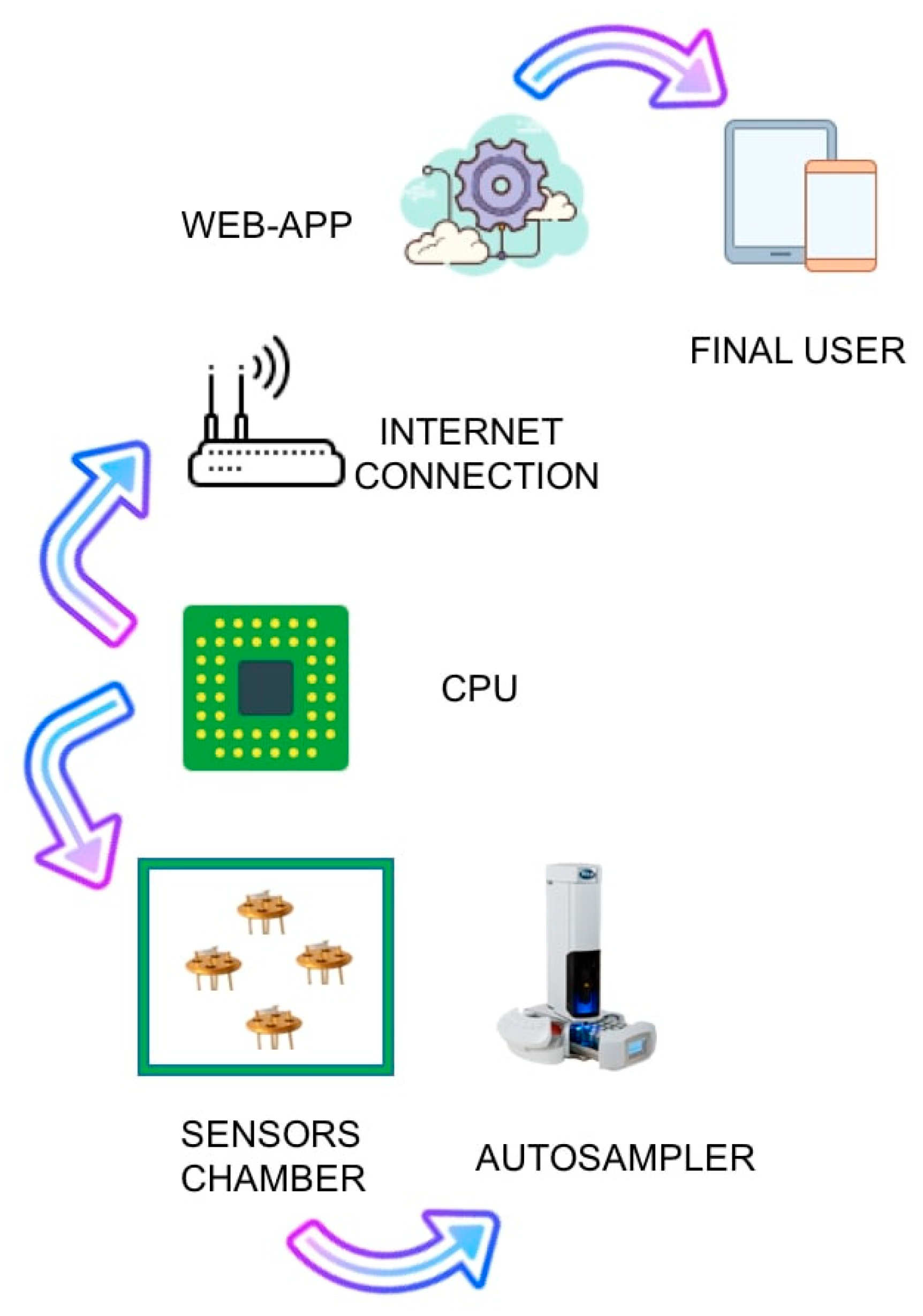

2.3. S3 Detection

2.4. Data Analysis Methods

3. Results and Discussion

3.1. Determination of VOCs

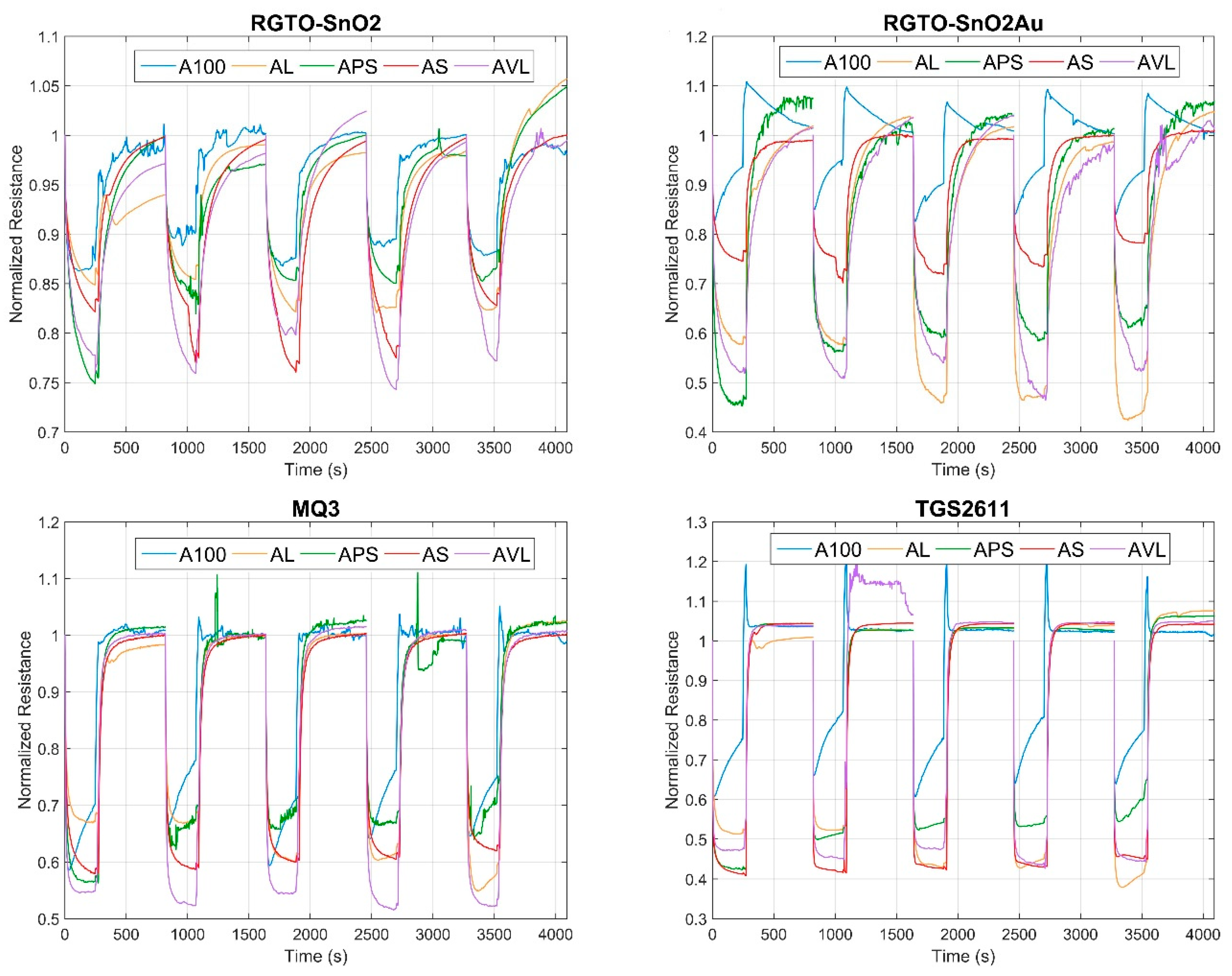

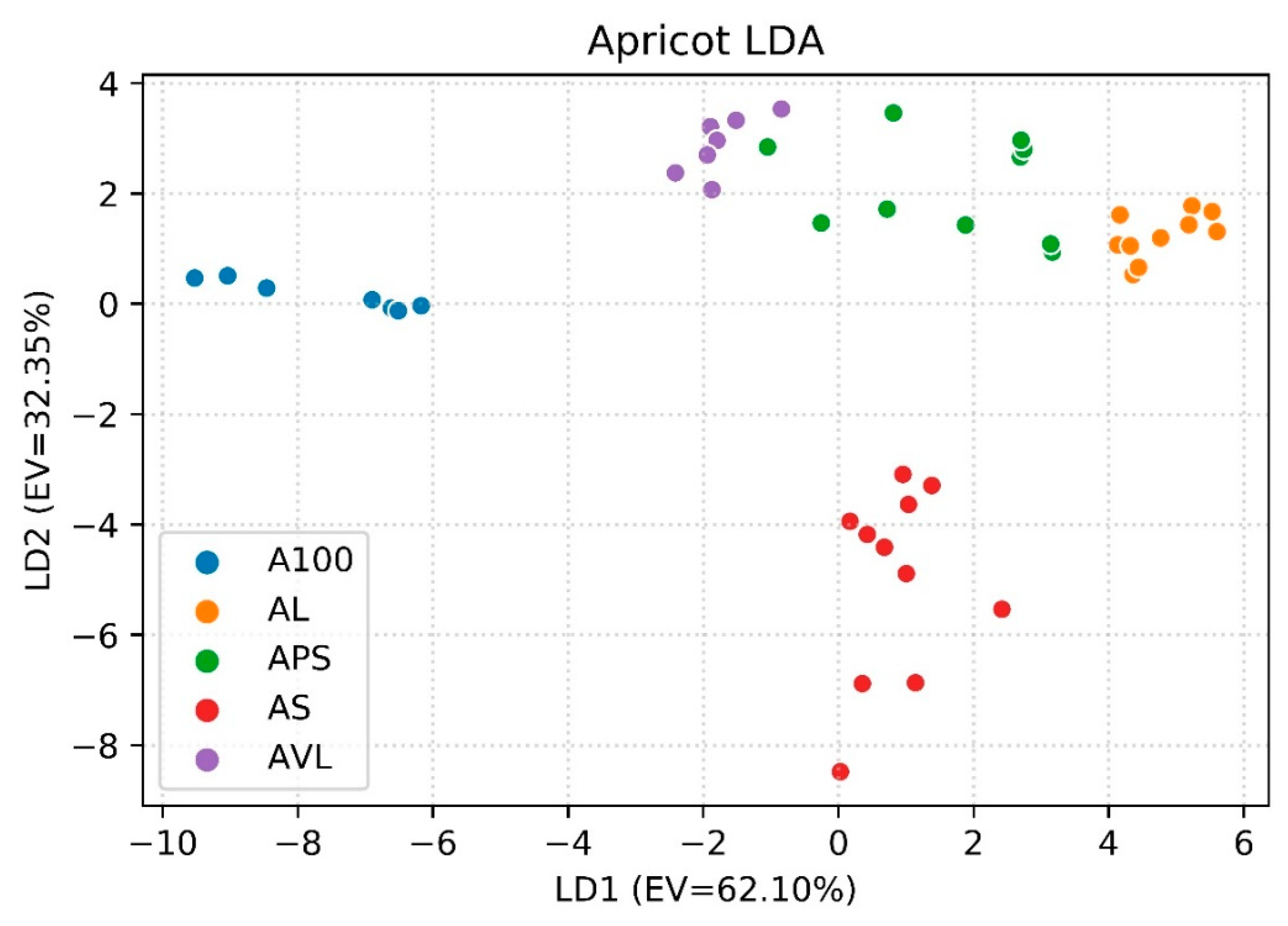

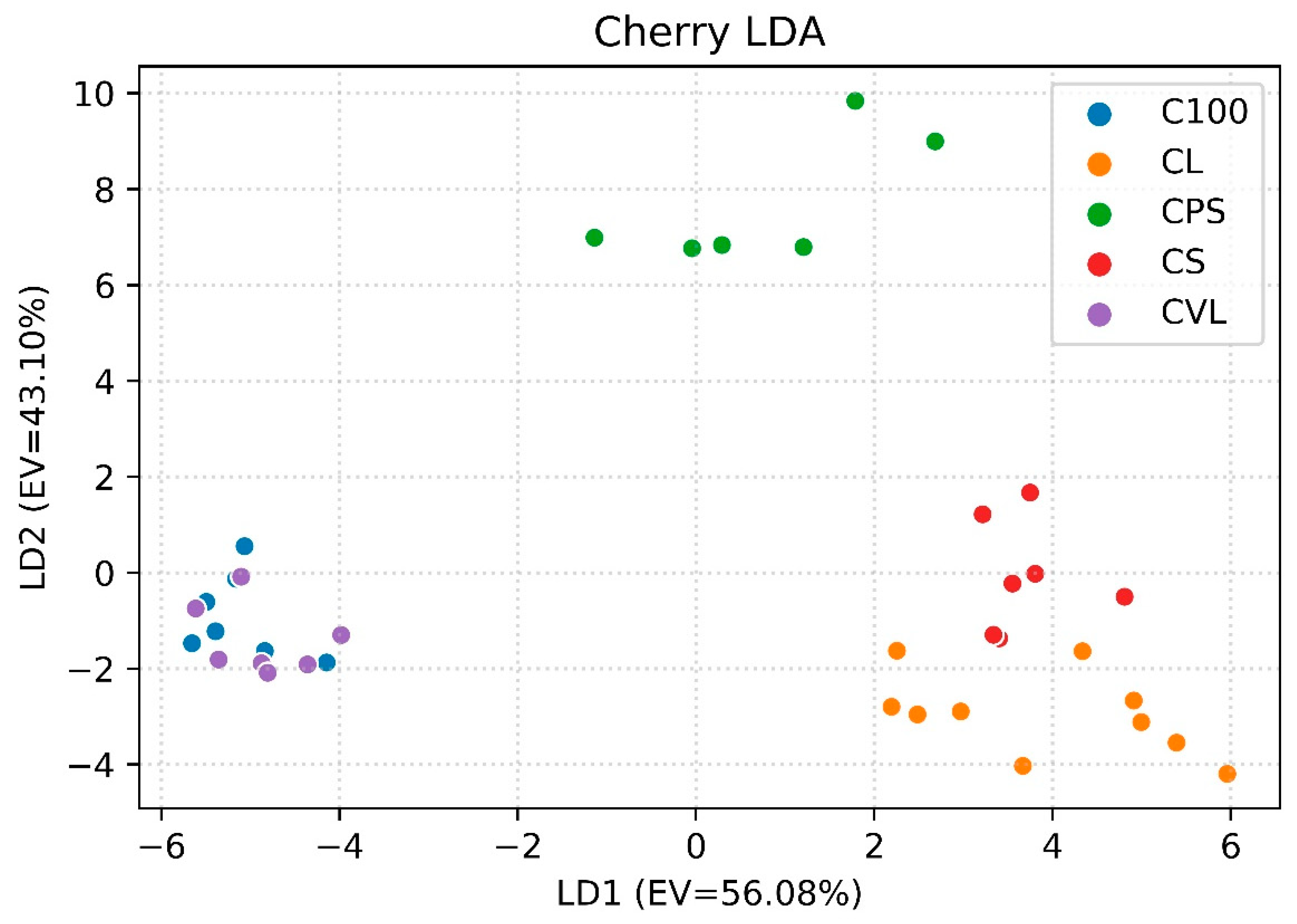

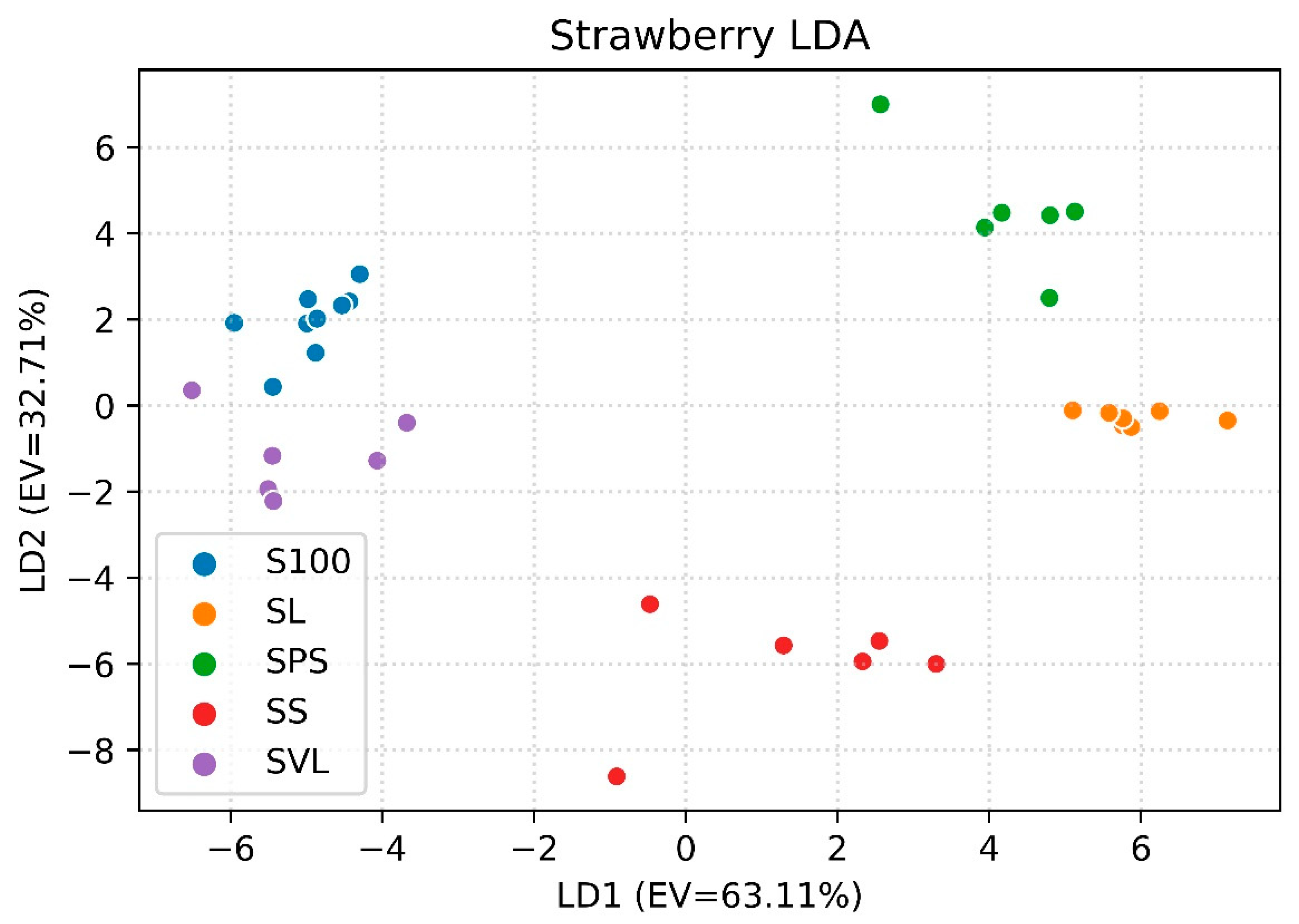

3.2. E-Nose Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Retention Time | Name | Mean |

|---|---|---|

| 1.655 | l-Alanine ethylamide, (S)- | 1.72 × 105 |

| 2.363 | Acetone | 8.67 × 104 |

| 2.980 | 1,3-Propanediol, diacetate | 1.25 × 106 |

| 4.136 | Pentanal | 4.27 × 106 |

| 6.103 | Hexanal | 2.53 × 105 |

| 6.707 | 2H-Pyran, 2-ethenyltetrahydro-2,6,6-trimethyl- | 1.21 × 106 |

| 9.000 | Cyclohexene, 1-methyl-5-(1-methylethenyl)-, (R)- | 2.22 × 105 |

| 9.150 | Eucalyptol | 1.76 × 105 |

| 9.455 | 4-Ethylbenzoic acid, 1-(cyclopentyl)ethyl ester | 1.68 × 105 |

| 10.310 | 5-Decen-1-ol, (E)- | 4.43 × 105 |

| 10.502 | 1-Pentanol | 4.96 × 105 |

| 11.248 | (+)-4-Carene | 2.92 × 105 |

| 11.319 | Acetoin | 1.97 × 105 |

| 11.717 | 1-Butanol, 2-methyl-, acetate | 3.27 × 105 |

| 11.786 | Hexane, 3-ethyl- | 6.91 × 104 |

| 11.964 | Cyclohexanone, 2,2,6-trimethyl- | 5.02 × 105 |

| 12.200 | 2-Buten-1-ol, 3-methyl- | 4.76 × 105 |

| 12.305 | 2,5-Octanedione | 3.58 × 105 |

| 12.523 | 5-Hepten-2-one, 6-methyl- | 1.37 × 106 |

| 13.261 | Cyclopropane, trimethyl(2-methyl-1-propenylidene)- | 5.67 × 104 |

| 13.682 | Nonanal | 1.62 × 105 |

| 13.748 | 1H-Pyrazole, 4,5-dihydro-5,5-dimethyl-4-isopropylidene- | 4.91 × 105 |

| 13.885 | Propanenitrile, 3-(1-methylethoxy)- | 1.02 × 105 |

| 14.000 | Ethane, 1,2-bis[(4-amino-3-furazanyl)oxy]- | 1.34 × 105 |

| 14.148 | Benzene, 1-cyclopropylmethyl-4-(1-methylethyl)- | 1.08 × 105 |

| 14.194 | Benzene, 1-cyclohexyl-3-methyl- | 4.04 × 104 |

| 14.255 | 2-Octenal, (E)- | 1.75 × 105 |

| 14.465 | α-Methyl-α-[4-methyl-3-pentenyl]oxiranemethanol | 1.55 × 106 |

| 14.527 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 5.00 × 105 |

| 14.689 | Acetic acid | 6.19 × 106 |

| 14.931 | Furfural | 3.52 × 107 |

| 15.244 | 1-Hexanol, 2-ethyl- | 2.50 × 105 |

| 15.573 | Ethanone, 1-(2-furanyl)- | 1.72 × 106 |

| 15.881 | Benzaldehyde | 3.08 × 106 |

| 16.143 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 3.03 × 107 |

| 16.286 | Naphthalene, 1,2,3,4-tetrahydro-1,1,6-trimethyl- | 6.42 × 105 |

| 16.605 | 2-Furancarboxaldehyde, 5-methyl- | 8.24 × 105 |

| 16.838 | Bicyclo[6.1.0]nonane, 9,9-dichloro- | 1.24 × 105 |

| 16.974 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 6.27 × 105 |

| 17.049 | 5,7-Octadien-2-ol, 2,6-dimethyl- | 5.47 × 105 |

| 17.272 | 1-Cyclohexene-1-carboxaldehyde, 2,6,6-trimethyl- | 1.44 × 106 |

| 17.441 | 2(5H)-Furanone, 4,5,5-trimethyl-3-(3-methyl-2-methylenebutyl)- | 2.03 × 106 |

| 17.502 | 1-methyl-4-(prop-1-en-2-yl)-7-oxabicyclo[4.1.0]heptan-2one | 4.42 × 105 |

| 17.770 | 2-Furanmethanol | 5.34 × 105 |

| 17.896 | Butanoic acid, 2-methyl- | 1.80 × 106 |

| 18.247 | L-α-Terpineol | 1.76 × 107 |

| 18.383 | Hexanoic acid, anhydride | 8.31 × 105 |

| 18.789 | 2,6-Octadiene, 1-(1-ethoxyethoxy)-3,7-dimethyl- | 2.59 × 105 |

| 18.968 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 1.14 × 106 |

| 19.276 | Dodecanedioic acid, bis(tert-butyldimethylsilyl) ester | 5.03 × 104 |

| 20.067 | Cyclopentaneundecanoic acid | 2.80 × 106 |

| 20.226 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 8.05 × 105 |

| 20.366 | 7-Octen-3-ol, 2,3,6-trimethyl- | 5.37 × 104 |

| 20.504 | Benzyl alcohol | 3.60 × 105 |

| 20.703 | 4-Acetyl-1-methylcyclohexene | 2.59 × 105 |

| 20.911 | Phenylethyl Alcohol | 3.78 × 105 |

| 21.252 | trans-β-Ionone | 9.88 × 105 |

| 21.433 | Bromoacetic acid, dodecyl ester | 3.20 × 105 |

| 21.790 | 4-Hexen-1-ol, 6-(2,6,6-trimethyl-1-cyclohexenyl)-4-methyl-, (E)- | 1.93 × 105 |

| 21.956 | Carbamic acid, phenyl ester | 1.90 × 105 |

| 22.244 | Nerolidyl acetate | 1.32 × 106 |

| 22.300 | 1,6,10-Dodecatrien-3-ol, 3,7,11-trimethyl-, [S-(Z)]- | 1.34 × 105 |

| 22.461 | Octanoic acid | 2.22 × 105 |

| 23.517 | 2(3H)-Furanone, 5-hexyldihydro- | 7.04 × 105 |

| 25.625 | 2(4H)-Benzofuranone, 5,6,7,7a-tetrahydro-4,4,7a-trimethyl- | 4.59 × 105 |

| 25.780 | gamma.-Dodecalactone | 5.03 × 104 |

| 26.326 | Benzoic acid | 4.44 × 105 |

| 26.615 | Tridecanoic acid | 6.65 × 104 |

| 26.890 | 5-Hydroxymethylfurfural | 1.52 × 105 |

| 26.973 | 2-tert-Butyl-4-hexylphenol | 4.69 × 104 |

| 27.331 | 1,2-Benzenedicarboxylic acid, bis(2-methylpropyl) ester | 2.48 × 105 |

| 27.729 | di(Butoxyethyl)adipate | 2.41 × 105 |

| 28.857 | Phosphine, 1,3-propanediylbis[bis(1-methylethyl)- | 6.88 × 104 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.390 | 2-Hexanone, 4-hydroxy-5-methyl-3-propyl- | 2.07 × 105 |

| 6.146 | Hexanal | 1.99 × 106 |

| 6.703 | 2H-Pyran, 2-ethenyltetrahydro-2,6,6-trimethyl- | 9.72 × 105 |

| 10.333 | 9-Dodecen-1-ol, acetate, (Z)- | 3.72 × 105 |

| 11.344 | Acetoin | 3.12 × 105 |

| 11.990 | Cyclohexanone, 2,2,6-trimethyl- | 4.54 × 105 |

| 12.214 | 2-Heptenal, (Z)- | 4.12 × 105 |

| 12.544 | 5-Hepten-2-one, 6-methyl- | 1.69 × 106 |

| 13.644 | Nonanal | 3.00 × 105 |

| 13.769 | 1H-Pyrazole, 4,5-dihydro-5,5-dimethyl-4-isopropylidene- | 9.69 × 105 |

| 14.037 | 1,3-Hexadiene, 3-ethyl-2-methyl- | 3.06 × 105 |

| 14.279 | 2-Octenal, (E)- | 3.51 × 105 |

| 14.485 | α-Methyl-α-[4-methyl-3-pentenyl]oxiranemethanol | 2.01 × 106 |

| 14.711 | Acetic acid | 5.22 × 106 |

| 14.951 | Furfural | 1.46 × 107 |

| 15.264 | 1-Hexanol, 2-ethyl- | 2.11 × 105 |

| 15.378 | 2,4-Heptadienal, (E,E)- | 1.14 × 105 |

| 15.903 | Benzaldehyde | 2.64 × 106 |

| 16.160 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 2.66 × 107 |

| 16.365 | Naphthalene, 1,2,3,4-tetrahydro-1,1,6-trimethyl- | 3.91 × 105 |

| 16.630 | 2-Furancarboxaldehyde, 5-methyl- | 2.51 × 105 |

| 16.766 | 3-Buten-2-ol, 4-(2,6,6-trimethyl-1-cyclohexen-1-yl)- | 1.80 × 105 |

| 16.994 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 1.13 × 106 |

| 17.292 | 1-Cyclohexene-1-carboxaldehyde, 2,6,6-trimethyl- | 1.82 × 106 |

| 17.461 | 1-methyl-4-(prop-1-en-2-yl)-7-oxabicyclo[4.1.0]heptan-2one | 1.11 × 106 |

| 17.913 | Butanoic acid, 2-methyl- | 9.28 × 105 |

| 18.266 | L-α-Terpineol | 1.97 × 107 |

| 19.006 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 7.98 × 105 |

| 19.754 | Bicyclo[3.1.0]hexane-6-methanol, 2-hydroxy-1,4,4-trimethyl- | 1.25 × 105 |

| 20.088 | Cyclopentaneundecanoic acid | 2.59 × 106 |

| 20.245 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 1.11 × 106 |

| 20.523 | Benzyl alcohol | 4.97 × 105 |

| 20.719 | 4-Acetyl-1-methylcyclohexene | 3.23 × 105 |

| 20.933 | Phenylethyl Alcohol | 2.65 × 105 |

| 21.276 | trans-β-Ionone | 1.26 × 106 |

| 21.990 | 4-(2,4,4-Trimethyl-cyclohexa-1,5-dienyl)-but-3-en-2-one | 1.69 × 105 |

| 22.262 | 1,6,10-Dodecatrien-3-ol, 3,7,11-trimethyl-, [S-(Z)]- | 1.92 × 105 |

| 22.482 | Octanoic acid | 1.83 × 105 |

| 23.537 | 2(3H)-Furanone, 5-hexyldihydro- | 4.82 × 105 |

| 25.648 | 2(4H)-Benzofuranone, 5,6,7,7a-tetrahydro-4,4,7a-trimethyl- | 6.93 × 105 |

| 26.342 | Benzoic acid | 7.11 × 105 |

| 26.630 | Tridecanoic acid | 1.04 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 4.129 | Pentanal | 4.47 × 106 |

| 6.164 | Hexanal | 8.99 × 105 |

| 6.723 | 2H-Pyran, 2-ethenyltetrahydro-2,6,6-trimethyl- | 5.27 × 106 |

| 9.027 | Cyclobutane, 1,2-bis(1-methylethenyl)-, trans- | 3.34 × 106 |

| 9.452 | Z-7-Decen-1-yl acetate | 1.68 × 106 |

| 10.333 | Bicyclo[3.1.0]hexane-6-methanol, 2-hydroxy-1,4,4-trimethyl- | 2.46 × 106 |

| 11.274 | (+)-4-Carene | 1.05 × 106 |

| 11.729 | 2-Propanone, 1-hydroxy- | 5.09 × 105 |

| 11.995 | Cyclohexanone, 2,2,6-trimethyl- | 8.28 × 105 |

| 12.325 | 2,5-Octanedione | 5.20 × 105 |

| 12.554 | 5-Hepten-2-one, 6-methyl- | 2.13 × 106 |

| 13.284 | 1,5,5-Trimethyl-6-methylene-cyclohexene | 3.09 × 105 |

| 13.654 | Nonanal | 5.36 × 105 |

| 13.775 | Isophorone | 7.89 × 105 |

| 14.169 | (1,4-Dimethylpent-2-enyl)benzene | 1.53 × 106 |

| 14.494 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 5.08 × 106 |

| 14.712 | Acetic acid | 4.14 × 106 |

| 14.958 | Furfural | 5.87 × 107 |

| 15.273 | 1-Hexanol, 2-ethyl- | 1.43 × 106 |

| 15.602 | Ethanone, 1-(2-furanyl)- | 2.85 × 106 |

| 15.853 | Benzaldehyde | 5.58 × 106 |

| 16.169 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 3.27 × 107 |

| 16.326 | Naphthalene, 1,2,3,4-tetrahydro-1,1,6-trimethyl- | 4.60 × 106 |

| 16.644 | 2-Furancarboxaldehyde, 5-methyl- | 1.56 × 106 |

| 16.732 | Megastigma-4,6(E),8(Z)-triene | 5.55 × 105 |

| 16.999 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 1.35 × 106 |

| 17.075 | 7-Octen-2-ol, 2-methyl-6-methylene- | 1.31 × 106 |

| 17.303 | 1-Cyclohexene-1-carboxaldehyde, 2,6,6-trimethyl- | 5.52 × 106 |

| 17.474 | 3-Buten-2-one, 3-methyl-4-(1,3,3-trimethyl-7-oxabicyclo[4.1.0]heptan-1-yl)- | 2.22 × 106 |

| 17.791 | 2-Furanmethanol | 6.00 × 105 |

| 17.968 | Benzene, 1,2,3,4-tetramethyl-4-(1-methylethenyl)- | 1.47 × 106 |

| 18.014 | L-α-Terpineol | 3.94 × 107 |

| 18.791 | Dodecanedioic acid, bis(tert-butyldimethylsilyl) ester | 2.13 × 105 |

| 18.999 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 3.89 × 106 |

| 20.095 | Geraniol | 2.88 × 106 |

| 20.257 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 7.75 × 105 |

| 20.526 | 2-Caren-10-al | 7.88 × 105 |

| 20.731 | 4-Acetyl-1-methylcyclohexene | 7.88 × 105 |

| 20.942 | Phenylethyl Alcohol | 5.97 × 105 |

| 21.285 | trans-β-Ionone | 1.44 × 106 |

| 21.808 | Calarene epoxide | 6.02 × 105 |

| 23.545 | 2(3H)-Furanone, 5-hexyldihydro- | 7.06 × 105 |

| 26.346 | Benzoic acid | 9.42 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.389 | Acetone | 5.95 × 105 |

| 2.978 | Ethyl Acetate | 2.50 × 106 |

| 4.160 | Pentanal | 8.99 × 105 |

| 6.176 | Hexanal | 8.03 × 105 |

| 6.775 | 2H-Pyran, 2-ethenyltetrahydro-2,6,6-trimethyl- | 7.54 × 105 |

| 9.439 | 1-Butanol, 3-methyl- | 4.50 × 105 |

| 10.384 | 3-Tridecene | 3.94 × 105 |

| 11.780 | 5,9-Dodecadien-2-one, 6,10-dimethyl-, (E,E))- | 2.58 × 105 |

| 12.052 | Cyclohexanone, 2,2,6-trimethyl- | 4.63 × 105 |

| 12.267 | 2-Heptenal, (Z)- | 3.15 × 105 |

| 12.377 | 2,5-Hexanedione | 2.04 × 105 |

| 12.599 | 5-Hepten-2-one, 6-methyl- | 1.25 × 106 |

| 13.816 | Isophorone | 6.51 × 105 |

| 14.092 | 1,3-Hexadiene, 3-ethyl-2-methyl- | 1.77 × 105 |

| 14.324 | 2-Octenal, (E)- | 9.62 × 104 |

| 14.529 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 1.35 × 106 |

| 14.773 | Acetic acid | 3.04 × 106 |

| 14.999 | Furfural | 2.40 × 107 |

| 15.644 | Ethanone, 1-(2-furanyl)- | 1.31 × 106 |

| 15.947 | Benzaldehyde | 3.03 × 106 |

| 16.201 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 3.80 × 106 |

| 16.346 | Nonanoic acid, hexyl ester | 9.07 × 105 |

| 16.685 | 2-Furancarboxaldehyde, 5-methyl- | 5.97 × 105 |

| 17.051 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 6.28 × 105 |

| 17.334 | 1-Cyclohexene-1-carboxaldehyde, 2,6,6-trimethyl- | 1.44 × 106 |

| 17.513 | 2-Dodecenoic acid | 3.84 × 105 |

| 17.837 | 2-Furanmethanol | 3.15 × 105 |

| 17.972 | Methyl 4-hydroxybutanoate | 7.85 × 105 |

| 18.311 | L-α-Terpineol | 4.16 × 106 |

| 18.495 | Heptanoic acid, 2-(acetyloxy)-, methyl ester | 3.10 × 105 |

| 19.036 | Oxime-, methoxy-phenyl-_ | 8.00 × 105 |

| 20.140 | Heptanoic acid | 1.15 × 106 |

| 20.285 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 5.00 × 105 |

| 20.568 | Benzyl alcohol | 3.02 × 105 |

| 20.766 | 4-Acetyl-1-methylcyclohexene | 1.18 × 105 |

| 20.970 | Butylated Hydroxytoluene | 3.31 × 105 |

| 21.315 | trans-β-Ionone | 8.17 × 105 |

| 21.499 | 1-Dodecanol | 2.48 × 105 |

| 21.815 | Orcinol | 9.89 × 104 |

| 22.305 | 1,6,10-Dodecatrien-3-ol, 3,7,11-trimethyl-, [S-(Z)]- | 1.76 × 105 |

| 22.533 | Octanoic acid | 2.29 × 105 |

| 23.644 | Tridecanoic acid | 3.83 × 105 |

| 24.685 | n-Decanoic acid | 1.09 × 105 |

| 25.712 | 2(4H)-Benzofuranone, 5,6,7,7a-tetrahydro-4,4,7a-trimethyl- | 3.01 × 105 |

| 26.432 | Benzoic acid | 2.70 × 105 |

| 26.555 | 5H-1-Pyrindine | 5.57 × 105 |

| 26.691 | Dodecanoic acid | 1.15 × 105 |

| 26.980 | 5-Hydroxymethylfurfural | 2.12 × 105 |

| 27.813 | Decanoic acid, decyl ester | 3.59 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.394 | Acetone | 4.03 × 106 |

| 3.110 | Ethyl Acetate | 3.14 × 106 |

| 4.127 | Pentanal | 2.52 × 106 |

| 6.126 | Hexanal | 2.12 × 106 |

| 6.684 | 2H-Pyran, 2-ethenyltetrahydro-2,6,6-trimethyl- | 1.56 × 106 |

| 9.437 | 3-Dodecyne | 7.22 × 105 |

| 10.308 | 3-Tridecene | 8.45 × 105 |

| 11.327 | Acetoin | 2.37 × 105 |

| 11.708 | 1-Butanol, 2-methyl-, acetate | 5.35 × 105 |

| 11.976 | Cyclohexanone, 2,2,6-trimethyl- | 9.01 × 105 |

| 12.200 | 2-Heptenal, (Z)- | 7.19 × 105 |

| 12.524 | 5-Hepten-2-one, 6-methyl- | 1.84 × 106 |

| 13.633 | Nonanal | 2.16 × 105 |

| 13.755 | 1H-Pyrazole, 4,5-dihydro-5,5-dimethyl-4-isopropylidene- | 1.11 × 106 |

| 14.023 | 1,3-Hexadiene, 3-ethyl-2-methyl- | 3.06 × 105 |

| 14.142 | (1,4-Dimethylpent-2-enyl)benzene | 2.37 × 105 |

| 14.267 | 2-Octenal, (E)- | 3.15 × 105 |

| 14.349 | 3-Furaldehyde | 4.23 × 105 |

| 14.469 | α-Methyl-α-[4-methyl-3-pentenyl]oxiranemethanol | 3.01 × 106 |

| 14.671 | Ammonium acetate | 9.60 × 106 |

| 14.932 | Furfural | 4.37 × 107 |

| 15.365 | 2,4-Heptadienal, (E,E)- | 1.60 × 105 |

| 15.578 | Ethanone, 1-(2-furanyl)- | 2.67 × 106 |

| 15.876 | Benzaldehyde | 7.65 × 106 |

| 16.143 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 4.83 × 106 |

| 16.303 | Naphthalene, 1,2,3,4-tetrahydro-1,1,6-trimethyl- | 9.30 × 105 |

| 16.615 | 2-Furancarboxaldehyde, 5-methyl- | 1.42 × 106 |

| 16.840 | Furo[3,4-b]furan-2,6(3H,4H)-dione, 4-ethyldihydro-3-methylene-, [3aR-(3aα,4β,6aα)]- | 2.39 × 105 |

| 16.976 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 8.61 × 105 |

| 17.276 | 3-Cyclohexene-1-carboxaldehyde, 1,3,4-trimethyl- | 1.85 × 106 |

| 17.444 | 3-Buten-2-one, 3-methyl-4-(1,3,3-trimethyl-7-oxabicyclo[4.1.0]heptan-1-yl)- | 7.53 × 105 |

| 17.760 | 2-Furanmethanol | 2.59 × 105 |

| 17.884 | Butanoic acid, 2-methyl- | 2.79 × 106 |

| 18.151 | Bicyclo[3.2.2]non-8-en-6-ol, (1R,5-cis,6-cis)- | 7.08 × 105 |

| 18.249 | L-α-Terpineol | 1.08 × 107 |

| 18.839 | Propanedioic acid, propyl- | 5.68 × 105 |

| 19.029 | Naphthalene, 1,2-dihydro-2,5,8-trimethyl- | 5.14 × 105 |

| 19.275 | Dodecanedioic acid, bis(tert-butyldimethylsilyl) ester | 1.76 × 105 |

| 19.950 | 4-Methylphenyl acetone | 1.61 × 105 |

| 20.067 | Heptanoic acid | 8.70 × 105 |

| 20.228 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (E)- | 5.53 × 105 |

| 20.500 | Benzyl alcohol | 6.87 × 105 |

| 20.708 | 4-Acetyl-1-methylcyclohexene | 2.21 × 105 |

| 20.926 | 3,5-Octadiene, 4,5-diethyl-, (E,Z)- | 2.10 × 105 |

| 21.257 | trans-β-Ionone | 1.12 × 106 |

| 21.466 | Cyclopentanol, 1,2-dimethyl-3-(1-methylethenyl)-, [1R-(1α,2β,3α)]- | 3.23 × 105 |

| 21.746 | 2,5-Furandicarboxaldehyde | 2.24 × 105 |

| 21.954 | Carbamic acid, N-(3-ethylphenyl)-, phenyl ester | 2.96 × 105 |

| 22.076 | 3-Furancarboxylic acid, methyl ester | 3.27 × 105 |

| 22.247 | 1,6,10-Dodecatrien-3-ol, 3,7,11-trimethyl- | 3.16 × 105 |

| 22.455 | Octanoic acid | 2.15 × 105 |

| 23.583 | 2(3H)-Furanone, 5-hexyldihydro- | 3.83 × 105 |

| 24.988 | Phenol, 2,4-bis(1,1-dimethylethyl)- | 2.94 × 105 |

| 25.624 | 2(4H)-Benzofuranone, 5,6,7,7a-tetrahydro-4,4,7a-trimethyl- | 4.65 × 105 |

| 26.270 | Benzoic acid | 1.53 × 107 |

| 26.889 | 5-Hydroxymethylfurfural | 6.05 × 105 |

| 27.803 | 4a,8a-Butano[1,4]dioxino[2,3-b]-1,4-dioxin, tetrahydro- | 1.45 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 1.835 | D-Alanine | 2.19 × 105 |

| 2.118 | Dimethyl sulfide | 2.55 × 105 |

| 4.207 | Pentanal | 9.61 × 106 |

| 5.183 | Butanoic acid, ethyl ester | 9.08 × 105 |

| 5.811 | 1-Penten-3-one, 2-methyl- | 1.53 × 106 |

| 5.853 | Benzothiophene-3-carboxylic acid, 4,5,6,7-tetrahydro-6-tert-butyl-2-cyclopropanoylamino-, ethyl ester | 7.09 × 104 |

| 6.121 | Hexanal | 2.94 × 106 |

| 7.200 | 3-Penten-2-one, (E)- | 5.80 × 105 |

| 7.664 | 3-Carene | 1.31 × 105 |

| 10.180 | Hexanoic acid, ethyl ester | 1.81 × 105 |

| 10.560 | 1-Pentanol | 5.81 × 105 |

| 11.401 | Acetoin | 5.90 × 105 |

| 11.449 | Octanal | 6.62 × 105 |

| 11.791 | 1-Octen-3-one | 1.82 × 106 |

| 12.261 | 2-Heptenal, (Z)- | 4.58 × 106 |

| 12.365 | 5-Hepten-2-one, 6-methyl- | 2.30 × 106 |

| 12.685 | 1-Hexanol | 1.76 × 105 |

| 13.682 | Nonanal | 4.64 × 105 |

| 13.888 | 2-Decen-1-ol, (E)- | 1.08 × 106 |

| 14.020 | 1,3-Hexadiene, 3-ethyl-2-methyl- | 1.20 × 105 |

| 14.322 | 2-Octenal, (E)- | 1.47 × 106 |

| 14.522 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 6.66 × 105 |

| 14.756 | Ammonium acetate | 6.16 × 106 |

| 14.992 | Furfural | 2.27 × 107 |

| 15.303 | 1-Hexanol, 2-ethyl- | 1.46 × 105 |

| 15.635 | Ethanone, 1-(2-furanyl)- | 1.94 × 106 |

| 15.929 | Benzaldehyde | 4.65 × 106 |

| 16.197 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 1.50 × 107 |

| 16.327 | 1-Octanol | 7.71 × 105 |

| 16.929 | 3(2H)-Furanone, 4-methoxy-2,5-dimethyl- | 2.56 × 106 |

| 17.095 | 2,4-Di-tert-butyl-6-(tert-butylamino)phenol | 4.56 × 104 |

| 17.109 | trans-2-Undecen-1-ol | 9.08 × 104 |

| 17.367 | Butanoic acid | 3.58 × 105 |

| 17.500 | Butanoic acid, 4-hydroxy- | 7.04 × 105 |

| 17.564 | 2-Decenal, (E)- | 4.68 × 105 |

| 17.770 | Acetophenone | 4.31 × 106 |

| 17.892 | Butanoic acid, 2-methyl- | 1.94 × 106 |

| 18.130 | β-d-Mannofuranoside, phenyl | 1.00 × 105 |

| 18.138 | Octadecanoic acid, 4-methyl- | 6.77 × 104 |

| 18.305 | L-α-Terpineol | 4.53 × 106 |

| 18.389 | 6,6,7-Trimethyl-octane-2,5-dione | 1.95 × 105 |

| 18.415 | Hexanoic acid, anhydride | 5.08 × 105 |

| 18.442 | n-Caproic acid vinyl ester | 2.52 × 105 |

| 18.736 | 2,6-Octadienal, 3,7-dimethyl-, (E)- | 6.19 × 105 |

| 18.981 | n-Octylsuccinic anhydride | 8.99 × 105 |

| 19.035 | Oxime-, methoxy-phenyl-_ | 6.87 × 105 |

| 19.228 | Pseduosarsasapogenin-5,20-dien methyl ether | 1.81 × 105 |

| 19.276 | 5α-Cholestan-2-one, oxime | 1.86 × 105 |

| 19.487 | Bicyclo[2.2.1]heptan-2-one, 1-(bromomethyl)-7,7-dimethyl-, (1S)- | 3.88 × 106 |

| 20.106 | Heptanoic acid | 2.58 × 106 |

| 20.283 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 7.55 × 105 |

| 20.559 | Benzyl alcohol | 3.59 × 105 |

| 20.971 | Phenylethyl Alcohol | 5.90 × 105 |

| 21.277 | 2,3-Dehydro-4-oxo-β-ionol | 2.17 × 105 |

| 21.322 | Stevioside | 1.33 × 105 |

| 21.486 | 1-Dodecanol | 3.28 × 105 |

| 21.627 | 4,4,8-Trimethyl-non-7-en-2-one | 1.60 × 105 |

| 21.775 | 6-Methyl-2-pyrazinylmethanol | 4.24 × 104 |

| 21.930 | Cyclopropanemethanol, α,2-dimethyl-2-(4-methyl-3-pentenyl)-, [1α(R*),2α]- | 4.83 × 104 |

| 21.955 | Phenol | 5.52 × 104 |

| 21.984 | Phosphonic acid, (p-hydroxyphenyl)- | 4.25 × 104 |

| 22.301 | Nerolidyl acetate | 1.04 × 107 |

| 22.522 | Octanoic acid | 3.00 × 105 |

| 23.194 | 2-Pentadecanone, 6,10,14-trimethyl- | 2.62 × 104 |

| 23.378 | 2-Furanmethanol, tetrahydro-α,α,5-trimethyl-5-(4-methyl-3-cyclohexen-1-yl)-, [2S-[2α,5β(R*)]]- | 9.90 × 105 |

| 23.578 | 2(3H)-Furanone, 5-hexyldihydro- | 2.78 × 106 |

| 23.925 | 2H-Pyran, 3,6-dihydro-4-methyl-2-(2-methyl-1-propenyl)- | 1.68 × 105 |

| 24.136 | Epiglobulol | 3.83 × 105 |

| 24.393 | Heptadecanal | 2.55 × 104 |

| 25.829 | gamma.-Dodecalactone | 4.77 × 105 |

| 26.403 | Benzoic acid | 4.52 × 105 |

| 26.663 | Dodecanoic acid | 1.88 × 105 |

| 26.955 | 5-Hydroxymethylfurfural | 1.16 × 105 |

| 27.411 | 1,2-Benzenedicarboxylic acid, bis(2-methylpropyl) ester | 1.58 × 105 |

| 27.726 | Decanoic acid, decyl ester | 1.44 × 105 |

| 27.778 | 4a,8a-Butano[1,4]dioxino[2,3-b]-1,4-dioxin, tetrahydro- | 7.34 × 104 |

| 27.810 | di(Butoxyethyl)adipate | 9.58 × 104 |

| 29.208 | 2-Propanol, 1-chloro-, phosphate (3:1) | 5.56 × 104 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.060 | Dimethyl sulfide | 8.70 × 105 |

| 4.132 | Pentanal | 5.78 × 106 |

| 5.156 | Butanoic acid, ethyl ester | 1.98 × 106 |

| 6.135 | Hexanal | 7.04 × 105 |

| 7.195 | Cyclopropanecarboxylic acid, 2-pentyl ester | 5.51 × 105 |

| 9.353 | 1-Butanol, 3-methyl- | 3.11 × 105 |

| 10.156 | Hexanoic acid, ethyl ester | 6.29 × 105 |

| 10.516 | 1-Pentanol | 4.40 × 105 |

| 11.356 | Acetoin | 9.62 × 105 |

| 11.750 | 1-Octen-3-one | 4.22 × 105 |

| 12.218 | 2-Heptenal, (Z)- | 8.23 × 105 |

| 12.325 | 2,5-Hexanedione | 4.04 × 105 |

| 12.553 | 5-Hepten-2-one, 6-methyl- | 6.21 × 105 |

| 13.644 | Nonanal | 3.32 × 105 |

| 13.851 | 2-Hexen-1-ol, (Z)- | 7.47 × 105 |

| 14.281 | 2-Octenal, (E)- | 3.27 × 105 |

| 14.485 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 8.44 × 105 |

| 14.708 | Ammonium acetate | 6.77 × 106 |

| 14.952 | Furfural | 1.07 × 107 |

| 15.264 | 2-Propyl-1-pentanol | 1.37 × 105 |

| 15.591 | Ethanone, 1-(2-furanyl)- | 1.08 × 106 |

| 15.893 | Benzaldehyde | 3.64 × 106 |

| 16.159 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 9.20 × 106 |

| 16.290 | 1-Octanol | 5.37 × 105 |

| 16.559 | Propanoic acid, 2-methyl- | 3.53 × 105 |

| 16.887 | 3(2H)-Furanone, 4-methoxy-2,5-dimethyl- | 2.39 × 106 |

| 17.239 | Butanoic acid, octyl ester | 1.73 × 105 |

| 17.340 | Heptanoic acid | 4.50 × 105 |

| 17.475 | Butanoic acid, 4-hydroxy- | 2.84 × 105 |

| 17.727 | Acetophenone | 6.67 × 105 |

| 17.914 | Butanoic acid, 2-methyl- | 2.87 × 106 |

| 18.265 | L-α-Terpineol | 4.02 × 106 |

| 18.446 | Sulfurous acid, isohexyl hexyl ester | 4.11 × 105 |

| 18.486 | Hexane, 3-bromo- | 3.00 × 105 |

| 18.694 | Isocaryophillene | 7.36 × 105 |

| 18.996 | Dimethylmalonic acid, monochloride, 2-octyl ester | 9.54 × 105 |

| 19.245 | 5β,6β-Epoxy-7α-bromocholestan-3β-ol | 3.92 × 105 |

| 19.450 | Bicyclo[2.2.1]heptan-2-one, 1-(bromomethyl)-7,7-dimethyl-, (1S)- | 4.92 × 106 |

| 20.088 | Heptanoic acid | 2.85 × 106 |

| 20.254 | 2-Piperidinone, N-[4-bromo-n-butyl]- | 5.61 × 105 |

| 20.523 | Benzyl alcohol | 6.02 × 105 |

| 20.932 | Phenylethyl Alcohol | 2.00 × 105 |

| 21.312 | Heptanoic acid | 6.97 × 104 |

| 22.118 | Humulane-1,6-dien-3-ol | 9.67 × 104 |

| 22.262 | Nerolidyl acetate | 1.11 × 107 |

| 22.479 | Octanoic acid | 2.40 × 105 |

| 22.852 | Cyclohexanone, 3-vinyl-3-methyl- | 6.77 × 104 |

| 23.325 | 2-Furanmethanol, tetrahydro-α,α,5-trimethyl-5-(4-methyl-3-cyclohexen-1-yl)-, [2S-[2α,5β(R*)]]- | 3.96 × 105 |

| 23.534 | 2(3H)-Furanone, 5-hexyldihydro- | 3.14 × 106 |

| 23.925 | 8-Nonene-2,4-diol, 8-methyl-, (R*,S*)- | 2.18 × 105 |

| 24.179 | Epiglobulol | 4.32 × 105 |

| 25.788 | .gamma.-Dodecalactone | 3.77 × 105 |

| 26.351 | Benzoic acid | 7.12 × 105 |

| 27.416 | 1,2-Benzenedicarboxylic acid, bis(2-methylpropyl) ester | 7.46 × 104 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.091 | Dimethyl sulfide | 9.65 × 106 |

| 4.130 | Pentanal | 6.03 × 106 |

| 5.149 | Butanoic acid, ethyl ester | 1.90 × 106 |

| 5.740 | 1-Penten-3-one, 2-methyl- | 8.67 × 105 |

| 6.109 | Hexanal | 1.73 × 106 |

| 7.168 | 3-Buten-2-one, 3-methyl- | 7.64 × 105 |

| 8.992 | Cyclobutane, 1,2-bis(1-methylethenyl)-, trans- | 1.69 × 107 |

| 10.334 | gamma.-Terpinene | 1.60 × 106 |

| 10.500 | 1-Pentanol | 2.75 × 105 |

| 10.982 | o-Cymene | 6.16 × 105 |

| 11.343 | Acetoin | 6.90 × 105 |

| 11.455 | Octanal | 2.79 × 105 |

| 11.500 | Nonanal | 4.33 × 105 |

| 11.742 | 1-Octen-3-one | 8.99 × 105 |

| 12.210 | 2-Heptenal, (Z)- | 2.60 × 106 |

| 12.529 | 5-Hepten-2-one, 6-methyl- | 1.22 × 106 |

| 13.807 | 2-Octene, 2-methyl-6-methylene- | 7.11 × 105 |

| 14.274 | 2-Octenal, (E)- | 8.26 × 105 |

| 14.479 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 1.72 × 106 |

| 14.704 | Ammonium acetate | 7.92 × 106 |

| 14.942 | Furfural | 1.88 × 107 |

| 15.259 | 1-Hexanol, 2-ethyl- | 2.08 × 106 |

| 15.585 | Ethanone, 1-(2-furanyl)- | 1.67 × 106 |

| 15.890 | Benzaldehyde | 1.55 × 107 |

| 16.153 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 9.33 × 106 |

| 16.285 | 1-Octanol | 7.25 × 105 |

| 16.420 | 2H-1,4-Benzodiazepin-2-one, 7-chloro-1,3-dihydro-5-phenyl-1-(trimethylsilyl)- | 5.76 × 105 |

| 16.708 | Bicyclo[2.2.1]heptan-2-ol, 1,3,3-trimethyl- | 1.06 × 106 |

| 16.883 | 3(2H)-Furanone, 4-methoxy-2,5-dimethyl- | 2.25 × 106 |

| 16.980 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 8.76 × 105 |

| 17.146 | 2-Decen-1-ol, (E)- | 2.09 × 105 |

| 17.355 | Cyclohexanol, 1-methyl-4-(1-methylethenyl)- | 1.17 × 106 |

| 17.454 | Butanoic acid, 4-hydroxy- | 6.96 × 105 |

| 17.727 | Acetophenone | 1.52 × 106 |

| 17.906 | Butanoic acid, 2-methyl- | 3.27 × 106 |

| 18.260 | L-α-Terpineol | 1.15 × 107 |

| 18.686 | Isocaryophillene | 9.64 × 105 |

| 18.989 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 9.34 × 105 |

| 19.237 | 5α-Cholestan-2-one, oxime | 3.48 × 105 |

| 19.442 | Bicyclo[2.2.1]heptan-2-one, 1-(bromomethyl)-7,7-dimethyl-, (1S)- | 4.56 × 106 |

| 20.084 | Heptanoic acid | 3.32 × 106 |

| 20.243 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 6.78 × 105 |

| 20.516 | Benzyl alcohol | 2.44 × 106 |

| 20.928 | Phenylethyl Alcohol | 4.36 × 105 |

| 21.308 | Stevioside | 1.47 × 105 |

| 22.071 | α-Cadinol | 5.56 × 106 |

| 22.261 | Nerolidyl acetate | 1.33 × 106 |

| 22.478 | Octanoic acid | 2.87 × 105 |

| 23.328 | 2-Furanmethanol, tetrahydro-α,α,5-trimethyl-5-(4-methyl-3-cyclohexen-1-yl)-, [2S-[2α,5β(R*)]]- | 5.57 × 105 |

| 23.528 | 2(3H)-Furanone, 5-hexyldihydro- | 3.30 × 106 |

| 23.930 | 2-Methyl-7-oxabicyclo[2.2.1]heptane | 3.06 × 105 |

| 24.140 | Propanoic acid, 2-(3-acetoxy-4,4,14-trimethylandrost-8-en-17-yl)- | 3.31 × 105 |

| 25.779 | 2(3H)-Furanone, 5-heptyldihydro- | 4.20 × 105 |

| 26.346 | Benzoic acid | 7.84 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.905 | Ethyl Acetate | 1.46 × 106 |

| 5.460 | Butanoic acid, 2-methyl-, ethyl ester | 3.57 × 105 |

| 10.195 | Hexanoic acid, ethyl ester | 4.05 × 105 |

| 11.416 | Acetoin | 7.36 × 105 |

| 11.774 | 2-Cyclopenten-1-one, 3-(acetyloxy)- | 1.40 × 105 |

| 14.430 | Octanoic acid, ethyl ester | 7.50 × 104 |

| 14.527 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 7.97 × 105 |

| 14.670 | 1-Octen-3-ol | 1.64 × 105 |

| 14.771 | Ammonium acetate | 4.18 × 106 |

| 14.999 | Furfural | 1.23 × 107 |

| 15.315 | 1-Hexanol, 2-ethyl- | 5.59 × 105 |

| 15.634 | Ethanone, 1-(2-furanyl)- | 1.48 × 106 |

| 15.936 | Benzaldehyde | 1.24 × 107 |

| 16.199 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 2.35 × 106 |

| 16.341 | 1-Octanol | 7.98 × 105 |

| 16.686 | 2-Furancarboxaldehyde, 5-methyl- | 3.77 × 105 |

| 16.933 | 3(2H)-Furanone, 4-methoxy-2,5-dimethyl- | 9.20 × 105 |

| 17.115 | 9-Methyl-10,12-hexadecadien-1-ol acetate | 2.87 × 105 |

| 17.245 | Methoxyacetic acid, 2-pentyl ester | 2.67 × 105 |

| 17.394 | Heptanoic acid | 4.50 × 105 |

| 17.511 | Decanoic acid, ethyl ester | 3.77 × 105 |

| 17.774 | Acetophenone | 8.89 × 105 |

| 17.967 | Butanoic acid, 2-methyl- | 1.59 × 106 |

| 18.165 | Octadecane-1,2-diol, bis(trimethylsilyl) ether | 4.53 × 105 |

| 18.309 | L-α-Terpineol | 1.47 × 106 |

| 18.495 | 1,5-Heptadien-4-ol, 3,3,6-trimethyl- | 3.54 × 105 |

| 18.729 | Bicyclo[5.2.0]nonane, 2-methylene-4,8,8-trimethyl-4-vinyl- | 2.31 × 105 |

| 19.035 | Oxime-, methoxy-phenyl-_ | 7.19 × 105 |

| 19.263 | 5α-Cholestan-2-one, oxime | 2.35 × 105 |

| 19.484 | Bicyclo[2.2.1]heptan-2-one, 1-(bromomethyl)-7,7-dimethyl-, (1S)- | 2.41 × 106 |

| 20.141 | Heptanoic acid | 1.24 × 106 |

| 20.573 | Benzyl alcohol | 2.85 × 105 |

| 20.975 | Phenylethyl Alcohol | 2.22 × 105 |

| 21.084 | 2,6-Bis(1,1-dimethylethyl)-4-(1-oxopropyl)phenol | 7.42 × 104 |

| 21.353 | Heptanoic acid | 2.65 × 105 |

| 21.486 | Formic acid, decyl ester | 2.65 × 105 |

| 22.300 | Nerolidyl acetate | 4.41 × 106 |

| 22.531 | Octanoic acid | 4.04 × 105 |

| 23.376 | 2-Furanmethanol, tetrahydro-α,α,5-trimethyl-5-(4-methyl-3-cyclohexen-1-yl)-, [2S-[2α,5β(R*)]]- | 5.82 × 105 |

| 23.579 | 2(3H)-Furanone, 5-hexyldihydro- | 7.91 × 105 |

| 23.790 | Acetohydrazide, 2-(4-morpholyl)-N2-[(4-methylcyclohex-3-enyl)methylene]- | 2.98 × 105 |

| 24.538 | 1-(3,3-Dimethyl-but-1-ynyl)-2,2,3,3-tetramethylcyclopropanecarboxylic acid | 9.59 × 104 |

| 24.682 | n-Decanoic acid | 1.67 × 105 |

| 25.830 | 2(3H)-Furanone, 5-heptyldihydro- | 2.25 × 105 |

| 26.429 | Benzoic acid | 3.39 × 105 |

| 26.552 | 5H-1-Pyrindine | 5.89 × 105 |

| 26.983 | 5-Hydroxymethylfurfural | 2.03 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 1.763 | N-Methylallylamine | 1.15 × 107 |

| 2.395 | Acetone | 1.28 × 107 |

| 2.865 | Ethyl Acetate | 5.66 × 106 |

| 3.335 | Ethanol | 4.63 × 106 |

| 4.055 | 2,3-Butanedione | 1.56 × 106 |

| 10.108 | Hexanoic acid, ethyl ester | 3.14 × 105 |

| 10.671 | Acetoin | 1.40 × 106 |

| 11.754 | Heptane, 2,3-dimethyl- | 2.52 × 105 |

| 12.183 | 1-Heptanol, 2-propyl- | 1.28 × 105 |

| 13.503 | CH3C(O)OCH(CH3)C(O)CH3 | 2.00 × 105 |

| 14.295 | 2-Octenal, (E)- | 5.69 × 105 |

| 14.505 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 1.23 × 106 |

| 14.649 | Ammonium acetate | 6.22 × 106 |

| 14.823 | Furfural | 1.35 × 107 |

| 15.616 | Ethanone, 1-(2-furanyl)- | 9.83 × 105 |

| 15.795 | Benzaldehyde | 2.34 × 107 |

| 16.123 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 3.87 × 106 |

| 16.245 | 2,3,4-Trifluorobenzoic acid, 4-tetradecyl ester | 1.01 × 106 |

| 16.848 | 3(2H)-Furanone, 4-methoxy-2,5-dimethyl- | 6.99 × 105 |

| 17.343 | n-Decanoic acid | 4.52 × 105 |

| 17.498 | Butanoic acid, 4-hydroxy- | 2.58 × 105 |

| 17.769 | Acetophenone | 1.21 × 106 |

| 17.926 | Butanoic acid, 2-methyl- | 1.78 × 106 |

| 18.264 | L-α-Terpineol | 2.98 × 106 |

| 18.695 | Bicyclo[5.2.0]nonane, 2-methylene-4,8,8-trimethyl-4-vinyl- | 3.43 × 105 |

| 18.968 | Oxime-, methoxy-phenyl-_ | 2.32 × 106 |

| 19.457 | Bicyclo[2.2.1]heptan-2-one, 1-(bromomethyl)-7,7-dimethyl-, (1S)- | 2.02 × 106 |

| 20.119 | Cyclopentylcarboxylic acid | 1.72 × 106 |

| 20.529 | Benzyl alcohol | 5.73 × 105 |

| 20.962 | Phenylethyl Alcohol | 4.96 × 105 |

| 21.337 | Heptanoic acid | 2.65 × 105 |

| 21.464 | 1-Dodecanol | 4.72 × 105 |

| 21.785 | 5-Methyl-2-pyrazinylmethanol | 2.17 × 105 |

| 22.014 | Phosphonic acid, (p-hydroxyphenyl)- | 2.39 × 105 |

| 22.105 | 2-Butanone, 4-(2,6,6-trimethyl-2-cyclohexen-1-yl)- | 5.26 × 105 |

| 22.279 | Nerolidyl acetate | 7.69 × 106 |

| 22.506 | Octanoic acid | 3.98 × 105 |

| 23.234 | Tetradecanal | 1.39 × 106 |

| 23.558 | 2(3H)-Furanone, 5-hexyldihydro- | 1.06 × 106 |

| 23.769 | Formic acid, 2,3-dimethylphenyl ester | 2.92 × 105 |

| 24.175 | Viridiflorol | 8.36 × 105 |

| 24.627 | Decanoic acid, silver(1+) salt | 3.79 × 105 |

| 25.025 | Phenol, 2,6-bis(1,1-dimethylethyl)- | 1.99 × 105 |

| 26.374 | Benzoic acid | 4.74 × 106 |

| 26.954 | 5-Hydroxymethylfurfural | 4.34 × 105 |

| 27.777 | Decanoic acid, cyclohexyl ester | 3.41 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 1.745 | Hydroperoxide, pentyl | 1.06 × 107 |

| 8.171 | β-Myrcene | 1.75 × 107 |

| 8.266 | D-Limonene | 8.70 × 108 |

| 10.300 | Benzenemethanimine | 1.26 × 106 |

| 10.985 | Benzene, 1-methyl-3-(1-methylethyl)- | 9.98 × 105 |

| 11.270 | (+)-4-Carene | 2.73 × 106 |

| 13.630 | Nonanal | 1.18 × 106 |

| 14.387 | Octanoic acid, ethyl ester | 2.28 × 106 |

| 14.700 | Acetic acid | 2.76 × 106 |

| 14.943 | Furfural | 5.77 × 106 |

| 15.258 | 2-Propyl-1-pentanol | 1.46 × 106 |

| 15.324 | α-Copaene | 1.17 × 106 |

| 15.881 | Benzaldehyde | 1.04 × 107 |

| 16.155 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 1.87 × 106 |

| 16.297 | 1-Octanol | 1.74 × 106 |

| 16.835 | Cyclohexane, 1-ethenyl-1-methyl-2,4-bis(1-methylethenyl)-, [1S-(1α,2β,4β)]- | 2.08 × 105 |

| 16.967 | Bicyclo[7.2.0]undec-4-ene, 4,11,11-trimethyl-8-methylene- | 4.18 × 106 |

| 17.366 | Cyclohexanol, 1-methyl-4-(1-methylethenyl)- | 3.91 × 106 |

| 18.048 | p-Menth-8-en-1-ol, stereoisomer | 7.96 × 105 |

| 18.264 | L-α-Terpineol | 2.01 × 107 |

| 18.679 | 1.4-Methano-1H-indene, octahydro-4-methyl-8-methylene-7-(1-methylethyl)-, [1S-(1α,3aβ,4α,7α,7aβ)]- | 7.58 × 105 |

| 19.101 | Naphthalene, 1,2,3,5,6,8a-hexahydro-4,7-dimethyl-1-(1-methylethyl)-, (1S-cis)- | 1.09 × 106 |

| 20.075 | 5-Hexenoic acid, 5-methyl- | 2.54 × 105 |

| 20.242 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (Z)- | 1.86 × 105 |

| 20.513 | Benzyl alcohol | 3.75 × 106 |

| 20.924 | Phenylethyl Alcohol | 1.81 × 105 |

| 26.307 | Benzoic acid | 5.70 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.394 | 1H-Tetrazole-1,5-diamine | 1.62 × 106 |

| 2.530 | Acetic acid, 2-[(acetyl)(2,2-dicyanoethenyl)amino]-, ethyl ester | 5.84 × 104 |

| 3.401 | Ethanol | 5.19 × 105 |

| 9.374 | 1-Butanol, 3-methyl- | 2.60 × 105 |

| 11.348 | Acetoin | 4.80 × 105 |

| 13.279 | 4-Dodecyne | 1.55 × 105 |

| 13.650 | Nonanal | 3.49 × 105 |

| 13.855 | 2-Hexen-1-ol, (E)- | 3.83 × 105 |

| 14.485 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 2.43 × 105 |

| 14.718 | Ammonium acetate | 2.03 × 106 |

| 14.949 | Furfural | 9.86 × 106 |

| 15.265 | 1-Hexanol, 2-ethyl- | 1.65 × 105 |

| 15.590 | Ethanone, 1-(2-furanyl)- | 1.03 × 106 |

| 15.890 | Benzaldehyde | 4.14 × 106 |

| 16.159 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 2.42 × 106 |

| 16.290 | 1-Octanol | 3.22 × 105 |

| 16.632 | 2-Furancarboxaldehyde, 5-methyl- | 3.47 × 105 |

| 16.855 | 1-Propene, 3-chloro-2-(chloromethyl)- | 1.00 × 105 |

| 16.979 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 2.04 × 105 |

| 17.249 | 2H-Pyran-2-one, tetrahydro- | 4.80 × 105 |

| 17.454 | Butyrolactone | 6.61 × 105 |

| 17.913 | Butanoic acid, 2-methyl- | 3.15 × 105 |

| 18.162 | 1,7-Dimethyl-4-oxa-tricyclo[5.2.1.0(2,6)]decane-3,5,8-trione | 2.57 × 105 |

| 18.268 | L-α-Terpineol | 1.07 × 106 |

| 18.484 | Methyl 7,9-tridecadienyl ether | 1.62 × 105 |

| 18.989 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 6.88 × 105 |

| 20.090 | Heptanoic acid | 8.43 × 105 |

| 20.262 | (1R,2R,3R,5S)-(−)-Isopinocampheol | 3.04 × 105 |

| 20.519 | Benzyl alcohol | 3.19 × 106 |

| 20.716 | 4-Acetyl-1-methylcyclohexene | 1.44 × 105 |

| 20.928 | Phenylethyl Alcohol | 2.74 × 105 |

| 21.292 | Acetic acid, 6,6-dimethyl-2-methylene-7-(3-oxobutylidene)oxepan-3-ylmethyl ester | 1.43 × 105 |

| 22.258 | Nerolidyl acetate | 2.45 × 105 |

| 23.365 | Octadecanal | 2.70 × 105 |

| 23.535 | 2(3H)-Furanone, 5-hexyldihydro- | 3.88 × 105 |

| 23.715 | Phenol, 2-methoxy-3-(2-propenyl)- | 7.59 × 104 |

| 25.785 | Ethanol, 2-[2-[(tetrahydro-2H-pyran-2-yl)oxy]ethoxy]- | 2.81 × 104 |

| 25.850 | 8-Methyl-hexahydro-pyrano[3,2-b]pyran-2-one | 7.16 × 104 |

| 26.347 | Benzoic acid | 5.87 × 105 |

| 26.645 | 2-Propenoic acid, 3-(2-hydroxyphenyl)-, (E)- | 3.05 × 105 |

| 29.615 | 2-[2-[2-[2-[2-[2-[2-[2-[2-(2-Methoxyethoxy)ethoxy]ethoxy]ethoxy]ethoxy]ethoxy]ethoxy]ethoxy]ethoxy]ethanol | 3.46 × 104 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.375 | 2-Heptanone, 7,7-dichloro- | 7.84 × 105 |

| 3.379 | Ethanol | 2.22 × 105 |

| 4.730 | 11H-Naphtho[1,2-b]thieno[3,4-d]pyran-11-one, 1-amino-3-methyl- | 1.47 × 106 |

| 8.998 | Cyclobutane, 1,2-bis(1-methylethenyl)-, trans- | 9.23 × 106 |

| 10.336 | .gamma.-Terpinene | 8.00 × 105 |

| 10.986 | Benzene, 1,2,4,5-tetramethyl- | 1.98 × 105 |

| 11.346 | Acetoin | 5.52 × 105 |

| 12.583 | 2,6-Lutidine 3,5-dichloro-4-dodecylthio- | 6.28 × 104 |

| 13.268 | 7-Oxabicyclo[4.1.0]heptane, 1-methyl-4-(1-methylethenyl)- | 8.64 × 104 |

| 13.525 | Acetic acid, 2-ethylhexyl ester | 8.29 × 103 |

| 13.642 | Nonanal | 2.11 × 105 |

| 13.848 | 2-Hexen-1-ol, (E)- | 3.27 × 105 |

| 14.475 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 5.11 × 105 |

| 14.712 | Ammonium acetate | 2.00 × 106 |

| 14.945 | Furfural | 7.46 × 106 |

| 15.261 | 1-Hexanol, 2-ethyl- | 1.37 × 106 |

| 15.585 | Ethanone, 1-(2-furanyl)- | 8.11 × 105 |

| 15.897 | Benzaldehyde | 2.52 × 106 |

| 16.155 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 1.83 × 106 |

| 16.289 | 1-Octanol | 1.94 × 105 |

| 16.650 | 3-Cyclohexen-1-ol, 1-methyl-4-(1-methylethyl)- | 1.53 × 105 |

| 16.713 | Bicyclo[2.2.1]heptan-2-ol, 1,3,3-trimethyl- | 5.69 × 105 |

| 16.982 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 8.19 × 105 |

| 17.259 | 2(3H)-Furanone, dihydro-4-methyl- | 2.91 × 105 |

| 17.360 | p-Menth-8-en-1-ol, stereoisomer | 7.02 × 104 |

| 17.421 | Cyclohexanol, 1-methyl-4-(1-methylethenyl)- | 1.00 × 106 |

| 17.775 | 2-Furanmethanol | 2.19 × 105 |

| 17.910 | Butanoic acid, 2-methyl- | 5.10 × 105 |

| 18.262 | L-α-Terpineol | 7.82 × 106 |

| 18.679 | 1H-Benzocycloheptene, 2,4a,5,6,7,8,9,9a-octahydro-3,5,5-trimethyl-9-methylene- | 3.33 × 105 |

| 18.817 | Carvone | 1.42 × 105 |

| 19.010 | Naphthalene, 1,2-dihydro-1,5,8-trimethyl- | 4.19 × 105 |

| 19.152 | Naphthalene, 1,2,3,5,6,8a-hexahydro-4,7-dimethyl-1-(1-methylethyl)-, (1S-cis)- | 1.20 × 105 |

| 20.086 | Heptanoic acid | 8.43 × 105 |

| 20.250 | 5,9-Undecadien-2-one, 6,10-dimethyl-, (E)- | 2.22 × 105 |

| 20.720 | Nona-3,5-dien-2-one | 1.01 × 105 |

| 20.931 | Phenylethyl Alcohol | 4.73 × 105 |

| 21.295 | Acetic acid, 6,6-dimethyl-2-methylene-7-(3-oxobutylidene)oxepan-3-ylmethyl ester | 8.99 × 104 |

| 22.255 | 1,6,10-Dodecatrien-3-ol, 3,7,11-trimethyl-, [S-(Z)]- | 2.74 × 105 |

| 23.532 | 2(3H)-Furanone, 5-hexyldihydro- | 3.99 × 105 |

| 23.711 | Phenol, 2-methoxy-3-(2-propenyl)- | 1.45 × 105 |

| 25.853 | .gamma.-Dodecalactone | 5.64 × 104 |

| 26.354 | Benzoic acid | 3.24 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.511 | Ethyl Acetate | 1.78 × 106 |

| 12.525 | 5-Hepten-2-one, 6-methyl- | 1.16 × 105 |

| 13.279 | 7-Oxabicyclo[4.1.0]heptane, 1-methyl-4-(1-methylethenyl)- | 8.60 × 104 |

| 13.667 | Nonanal | 1.08 × 105 |

| 13.790 | 1H-Pyrazole, 4,5-dihydro-5,5-dimethyl-4-isopropylidene- | 3.13 × 105 |

| 14.505 | α-Methyl-α-[4-methyl-3-pentenyl]oxiranemethanol | 8.22 × 104 |

| 14.625 | Sulfurous acid, hexyl octyl ester | 1.15 × 105 |

| 14.779 | Ammonium acetate | 1.03 × 106 |

| 14.990 | Furfural | 1.51 × 107 |

| 15.305 | Acetic acid, dichloro-, heptyl ester | 7.47 × 105 |

| 15.636 | Ethanone, 1-(2-furanyl)- | 1.83 × 106 |

| 15.931 | Benzaldehyde | 4.84 × 107 |

| 16.195 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 1.05 × 106 |

| 16.345 | 2,3,4-Trifluorobenzoic acid, 4-tetradecyl ester | 3.43 × 105 |

| 16.672 | 2-Furancarboxaldehyde, 5-methyl- | 4.21 × 105 |

| 17.273 | Ethanol, 2-(2-ethoxyethoxy)- | 1.68 × 105 |

| 17.327 | 1-Cyclohexene-1-carboxaldehyde, 2,6,6-trimethyl- | 2.80 × 105 |

| 17.498 | Butanoic acid, 4-hydroxy- | 4.08 × 105 |

| 17.968 | Butanoic acid, 2-methyl- | 1.77 × 105 |

| 18.305 | L-α-Terpineol | 1.20 × 106 |

| 18.521 | Dodecanal | 2.45 × 105 |

| 18.785 | 1H-Imidazole, 4,5-dimethyl- | 9.47 × 104 |

| 18.903 | Naphthalene, decahydro-1,4a-dimethyl-7-(1-methylethyl)-, [1S-(1α,4aα,7α,8aβ)]- | 6.00 × 105 |

| 19.026 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 1.42 × 106 |

| 19.277 | N-Acetyl-2-ethylbutan-1-amine | 1.38 × 104 |

| 20.132 | Heptanoic acid | 5.47 × 105 |

| 20.284 | 6,8-Nonadien-2-one, 8-methyl-5-(1-methylethyl)-, (E)- | 2.48 × 105 |

| 20.561 | Benzyl alcohol | 1.01 × 106 |

| 20.755 | 4-Acetyl-1-methylcyclohexene | 1.70 × 105 |

| 20.965 | Phenol, 2,6-bis(1,1-dimethylethyl)-4-methyl-, methylcarbamate | 2.86 × 105 |

| 21.085 | 2,6-Bis(1,1-dimethylethyl)-4-(1-oxopropyl)phenol | 1.73 × 105 |

| 21.316 | 2-Butanone, 4-(2,6,6-trimethyl-2-cyclohexen-1-ylidene)- | 2.91 × 105 |

| 21.477 | 1-Dodecanol | 2.12 × 105 |

| 21.809 | 6-Methyl-2-pyrazinylmethanol | 2.53 × 105 |

| 22.010 | Acetic acid, phenyl ester | 1.72 × 105 |

| 22.526 | Octanoic acid | 2.46 × 105 |

| 23.244 | 1H-Indene-4-acetic acid, 6-(1,1-dimethylethyl)-2,3-dihydro-1,1-dimethyl- | 1.31 × 105 |

| 23.641 | Pentadecanoic acid | 2.94 × 105 |

| 23.757 | Eugenol | 4.60 × 105 |

| 24.541 | 1-(3,3-Dimethyl-but-1-ynyl)-2,2,3,3-tetramethylcyclopropanecarboxylic acid | 2.44 × 105 |

| 25.776 | Formic acid, 2,4,6-tri-t-butyl-phenyl ester | 3.35 × 105 |

| 26.430 | Benzoic acid | 2.09 × 105 |

| 26.545 | 5H-1-Pyrindine | 5.30 × 105 |

| 26.972 | 5-Hydroxymethylfurfural | 3.01 × 105 |

| 28.302 | 1H-Inden-5-ol, 2,3-dihydro-1,1,3,3-tetramethyl-4,6-bis(1-methylethyl)- | 1.20 × 105 |

| 28.885 | Terephthalic acid, hexyl tridec-2-yn-1-yl ester | 2.33 × 105 |

| Retention Time | Name | Mean |

|---|---|---|

| 2.408 | Acetone | 4.15 × 106 |

| 11.348 | Acetoin | 1.36 × 105 |

| 13.265 | 3-Dodecyne | 2.30 × 105 |

| 13.635 | Nonanal | 1.90 × 105 |

| 13.751 | 1H-Pyrazole, 4,5-dihydro-5,5-dimethyl-4-isopropylidene- | 3.94 × 105 |

| 14.021 | 1,3-Hexadiene, 3-ethyl-2-methyl- | 1.75 × 105 |

| 14.473 | Ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl)propan-2-yl carbonate | 2.16 × 105 |

| 14.686 | Ammonium acetate | 4.18 × 106 |

| 14.929 | Furfural | 1.26 × 107 |

| 15.367 | 2,4-Heptadienal, (E,E)- | 3.62 × 105 |

| 15.579 | Ethanone, 1-(2-furanyl)- | 1.52 × 106 |

| 15.874 | Benzaldehyde | 8.93 × 107 |

| 16.143 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 1.18 × 106 |

| 16.611 | 2-Furancarboxaldehyde, 5-methyl- | 4.04 × 105 |

| 16.850 | 4-Cyclopentene-1,3-dione | 5.89 × 104 |

| 16.990 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 1.11 × 105 |

| 17.279 | 1-Cyclohexene-1-carboxaldehyde, 2,6,6-trimethyl- | 3.54 × 105 |

| 17.432 | Butanoic acid, 4-hydroxy- | 4.79 × 105 |

| 17.888 | Butanoic acid, 2-methyl- | 7.36 × 105 |

| 18.152 | 3-Cyclohexene-1-acetaldehyde, α,4-dimethyl- | 3.44 × 105 |

| 18.251 | L-α-Terpineol | 1.63 × 106 |

| 18.975 | 1, 1, 5-Trimethyl-1, 2-dihydronaphthalene | 9.02 × 105 |

| 19.875 | 2-Buten-1-one, 1-(2,6,6-trimethyl-1,3-cyclohexadien-1-yl)-, (E)- | 8.59 × 104 |

| 20.069 | Heptanoic acid | 4.08 × 105 |

| 20.230 | α-Ionone | 2.65 × 105 |

| 20.502 | Benzyl alcohol | 2.75 × 106 |

| 20.705 | 3-Buten-2-ol, 4-(2,6,6-trimethyl-2-cyclohexen-1-yl)-, (3E)- | 2.31 × 105 |

| 20.916 | Phenylethyl Alcohol | 1.52 × 105 |

| 21.259 | trans-β-Ionone | 3.18 × 105 |

| 21.740 | 2,5-Furandicarboxaldehyde | 1.40 × 105 |

| 21.955 | Phenol | 1.57 × 105 |

| 22.080 | 3-Furancarboxylic acid, methyl ester | 2.73 × 105 |

| 23.699 | Eugenol | 2.11 × 105 |

| 24.410 | Heptadecanal | 2.78 × 105 |

| 24.993 | Phenol, 3,5-bis(1,1-dimethylethyl)- | 1.94 × 105 |

| 25.405 | l-(+)-Ascorbic acid 2,6-dihexadecanoate | 1.36 × 106 |

| 26.258 | Benzoic acid | 2.30 × 107 |

| 26.890 | 5-Hydroxymethylfurfural | 5.10 × 105 |

References

- DECRETO LEGISLATIVO 20 Febbraio 2004, n. 50 Attuazione Della Direttiva 2001/113/CE Concernente le Confetture, le Gelatine e le Marmellate di Frutta, Nonche’ la Crema di Marroni, Destinate All’Alimentazione umana. (GU n.49 del 28-2-2004—Suppl. Ordinario n. 30). Available online: https://www.normattiva.it/uri-res/N2Ls?urn:nir:stato:decreto.legislativo:2004-2-20;50!vig= (accessed on 14 November 2019).

- Unimac-Gherri Food Packaging Equipment. Available online: https://www.unimac-gherri.com/notizie-e-eventi/203-marmellate-soluzioni-innovative-per-un-mercato-in-crescita (accessed on 14 November 2019).

- El Hadi, M.A.M.; Zhang, F.-J.; Wu, F.-F.; Zhou, C.-H.; Tao, J. Advances in Fruit Aroma Volatile Research. Molecules 2013, 18, 8200–8229. [Google Scholar] [CrossRef] [PubMed]

- Nieminen, T.; Neubauer, P.; Sivelä, S.; Vatamo, S.; Silfverberg, P.; Salkinoja-Salonen, M. Volatile compounds produced by fungi grown in strawberry jam. LWT Food Sci. Technol. 2008, 41, 2051–2056. [Google Scholar] [CrossRef]

- Im, S.; Lee, M.K.; Yunc, Y.M.; Chod, S.K.; Kim, D.H. Effect of storage time and temperature on hydrogen fermentation of food waste on hydrogen fermentation od food waste. Int. J. Hydrogen Energy 2019. [Google Scholar] [CrossRef]

- Yildirim, R.M.; Arici, M. Effect of the fermentation temperature on the degradation of phytic acid in whole-wheat sourdough bread. LWT 2019, 112, 108224. [Google Scholar] [CrossRef]

- Delatour, T.; Huertas-Pérez, J.F.; Dubois, M.; Theurillat, X.; Desmarchelier, A.; Ernest, M.; Stadler, R.H. Thermal degradation of 2-furoic acid and furfuryl alcohol as pathways in the formation of furan and 2-methylfuran in food. Food Chem. 2019, 303, 125406. [Google Scholar] [CrossRef]

- Rocchi, R.; Mascini, M.; Faberi, A.; Sergi, M.; Compagnone, D.; di Martino, V.; Carradori, S.; Pittia, P. Comparison of IRMS, GC-MS and E-Nose data for the discrimination of saffron samples with different origin, process and age. Food Control 2019, 106, 106736. [Google Scholar] [CrossRef]

- Ziółkowska, A.; Wąsowicz, E.; Jeleń, H.H. Differentiation of wines according to grape variety and geographical origin based on volatiles profiling using SPME-MS and SPME-GC/MS methods. Food Chem. 2016, 213, 714–720. [Google Scholar] [CrossRef]

- Yang, Y.-N.; Zheng, F.-P.; Yu, A.-N.; Sun, B.-G. Changes of the free and bound volatile compounds in Rubus corchorifolius L. f. fruit during ripening. Food Chem. 2019, 287, 232–240. [Google Scholar] [CrossRef]

- Gao, J.; Wu, B.-P.; Gao, L.-X.; Liu, H.-R.; Zhang, B.; Sun, C.-D.; Chen, K.-S. Glycosidically bound volatiles as affected by ripening stages of Satsuma mandarin fruit. Food Chem. 2018, 240, 1097–1105. [Google Scholar] [CrossRef]

- Silva, J.S.; Damiani, C.; Da Cunha, M.C.; Carvalho, E.E.N.; Boas, E.V.D.B.V. Volatile profiling of pitanga fruit (Eugenia uniflora L.) at different ripening stages using solid-phase microextraction and mass spectrometry coupled with gas chromatography. Sci. Hortic. 2019, 250, 366–370. [Google Scholar] [CrossRef]

- Porto-Figueira, P.; Freitas, A.; Cruz, C.J.; Figueira, J.A.; Câmara, J.S. Profiling of passion fruit volatiles: An effective tool to discriminate between species and varieties. Food Res. Int. 2015, 77, 408–418. [Google Scholar] [CrossRef]

- Sdiri, S.; Rambla, J.L.; Besada, C.; Granell, A.; Salvador, A. Changes in the volatile profile of citrus fruit submitted to postharvest degreening treatment. Postharvest Biol. Technol. 2017, 133, 48–56. [Google Scholar] [CrossRef]

- Wu, Q.; Tao, X.; Ai, X.; Luo, Z.; Mao, L.; Ying, T.; Li, L. Effect of exogenous auxin on aroma volatiles of cherry tomato (Solanum lycopersicum L.) fruit during postharvest ripening. Postharvest Boil. Technol. 2018, 146, 108–116. [Google Scholar] [CrossRef]

- Xu, L.; Wang, X.; Huang, Y.; Wang, Y.; Zhu, L.; Wu, R. A predictive model for the evaluation of flavor attributes of raw and cooked beef based on sensor array analyses. Food Res. Int. 2019, 122, 16–24. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Núñez-Carmona, E.; Sberveglieri, V.; Zappa, D.; Comini, E.; Sberveglieri, G. Application of a Novel S3 Nanowire Gas Sensor Device in Parallel with GC-MS for the Identification of Rind Percentage of Grated Parmigiano Reggiano. Sensors 2018, 18, 1617. [Google Scholar] [CrossRef]

- Núñez-Carmona, E.; Abbatangelo, M.; Sberveglieri, V. Innovative Sensor Approach to Follow Campylobacter jejuni Development. Biosensors 2019, 9, 8. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Carmona, N.; Duina, G.; Sberveglieri, V.; Núñez-Carmona, E. Multidisciplinary Approach to Characterizing the Fingerprint of Italian EVOO. Molecules 2019, 24, 1457. [Google Scholar] [CrossRef]

- Hansen, A.-M.S.; Frandsen, H.L.; Fromberg, A. Authenticity of raspberry flavor in food products using SPME-chiral-GC-MS. Food Sci. Nutr. 2016, 4, 348–354. [Google Scholar] [CrossRef]

- Gökbulut, I.; Karabulut, I. SPME–GC–MS detection of volatile compounds in apricot varieties. Food Chem. 2012, 132, 1098–1102. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, J.; Chen, S.; Wu, D.; Liu, D.; Ye, X. Characterization of aroma-active volatiles in three Chinese bayberry (Myrica rubra) cultivars using GC–MS–olfactometry and an electronic nose combined with principal component analysis. Food Res. Int. 2015, 72, 8–15. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Carmona, E.N.; Sberveglieri, V. Application of a novel S3 nanowire gas sensor device in parallel with GC-MS for the identification of Parmigiano Reggiano from US and European competitors. J. Food Eng. 2018, 236, 36–43. [Google Scholar] [CrossRef]

- Abbatangelo, M.; Núñez-Carmona, E.; Sberveglieri, V. Novel equipment for food quality control: An IoT nanowire gas sensors array. Chem. Eng. Trans. 2019, 75, 25–30. [Google Scholar]

- Sberveglieri, G. Recent developments in semiconducting thin-film gas sensors. Sens. Actuators B Chem. 1995, 23, 103–109. [Google Scholar] [CrossRef]

- Comini, E.; Ottini, L.; Faglia, G.; Sberveglieri, G. SnO2 RGTO UV Activation for CO Monitoring. IEEE Sens. J. 2004, 4, 17–20. [Google Scholar] [CrossRef]

- Dieguez, A.; Romano-Rodrıguez, A.; Morante, J.; Sangaletti, L.; Depero, L.E.; Comini, E.; Faglia, G.; Sberveglieri, G. Influence of the completion of oxidation on the long-term response of RGTO SnO2 gas sensors. Sens. Actuators B Chem. 2000, 66, 40–42. [Google Scholar] [CrossRef]

- Comini, E.; Faglia, G.; Sberveglieri, G.; Pan, Z.; Wang, Z.L. Stable and highly sensitive gas sensors based on semiconducting oxide nanobelts. Appl. Phys. Lett. 2002, 81, 1869–1871. [Google Scholar] [CrossRef]

- Sberveglieri, G.; Concina, I.; Comini, E.; Falasconi, M.; Ferroni, M.; Sberveglieri, V. Synthesis and integration of tin oxide nanowires into an electronic nose. Vacuum 2012, 86, 532–535. [Google Scholar] [CrossRef]

- Zappa, D.; Comini, E.; Zamani, R.; Arbiol, J.; Morante, J.; Sberveglieri, G. Preparation of copper oxide nanowire-based conductometric chemical sensors. Sens. Actuators B Chem. 2013, 182, 7–15. [Google Scholar] [CrossRef]

- Introduction to Organic Laboratory Techniques. Available online: https://www.researchgate.net/publication/313056682_Introduction_to_organic_laboratory_techniques_4th_ed (accessed on 2 January 2006).

- Food additives permitted for direct addition to food for human consumption, FDA part 172—Subpart F, Flavoring Agents and Related Substances Sec. 172.515 Synthetic flavoring substances and adjuvants. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=172.515 (accessed on 27 November 2019).

- Australia New Zealand Food Standards. Code Standard 1.2.4—Labelling of Ingredients. Available online: comlaw.gov.au (accessed on 14 November 2019).

- Hoydonckx, H.E.; van Rhijn, W.M.; van Rhijn, W.; de Vos, D.E.; Jacobs, P.A. Furfural and Derivatives. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2007. [Google Scholar] [CrossRef]

- Wang, Y.; Juliani, H.R.; Simon, J.E.; Ho, C.-T. Amino acid-dependent formation pathways of 2-acetylfuran and 2,5-dimethyl-4-hydroxy-3[2H]-furanone in the Maillard reaction. Food Chem. 2009, 115, 233–237. [Google Scholar] [CrossRef]

- Scott, H.R.; Scott, L.E. Process of Treating Nut Kernels to Produce Food Ingredients. U.S. Patent US1416128A, 16 May 1922. [Google Scholar]

- Chambers, A.; Whitaker, V.M.; Gibbs, B.; Plotto, A.; Folta, K.M. Detection of the linalool-producing NES1 variant across diverse strawberry (Fragaria spp.) accessions. Plant Breed. 2012, 131, 437–443. [Google Scholar] [CrossRef]

- Chouhan, S.; Sharma, K.; Guleria, S. Antimicrobial Activity of Some Essential Oils—Present Status and Future Perspectives. Medicines 2017, 4, 58. [Google Scholar] [CrossRef] [PubMed]

- Hui, Y.H. Handbook of Fruit and Vegetable Flavors; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 978-0-470-22721-3. [Google Scholar]

- Burdock, G.A. Fenaroli’s Handbook of Flavor Ingredients, 5th ed.; CRC Press: Boca Raton, FL, USA, 2005; p. 15. ISBN 0-8493-3034-3. [Google Scholar]

- Günzler, H. Analytiker-Taschenbuch 21 (in German); Springer: Berlin/Heidelberg, Germany, 2000; p. 39. ISBN 3-540-66232-4. [Google Scholar]

- Yao, S.-S.; Guo, W.-F.; Lu, Y.; Jiang, Y.-X. Flavor Characteristics of Lapsang Souchong and Smoked Lapsang Souchong, a Special Chinese Black Tea with Pine Smoking Process. J. Agric. Food Chem. 2005, 53, 8688–8693. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.-J.; Maimaiti, A.S.; Mou, H.-M.; Liu, G.-J. Hexanoic acid 2-(diethylamino)ethyl ester enhances chilling tolerance in strawberry seedlings by impact on photosynthesis and antioxidants. Biol. Plant. 2001, 55, 793–796. [Google Scholar] [CrossRef]

- Gaborieau, S.; Cendres, A.; Page, D.; Ginies, C.; Renard, C.M. Variability of free and glycosylated volatiles from strawberries destined for the fresh market and for processing, assessed using direct enzymatic hydrolysis. LWT 2018, 98, 187–196. [Google Scholar] [CrossRef]

- Mo, E.K.; Sung, C.K. Phenylethyl alcohol (PEA) application slows fungal growth and maintains aroma in strawberry. Postharvest Boil. Technol. 2007, 45, 234–239. [Google Scholar] [CrossRef]

- Lu, H.; Wang, K.; Wang, L.; Li, D.; Yan, J.; Ban, Z.; Luo, Z.; Li, L.; Yang, D. Effect of superatmospheric oxygen exposure on strawberry (Fragaria × ananassa Fuch.) volatiles, sensory and chemical attributes. Postharvest Boil. Technol. 2018, 142, 60–71. [Google Scholar] [CrossRef]

- Fu, X.; Cheng, S.; Zhang, Y.; Du, B.; Feng, C.; Zhou, Y.; Mei, X.; Jiang, Y.; Duan, X.; Yang, Z. Differential responses of four biosynthetic pathways of aroma compounds in postharvest strawberry (Fragaria × ananassa Duch.) under interaction of light and temperature. Food Chem. 2017, 221, 356–364. [Google Scholar] [CrossRef]

- Liu, B.; Jiao, W.; Wang, B.; Shen, J.; Zhao, H.; Jiang, W. Near freezing point storage compared with conventional low temperature storage on apricot fruit flavor quality (volatile, sugar, organic acid) promotion during storage and related shelf life. Sci. Hortic. 2019, 249, 100–109. [Google Scholar] [CrossRef]

- Guillot, S.; Peytavi, L.; Bureau, S.; Boulanger, R.; Lepoutre, J.; Crouzet, J.; Schorrgalindo, S. Aroma characterization of various apricot varieties using headspace-solid phase microextraction combined with gas chromatography–mass spectrometry and gas chromatography-olfactometry. Food Chem. 2006, 96, 147–155. [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, Q.-A.; Yao, J.-L.; Zhang, X.-Y. Changes of amygdalin and volatile components of apricot kernels during the ultrasonically-accelerated debitterizing. Ultrason. Sonochem. 2019, 58, 104614. [Google Scholar] [CrossRef]

- Chen, M.-X.; Chen, X.-S.; Wang, X.-G.; Ci, Z.-J.; Liu, X.-L.; He, T.-M.; Zhang, L.-J. Comparison of Headspace Solid-Phase Microextraction with Simultaneous Steam Distillation Extraction for the Analysis of the Volatile Constituents in Chinese Apricot. Agric. Sci. China 2006, 5, 879–884. [Google Scholar] [CrossRef]

- Cozzolino, R.; Martignetti, A.; Cefola, M.; Pace, B.; Capotorto, I.; De Giulio, B.; Montemurro, N.; Pellicano, M. Volatile metabolites, quality and sensory parameters of “Ferrovia” sweet cherry cold stored in air or packed in high CO2 modified atmospheres. Food Chem. 2019, 286, 659–668. [Google Scholar] [CrossRef] [PubMed]

| Taste | Sample Code | Ingredients |

|---|---|---|

| Apricot | APS | Apricots; grape sugar; gelling agent: pectin; acidity correctors: citric acid and calcium citrate. Fruit used 70 g per 100 g. |

| AL | Apricots; apple sugar; gelling agent: pectin; acidity corrector: calcium citrate. Fruit used 50 g per 100 g. | |

| AS | Apricots; fructose; water; gelling agent: pectin; acidity corrector: citric acid; calcium citrate; sweetener: steviol glycosides. Fruit used: 50 g per 100 g. | |

| A100 | Apricots; grape sugar; concentrated lemon juice; gelling agent: fruit pectin. Used apricots: 100g per 100 g of product. | |

| AVL | Apricots; sugar; gelling agent: pectin; acidity correctors: citric acid and calcium citrate; sweetener: steviol glycosides. Fruit used 70 g per 100 g. | |

| Strawberry | SPS | Strawberry; grape sugar; gelling agent: pectin; acidity corrector: citric acid; concentrated elderberry juice. Fruit used 70 g per 100 g. |

| SL | Strawberries; apple sugar; gelling agent: pectin; acidity corrector: citric acid and calcium citrate; red fruit juice; concentrated elderberry juice. Fruit used 50 g per 100 g. | |

| SS | Strawberries; fructose; water; gelling agent: pectin; acidity corrector: citric acid and calcium citrate; concentrated elderberry juice; sweetener: steviol glycosides. Fruit used: 50 g per 100 g. | |

| S100 | Strawberries; grape sugar; gelling agent: pectin; concentrated lemon juice; concentrated elderberry juice. Used strawberries: 100 g per 100 g of product. | |

| SVL | Strawberries; sugar; gelling agent: pectin; acidity correctors: citric acid and calcium citrate; concentrated elderberry juice; sweetener: steviol glycosides. Fruit used 70 g per 100 g. | |

| Cherry | CPS | Cherries; sugar; concentrated lemon juice; gelling agent: pectin; acidity corrector: calcium citrate. Fruit used 50 g per 100 g of product. |

| CL | Cherries; apple sugar; gelling agent: pectin; acidity correctors: citric acid and calcium citrate. Fruit used 50 g per 100 g. | |

| CS | Cherries; fructose; water; gelling agent: pectin; acidity corrector: citric acid and calcium citrate; sweetener: steviol glycosides. Fruit used: 50 g per 100 g. | |

| C100 | Cherries; grape sugar; concentrated lemon juice; gelling agent: fruit pectin. Used cherries: 100 g per 100 g of product. | |

| CVL | Cherries; sugar; gelling agent: pectin; acidity correctors: citric acid and calcium citrate; sweetener: steviol glycosides. Fruit used 70 g per 100 g. |

| Materials | Morphology | Working Temperature (°C) |

|---|---|---|

| SnO2 + Au | RGTO | 400 |

| SnO2 | RGTO | 400 |

| CuO | Nanowire | 350 |

| SnO2 + Au | Nanowire | 350 |

| SnO2 | Nanowire | 350 |

| Taste | Sample Code | Number of Replicas for S3 |

|---|---|---|

| Apricot | APS | 10 |

| AL | 10 | |

| AS | 11 | |

| A100 | 7 | |

| AVL | 7 | |

| Strawberry | SPS | 6 |

| SL | 7 | |

| SS | 6 | |

| S100 | 9 | |

| SVL | 6 | |

| Cherry | CPS | 6 |

| CL | 10 | |

| CS | 7 | |

| C100 | 7 | |

| CVL | 7 |

| Retention Time | Compound | SPS | SVL | S100 | SL | SS | Description |

|---|---|---|---|---|---|---|---|

| 11.343 | Acetoin | 5.90 × 105 | 9.62 × 105 | 6.90 × 105 | 7.36 × 105 | 1.40 × 106 | Pleasant, buttery odor. Acetoin is used as a food flavoring (in baked goods) and as a fragrance. It can be found in apples, butter, yogurt, asparagus, blackcurrants, blackberries, wheat, broccoli, brussels sprouts, cantaloupes and maple [31]. |

| 14.527 | Linalool oxide | 6.66 × 105 | 8.44 × 105 | 1.72 × 106 | 7.97 × 105 | 1.23 × 106 | Furanoid with floral odor type, and musty, camphoreous, herbal, balsamic, and pine notes. Other name: 2-(5-ethenyl-5-methyloxolan-2-yl) propan-2-yl ethyl carbonate (IUPAC) [32]. |

| 14.689 | Ammonium acetate | 6.16 × 106 | 6.77 × 106 | 7.92 × 106 | 4.18 × 106 | 6.22 × 106 | Slight odor of acetic acid. Its use as a food additive regulator of acidity is authorized in Australia and New Zealand, where it is identified by the number INS 264 and in the European Union where it is identified by the code E264 [33]. |

| 14.931 | Furfural | 2.27 × 107 | 1.07 × 107 | 1.88 × 107 | 1.23 × 107 | 1.35 × 107 | The compound is an aldehyde group attached to the 2-position of furan. It is a product of the acid catalyzed dehydration of five-carbon sugars (pentoses), particularly xylose. These sugars may be obtained from hemicellulose present in lignocellulosic biomass, which can be extracted from most terrestrial plants. It is found in many foods: coffee (55–255 mg/kg) and whole-grain bread (26 mg/kg). When heated in the presence of acids, furfural irreversibly polymerizes, acting as a thermosetting polymer [34]. |

| 15.585 | Ethanone and 1-(2-furanyl)- | 1.94 × 106 | 1.08 × 106 | 1.67 × 106 | 1.48 × 106 | 9.83 × 105 | It is found in alcoholic beverages. It is present in cooked apples, marasca cherry, wine grapes, peach, strawberry, plum, blueberry, asparagus, kohlrabi, baked potatoes, pineapple, bread products, rice, yogurt, wines, soy, and black tea. It contributes to the aroma of many foods and beverages. It is used in aromatic compositions. Another name: 2-acetylfuran [35]. |

| 15.893 | Benzaldehyde | 4.65 × 106 | 3.64 × 106 | 1.55 × 107 | 1.24 × 107 | 2.34 × 107 | Benzaldehyde has a role as a flavoring agent, fragrance and a plant metabolite. Benzaldehyde can be derived from natural sources and is colorless liquid that turns to brown on exposure to air. It is an aromatic aldehyde that carries a single formyl group with an almond smell. Benzaldehyde was first extracted from bitter almonds [36]. |

| 16.159 | 1,6-octadien-3-ol and 3,7-dimethyl- | 1.50 × 107 | 9.20 × 106 | 9.33 × 106 | 2.35 × 106 | 3.87 × 106 | Known as linalool, it is a monoterpene abundantly present in the essence of rosewood. It is also found free or combined in the natural essential oils of coriander, basil, lavender or bergamot. It has an antimicrobial effect and it is present in the total pull of volatile organic compounds (VOCs) of many fruits and flowers. It is confirmed that linalool is the most important compound for strawberry flavor [37,38]. |

| 16.921 | 3(2H)-furanone and 4-methoxy-2,5-dimethyl- | 2.56 × 106 | 2.39 × 106 | 2.25 × 106 | 9.20 × 105 | 6.99 × 105 | Furanone methyl ether typical of strawberries. Nice, caramelic, sweet moldy mushroom, vegetable potato, burnt sugar, nut skin, wasabi, fruity, brandy with cocoa and coffee notes [39]. |

| 17.769 | Acetophenone | 4.31 × 106 | 6.67 × 105 | 1.52 × 106 | 8.89 × 105 | 1.21 × 106 | It is the simplest aromatic ketone and an ingredient in fragrances that resemble almond, cherry, honeysuckle, jasmine, and strawberry. It is used in chewing gum. It is also listed as an approved excipient by the U.S. Food and Drug Administration (FDA) [40]. |

| 17.944 | Butanoic acid and 2-methyl- | 1.94 × 106 | 2.87 × 106 | 3.27 × 106 | 1.59 × 106 | 1.78 × 106 | (S)-2-Methylbutyric acid has a pleasantly sweet, fruity odor. (R)-2-methylbutanoic acid has a pervasive, cheesy, and sweaty odor [41]. |

| 18.305 | L-α-terpineol | 4.53 × 106 | 4.02 × 106 | 1.15 × 107 | 1.47 × 106 | 2.98 × 106 | α-Terpineol is a monoterpene alcohol that has been isolated from a variety of sources such as cajuput oil, pine oil, and petitgrain oil. It has a characteristic lilac odor, with a sweet taste reminiscent of peach on dilution. It is found in the composition of various essential oils [39,42]. |

| 20.141 | Heptanoic acid | 2.58 × 106 | 2.85 × 106 | 3.32 × 106 | 1.24 × 106 | 2.65 × 105 | It makes part of flavoring agents and related substances. Cheese and other dairy-type flavors, and ripe fruit especially apple and strawberry [43]. |

| 20.573 | Benzyl alcohol | 3.59 × 105 | 6.02 × 105 | 2.44 × 106 | 2.85 × 105 | 5.73 × 105 | Benzyl alcohol is an aromatic alcohol and a colorless liquid with a mild pleasant aromatic odor. It is a component of some essential oils such as jasmine, neroli, violet and ylang-ylang. It can be used as a preservative [44]. |

| 20.975 | Phenylethyl alcohol | 5.90 × 105 | 2.00 × 105 | 4.36 × 105 | 2.22 × 105 | 4.96 × 105 | Also known as 2-phenylethanol, it is an organic compound that consists of a phenethyl group attached to an OH group. It is a colorless liquid that is widely available in nature, found in a variety of essential oils. It has a pleasant floral odor [45]. |

| 22.531 | Octanoic acid | 3.00 × 105 | 2.40 × 105 | 2.87 × 105 | 4.04 × 105 | 3.98 × 105 | Octanoic acid is a volatile organic acid detected in strawberry jam at a conc of 2.9 mg/kg. [44,46]. |

| 23.573 | 2(3H)-furanone and 5-hexyldihydro- | 2.78 × 106 | 3.14 × 106 | 3.30 × 106 | 7.91 × 105 | 1.06 × 106 | A furan compound linked to a ketone group with a fruity peach flavor [40]. |

| 26.429 | Benzoic acid | 4.52 × 105 | 7.12 × 105 | 7.84 × 105 | 3.39 × 105 | 4.74 × 106 | A simple aromatic carboxylic acid that occurs naturally in many plants and serves as an intermediate in the biosynthesis of many secondary metabolites, and it is found in post-harvested strawberries up to 29 mg/kg [47]. |

| Retention Time | Compound | APS | AVL | A100 | AL | AS | Description |

|---|---|---|---|---|---|---|---|

| 6.130 | Hexanal | 2.53 × 105 | 1.99 × 106 | 8.99 × 105 | 8.03 × 105 | 2.12 × 106 | Also called hexanaldehyde or caproaldehyde, it is an alkyl aldehyde. Its scent resembles freshly cut grass, with a powerful, penetrating characteristic fruity odor and taste. It occurs naturally and contributes a hay-like “off-note” flavor in green peas [21,39,48]. |

| 6.707 | Linalool oxide | 1.21 × 106 | 9.72 × 105 | 5.27 × 106 | 7.54 × 105 | 1.56 × 106 | Furanoid with floral odor type, with musty, camphoreous, herbal, balsamic, and pine notes. Linaloil oxide is found in alcoholic beverages. It is an aromatic and fragrant ingredient. Linaloile oxide is present in roselle tea, muscat grapes, lime oil, alfalfa, Riesling wine, grapefruit, yellow passion fruit, apricot, blackberry, blueberry, and nectarine. Other name: 2-(5-ethenyl-5-methyloxolan-2-yl) propan-2-yl ethyl carbonate (IUPAC) [32]. |

| 11.964 | Cyclohexanone, 2,2,6-trimethyl- | 5.02 × 105 | 4.54 × 105 | 8.28 × 105 | 4.63 × 105 | 9.01 × 105 | Found in bilberries, passion fruit and tea. Also found in apricot, bilberry, white wine, black tea, green tea, microbial fermented tea, brewed tea, yellow passion fruit juice and dill herb [40]. |

| 12.523 | 5-Hepten-2-one, 6-methyl- | 1.37 × 106 | 1.69 × 106 | 2.13 × 106 | 1.25 × 106 | 1.84 × 106 | Also known as sulcatone, it is an unsaturated methylated ketone with a citrus-like, fruity odor. Sulcatone is one of a number of mosquito attractants and has been also found in apricot scent [39,49]. |

| 14.931 | Furfural | 3.52 × 107 | 1.46 × 107 | 5.87 × 107 | 2.40 × 107 | 4.37 × 107 | The compound is an aldehyde group attached to the 2-position of furan. It is a product of the acid catalyzed dehydration of five-carbon sugars (pentoses), particularly xylose. These sugars may be obtained from hemicellulose present in lignocellulosic biomass, which can be extracted from most terrestrial plants. It is found in many foods: coffee (55–255 mg/kg) and whole-grain bread (26 mg/kg). When heated in the presence of acids, furfural irreversibly polymerizes, acting as a thermosetting polymer [34,39]. |

| 15.881 | Benzaldehyde | 3.08 × 106 | 2.64 × 106 | 5.58 × 106 | 3.03 × 106 | 7.65 × 106 | A colorless liquid that turns to brown on exposure to air. Benzaldehyde has a characteristic odor and aromatic taste, similar to bitter almond, and is also produced during the ripening of apricots [39,50]. |

| 16.143 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 3.03 × 107 | 2.66 × 107 | 3.27 × 107 | 3.80 × 106 | 4.83 × 106 | Known as linalool, it is a monoterpene abundantly present in the essence of rosewood. It is also found free or combined in the natural essential oils of coriander, basil, lavender or bergamot. It has an antimicrobial effect and it is present in the total pull of volatile organic compounds (VOCs) of many flowers and fruits such as apricots [39,48]. |

| 16.605 | 2-Furancarboxaldehyde, 5-methyl- | 8.24 × 105 | 2.51 × 105 | 1.56 × 106 | 5.97 × 105 | 1.42 × 106 | Organic compounds known as aryl-aldehydes; it contains an aldehyde group directly attached to an aromatic ring. It is found in pepper (c. annuum). The 5-methyl-2-furancarboxaldehyde is isolated from brown algae and other plant sources, doubtless as a secondary produced from saccharides [39,48,50]. |

| 16.974 | 3-Cyclohexen-1-ol, 4-methyl-1-(1-methylethyl)-, (R)- | 6.27 × 105 | 1.13 × 106 | 1.35 × 106 | 6.28 × 105 | 8.61 × 105 | It is also known as 4-terpineol and is a flavoring ingredient found in the aroma of apricots. It has a role as a plant metabolite, antibacterial agent, antioxidant, anti-inflammatory agent, and antiparasitic agent [51]. |

| 18.247 | L-α-Terpineol | 1.76 × 107 | 1.97 × 107 | 3.94 × 107 | 4.16 × 106 | 1.08 × 107 | α-Terpineol is a monoterpene alcohol that has been isolated from a variety of sources such as cajuput oil, pine oil, and petitgrain oil. It has a characteristic lilac odor with a sweet taste reminiscent of peach on dilution. It is found in the composition of various essential oils [39,42,51]. |

| 20.703 | 4-Acetyl-1-methylcyclohexene | 2.59 × 105 | 3.23 × 105 | 7.88 × 105 | 1.18 × 105 | 2.21 × 105 | It is found in cereals and cereal products. The 4-Acetyl-1-methylcyclohexene is a flavoring ingredient. It is isolated from the famine food Santalum album (sandalwood) [48]. |

| 21.252 | trans-.beta.-Ionone | 9.88 × 105 | 1.26 × 106 | 1.44 × 106 | 8.17 × 105 | 1.12 × 106 | β-Ionone has a characteristic violet-like odor, and is fruitier and woodier than α-ionone. |

| 26.326 | Benzoic acid | 4.44 × 105 | 7.11 × 105 | 9.42 × 105 | 2.70 × 105 | 1.53 × 107 | It is a simple aromatic carboxylic acid that occurs naturally in many plants and serves as an intermediate in the biosynthesis of many secondary metabolites. It is found during the ripening of apricots [50] and in post-harvest strawberries up to 29 mg/kg [47]. |

| Retention Time | Compound | CPS | CVL | C100 | CL | CS | Description |

|---|---|---|---|---|---|---|---|

| 13.630 | Nonanal | 1.18 × 106 | 3.49 × 105 | 2.11 × 105 | 1.08 × 105 | 1.90 × 105 | Nonanal has a strong, fatty odor, developing an orange and rose note on dilution. It has a fatty, citrus-like flavor [39,40,52]. |

| 14.943 | Furfural | 5.77 × 106 | 9.86 × 106 | 7.46 × 106 | 1.51 × 107 | 1.26 × 107 | The compound is an aldehyde group attached to the 2-position of furan. It is a product of the acid catalyzed dehydration of five-carbon sugars (pentoses), particularly xylose. These sugars may be obtained from hemicellulose present in lignocellulosic biomass, which can be extracted from most terrestrial plants. It is found in many foods: coffee (55–255 mg/kg) and whole-grain bread (26 mg/kg). When heated in the presence of acids, furfural irreversibly polymerizes, acting as a thermosetting polymer [34,39,40]. |

| 15.881 | Benzaldehyde | 1.04 × 107 | 4.14 × 106 | 2.52 × 106 | 4.84 × 107 | 8.93 × 107 | Benzaldehyde has a role as a flavoring agent, fragrance and a plant metabolite. It is an aromatic aldehyde that carries a single formyl group. Benzaldehyde can be derived from natural source and is colorless liquid that turns to brown on exposure to air. Benzaldehyde has a characteristic odor and aromatic taste, similar to bitter almond, and is also produced during the ripening of apricots and cherries [36,39,50,52]. |

| 16.155 | 1,6-Octadien-3-ol, 3,7-dimethyl- | 1.87 × 106 | 2.42 × 106 | 1.83 × 106 | 1.05 × 106 | 1.18 × 106 | Known as linalool, it is a monoterpene abundantly present in the essence of rosewood. It is also found free or combined in the natural essential oils of coriander, basil, lavender or bergamot. It has an antimicrobial effect and is present in the total pull of VOCs of many flowers and fruits as apricots and cherries [39,48,52]. |

| 18.264 | L-α-Terpineol | 2.01 × 107 | 1.07 × 106 | 7.82 × 106 | 1.20 × 106 | 1.63 × 106 | α-Terpineol is a monoterpene alcohol that has been isolated from a variety of sources such as cajuput oil, pine oil, and petitgrain oil. It has a characteristic lilac odor, with a sweet taste reminiscent of peach on dilution. It is found in the composition of various essential oils [39,42,51,52]. |

| 26.307 | Benzoic acid | 5.70 × 105 | 5.87 × 105 | 3.24 × 105 | 2.09 × 105 | 2.30 × 106 | It is a simple aromatic carboxylic acid that occurs naturally in many plants and serves as an intermediate in the biosynthesis of many secondary metabolites. It is found during the ripening of apricots [50] and in post-harvest strawberries up to 29 mg/kg [47]. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Núñez-Carmona, E.; Abbatangelo, M.; Zottele, I.; Piccoli, P.; Tamanini, A.; Comini, E.; Sberveglieri, G.; Sberveglieri, V. Nanomaterial Gas Sensors for Online Monitoring System of Fruit Jams. Foods 2019, 8, 632. https://doi.org/10.3390/foods8120632

Núñez-Carmona E, Abbatangelo M, Zottele I, Piccoli P, Tamanini A, Comini E, Sberveglieri G, Sberveglieri V. Nanomaterial Gas Sensors for Online Monitoring System of Fruit Jams. Foods. 2019; 8(12):632. https://doi.org/10.3390/foods8120632

Chicago/Turabian StyleNúñez-Carmona, Estefanía, Marco Abbatangelo, Ivano Zottele, Pierpaolo Piccoli, Armando Tamanini, Elisabetta Comini, Giorgio Sberveglieri, and Veronica Sberveglieri. 2019. "Nanomaterial Gas Sensors for Online Monitoring System of Fruit Jams" Foods 8, no. 12: 632. https://doi.org/10.3390/foods8120632

APA StyleNúñez-Carmona, E., Abbatangelo, M., Zottele, I., Piccoli, P., Tamanini, A., Comini, E., Sberveglieri, G., & Sberveglieri, V. (2019). Nanomaterial Gas Sensors for Online Monitoring System of Fruit Jams. Foods, 8(12), 632. https://doi.org/10.3390/foods8120632