High-Protein Nutritious Flatbreads and an Option for Gluten-Sensitive Individuals

Abstract

1. Introduction

1.1. Quinoa

1.2. Wheat

1.3. Peanuts

1.4. Broccoli

1.5. Beets

2. Materials and Methods

2.1. Materials and Composition

2.2. Flatbread Making Process

2.3. Sensory Evaluation

2.4. Physical Analysis

2.4.1. Water Activity

2.4.2. True Density

2.4.3. Bulk Density

2.4.4. Texture Analysis

2.4.5. Color Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Sensory Evaluation Analysis

3.2. Acceptability

3.3. Physical Analysis

3.4. Conclusions

4. Statement

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parimala, K.R.; Sudha, M.L. Wheat—based traditional flat breads of India. Crit. Rev. Food Sci. Nutr. 2015, 55, 67–81. [Google Scholar] [CrossRef] [PubMed]

- Product Development Contest 2019, American Society for Baking: Flatbreads. Available online: https://www.cpp.edu/~agri/news/2019-asb-product-development-winners.shtml (accessed on 18 November 2019).

- USDA Nutrition Policy and Promotion; Dietary Guidelines for Americans. Available online: http://health.gov/dietaryguidelines/2015/guidelines/ (accessed on 18 November 2019).

- Mother-Jones. No, Feeding Hungry Kids and Seniors Isn’t a Waste of Money. Available online: https://www.motherjones.com/politics/2017/03/trump-budget-school-meals-on-wheels/ (accessed on 18 November 2019).

- Kahlon, T.S.; Smith, G.E. In Vitro Binding of Bile Acids by Spinach, Kale, Brussels sprouts, Broccoli, Mustard greens, Peppers green, Cabbage and Collards. Food Chem. 2007, 100, 1531–1536. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Chapman, M.; Smith, G.E. In vitro binding of bile acids by okra, beets, asparagus, eggplant, turnips, green beans, carrots, and cauliflower. Food Chem. 2007, 103, 676–680. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Chiu, M.M.; Chapman, M. Steam Cooking Significantly Improves In Vitro Bile Acid Binding of Beets, Eggplant, Asparagus, Carrots, Green beans and Cauliflower. Nutr. Res. 2007, 27, 750–755. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Chiu, M.M.; Chapman, M. Steam Cooking Significantly Improves In Vitro Bile Acid Binding of Collard greens, Kale, Mustard greens, Broccoli, Green bell pepper and Cabbage. Nutr. Res. 2008, 28, 351–357. [Google Scholar] [CrossRef] [PubMed]

- Kahlon, T.S.; Milczarek, R.R.; Chiu, M.M. In Vitro Bile Acid Binding of Mustard greens, Kale, Broccoli, Cabbage and Green bell pepper Improves with Sautéing Compared with Raw or Other Methods of Preparation. Food Nutr. Sci. 2012, 3, 951–958. [Google Scholar]

- Kahlon, T.S.; Milczarek, R.R.; Chiu, M.M. In Vitro Bile Acid Binding of Kale, Mustard greens, Broccoli, Cabbage and Green bell pepper Improves with Microwave Cooking. Vegetos 2012, 25, 29–36. [Google Scholar]

- Whole Grain Council. Available online: https://wholegrainscouncil.org/whole-grains-101/health-studies (accessed on 18 November 2019).

- Halnaes, A.; Kyro, C.; Anderson, I.; Lacoppidan, S.; Overvad, K. Intake of whole grains is associated with lower risk of myocardial infarction: The Danish Diet, Cancer and Health Cohort. Am. J. Clin. Nutr. 2016, 103, 999–1007. [Google Scholar] [CrossRef] [PubMed]

- Hollon, J.R.; Cureton, P.A.; Martin, M.L.; Puppa, E.L.; Fasano, A. Trace gluten contamination may play a role in mucosal and clinical recovery in a subgroup of diet-adherent non-responsive celiac disease patients. BMC Gastroenterol. 2013, 13, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Hietikko, M.; Koskinen, O.; Kurppa, K.; Laurila, K.; Saavalainen, P.; Salmi, T.; Ilus, T.; Huhtala, H.; Kaukinen, K.; Lindfors, K. Small-intestinal TG2-specific plasma cells at different stages of coeliac disease. MBC Immunol. 2018, 19, 36–43. [Google Scholar] [CrossRef] [PubMed]

- Lebwohl, B.; Ludvigsson, J.F.; Green, P.H. Celiac disease and non-celiac gluten sensitivity. BMJ 2015, 351, h4347. [Google Scholar] [CrossRef] [PubMed]

- Kahlon, T.S.; Chiu, M.M. Whole Grain Gluten-free Flat Breads. Cereal Food. World 2012, 57, 6–9. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Chiu, M.M. Ancient whole gain gluten-free flatbreads. Food Nutr. Sci. 2014, 5, 1717–1724. [Google Scholar]

- Kahlon, T.S.; Avena-Bustillos, R.J.; Chiu, M.M.; Kahlon, A.K. Sensory evaluation of ancient whole grain gluten-free buckwheat, peanut oilcake, beets flatbreads. Nutr. Food Sci. Int. J. 2018, 7, 555722. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Avena-Bustillos, R.J.; Chiu, M.M.; Kahlon, A.K. Ancient whole grain gluten-free quinoa, high protein, vegetable flatbreads. Int. J. Food Nutr. Res. 2019, 3, 1–11. [Google Scholar]

- Crawford, L.M.; Kahlon, T.S.; Chiu, M.M.; Wang, S.C.; Friedman, M. Acrylamide Content of Experimental and Commercial Flatbreads. J. Food Sci. 2019, 84, 659–666. [Google Scholar] [CrossRef] [PubMed]

- Crawford, L.M.; Kahlon, T.S.; Chiu, M.M.; Wang, S.C.; Friedman, M. Acrylamide Content of Experimental Flatbreads Prepared from Potato, Quinoa, and Wheat Flours with Added Fruit and Vegetable Peels and Mushroom Powders. Foods 2019, 8, 228. [Google Scholar] [CrossRef] [PubMed]

- World Production of Quinoa 2016. Available online: https://www.worldatlas.com/articles/the-top-quinoa-producing-countries-in-the-world.html (accessed on 27 April 2017).

- The Food and Agricultural Organization of the United Nations (FAO). Press Release Note No. 6367, 24 October 2012 Officially Declared that the Year 2013 Be Recognized as The International Year of the Quinoa; FAO: Rome, Italy, 2012. [Google Scholar]

- World Wheat Production 2019–2020. Available online: http://www.worldagriculturalproduction.com/crops/wheat.aspx (accessed on 18 November 2019).

- American Peanut Council. Available online: https://www.peanutsusa.com/about-apc/the-peanut-industry.html (accessed on 18 November 2019).

- Broccoli Production 2017. Available online: https://en.wikipedia.org/wiki/Broccoli#Production (accessed on 18 November 2019).

- Beets World Crops. Available online: https://worldcrops.org/crops/beets (accessed on 18 November 2019).

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 17th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000; Method 990.03. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 14th ed.; Association of Analytical Chemists: Washington DC, USA, 1984; Method 27.006. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists, 15th ed.; Association of Official Analytical Chemist: Washington DC, USA, 1990; Methods 923.03 and 935.29. [Google Scholar]

- Water Activity in Foods Safefoods 360. Available online: https://safefood360.com/free-resources/whitepapers/preview/water-activity-in-foods/ (accessed on 18 November 2019).

- US Food & Drug Administration (FDA) Inspection Guides. Available online: https://www.fda.gov/iceci/inspections/ (accessed on 18 November 2019).

| Ingredients | Protein | Fat | Minerals | Dietary Fiber | Carbohy-Drates | DM | Water |

|---|---|---|---|---|---|---|---|

| Quinoa | 13.14 ± 0.01 | 6.56 ± 0.12 | 2.02 ± 0.01 | 8.28 ± 0.77 | 68.89 ± 0.05 | 90.61 ± 0.02 | 9.39 ± 0.02 |

| Wheat | 11.80 ± 0.03 | 3.61 ± 0.11 | 1.67 ± 0.01 | 12.56 ± 0.24 | 72.59 ± 0.05 | 89.67 ± 0.30 | 10.33 ± 0.30 |

| Peanut Oilcake | 46.01 ± 0.02 | 10.64 ± 0.14 | 4.34 ± 0.01 | 13.69 ± 1.11 | 30.93 ± 0.06 | 91.92 ± 0.05 | 8.08 ± 0.05 |

| Broccoli | 3.57 ± 0.33 | 0.45 ± 0.07 | 0.94 ± 0.07 | 4.72 ± 0.62 | 4.80 ± 0.08 | 9.76 ± 0.07 | 90.24 ± 0.07 |

| Beets | 2.39 ± 0.47 | 0.13 ± 0.01 | 1.27 ± 0.06 | 2.80 ± 0.45 | 10.99 ± 0.34 | 14.78 ± 0.44 | 85.22 ± 0.44 |

| Flatbreads | Quinoa g | Wheat g | Peanut Oilcake, g | Broccoli g | Beets g | Salt, g | Water, mL/100 g Ingredients |

|---|---|---|---|---|---|---|---|

| QPCBROC | 36.10 | __ | 36.10 | 27.07 | -- | 0.73 | 50.7 |

| WPCBROC | -- | 36.10 | 36.10 | 27.07 | -- | 0.73 | 54.1 |

| QPCBEET | 36.10 | -- | 36.10 | -- | 27.07 | 0.76 | 36.4 |

| WPCBEET | -- | 36.10 | 36.10 | -- | 27.07 | 0.73 | 36.10 |

| Flatbreads | Color/ Appearance | Odor/ Aroma | Taste/ Flavor | Texture/ Mouth Feel | Acceptance |

|---|---|---|---|---|---|

| QPCBROC | 4.25 ± 0.09 a | 4.04 ± 0.09 a | 3.80 ± 0.12 a | 3.59 ± 0.11 a | 1.83 ± 0.04 a |

| WPCBROC | 3.78 ± 0.09 b | 3.74 ± 0.10 bc | 3.59 ± 0.12 ab | 3.43 ± 0.11 ab | 1.70 ± 0.05 a |

| QPCBEET | 4.14 ± 0.09 a | 3.95 ± 0.09 ab | 3.40 ± 0.12 b | 3.40 ± 0.12 ab | 1.78 ± 0.05 a |

| WPCBEET | 4.05 ± 0.10 a | 3.54 ± 0.10 c | 3.38 ± 0.12 b | 3.16 ± 0.12 b | 1.69 ± 0.05 a |

| Flatbreads | Aw, ERH/100 | ρt, kg/m3 | ρb, kg/m3 | Porosity, % | Expansion, % | Break Force, g | Stretchability, mm |

|---|---|---|---|---|---|---|---|

| QPCBROC | 0.94 ± 0.01 a | 1.40 ± 0.01 a | 0.78 ± 0.01 b | 0.44 ± 0.02 a | 1.81 ± 0.05 a | 1150 ± 110 c | 7.31 ± 0.61 a |

| WPCBROC | 0.94 ± 0.01 a | 1.43 ± 0.01 a | 0.90 ± 0.01 a | 0.38 ± 0.01 b | 1.6 0± 0.02 b | 1341 ± 169 c | 6.67 ± 0.80 a |

| QPCBEET | 0.92 ± 0.01 b | 1.44 ± 0.01 a | 0.93 ± 0.03 a | 0.35 ± 0.01 bc | 1.55 ± 0.03 bc | 2189 ± 91 a | 4.25 ± 0.34 b |

| WPCBEET | 0.94 ± 0.01 a | 1.41 ± 0.01 a | 0.94 ± 0.01 a | 0.33 ± 0.01 c | 1.50 ± 0.01 c | 1802 ± 65 b | 7.30 ± 0.20 a |

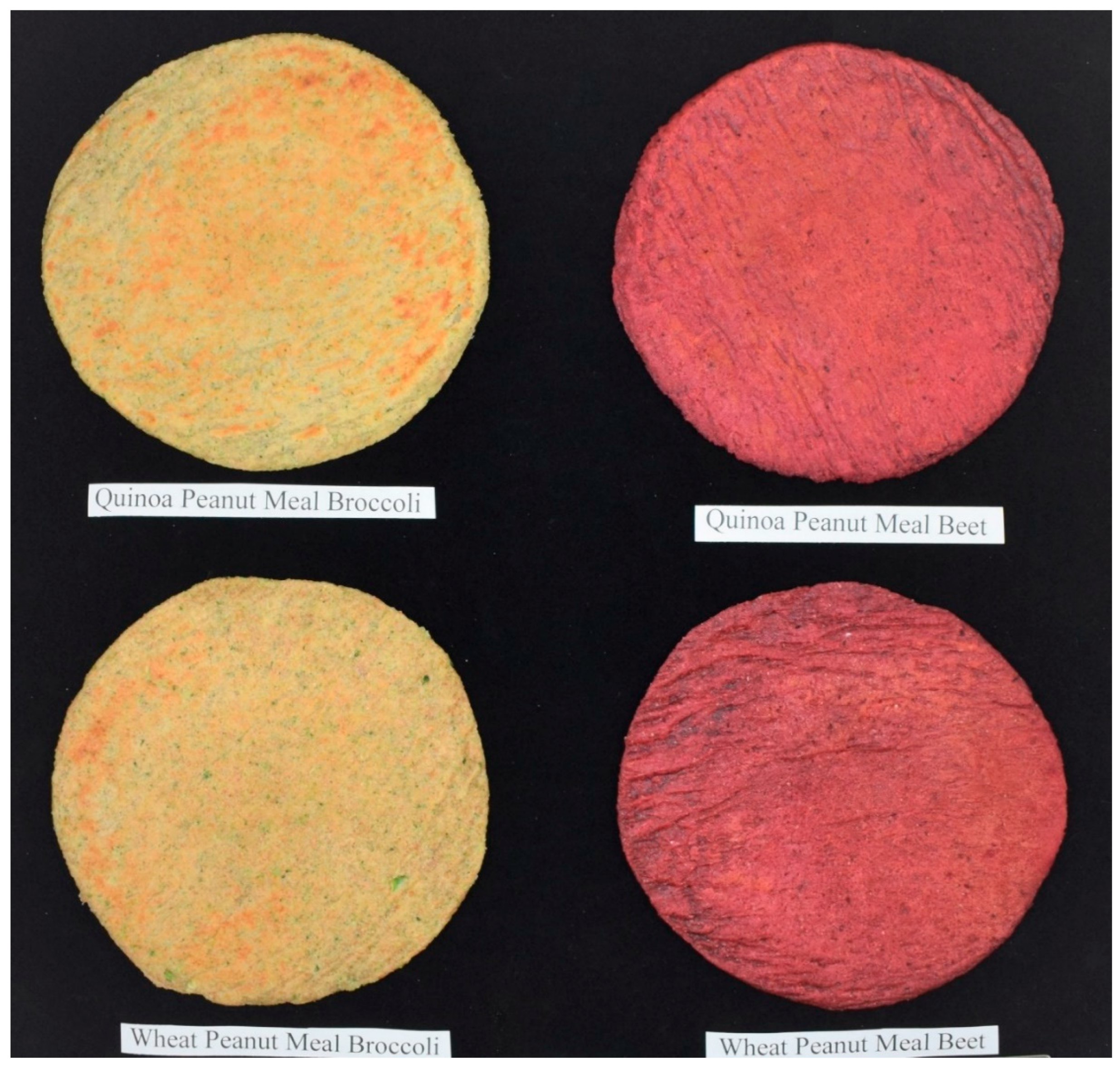

| Flatbreads | L* (Black = 0, White =100) | a* (Green −, Red +) | b* (Blue −, Yellow +) |

|---|---|---|---|

| QPCBROC | 55.97 ± 0.59 b | 7.29 ± 0.66 c | 27.60 ± 0.42 a |

| WPCBROC | 57.40 ± 0.33 a | 5.34 ± 0.34 d | 23.27 ± 0.45 b |

| QPCBEET | 36.40 ± 0.18 d | 24.85 ± 0.23 b | 14.38 ± 0.44 c |

| WPCBEET | 40.11 ± 0.42 c | 26.76 ± 0.07 a | 9.44 ± 0.35 d |

| Flatbreads | Protein | Fat | Minerals | Dietary Fiber | Carbohydrates | DM |

|---|---|---|---|---|---|---|

| QPCBROC | 32.82 ± 0.01 a | 5.80 ± 0.03 a | 4.40 ± 0.01 a | 11.41 ± 0.48 b | 56.98 ± 0.02 c | 64.70 ± 0.29 |

| WPCBROC | 30.58 ± 0.06 c | 4.70 ± 0.03 b | 4.25 ± 0.02 c | 13.32 ± 0.38 a | 60.47 ± 0.04 a | 65.56 ± 0.46 |

| QPCBEET | 31.95 ± 0.05 b | 5.34 ± 0.39 ab | 4.35 ± 0.01 b | 10.71 ± 0.45 c | 58.36 ± 0.15 b | 68.74 ± 0.27 |

| WPCBEET | 29.55 ± 0.02 d | 5.15 ± 0.07 ab | 4.13 ± 0.01 d | 13.14 ± 0.35 a | 61.17 ± 0.03 a | 66.35 ± 0.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kahlon, T.S.; Avena-Bustillos, R.J.; Brichta, J.L.; Kahlon, A.K. High-Protein Nutritious Flatbreads and an Option for Gluten-Sensitive Individuals. Foods 2019, 8, 591. https://doi.org/10.3390/foods8110591

Kahlon TS, Avena-Bustillos RJ, Brichta JL, Kahlon AK. High-Protein Nutritious Flatbreads and an Option for Gluten-Sensitive Individuals. Foods. 2019; 8(11):591. https://doi.org/10.3390/foods8110591

Chicago/Turabian StyleKahlon, Talwinder S., Roberto J. Avena-Bustillos, Jenny L. Brichta, and Ashwinder K. Kahlon. 2019. "High-Protein Nutritious Flatbreads and an Option for Gluten-Sensitive Individuals" Foods 8, no. 11: 591. https://doi.org/10.3390/foods8110591

APA StyleKahlon, T. S., Avena-Bustillos, R. J., Brichta, J. L., & Kahlon, A. K. (2019). High-Protein Nutritious Flatbreads and an Option for Gluten-Sensitive Individuals. Foods, 8(11), 591. https://doi.org/10.3390/foods8110591