The Effects of Milling Conditions on the Particle Size, Quality, and Noodle-Making Performance of Whole-Wheat Flour: A Mortar Mill Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mortar-Milled WWFs and Analysis of Their Particle Sizes

2.3. Measuring Moisture, Ash, Total Starch, and Damaged Starch Contents of Mortar-Milled WWFs

2.4. Analysis of SRC of Mortar-Milled WWFs

2.5. Analysis of SDS Sedimentation Volume of Mortar-Milled WWFs

2.6. Analysis of the Mixograph Properties of Mortar-Milled WWFs

2.7. Analysis of Total Phenolic Content (TPC) and Antioxidant Activity in Mortar-Milled WWFs

2.8. Preparation of Noodles Using Mortar-Milled WWFs and Evaluation of Noodle Quality

2.9. Statistical Analysis

3. Results and Discussion

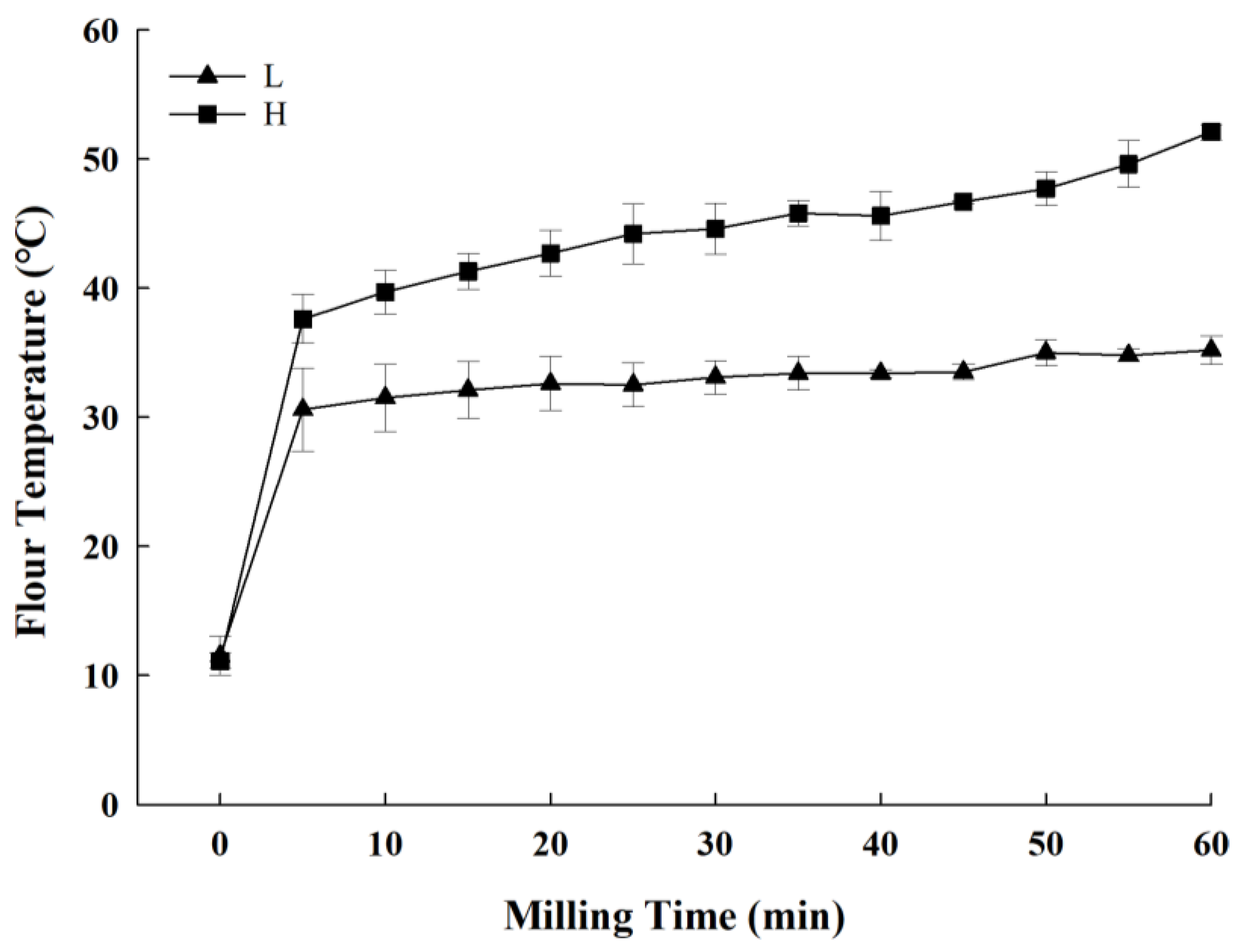

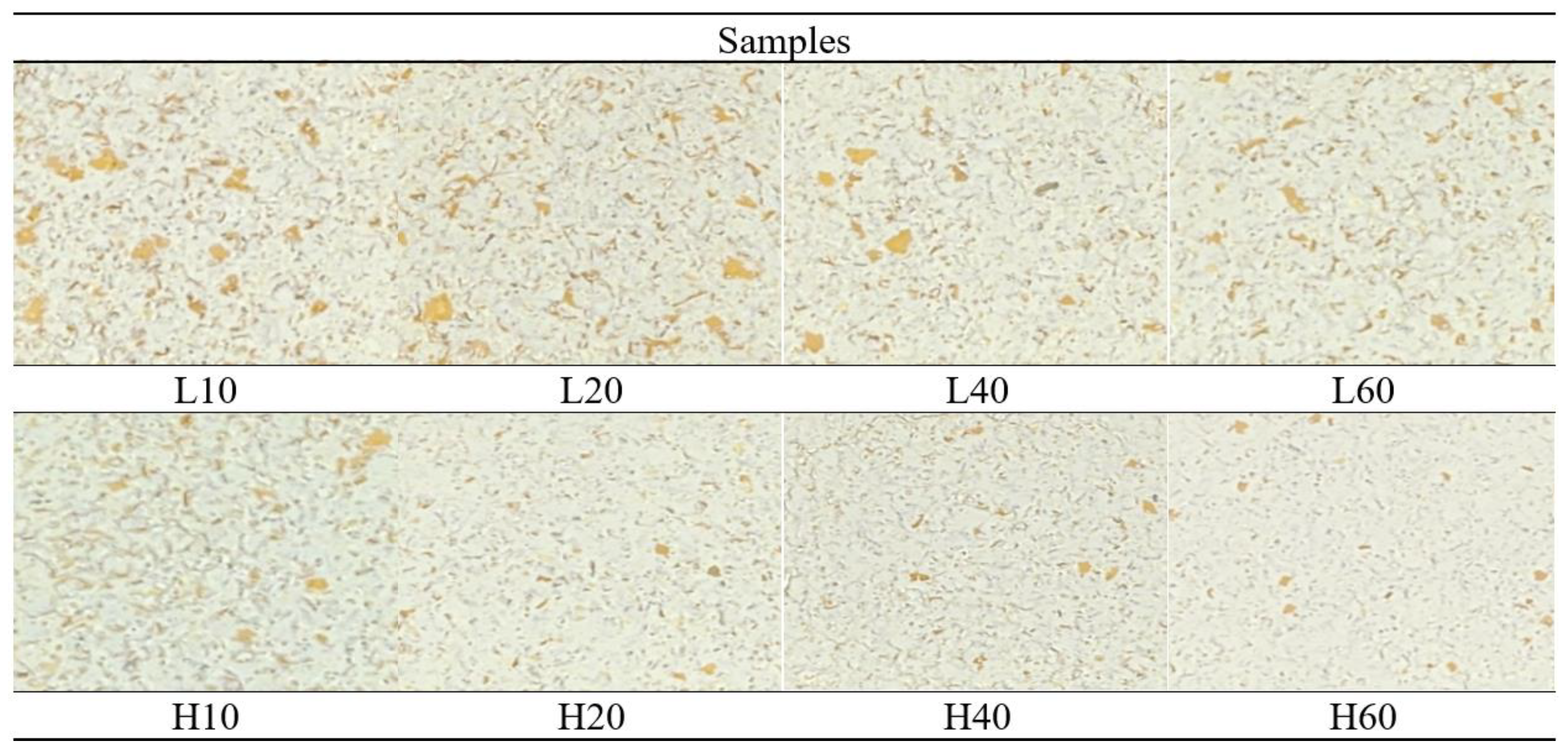

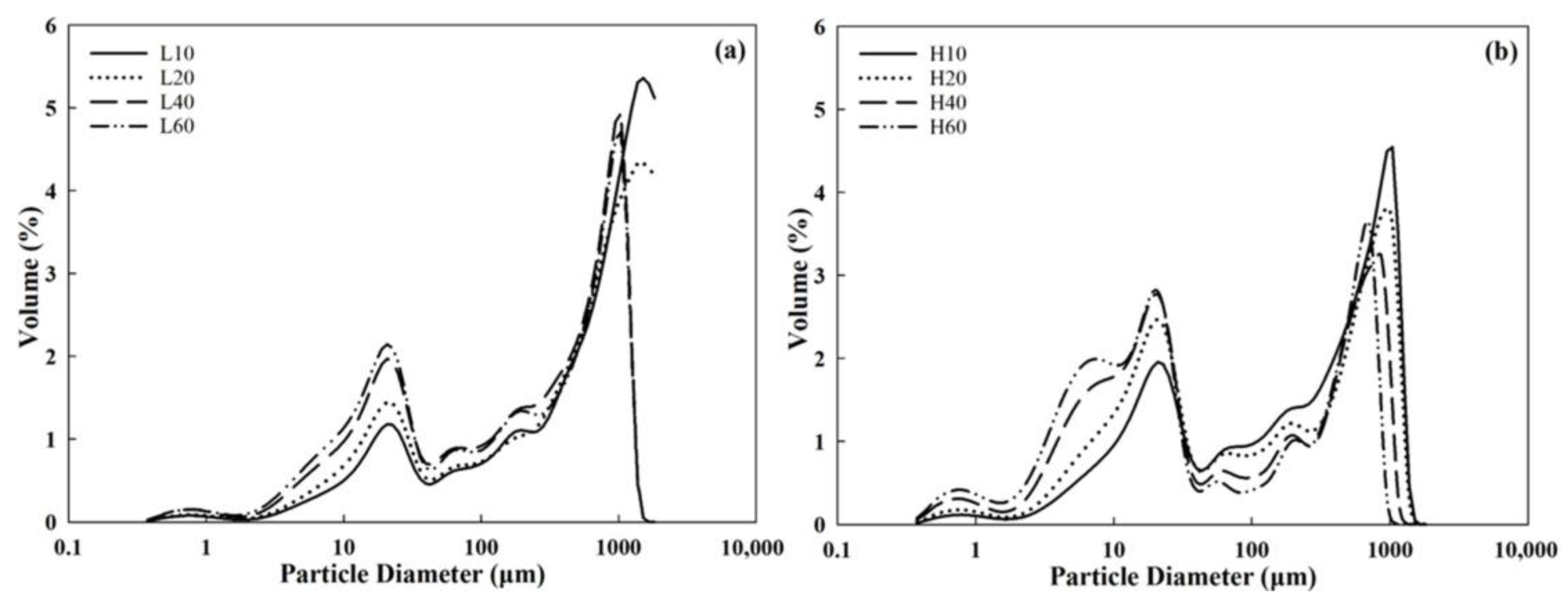

3.1. Appearance and Particle Size Distribution of WWFs

3.2. Moisture, Ash, Total Starch, and Damaged Starch Contents of WWFs

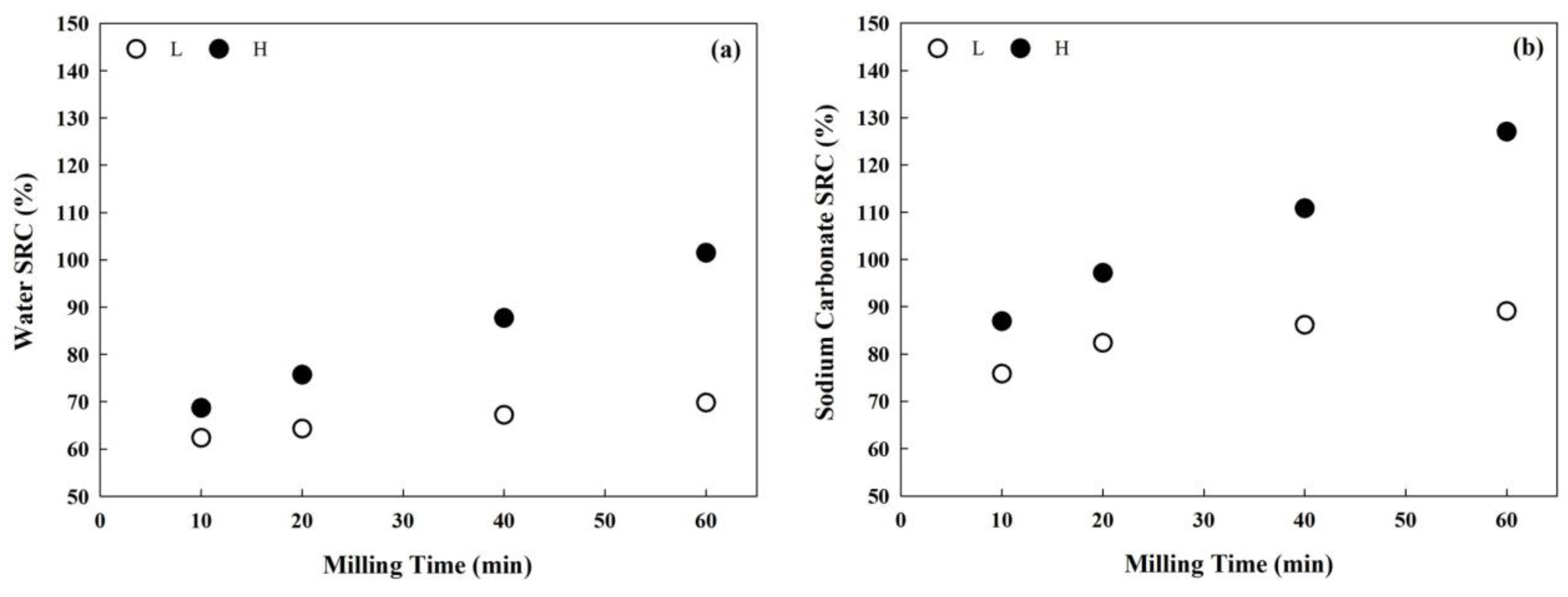

3.3. SRC of WWFs

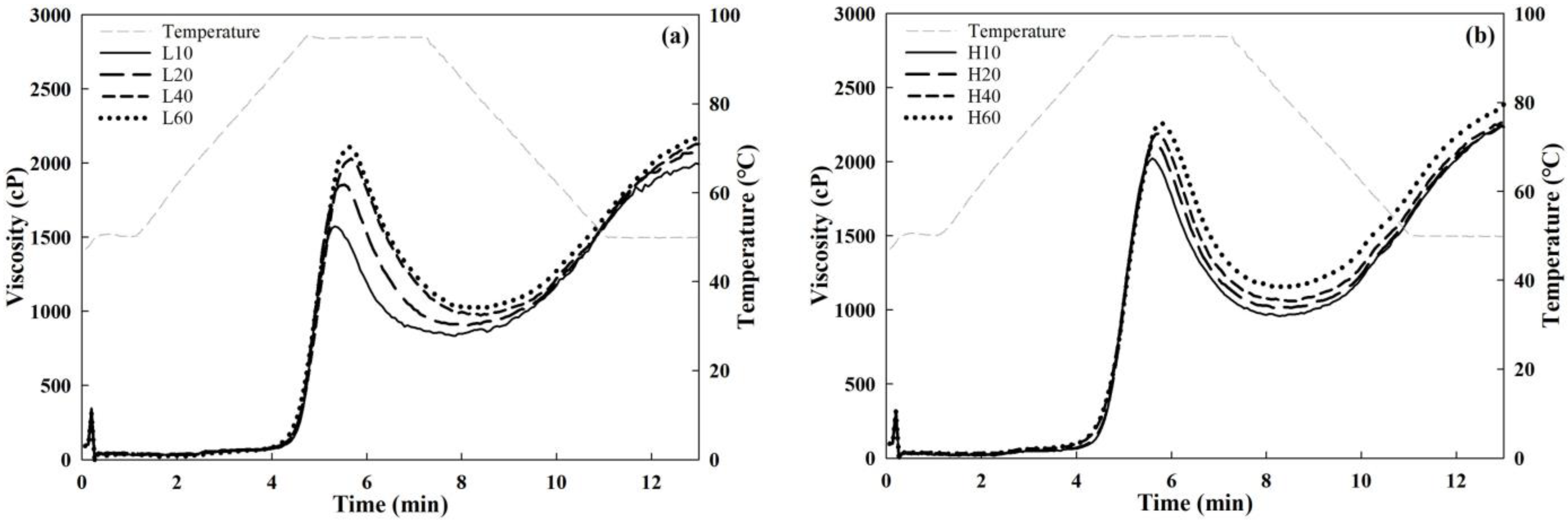

3.4. Pasting Properties of WWFs

3.5. SDS Sedimentation Volume of WWFs

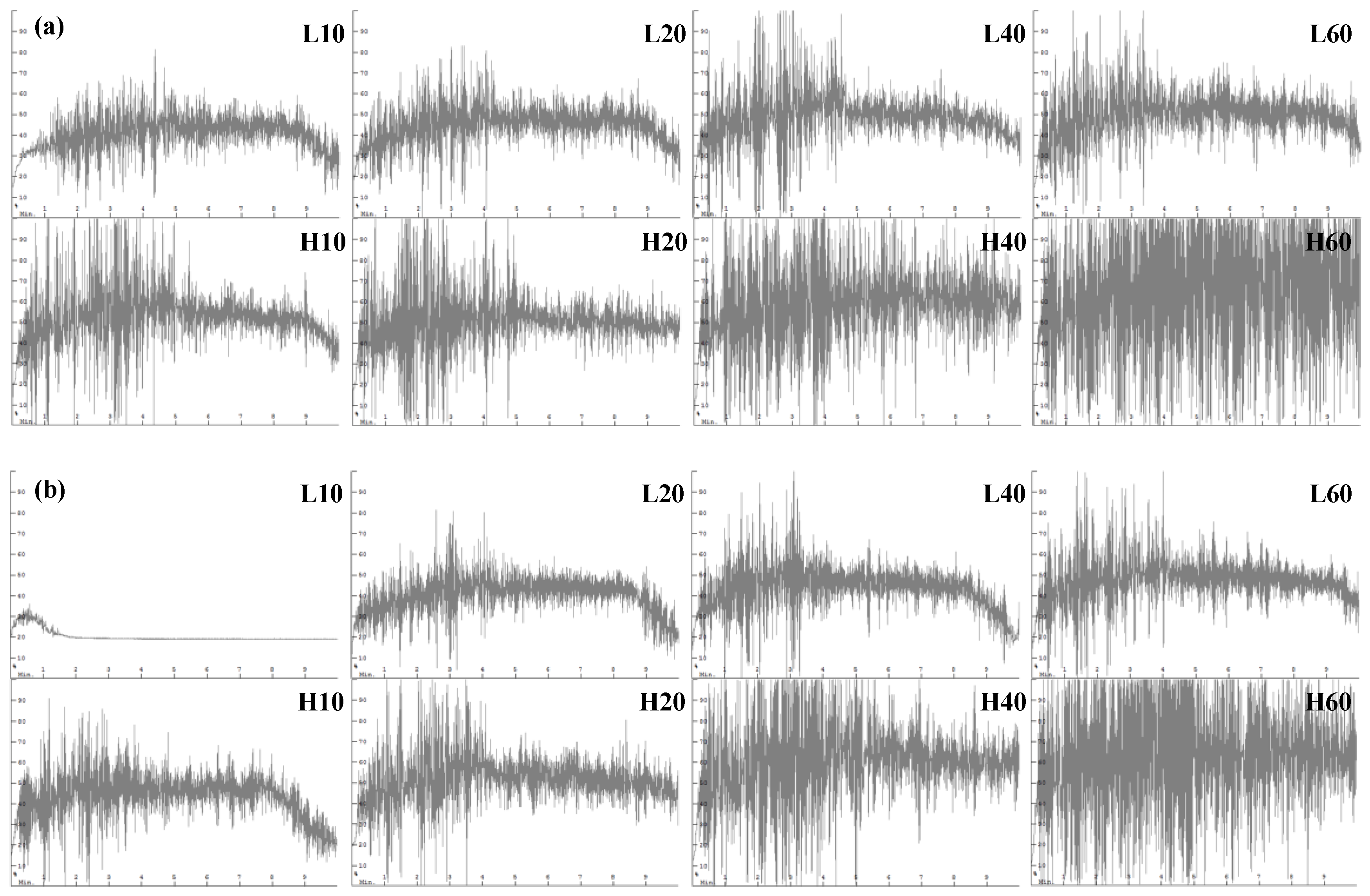

3.6. Dough Mixing Properties of WWFs

3.7. TPC and Antioxidant Activity in Mortar-Milled WWFs

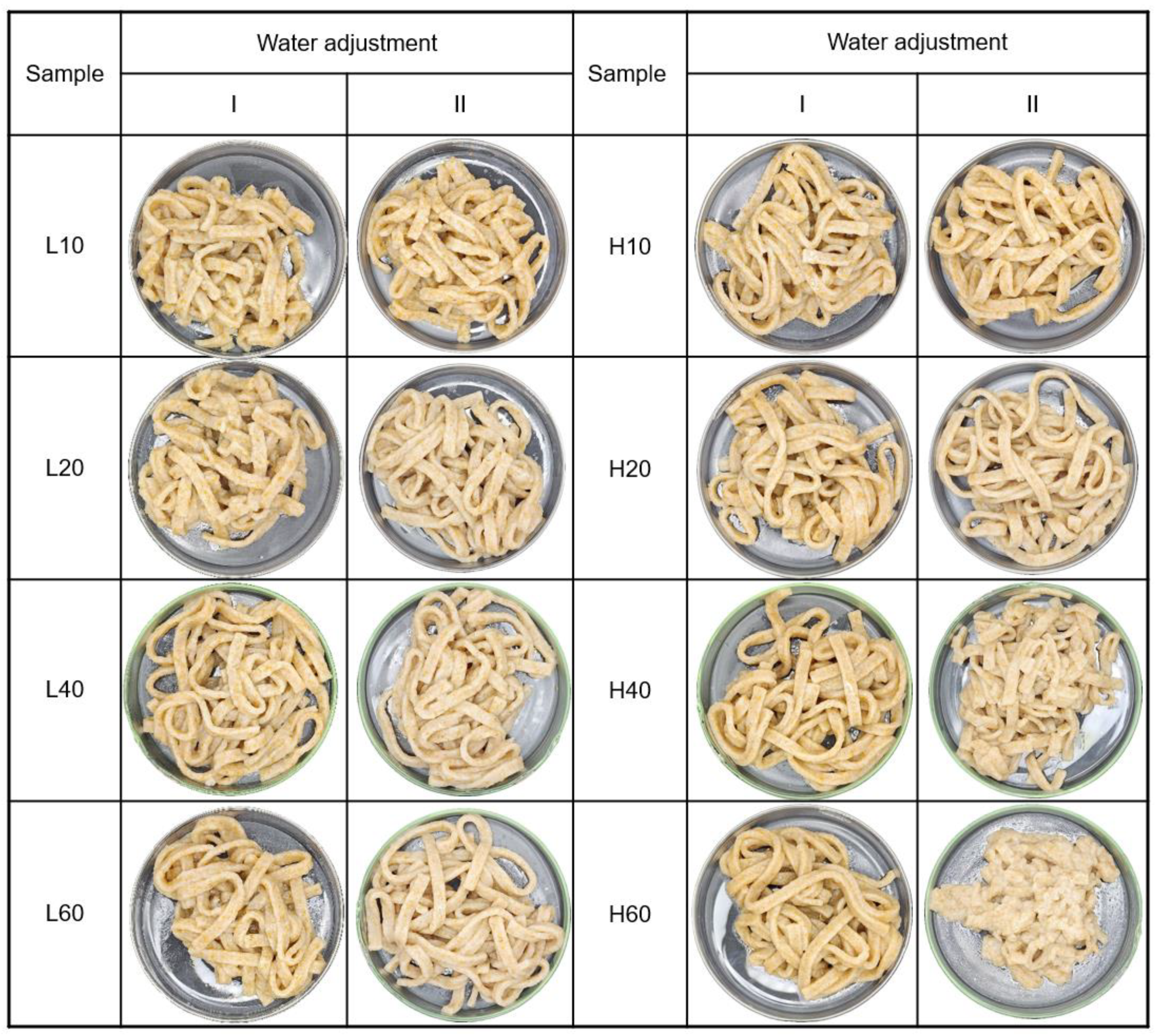

3.8. Color and Textural Properties of Fresh Noodles Made from Mortar-Milled WWFs

3.9. Quality Characteristics of Cooked Noodles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WWF | Whole-wheat flour |

| SRC | Solvent-retention capacity |

| SDS | Sodium dodecyl sulfate |

| TPC | Total phenolic content |

| TPA | Texture profile analysis |

| RVA | Rapid viscosity analyzer |

| ABTS | 2,2′-aznio-bis(3-ethylbenzothiazoline-6-sulfonic acid) |

| R/E | Resistance to extensibility ratio |

| AACC | American Association of Cereal Chemists |

References

- Korea Flour Mills Industrial Association. Flour Consumption per Capita by Year. 2023. Available online: http://www.kofmia.org/data/stat_idx04.jsp (accessed on 3 July 2024).

- Kang, C.S.; Kim, K.H.; Cheong, Y.K.; Kim, H.S.; Kim, Y.J.; Choi, I.; Park, J.C.; Shin, S.H.; Son, J.H.; Kim, K.H.; et al. A New Wheat Variety, “Hojoong” with Pre-Harvest Sprouting Resistance, Low Amylose Content and Good Noodles Quality. The Proceedings of the Korean Breeding Society. July 2013. p. 72. Available online: https://db.koreascholar.com/Article/Detail/294531 (accessed on 1 February 2025).

- Tong, L.T.; Zhong, K.; Liu, L.; Qiu, J.; Guo, L.; Zhou, X.; Cao, L.; Zhou, S. Effects of dietary wheat bran arabinoxylans on cholesterol metabolism of hypercholesterolemic hamsters. Carbohydr. Polym. 2014, 112, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Wang, Z.; Guo, X.; Wang, F.; Huang, J.; Sun, B.; Wang, X. Sourdough improves the quality of whole-wheat flour products: Mechanisms and challenges—A review. Food Chem. 2021, 360, 130038. [Google Scholar] [CrossRef]

- Doblado-Maldonado, A.F.; Pike, O.A.; Sweley, J.C.; Rose, D.J. Key issues and challenges on whole wheat flour milling and storage. J. Cereal Sci. 2012, 56, 119–126. [Google Scholar] [CrossRef]

- Jones, J.M.; Adams, J.; Harriman, C.; Miller, C.; Van der Kamp, J.W. Nutritional impacts of different whole grain milling techniques: A review of milling practices and existing data. Cereal Foods World 2015, 60, 130–139. [Google Scholar] [CrossRef]

- Song, Y.Y.; Wang, Y.H.; Chen, J. Physicochemical properties of wheat flour with different particle size ranges. Mod. Food Sci. Technol. 2016, 32, 116–120. [Google Scholar]

- Guo, P.; Yu, J.; Wang, S.; Wang, S.; Copeland, L. Effects of particle size and water content during cooking on the physicochemical properties and in vitro starch digestibility of milled durum wheat grains. Food Hydrocoll. 2018, 77, 445–453. [Google Scholar] [CrossRef]

- Lai, S.; Liu, J.; Zhang, Y.; Wang, Y.; Li, G.; Cui, Q. Effects of wheat bran micronization on the quality of reconstituted whole-wheat flour and its cooked noodles. Processes 2022, 10, 1001. [Google Scholar] [CrossRef]

- Park, G.; Cho, H.; Kim, K.; Kweon, M. Quality characteristics and antioxidant activity of fresh noodles formulated with flour-bran blends varied by particle size and blend ratio of purple-colored wheat bran. Processes 2022, 10, 584. [Google Scholar] [CrossRef]

- Ma, S.; Wang, C.; Li, L.; Wang, X. Effects of particle size on the quality attributes of wheat flour made by the milling process. Cereal Chem. 2020, 97, 172–182. [Google Scholar] [CrossRef]

- Monnet, A.-F.; Eurieult, A.; Berland, S.; Almeida, G.; Jeuffroy, M.-H.; Michon, C. Damaged starch in pea versus wheat flours: Fragmentation behavior and contribution of fine and coarse fractions. Cereal Chem. 2019, 96, 465–477. [Google Scholar] [CrossRef]

- Siliveru, K.; Ambrose, R.K.; Vadlani, P.V. Signficance of composition and particle size on the shear flow properties of wheat flour. J. Sci. Food Agric. 2017, 97, 2300–2306. [Google Scholar] [CrossRef] [PubMed]

- Carcea, M.; Turfani, V.; Narducci, V.; Melloni, S.; Galli, V.; Tullio, V. Stone milling versus roller milling in soft wheat: Influence on products composition. Foods 2019, 9, 3. [Google Scholar] [CrossRef] [PubMed]

- Cappelli, A.; Oliva, N.; Cini, E. Stone milling versus roller milling: A systematic review of the effects on wheat flour quality, dough rheology, and bread characteristics. Trends Food Sci. Technol. 2020, 97, 147–155. [Google Scholar] [CrossRef]

- Navarro, J.L.; Moiraghi, M.; Quiroga, F.M.; León, A.E.; Steffolani, M.E. Effect of wholewheat flour particle shape obtained by different milling processes on physicochemical characteristics and quality of bread. Food Technol. Biotechnol. 2020, 58, 325. [Google Scholar] [CrossRef]

- Leonardi, M.; Villacampa, M.; Menéndez, J.C. Multicomponent mechanochemical synthesis. Chem. Sci. 2018, 9, 2042–2064. [Google Scholar] [CrossRef] [PubMed]

- Amer, H.; Zhou, Z.; Corradini, M.G.; Joye, I.J.; Rogers, M.A. Wheat milling across history altered bioaccessibility assessed using TIM-1 in vitro digestion model. Food Res. Int. 2023, 174, 113521. [Google Scholar] [CrossRef]

- AACC. Approved Method of Analysis, 11th ed.; Method 08-01.01, 44-15.02, 54-40.02, 56-11.02, 56-71.01; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Kweon, M.; Slade, L.; Levine, H. Solvent retention capacity (SRC) testing of wheat flour: Principles and value in predicting flour functionality in different wheat-based food processes and in wheat breeding—A review. Cereal Chem. 2011, 88, 537–552. [Google Scholar] [CrossRef]

- Yu, L.; Beta, T. Identification and antioxidant properties of phenolic compounds during production of bread from purple wheat grains. Molecules 2015, 20, 15525–15549. [Google Scholar] [CrossRef]

- Wang, X.; Kweon, M. Quality of US soft red wheat flours and their suitability for making fresh noodles. Korean J. Food Cook. Sci. 2021, 37, 134–143. [Google Scholar]

- Prabhasankar, P.; Haridas Rao, P. Effect of different milling methods on chemical composition of whole wheat flour. Eur. Food Res. Technol. 2001, 213, 465–469. [Google Scholar] [CrossRef]

- Moon, Y.; Xia, T.; Cho, H.; Kweon, M. Comparison of particle size and quality characteristics of commercial whole wheat flours made from Korean domestic wheat and foreign wheat. Korean J. Food Cook. Sci. 2021, 37, 41–52. [Google Scholar] [CrossRef]

- van Rooyen, J.; Simsek, S.; Oyeyinka, S.A.; Manley, M. Holistic View of Starch Chemistry, Structure and Functionality in Dry Heat-Treated Whole Wheat Kernels and Flour. Foods 2022, 11, 207. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Flores, R.A. Effects of flour particle size on the textural properties of flour tortillas. J. Cereal Sci. 2000, 31, 263–272. [Google Scholar] [CrossRef]

- Slade, L.; Levine, H. Water and the glass transition—Dependence of the glass transition on composition and chemical structure: Special implications for flour functionality in cookie baking. J. Food Eng. 1995, 24, 431–509. [Google Scholar] [CrossRef]

- Ranhotra, G.S.; Gelroth, J.A.; Eisenbraun, G.J. Correlation between chopin and AACC methods of determining damaged starch. Cereal Chem. 1993, 70, 236–237. [Google Scholar]

- Gu, Y.; Qian, X.; Sun, B.; Ma, S.; Tian, X.; Wang, X. Nutritional composition and physicochemical properties of oat flour sieving fractions with different particle size. LWT-Food Sci. Technol. 2022, 154, 112757. [Google Scholar] [CrossRef]

- Niu, M.; Hou, G.G.; Wang, L.; Chen, Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014, 60, 382–388. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of flour particle size and damaged starch on the quality of cookies. J. Food Sci. Technol. 2014, 51, 1342–1348. [Google Scholar] [CrossRef]

- León, A.E.; Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; Rosell, C.M. Effect of damaged starch levels on flour-thermal behaviour and bread staling. Eur. Food Res. Technol. 2006, 224, 187–192. [Google Scholar] [CrossRef]

- Barrera, G.N.; Bustos, M.C.; Iturriaga, L.; Flores, S.K.; León, A.E.; Ribotta, P.D. Effect of damaged starch on the rheological properties of wheat starch suspensions. J. Food Eng. 2013, 116, 233–239. [Google Scholar] [CrossRef]

- Wang, S.; Copeland, L. Molecular disassembly of starch granules during gelatinization and its effect on starch digestibility: A review. Food Funct. 2013, 4, 1564–1580. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.A.; Kulathunga, J.; Ray, A.; Ohm, J.-B.; Islam, S. Particle size reduction influences starch and protein functionality, and nutritional quality of stone milled whole wheat flour from hard red spring wheat. Food Biosci. 2024, 61, 104612. [Google Scholar] [CrossRef]

- Liu, S.; Shen, M.; Xiao, Y.; Luo, Y.; Xie, J. Effect of maize, potato, and pea starches with Mesona chinensis polysaccharide on pasting, gelatinization properties, granular morphology and digestion. Food Hydrocoll. 2020, 108, 106047. [Google Scholar] [CrossRef]

- Cubadda, R.; Carcea, M.; Marconi, E.; Trivisonno, M.C. Influence of protein content on durum wheat gluten strength determined by the SDS sedimentation test and by other methods. Cereal Foods World 2007, 52, 273–277. [Google Scholar] [CrossRef]

- Maghirang, E.B.; Lookhart, G.L.; Bean, S.R.; Pierce, R.O.; Xie, F.E.N.G.; Caley, M.S.; Wilson, J.D.; Seabourn, B.W.; Ram, M.S.; Park, S.H.; et al. Comparison of quality characteristics and breadmaking functionality of hard red winter and hard red spring wheat. Cereal Chem. 2006, 83, 520–528. [Google Scholar] [CrossRef]

- Dewey, W.G. Some possible modifications and uses of the sedimentation test in a wheat breeding program. Crop Sci. 1963, 3, 546–549. [Google Scholar] [CrossRef]

- Morris, C.F.; Paszczynska, B.; Bettge, A.D.; King, G.E. A critical examination of the sodium dodecyl sulfate (SDS) sedimentation test for wheat meals. J. Sci. Food Agric. 2007, 87, 607–615. [Google Scholar] [CrossRef]

- Bressiani, J.; Oro, T.; Da Silva, P.M.L.; Montenegro, F.M.; Bertolin, T.E.; Gutkoski, L.C.; Gularte, M.A. Influence of milling whole wheat grains and particle size on thermo-mechanical properties of flour using Mixolab. Czech J. Food Sci. 2019, 37, 276–284. [Google Scholar] [CrossRef]

- Lin, S.; Gao, J.; Jin, X.; Wang, Y.; Dong, Z.; Ying, J.; Zhou, W. Whole-wheat flour particle size influences dough properties, bread structure and in vitro starch digestibility. Food Funct. 2020, 11, 3610–3620. [Google Scholar] [CrossRef]

- Li, C.; Tilley, M.; Chen, R.; Siliveru, K.; Li, Y. Effect of bran particle size on rheology properties and baking quality of wholewheat flour from four differential varieties. LWT-Food Sci. Technol. 2023, 175, 114504. [Google Scholar] [CrossRef]

- Cai, M.; Shen, C.; Jin Li, Y.; Xiong, S.; Li, F. Effects of particle size on quality characteristics of stone-milled whole wheat flour. J. Sci. Food Agric. 2023, 103, 2483–2491. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Hou, G.G.; Lee, B.; Marquart, L.; Dubat, A. Effects of particle size on the quality attributes of reconstituted whole wheat flour and tortilla made from it. J. Cereal Sci. 2016, 71, 145–152. [Google Scholar] [CrossRef]

- Zhou, K.; Laux, J.; Yu, L. Comparison of Swiss red wheat grain and fractions for their antioxidant properties. J. Agric. Food Chem. 2004, 52, 1118–1123. [Google Scholar] [CrossRef] [PubMed]

- Lai, S.; Chen, Z.; Zhang, Y.; Li, G.; Wang, Y.; Cui, Q. Micronization effects on structural, functional, and antioxidant properties of wheat bran. Foods 2023, 12, 98. [Google Scholar] [CrossRef]

- Jiang, Y.; Qi, Z.; Li, J.; Gao, J.; Xie, Y.; Henry, C.J.; Zhou, W. Role of superfine grinding in purple-whole wheat flour. Part 1: Impacts of size reduction on anthocyanin profile, physicochemical and antioxidant properties. LWT Food Sci. Technol. 2024, 197, 115940. [Google Scholar] [CrossRef]

- Rosa, N.N.; Barron, C.; Gaiani, C.; Dufour, C.; Micard, V. Ultra-fine grinding increases the antioxidant capacity of wheat bran. J. Cereal Sci. 2013, 57, 84–90. [Google Scholar] [CrossRef]

- Brewer, L.R.; Kubola, J.; Siriamornpun, S.; Herald, T.J.; Shi, Y.-C. Wheat bran particle size influence on physicochemical extractability and oxidant properties. Food Chem. 2014, 152, 483–490. [Google Scholar] [CrossRef]

- Zhang, Y.; Truzzi, F.; D’Amen, E.; Dinelli, G. Effect of storage conditions and time on the polyphenol content of wheat flours. Processes 2021, 9, 248. [Google Scholar] [CrossRef]

- Hatcher, D.W.; Kruger, J.E.; Anderson, M.J. Influence of water absorption on the processing and quality of oriental noodles. Cereal Chem. 1999, 76, 566–572. [Google Scholar] [CrossRef]

- Xiong, L.; Zhang, B.; Niu, M.; Zhao, S. Protein polymerization and water mobility in whole-wheat dough influenced by bran particle size distribution. LWT-Food Sci. Technol. 2017, 82, 396–403. [Google Scholar] [CrossRef]

- Li, M.; Li, L.; Sun, B.; Ma, S. Interaction of wheat bran dietary fiber-gluten protein affects dough product: A critical review. Int. J. Biol. Macromol. 2024, 255, 128199. [Google Scholar] [CrossRef] [PubMed]

- Baek, N.; Kweon, M. Comparison in the dry noodle-making performance of US soft wheat flours with different gluten strength. Korean J. Food Cook. Sci. 2022, 38, 160–169. [Google Scholar]

- Dhaka, V.; Khatkar, B. Influence of gluten addition on rheological, pasting, thermal, textural properties and bread making quality of wheat varieties. Qual. Assur. Saf. Crops Foods 2015, 7, 239–249. [Google Scholar] [CrossRef]

- Li, M.; Dhital, S.; Wei, Y. Multilevel structure of wheat starch and its relationship to noodle eating qualities. Comp. Rev. Food Sci. Food Saf. 2017, 16, 1042–1055. [Google Scholar] [CrossRef]

- Chen, J.S.; Fei, M.J.; Shi, C.I.; Tian, J.C.; Sun, C.L.; Zhang, H.; Ma, Z.; Domg, H.X. Effect of particle size and addition level of wheat bran on quality of dry white Chinese noodles. J. Cereal Sci. 2011, 53, 217–224. [Google Scholar] [CrossRef]

- Park, C.S.; Baik, B.K. Flour characteristics related to optimum water absorption of noodle dough for making white salted noodles. Cereal Chem. 2002, 79, 867–873. [Google Scholar] [CrossRef]

- Hou, G.G.; Saini, R.; Ng, P.K. Relationship between physicochemical properties of wheat flour, wheat protein composition, and textural properties of cooked Chinese white salted noodles. Cereal Chem. 2013, 90, 419–429. [Google Scholar] [CrossRef]

| Sample | Particle Size (μm) | ||

|---|---|---|---|

| d10 | d50 | d90 | |

| L10 | 20 ± 0 h(1) | 692 ± 10 g | 1673 ± 1 g |

| L20 | 16 ± 0 g | 552 ± 1 f | 1605 ± 3 f |

| L40 | 11 ± 0 e | 246 ± 1 d | 1066 ± 2 d |

| L60 | 9 ± 0 d | 203 ± 3 c | 1058 ± 0 d |

| H10 | 12 ± 0 f | 250 ± 4 d | 1051 ± 0 d |

| H20 | 8 ± 0 c | 143 ± 5 b | 1002 ± 10 c |

| H40 | 5 ± 0 b | 34 ± 1 a | 816 ± 8 b |

| H60 | 4 ± 0 a | 24 ± 0 a | 681 ± 1 a |

| Sample | Moisture Content (%) | Ash Content (%) | Total Starch Content (%) | Damaged Starch Content (%) |

|---|---|---|---|---|

| L10 | 13.4 ± 0.1 g(1) | 1.48 ± 0.02 ab | 51.9 ± 0.0 a | 2.0 ± 0.1 a |

| L20 | 13.0 ± 0.0 f | 1.48 ± 0.02 ab | 53.3 ± 0.0 b | 2.4 ± 0.2 b |

| L40 | 12.2 ± 0.1 d | 1.50 ± 0.00 abc | 54.7 ± 0.0 c | 3.1 ± 0.2 c |

| L60 | 12.0 ± 0.0 d | 1.55 ± 0.02 cd | 55.4 ± 0.2 d | 3.5 ± 0.1 c |

| H10 | 12.5 ± 0.1 e | 1.45 ± 0.02 a | 55.4 ± 0.0 d | 3.3 ± 0.2 c |

| H20 | 11.1 ± 0.1 c | 1.53 ± 0.03 bcd | 55.6 ± 0.0 d | 5.0 ± 0.2 d |

| H40 | 7.9 ± 0.1 b | 1.57 ± 0.00 de | 56.9 ± 0.1 e | 7.0 ± 0.2 e |

| H60 | 5.7 ± 0.0 a | 1.61 ± 0.02 e | 59.2 ± 0.0 f | 10.6 ± 0.2 f |

| Sample | Peak Viscosity (cP) | Breakdown Viscosity (cP) | Final Viscosity (cP) | Setback Viscosity (cP) | Peak Time (min) | Pasting Temperature (°C) |

|---|---|---|---|---|---|---|

| L10 | 1578 ± 5 a(1) | 747 ± 7 a | 1991 ± 8 a | 1160 ± 2 a | 5.38 ± 0.03 a | 90.6 ± 0.8 c |

| L20 | 1860 ± 6 b | 961 ± 12 b | 2074 ± 26 b | 1176 ± 13 a | 5.49 ± 0.03 ab | 90.1 ± 0.3 bc |

| L40 | 2043 ± 18 c | 1074 ± 13 cd | 2130 ± 6 bc | 1161 ± 4 a | 5.60 ± 0.06 bc | 89.3 ± 0.4 abc |

| L60 | 2112 ± 13 d | 1085 ± 4 cde | 2170 ± 11 cd | 1143 ± 4 a | 5.62 ± 0.03 c | 88.5 ± 0.4 ab |

| H10 | 2015 ± 20 c | 1051 ± 17 c | 2220 ± 13 de | 1256 ± 15 b | 5.62 ± 0.03 c | 90.4 ± 0.0 c |

| H20 | 2123 ± 14 d | 1112 ± 2 def | 2249 ± 18 ef | 1238 ± 10 b | 5.69 ± 0.03 cd | 89.6 ± 0.0 bc |

| H40 | 2192 ± 1 e | 1124 ± 11 f | 2308 ± 37 f | 1240 ± 26 b | 5.71 ± 0.03 cd | 88.5 ± 0.5 ab |

| H60 | 2251 ± 10 f | 1101 ± 8 ef | 2377 ± 8 g | 1227 ± 5 b | 5.80 ± 0.00 d | 88.0 ± 0.7 a |

| Sample | SDS Sedimentation (mL) | ||

|---|---|---|---|

| 20 min | 40 min | 60 min | |

| L10 | 16.5 ± 0.5 c(1) | 16.5 ± 0.5 d | 16.5 ± 0.5 a |

| L20 | 15.3 ± 0.3 c | 15.5 ± 0.5 d | 15.5 ± 0.5 a |

| L40 | 15.8 ± 0.3 c | 16.0 ± 0.0 d | 16.0 ± 0.0 a |

| L60 | 16.3 ± 0.3 c | 16.3 ± 0.3 d | 16.3 ± 0.3 a |

| H10 | 14.5 ± 0.5 bc | 14.5 ± 0.5 cd | 15.1 ± 0.1 b |

| H20 | 12.8 ± 0.8 b | 12.8 ± 0.3 bc | 14.0 ± 1.0 ab |

| H40 | 10.3 ± 0.3 ba | 11.5 ± 0.5 ab | 12.5 ± 0.5 ab |

| H60 | 9.0 ± 0.0 a | 9.8 ± 0.3 a | 11.0 ± 0.0 a |

| Sample | Total Phenolic Content (mg GAE/100 g) | ABTS Radical-Scavenging Activity (mg TE/100 g) |

|---|---|---|

| L10 | 426.9 ± 1.8 a(1) | 330.6 ± 5.9 e |

| L20 | 438.9 ± 1.9 b | 326.5 ± 1.1 e |

| L40 | 463.4 ± 7.0 cd | 274.2 ± 2.2 c |

| L60 | 442.7 ± 2.4 c | 267.3 ± 5.3 bc |

| H10 | 438.8 ± 1.6 b | 288.8 ± 3.7 d |

| H20 | 460.8 ± 1.1 c | 266.1 ± 2.2 bc |

| H40 | 467.3 ± 4.8 cd | 255.9 ± 2.1 a |

| H60 | 472.0 ± 4.1 d | 260.5 ± 0.9 ab |

| Sample | Water Adjustment | Water Addition (g) | Color | Texture of Fresh Noodles | ||||

|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | Resistance (N) | Extensibility (mm) | R/E | |||

| L10 | I | 36.7 | 67.3 ± 1.2 fg(1) | 7.6 ± 0.7 a | 16.8 ± 1.2 a | 0.28 ± 0.02 b | 2.41 ± 0.20 def | 0.12 ± 0.01 a |

| II | 38.0 | 63.1 ± 0.6 cd | 9.3 ± 0.3 b | 19.4 ± 0.8 b | 0.34 ± 0.02 bcd | 2.58 ± 0.05 fgh | 0.13 ± 0.01 ab | |

| L20 | I | 37.1 | 64.9 ± 0.7 de | 8.2 ± 0.3 a | 17.7 ± 0.5 a | 0.33 ± 0.04 bc | 2.46 ± 0.19 def | 0.14 ± 0.02 ab |

| II | 39.2 | 61.7 ± 0.2 bc | 9.3 ± 0.1 b | 19.4 ± 0.4 b | 0.36 ± 0.03 cde | 2.49 ± 0.05 efg | 0.15 ± 0.01 b | |

| L40 | I | 37.6 | 66.0 ± 0.1 ef | 7.9 ± 0.1 a | 16.8 ± 0.4 a | 0.34 ± 0.0 cd | 2.44 ± 0.03 def | 0.14 ± 0.01 ab |

| II | 41.0 | 60.6 ± 0.2 ab | 9.8 ± 0.2 bc | 20.0 ± 0.3 b | 0.40 ± 0.03 e | 2.71 ± 0.05 ghi | 0.15 ± 0.01 b | |

| L60 | I | 38.2 | 65.9 ± 0.4 ef | 8.1 ± 0.3 a | 17.2 ± 0.6 a | 0.38 ± 0.03 cde | 2.55 ± 0.06 cd | 0.15 ± 0.01 b |

| II | 42.6 | 61.4 ± 0.3 bc | 9.3 ± 0.1 b | 19.4 ± 0.1 b | 0.38 ± 0.03 cde | 2.70 ± 0.02 fgh | 0.14 ± 0.01 ab | |

| H10 | I | 37.9 | 65.0 ± 1.7 de | 8.1 ± 0.4 a | 17.2 ± 0.8 a | 0.39 ± 0.03 de | 2.78 ± 0.16 hi | 0.14 ± 0.01 ab |

| II | 41.9 | 61.2 ± 0.1 bc | 9.9 ± 0.1 bc | 20.5 ± 0.1 b | 0.39 ± 0.02 de | 2.87 ± 0.04 i | 0.14 ± 0.01 ab | |

| H20 | I | 39.3 | 66.2 ± 0.3 efg | 7.8 ± 0.1 a | 16.5 ± 0.3 a | 0.36 ± 0.03 cde | 2.44 ± 0.10 def | 0.15 ± 0.01 b |

| II | 46.2 | 59.8 ± 0.1 ab | 10.3 ± 0.1 c | 20.9 ± 0.1 b | 0.40 ± 0.02 e | 2.23 ± 0.06 d | 0.18 ± 0.01 c | |

| H40 | I | 41.7 | 68.1 ± 0.6 g | 7.4 ± 0.5 a | 16.2 ± 0.9 a | 0.33 ± 0.01 bc | 2.28 ± 0.16 de | 0.15 ± 0.01 b |

| II | 53.5 | 60.8 ± 0.6 ab | 9.6 ± 0.3 bc | 19.8 ± 0.2 b | 0.18 ± 0.01 a | 1.53 ± 0.10 b | 0.11 ± 0.01 a | |

| H60 | I | 44.5 | 66.1 ± 1.3 efg | 7.8 ± 0.3 a | 16.6 ± 0.5 a | 0.33 ± 0.02 bc | 1.78 ± 0.07 c | 0.19 ± 0.01 c |

| II | 61.9 | 59.1 ± 0.2 a | 9.7 ± 0.2 bc | 19.7 ± 0.2 b | 0.13 ± 0.01 a | 0.97 ± 0.10 a | 0.13 ± 0.02 ab | |

| Sample | Water Adjustment | Weight Gain (%) | Turbidity (ΔA hr−1 g flour−1) | Textural Parameter of Cooked Noodles | ||||

|---|---|---|---|---|---|---|---|---|

| Firmness (N) | Resilience | Cohesiveness | Springiness | Chewiness (mJ) | ||||

| L10 | I | 252 ± 8 bc(1) | 1.20 ± 0.01 j | 5.8 ± 0.2 b | 0.12 ± 0.01 ab | 0.34 ± 0.02 abc | 0.65 ± 0.04 a | 2.2 ± 0.2 b |

| II | 259 ± 9 bc | 1.41 ± 0.01 k | 5.5 ± 0.4 b | 0.11 ± 0.02 a | 0.31 ± 0.03 a | 0.64 ± 0.04 a | 2.0 ± 0.4 b | |

| L20 | I | 255 ± 0 bc | 1.12 ± 0.01 gh | 5.9 ± 0.2 b | 0.13 ± 0.01 abc | 0.35 ± 0.02 abcd | 0.67 ± 0.05 abc | 2.4 ± 0.2 bc |

| II | 254 ± 0 bc | 0.91 ± 0.01 b | 6.4 ± 0.3 c | 0.11 ± 0.01 ab | 0.33 ± 0.03 ab | 0.67 ± 0.04 ab | 2.4 ± 0.3 bc | |

| L40 | I | 241 ± 1 abc | 1.14 ± 0.02 h | 6.9 ± 0.3 de | 0.12 ± 0.02 ab | 0.35 ± 0.02 abcd | 0.68 ± 0.02 abcd | 2.8 ± 0.3 cd |

| II | 248 ± 2 bc | 0.94 ± 0.00 c | 7.0 ± 0.4 def | 0.14 ± 0.01 bcd | 0.38 ± 0.03 cdef | 0.72 ± 0.03 cdef | 3.1 ± 0.3 de | |

| L60 | I | 236 ± 3 ab | 1.01 ± 0.00 d | 6.7 ± 0.3 cde | 0.13 ± 0.02 abc | 0.35 ± 0.02 abcd | 0.68 ± 0.04 abcd | 2.9 ± 0.3 cd |

| II | 247 ± 1 bc | 1.16 ± 0.00 i | 7.3 ± 0.2 fg | 0.13 ± 0.02 bcd | 0.39 ± 0.03 def | 0.74 ± 0.03 ef | 3.5 ± 0.4 e | |

| H10 | I | 268 ± 8 c | 1.12 ± 0.01 g | 6.9 ± 0.2 de | 0.13 ± 0.02 abc | 0.36 ± 0.04 bcde | 0.68 ± 0.03 abcd | 2.9 ± 0.4 cd |

| II | 248 ± 7 bc | 0.77 ± 0.00 a | 7.3 ± 0.3 fg | 0.13 ± 0.02 bcd | 0.37 ± 0.03 cdef | 0.71 ± 0.03 bcdef | 3.1 ± 0.3 de | |

| H20 | I | 260 ± 6 bc | 1.03 ± 0.01 e | 7.1 ± 0.3 ef | 0.13 ± 0.02 bcd | 0.38 ± 0.03 cdef | 0.70 ± 0.03 bcde | 3.2 ± 0.4 de |

| II | 240 ± 6 abc | 1.21 ± 0.01 j | 6.7 ± 0.2 cd | 0.15 ± 0.01 cd | 0.40 ± 0.01 ef | 0.74 ± 0.03 ef | 3.0 ± 0.1 de | |

| H40 | I | 251 ± 7 bc | 1.07 ± 0.01 f | 8.2 ± 0.1 h | 0.16 ± 0.01 de | 0.41 ± 0.02 fg | 0.73 ± 0.03 def | 4.2 ± 0.4 f |

| II | 213 ± 7 a | 1.91 ± 0.01 l | 3.2 ± 0.3 a | 0.11 ± 0.02 ab | 0.37 ± 0.02 bcdef | 0.72 ± 0.02 bcdef | 1.1 ± 0.0 a | |

| H60 | I | 256 ± 15 bc | 1.08 ± 0.00 f | 7.6 ± 0.1 g | 0.18 ± 0.02 e | 0.45 ± 0.03 g | 0.76 ± 0.03 f | 4.2 ± 0.4 f |

| II | 211 ± 10 a | 2.21 ± 0.02 m | N/A | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moon, J.; Moon, Y.; Kweon, M. The Effects of Milling Conditions on the Particle Size, Quality, and Noodle-Making Performance of Whole-Wheat Flour: A Mortar Mill Study. Foods 2025, 14, 1609. https://doi.org/10.3390/foods14091609

Moon J, Moon Y, Kweon M. The Effects of Milling Conditions on the Particle Size, Quality, and Noodle-Making Performance of Whole-Wheat Flour: A Mortar Mill Study. Foods. 2025; 14(9):1609. https://doi.org/10.3390/foods14091609

Chicago/Turabian StyleMoon, Jeonghan, Yujin Moon, and Meera Kweon. 2025. "The Effects of Milling Conditions on the Particle Size, Quality, and Noodle-Making Performance of Whole-Wheat Flour: A Mortar Mill Study" Foods 14, no. 9: 1609. https://doi.org/10.3390/foods14091609

APA StyleMoon, J., Moon, Y., & Kweon, M. (2025). The Effects of Milling Conditions on the Particle Size, Quality, and Noodle-Making Performance of Whole-Wheat Flour: A Mortar Mill Study. Foods, 14(9), 1609. https://doi.org/10.3390/foods14091609