Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective

Abstract

1. Introduction

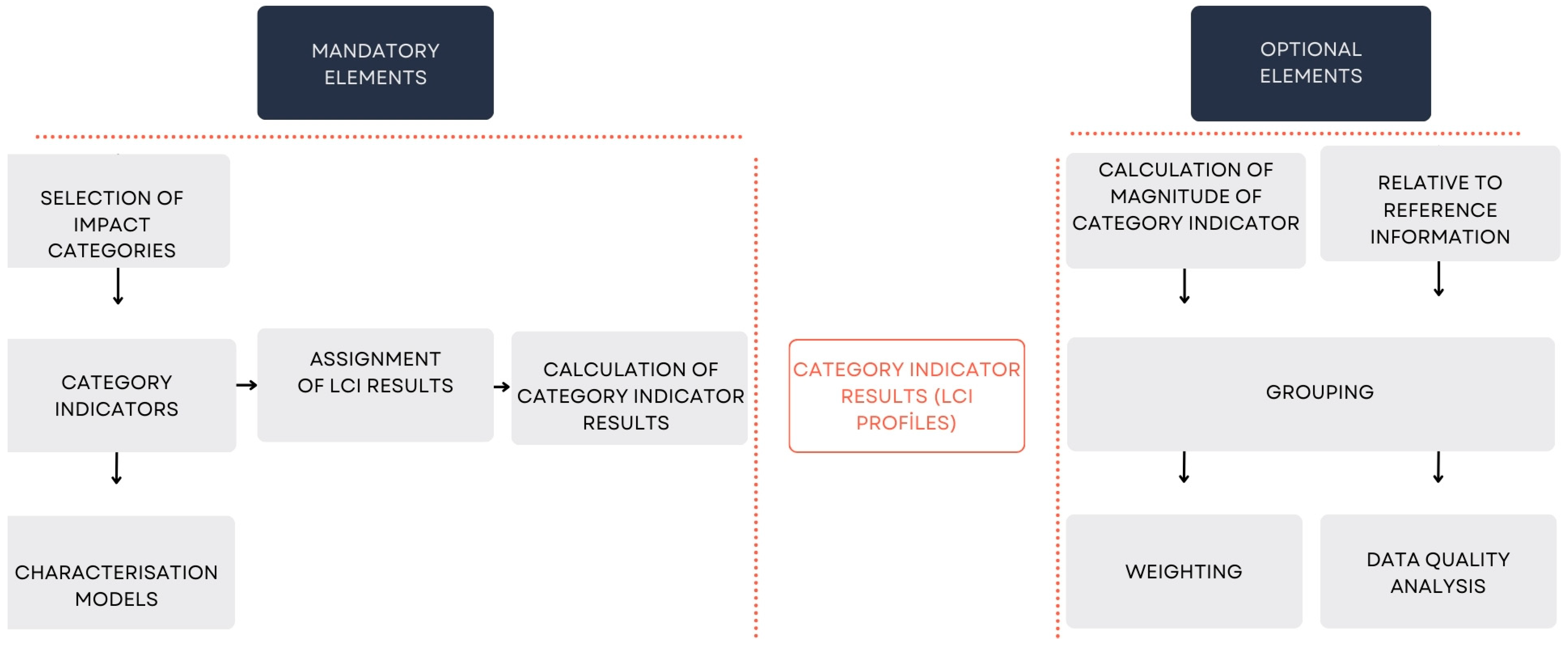

2. Methodology

3. LCA and Circular Economy in Food Production

4. Farm-Level LCA: Inputs, Outputs, and Environmental Impact

5. LCA in Food Processing: Efficiency and Sustainability

6. LCA in Wine and Fermented Beverages Production

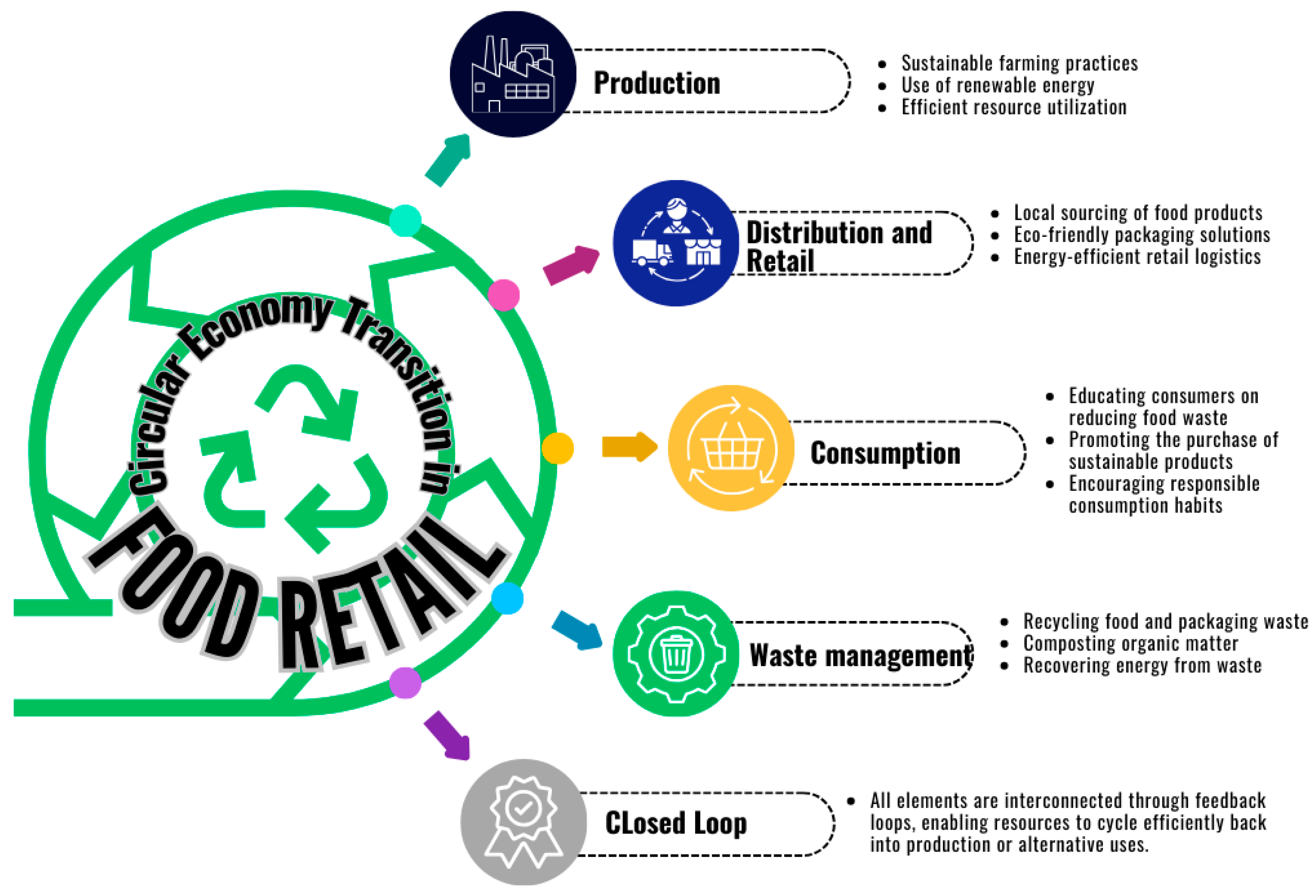

7. LCA of Packaging and Distribution: Closing the Loop

8. LCA in Retail and Consumption: Waste Management and Recycling

9. LCA of End-of-Life: Food Waste, Recycling, and Resource Recovery

10. Challenges in Applying LCA to Food Systems from a Circular Economy Perspective

11. Policy Implications: Supporting Circular Economy Through LCA in Food Production

12. Future Perspectives and Innovations in LCA for Sustainable Food Systems

13. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Glaros, A.; Marquis, S.; Major, C.; Quarshie, P.; Ashton, L.; Green, A.G.; Kc, K.B.; Newman, L.; Newell, R.; Yada, R.Y.; et al. Horizon scanning and review of the impact of five food and food production models for the global food system in 2050. Trends Food Sci. Technol. 2022, 119, 550–564. [Google Scholar] [CrossRef]

- Batool, F.; Kurniawan, T.A.; Mohyuddin, A.; Othman, M.H.D.; Aziz, F.; Al-Hazmi, H.E.; Goh, H.H.; Anouzla, A. Environmental impacts of food waste management technologies: A critical review of life cycle assessment (LCA) studies. Trends Food Sci. Technol. 2024, 143, 104287. [Google Scholar] [CrossRef]

- Falcone, G.; Fazari, A.; Vono, G.; Gulisano, G.; Strano, A. Application of the LCA approach to the citrus production chain—A systematic review. Clean. Environ. Syst. 2024, 12, 100156. [Google Scholar] [CrossRef]

- Sheikh, Z.A.; Ashraf, S.; Weesakul, S.; Ali, M.; Hanh, N.C. Impact of climate change on farmers and adaptation strategies in Rangsit, Thailand. Environ. Chall. 2024, 15, 100902. [Google Scholar] [CrossRef]

- European Environment Agency. Life-Cycle Assessment (LCA): A Guide to Approaches, Experiences and Information Sources; European Environment Agency: Copenhagen, Denmark, 1997. [Google Scholar]

- Arias, A.; Feijoo, G.; Moreira, M.T. Assessing of the most appropriate biotechnological strategy for the recovery of antioxidants from beet wastes by applying the life cycle assessment (LCA) methodology. Food Bioprod. Process. 2022, 135, 178–189. [Google Scholar] [CrossRef]

- Abad-Gonzalez, J.; Nadi, F.; Pérez-Neira, D. Energy-water-food security nexus in mung bean production in Iran: An LCA approach. Ecol. Indic. 2024, 158, 111442. [Google Scholar] [CrossRef]

- Thomas, C.; Grémy-Gros, C.; Perrin, A.; Symoneaux, R.; Maître, I. Implementing LCA early in food innovation processes: Study on spirulina-based food products. J. Clean. Prod. 2020, 268, 121793. [Google Scholar] [CrossRef]

- Zhen, H.; Qiao, Y.; Ju, X.; Hashemi, F.; Knudsen, M.T. Organic conversion tea farms can have comparable economic benefits and less environmental impacts than conventional ones—A case study in China. Sci. Total Environ. 2023, 877, 162698. [Google Scholar] [CrossRef] [PubMed]

- Arvanitoyannis, I.S. ISO 14040: Life Cycle Assessment (LCA)—Principles and Guidelines. In Waste Management for the Food Industries; Arvanitoyannis, I.S., Ed.; Academic Press: Cambridge, MA, USA, 2008; pp. 97–132. [Google Scholar] [CrossRef]

- Bruhn, S.; Gislason, S.; Røgild, T.; Andreasen, M.; Ditlevsen, F.; Larsen, J.; Sønderholm, N.; Fossat, S.; Birkved, M. Pioneering historical LCA—A perspective on the development of personal carbon footprint 1860–2020 in Denmark. Sustain. Prod. Consum. 2024, 46, 582–599. [Google Scholar] [CrossRef]

- Cai, H.; Biesbroek, S.; Wen, X.; Fan, S.; van ’t Veer, P.; Talsma, E.F. Environmental footprints of Chinese foods and beverages: Literature-based construction of a LCA database. Data Brief 2022, 42, 108244. [Google Scholar] [CrossRef]

- Chen, J.; Wang, S.; Zhong, H.; Chen, B.; Fang, D. Assessing agricultural greenhouse gas emission mitigation by scaling up farm size: An empirical analysis based on rural household survey data. Sci. Total Environ. 2024, 933, 173077. [Google Scholar] [CrossRef] [PubMed]

- Torres-Miralles, M.; Kyttä, V.; Jeanneret, P.; Lamminen, M.; Manzano, P.; Tuomisto, H.L.; Herzon, I. Applying life cycle assessment to European high nature value farming systems: Environmental impacts and biodiversity. Agric. Syst. 2024, 220, 104096. [Google Scholar] [CrossRef]

- SETAC—Integrated Environmental Assessment and Management Published by Wiley Periodicals LLC on Behalf of Society of Environmental Toxicology & Chemistry. Available online: https://www.lifecycleinitiative.org/activities/life-cycle-assessment-data-and-methods/global-guidance-for-life-cycle-impact-assessment-indicators-and-methods-glam/lcia-cf/ (accessed on 17 February 2025).

- Colley, T.A.; Birkved, M.; Olsen, S.I.; Hauschild, M.Z. Using a gate-to-gate LCA to apply circular economy principles to a food processing SME. J. Clean. Prod. 2020, 251, 119566. [Google Scholar] [CrossRef]

- Irawan, A.; McLellan, B.C. A comparison of life cycle assessment (LCA) of Andungsari Arabica coffee processing technologies towards lower environmental impact. J. Clean. Prod. 2024, 447, 141561. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Härri, A.; Levänen, J.; Niinimäki, K. Exploring the Role of Social Life Cycle Assessment in Transition to Circular Economy: A Systematic Review. Resources 2024, 207, 107702. [Google Scholar] [CrossRef]

- Romero-Perdomo, F.; González-Curbelo, M.Á. Integrating Multi-Criteria Techniques in Life-Cycle Tools for the Circular Bioeconomy Transition of Agri-Food Waste Biomass: A Systematic Review. Sustainability 2023, 15, 5026. [Google Scholar] [CrossRef]

- Bigliardi, B.; Dolci, V.; Filippelli, S.; Pini, B.; Petroni, A.; Tagliente, L. Circular economy in the food supply chain: A literature review. Procedia Comput. Sci. 2024, 232, 3024–3033. [Google Scholar] [CrossRef]

- Rani, A.; Negi, S.; Fan, C.; Lam, S.S.; Kim, H.; Pan, S.Y. Revitalizing plastic wastes employing bio-circular-green economy principles for carbon neutrality. J. Hazard. Mater. 2024, 472, 134394. [Google Scholar] [CrossRef]

- Pomoni, D.I.; Koukou, M.K.; Vrachopoulos, M.G.; Vasiliadis, L. Circular economy: A multilevel approach for natural resources and wastes under an agri-food perspective. Water-Energy Nexus 2024, 7, 103–123. [Google Scholar] [CrossRef]

- Viscardi, S.; Colicchia, C. A classification of food products to enhance circular economy and reduce waste: A systematic literature review. Resour. Conserv. Recycl. Adv. 2024, 23, 200229. [Google Scholar] [CrossRef]

- Kaul, K.; Rajauria, G.; Singh, R. Valorization of agro-industrial waste for pectinase production and its influence on circular economy. Food Bioprod. Process. 2024, 148, 141–153. [Google Scholar] [CrossRef]

- Cervantes, P.L.; Xicotencatl, R.I.F.; Cador, C.M.; Kinney, I.S. Circular economy and food safety: A focus on ONE health. Appl. Food Res. 2024, 4, 100509. [Google Scholar] [CrossRef]

- Arijeniwa, V.F.; Akinsemolu, A.A.; Chukwugozie, D.C.; Onawo, U.G.; Ochulor, C.E.; Nwauzoma, U.M.; Kawino, D.A.; Onyeaka, H. Closing the loop: A framework for tackling single-use plastic waste in the food and beverage industry through circular economy—A review. J. Environ. Manag. 2024, 359, 120816. [Google Scholar] [CrossRef] [PubMed]

- Baker, J.S.; Van Houtven, G.; Cai, Y.; Moreda, F.; Wade, C.; Henry, C.; Redmon, J.H.; Kondash, A.J. A Hydro-Economic Methodology for the Food-Energy-Water Nexus: Valuation and Optimization of Water Resources; RTI Press Methods Report No. MR-0044-2105; RTI Press: Durham, NC, USA, 2021. [Google Scholar] [CrossRef]

- Viles, E.; Kalemkerian, F.; Garza-Reyes, J.A.; Antony, J.; Santos, J. Theorizing the principles of sustainable production in the context of circular economy and Industry 4.0. Sustain. Prod. Consum. 2022, 33, 1043–1058. [Google Scholar] [CrossRef]

- Kusumowardani, N.; Tjahjono, B.; Lazell, J.; Bek, D.; Theodorakopoulos, N.; Andrikopoulos, P.; Priadi, C.R. A circular capability framework to address food waste and losses in the agri-food supply chain: The antecedents, principles and outcomes of circular economy. J. Bus. Res. 2022, 142, 17–31. [Google Scholar] [CrossRef]

- Chowdhury, H.; Asiabanpour, B. A circular economy integration approach into vertical farming with computer-based simulation model for resource optimization and waste reduction. J. Clean. Prod. 2024, 470, 143256. [Google Scholar] [CrossRef]

- Bartocci, P.; Zampilli, M.; Liberti, F.; Pistolesi, V.; Massoli, S.; Bidini, G.; Fantozzi, F. LCA analysis of food waste co-digestion. Sci. Total Environ. 2020, 709, 136187. [Google Scholar] [CrossRef]

- Putra, M.P.I.F.; Pradhan, P.; Kropp, J.P. A systematic analysis of water-energy-food security nexus: A South Asian case study. Sci. Total Environ. 2020, 728, 138451. [Google Scholar] [CrossRef]

- Bianco, G.B. Climate change adaptation, coffee, and corporate social responsibility: Challenges and opportunities. International J. Corp. Soc. Responsib. 2020, 5, 3. [Google Scholar] [CrossRef]

- International Cocoa Organization (ICCO). Production of Cocoa Beans. 2023. Available online: https://www.icco.org/wp-content/uploads/Production_QBCS-XLIX-No.-4.pdf (accessed on 20 February 2025).

- Armengot, L.; Beltrán, M.J.; Schneider, M.; Simón, X.; Pérez-Neira, D. Food-energy-water nexus of different cacao production systems from a LCA approach. J. Clean. Prod. 2021, 304, 126941. [Google Scholar] [CrossRef]

- FAO. Life Cycle Assessment for Sustainable Food Systems: A Webinar; FAO: Rome, Italy, 2021; Available online: https://www.fao.org/ (accessed on 10 April 2025).

- European Union. Eurostat Regional Yearbook—2022 Edition; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar] [CrossRef]

- Caicedo-Vargas, C.; Pérez-Neira, D.; Abad-González, J.; Gallar, D. Assessment of the environmental impact and economic performance of cacao agroforestry systems in the Ecuadorian Amazon region: An LCA approach. Sci. Total Environ. 2022, 849, 157795. [Google Scholar] [CrossRef]

- Chen, X.; Corson, M.S. Influence of emission-factor uncertainty and farm-characteristic variability in LCA estimates of environmental impacts of French dairy farms. J. Clean. Prod. 2014, 81, 150–157. [Google Scholar] [CrossRef]

- O’Brien, D.; Markiewicz-Keszycka, M.; Herron, J. Environmental impact of grass-based cattle farms: A life cycle assessment of nature-based diversification scenarios. Resour. Environ. Sustain. 2023, 14, 100126. [Google Scholar] [CrossRef]

- Chen, X.; Chen, F.; Yang, Q.; Gong, W.; Wang, J.; Li, Y.; Wang, G. An environmental food packaging material part I: A case study of life-cycle assessment (LCA) for bamboo fiber environmental tableware. Ind. Crops Prod. 2023, 194, 116279. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J.; Martinát, S.; van der Horst, D. Changes in Feedstocks of Rural Anaerobic Digestion Plants: External Drivers Towards a Circular Bioeconomy. Renew. Sustain. Energy Rev. 2021, 148, 111344. [Google Scholar] [CrossRef]

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resources 2023, 194, 107001. [Google Scholar] [CrossRef]

- Santolin, J.; Vlaeminck, S.E.; Appiah-Twum, H.; Van Winckel, T.; Spiller, M. Consequential LCA of NPK fertilizers from microbial, animal, plant, and mineral origin highlights resource constraints and environmental impacts. J. Clean. Prod. 2024, 457, 142312. [Google Scholar] [CrossRef]

- ISO 22000:2018; Food Safety Management Systems—Requirements for Any Organization in the Food Chain. International Organization for Standardization (ISO): Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/65464.html (accessed on 17 February 2025).

- Ruiz-Real, J.L.; Uribe-Toril, J.; De Pablo Valenciano, J.; Gázquez-Abad, J.C. Social Economy and the Transition Towards Circular Economy: A Survey-Based Approach. Technol. Forecast. Soc. Change 2021, 166, 120618. [Google Scholar] [CrossRef]

- Cudečka-Puriņa, N.; Atstāja, D.; Koval, V.; Purviņš, M.; Nesenenko, P.; Tkach, O. Achievement of Sustainable Development Goals through the Implementation of Circular Economy and Developing Regional Cooperation. Energies 2022, 15, 4072. [Google Scholar] [CrossRef]

- Singh, S.; Sinha, A.; Thakur, M. A Review of Circularity Indicators and Psychological Factors: A Comprehensive Analysis of Circularity Practices in Organizations. Resources 2022, 180, 106219. [Google Scholar]

- Rahman, M.; Ali, M.H.; Islam, M.M. Ensuring Sustainable Consumption Behaviours in Circular Economy Engagement. J. Clean. Prod. 2023, 385, 135692. [Google Scholar] [CrossRef]

- Kovacic, Z.; Strand, R.; Völker, T. European Circular Economy Policy-Making in Sustainability and Resource Management Development. Sustain. Prod. Consum. 2021, 28, 1312–1324. [Google Scholar] [CrossRef]

- Guerra, M.; Ferreira, F.; Oliveira, A.; Pinto, T.; Teixeira, C. Drivers of Environmental Sustainability in the Wine Industry: A Life Cycle Assessment Approach. Sustainability 2024, 16, 5613. [Google Scholar] [CrossRef]

- Gagneten, M.; Quentier, C.; Passot, S.; Cenard, S.; Fonseca, F.; Pénicaud, C. Joining environmental impacts and product quality in Life Cycle Assessment: The case of the production and storage of lactic acid bacteria concentrates. Clean. Environ. Syst. 2024, 15, 100245. [Google Scholar] [CrossRef]

- Ferrara, C.; Feo, G. Life Cycle Assessment Application to the Wine Sector: A Critical Review. Sustainability 2018, 10, 395. [Google Scholar] [CrossRef]

- Panizzon, T.; Salton, G.; Schneider, V.; Poletto, M. Identifying Hotspots and Most Relevant Flows for Red and White Wine Production in Brazil through Life Cycle Assessment: A Case Study. Resources 2024, 13, 88. [Google Scholar] [CrossRef]

- Catalán, E.; Sánchez, A. Solid-State Fermentation (SSF) versus Submerged Fermentation (SmF) for the Recovery of Cellulases from Coffee Husks: A Life Cycle Assessment (LCA) Based Comparison. Energies 2020, 13, 2685. [Google Scholar] [CrossRef]

- Harb, W.; Zaydan, R.; Vieira, M. Improving environmental performance in wine production by life cycle assessment: Case of Lebanese wine. Int. J. Life Cycle Assess. 2021, 26, 1146–1159. [Google Scholar] [CrossRef]

- Iannone, R.; Miranda, S.; Riemma, S.; Marco, I. Improving environmental performances in wine production by a life cycle assessment analysis. J. Clean. Prod. 2016, 111, 172–180. [Google Scholar] [CrossRef]

- D’Ascenzo, F.; Vinci, G.; Maddaloni, L.; Ruggeri, M.; Savastano, M. Application of Life Cycle Assessment in Beer Production: Systematic Review. Beverages 2024, 10, 86. [Google Scholar] [CrossRef]

- Marco, I.; Miranda, S.; Riemma, S.; Iannone, R. Life Cycle Assessment of Ale and Lager Beers Production. Chem. Eng. Trans. 2016, 49, 337–342. [Google Scholar] [CrossRef]

- Eriksson, O.; Jonsson, D.; Hillman, K. Life cycle assessment of Swedish single malt whisky. J. Clean. Prod. 2016, 112, 229–237. [Google Scholar] [CrossRef]

- Zambelli, M.; Giovenzana, V.; Casson, A.; Tugnolo, A.; Pampuri, A.; Vignati, S.; Beghi, R.; Guidetti, R. Is there mutual methodology among the environmental impact assessment studies of wine production chain? A systematic review. Sci. Total Environ. 2022, 857, 159531. [Google Scholar] [CrossRef] [PubMed]

- Brandão, M. The Role of Life Cycle Assessment in Supporting the Transition Towards Sustainable Production and Consumption Systems: The Case of Biofuels and Climate Change. In Handbook of Sustainability Science in the Future; Leal Filho, W., Azul, A.M., Doni, F., Salvia, A.L., Eds.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Keșa, A.; Pop, C.; Mudura, E.; Salanță, L.; Pasqualone, A.; Darab, C.; Burja-Udrea, C.; Zhao, H.; Coldea, T. Strategies to Improve the Potential Functionality of Fruit-Based Fermented Beverages. Plants 2021, 10, 2263. [Google Scholar] [CrossRef] [PubMed]

- Saberian, M.; Li, J.; Kilmartin-Lynch, S.; Boroujeni, M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021, 769, 145527. [Google Scholar] [CrossRef]

- Accorsi, R.; Battarra, I.; Guidani, B.; Manzini, R.; Ronzoni, M.; Volpe, L. Augmented spatial LCA for comparing reusable and recyclable food packaging containers networks. J. Clean. Prod. 2022, 375, 134027. [Google Scholar] [CrossRef]

- Brenton, P.; Chemutai, V.; Pangestu, M. Trade and Food Security in a Climate Change-Impacted World; The World Bank: Washington, DC, USA, 2021; Available online: https://documents1.worldbank.org/curated/en/099062423145035506/pdf/P17695104b50e7090087fd0f31f76e77f36.pdf (accessed on 17 February 2025).

- Organisation for Economic Co-operation and Development (OECD). Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- Schwarz, A.E.; Ligthart, T.N.; Bizarro, D.G.; De Wild, P.; Vreugdenhil, B.; van Harmelen, T. Plastic recycling in a circular economy: Determining environmental performance through an LCA matrix model approach. Waste Manag. 2021, 121, 331–342. [Google Scholar] [CrossRef]

- Accorsi, R.; Versari, L.; Manzini, R. Glass vs. plastic: Life cycle assessment of extra-virgin olive oil bottles across global supply chains. Sustainability 2015, 7, 2818–2840. [Google Scholar] [CrossRef]

- Sazdovski, I.; Bala, A.; Fullana-i-Palmer, P. Linking LCA literature with circular economy value creation: A review on beverage packaging. Sci. Total Environ. 2021, 771, 145322. [Google Scholar] [CrossRef] [PubMed]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Ekvall, T. Attributional and Consequential Life Cycle Assessment. In Sustainability Assessment at the 21st Century; IntechOpen: London, UK, 2019; Available online: https://www.intechopen.com/chapters/69212 (accessed on 19 February 2025).

- Sala, S. Life Cycle Assessment for Supporting Policies in the EU: An Overview of Some Pilot Initiatives for the Monitoring and Evaluation of Policies. In Proceedings of the LCA4Regions Conference; European Commission—Joint Research Centre: Brussels, Belgium, 2021; Available online: https://projects2014-2020.interregeurope.eu/fileadmin/user_upload/tx_tevprojects/library/file_1638135375.pdf (accessed on 19 February 2025).

- Guinée, J.B.; Heijungs, R.; Huppes, G. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- The Recycling Partnership. 2020 State of Curbside Recycling Report; The Recycling Partnership: Falls Church, VA, USA, 2020; Available online: https://recyclingpartnership.org/wp-content/uploads/dlm_uploads/2020/02/2020-State-of-Curbside-Recycling.pdf (accessed on 20 February 2025).

- Pratibha, G.; Srinivas, I.; Raju, B.M.K.; Suvana, S.; Rao, K.V.; Rao, M.S.; Jha, A.; Anna, S.; Prabhakar, M.; Singh, V.K.; et al. Do rainfed production systems have lower environmental impact over irrigated production systems? On-farm mitigation strategies. Sci. Total Environ. 2024, 917, 170190. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-García, E.; Martínez-Falcó, J.; Marco-Lajara, B.; Manresa-Marhuenda, E. Revolutionizing the circular economy through new technologies: A new era of sustainable progress. Environ. Technol. Innov. 2024, 33, 103509. [Google Scholar] [CrossRef]

- European Environment Agency. Nearly 40 Percent of Plastic Demand Comes from the Production of Plastic Packaging; European Environment Agency: Copenhagen, Denmark, 2023; Available online: https://www.eea.europa.eu/en/analysis/maps-and-charts/nearly-40-percent-of-plastic (accessed on 21 February 2025).

- Duarte, P.; Silva, S.C.; Roza, A.S.; Carmo Dias, J. Enhancing consumer purchase intentions for sustainable packaging products: An in-depth analysis of key determinants and strategic insights. Sustain. Futures 2024, 7, 100193. [Google Scholar] [CrossRef]

- Corigliano, O.; Algieri, A. A comprehensive investigation on energy consumptions, impacts, and challenges of the food industry. Energy Convers. Manag. X 2024, 23, 100661. [Google Scholar] [CrossRef]

- Kasaeian, A.; Hosseini, S.M.; Sheikhpour, M.; Mahian, O.; Yan, W.-M.; Wongwises, S. Applications of eco-friendly refrigerants and nanorefrigerants: A review. Renew. Sustain. Energy Rev. 2018, 96, 91–99. [Google Scholar] [CrossRef]

- Eid, E.; Foster, A.; Alvarez, G.; Ndoye, F.-T.; Leducq, D.; Evans, J. Modelling energy consumption in a Paris supermarket to reduce energy use and greenhouse gas emissions using EnergyPlus. Int. J. Refrig. 2024, 168, 1–8. [Google Scholar] [CrossRef]

- Pandiyan, P.; Saravanan, S.; Usha, K.; Kannadasan, R.; Alsharif, M.H.; Kim, M.-K. Technological advancements toward smart energy management in smart cities. Energy Rep. 2023, 10, 648–677. [Google Scholar] [CrossRef]

- Cooreman-Algoed, M.; Boone, L.; Taelman, S.E.; Van Hemelryck, S.; Brunson, A.; Dewulf, J. Impact of consumer behaviour on the environmental sustainability profile of food production and consumption chains—A case study on chicken meat. Resour. Conserv. Recycl. 2022, 178, 106089. [Google Scholar] [CrossRef]

- Rahman, T.; Deb, N.; Alam, M.Z.; Moniruzzaman, M.; Miah, M.S.; Horaira, M.A.; Kamal, R. Navigating the contemporary landscape of food waste management in developing countries: A comprehensive overview and prospective analysis. Heliyon 2024, 10, e33218. [Google Scholar] [CrossRef] [PubMed]

- Gariba, M.I.; Rehman, F.U.; Prokop, V.; Giglio, C. Be digital to be sustain-able! The mediating role of sustainable supply chain practices in triggering the effects of digi-talisation on Sustainable Development Goals in the European Union. Oeconomia Copernic. 2024, 15, 1383–1425. [Google Scholar] [CrossRef]

- Mousania, Z.; Angulo, A.V.; Poon, J.P.H.; Atkinson, J.D. Quantifying the environmental impact of transportation for plastic film packaging end-of-life: Landfill, incineration, physical recycling, or chemical recycling. Resour. Conserv. Recycl. 2024, 207, 107681. [Google Scholar] [CrossRef]

- Dziadowiec, D.; Matykiewicz, D.; Szostak, M.; Andrzejewski, J. Overview of the cast polyolefin film extrusion technology for multi-layer packaging applications. Materials 2023, 16, 1071. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or refurbished as CE 3.0?—Exploring controversies in the conceptualization of the circular economy through a focus on history and resource value retention options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Manzoor, S.; Fayaz, U.; Dar, A.H.; Dash, K.K.; Shams, R.; Bashir, I.; Pandey, V.K.; Abdi, G. Sustainable development goals through reducing food loss and food waste: A comprehensive review. Future Foods 2024, 9, 100362. [Google Scholar] [CrossRef]

- Swetha, B.S.; Prabhakar, I.; Veeresh; Ainapur, S.D. Food waste reduction and sustainable food systems: Strategies, challenges, and future directions. J. Sci. Res. Rep. 2024, 30, 328–336. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Pathways for Food Waste Management and Prevention (No Appendices, 508 Compliant); U.S. Environmental Protection Agency: Washington, DC, USA, 2023. Available online: https://www.epa.gov/system/files/documents/2023-10/part2_wf-pathways_report_formatted_no-appendices_508-compliant.pdf (accessed on 10 February 2025).

- Zhu, J.; Luo, Z.; Sun, T.; Li, W.; Zhou, W. Cradle-to-grave emissions from food loss and waste represent half of total greenhouse gas emissions from food systems. Nat. Food 2023, 4, 247–256. [Google Scholar] [CrossRef]

- Brancoli, P.; Bolton, K.; Eriksson, M. Environmental impacts of waste management and valorisation pathways for surplus bread in Sweden. Waste Manag. 2020, 117, 136–145. [Google Scholar] [CrossRef] [PubMed]

- Eriksson, M.; Bartek, L.; Löfkvist, K.; Malefors, C.; Olsson, M.E. Environmental assessment of upgrading horticultural side streams—The case of unharvested broccoli leaves. Sustainability 2021, 13, 5327. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste management through composting: Challenges and potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Sundin, N.; Persson Osowski, C.; Strid, I.; Eriksson, M. Surplus food donation: Effectiveness, carbon footprint, and rebound effect. Resour. Conserv. Recycl. 2022, 179, 106093. [Google Scholar] [CrossRef]

- Cucina, M. Integrating anaerobic digestion and composting to boost energy and material recovery from organic wastes in the Circular Economy framework in Europe: A review. Bioresour. Technol. Rep. 2023, 24, 101642. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl Microbiol Biotechnol 2010, 85, 849–860. [Google Scholar] [CrossRef]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef]

- Diaz-Elsayed, N.; Rezaei, N.; Guo, T.; Mohebbi, S.; Zhang, Q. Wastewater-based resource recovery technologies across scale: A review. Resour. Conserv. Recycl. 2019, 145, 94–112. [Google Scholar] [CrossRef]

- Donner, M.; Erraach, Y.; López-i-Gelats, F.; Manuel-i-Martin, J.; Yatribi, T.; Radić, I.; El Hadad-Gauthier, F. Circular bioeconomy for olive oil waste and by-product valorisation: Actors’ strategies and conditions in the Mediterranean area. J. Environ. Manag. 2022, 321, 115836. [Google Scholar] [CrossRef] [PubMed]

- Martínez Salgado, M.M.; Ortega Blu, R.; Janssens, M.; Fincheira, P. Grape Pomace Compost as a Source of Organic Matter: Evolution of Quality Parameters to Evaluate Maturity and Stability. J. Clean. Prod. 2019, 216, 56–63. [Google Scholar] [CrossRef]

- Lopes, J.d.C.; Madureira, J.; Margaça, F.M.A.; Cabo Verde, S. Grape Pomace: A Review of Its Bioactive Phenolic Compounds, Health Benefits, and Applications. Molecules 2025, 30, 362. [Google Scholar] [CrossRef]

- Angeloni, G.; Spadi, A.; Corti, F.; Calcaprina, M.; Carpi, G.; Maioli, F.; Parenti, A.; Masella, P. Advancing circular economy in olive oil production: Comparing maturation systems for vermicompost creation from olive pomace. Biomass 2024, 4, 1178–1190. [Google Scholar] [CrossRef]

- Rossi, L.; Regni, L.; Rinaldi, S.; Sdringola, P.; Calisti, R.; Brunori, A.; Dini, F.; Proietti, P. Long-Term Water Footprint Assessment in a Rainfed Olive Tree Grove in the Umbria Region, Italy. Agriculture 2020, 10, 8. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Amin, M.B. Circular economy and sustainable practices in the food industry: A comprehensive bibliometric analysis. Clean. Responsible Consum. 2024, 14, 100206. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Enegbuma, W.I.; Donn, M. Challenges in life cycle assessment implementation for construction environmental product declaration development: A mixed approach and global perspective. Sustain. Prod. Consum. 2024, 49, 502–528. [Google Scholar] [CrossRef]

- Erakca, M.; Baumann, M.; Helbig, C.; Weil, M. Systematic review of scale-up methods for prospective life cycle assessment of emerging technologies. J. Clean. Prod. 2024, 451, 142161. [Google Scholar] [CrossRef]

- Ebadi Torkayesh, A.; Rajaeifar, M.A.; Rostom, M.; Malmir, B.; Yazdani, M.; Suh, S.; Heidrich, O. Integrating Life Cycle Assessment and Multi-Criteria Decision Making for Sustainable Waste Management: Key Issues and Recommendations for Future Studies. Renew. Sustain. Energy Rev. 2022, 168, 112819. [Google Scholar] [CrossRef]

- Khan, J.A.; Raman, A.M.; Sambamoorthy, N.; Prashanth, K. Research Methodology (Methods, Approaches and Techniques); San International Scientific Publications: Kanyakumari, India, 2023; Available online: https://doi.org/10.59646/rmmethods/040 (accessed on 25 February 2025).

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Olander, L.P.; Johnston, R.J.; Tallis, H.; Kagan, J.; Maguire, L.A.; Polasky, S.; Urban, D.; Boyd, J.; Wainger, L.; Palmer, M. Benefit relevant indicators: Ecosystem services measures that link ecological and social outcomes. Ecol. Indic. 2018, 85, 1262–1272. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Guidelines for Social Life Cycle Assessment of Products and Organizations 2020; Benoît Norris, C., Traverso, M., Neugebauer, S., Ekener, E., Schaubroeck, T., Russo Garrido, S., Berger, M., Valdivia, S., Lehmann, A., Finkbeiner, M., et al., Eds.; UNEP: Nairobi, Kenya, 2020. [Google Scholar]

- Hysa, E.; Kruja, A.; Ur Rehman, N.; Laurenti, R. Circular economy innovation and environmental sustainability impact on economic growth: An integrated model for sustainable development. Sustainability 2020, 12, 4831. [Google Scholar] [CrossRef]

- Piadeh, F.; Offie, I.; Behzadian, K.; Rizzuto, J.P.; Bywater, A.; Córdoba-Pachón, J.-R.; Walker, M. A critical review for the impact of anaerobic digestion on the sustainable development goals. J. Environ. Manag. 2024, 349, 119458. [Google Scholar] [CrossRef]

- Chenavaz, R.Y.; Dimitrov, S. From waste to wealth: Policies to promote the circular economy. J. Clean. Prod. 2024, 443, 141086. [Google Scholar] [CrossRef]

- Perramon, J.; Bagur-Femenías, L.; Alonso-Almeida, M.M.; Llach, J. Does the transition to a circular economy contribute to business resilience and transformation? Evidence from SMEs. J. Clean. Prod. 2024, 453, 142279. [Google Scholar] [CrossRef]

- Ay, H.M.; Söylemez, A.; Güneş Ay, N. The Importance of Green Bonds in Financing the Sustainable Environment. Paradigma. J. Econ. Manag. Res. 2023, 12, 72–79. [Google Scholar]

- Enriquez, S.; Sánchez-Triana, E.; Guerra López, M.G. Economic instruments and financial mechanisms for the adoption of a circular economy. In An Introduction to Circular Economy; Liu, L., Ramakrishna, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Forum Institutional. Consumers Want Sustainable Options: What Food Producers, Suppliers, and Retailers Can Do Now. World Economic Forum, 16 January 2023. Available online: https://www.weforum.org/stories/2023/01/consumer-power-net-zero-food-producer-retailer-davos23/ (accessed on 27 February 2025).

- Deshmukh, P.; Tare, H. Green marketing and corporate social responsibility: A review of business practices. Multidiscip. Rev. 2024, 7, e2024059. [Google Scholar] [CrossRef]

- Fu, Y.; Kok, R.A.W.; Dankbaar, B.; Ligthart, P.E.M.; van Riel, A.C.R. Factors affecting sustainable process technology adoption: A systematic literature review. J. Clean. Prod. 2018, 205, 226–251. [Google Scholar] [CrossRef]

- FSN Forum. Payments for Environmental Services (PES) in Theory and Practice: Lessons Learned and Way Forward; Global Forum on Food Security and Nutrition (FSN Forum), 25 February–18 March 2013. Available online: https://www.fao.org/fsnforum/consultation/payments-environmental-services-pes-theory-and-practice-lessons-learned-and-way (accessed on 4 March 2025).

- Uribe-Toril, J.; Ruiz-Real, J.L.; Galindo Durán, A.C.; Torres Arriaza, J.A.; de Pablo Valenciano, J. The circular economy and retail: Using deep learning to predict business survival. Environ. Sci. Eur. 2022, 34, 2. [Google Scholar] [CrossRef]

- Brennan, S.; Bravo Gonzalez, R.; Puzniak-Holford, M.; Kilsby, R.; Subramoni, A. EU Regulation Drives the Sustainability Transition. Deloitte. Available online: https://www2.deloitte.com/us/en/insights/environmental-social-governance/transition-to-net-zero.html (accessed on 4 March 2025).

- Economou, F.; Chatziparaskeva, G.; Papamichael, I.; Loizia, P.; Voukkali, I.; Navarro-Pedreño, J.; Klontza, E.; Lekkas, D.; Naddeo, V.; Zorpas, A. The Concept of Food Waste and Food Loss Prevention and Measuring Tools. Waste Manag. Res. 2024, 42, 651–669. [Google Scholar] [CrossRef]

- Borghino, N.; Corson, M.; Nitschelm, L.; Wilfart, A.; Fleuet, J.; Moraine, M.; Breland, T.A.; Lescoat, P.; Godinot, O. Contribution of LCA to decision making: A scenario analysis in territorial agricultural production systems. J. Environ. Manag. 2021, 287, 112288. [Google Scholar] [CrossRef] [PubMed]

- European Union. Circular Economy Action Plan: For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020; Available online: https://ec.europa.eu/environment/circular-economy/ (accessed on 24 February 2025).

- Polyportis, A.; De Keyzer, F.; van Prooijen, A.M.; Peiffer, L.C.; Wang, Y. Addressing Grand Challenges in Sustainable Food Transitions: Opportunities Through the Triple Change Strategy. Circ. Econ. Sust. 2024, 1–20. [Google Scholar] [CrossRef]

- Plociennik, C.; Nazeri, A.; Rimaz, M.H.; Knetsch, S.; Lopes, A.D.C.P.; Hagedorn, T.; Baehr, J.; Vogelgesang, M.; Li, C.; Benner, W.; et al. Connecting producers and recyclers: A digital product passport concept and implementation suitable for end-of-life management. Procedia CIRP 2024, 122, 831–836. [Google Scholar] [CrossRef]

- Lu, T.; Halog, A. Towards better life cycle assessment and circular economy: On recent studies on interrelationships among environmental sustainability, food systems, and diet. Int. J. Sustain. Dev. World Ecol. 2020, 27, 515–523. [Google Scholar] [CrossRef]

- Idrissi, Z.K.; Lachgar, M.; Hrimech, H. Blockchain, IoT and AI in logistics and transportation: A systematic review. Transp. Econ. Manag. 2024, 2, 275–285. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, W.; Wen, H.; Li, S. Promoting green technology innovation through policy synergy: Evidence from the dual pilot policy of low-carbon city and innovative city. Econ. Anal. Policy 2024, 84, 957–977. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G. Digital Product Passport: A Pathway to Circularity and Sustainability in Modern Manufacturing. Sustainability 2024, 16, 396. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Action Plan: The EU’s New Circular Action Plan Paves the Way for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020; Available online: https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en (accessed on 7 March 2025).

- Panza, L.; Bruno, G.; Lombardi, F. Integrating Absolute Sustainability and Social Sustainability in the Digital Product Passport to Promote Industry 5.0. Sustainability 2023, 15, 12552. [Google Scholar] [CrossRef]

- King, M.R.N.; Timms, P.D.; Mountney, S. A proposed universal definition of a Digital Product Passport Ecosystem (DPPE): Worldviews, discrete capabilities, stakeholder requirements and concerns. J. Clean. Prod. 2023, 384, 135538. [Google Scholar] [CrossRef]

- Zhang, A.; Seuring, S. Digital product passport for sustainable and circular supply chain management: A structured review of use cases. Int. J. Logist. Res. Appl. 2024, 27, 2513–2540. [Google Scholar] [CrossRef]

- Dervishaj, A.; Gudmundsson, K. From LCA to circular design: A comparative study of digital tools for the built environment. Resour. Conserv. Recycl. 2024, 200, 107291. [Google Scholar] [CrossRef]

- El Haouat, Z.; Essalih, S.; Bennouna, F.; Ramadany, M.; Amegouz, D. Environmental optimization and operational efficiency: Analyzing the integration of life cycle assessment (LCA) into ERP systems in Moroccan companies. Results Eng. 2024, 22, 102131. [Google Scholar] [CrossRef]

| Phases | Description |

|---|---|

| Goal Definition and Scoping | Establishing assessment objectives, system boundaries, and functional units. |

| Inventory Analysis | Collecting and quantifying data on resource use, emissions, and waste throughout the life cycle. |

| Impact Assessment | Evaluation of environmental impact through three steps: classification, characterization, and valuation. |

| Improvement Analysis | Identifying strategies to reduce significant environmental impacts and implement sustainable practices. |

| Study | Method | Sector | Key Indicators Compared | Economic/Social Findings |

|---|---|---|---|---|

| [19] | LCC | Olive oil | Processing cost, energy recovery | Valorization reduces costs by ~25% |

| [18] | SLCA | Coffee, cocoa | Labor rights, child labor, wages | Social outcomes vary with scale |

| [12] | LCA | Chinese foods | Carbon, water footprint | Fresh vegetables lower GHG per kg |

| Principle | Description | Ref. |

|---|---|---|

| Design Out Waste | Minimize waste throughout production by optimizing inputs, reducing losses, and reusing byproducts. | [21,22,23] |

| Keep Materials in Use | Recycle nutrients and materials into the production system to reduce dependency on new resources. | [24] |

| Regenerate Natural Systems | Focus on sustainable farming practices regenerating soil health, biodiversity, and ecosystems. | [25] |

| Shift to Renewable Inputs | Utilize renewable energy sources and biodegradable materials to minimize the environmental impact. | [22,26] |

| Encourage Nutrient Recovery | Implement strategies to recover nutrients (e.g., composting, anaerobic digestion) and reduce nutrient pollution. | [20] |

| Promote Biodiversity | Integrate diverse crops, livestock, and natural habitats to build resilience and sustainability in food systems. | [26,27] |

| Optimize Resource Efficiency | Maximize the efficiency of water, energy, and land use by utilizing precision farming techniques wherever possible. | [28] |

| Strengthen Local Supply Chains | Prioritize local sourcing and shorten supply chains to reduce emissions and promote regional economies. | [25] |

| Engage in Transparent and Responsible Practices | Ensure clear communication on production practices and engage with stakeholders to maintain accountability and transparency. | [29] |

| Encourage Circular Innovation | Invest in R&D for circular models, like upcycling food waste, closed-loop systems, and sustainable packaging alternatives. | [27,30] |

| Application Type | Functionality | Use Cases | Ref. |

|---|---|---|---|

| Data Processing and Validation | Automates data cleaning and ensures accuracy | AI-based platforms standardize LCA datasets for consistency across industries. | [142] |

| Predictive Modeling | Anticipates environmental impacts | Predicts GHG emissions and resource use under various scenarios. | [118] |

| Ontology Creation | Develop frameworks for DPPs | AI creates digital frameworks integrating LCA and DPP for circular economy metrics. | [20] |

| Process Optimization | Improves resource efficiency | AI identifies hotspots in production processes, enabling targeted interventions. | [21] |

| Decision Support Systems | Guides sustainable policy making | Provides recommendations for material selection and end-of-life strategies based on LCA data. | [8] |

| Dynamic Impact Analysis | Real-time monitoring and feedback | Tracks live emissions data to adjust operational parameters dynamically. | [94] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, C.; Güneş, S.; Vilela, A.; Gomes, R. Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective. Foods 2025, 14, 1553. https://doi.org/10.3390/foods14091553

Marques C, Güneş S, Vilela A, Gomes R. Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective. Foods. 2025; 14(9):1553. https://doi.org/10.3390/foods14091553

Chicago/Turabian StyleMarques, Catarina, Sinem Güneş, Alice Vilela, and Reinaldo Gomes. 2025. "Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective" Foods 14, no. 9: 1553. https://doi.org/10.3390/foods14091553

APA StyleMarques, C., Güneş, S., Vilela, A., & Gomes, R. (2025). Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective. Foods, 14(9), 1553. https://doi.org/10.3390/foods14091553