A Comparison of the Physicochemical Properties and Sensory Attributes of Ricotta Cheeses Purchased from Retail Outlets in Poland

Abstract

1. Introduction

2. Materials and Methods

2.1. Analytical Methods

2.2. Statistical Analysis

3. Results

3.1. Physicochemical Properties of Ricotta Cheeses

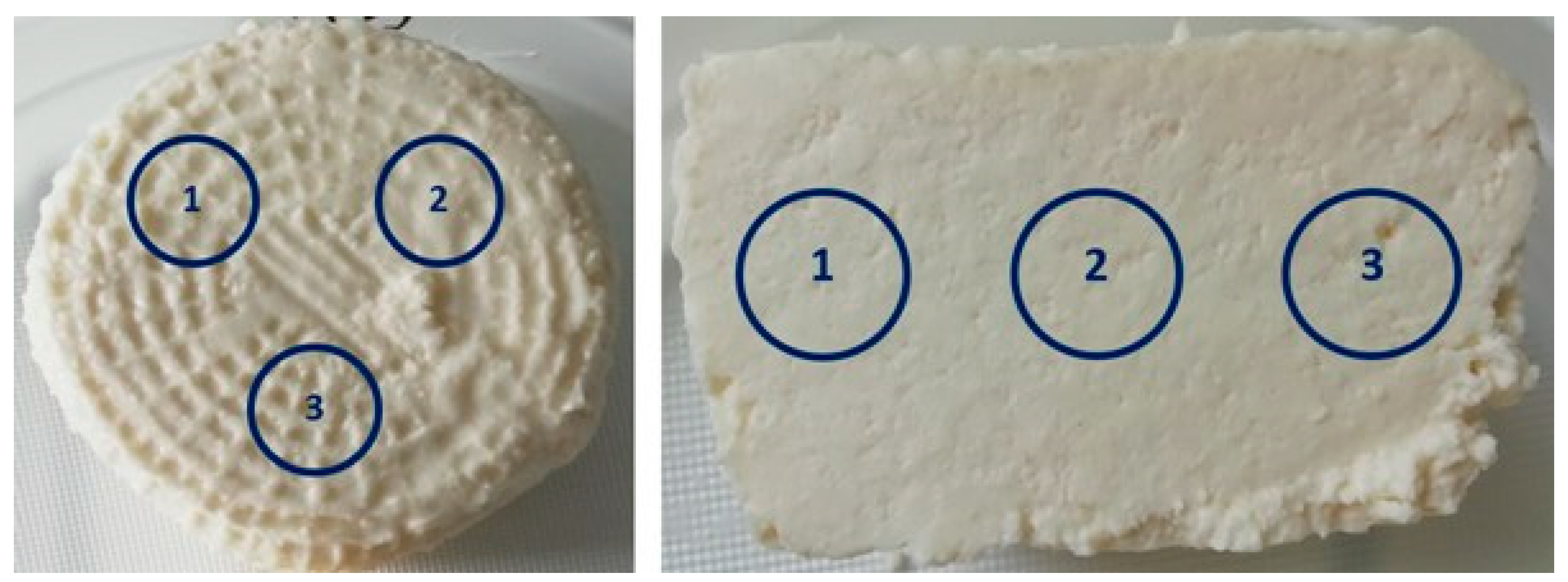

3.2. Color Parameters of Ricotta Cheeses

3.3. Sensory Quality of Ricotta Cheeses

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Obrusiewicz, T. Dairy Technology, Part 2; School and Pedagogical Publishers: Warsaw, Poland, 1995; pp. 1–364. ISBN 83-02-02184-9. (In Polish) [Google Scholar]

- Chwastowska-Siwiecka, I. Ricotta cheese-production, characteristics and quality features. Food Ind. 2021, 10, 32–39. (In Polish) [Google Scholar] [CrossRef]

- Mucchetti, G.; Neviani, E. Microbiologia e Tecnologia Lattiero-Casearia; Qualità e sicurezza, Tecniche Nuove Editore: Milano, Italiano, 2006; pp. 1–880. ISBN 978-88-481-1817-0. [Google Scholar]

- Pizzillo, M.; Claps, S.; Cifuni, G.F.; Fedele, V.; Rubino, R. Effect of goat breed on the sensory, chemical and nutritional characteristics of ricotta cheese. Livest. Prod. Sci. 2005, 94, 33–40. [Google Scholar] [CrossRef]

- Jasińska, M.; Skryplonek, K. Characterisctic of selected quality features of ricotta cheeses during refrigerated storage. Pol. J. Comm. Sci. 2015, 2, 80–91. (In Polish) [Google Scholar]

- Mangione, G.; Caccamo, M.; Natalello, A.; Licitra, G. Graduate Student Literature Review: History, technologies of production, and characteristics of ricotta cheese. J. Dairy Sci. 2023, 106, 3807–3826. [Google Scholar] [CrossRef]

- Salvatore, E.; Pes, M.; Falchi, G.; Pagnozzi, D.; Furesi, S.; Fiori, M.; Roggio, T.; Addis, M.F.; Pirisi, A. Effect of whey concentration on protein recovery in fresh ovine ricotta cheese. J. Dairy Sci. 2014, 97, 4686–4694. [Google Scholar] [CrossRef]

- Siemianowski, K.; Mickiewicz, D.; Lis, A.; Tońska, E. Rheological properties, texture and color of ricotta available on the Polish market. Acta Agroph. 2016, 23, 695–704. (In Polish) [Google Scholar]

- Kamel, B.; Boubaker, K.; Attia, H. Implementation of ricotta cheese production process in Tunisia. Int. Food Res. J. 2013, 20, 2343–2348. [Google Scholar]

- Modler, H.W.; Emmons, D.B. The use of continuous ricotta processing to reduce ingredient cost in ‘further processed’ cheese products. Int. Dairy J. 2001, 11, 517–523. [Google Scholar] [CrossRef]

- Guatemim, E.L.X.; da Silveira, S.M.; Millezi, A.F.; Ferenz, M.; Costa, K.D.; Rossi, P.; Bampi, G.B. Evaluation of the microbiological quality of ricotta cheese commercialized in Santa Catarina, Brazil. Food Sci. Technol. 2016, 36, 612–615. [Google Scholar] [CrossRef]

- Abdel-Razig, K.A.; AlGamry, A.S. Effect of natural acidifying agents and storage temperature on quality of unripend whey cheese. J. Sci. Technol. 2009, 10, 119–129. [Google Scholar]

- El-Sheikh, M.; Farrag, A.; Zaghloul, A. Ricotta Cheese from Whey Protein Concentrate. J. Am. Sci. 2010, 6, 321–325. [Google Scholar]

- Żulewska, J. Acid-heat coagulated cheese- alternative for whey. Pol. Dairy J. 2018, 5, 3–7. (In Polish) [Google Scholar]

- Maubois, J.-L.; Kosikowski, F.V. Making ricotta cheese by ultrafiltration. J. Dairy Sci. 1978, 61, 881–884. [Google Scholar] [CrossRef]

- Kowalik, J.; Łobacz, A.; Żulewska, J.; Rapacka, A. Ricotta and mascarpone cheeses-production and food safety aspects. Pol. Dairy J. 2019, 4, 36–40. (In Polish) [Google Scholar]

- Madalozzo, E.S.; Sauer, E.; Nagata, N. Determination of fat, protein and moisture in ricotta cheese by near infrared spectroscopy and multivariate calibration. J. Food Sci. Technol. 2015, 52, 1649–1655. [Google Scholar] [CrossRef] [PubMed]

- Fedele, V. Grazing for different quality of cheeses. Caseus Int. 2001, 2, 36–40. [Google Scholar]

- Morand-Fehr, P.; Sanz Sampelayo, M.R.; Fedele, Y.V.; Le Frileux, Y.; Eknaes, M.; Schmidely, P.; Giger-Reverdin, S.; Bas, P.; Rubino, R.; Havrevoll, O.; et al. Effects of feeding on the quality of goat milk and cheeses. Session 5: Nutrition and feeding strategies. In Proceedings of the 7th International Conference on Goats, Tours, France, 15–21 May 2000; pp. 53–58. Available online: https://www.iga-goatworld.com/7th-icg-tours-france.html (accessed on 25 December 2024).

- Rubino, R.; Moioli, B.; Fedele, V.; Pizzillo, M.; Morand-Fehr, P. Milk production of goats grazing native pasture under different supplementation regimes in southern Italy. Small Rumin. Res. 1995, 17, 213–221. [Google Scholar] [CrossRef]

- Agabriel, C.; Coulon, J.B.; Journal, C.; Sibra, C.; Albouy, H. Variabilité des caractéristiques des fromages saint-nectaire fermiers: Relations avec la composition du lait et les conditions de production. Le Lait 1999, 79, 291–302. [Google Scholar] [CrossRef]

- Ferlay, A.; Martin, B.; Pradel, P.; Coulon, J.B.; Chilliard, Y. Influence of grass-based diets on milk fatty acid composition and milk lipolytic system in Tarentaise and Montbeliarde cow breeds. J. Dairy Sci. 2006, 89, 4026–4041. [Google Scholar] [CrossRef]

- Romanzin, A.; Corazzin, M.; Piasentier, E.; Bovolenta, S. Effect of rearing system (mountain pasture vs. indoor) of Simmental cows on milk composition and Montasio cheese characteristics. J. Dairy Res. 2013, 80, 390–399. [Google Scholar] [CrossRef]

- Smithers, G.W. Whey and whey proteins- From ‘gutter-to-gold’. Int. Dairy J. 2008, 18, 695–704. [Google Scholar] [CrossRef]

- Pintado, M.E.; Macedo, A.C.; Malcata, F.X. Review: Technology, chemistry and microbiology of whey cheeses. Food Sci. Technol. Int. 2001, 7, 105–116. [Google Scholar] [CrossRef]

- Kolanowski, W. We serve cheese. Przegl. Gastr. 2005, 4, 59. (In Polish) [Google Scholar]

- Surażyński, A.; Nowak, H.; Kłobukowski, J. „Ricotta”- type cheeses made from heat-acid coagulated milk. Pol. Dairy J. 1977, 3, 83–85. (In Polish) [Google Scholar]

- Kłobukowski, J.; Cichoń, R. Nutritive value of some dairy products. Part II. Food Ind. 2000, 3, 40–41. (In Polish) [Google Scholar]

- PN-A-86232:1973; Milk and Dairy Products-Cheeses-Methods of Analysis. Polish Committee for Standardization: Warsaw, Poland, 1973; pp. 1–12. (In Polish)

- Commission Internationale de L’éclairage (CIE). Recommendations on Uniform Color Spaces, Color-Difference Equations, Psychometric Color Terms; Suppl. No. 2 to CIE Publication No. 15 (E-1.3.1), 1971/(TC1-3); Bureau Central de la CIE: Paris, France, 1978. [Google Scholar]

- Rodriguez-Aguilera, R.; Oliveira, J.C.; Montanez, J.C.; Mahajan, P.V. Effect of modified atmosphere packaging on quality factors and shelf-life of surface mould ripened cheese: Part I constant temperature. LWT-Food Sci. Technol. 2011, 44, 330–336. [Google Scholar] [CrossRef]

- Rufián-Henares, J.Á.; Guerra-Hernandez, E.; García-Villanova, B. Colour measurement as indicator for controlling the manufacture and storage of enteral formulas. Food Control 2006, 17, 489–493. [Google Scholar] [CrossRef]

- ISO 4121:2003; Sensory Analysis-Guidelines for the Use of Quantitative Response Scales. International Organization for Standardization (ISO): Geneva, Switzerland, 2003.

- ISO 8586:2023; Sensory Analysis-Selection and Training of Sensory Assessors. International Organization for Standardization (ISO): Geneva, Switzerland, 2023.

- PN-A-86300:1991; Milk and Dairy Products-Unripened Curd Cheese. Polish Committee for Standardization: Warsaw, Poland, 1991; pp. 1–7. (In Polish)

- PN-A-86300:1991/Az2:1997; Milk and Dairy Products-Unripened Curd Cheese. Polish Committee for Standardization: Warsaw, Poland, 1997; pp. 1–2. (In Polish)

- ISO 6658:2017; Sensory Analysis-Methodology-General Guidance. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- Panfil-Kuncewicz, H.; Lis, A.; Majewska, M. Effect of active packaging on microbiological shelf-life and sensory parameters of tvorog cheeses. Food Sci. Technol. Qual. 2014, 2, 190–203. Available online: https://wydawnictwo.pttz.org/wp-content/uploads/2015/02/14_Panfil.pdf (accessed on 5 December 2024). (In Polish). [CrossRef]

- StatSoft Inc. STATISTICA (Data Analysis Software System), Version 13.3; StatSoft Inc.: Tulsa, OK, USA, 2017. Available online: www.statsoft.com (accessed on 5 December 2024).

- Davies, C.G.A.; Labuza, T.P. The Maillard Reaction Application to Confectionery Products; Confectionery Science, Pennsylvania State University Press: University Park, PA, USA, 1997; pp. 35–66. [Google Scholar]

- Francis, F.J.; Clydesdale, F.M. Food Colorimetry: Theory and Applications; The AVI Publishing Company Inc.: Westport, CT, USA, 1975; pp. 417–423. [Google Scholar]

- Giangolini, G.; Amatiste, S.; Filippetti, F.; Boselli, C.; Fagiolo, A.; Rosati, R. Chemical composition of “Ricotta Romana” cheese. Sci. Tec. Latt.-Casearia. 2009, 60, 131–135. [Google Scholar]

- Souza, M.R.; Morais, C.F.D.; Corrêa, C.E.S.; Rodrigues, R. Physico-chemical properties of Ricotta cheese marketed in Belo Horizonte, Minas Gerais. Rev. Hig. Aliment. 2000, 14, 68–71. (In Brazilian) [Google Scholar]

- Sulieman, A.M.E.; Eljack, A.S.; Salih, Z.A. Quality Evaluation of “Ricotta” Cheese Produced at Laboratory Level. Int. J. Food Sci. Nutr. Eng. 2012, 2, 108–112. [Google Scholar] [CrossRef]

- Borba, K.K.S.; Silva, F.A.; Madruga, M.S.; Queiroga, R.C.R.E.; Souza, E.L.; Magnani, M. The effect of storage on nutritional, textural and sensory characteristics of creamy ricotta made from whey as well as cow’s milk and goat’s milk. Int. J. Food Sci. Tech. 2014, 49, 1279–1286. [Google Scholar] [CrossRef]

- Ortiz Araque, L.C.; Darre, M.; Ortiz, C.M.; Massolo, J.F.; Vicente, A.R. Quality and yield of Ricotta cheese as affected by milk fat content and coagulant type. Int. J. Dairy Technol. 2018, 71, 340–346. [Google Scholar] [CrossRef]

- Streiff, P.J.; Nilson, K.M.; Dutwe, A.H.; Atherton, H.V. Whey Ricotta Cheese Manufactured from Fluid and Condensed Whey. J. Food Prot. 1979, 42, 552–554. [Google Scholar] [CrossRef]

- Tripaldi, C.; Rinaldi, S.; Palocci, G.; Di Giovanni, S.; Campagna, M.C.; Di Russo, C.; Zottola, T. Chemical and microbiological characteristics of homogenised Ricotta Cheese produced from buffalo whey. Ital. J. Food Sci. 2020, 32, 292–309. [Google Scholar] [CrossRef]

- Jelen, P. Whey cheeses and beverages. In Whey and Lactose Processing; Zadow, J.G., Ed.; Elsevier Science Publishers Ltd.: London, UK, 1992; pp. 157–195. [Google Scholar]

- Esper, L.M.R.; Bonets, P.A.; Kuaye, A.Y. Avaliação das características físico-químicas de ricotas comercializadas no município de Campinas-SP e da conformidade das informações nutricionais declaradas nos rótulos. Rev. Inst. Adolfo Lutz 2007, 66, 299–304. [Google Scholar] [CrossRef]

- Mancuso, I.; Cardamone, C.; Fiorenza, G.; Macaluso, G.; Arcuri, L.; Miraglia, V.; Scatassa, M.L. Sensory and microbiological evaluation of traditional ovine ricotta cheese in modified atmosphere packaging. Ital. J. Food Saf. 2014, 3, 1725–1727. [Google Scholar] [CrossRef]

- Modler, H.W. Development of a Continuous Process for the Production of Ricotta Cheese. J. Dairy Sci. 1988, 71, 2003–2009. [Google Scholar] [CrossRef]

- Di Pierro, P.; Sorrentino, A.; Mariniello, L.; Giosafatto, C.V.L. Chitosan/whey protein film as active coating to extend Ricotta cheese shelf-life. LWT-Food Sci. Technol. 2011, 44, 2324–2327. [Google Scholar] [CrossRef]

- Martins, J.T.; Cerqueira, M.A.; Souza, B.W.S.; Do Carmo Avides, M.; Vicente, A.A. Shelf Life Extension of Ricotta Cheese Using Coatings of Galactomannans from Non-conventional Sources Incorporating Nisin against Listeria monocytogenes. J. Agric. Food Chem. 2010, 58, 1884–1891. [Google Scholar] [CrossRef]

- DTU. National Food Institute: Cheese Whey; Department of Nutrition, Technical University of Denmark: Lyngby, Denmark, 2009. [Google Scholar]

- Karczewska, D.; Pikul, J.; Płuszka, H.; Chudy, S. Changes in selected physicochemical characteristics of traditionally packaged tvarog in dependence on the type of packaging material used. Chłodnictwo 2005, 10, 46–51. (In Polish) [Google Scholar]

- Dobrzańska, A.; Cais-Sokolińska, D. Measuring the brightness and coordinate trichromaticity milk protein preparations. ABiD 2014, 3, 267–272. (In Polish) [Google Scholar]

- Rój, A.; Przybyłowski, P. Colour measurement of natural yoghurts. Bromat. Chem. Toksykol. 2012, 45, 813–816. (In Polish) [Google Scholar]

- Bzducha, A.; Obiedziński, M.W. Instrumental methods for estimation of ripeness of fermented dairy products. Food Ind. 2006, 10, 40–43. (In Polish) [Google Scholar]

- McMahnon, D.J.; Fife, R.L.; Oberg, C.J. Water Partitioning in Mozzarella Cheese and Its Relationship to Cheese Meltability. J. Dairy Sci. 1999, 82, 1361–1369. [Google Scholar] [CrossRef]

| Specification | Producer | |||

|---|---|---|---|---|

| A (per 100 g) | B (per 100 g) | C (per 100 g) | D (per 100 g) | |

| Composition | Pasteurized milk whey (80%), pasteurized milk (19%), pasteurized sweet cream, salt, acidity regulator: citric acid | Milk whey, pasteurized milk, salt, acidity regulator: citric acid | Milk whey, salt, acidity regulator: citric acid | Milk whey, salt, acidity regulator: citric acid |

| Net weight | 250 g | 220 g | 250 g | 240 g |

| Fat, including saturated fatty acids | 22 g 15 g | 14 g 9.8 g | 9.5 g 6.7 g | 11 g 7.3 g |

| Protein | 11 g | 12 g | 8.4 g | 9.7 g |

| Carbohydrates, including sugars | 3.7 g 3.2 g | 3.6 g 3.0 g | 4.3 g 3.8 g | 3.3 g 3.3 g |

| Salt | 0.30 g | 0.50 g | 0.32 g | 0.30 g |

| Energy value | 1051 kJ/254 kcal | 783 kJ/188 kcal | 567 kJ/136 kcal | 628 kJ/151 kcal |

| Storage temperature | 1–8 °C | 1–8 °C | 0–4 °C | 2–6 °C |

| Parameter | Producer | p Value | |||

|---|---|---|---|---|---|

| A (n = 10) | B (n = 10) | C (n = 10) | D (n = 10) | ||

| Moisture content (%) | 55.38 D ±0.50 | 58.30 C ±0.32 | 73.52 A ±0.24 | 72.57 B ±0.65 | 0.001 |

| pH | 5.83 ±0.39 | 5.63 b ±0.05 | 5.96 ±0.28 | 6.19 a ±0.16 | 0.050 |

| Titratable acidity (°SH) | 19.00 A ±0.82 | 15.00 B ±1.83 | 8.00 C ±0.01 | 9.00 C ±0.82 | 0.001 |

| Shear force (N) | 4.60 A ±0.46 | 1.79 B ±0.13 | 1.08 C ±0.03 | 1.54 BC ±0.36 | 0.001 |

| Parameter | Producer | p Value | |||

|---|---|---|---|---|---|

| A (n = 10) | B (n = 10) | C (n = 10) | D (n = 10) | ||

| On the Surface | |||||

| L*—lightness | 93.33 A ±0.22 | 90.93 C ±0.64 | 92.14 B ±0.67 | 92.76 AB ±0.81 | 0.001 |

| a*—redness | 0.63 B ±0.05 | 2.65 A ±0.04 | −0.18 C ±0.06 | −0.29 D ±0.06 | 0.001 |

| b*—yellowness | 14.43 B ±0.68 | 15.95 A ±0.20 | 7.78 C ±0.17 | 10.37 D ±0.77 | 0.001 |

| WI—whiteness index | 84.08 C ±0.56 | 81.45 D ±0.24 | 88.90 A ±0.96 | 87.34 B ±0.98 | 0.001 |

| YI—yellowness index | 22.09 B ±1.00 | 25.06 A ±0.23 | 12.06 D ±0.27 | 15.97 C ±1.07 | 0.001 |

| At the Cross-Section | |||||

| L*—lightness | 94.03 AC ±0.26 | 91.85 B ±0.84 | 94.62 A ±0.43 | 93.40 C ±0.73 | 0.001 |

| a*—redness | 0.59 B ±0.03 | 2.31 A ±0.11 | −0.06 C ±0.01 | −0.42 D ±0.09 | 0.001 |

| b*—yellowness | 13.27 B ±0.18 | 14.53 A ±0.25 | 8.55 C ±0.10 | 10.21 D ±0.95 | 0.001 |

| WI—whiteness index | 85.44 B ±0.20 | 82.85 C ±0.79 | 89.89 A ±0.29 | 87.79 D ±1.04 | 0.001 |

| YI—yellowness index | 20.15 B ±0.29 | 22.59 A ±0.25 | 12.91 C ±0.19 | 15.62 D ±1.09 | 0.001 |

| Parameter (Point Score) | Producer | p Value | |||

|---|---|---|---|---|---|

| A (n = 10) | B (n = 10) | C (n = 10) | D (n = 10) | ||

| Color | 4.72 A ±0.09 | 3.47 B ±0.30 | 4.86 A ±0.13 | 4.75 A ±0.18 | 0.001 |

| External appearance at the cross-section | 4.89 Aa ±0.18 | 4.08 Ab ±0.59 | 4.86 Aa ±0.20 | 3.08 B ±0.86 | 0.001 |

| Structure and consistency | 4.75 ACa ±0.14 | 4.27 Ab ±0.29 | 4.86 C ±0.07 | 2.52 B ±0.57 | 0.001 |

| Aroma | 4.69 Aa ±0.16 | 4.30 Ab ±0.34 | 3.55 B ±0.25 | 4.41 A ±0.23 | 0.001 |

| Taste | 4.67 A ±0.21 | 4.11 B ±0.25 | 3.47 C ±0.50 | 4.47 AB ±0.22 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chwastowska-Siwiecka, I.; Kaca, A.; Miciński, J. A Comparison of the Physicochemical Properties and Sensory Attributes of Ricotta Cheeses Purchased from Retail Outlets in Poland. Foods 2025, 14, 1413. https://doi.org/10.3390/foods14081413

Chwastowska-Siwiecka I, Kaca A, Miciński J. A Comparison of the Physicochemical Properties and Sensory Attributes of Ricotta Cheeses Purchased from Retail Outlets in Poland. Foods. 2025; 14(8):1413. https://doi.org/10.3390/foods14081413

Chicago/Turabian StyleChwastowska-Siwiecka, Iwona, Agnieszka Kaca, and Jan Miciński. 2025. "A Comparison of the Physicochemical Properties and Sensory Attributes of Ricotta Cheeses Purchased from Retail Outlets in Poland" Foods 14, no. 8: 1413. https://doi.org/10.3390/foods14081413

APA StyleChwastowska-Siwiecka, I., Kaca, A., & Miciński, J. (2025). A Comparison of the Physicochemical Properties and Sensory Attributes of Ricotta Cheeses Purchased from Retail Outlets in Poland. Foods, 14(8), 1413. https://doi.org/10.3390/foods14081413