Digestibility and Quality Characteristics of Noodles with Added Malic-Acid-Modified Wheat Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Isolating Starch

2.3. Modifying Starch with Malic Acid

2.4. Preparation of MAS-Added Noodles

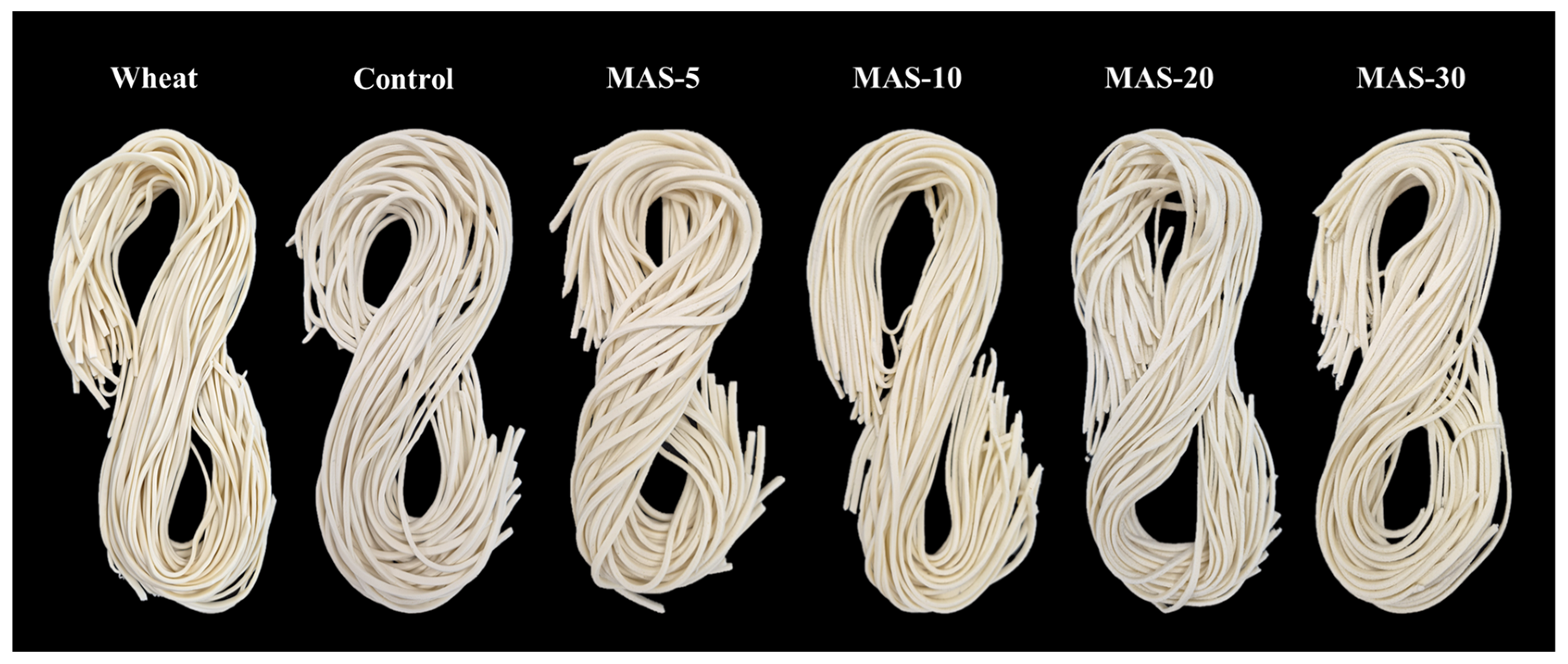

2.5. Color and Appearance of the MAS-Added Noodles

2.6. Texture Profiles of the Cooked Noodles

2.7. Tensile Strengths of the Cooked Noodles

2.8. Cooking Properties of the Noodles

2.9. Amount of Leached Solids

2.10. In Vitro Noodle Digestibility

2.11. Statistical Analysis

3. Results and Discussion

3.1. Color and Appearance Characteristics of the MAS-Added Noodles

3.2. Textures of the MAS-Added Noodles

3.3. Tensile Strengths of the MAS-Added Noodles

3.4. Cooking Characteristics of MAS-Added Noodles

3.5. Starch Digestibilities of the MAS-Added Noodles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MAS | malic acid-modified starch |

| RDS | rapidly digestible starch |

| SDS | slowly digestible starch |

| RS | resistant starch |

References

- Bertoft, E. Understanding starch structure: Recent progress. Agronomy 2017, 7, 56. [Google Scholar] [CrossRef]

- Copeland, L.; Blazek, J.; Salman, H.; Tang, M.C. Form and functionality of starch. Food Hydrocoll. 2009, 23, 1527–1534. [Google Scholar] [CrossRef]

- Wang, S.; Guo, P. Botanical sources of starch. In Starch Structure, Functionality and Application in Foods; Wang, S., Ed.; Springer: Singapore, 2020; pp. 9–27. [Google Scholar]

- Aller, E.E.; Abete, I.; Astrup, A.; Martinez, J.A.; van Baak, M.A. Starches, sugars and obesity. Nutrients 2011, 3, 341–369. [Google Scholar] [CrossRef]

- Seung, D. Amylose in starch: Towards an understanding of biosynthesis, structure and function. New Phytol. 2020, 228, 1490–1504. [Google Scholar] [CrossRef]

- Svihus, B.; Hervik, A.K. Digestion and metabolic fates of starch, and its relation to major nutrition-related health problems: A review. Starch-Stärke 2016, 68, 302–313. [Google Scholar] [CrossRef]

- Nag, S.; Majumder, S. Starch, gallic acid, their inclusion complex and their effects in diabetes and other diseases—A review. Food Sci. Nutr. 2023, 11, 1612–1621. [Google Scholar] [CrossRef]

- Dundar, A.N.; Gocmen, D. Effects of autoclaving temperature and storing time on resistant starch formation and its functional and physicochemical properties. Carbohydr. Polym. 2013, 97, 764–771. [Google Scholar] [CrossRef]

- Na, J.H.; Jeong, G.A.; Park, H.J.; Lee, C.J. Impact of esterification with malic acid on the structural characteristics and in vitro digestibilities of different starches. Int. J. Biol. Macromol. 2021, 174, 540–548. [Google Scholar] [CrossRef]

- Vatanasuchart, N.; Niyomwit, B.; Wongkrajang, K. Resistant starch content, in vitro starch digestibility and physico-chemical properties of flour and starch from Thai bananas. Maejo Int. J. Sci. Technol. 2012, 6, 259–271. [Google Scholar]

- Birt, D.F.; Boylston, T.; Hendrich, S.; Jane, J.-L.; Hollis, J.; Li, L.; McClelland, J.; Moore, S.; Phillips, G.J.; Rowling, M. Resistant starch: Promise for improving human health. Adv. Nutr. 2013, 4, 587–601. [Google Scholar] [CrossRef]

- Wolf, B.W.; Wolever, T.M.S.; Bolognesi, C.; Zinker, B.A.; Garleb, K.A. Glycemic response to a rapidly digested starch is not affected by the addition of an indigestible dextrin in humans. Nutr. Res. 2001, 21, 1099–1106. [Google Scholar] [CrossRef]

- Xie, X.; Liu, Q. Development and physicochemical characterization of new resistant citrate starch from different corn starches. Starch-Stärke 2004, 56, 364–370. [Google Scholar] [CrossRef]

- Remya, R.; Jyothi, A.N.; Sreekumar, J. Effect of chemical modification with citric acid on the physicochemical properties and resistant starch formation in different starches. Carbohydr. Polym. 2018, 202, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Klostermann, C.; Buwalda, P.; Leemhuis, H.; de Vos, P.; Schols, H.; Bitter, J. Digestibility of resistant starch type 3 is affected by crystal type, molecular weight and molecular weight distribution. Carbohydr. Polym. 2021, 265, 118069. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Tovar, J. Update of the concept of type 5 resistant starch (RS5): Self-assembled starch V-type complexes. Trends Food Sci. Technol. 2021, 109, 711–724. [Google Scholar] [CrossRef]

- Khawas, P.; Deka, S.C. Effect of modified resistant starch of culinary banana on physicochemical, functional, morphological, diffraction, and thermal properties. Int. J. Food Prop. 2017, 20, 133–150. [Google Scholar] [CrossRef]

- Perera, A.; Meda, V.; Tyler, R. Resistant starch: A review of analytical protocols for determining resistant starch and of factors affecting the resistant starch content of foods. Food Res. Int. 2010, 43, 1959–1974. [Google Scholar] [CrossRef]

- Hung, P.V.; Vien, N.L.; Lan Phi, N.T. Resistant starch improvement of rice starches under a combination of acid and heat-moisture treatments. Food Chem. 2016, 191, 67–73. [Google Scholar] [CrossRef]

- Lockyer, S.; Nugent, A. Health effects of resistant starch. Nutr. Bull. 2017, 42, 10–41. [Google Scholar] [CrossRef]

- Giuberti, G.; Marti, A.; Fortunati, P.; Gallo, A. Gluten free rice cookies with resistant starch ingredients from modified waxy rice starches: Nutritional aspects and textural characteristics. J. Cereal Sci. 2017, 76, 157–164. [Google Scholar] [CrossRef]

- Pang, Z.; Xu, R.; Luo, T.; Che, X.; Bansal, N.; Liu, X. Physiochemical properties of modified starch under yogurt manufacturing conditions and its relation to the properties of yogurt. J. Food Eng. 2019, 245, 11–17. [Google Scholar] [CrossRef]

- Majzoobi, M.; Hedayati, S.; Habibi, M.; Ghiasi, F.; Farahnaky, A. Effects of corn resistant starch on the physicochemical properties of cake. J. Agric. Sci. Technol. 2014, 16, 569–576. [Google Scholar]

- Yousif, E.; Gadallah, M.E.; Sorour, A.M. Physico-chemical and rheological properties of modified corn starches and its effect on noodle quality. Ann. Agric. Sci. 2012, 57, 19–27. [Google Scholar] [CrossRef]

- Chae, R.; Jeong, G.A.; Kim, H.-J.; Lee, C.J. Quality characteristics of cookies added with octenyl succinyl anhydride-modified wheat starch. Food Eng. Prog. 2023, 27, 388–393. [Google Scholar] [CrossRef]

- Alexander, V.; Sobhi, B.; Joseph, S.; Beta, T.; Malunga, L.N. Exploring the noodle-making potential and digestibility of native oat starch and citric acid cross-linked resistant oat starch. Cereal Chem. 2025, 102, 342–351. [Google Scholar] [CrossRef]

- Kim, H.R.; Jeong, G.A.; Bae, J.-E.; Hong, J.S.; Choi, H.-D.; Lee, C.J. Impact of chemical modification by immersion with malic acid on the physicochemical properties and resistant starch formation in rice. J. Food Sci. 2022, 87, 1058–1068. [Google Scholar] [CrossRef]

- Lee, C.J.; Na, J.H.; Park, J.-Y.; Chang, P.-S. Structural Characteristics and In Vitro Digestibility of Malic Acid-Treated Corn Starch with Different pH Conditions. Molecules 2019, 24, 1900. [Google Scholar] [CrossRef]

- Mansur, A.R.; Jeong, G.A.; Lee, C.J. Preparation, physicochemical properties, and in vivo digestibility of thermostable resistant starch from malic acid-treated wheat starch. Food Res. Int. 2022, 162, 112159. [Google Scholar] [CrossRef]

- Kim, H.-S.; Huber, K.C. Channels within soft wheat starch A-and B-type granules. J. Cereal Sci. 2008, 48, 159–172. [Google Scholar] [CrossRef]

- Kim, S.-K.; Kim, H.-R.; Bang, J.-B. Effects of alkaline reagent on the rheological properties of wheat flour and noodle property. Korean J. Food Sci. Technol. 1996, 28, 58–65. [Google Scholar]

- Englyst, H.N.; Kingman, S.; Cummings, J. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, S33–S50. [Google Scholar] [PubMed]

- Shin, S.I.; Lee, C.J.; Kim, D.-I.; Lee, H.A.; Cheong, J.-J.; Chung, K.M.; Baik, M.-Y.; Park, C.S.; Kim, C.H.; Moon, T.W. Formation, characterization, and glucose response in mice to rice starch with low digestibility produced by citric acid treatment. J. Cereal Sci. 2007, 45, 24–33. [Google Scholar] [CrossRef]

- Yaver, E.; Bilgiçli, N. Effect of ultrasonicated lupin flour and resistant starch (type 4) on the physical and chemical properties of pasta. Food Chem. 2021, 357, 129758. [Google Scholar] [CrossRef] [PubMed]

- Jeong, G.; Chae, R.; Lee, C. Digestibility and quality characteristics of noodles added with octenyl succinic anhydride-modified wheat starch. Food Eng. Prog. 2023, 27, 236–242. [Google Scholar] [CrossRef]

- Lin, D.; Zhou, W.; Yang, Z.; Zhong, Y.; Xing, B.; Wu, Z.; Chen, H.; Wu, D.; Zhang, Q.; Qin, W. Study on physicochemical properties, digestive properties and application of acetylated starch in noodles. Int. J. Biol. Macromol. 2019, 128, 948–956. [Google Scholar] [CrossRef]

- Liu, J.; Meenu, M.; Xu, B. Effect of unripe banana flour and wheat gluten on physicochemical characteristics and sensory properties of white salted noodles. J. Food Process. Preserv. 2020, 44, e14513. [Google Scholar] [CrossRef]

- Li, M.; Sun, Q.-J.; Han, C.-W.; Chen, H.-H.; Tang, W.-T. Comparative study of the quality characteristics of fresh noodles with regular salt and alkali and the underlying mechanisms. Food Chem. 2018, 246, 335–342. [Google Scholar] [CrossRef]

- Lee, C.H.; Cho, J.K.; Lee, S.J.; Koh, W.; Park, W.; Kim, C.H. Enhancing β-carotene content in Asian noodles by adding pumpkin powder. Cereal Chem. 2002, 79, 593–595. [Google Scholar] [CrossRef]

- Hong, J.; Li, C.; An, D.; Liu, C.; Li, L.; Han, Z.; Zeng, X.A.; Zheng, X.; Cai, M. Differences in the rheological properties of esterified total, A-type, and B-type wheat starches and their effects on the quality of noodles. J. Food Process. Preserv. 2020, 44, e14342. [Google Scholar] [CrossRef]

- Hoseney, R.C. Principles of Cereal Science and Technology; American Association of Cereal Chemists, Inc.: St. Paul, MN, USA, 1994; p. 270. [Google Scholar]

- Obadi, M.; Xu, B. Review on the physicochemical properties, modifications, and applications of starches and its common modified forms used in noodle products. Food Hydrocoll. 2021, 112, 106286. [Google Scholar] [CrossRef]

- Jeong, G.A.; Han, S.H.; Park, J.Y.; Shin, Y.L.; Lee, S.J.; Lee, C.J. Quality characteristics of noodles supplemented with rice flour and alkaline reagent. Korean J. Food Sci. Technol. 2019, 51, 237–242. [Google Scholar]

- Shukri, R.; Shi, Y.C. Structure and pasting properties of alkaline-treated phosphorylated cross-linked waxy maize starches. Food Chem. 2017, 214, 90–95. [Google Scholar] [CrossRef] [PubMed]

| Sample | Ingredients (g) | ||||

|---|---|---|---|---|---|

| Wheat Flour | Modified Starch | Native Starch | Salt | Water | |

| Wheat | 1000 | – | – | 10.0 | 340 |

| Control | 800 | – | 200 | 10.0 | 340 |

| MAS-5 | 950 | 50 | – | 10.0 | 340 |

| MAS-10 | 900 | 100 | – | 10.0 | 340 |

| MAS-20 | 800 | 200 | – | 10.0 | 340 |

| MAS-30 | 700 | 300 | – | 10.0 | 340 |

| Item | Condition | |

|---|---|---|

| Test type | TPA test | Tensile strength test |

| Measurement type | Two bite compression | Return to start |

| Sample size | 3.0 × 2.2 × 50 mm | 3.0 × 2.2 × 300 mm |

| Probe | 35 mm dia, circle | Spaghetti/Noodle tensile rig |

| Test speed | 1.0 mm/s | 2.0 mm/s |

| Deformation | 50% | 120 mm |

| Trigger force | 0.049 N | 0.049 N |

| Sample | Hunter’s Color Value | ||||

|---|---|---|---|---|---|

| L* | a* | b* | ΔE | ||

| Uncooked noodle sheet | Wheat | 76.5 ± 0.76 b | 0.37 ± 0.06 b | 16.4 ± 1.12 b | 78.2 ± 0.97 b |

| Control | 73.1 ± 0.54 a | −1.76 ± 0.13 a | 16.1 ± 0.16 ab | 74.9 ± 0.55 a | |

| MAS-5 | 82.1 ± 0.78 c | 0.74 ± 0.10 c | 22.3 ± 0.44 d | 85.1 ± 0.65 c | |

| MAS-10 | 85.4 ± 0.52 d | 0.52 ± 0.02 b | 18.3 ± 0.12 c | 87.3 ± 0.53 d | |

| MAS-20 | 86.5 ± 0.31 e | 0.47 ± 0.02 b | 17.0 ± 0.07 b | 88.2 ± 0.31 d | |

| MAS-30 | 88.2 ± 0.54 f | 0.35 ± 0.16 b | 15.3 ± 0.34 a | 89.5 ± 0.54 e | |

| Cooked noodle sheet | Wheat | 69.0 ± 1.29 d | −6.05 ± 0.84 b | 9.72 ± 0.83 b | 70.0 ± 1.28 e |

| Control | 54.0 ± 2.00 c | −11.6 ± 0.86 a | 3.62 ± 1.02 a | 55.4 ± 1.77 d | |

| MAS-5 | 66.7 ± 2.08 d | −4.10 ± 0.68 c | 19.7 ± 0.68 d | 69.7 ± 2.15 e | |

| MAS-10 | 26.7 ± 0.50 b | −3.30 ± 0.31 cd | 16.1 ± 0.44 c | 31.4 ± 0.44 c | |

| MAS-20 | 4.58 ± 0.77 a | −2.85 ± 0.49 d | 10.2 ± 0.81 b | 11.5 ± 0.93 b | |

| MAS-30 | 2.44 ± 1.25 a | −1.55 ± 0.05 e | 4.55 ± 0.52 a | 5.45 ± 0.92 a | |

| Sample | TPA | ||||

|---|---|---|---|---|---|

| Hardness (N) | Springiness | Cohesiveness | Chewiness (N·mm) | Gumminess (N) | |

| Wheat | 28.3 ± 0.88 c | 0.116 ± 0.015 a | 0.155 ± 0.003 d | 0.502 ± 0.084 d | 4.48 ± 0.077 d |

| Control | 15.9 ± 2.09 b | 0.092 ± 0.007 b | 0.125 ± 0.006 c | 0.184 ± 0.039 bc | 2.00 ± 0.332 b |

| MAS-5 | 28.2 ± 1.62 c | 0.082 ± 0.002 ab | 0.107 ± 0.009 b | 0.250 ± 0.022 c | 3.03 ± 0.245 c |

| MAS-10 | 27.1 ± 2.08 c | 0.083 ± 0.007 ab | 0.107 ± 0.011 b | 0.241 ± 0.033 c | 2.88 ± 0.211 c |

| MAS-20 | 17.0 ± 1.21 b | 0.083 ± 0.011 ab | 0.097 ± 0.010 ab | 0.138 ± 0.033 ab | 1.65 ± 0.191 b |

| MAS-30 | 11.3 ± 0.70 a | 0.073 ± 0.006 a | 0.085 ± 0.008 a | 0.070 ± 0.010 a | 0.95 ± 0.048 a |

| Sample | Tension | |

|---|---|---|

| Force (N) | Distance (mm) | |

| Wheat | 0.379 ± 0.018 e | 46.0 ± 3.56 e |

| Control | 0.106 ± 0.012 b | 17.5 ± 1.68 b |

| MAS-5 | 0.149 ± 0.006 d | 25.2 ± 2.84 d |

| MAS-10 | 0.124 ± 0.007 c | 20.7 ± 0.35 c |

| MAS-20 | 0.063 ± 0.004 a | 4.70 ± 3.39 a |

| MAS-30 | N.D. | N.D. |

| Sample | Cooked Noodle | Cooking Water | ||

|---|---|---|---|---|

| Weight (g) | Volume (mL) | Water Absorption (%) | Turbidity (675 nm) | |

| Wheat | 54.7 ± 0.02 e | 195 ± 1.00 d | 118 ± 1.33 e | 0.185 ± 0.031 a |

| Control | 66.0 ± 0.03 f | 211 ± 0.58 e | 164 ± 2.85 f | 0.194 ± 0.020 a |

| MAS-5 | 48.8 ± 0.01 d | 193 ± 0.58 d | 94.9 ± 1.32 e | 0.262 ± 0.019 a |

| MAS-10 | 40.9 ± 0.01 c | 188 ± 1.53 c | 63.4 ± 3.31 d | 0.422 ± 0.044 b |

| MAS-20 | 33.9 ± 0.10 b | 177 ± 1.00 b | 35.0 ± 1.48 b | 0.637 ± 0.047 c |

| MAS-30 | 28.4 ± 0.02 a | 172 ± 1.00 a | 13.5 ± 3.56 a | 1.282 ± 0.080 d |

| Sample | RDS (%) | SDS (%) | RS (%) |

|---|---|---|---|

| Wheat | 78.9 ± 0.81 f | 2.96 ± 0.54 bc | 18.1 ± 0.96 a |

| Control | 81.5 ± 0.96 e | 0.57 ± 0.69 a | 17.9 ± 0.64 a |

| MAS-5 | 75.5 ± 0.27 d | 2.57 ± 0.30 b | 22.0 ± 0.25 b |

| MAS-10 | 71.0 ± 0.65 c | 3.08 ± 0.49 bc | 25.9 ± 0.54 c |

| MAS-20 | 61.6 ± 1.01 b | 3.73 ± 0.52 c | 34.7 ± 0.13 d |

| MAS-30 | 50.9 ± 0.44 a | 5.74 ± 0.24 d | 43.3 ± 0.67 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, G.A.; Lee, I.; Lee, C.J. Digestibility and Quality Characteristics of Noodles with Added Malic-Acid-Modified Wheat Starch. Foods 2025, 14, 1348. https://doi.org/10.3390/foods14081348

Jeong GA, Lee I, Lee CJ. Digestibility and Quality Characteristics of Noodles with Added Malic-Acid-Modified Wheat Starch. Foods. 2025; 14(8):1348. https://doi.org/10.3390/foods14081348

Chicago/Turabian StyleJeong, Gyeong A, Inae Lee, and Chang Joo Lee. 2025. "Digestibility and Quality Characteristics of Noodles with Added Malic-Acid-Modified Wheat Starch" Foods 14, no. 8: 1348. https://doi.org/10.3390/foods14081348

APA StyleJeong, G. A., Lee, I., & Lee, C. J. (2025). Digestibility and Quality Characteristics of Noodles with Added Malic-Acid-Modified Wheat Starch. Foods, 14(8), 1348. https://doi.org/10.3390/foods14081348