Allocation of Strategic Positions for Storage of Meat Products Requiring Cold Chain

Abstract

1. Introduction

- Application of a mathematical optimization model tailored to the strategic allocation of cold storage positions within the meat industry, specifically addressing the challenges associated with temperature-sensitive meat products, shelf-life variation, and stringent sanitary regulations. This study fills a critical gap in cold chain logistics by optimizing the layout of warehouses for sausages and other processed meats.

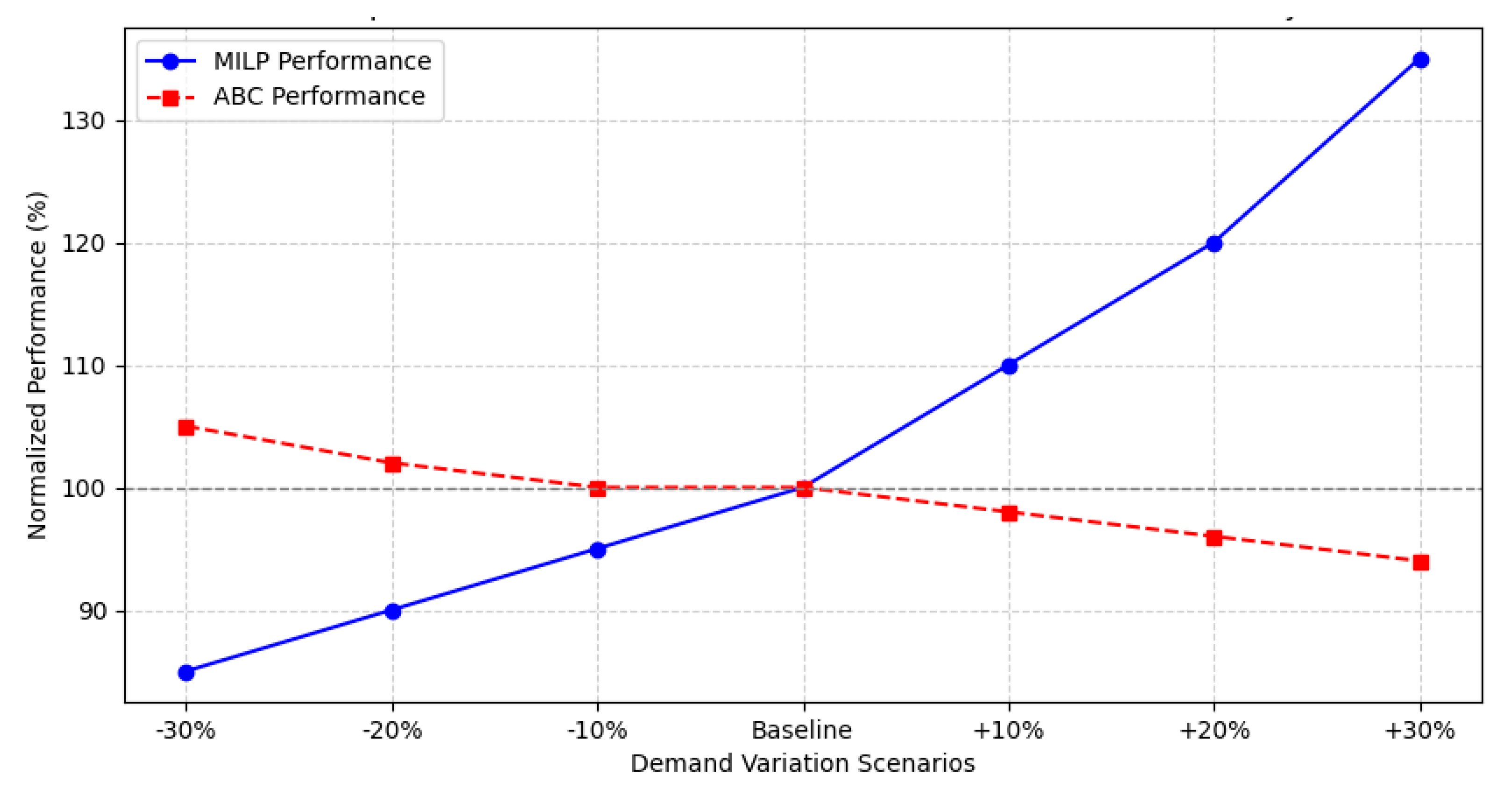

- Development of an adaptable and robust model capable of managing demand fluctuations in the meat supply chain, ensuring operational stability in response to market variations and seasonal consumption patterns. This characteristic is especially relevant given the perishable nature of meat products and the economic impact of excess or lack of stocks.

- Improve the sustainability of the meat industry by minimizing spoilage and waste through better inventory and space management while optimizing energy consumption in refrigerated storage. This aligns with the overall sustainability objectives specific to the meat sector, reducing both economic losses and environmental impact.

- Validation of a sector-specific storage strategy, demonstrating that mathematical optimization techniques can significantly improve storage efficiency, logistical performance, and compliance with meat industry standards. Although the methodology can be adapted to other perishable products, its main contribution remains in the context of meat processing and distribution.

2. Related Work

3. Materials and Methods

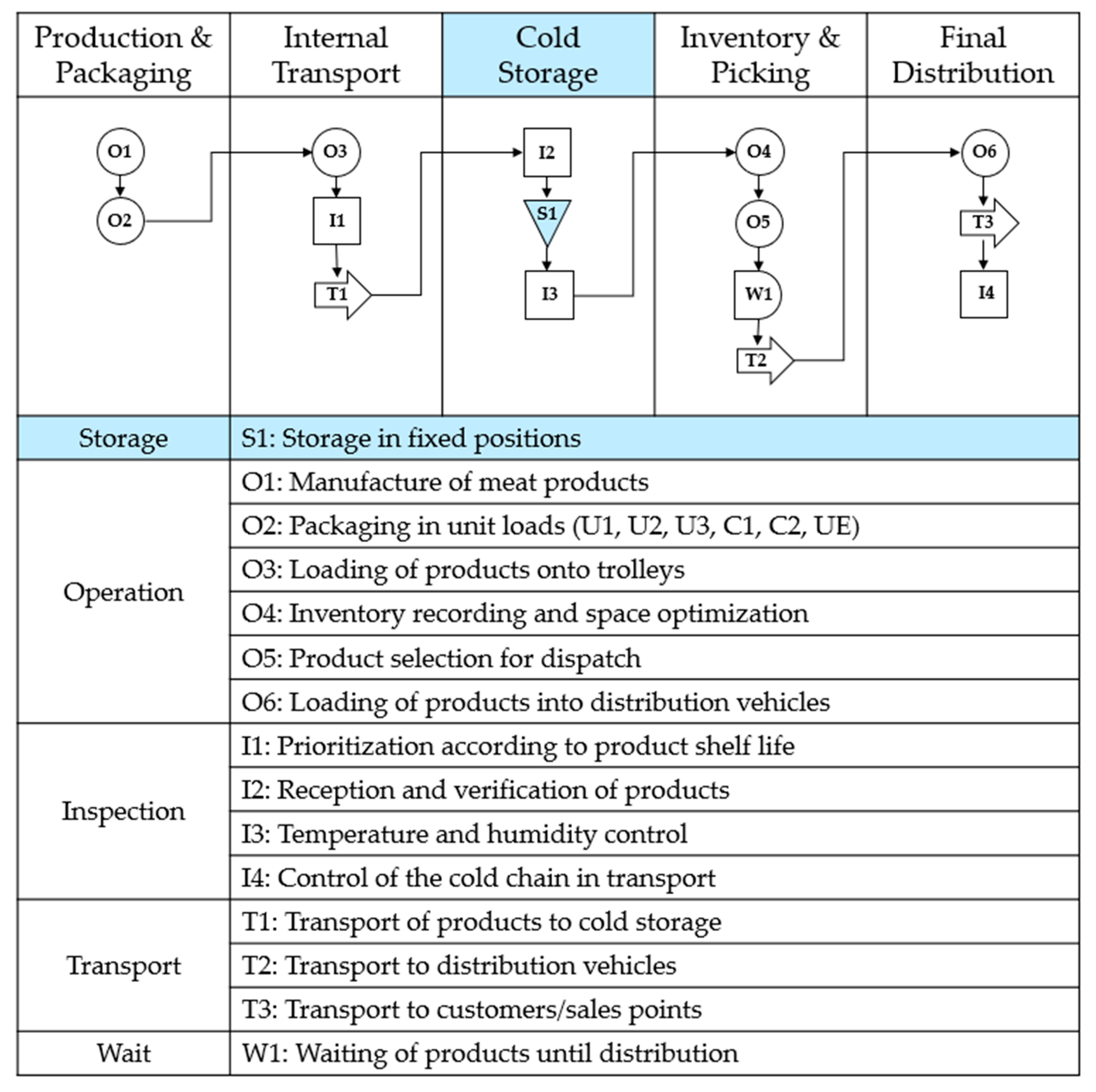

3.1. Cold Storage Logistics Chain Flow

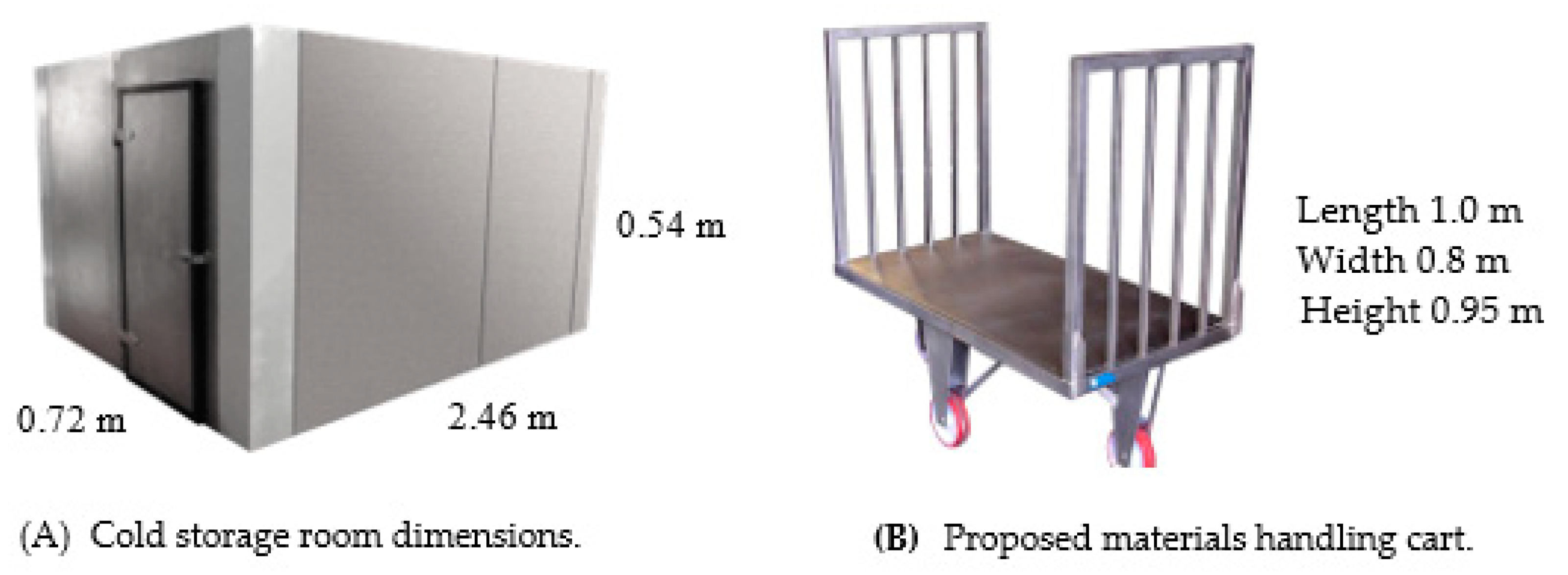

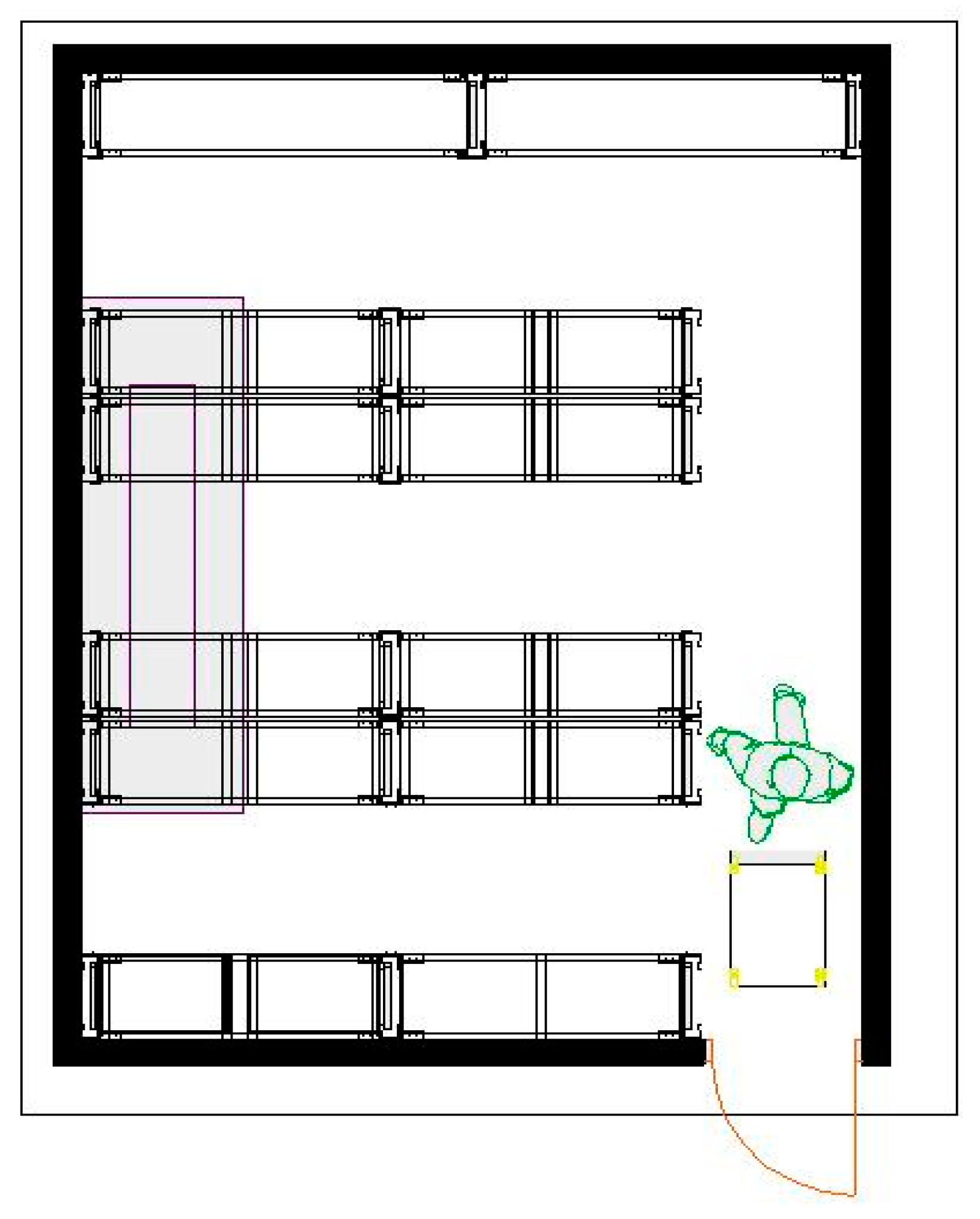

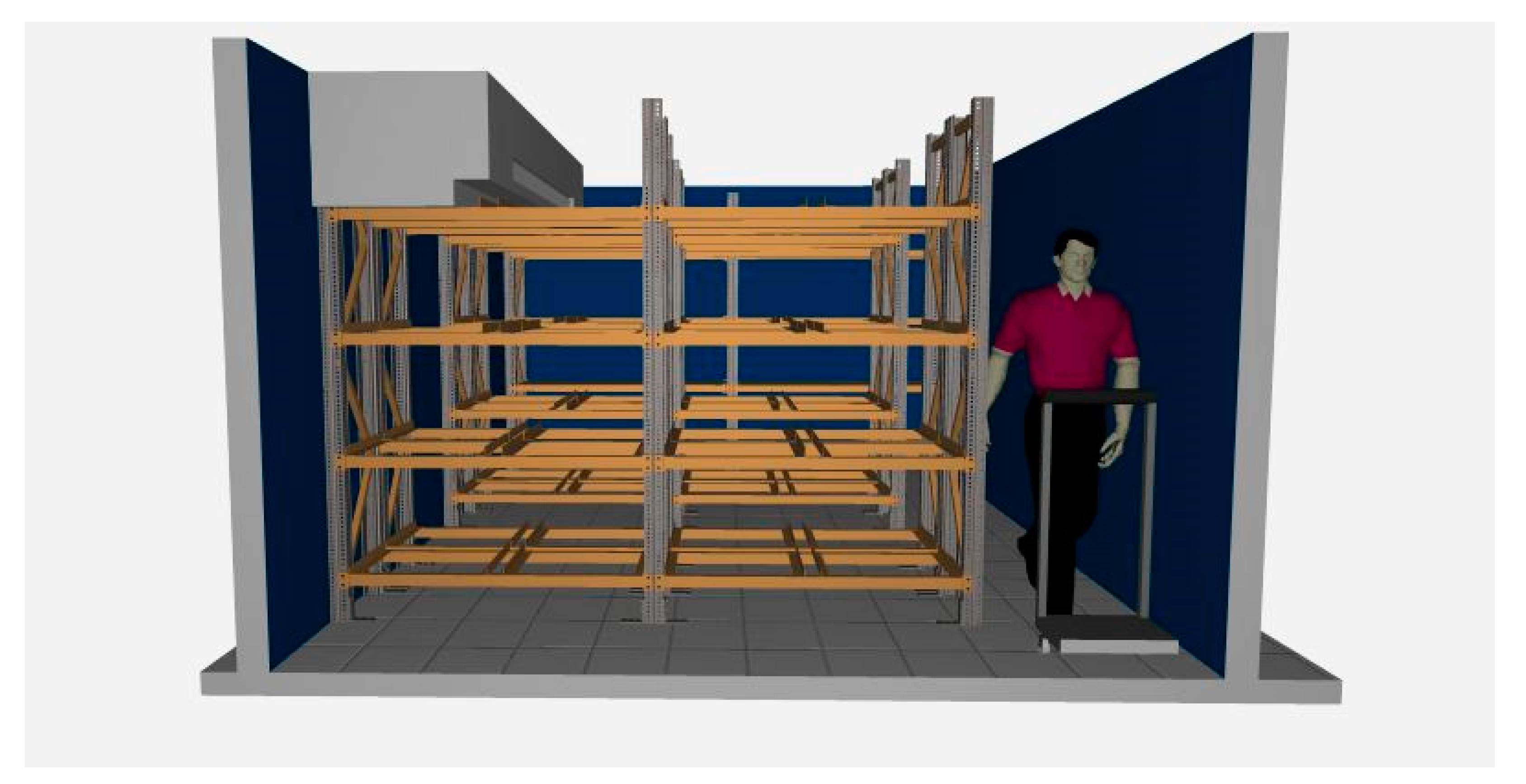

3.2. Storage System and Material Handling Optimization

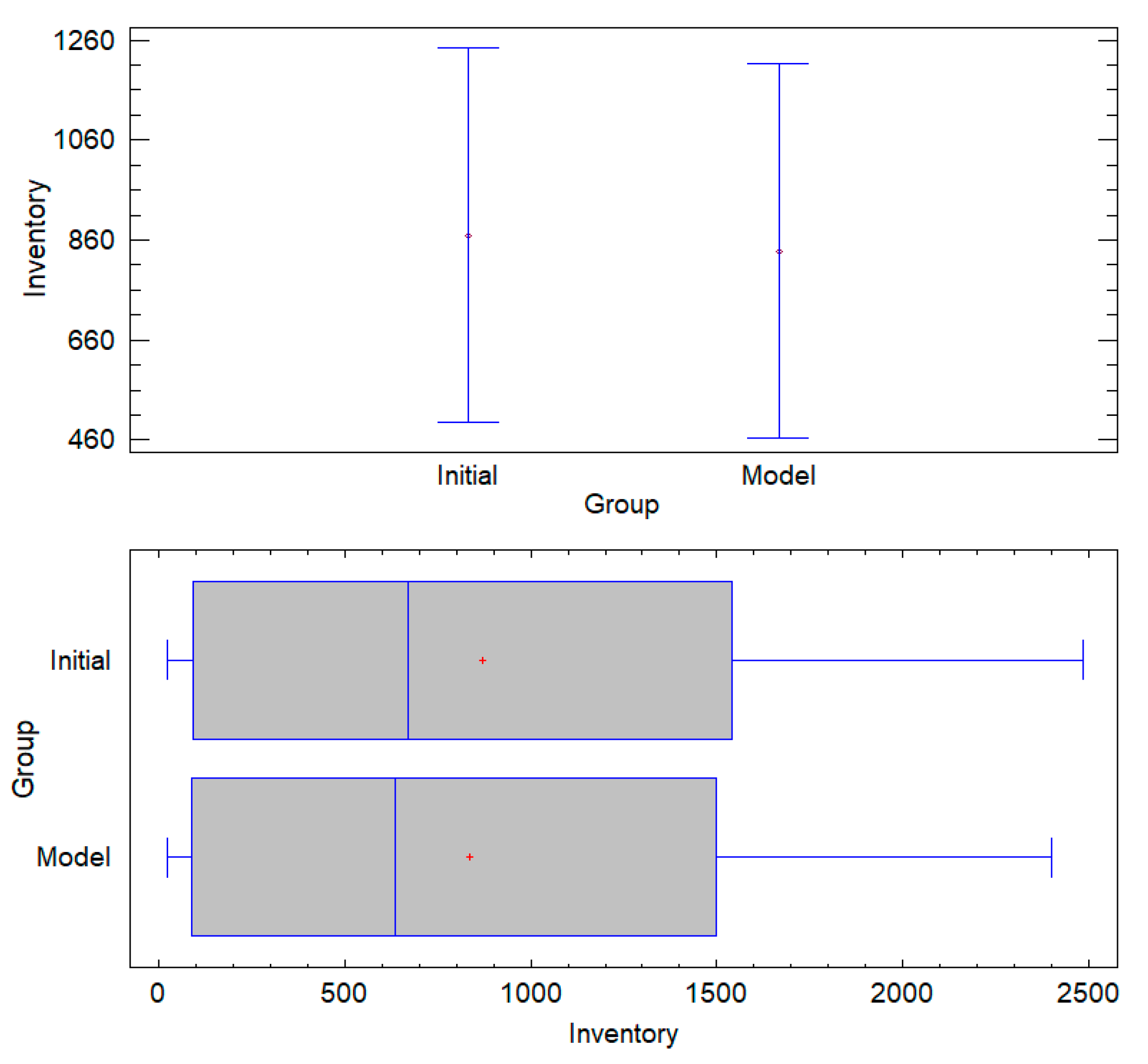

3.3. Inventory Management and Data Analysis

3.4. Hypothesis Development

- Null Hypothesis (H0)

- Alternative Hypothesis (H1)

3.5. Impact on Cold Chain Logistics

3.6. Mathematical Optimization Model

4. Results

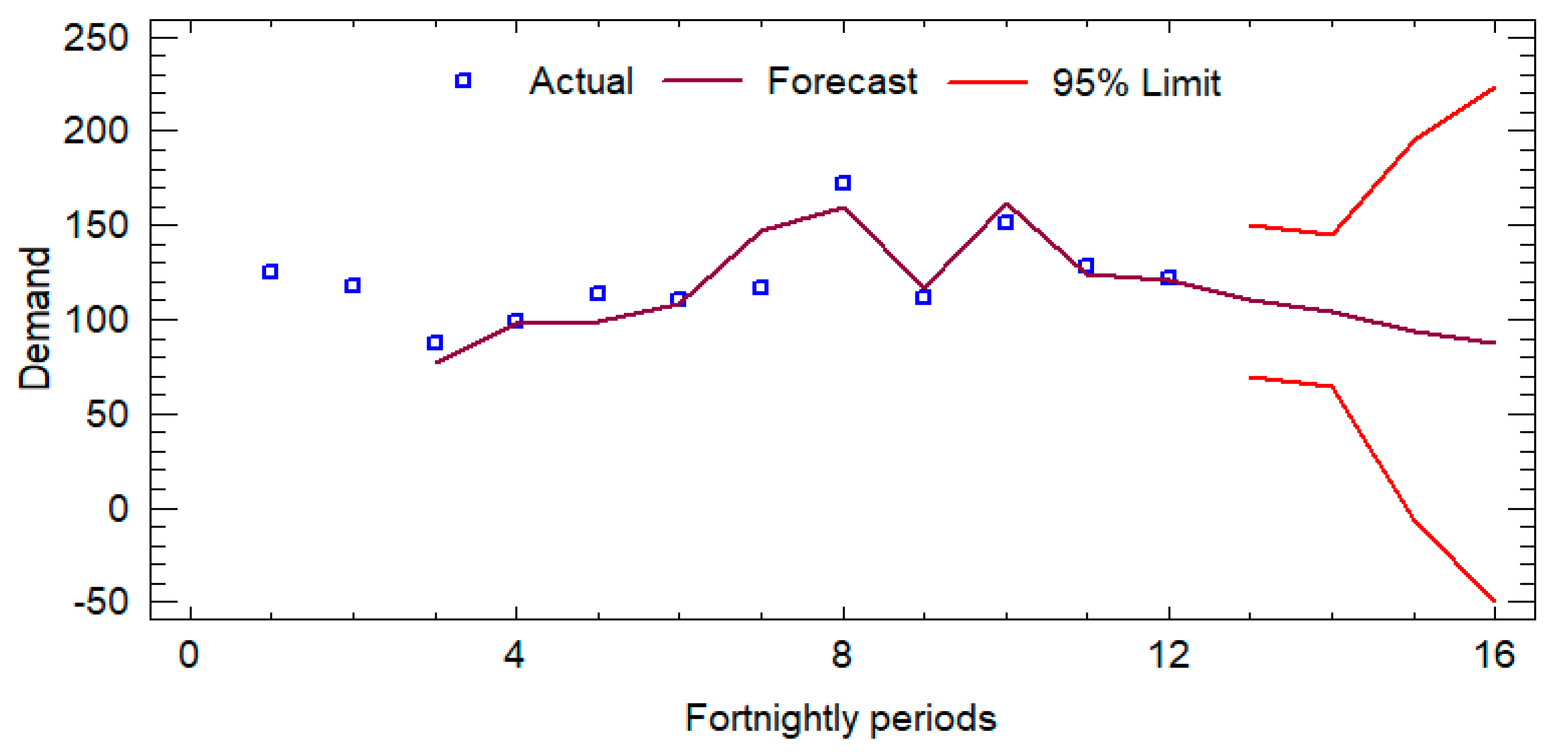

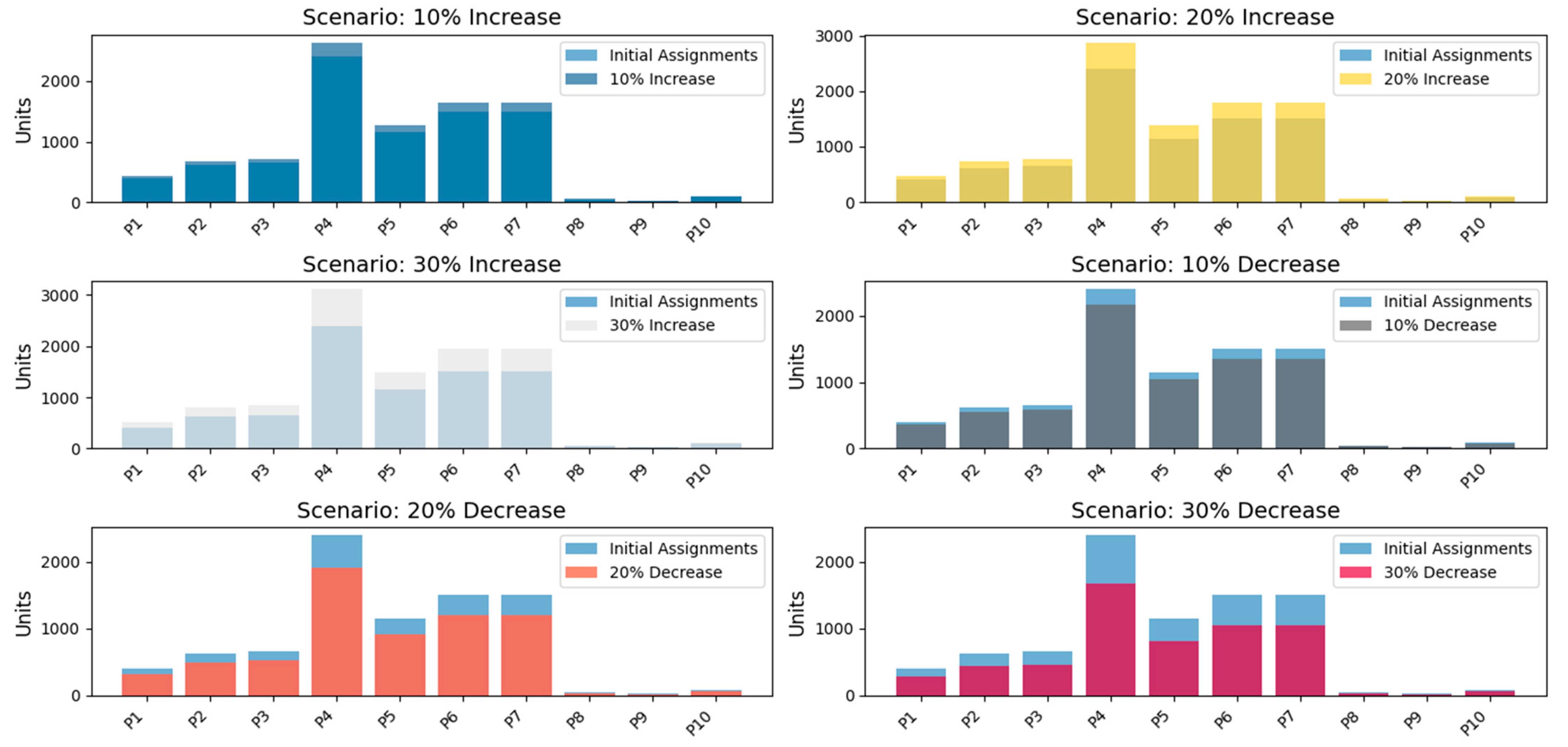

4.1. Impact of Demand Increases

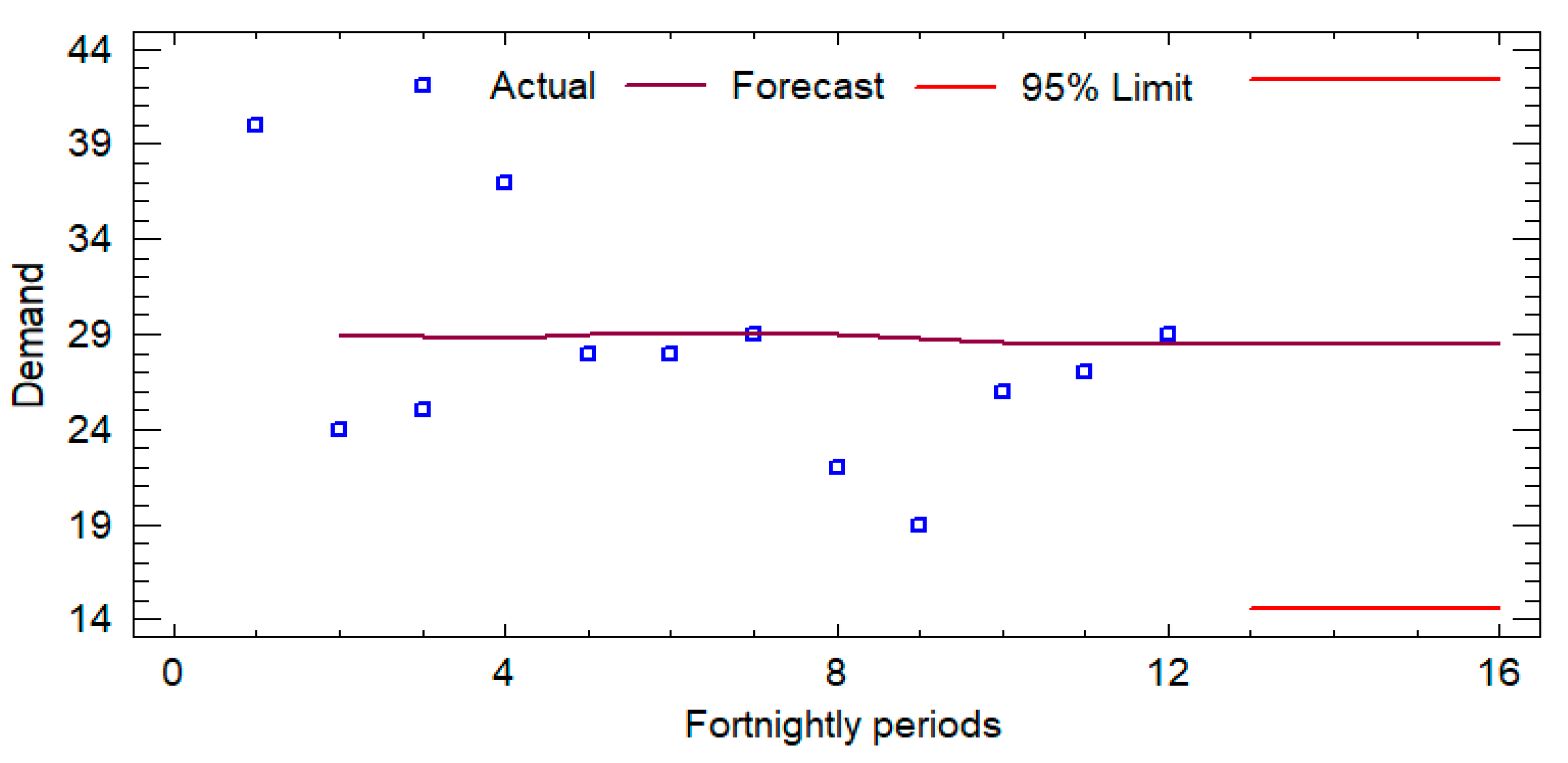

4.2. Impact of Demand Decreases

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, C.W.R.; Chen, H.Y.S. Dynamic allocation of uncertain supply for the perishable commodity supply chain. Int. J. Prod. Res. 2003, 41, 3119–3138. [Google Scholar] [CrossRef]

- Jing, F.; Mu, Y. Dynamic lot-sizing model under perishability, substitution, and limited storage capacity. Comput. Oper. Res. 2020, 122, 104978. [Google Scholar] [CrossRef]

- Golestani, M.; Moosavirad, S.H.; Asadi, Y.; Biglari, S. A multi-objective green hub location problem with multi item-multi temperature joint distribution for perishable products in cold supply chain. Sustain. Prod. Consum. 2021, 27, 1183–1194. [Google Scholar] [CrossRef]

- Singh, R.K.; Gunasekaran, A.; Kumar, P. Third party logistics (3PL) selection for cold chain management: A fuzzy AHP and fuzzy TOPSIS approach. Ann. Oper. Res. 2018, 267, 531–553. [Google Scholar] [CrossRef]

- Hertog, M.L.; Uysal, I.; McCarthy, U.; Verlinden, B.M.; Nicolaï, B.M. Shelf life modelling for first-expired-first-out warehouse management. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130306. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Z.; Cao, C. Technologies and fabrication of intelligent packaging for perishable products. Appl. Sci. 2019, 9, 4858. [Google Scholar] [CrossRef]

- Brecht, J.; Sargent, S.; Brecht, P.; Sáenz, J.; Rodowick, L. Protecting Perishable Foods During Transport by Truck and Rail: HS1328, 4/2019; Powered by EDIS; University of Florida: Gainesville, FL, USA, 2019; Available online: http://www.dx.doi.org/10.9752/TS230.04-2019 (accessed on 26 November 2024).

- Zhou, Z.; Ma, J.; Li, K.; Zhang, W.; Tu, X.; Liu, L.; Xu, J.; Zhang, H. A plant leaf-mimetic membrane with controllable gas permeation for efficient preservation of perishable products. ACS Nano 2021, 15, 8742–8752. [Google Scholar] [CrossRef] [PubMed]

- Chung, J. Effective pricing of perishables for a more sustainable retail food market. Sustainability 2019, 11, 4762. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S. Safe storage and preservation techniques in commercialized agriculture. In Natural Remedies for Pest, Disease and Weed Control; Academic Press: Cambridge, MA, USA, 2020; pp. 221–234. [Google Scholar] [CrossRef]

- Theophilus, O.; Dulebenets, M.; Pasha, J.; Lau, Y.; Fard AM, F.; Mazaheri, A. Truck scheduling optimization at a cold-chain cross-docking terminal with product perishability considerations. Comput. Ind. Eng. 2021, 156, 107240. [Google Scholar] [CrossRef]

- Mobolade, A.J.; Bunindro, N.; Sahoo, D.; Rajashekar, Y. Traditional methods of food grains preservation and storage in Nigeria and India. Ann. Agric. Sci. 2019, 64, 196–205. [Google Scholar] [CrossRef]

- Torres-Sánchez, R.; Martínez-Zafra, M.T.; Castillejo, N.; Guillamón-Frutos, A.; Artés–Hernández, F. Real-time monitoring system for shelf life estimation of fruit and vegetables. Sensors 2020, 20, 1860. [Google Scholar] [CrossRef] [PubMed]

- Shin, M.; Lee, H.; Ryu, K.; Cho, Y.; Son, Y. A two-phased perishable inventory model for production planning in a food industry. Comput. Ind. Eng. 2019, 133, 175–185. [Google Scholar] [CrossRef]

- Aka, S.; Akyüz, G. An inventory and production model with fuzzy parameters for the food sector. Sustain. Prod. Consum. 2021, 26, 627–637. [Google Scholar] [CrossRef]

- Manouchehri, F.; Nookabadi, A.; Kadivar, M. Production routing in perishable and quality degradable supply chains. Heliyon 2020, 6, e03376. [Google Scholar] [CrossRef]

- Wucher, H.; Klingshirn, A.; Brugger, L.; Stamminger, R.; Geppert, J.; Kölzer, B. Tackling food waste: Impact of German consumer behaviour on food in chilled storage. Foods 2020, 9, 1462. [Google Scholar] [CrossRef]

- Iversen LJ, L.; Rovina, K.; Vonnie, J.; Matanjun, P.; Erna, K.H.; Funk, A.A. The emergence of edible and food-application coatings for food packaging: A review. Molecules 2022, 27, 5604. [Google Scholar] [CrossRef]

- Mahmood, M.H.; Sultan, M.; Miyazaki, T. Significance of temperature and humidity control for agricultural products storage: Overview of conventional and advanced options. Int. J. Food Eng. 2019, 15, 20190063. [Google Scholar] [CrossRef]

- Cappelli, A.; Bini, A.; Cini, E. The effects of storage time and environmental storage conditions on flour quality, dough rheology, and biscuit characteristics: The case study of a traditional italian biscuit (Biscotto di Prato). Foods 2022, 11, 209. [Google Scholar] [CrossRef]

- Tavill, G. Industry challenges and approaches to food waste. Physiol. Behav. 2020, 223, 112993. [Google Scholar] [CrossRef]

- Nikolicic, S.; Kilibarda, M.; Maslaric, M.; Mircetic, D.; Bojic, S. Reducing food waste in the retail supply chains by improving efficiency of logistics operations. Sustainability 2021, 13, 6511. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Gola, A.; Mieszkalski, L. Potential routes to the sustainability of the food packaging industry. Sustainability 2022, 14, 3924. [Google Scholar] [CrossRef]

- Lins, M.; Zandonadi, R.P.; Raposo, A.; Ginani, V. Food waste on foodservice: An overview through the perspective of sustainable dimensions. Foods 2021, 10, 1175. [Google Scholar] [CrossRef] [PubMed]

- Slorach, P.C.; Jeswani, H.; Cuéllar-Franca, R.; Azapagic, A. Environmental and economic implications of recovering resources from food waste in a circular economy. Sci. Total Environ. 2019, 693, 133516. [Google Scholar] [CrossRef] [PubMed]

- Albizzati, P.F.; Tonini, D.; Astrup, T. A quantitative sustainability assessment of food waste management in the European Union. Environ. Sci. Technol. 2021, 55, 16099–16109. [Google Scholar] [CrossRef]

- Oishi, R. Food Waste caused by Excess Inventory at Retail Stores in Japan. J. Ecol. Nat. Resour. 2022, 6, 1–7. [Google Scholar] [CrossRef]

- Paam, P.; Berretta, R.; Heydar, M.; García-Flores, R. The impact of inventory management on economic and environmental sustainability in the apple industry. Comput. Electron. Agric. 2019, 163, 104848. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Awasthi, A.; Sharma, G.; Cysneiros, D.; Nayak, S.; Thakur, V.; Naidu, R.; Pandey, A.; Gupta, V. Minimizing hazardous impact of food waste in a circular economy—Advances in resource recovery through green strategies. J. Hazard. Mater. 2021, 416, 126154. [Google Scholar] [CrossRef]

- Areche, F.O.; Gondal, A.H.; Landeo, O.T.; Rodríguez, A.R.; Pérez, P.L.; Huaman, J.T.; Roman, A.V.; Correo, R.J.M. Innovative trends in reducing food waste and ensuring a more sustainable food system and environment. In CABI Review; CAB International: Wallingford, UK, 2022. [Google Scholar] [CrossRef]

- Baruffaldi, G.; Accorsi, R.; Volpe, L.; Manzini, R.; Nilsson, F. Sustainable operations in reusable food packaging networks. In Sustainable Food Supply Chains; Academic Press: Cambridge, MA, USA, 2019; pp. 293–304. [Google Scholar] [CrossRef]

- Qu, H.; Masud, M.; Islam, M.; Khan MI, H.; Ananno, A.A.; Karim, A. Sustainable food drying technologies based on renewable energy sources. Crit. Rev. Food Sci. Nutr. 2022, 62, 6872–6886. [Google Scholar] [CrossRef]

- Ravandi, B.; Jovanovic, N. Impact of plate size on food waste: Agent-based simulation of food consumption. Resour. Conserv. Recycl. 2019, 149, 550–565. [Google Scholar] [CrossRef]

- Fernandes, P.A.; Moreira, S.A.; Santos, M.D.; Duarte, R.V.; Santos, D.I.; Inácio, R.S.; Saraiva, J.A. Hyperbaric storage at variable room temperature—A new preservation methodology for minced meat compared to refrigeration. J. Sci. Food Agric. 2019, 99, 3276–3282. [Google Scholar] [CrossRef]

- Santos, M.D.; Castro, R.; Delgadillo, I.; Saraiva, J.A. Improvement of the refrigerated preservation technology by hyperbaric storage for raw fresh meat. J. Sci. Food Agric. 2020, 100, 969–977. [Google Scholar] [CrossRef] [PubMed]

- Melro, E.; Antunes, F.; Cruz, I.; Ramos, P.E.; Carvalho, F.; Alves, L. Morphological, textural and physico-chemical characterization of processed meat products during their shelf life. Food Struct. 2020, 26, 100164. [Google Scholar] [CrossRef]

- Dabasso, B.G.; Makokha, A.O.; Onyango, A.N.; Mathara, J.M.; Badake, Q.D. Effect of Temperature, Storage Containers and Improved Hygiene on Microbial Safety and Chemical Quality of Traditional Meat Products. Eur. J. Agric. Food Sci. 2021, 3, 71–77. [Google Scholar] [CrossRef]

- Tikhonov, S.; Tikhonova, N.; Lazarev, V.; Samokhvalova, E.; Minukhin, L.; Pischikov, G. Ultra-high pressure chilled meat processing: A promising storage method. E3S Web Conf. 2020, 176, 03022. [Google Scholar] [CrossRef]

- Minner, S.; Transchel, S. Periodic review inventory-control for perishable products under service-level constraints. OR Spectr. 2010, 32, 979–996. [Google Scholar] [CrossRef]

- Murmu, V.; Kumar, D.; Sarkar, B.; Mor, R.; Jha, A.K. Sustainable inventory management based on environmental policies for the perishable products under first or last in and first out policy. J. Ind. Manag. Optim. 2023, 19, 4764–4803. [Google Scholar] [CrossRef]

- Parlar, M.; Perry, D.; Stadje, W. FIFO versus LIFO issuing policies for stochastic perishable inventory systems. Methodol. Comput. Appl. Probab. 2011, 13, 405–417. [Google Scholar] [CrossRef]

- Bertolini, M.; Bottani, E.; Rizzi, A.; Volpi, A.; Renzi, P. Shrinkage reduction in perishable food supply chain by means of an RFID-based FIFO management policy. Int. J. RF Technol. 2013, 5, 123–136. [Google Scholar] [CrossRef]

- Tootkaleh, E.A.; Afshar-Nadjafi, B.; Seifbarghy, M. Vendor managed inventory policy for perishable products under a combination of FIFO-LIFO stock control. Lat. Am. Appl. Res. 2024, 54, 133–142. [Google Scholar] [CrossRef]

- Bao, L.N.; Le, D.H.; Nguyễn, D. Application of combinatorial optimization in logistics. In Proceedings of the 2018 4th International Conference on Green Technology and Sustainable Development (GTSD), Ho Chi Minh City, Vietnam, 23–24 November 2018; pp. 329–334. [Google Scholar] [CrossRef]

- Alamri, A.; Syntetos, A. Beyond LIFO and FIFO: Exploring an allocation-in-fraction-out (AIFO) policy in a two-warehouse inventory model. Int. J. Prod. Econ. 2018, 206, 33–45. [Google Scholar] [CrossRef]

- Bo, V.; Bortolini, M.; Malaguti, E.; Monaci, M.; Mora, C.; Paronuzzi, P. Models and algorithms for integrated production and distribution problems. Comput. Ind. Eng. 2021, 154, 107003. [Google Scholar] [CrossRef]

- Novellani, S. Models and algorithms for the optimization of real-world routing and logistics problems. 4OR-Q. J. Oper. Res. 2016, 14, 331–332. [Google Scholar] [CrossRef]

- Ballou, R.H. Business Logistics/Supply Chain Management: Planning, Organizing, and Controlling the Supply Chain; Pearson Education: Chennai, India, 2007. [Google Scholar]

- Ghiani, G.; Laporte, G.; Musmanno, R. Introduction to Logistics Systems Planning and Control; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Mastos, T.D.; Gotzamani, K.; Ieromonachou, P.; Tsiotras, G. A Structural Equation Model for Sustainable Supply Chain Management in the Food Industry. Foods 2024, 13, 3713. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, X.; Zhou, J.; Zhou, T.; Lin, T.; Xu, C.; Zhao, W. Cold-Chain-Food-Related COVID-19 Surveillance in Guangzhou between July 2020 and December 2022. Foods 2023, 12, 2701. [Google Scholar] [CrossRef]

- Vidal, G.H.; Hernandez, D.A.; Eslava, E.F.; Coronado-Hernández, J.R.; Ibáñez SF, U. Mathematical modelling of purchasing optimization for an MRP system with containerization constraints. Opsearch 2024, 61, 1108–1130. [Google Scholar] [CrossRef]

- Vidal, G.H. Deterministic and stochastic inventory models in production systems: A review of the literature. Process Integr. Optim. Sustain. 2023, 7, 29–50. [Google Scholar] [CrossRef]

- Vidal, G.H.; Guerrero, C.M. Deterministic inventory models with non-perishable product: A comparative study. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 2500–2517. [Google Scholar] [CrossRef]

- Tong, C. An Efficient Intelligent Semi-Automated Warehouse Inventory Stocktaking System. arXiv 2023, arXiv:2309.12365. [Google Scholar] [CrossRef]

- Nahmias, S. Inventory depletion management when the field life is random. Manag. Sci. 1974, 20, 1276–1283. [Google Scholar] [CrossRef]

| Reference | Product | Code | Quantity |

|---|---|---|---|

| U1 | Hamburger | P1 | 36 packs of 6 units |

| Bologna | P2 | 54 packs of 250 g | |

| U2 | Salami | P3 | 30 units |

| String sausage | P4 | 108 units | |

| U3 | Hot dog | P5 | 21 packs of 13 units |

| Chorizo sausage | P6 | 27 packs of 4 units | |

| Butifarra sausage | P7 | 27 packs of 16 units | |

| C1 | Fish boxes | P8 | Not placed in trays |

| C2 | Chicken pasta | P9 | Not placed in trays |

| UE | Bags of ice | P10 | 4 bags of 15 kg |

| Product | Code | Average Inventory Level |

|---|---|---|

| Hamburger | P1 | 432 |

| Bologna | P2 | 648 |

| Salami | P3 | 690 |

| String sausage | P4 | 2484 |

| Hot dog | P5 | 1197 |

| Chorizo sausage | P6 | 1539 |

| Butifarra sausage | P7 | 1539 |

| Fish boxes | P8 | 50 |

| Chicken pasta | P9 | 25 |

| Ice | P10 | 92 |

| Type | Symbol | Definition |

|---|---|---|

| Sets | J | Set of products (e.g., hamburgers, salami). |

| K | Set of storage positions. | |

| R | Set of chamber access/exit doors. | |

| Parameters | Cjk | Cost of assigning product j to position k. Calculated as a function of the number of manipulations and travel time. |

| pjr | Number of times product j is manipulated through door r. | |

| mj | Total number of positions required for product j. | |

| trk | Average travel time from gate r to position k. | |

| Variable | xjk | Binary variable that takes value 1 if product j is assigned to position k; 0 otherwise. |

| Storage Position | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Level 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Time | 4.39 | 3.65 | 2.9 | 2.16 | 2.4 | 3.14 | 3.88 | 4.63 | 5.59 | 4.84 | 4.1 | 3.36 | 3.6 | 4.34 | 5.08 | 5.88 | 4.56 | 5.3 | 6.04 | 6.79 |

| Level 2 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 |

| Time | 4.66 | 3.92 | 3.18 | 2.43 | 2.67 | 3.42 | 4.16 | 4.9 | 5.86 | 5.12 | 4.38 | 3.63 | 3.87 | 4.62 | 5.36 | 6.15 | 4.83 | 5.58 | 6.32 | 7.06 |

| Level 3 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 |

| Time | 4.94 | 4.2 | 3.45 | 2.71 | 2.95 | 3.69 | 4.44 | 5.18 | 6.14 | 5.4 | 4.65 | 3.91 | 4.15 | 4.89 | 5.64 | 6.43 | 5.11 | 5.85 | 6.59 | 7.34 |

| Level 4 | 61 | 62 | 63 | 64 | 65 | 66 | 67 | 68 | 69 | 70 | 71 | 72 | 73 | 74 | 75 | 76 | 77 | 78 | 79 | 80 |

| Time | 5.22 | 4.47 | 3.73 | 2.99 | 3.23 | 3.97 | 4.74 | 5.46 | 6.41 | 5.67 | 4.93 | 4.18 | 4.42 | 5.17 | 5.91 | 6.7 | 5.38 | 6.13 | 6.87 | 7.61 |

| Level 5 | 81 | 82 | 83 | 84 | 85 | 86 | 87 | 88 | 89 | 90 | 91 | 92 | 93 | 94 | 95 | 96 | 97 | 98 | 99 | 100 |

| Time | 5.49 | 4.75 | 4 | 3.26 | 3.5 | 4.24 | 4.99 | 5.73 | 6.69 | 5.95 | 5.2 | 4.46 | 4.7 | 5.44 | 6.19 | 6.98 | 5.66 | 6.4 | 7.15 | 7.89 |

| Level 6 | 101 | 102 | 103 | 104 | 105 | 106 | 107 | 108 | 109 | 110 | 111 | 112 | 113 | 114 | 115 | 116 | 117 | 118 | 119 | 120 |

| Time | 5.77 | 5.02 | 4.28 | 3.54 | 3.78 | 4.52 | 5.26 | 6.01 | 6.97 | 6.22 | 5.48 | 4.74 | 4.98 | 5.72 | 6.46 | 7.25 | 5.94 | 6.68 | 7.42 | 8.17 |

| Level 7 | 121 | 122 | 123 | 124 | 125 | 126 | 127 | 128 | 129 | 130 | 131 | 132 | 133 | 134 | 135 | 136 | 137 | 138 | 139 | 140 |

| Time | 6.04 | 5.3 | 4.56 | 3.81 | 4.05 | 4.8 | 5.54 | 6.28 | 7.24 | 6.5 | 5.76 | 5.01 | 5.25 | 6 | 6.74 | 7.53 | 6.21 | 6.95 | 7.7 | 8.44 |

| Level 8 | 141 | 142 | 143 | 144 | 145 | 146 | 147 | 148 | 149 | 150 | 151 | 152 | 153 | 154 | 155 | 156 | 157 | 158 | 159 | 160 |

| Time | 6.32 | 5.58 | 4.83 | 4.09 | 4.33 | 5.07 | 5.82 | 6.56 | 7.52 | 6.77 | 6.03 | 5.29 | 5.53 | 6.27 | 7.01 | 7.81 | 6.49 | 7.23 | 7.97 | 8.72 |

| Storage Position | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Level 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Load Unit | U3 | U2 | U2 | U2 | U2 | U2 | U1 | U3 | UE | U3 | U1 | U2 | U2 | U3 | U3 | UE | U3 | U3 | UE | |

| Level 2 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 |

| Load Unit | U3 | U2 | U2 | U2 | U2 | U3 | UE | U3 | U2 | U1 | U3 | U3 | U3 | UE | ||||||

| Level 3 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 | 50 | 51 | 52 | 53 | 54 | 55 | 56 | 57 | 58 | 59 | 60 |

| Load Unit | U3 | U3 | U2 | U2 | U2 | U2 | U3 | U3 | U3 | U3 | U1 | U1 | U3 | UE | U3 | UE | ||||

| Level 4 | 61 | 62 | 63 | 64 | 65 | 66 | 67 | 68 | 69 | 70 | 71 | 72 | 73 | 74 | 75 | 76 | 77 | 78 | 79 | 80 |

| Load Unit | U3 | U3 | U2 | U2 | U2 | U1 | U3 | U3 | UE | U3 | U3 | U3 | U3 | UE | U3 | UE | ||||

| Level 5 | 81 | 82 | 83 | 84 | 85 | 86 | 87 | 88 | 89 | 90 | 91 | 92 | 93 | 94 | 95 | 96 | 97 | 98 | 99 | 100 |

| Load Unit | U3 | U3 | U1 | U2 | U2 | U3 | U3 | UE | UE | U3 | U3 | U3 | U3 | UE | ||||||

| Level 6 | 101 | 102 | 103 | 104 | 105 | 106 | 107 | 108 | 109 | 110 | 111 | 112 | 113 | 114 | 115 | 116 | 117 | 118 | 119 | 120 |

| Load Unit | UE | U3 | U3 | U2 | U2 | U3 | U3 | UE | U3 | U3 | U3 | UE | UE | |||||||

| Level 7 | 121 | 122 | 123 | 124 | 125 | 126 | 127 | 128 | 129 | 130 | 131 | 132 | 133 | 134 | 135 | 136 | 137 | 138 | 139 | 140 |

| Load Unit | UE | U3 | U3 | U1 | U1 | U3 | U3 | UE | U3 | U3 | UE | |||||||||

| Level 8 | 141 | 142 | 143 | 144 | 145 | 146 | 147 | 148 | 149 | 150 | 151 | 152 | 153 | 154 | 155 | 156 | 157 | 158 | 159 | 160 |

| Load Unit | UE | U3 | U1 | U3 | U3 | UE | UE | U3 | U3 | |||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera, F.J.O.; Berrio, C.A.P.; Herrera-Vidal, G.; Adarme, W.; Linfati, R.; Gatica, G.; Coronado-Hernández, J.R. Allocation of Strategic Positions for Storage of Meat Products Requiring Cold Chain. Foods 2025, 14, 1010. https://doi.org/10.3390/foods14061010

Herrera FJO, Berrio CAP, Herrera-Vidal G, Adarme W, Linfati R, Gatica G, Coronado-Hernández JR. Allocation of Strategic Positions for Storage of Meat Products Requiring Cold Chain. Foods. 2025; 14(6):1010. https://doi.org/10.3390/foods14061010

Chicago/Turabian StyleHerrera, Fernando J. Olier, Carlos A. Porto Berrio, Germán Herrera-Vidal, Wilson Adarme, Rodrigo Linfati, Gustavo Gatica, and Jairo R. Coronado-Hernández. 2025. "Allocation of Strategic Positions for Storage of Meat Products Requiring Cold Chain" Foods 14, no. 6: 1010. https://doi.org/10.3390/foods14061010

APA StyleHerrera, F. J. O., Berrio, C. A. P., Herrera-Vidal, G., Adarme, W., Linfati, R., Gatica, G., & Coronado-Hernández, J. R. (2025). Allocation of Strategic Positions for Storage of Meat Products Requiring Cold Chain. Foods, 14(6), 1010. https://doi.org/10.3390/foods14061010