Synergistic Effect of Thermosonication on the Stability of Bioactive Compounds and Antioxidant Activity of Blackberry Juice

Abstract

1. Introduction

2. Material and Methods

2.1. Raw Material

2.2. Preparation of Blackberry Juice

2.3. Experimental Designer

2.4. Thermosonication

2.5. Convencional Heat Treatment

2.6. Physicochemical Characterization of Blackberry Juice

2.7. Bioactive Compounds

2.7.1. Obtaining Extracts

2.7.2. Determination of Anthocyanins

2.7.3. Determination of Total Phenolic Compounds

2.7.4. Determination of Antioxidant Activity

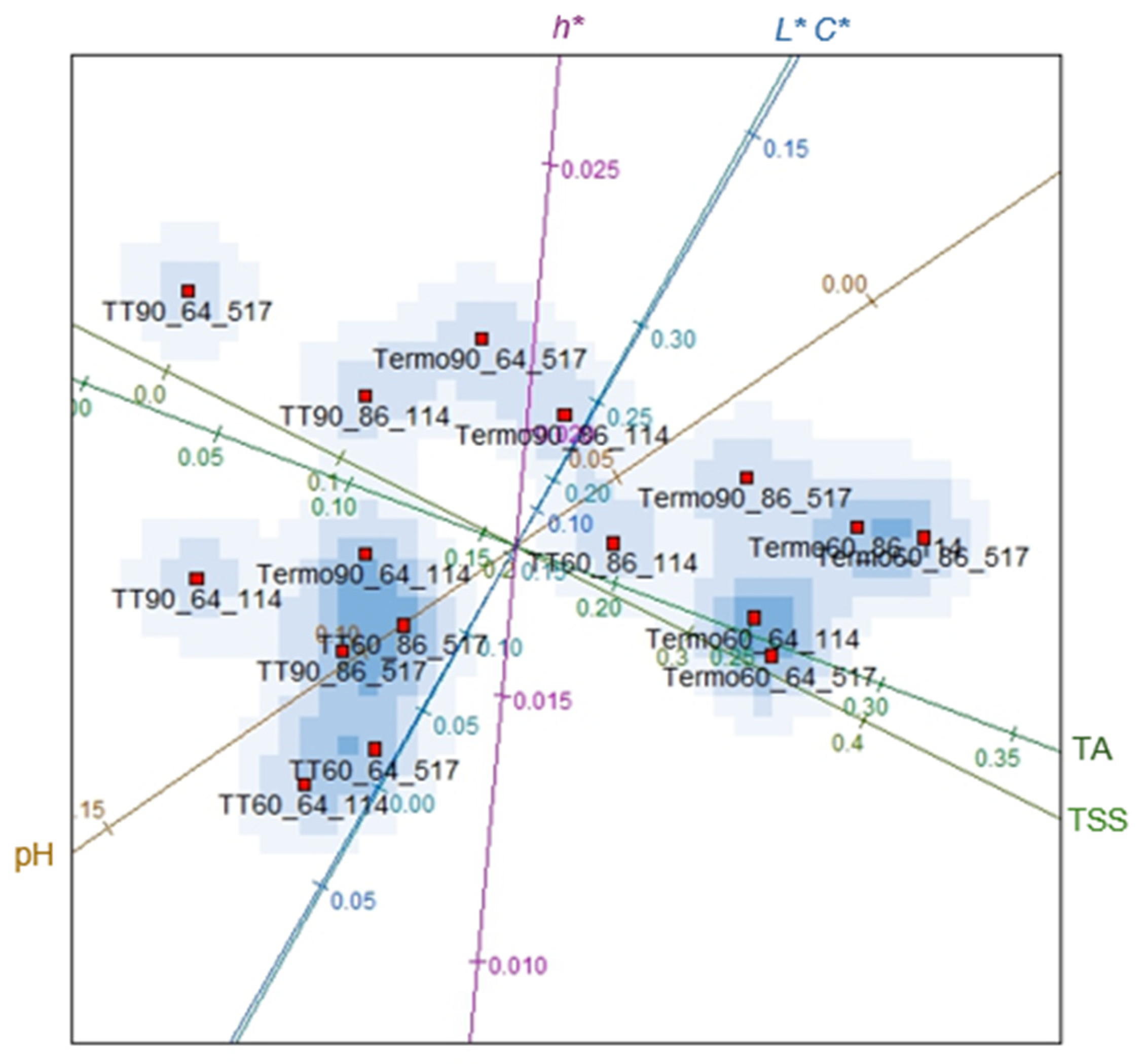

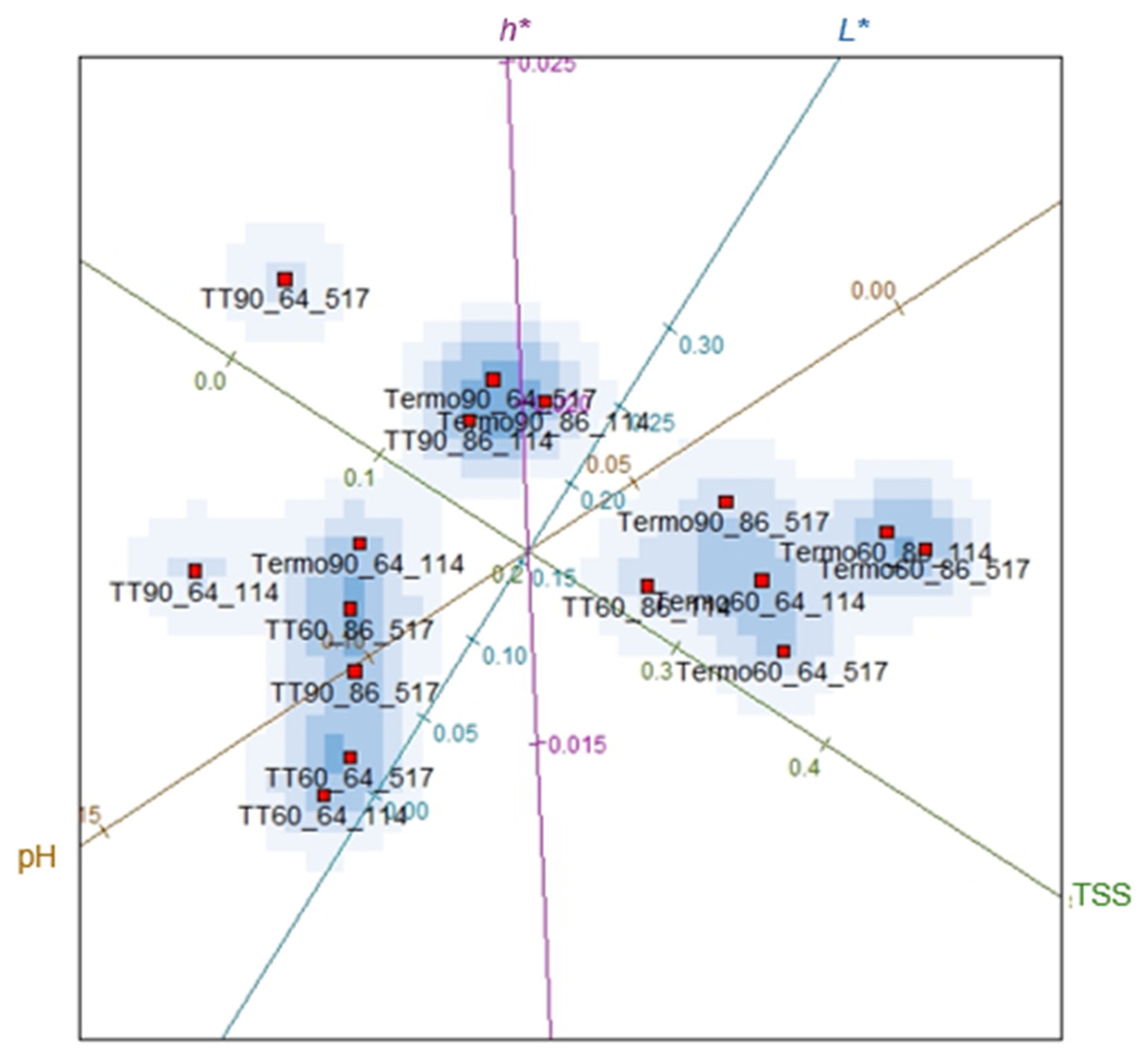

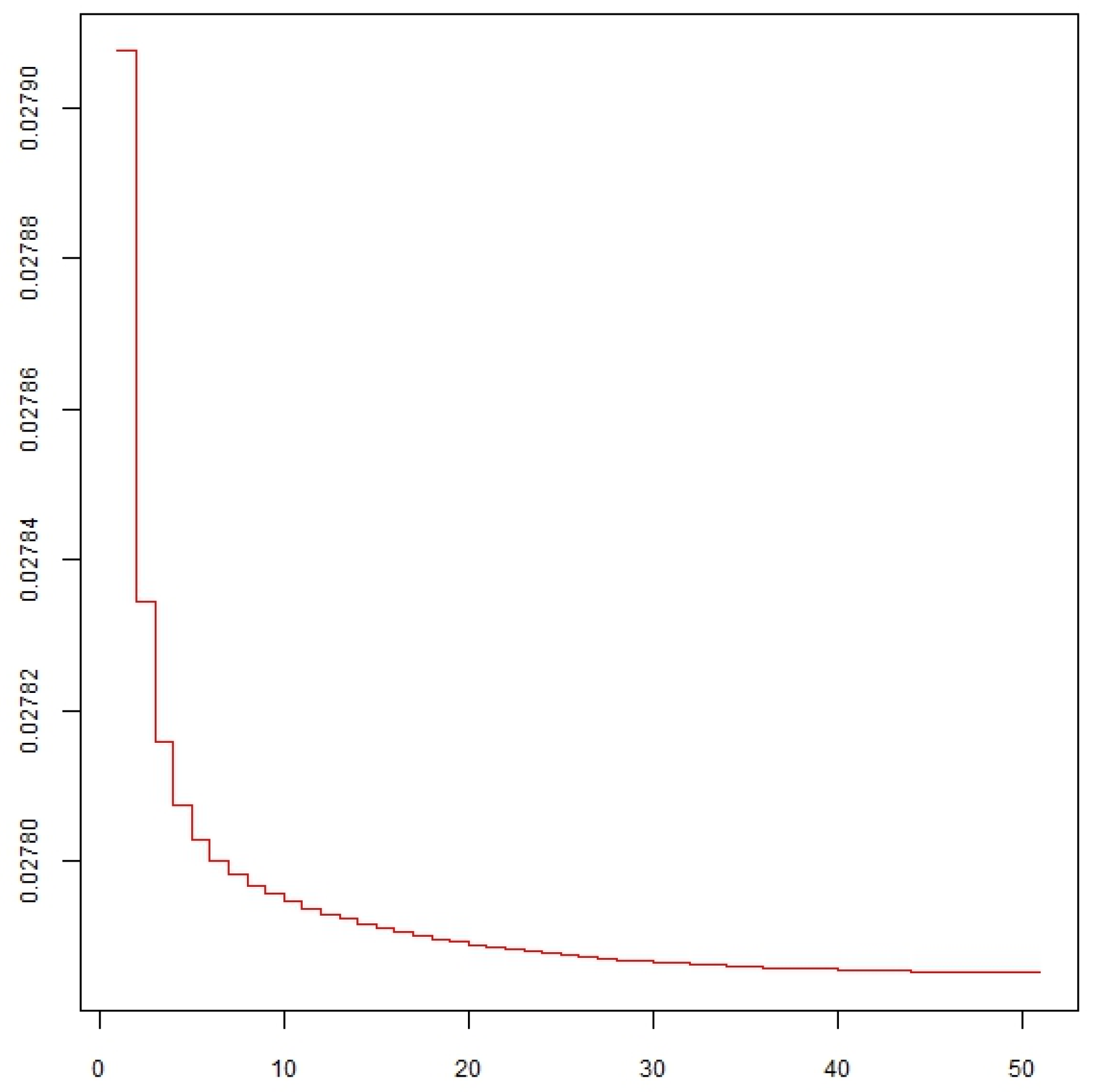

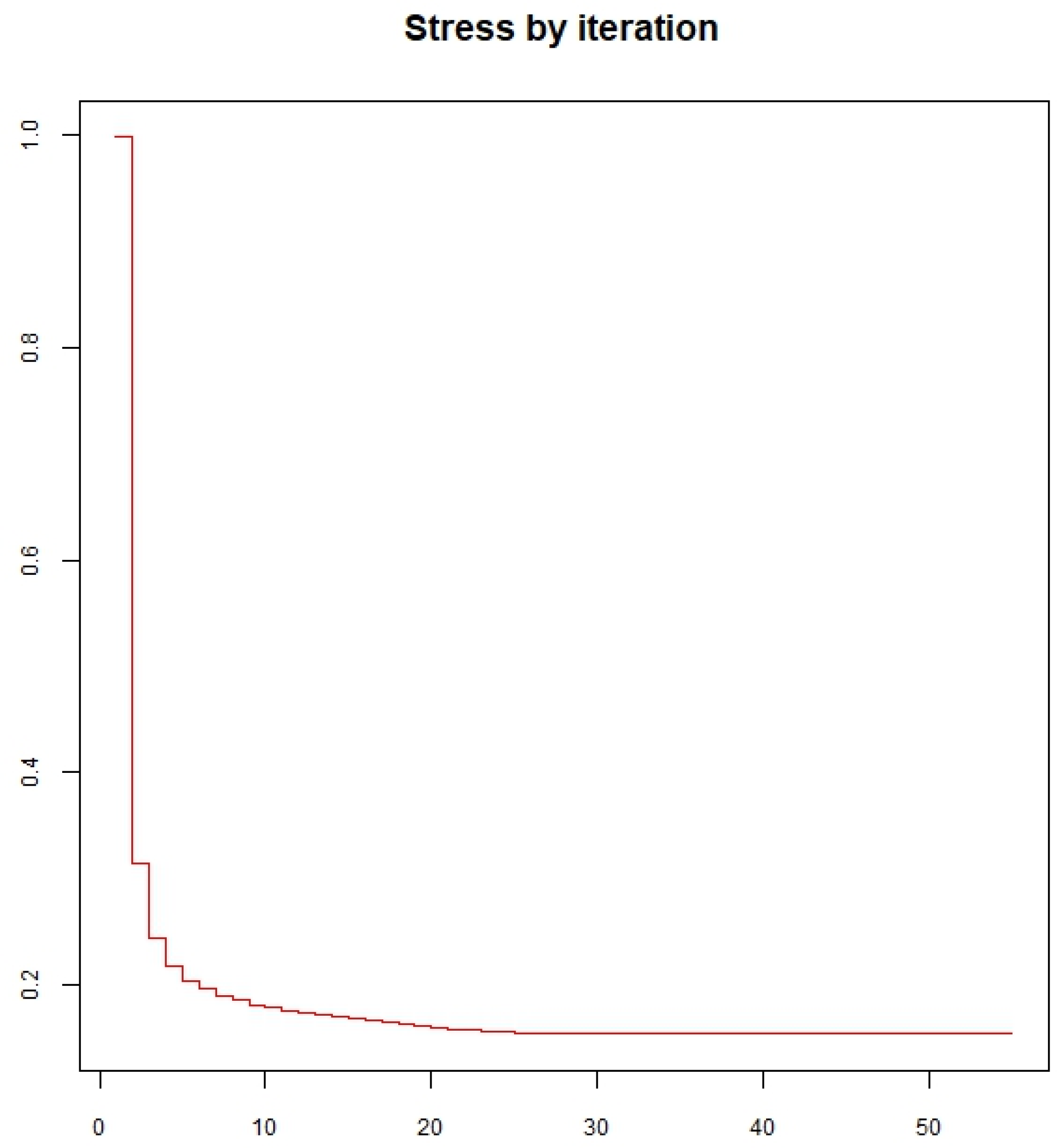

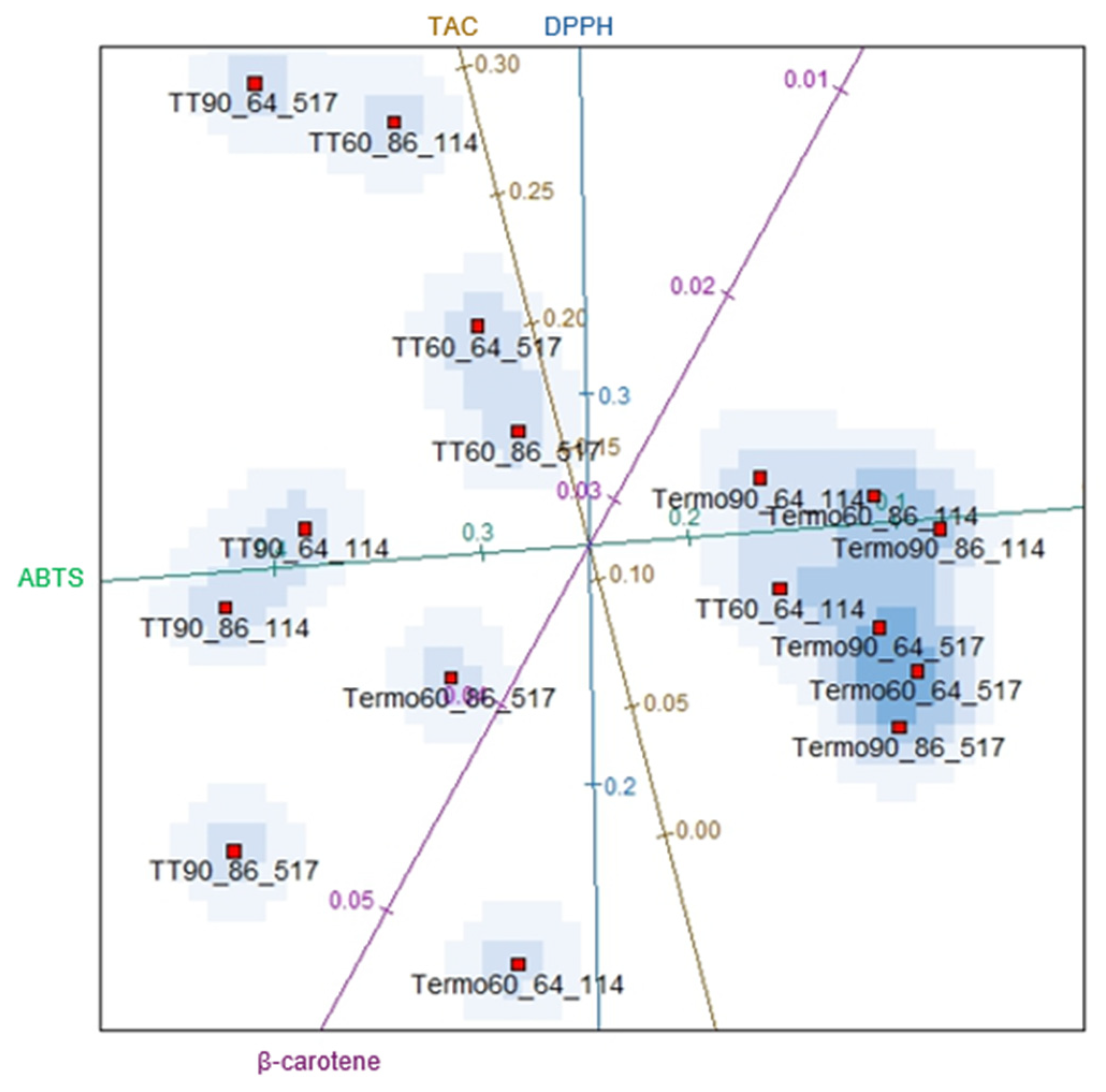

2.8. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Characteristics of Blackberry Juice

3.2. Bioactive Compounds and Antioxidant Activity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kesavan, R.; Krishnan, G.S.; Nayak, P.K. Influence of thermosonication and pasteurization on the quality attributes of kutkura (Meyna spinosa) juice. Appl. Food Res. 2023, 3, 100268. [Google Scholar] [CrossRef]

- Kodikara, C.; Netticadan, T.; Bandara, N.; Wijekoon, C.; Sura, S. A new UHPLC-HRMS metabolomics approach for the rapid and comprehensive analysis of phenolic compounds in blueberry, raspberry, blackberry, cranberry and cherry fruits. Food Chem. 2024, 445, 138778. [Google Scholar] [CrossRef]

- Halim, M.A.; Kanan, K.A.; Nahar, T.; Rahman, M.J.; Ahmed, K.S.; Hossain, H.; Mozumder, N.H.M.R.; Ahmed, M. Metabolic profiling of phenolics of the extracts from the various parts of blackberry plant (Syzygium cumini L.) and their antioxidant activities. LWT–Food Sci. Technol. 2022, 167, 113813. [Google Scholar] [CrossRef]

- Bortolini, D.G.; Maciel, G.M.; Fernandes, I.A.A.; Rossetto, R.; Brugnari, T.; Ribeiro, V.R.; Haminiuk, C.W.I. Biological potential and technological applications of red fruits: An overview. Food Chem. Adv. 2022, 1, 100014. [Google Scholar] [CrossRef]

- Gil-Martínez, L.; Mut-Salud, N.; Ruiz-García, J.Á.; Falcón-Piñeiro, A.; Maijó-Ferré, M.; Baños, A.; Torre-Ramírez, J.M.D.L.; Guillamón, E.; Verardo, V.; Gómez-Caravaca, A.M. Phytochemicals determination, and antioxidant, antimicrobial, anti-inflammatory and anticancer activities of blackberry fruits. Foods 2023, 12, 1505. [Google Scholar] [CrossRef]

- Albert, C.; Codinã, G.G.; Héjja, M.; András, C.D.; Chetrariu, A.; Dabjja, A. Study of antioxidant activity of garden blackberries (Rubus fruticosus L.) extracts obtained with different extraction solvents. Appl. Sci. 2022, 12, 4004. [Google Scholar] [CrossRef]

- Xu, B.; Feng, M.; Chitrakar, B.; Cheng, J.; Wei, B.; Wang, B.; Zhou, C.; Ma, H. Multi-frequency power thermosonication treatments of clear strawberry juice: Impact on color, bioactive compounds, flavor volatiles, microbial and polyphenol oxidase inactivation. Innov. Food Sci. Emerg. Technol. 2023, 84, 103295. [Google Scholar] [CrossRef]

- Nayak, P.K.; Chandrasekar, C.M.; Gogoi, S.; Kesavan, R.K. Impact of thermal and thermosonication treatments of amora (Spondius pinnata) juice and prediction of quality changes using artificial neural networks. Biosyst. Eng. 2022, 223, 169–181. [Google Scholar] [CrossRef]

- Aghajanzadeh, S.; Ziaiifar, A.M.; Verkerk, R. Effect of thermal and non-thermal treatments on the color of citrus juice: A review. Food Rev. Int. 2023, 39, 3555–3577. [Google Scholar] [CrossRef]

- Suo, G.; Zhou, C.; Su, W.; Hu, X. Effects of ultrasonic treatment on color, carotenoid content, enzyme activity, rheological properties, and microstructure of pumpkin juice during storage. Ultrason. Sonochem. 2022, 84, 105974. [Google Scholar] [CrossRef]

- Salazar-Orbea, G.L.; García-Villalba, R.; Bernal, M.J.; Hernández, A.; Tomás-Barberán, F.A.; Sánchez-Siles, L.M. Stability of phenolic compounds in apple and strawberry: Effect of different processing techniques in industrial set up. Food Chem. 2023, 401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, J.; Fan, L.; Kilmartin, P.A. Degradation of cyanidin-3-O-glucoside induced by antioxidant compounds in model Chinese bayberry wine: Kinetic studies and mechanisms. Food Chem. 2022, 373, 131426. [Google Scholar] [CrossRef] [PubMed]

- Badin, E.E.; Rossi, Y.E.; Montenegro, M.A.; Ibarz, A.; Ribotta, P.D.; Lespinard, A.R. Thermal processing of raspberry pulp: Effect on the color and bioactive compounds. Food Bioprod. Process. 2020, 124, 469–477. [Google Scholar] [CrossRef]

- Pérez-Grijalva, B.; Herrera-Sotero, M.; Mora-Escobedo, R.; Zebadúa-García, J.C.; Silva-Hernández, E.; Oliart-Ros, R.; Pérez-Cruz, C.; Guzmán-Gerónimo, R. Effect of microwaves and ultrasound on bioactive compounds and microbiological quality of blackberry juice. LWT–Food Sci. Technol. 2018, 87, 47–53. [Google Scholar] [CrossRef]

- Qi, Q.; Chu, M.; Yu, X.; Xie, Y.; Li, Y.; Du, Y.; Liu, X.; Zhang, Z.; Shi, J.; Yan, N. Anthocyanins and Proanthocyanidins: Chemical structures, food sources, bioactivities, and product development. Food Rev. Int. 2023, 39, 4581–4609. [Google Scholar] [CrossRef]

- Nunes, B.V.; Silva, C.N.; Bastos, S.C.; Souza, V.R. Microbiological inactivation by ultrasound in liquid products. Food Bioprocess Tech. 2022, 15, 2185–2209. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, J.; Zhao, T.; Yang, X.; Zhang, J.; Yang, H. Bioavailability and mechanisms of dietary polyphenols affected by non-thermal processing technology in fruits and vegetables. Curr. Res. Food Sci. 2024, 8, 100715. [Google Scholar] [CrossRef]

- Sun, M.; Zhuang, Y.; Gu, Y.; Zhang, G.; Fan, X.; Ding, Y. A comprehensive review of the application of ultrasonication in the production and processing of edible mushrooms: Drying, extraction of bioactive compounds, and post-harvest preservation. Ultrason. Sonochem. 2024, 102, 106763. [Google Scholar] [CrossRef]

- Zhang, Q.A.; Zheng, H.; Lin, J.; Nie, G.; Fan, X.; García-Martín, J.F. The state-of-the-art research of the application of ultrasound to winemaking: A critical review. Ultrason. Sonochem. 2023, 95, 106384. [Google Scholar] [CrossRef]

- Abdulstar, A.R.; Altemimi, A.B.; Al-Hilphy, A.R. Exploring the power of Thermosonication: A comprehensive review of its applications and impact in the food industry. Foods 2023, 12, 1459. [Google Scholar] [CrossRef]

- Baltacıoğlu, H. Thermosonication of peach juice: Investigation of PPO and POD activities, physicochemical and bioactive compounds changes, and development of FT-IR–based chemometric models for the evaluation of quality. Int. J. Food Sci. Technol. 2022, 57, 1688–1697. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, L.; Liu, X.; Hasan, K.M.F.; Li, H.; Zhou, S.; Zhang, Q.; Zhou, Y. Effect of thermosonication treatment on blueberry juice quality: Total phenolics, flavonoids, anthocyanin, and antioxidant activity. LWT–Food Sci Technol. 2021, 150, 112021. [Google Scholar] [CrossRef]

- Manzoor, M.F.; Xu, B.; Khan, S.; Shukat, R.; Ahmad, N.; Imran, M.; Rehman, A.; Karrar, E.; Aadil, R.M.; Korma, S.A. Impact of high-intensity thermosonication treatment on spinach juice: Bioactive compounds, rheological, microbial, and enzymatic activities. Ultrason. Sonochem. 2021, 78, 105740. [Google Scholar] [CrossRef] [PubMed]

- Kalsi, B.S.; Singh, S.; Alam, M.S.; Bhatia, S. Application of thermosonication for guava juice processing: Impacts on bioactive, microbial, enzymatic and quality attributes. Ultrason. Sonochem. 2023, 99, 106595. [Google Scholar] [CrossRef]

- Tremarin, A.; Canbaz, E.A.; Brandão, T.R.S.; Silva, C.L.M. Modelling Alicyclobacillus acidoterrestris inactivation in apple juice using thermosonication treatments. LWT–Food Sci. Technol. 2019, 102, 159–163. [Google Scholar] [CrossRef]

- Tahi, A.A.; Sousa, S.; Madani, K.; Silva, C.L.M.; Miller, F.A. Ultrasound and heat treatment effects on Staphylococcus aureus cell viability in orange juice. Ultrason. Sonochem. 2021, 78, 105743. [Google Scholar] [CrossRef]

- Sasikumar, R.; Pradhan, D.; Deka, S.C. Effects of thermosonication process on inactivation of Escherichia coli and Saccharomyces cerevisiae and its survival kinetics modeling in khoonphal (Haematocarpus validus) juice to extend its shelf life. J. Food Process Preserv. 2019, 43, e14220. [Google Scholar] [CrossRef]

- Çol, B.G.; Akhan, M.; Sancar, B.Ç.; Turkol, M.; Yikmis, S.; Hecer, C. Effect of thermosonication on amino acids, phenolic compounds, sensory properties and microbial quality in freshly squeezed verjuice. Foods 2023, 12, 2167. [Google Scholar] [CrossRef]

- Yikmis, S.; Erdal, B.; Doguer, C.; Levent, O.; Turkol, M.; Demirok, N.T. Thermosonication processing of red onion juice (Allium cepa L.): Anticancer, antibacterial, antihypertensive and antidiabetic effects. Processes 2024, 12, 517. [Google Scholar] [CrossRef]

- Qiu, X.; Su, J.; Nie, J.; Zhang, Z.; Ren, J.; Wang, S.; Pei, Y.; Li, X. Effects of thermosonication on the antioxidant capacity and physicochemical, bioactive, microbiological and sensory qualities of blackcurrant juice. Foods 2024, 13, 809. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Ye, J.; Vanga, S.K.; Raghavan, V. Influence of high-intensity ultrasound on bioactive compounds of strawberry juice: Profiles of ascorbic acid, phenolics, antioxidant activity and microstructure. Food Control 2019, 96, 128–136. [Google Scholar] [CrossRef]

- Kesavan, R.K.; Begum, S.; Das, P.; Nayak, P.K. Hindrance effect of thermosonication and non-thermal processing on quality characteristics of fruit juices: An overview. J. Food Process Eng. 2023, 46, 14310. [Google Scholar] [CrossRef]

- Brazilian Soil Classification System. Brazilian Agricultural Research Corporation (Embrapa Soils), 5th ed.; Ministry of Agriculture, Livestock and Food Supply: Brasilia, Brazil, 2018; 355p.

- Cheng, C.X.; Jia, M.; Gui, Y.; Ma, Y. Comparison of the effects of new processing technologies and conventional thermal pasteurization on the nutritional quality and aroma of tangerine (Citrus unshiu) juice. Innov. Food Sci. Emerg. Technol. 2020, 64, 102425. [Google Scholar] [CrossRef]

- Sanchéz, B.A.O.; Celestino, S.M.C.; Gloria, M.B.A.; Celestino, I.C.; Lozada, M.I.O.; Júnior, D.A.S.; Alencar, E.R.; Oliveira, L.L. Pasteurization of passion fruit Passiflora setacea pulp to optimize bioactive compounds retention. Food Chem. X 2020, 6, 100084. [Google Scholar] [CrossRef]

- Bayati, M.; Tavakoli, M.M.; Ebrahimi, S.N.; Aliahmadi, A.; Rezadoost, H. Optimization of effective parameters in cold pasteurization of pomegranate juice by response surface methodology and evaluation of physicochemical characteristics. LWT–Food Sci. Technol. 2021, 147, 111679. [Google Scholar] [CrossRef]

- Geraldi, M.V.; Cazarin, C.B.B.; Dias-Audiberti, F.L.; Pereira, G.A.; Carvalho, G.G.; Kabuki, D.Y.; Catharino, R.R.; Pastore, G.M.; Behrens, J.H.; Cristianini, M.; et al. Influence of high isostatic pressure and thermal pasteurization on the chemical composition, color, antioxidant properties and sensory evaluation of jaboticaba juice. LWT–Food Sci. Technol. 2021, 139, 110548. [Google Scholar] [CrossRef]

- State Department of Health, Adolfo Lutz. Physicochemical Methods for Food Analysis, 4th ed.; Analytical Standards of the Adolfo Lutz Institute: Sao Paulo, Brazil, 2008. [Google Scholar]

- Mohideen, F.W.; Solval, K.M.; Li, J.; Zhang, J.; Chouljenko, A.; Chotiko, A.; Prudente, A.D.; Bankston, J.D.; Sathivel, S. Effect of continuous ultra-sonication on microbial counts and physico-chemical properties of blueberry (Vaccinium corymbosum) juice. LWT–Food Sci. Technol. 2015, 60, 563–570. [Google Scholar] [CrossRef]

- Larrauri, J.A.; Rupérez, P.; Saura-Calixto, F. Effect of drying temperature on the stability of polyphenols and antioxidant activity of red grape pomace peels. J. Agric. Food Chem. 1997, 45, 1390–1393. [Google Scholar] [CrossRef]

- Lee, J.; Durst, R.W.; Wrolstad, R.E. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method: Collaborative study. J. AOAC Int. 2005, 88, 1269–1278. [Google Scholar] [CrossRef]

- Waterhouse, A.L. Polyphenolics: Determination of total phenolics. Curr. Prot. Anal. Food Chem. 2002, 6, I1-1. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Rufino, M.S.M.; Alves, R.E.; Brito, E.S.; Morais, S.M.; Sampaio, C.G.; Pérez-Giménez, J.; Saura-Calixto, F.D. Metodologia Científica: Determinação da atividade antioxidante total em frutas pela captura do radical livre DPPH. Comunicado Técnico. 2009, 127. [Google Scholar]

- Rufino, M.S.M.; Alves, R.E.; Brito, E.S.; Mancini, F.J.; Moreira, A.V.B. Metodologia Científica: Determinação da atividade antioxidante total em frutas no sistema beta-caroteno/ácido linoléico. Comunicado Técnico 2006, 126. [Google Scholar]

- Leeuw, J.D. Convergence of the majorization method for multidomen-sional Scaling 1. Introduction recent research in multidimensional scaling has moved in the direction of proposing m. J. Class. 1988, 180, 163–180. [Google Scholar]

- Jaworska, N.; Chupetlovska-Anastasova, A. A Review of Multidimensional Scaling (MDS) and its utility in various psychological domains. Quant. Methods Psychol. 2009, 5, 1–10. [Google Scholar] [CrossRef]

- Kruskal, J.B. Nonmetric multidimensional scaling: A numerical method. Psychometrika 1964, 29, 115–129. [Google Scholar] [CrossRef]

- Core, R.T. R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing, Vienna. 2022. Available online: https://www.R-project.org (accessed on 24 February 2025).

- Tomadoni, B.; Cassani, L.; Viacava, G.; Moreira, M.D.R.; Ponce, A. Effect of ultrasound and storage time on quality attributes of strawberry juice. J. Food Process Eng. 2017, 40, 1–8. [Google Scholar] [CrossRef]

- Maia, G.A.; Sousa, P.H.M.; Santos, G.M.; Silva, D.S.; Fernandes, A.G.; Prado, G.M. Effect of processing on acerola juice components. Food Sci. Technol. 2007, 27, 130–134. [Google Scholar] [CrossRef]

- Atalar, I.; Gul, O.; Saricaoglu, F.T.; Besir, A.; Gul, L.B.; Yazici, F. Influence of thermosonication (TS) process on the quality parameters of high pressure homogenized hazelnut milk from hazelnut oil by-products. J. Food Sci. Technol. 2019, 56, 1405–1415. [Google Scholar] [CrossRef]

- Alves, L.L.; Santos, R.L.; Bayer, B.L.; Devens, A.L.M.; Cichoski, A.J.; Mendonça, C.R.B. Thermosonication of tangerine juice: Effects on quality characteristics, bioactive compounds, and antioxidant activity. J. Food Process Preserv. 2021, 44, e14914. [Google Scholar] [CrossRef]

- Souza, F.C.A.; Gomes, S.M.L.; Oliveira, B.K.; Paiva, L.A.J.; Moreira, M.J.; Sanches, E.A.; Santos, F.F.; Bakry, A.M.; Nicolau, P.B.; Campelo, P.H. Thermosonication applied on camu–camu nectars processing: Effect on bioactive compounds and quality parameters. Food Biop. Process. 2019, 116, 212–218. [Google Scholar] [CrossRef]

- Bora, S.J.; Handique, J.; Sit, N. Effect of ultrasound and enzymatic pre-treatment on yield and properties of banana juice. Ultrason. Sonochem. 2017, 37, 445–451. [Google Scholar] [CrossRef]

- Anaya-Esparza, L.M.; Méndez-Robles, M.D.; Sayago-Ayerdi, S.G.; García-Magaña, M.L.; Ramírez-Mares, M.V.; Sánchez-Burgos, J.A.; Montalvo-González, E. Effect of thermosonication on pathogenic bacteria, quality attributes and stability of soursop nectar during refrigerated storage. CYTA–J. Food 2017, 15, 592–600. [Google Scholar] [CrossRef]

- Gani, A.; Baba, W.N.; Ahmad, M.; Shah, U.; Khan, A.A.; Wani, I.A.; Masoodi, F.A.; Gani, A. Effect of ultrasound treatment on physico-chemical, nutraceutical and microbial quality of strawberry. LWT–Food Sci. Technol. 2016, 66, 496–502. [Google Scholar] [CrossRef]

- Zou, Y.; Hou, X. Sonication enhances quality and antioxidant activity of blueberry juice. Food Sci. Technol. 2017, 37, 599–603. [Google Scholar] [CrossRef]

- Aguilar, K.; Garvín, A.; Ibarz, A.; Augusto, P.E.D. Ascorbic acid stability in fruit juices during thermosonication. Ultrason. Sonochem. 2017, 37, 375–381. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Cansino, N.S.; Ramírez-Moreno, E.; León-Rivera, J.E.; Delgado-Olivares, L.; Alanís-García, E.; Ariza-Ortega, J.A.; Manríquez-Torres, J.J.; Jaramillo-Bustos, D.P. Shelf life, physicochemical, microbiological and antioxidant properties of purple cactus pear (Opuntia ficus indica) juice after thermoultrasound treatment. Ultrason. Sonochem. 2015, 27, 277–286. [Google Scholar] [CrossRef]

- Ordóñez-Santos, L.E.; Martínez-Girón, J.; Arias-Jaramillo, M.E. Effect of ultrasound treatment on visual color, vitamin C, total phenols, and carotenoids content in Cape gooseberry juice. Food Chem. 2017, 233, 96–100. [Google Scholar] [CrossRef]

- Kalsi, B.S.; Singh, S.; Alam, M.S. Influence of ultrasound processing on the quality of guava juice. J. Food Process Eng. 2022, 46, e14163. [Google Scholar] [CrossRef]

- Ruiz-de-Anda, D.; Ventura-Lara, M.G.; Rodríguez-Hernández, G.; Ozuna, C. The impact of power ultrasound application on physicochemical, antioxidant, and microbiological properties of fresh orange and celery juice blend. J. Food Meas. Charact. 2019, 13, 3140–3148. [Google Scholar] [CrossRef]

- Martínez-Flores, H.E.; Garnica-Romo, M.G.; Bermúdez-Aguirre, D.; Pokhrel, P.R.; Barbosa-Cánovas, G.V. Physico-chemical parameters, bioactive compounds and microbial quality of thermo-sonicated carrot juice during storage. Food Chem. 2015, 172, 650–656. [Google Scholar] [CrossRef] [PubMed]

- Basumatary, B.; Nayak, M.; Nayak, P.K.; Kesavan, R.K. Assessment of quality changes of tangor fruit juice after pasteurization and thermosonication treatments. J. Food Process Eng. 2022, 45, e14170. [Google Scholar] [CrossRef]

- Nadeem, M.; Ubaid, N.; Qureshi, T.M.; Munir, M.; Mehmood, A. Effect of ultrasound and chemical treatment on total phenol, flavonoids and antioxidant properties on carrot-grape juice blend during storage. Ultrason. Sonochem. 2018, 45, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Wahia, H.; Zhou, C.; Fakayode, O.A.; Amanor-Atiemoh, R.; Zhang, L.; Taiye Mustapha, A.; Zhang, J.; Xu, B.; Zhang, R.; Ma, H. Quality attributes optimization of orange juice subjected to multi-frequency thermosonication: Alicyclobacillus acidoterrestris spore inactivation and applied spectroscopy ROS characterization. Food Chem. 2021, 361, 130108. [Google Scholar] [CrossRef]

- Margean, A.; Lupu, M.I.; Alexa, E.; Padureanu, V.; Canja, C.M.; Cocan, I.; Negrea, M.; Calefariu, G.; Poiana, M.A. An overview of effects induced by pasteurization and high-power ultrasound treatment on the quality of red grape juice. Molecules 2020, 25, 1669. [Google Scholar] [CrossRef]

- Mtaoua, H.; Sánchez-Vega, R.; Ferchichi, A.; Martín-Belloso, O. Impact of high-intensity pulsed electric fields or thermal treatment on the quality attributes of date juice through storage. J. Food Process Pres. 2017, 41, e13052. [Google Scholar] [CrossRef]

- Nadulski, R.; Kobus, Z.; Wilczynski, K.; Sobczak, P.; Panasiewicz, M.; Zukiewicz-Sobczak, W.; Szparaga, A. Effect of extraction method and thermosonication on apple juice quality. Appl. Sci. 2019, 9, 3977. [Google Scholar] [CrossRef]

- Sharayei, P.; Azarpazhooh, E.; Zomorodi, S.; Ramaswamy, H.S. Ultrasound assisted extraction of bioactive compounds from pomegranate (Punica granatum L.) peel. LWT–Food Sci. Technol. 2019, 101, 342–350. [Google Scholar] [CrossRef]

- Tiwari, B.K. Ultrasound: A clean, green extraction technology. TrAC–Trends Anal. Chem. 2015, 71, 100–109. [Google Scholar] [CrossRef]

- Anaya-Esparza, L.M.; Velázquez-Estrada, R.M.; Sayago-Ayerdi, S.G.; Sánchez-Burgos, J.A.; Ramírez-Mares, M.V.; García-Magaña, M.L.; Montalvo-González, E. Effect of thermosonication on polyphenol oxidase inactivation and quality parameters of soursop nectar. LWT–Food Sci. Technol. 2017, 75, 545–551. [Google Scholar] [CrossRef]

- Dias, D.R.C.; Barros, Z.M.P.; Carvalho, C.B.O.; Honorato, F.A.; Guerra, N.B.; Azoubel, P.M. Effect of sonication on soursop juice quality. LWT–Food Sci. Technol. 2015, 62, 883–889. [Google Scholar] [CrossRef]

- Kovačević, D.B.; Bilobrk, J.; Buntić, B.; Bosiljkov, T.; Karlović, S.; Rocchetti, G.; Lucini, L.; Barba, F.J.; Lorenzo, J.M.; Putnik, P. High-power ultrasound altered the polyphenolic content and antioxidant capacity in cloudy apple juice during storage. J. Food Process Pres. 2019, 43, e14023. [Google Scholar] [CrossRef]

- Markovinović, A.B.; Putnik, P.; Bičanić, P.; Brdar, D.; Duralija, B.; Pavlić, B.; Milošević, S.; Rocchetti, G.; Lucini, L.; Kovačević, D.B. A chemometric investigation on the functional potential in High Power Ultrasound (HPU) processed strawberry juice made from fruits harvested at two stages of ripeness. Molecules 2023, 28, 138. [Google Scholar] [CrossRef] [PubMed]

- Lafarga, T.; Ruiz-Aguirre, I.; Abadias, M.; Viñas, I.; Bobo, G.; Aguiló-Aguayo, I. Effect of thermosonication on the bioaccessibility of antioxidant compounds and the microbiological, physicochemical, and nutritional quality of an anthocyanin-enriched tomato juice. Food Bioprocess Tech. 2019, 12, 147–157. [Google Scholar] [CrossRef]

- Hooshyar, L.; Hesari, J.; Azadmard-Damirchi, S. Investigation of selected thermal and non-thermal preservative techniques to produce high quality and safe to drink sour cherry, red grape and pomegranate juices. J. Food Sci. Technol. 2020, 57, 1689–1697. [Google Scholar] [CrossRef]

- Ramírez-Melo, L.M.; Cruz-Cansino, N.S.; Delgado-Olivares, L.; Ramírez-Moreno, E.; Zafra-Rojas, Q.Y.; Hernández-Traspeña, J.L.; Suárez-Jacobo, Á. Optimization of antioxidant activity properties of a thermosonicated beetroot (Beta vulgaris L.) juice and further in vitro bioaccessibility comparison with thermal treatments. LWT–Food Sci. Technol. 2022, 154, 112780. [Google Scholar] [CrossRef]

- Saikia, S.; Mahnot, N.K.; Mahanta, C.L. A comparative study on the effect of conventional thermal pasteurisation, microwave and ultrasound treatments on the antioxidant activity of five fruit juices. Food Sci. Technol. Int. 2016, 22, 288–301. [Google Scholar] [CrossRef]

- Chitgar, M.F.; Aalami, M.; Kadkhodaee, R.; Maghsoudlou, Y.; Milani, E. Effect of thermosonication and thermal treatments on phytochemical stability of barberry juice copigmented with ferulic acid and licorice extract. Innov. Food Sci. Emerg. Technol. 2018, 50, 102–111. [Google Scholar] [CrossRef]

- Yıkmış, S.; Ozer, H.; Levent, O.; Çöl, B.G.; Erdal, B. Effect of thermosonication and thermal treatments on antidiabetic, antihypertensive, mineral elements and in vitro bioaccessibility of bioactive compounds in freshly squeezed pomegranate juice. J. Food Meas. Char. 2022, 16, 3023–3041. [Google Scholar] [CrossRef]

- Raju, S.; Deka, S.C. Influence of thermosonication treatments on bioactive compounds and sensory quality of fruit (Haematocarpus validus) juice. J. Food Process Pres. 2018, 42, e13701. [Google Scholar] [CrossRef]

- Strieder, M.M.; Neves, M.I.L.; Belinato, J.R.; Silva, E.K.; Meireles, M.A.A. Impact of thermosonication processing on the phytochemicals, fatty acid composition and volatile organic compounds of almond-based beverage. LWT–Food Sci. Technol. 2022, 154, 112579. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Šimunek, M.; Evačić, S.; Markov, K.; Smoljanić, G.; Frece, J. Influence of high power ultrasound on selected moulds, yeasts and Alicyclobacillus acidoterrestris in apple, cranberry and blueberry juice and nectar. Ultrasonics 2018, 83, 3–17. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Cai, C.; Wang, Y.; Zheng, X. Effects of ultrasound processing on physicochemical parameters, antioxidants, and color quality of bayberry juice. J. Food Qual. 2019. [Google Scholar] [CrossRef]

| Treatments | Temperature (X1) | Time (X2) | ||

|---|---|---|---|---|

| Coded | Real | Coded | Real | |

| 1 | −1 | 64 °C | −1 | 114 s |

| 2 | −1 | 64 °C | 1 | 517 s |

| 3 | 1 | 86 °C | −1 | 114 s |

| 4 | 1 | 86 °C | 1 | 517 s |

| 5 | −1.41 | 60 °C | 0 | 315 s |

| 6 | 1.41 | 90 °C | 0 | 315 s |

| 7 | 0 | 75 °C | −1.41 | 30 s |

| 8 | 0 | 75 °C | 1.41 | 600 s |

| 9 | 0 | 75 °C | 0 | 315 s |

| 10 | 0 | 75 °C | 0 | 315 s |

| 11 | 0 | 75 °C | 0 | 315 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, C.N.d.; Carmo, J.R.d.; Nunes, B.V.; Demoliner, F.; Souza, V.R.d.; Bastos, S.C. Synergistic Effect of Thermosonication on the Stability of Bioactive Compounds and Antioxidant Activity of Blackberry Juice. Foods 2025, 14, 901. https://doi.org/10.3390/foods14050901

Silva CNd, Carmo JRd, Nunes BV, Demoliner F, Souza VRd, Bastos SC. Synergistic Effect of Thermosonication on the Stability of Bioactive Compounds and Antioxidant Activity of Blackberry Juice. Foods. 2025; 14(5):901. https://doi.org/10.3390/foods14050901

Chicago/Turabian StyleSilva, Cristiane Nunes da, Juliana Rodrigues do Carmo, Bruna Vieira Nunes, Fernanda Demoliner, Vanessa Rios de Souza, and Sabrina Carvalho Bastos. 2025. "Synergistic Effect of Thermosonication on the Stability of Bioactive Compounds and Antioxidant Activity of Blackberry Juice" Foods 14, no. 5: 901. https://doi.org/10.3390/foods14050901

APA StyleSilva, C. N. d., Carmo, J. R. d., Nunes, B. V., Demoliner, F., Souza, V. R. d., & Bastos, S. C. (2025). Synergistic Effect of Thermosonication on the Stability of Bioactive Compounds and Antioxidant Activity of Blackberry Juice. Foods, 14(5), 901. https://doi.org/10.3390/foods14050901