Effects of Adding Micronutrient Mixtures to a Model Dark Chocolate System and Partially Replacing the Fat Phase with a Structuring Oleogel

Abstract

1. Introduction

2. Materials and Methods

2.1. Oleogel Preparation

2.2. Chocolate Preparation

2.3. Chocolate Production

- Illustration 1—Sequency of chocolate production (WA-FA20).

2.4. Nutritional Composition (Ash and Moisture)

2.5. Total Lipids and Fatty Acid Profile

2.6. Triacylglycerol Determination

2.7. Water Activity Determination

2.8. Color Analysis

2.9. Thermal Analysis (DSC—Differential Scanning Calorimetry)

2.10. Physical and Structural Analyses of Chocolates

2.10.1. Texture Determination

2.10.2. Rheological Analysis

- Ʈ = Shear stress;

- Ʈo = Yield stress;

- Ƞc = Plastic viscosity;

- Υ = Shear rate.

2.11. Determination of Zinc and Selenium

2.12. Statistical Analysis

3. Results

3.1. Moisture, Water Activity, and pH Analysis

3.2. Color Analysis

3.3. Thermal Analysis DSC

3.3.1. Melting Analysis

3.3.2. Crystallization Thermal Analysis

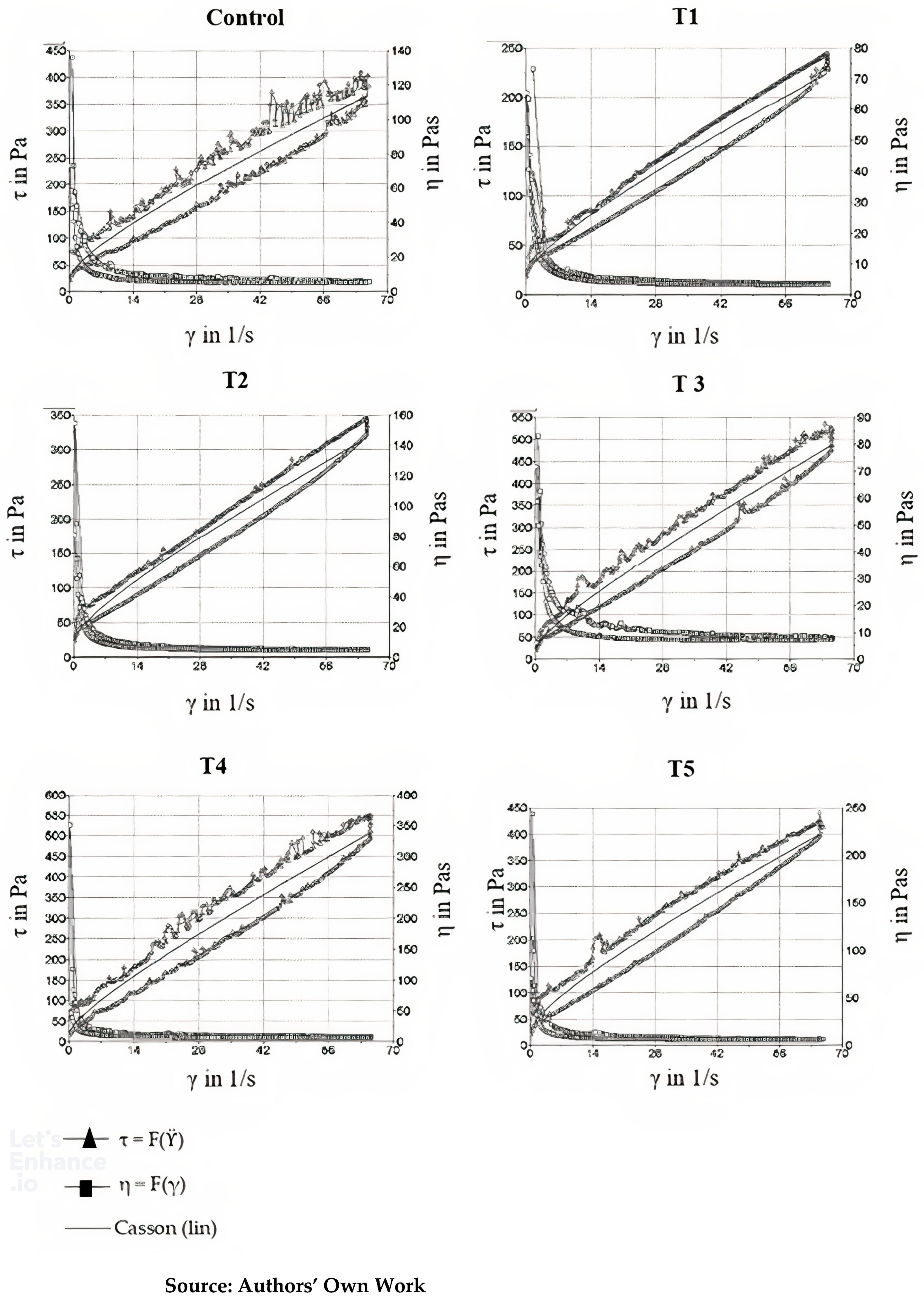

3.4. Rheological Analysis

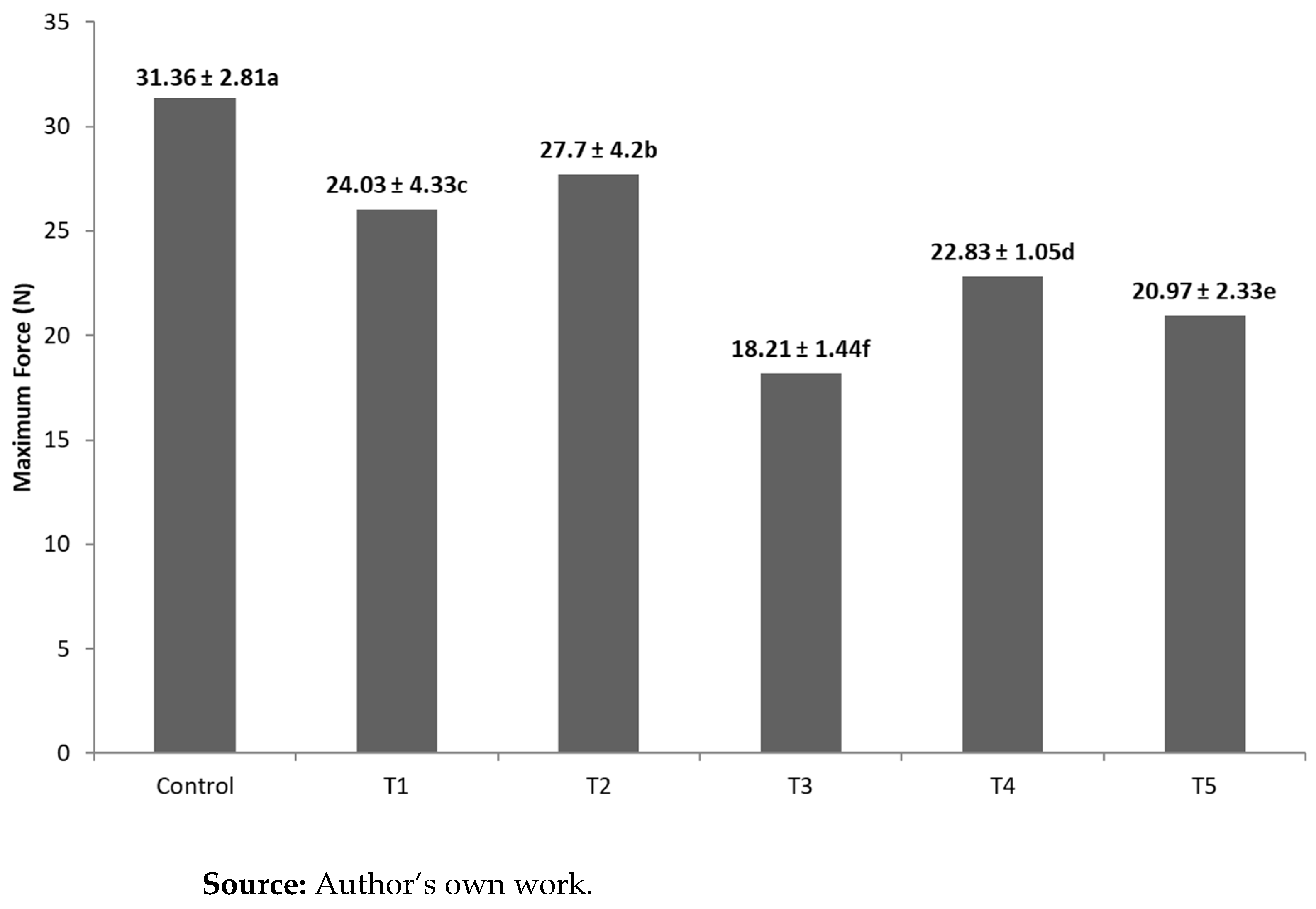

3.5. Texture

3.6. Total Lipids, Fatty Acid Profile, and Triacylglycerols

3.7. Determinations of Selenium and Zinc

4. Discussion

4.1. Moisture, Water Activity, and pH Analysis

4.2. Color Analysis

4.3. Thermal Analysis DSC

4.3.1. Melting Analysis

4.3.2. Crystallization Thermal Analysis

4.4. Rheological Analysis

4.5. Texture

4.6. Total Lipids, Fatty Acid Profile, and Triacylglycerols

4.7. Determinations of Selenium and Zinc

4.8. Chocolate with Oleogels

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutiérrez, T.J. State-of-the-art chocolate manufacture: A review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1313–1344. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Zhang, W.W.; Ni, Z.J.; Thakur, K.; Zhang, J.G.; Hu, F.; Wei, Z.J. Development and characterization of novel Lycium barbarum seed oil-based oleogels and their application in functional chocolate. Food Biosci. 2023, 56, 103155. [Google Scholar] [CrossRef]

- Pirouzian, H.R.; Konar, N.; Palabiyik, I.; Oba, S.; Toker, O.S. Pre-crystallization process in chocolate: Mechanism, importance and novel aspects. Food Chem. 2020, 321, 126718. [Google Scholar] [CrossRef] [PubMed]

- Toker, O.S.; Konar, N.; Pirouzian, H.R.; Oba, S.; Polat, D.G.; Palabiyik, I.; Poyrazoglu, E.S.; Sagdic, O. Developing functional white chocolate by incorporating different forms of EPA and DHA-Effects on product quality. LWT 2018, 87, 177–185. [Google Scholar] [CrossRef]

- Faccinetto-Beltrán, P.; Gómez-Fernández, A.R.; Santacruz, A.; Jacobo-Velázquez, D.A. Chocolate as Carrier to Deliver Bioactive Ingredients: Current Advances and Future Perspectives. Foods 2021, 10, 2065. [Google Scholar] [CrossRef]

- Lannes, S.C.S. Chocolate and Cocoa Products as a Source of Health and Wellness. In Global Food Security and Wellness; Barbosa-Cánovas, G.V., Pastore, G.M., Candoğan, K., Meza, I.G.M., da Silva Lannes, S.C., Buckle, K., Yada, R.Y., Rosenthal, A., Eds.; Springer: New York, NY, USA, 2017; pp. 175–194. [Google Scholar] [CrossRef]

- Agibert, S.A.C.; Lannes, S.C.S. Dark chocolate with a high oleic peanut oil microcapsule. J. Sci. Food Agric. 2018, 98, 5591–5597. [Google Scholar] [CrossRef]

- Lorenzo, N.D.; dos Santos, O.V.; da Silva Lannes, S.C. Structure and nutrition of dark chocolate with pequi mesocarp (Caryocar villosum (Alb.) Pers.). Food Sci. Technol. 2022, 42, e88021. [Google Scholar] [CrossRef]

- Sun, H.; Xu, J.; Lu, X.; Xu, Y.; Regenstein, J.M.; Zhang, Y.; Wang, F. Development and characterization of monoglyceride oleogels prepared with crude and refined walnut oil. LWT 2022, 154, 112769. [Google Scholar] [CrossRef]

- Da Silva, R.C.; Ferdaus, M.J.; Foguel, A.; da Silva, T.L.T. Oleogels as a Fat Substitute in Food: A Current Review. Gels 2023, 9, 180. [Google Scholar] [CrossRef]

- Stanciu, I. Investigation Rheological Behavior of Chocolate. Orient. J. Chem. 2024, 40, 1087–1090. [Google Scholar] [CrossRef]

- Konar, N.; Palabiyik, I.; Karimidastjerd, A.; Toker, O.S. Chocolate microstructure: A comprehensive review. Food Res. Int. 2024, 196, 115091. [Google Scholar] [CrossRef] [PubMed]

- Fayaz, G.; Goli, S.A.H.; Kadivar, M.; Valoppi, F.; Barba, L.; Balducci, C.; Conte, L.; Calligaris, S.; Nicoli, M.C. Pomegranate seed oil organogels structured by propolis wax, beeswax, and their mixture. Eur. J. Lipid Sci. Technol. 2017, 119, 1700032. [Google Scholar] [CrossRef]

- Li, M.; Song, X.; Li, J.; Chen, X.; Li, J.; Hou, C. Safety assessment of oil extracted from lacquer (Toxicodendron vernicifluum (Stokes) F.A. Barkley) seed: Acute and subchronic toxicity studies in rats. J. Ethnopharmacol. 2023, 302, 115901. [Google Scholar] [CrossRef]

- Saffold, A.C.; Acevedo, N.C. Development of novel rice bran wax/gelatin-based biphasic edible gels and characterization of their microstructural, thermal, and mechanical properties. Food Bioproc. Technol. 2021, 14, 2219–2230. [Google Scholar] [CrossRef]

- Da Silva Santos, P.H.; da Silva Lannes, S.C. Application of organogel-like structured system as an alternative for reducing saturated fatty acid and replacing fat in milk ice cream. J. Food Process. Preserv. 2022, 46, e16932. [Google Scholar] [CrossRef]

- Gonçalves, E.V.; Lannes, S.C.S. Chocolate rheology: A review. Food Sci. Technol. 2010, 30, 845–885. [Google Scholar] [CrossRef]

- Mewis, J.; Wagner, N.J. Thixotropy. Adv. Colloid Interface Sci. 2009, 147–148, 214–227. [Google Scholar] [CrossRef]

- Kumbár, V.; Kouřilová, V.; Dufková, R.; Votava, J.; Hřivna, L. Rheological and Pipe Flow Properties of Chocolate Masses at Different Temperatures. Foods 2021, 10, 2519. [Google Scholar] [CrossRef]

- Espert, M.; Salvador, A.; Sanz, T. Cellulose ether oleogels obtained by emulsion-templated approach without additional thickeners. Food Hydrocoll. 2020, 109, 106085. [Google Scholar] [CrossRef]

- AOAC—Association of Official Analytical Chemists. Official Methods of Analysis of AOAC International, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Schetty, O.; Anker, P.; Junker, E.; Kleinert, J. Schweizerisches Iebensmittelbuch, 5th ed.; cap36C edn; Bundesamt für Gesundheit, Abteilung Lebensmittelsicherheit: Bern, Switzerland, 1969; Volume 3, pp. 47–51. [Google Scholar]

- Da Silva Lannes, S.C. Estudo das Propriedades Físico-Químicas e de Textura de Chocolates. Doutorado em Tecnologia de Alimentos; Universidade de São Paulo: São Paulo, Brazil, 1997. [Google Scholar] [CrossRef]

- Hartman, L.; Lago, R.C.A. Rapid Preparation of Fatty Acid Methyl Esters from Lipids. Lab. Pract. 1973, 22, 475–476. [Google Scholar]

- AOCS—American Oil Chemists’ Society. Official Methods and Recommended Practices of the American Oil Chemists’ Society, 5th ed.; AOCS: Champaign, IL, USA, 1997. [Google Scholar]

- da Silva Lannes, S.C.; Medeiros, M.L. Rheological properties of chocolate drink from cupuassu. Int. J. Food Eng. 2008, 4, 1–11. [Google Scholar] [CrossRef]

- IOCCC—International Office of Cocoa, Chocolate and Sugar Confectionery. Viscosity of Cocoa and Chocolate Products; Analytical Method; IOCCC: Hardricourt, France, 2000; p. 46. [Google Scholar]

- Devos, N.; Reyman, D.; Sanchez-Cortés, S. Chocolate composition and its crystallization process: A multidisciplinary analysis. Food Chem. 2021, 342, 128301. [Google Scholar] [CrossRef] [PubMed]

- Beckett, S.T. The Science of Chocolate, 3rd ed.; Royal Society of Chemistry: London, UK, 2019. [Google Scholar]

- Santos, O.V.; Corrêa, N.C.F.; Carvalho, R.N., Jr.; Costa, C.E.F.; Lannes, S.C.S. Yield, nutritional quality, and thermal-oxidative stability of Brazil nut oil (Bertolletia excelsa H.B.K) obtained by supercritical extraction. J. Food Eng. 2013, 117, 499–504. [Google Scholar] [CrossRef]

- Hřivna, L.; Machálková, L.; Burešová, I.; Nedomová, Š.; Gregor, T. Texture, color, and sensory changes occurring in chocolate bars with filling during storage. Food Sci. Nutr. 2021, 9, 4863–4873. [Google Scholar] [CrossRef]

- Afoakwa, E.O. Chocolate Science and Technology, 2nd ed.; Jonh Wiley & Sons Ltd.: London, UK, 2016. [Google Scholar]

- da Silva, T.L.T.; Martini, S. Recent Advances in Lipid Crystallization in the Food Industry. Annu. Rev. Food Sci. Technol. 2024, 15, 355–379. [Google Scholar] [CrossRef]

- Glicerina, V.; Tylewicz, U.; Canali, G.; Siroli, L.; Dalla Rosa, M.; Lanciotti, R.; Romani, S.V. Influence of two different cocoa-based coatings on quality characteristics of fresh-cut fruits during storage. LWT 2019, 101, 152–160. [Google Scholar] [CrossRef]

- de Jesus Silva, G.; Gonçalves, B.H.R.F.; Conceição, D.G.; de Jesus, J.C.; Vidigal, M.C.T.R.; Simiqueli, A.A.; Bonomo, R.C.F.; Ferrão, S.P.B. Microstructural and rheological behavior of buffalo milk chocolates. J. Food Sci. Technol. 2022, 59, 572–582. [Google Scholar] [CrossRef]

- Ewens, H.; Metilli, L.; Simone, E. Analysis of the effect of recent reformulation strategies on the crystallization behaviour of cocoa butter and the structural properties of chocolate. Curr. Res. Food Sci. 2021, 4, 105–114. [Google Scholar] [CrossRef]

- Masuchi, M.H.; Grimaldi, R.; Kieckbusch, T.G. Effects of sorbitan monostearate and monooleate on the crystallization and consistency behaviors of cocoa butter. J. Am. Oil Chem. Soc. 2014, 91, 1111–1120. [Google Scholar] [CrossRef]

- Calder, P.C. Functional Roles of Fatty Acids and Their Effects on Human Health. J. Parenter. Enter. Nutr. 2015, 39, 18S–32S. [Google Scholar] [CrossRef]

- Colella, M.F.; Marino, N.; Oliviero Rossi, C.; Seta, L.; Caputo, P.; De Luca, G. Triacylglycerol Composition and Chemical-Physical Properties of Cocoa Butter and Its Derivatives: NMR, DSC, X-ray, Rheological Investigation. Int. J. Mol. Sci. 2023, 24, 2090. [Google Scholar] [CrossRef] [PubMed]

- Djuricic, I.; Calder, P.C. Beneficial Outcomes of Omega-6 and Omega-3 Polyunsaturated Fatty Acids on Human Health: An Update for 2021. Nutrients 2021, 13, 2421. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, M.D.; Cofrades, S.; Espert, M.; Sanz, T.; Salvador, A. Development of Chocolates with Improved Lipid Profile by Replacing Cocoa Butter with an Oleogel. Gels 2021, 7, 220. [Google Scholar] [CrossRef] [PubMed]

- Maki, K.C.; Dicklin, M.R.; Kirkpatrick, C.F. Saturated fats and cardiovascular health: Current evidence and controversies. J. Clin. Lipidol. 2021, 15, 765–772. [Google Scholar] [CrossRef]

- Evans, J.R.; Lawrenson, J.G. Antioxidant vitamin and mineral supplements for slowing the progression of age-related macular degeneration. Cochrane Database Syst. Rev. 2023, 2023, CD000254. [Google Scholar] [CrossRef]

- Valdivia-Culqui, J.E.; Maicelo-Quintana, J.L.; Cayo-Colca, I.S.; Medina-Mendoza, M.; Castro-Alayo, E.M.; Balcázar-Zumaeta, C.R. Oleogel Systems for Chocolate Production: A Systematic Review. Gels 2024, 10, 561. [Google Scholar] [CrossRef]

- Bascuas, S.; Espert, M.; Llorca, E.; Quiles, A.; Salvador, A.; Hernando, I. Structural and sensory studies on chocolate spreads with hydrocolloid-based oleogels as a fat alternative. LWT 2021, 135, 110228. [Google Scholar] [CrossRef]

- Almeida, P.F.; da Silva Lannes, S.C. Effects of chicken by-product gelatin on the physicochemical properties and texture of chocolate spread. J. Text. Stud. 2017, 48, 392–402. [Google Scholar] [CrossRef]

| Ingredients | Percentage % | |||||

|---|---|---|---|---|---|---|

| C | T1 | T2 | T3 | T4 | T5 | |

| Cocoa liquor | 50 | 50 | 50 | 53 | 53 | 53 |

| Cocoa butter | 10 | 10 | 10 | 7.0 | 7.0 | 7.0 |

| Sugar | 39 | 39 | 39 | 36 | 36 | 36 |

| Soy lecithin | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| PGPR | 0.3 | 0.2 | 0.1 | 0.3 | 0.2 | 0.1 |

| Vanillin | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Premix 1 | - | 0.1 | - | - | 0.1 | - |

| Premix 2 | - | - | 0.2 | - | - | 0.2 |

| Oleogel | - | - | - | 3.0 | 3.0 | 3.0 |

| Moisture | Water Activity | pH | |

|---|---|---|---|

| Control | 3.40 ± 0.14 a | 0.55 ± 0.010 a | 5.55 ± 0.05 a |

| T1 | 3.46 ± 0.26 a | 0.54 ± 0.005 a | 5.25 ± 0.06 b |

| T2 | 3.38 ± 0.05 a | 0.55 ± 0.003 a | 5.10 ± 0.07 c |

| T3 | 3.65 ± 0.11 a | 0.60 ± 0.007 b | 5.34 ± 0.02 b |

| T4 | 3.62 ± 0.47 a | 0.56 ± 0.015 a | 4.98 ± 0.02 cd |

| T5 | 3.54 ± 0.31 a | 0.53 ± 0.009 a | 4.93 ± 0.02 d |

| L* | a* | b* | Whiteness Index | C* | h° | |

|---|---|---|---|---|---|---|

| Control | 28.02 ± 0.59 a | 8.29 ± 0.57 a | 5.22 ± 0.72 a | 27.34 ± 0.64 a | 9.86 ± 0.46 a | 35.04 ± 1.11 a |

| T1 | 28.98 ± 0.84 a | 8.03 ± 0.18 a | 5.43 ± 0.72 a | 27.98 ± 0.77 a | 9.76 ± 0.56 a | 31.86 ± 1.05 b |

| T2 | 28.24 ± 0.26 a | 8.44 ± 0.64 a | 5.59 ± 0.17 a | 27.49 ± 0.33 a | 9.76 ± 0.56 a | 33.12 ± 1.23 ab |

| T3 | 29.01 ± 0.57 a | 8.54 ± 0.28 a | 5.48 ± 0.33 a | 28.64 ± 0.65 a | 10.44 ± 0.58 a | 31.87 ± 1.38 b |

| T4 | 29.5 ± 0.15 a | 8.03 ± 0.32 a | 4.92 ± 0.24 a | 28.88 ± 0.11 a | 9.32 ± 0.34 a | 32.05 ± 0.52 b |

| T5 | 29.3 ± 0.39 a | 8.56 ±0.74 a | 4.83 ± 0.54 a | 28.41 ±0.34 a | 10.14 ± 0.58 a | 32.47 ± 1.42 ab |

| Melting Onset Tonset (°C) | Melting Peak Tpeak (°C) | Melting End Tend (°C) | Melting Enthalpy (J·g−1) | |

|---|---|---|---|---|

| Control | 25.45 ±0.08 a | 32.64 ± 0.70 b | 37.9 ± 1.19 c | 44.16 ± 0.09 a |

| T1 | 25.41 ± 0.05 ab | 33.66 ± 0.27 ab | 38.74 ± 0.12 bc | 38.81 ± 0.63 b |

| T2 | 25.44 ± 0.00 ab | 33.32 ± 0.24 b | 38.77 ± 0.03 bc | 43.10 ± 0.94 a |

| T3 | 25.39 ± 0.04 ab | 33.60 ± 0.53 ab | 39.15 ± 0.06 ab | 43.97 ± 0.88 a |

| T4 | 25.37 ± 0.00 ab | 34.80 ± 0.73 a | 40.44 ± 0.55 a | 49.04 ± 0.36 a |

| T5 | 25.31 ± 0.04 b | 33.64 ± 0.48 ab | 38.35 ± 0.52 bc | 42.16 ± 0.59 b |

| Crystallization Tonset (°C) | Crystallization Peak (°C) | Melting Tend (°C) | Crystallization Enthalpy (J·g−1) | |

|---|---|---|---|---|

| Control | 24.04 ± 0.74 a | 14.19 ± 0.21 a | 0.81 ± 0.03 b | 25.67 ± 0.81 a |

| T1 | 23.48 ± 0.05 a | 13.19 ± 0.09 b | 0.76 ± 0.05 b | 23.83 ± 0.46 c |

| T2 | 23.22 ± 0.16 a | 13.27 ± 0.00 b | 0.75± 0.03 b | 22.85 ± 0.79 e |

| T3 | 23.25 ± 0.15 b | 13.06 ± 0.02 b | 0.14 ± 0.05 c | 21.39 ± 0.88 f |

| T4 | 23.14 ± 0.05 b | 13.19 ± 0.07 b | 1.18 ± 0.21 a | 24.01 ± 0.95 b |

| T5 | 22.85 ± 0.04 b | 13.21 ± 0.11 b | 0.62 ± 0.02 b | 23.34 ± 0.39 d |

| Casson Viscosity (Pa·s) | Yield Stress (Pa) | Thixotropy (Pa·s−1) × 10−3 | R² | |

|---|---|---|---|---|

| Control | 2.88 ± 0.62 ab | 21.69 ± 1.1 a | 6842 | 0.92 ± 0.04 |

| T1 | 2.36 ± 0.39 b | 20.40 ± 0.76 a | 2163 | 0.95 ± 0.00 |

| T2 | 2.33 ± 0.87 b | 16.50 ± 1.57 a | 2435 | 0.97 ± 0.19 |

| T3 | 4.93 ± 0.28 a | 20.82 ± 1.47 a | 7276 | 0.94 ± 0.00 |

| T4 | 4.36 ± 1.50 ab | 16.43 ± 0.66 a | 7008 | 0.90 ± 0.07 |

| T5 | 3.49 ± 0.16 ab | 43.72 ± 1.94 b | 7781 | 0.94 ± 0.02 |

| Fatty Acids | Control | T3 |

|---|---|---|

| Palmitic (C16:0) | 29.51 ± 0.02 a | 24.91 ± 0.15 b |

| Palmitoleic (C16:1) | 0.55 ± 0.02 | 0 |

| Stearic (C18:0) | 39.97 ± 1.91 a | 33.05 ± 0.15 b |

| Oleic (C18:1n9c) | 28.65 ± 3.16 a | 33.08 ± 0.03 a |

| Linoleic (C18:2n6c) | 0.81 ± 0.15 b | 4.89 ± 0.53 a |

| Arachidic (C20:0) | 1.23 ± 0.05 a | 1.07 ± 0.01 b |

| Saturated Fatty Acids (SFAs) | 70.20 ± 3.34 a | 62.03 ± 0.24 b |

| Monounsaturated Fatty Acids (MUFAs) | 28.91 ± 2.85 a | 33.08 ± 0.03 a |

| Polyunsaturated Fatty Acids (PUFAs) | 1.23 ± 0.18 a | 4.89 ± 0.28 b |

| Carbon Content of Triacylglycerol (%) | |||

|---|---|---|---|

| Control | T3 | ||

| T48 | 2.76 ± 0.27 a | 1.69 ± 0.08 b | |

| T50 | 19.20 ± 1.34 a | 14.82 ± 0.23 b | POP |

| T52 | 42.62 ± 1.07 a | 41.23 ± 0.36 a | POS |

| T54 | 33.21 ± 1.66 b | 40.61 ± 0.40 a | SOS |

| T56 | 2.22 ± 0.18 a | 1.62 ± 0.13 b | |

| T58 | 0.02 ± 0.03 a | 0.03 ± 0.03 a | |

| Se (%) | Zn (%) | |

|---|---|---|

| Control | <LD | 1.67 ± 0.03 c |

| T1 | <LD | 1.95 ± 0.06 b |

| T2 | <LD | 2.10 ± 0.11 b |

| T5 | <LD | 2.42 ± 0.02 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, P.H.S.; Suzuki, C.K.; Lannes, S.C.d.S. Effects of Adding Micronutrient Mixtures to a Model Dark Chocolate System and Partially Replacing the Fat Phase with a Structuring Oleogel. Foods 2025, 14, 430. https://doi.org/10.3390/foods14030430

Santos PHS, Suzuki CK, Lannes SCdS. Effects of Adding Micronutrient Mixtures to a Model Dark Chocolate System and Partially Replacing the Fat Phase with a Structuring Oleogel. Foods. 2025; 14(3):430. https://doi.org/10.3390/foods14030430

Chicago/Turabian StyleSantos, Paulo Henrique Silva, Cristina Kaori Suzuki, and Suzana Caetano da Silva Lannes. 2025. "Effects of Adding Micronutrient Mixtures to a Model Dark Chocolate System and Partially Replacing the Fat Phase with a Structuring Oleogel" Foods 14, no. 3: 430. https://doi.org/10.3390/foods14030430

APA StyleSantos, P. H. S., Suzuki, C. K., & Lannes, S. C. d. S. (2025). Effects of Adding Micronutrient Mixtures to a Model Dark Chocolate System and Partially Replacing the Fat Phase with a Structuring Oleogel. Foods, 14(3), 430. https://doi.org/10.3390/foods14030430