The Use of Industry 4.0 and 5.0 Technologies in the Transformation of Food Services: An Integrative Review

Abstract

1. Introduction

2. Materials and Methods

2.1. Eligibility Criteria

2.2. Information Source

2.3. Search Strategy

2.3.1. Group 1

2.3.2. Group 2

2.4. Study Selection

2.5. Data Collection Process

3. Results

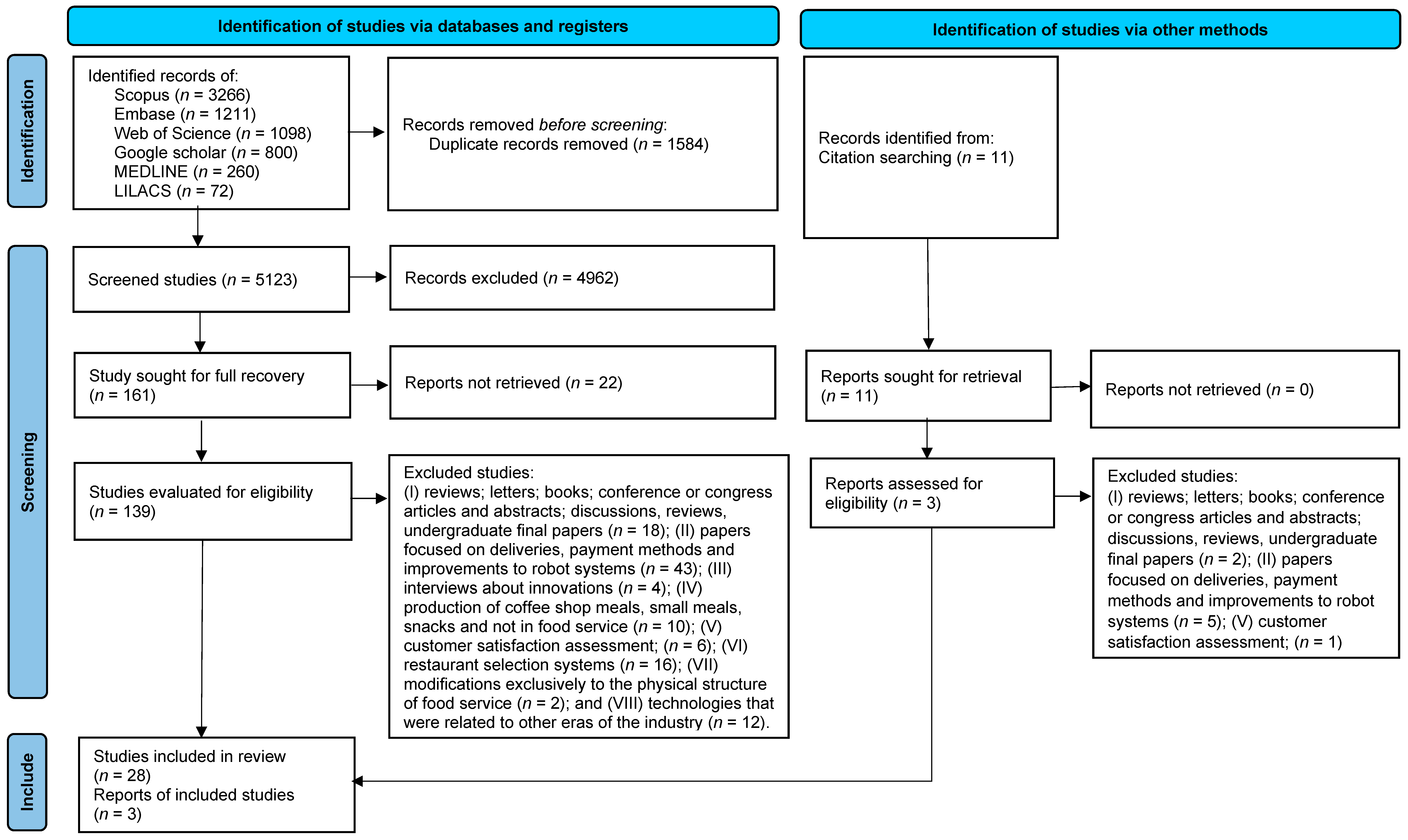

3.1. Selection of Studies

3.2. Studies’ Characteristics

4. Discussion

4.1. Distribution of Studies by Country or Region

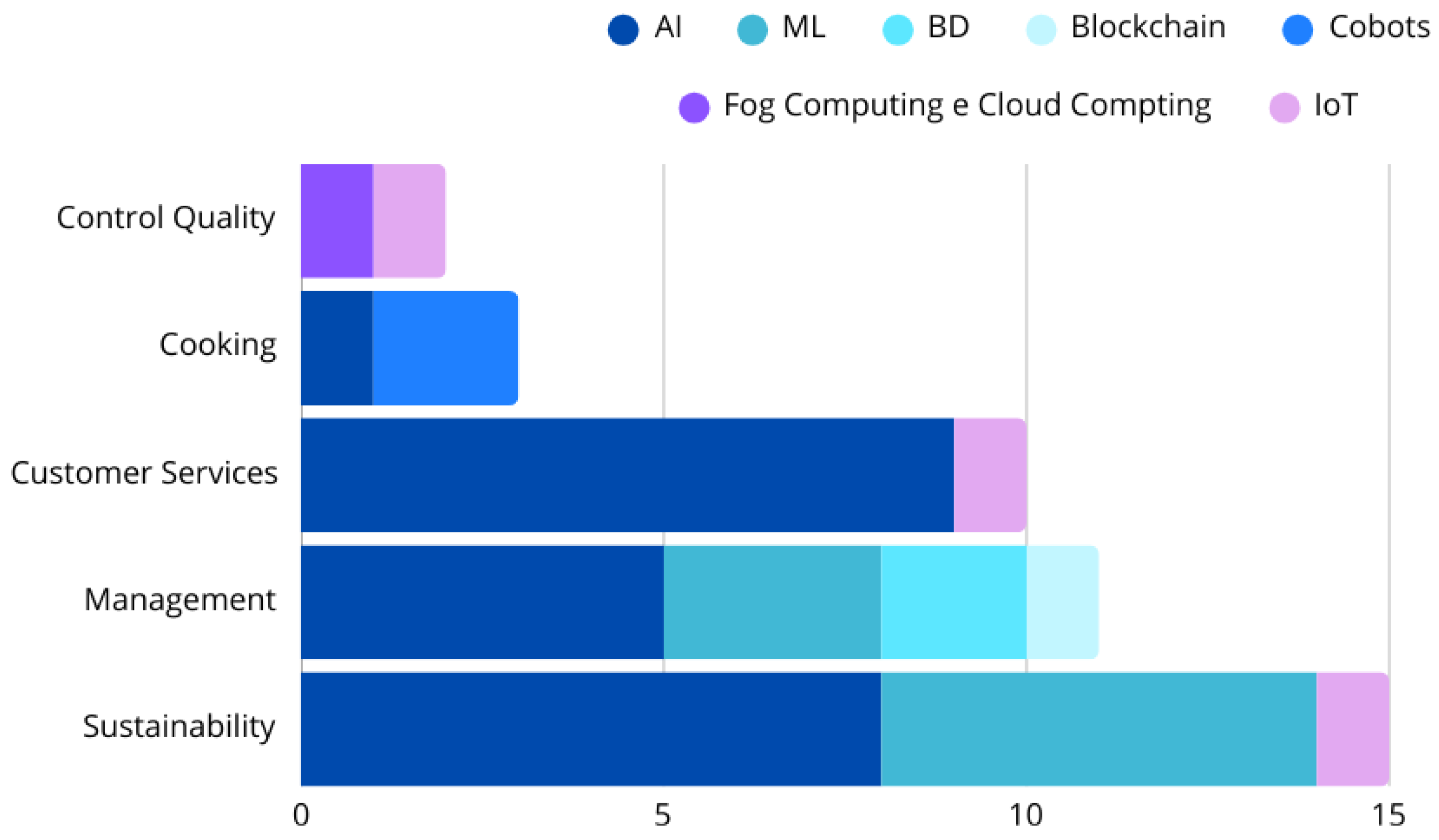

4.2. Perspectives and Employed Technologies

4.3. Study Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Glossary

| AI—Artificial Intelligence | A branch of science that allows machines to learn, reason, and act like humans [17]. |

| BD—Big Data | A comprehensive and varied collection of data gathered from multiple sources, including consumption, customer, product data, and potential routes [17]. |

| Big Data Analytics | The analysis of large and diverse datasets from various sources aims to define distinct profiles [12]. |

| Blockchain | A decentralized management system for various connected heterogeneous devices, characterized by immutability, encryption, resistance to data tampering, and enhanced security. This system is applicable for traceability and monitoring of orders, payments, accounts, and other transactions [16]. |

| Cloud Computing | A technology that enables remote access to information technology services [17]. |

| Cobot—Collaborative Robotics | Enhances flexibility and automation in assembly lines, utilizing collaborative robots in restaurants for serving customers, delivering food, and collecting and washing dishes [17]. |

| Deep Learning | A branch of AI used for complex pattern recognition tasks, such as image classification and object detection, because of its ability to learn hierarchical data representations [4]. |

| Digital Twins | A virtual representation of a physical object or system [17]. |

| Edge Computing | Enables data processing and the execution of actions in real-time [17]. |

| IoE—Internet of Everything | Integrating devices, people, and processes [4]. |

| IoT—Internet of Things | Solely considers the connection between devices [4]. |

| ML—Machine Learning | A subset of AI that employs algorithms to analyze data and learn from it [4]. |

| Sixth-generation wireless (6G) | Multi-layered, highly dynamic broadband [12]. |

Appendix A

| Section | Item | PRISMA-ScR Checklist Item | Reported on Page |

|---|---|---|---|

| Title | |||

| Title | 1 | Identify the report as a scoping review. | 1 |

| Absctract | |||

| Structured summary | 2 | Provide a structured summary that includes the following (as applicable): background, objectives, eligibility criteria, sources of evidence, charting methods, results, and conclusions that relate to the review questions and objectives. | 1 |

| Introduction | |||

| Rationale | 3 | Describe the rationale for the review in the context of what is already known. Explain why the review questions/objectives lend themselves to a scoping review approach. | 2–3 |

| Objectives | 4 | Provide an explicit statement of the questions and objectives being addressed with reference to their key elements (e.g., population or participants, concepts, and context) or other relevant key elements used to conceptualize the review questions and/or objectives. | 3 |

| Methods | |||

| Protocol and registration | 5 | Indicate whether a review protocol exists; state if and where it can be accessed (e.g., a web address); and, if available, provide registration information, including the registration number. | 3 |

| Eligibility criteria | 6 | Specify characteristics of the sources of evidence used as eligibility criteria (e.g., years considered, language, and publication status) and provide a rationale. | 3–4 |

| Information sources | 7 | Describe all information sources in the search (e.g., databases with dates of coverage and contact with authors to identify additional sources), as well as the date the most recent search was executed. | 4 |

| Search | 8 | Present the full electronic search strategy for at least 1 database, including any limits used, such that it could be repeated. | 5 |

| Selection of sources of evidence | 9 | State the process for selecting sources of evidence (i.e., screening and eligibility) included in the scoping review. | 5 |

| Data charting process | 10 | Describe the methods of charting data from the included sources of evidence (e.g., calibrated forms or forms that have been tested by the team before their use and whether data charting was performed independently or in duplicate) and any processes for obtaining and confirming data from investigators. | 5 |

| Data items | 11 | List and define all variables for which data were sought and any assumptions and simplifications made. | 5–6 |

| Critical appraisal of individual sources of evidence | 12 | If performed, provide a rationale for conducting a critical appraisal of included sources of evidence; describe the methods used and how this information was used in any data synthesis (if appropriate). | - |

| Synthesis of results | 13 | Describe the methods of handling and summarizing the data that were charted. | 5–6 |

| Results | |||

| Selection of sources of evidence | 14 | Give the number of sources of evidence screened, assessed for eligibility, and included in the review, with reasons for exclusions at each stage, ideally using a flow diagram. | 6 |

| Characteristics of sources of evidence | 15 | For each source of evidence, present characteristics for which data were charted and provide the citations. | 7–12 |

| Critical appraisal of sources of evidence | 16 | If performed, present data on critical appraisal of included sources of evidence (see item 12). | - |

| Results of individual sources of evidence | 17 | For each included source of evidence, present the relevant data that were charted that relate to the review questions and objectives. | 7–12 |

| Synthesis of results | 18 | Summarize and/or present the charting results as they relate to the review questions and objectives. | 6–12 |

| Discussion | |||

| Summary of evidence | 19 | Summarize the main results (including an overview of concepts, themes, and types of evidence available), link to the review questions and objectives, and consider the relevance to key groups. | 12–17 |

| Limitations | 20 | Discuss the limitations of the scoping review process. | 16–17 |

| Conclusions | 21 | Provide a general interpretation of the results with respect to the review questions and objectives, as well as potential implications and/or next steps. | 18 |

| Funding | |||

| Funding | 22 | Describe sources of funding for the included sources of evidence, as well as sources of funding for the scoping review. Describe the role of the funders of the scoping review. | 18 |

Appendix B

| Service Perspective | Reference, Year, and Country | Objectives | Results | Type of Industry | Stage |

|---|---|---|---|---|---|

| Cooking | Anami, Burkpalli (2009) [21] India | To propose a methodology for the identification and classification of boiled food grains based on the level of boiling using two color models, HSV and L*a*b*, in the Indian context. | It proved efficient in identifying the cooking of grains, which can assist in quality control and the development of equipment for the automation of industrial kitchens. | 4.0 | Test |

| Junge et al. (2020) [22] United Kingdom | To introduce the concept of food quality optimization and its challenges with an automated omelet cooking robotic system. | It demonstrated the potential for optimized preparation and the ability to personalize preparations for a group of individuals with distinct dietary preferences. | 5.0 | Test | |

| Ronzoni et al. (2021) [23] Italy | To provide a novel support–design framework for the cooperative robot system in labor-intensive manufacturing processes to aid layout and task scheduling design. | The proposed layout of a collaborative cobot for the end-of-line that is accessible, ergonomically convenient, and safe for workers. The test bench confirmed that it is a facilitating tool for the integration of human–robot technologies in current manufacturing systems under budgetary and workforce constraints. It improved performance, safety, and worker satisfaction. | 5.0 | Test | |

| Customer Services | Acosta et al. (2006) [24] Spain | To present a highly specialized autonomous robot. | The tested robot successfully classified the various types of utensils, proving efficient in collecting utensils from tables. | 4.0 | Test |

| Tan et al. (2011) [25] China | To integrate radio frequency identification (RFID), wireless local area network, database technologies, and a menu recommender to develop an intelligent e-restaurant for customer-centric service. | It allowed waiters to identify customers by RFID and recommend personalized menus with good practical potential for offering a customer-centric service. | 5.0 | Test | |

| Cheong et al. (2016) [26] Singapore | To develop a prototype of a mecanum-wheeled based mobile waiter robot for trial runs in a casual dining food outlet. | The robot performed well in serving customers, but improvements were suggested to enhance its agility and localization accuracy. | 4.0 | Test | |

| Li et al. (2018) [27] China | To conduct an exploratory study on an intelligent food choice method that recommends dishes by predicting an individual’s dietary preference, including ingredients, types of spices, price, etc. | AI using the MAR MTF (multi-attribute relation matrix tri-factorization—an algorithm that combines attributes), combining data on ingredients, seasonings, and prices, demonstrated significantly superior performance compared to traditional models for accuracy in predicting consumer food preferences, recommendations, and service personalization. | 5.0 | Test | |

| Roanes-Lozano et al. (2019) [28] Spain | To develop a prototype of a functional approach to personalized menu generation using set operations. | It showed speed in generating a menu instantly according to the customer’s dietary characteristics and the availability of ingredients in the restaurant. | 5.0 | Test | |

| Tallam, Joseph (2019) [29] India | To focus on the movement of a robot in identified locations based on the Bluetooth module. | It demonstrated operational efficiency by successfully connecting to mobile devices, recognizing table numbers, and delivering orders accurately; the use of infrared sensors aided navigation and obstacle prevention, ensuring efficient movement and reducing service time. | 4.0 | Test | |

| Chen et al. (2022) [30] China | To introduce the development of a service robot that is designed for food service in fast food restaurants with the innovative improvement of mapping, localization, and navigation. | Compared to well-trained waiters, the robots took longer to serve (1 min for waiters vs. 2 to 3 min for robots). Delivery interruptions occurred in 18% of attempts due to obstacles in the planned path; an additional 14% due to network interruption failures; and 9% due to dirt detection errors in their scanner sensor. Considering these issues along with the high acquisition and maintenance costs, there was a refusal to use robots by the majority of services. | 5.0 | Implemented | |

| Huang et al. (2022) [31] China | To propose a dish scheduling model for traditional Chinese restaurants based on hybrid multiple criteria decision-making (MCDM) algorithms and a double-layer queuing structure (DLQS). | The system was able to analyze and establish the relationship between classification rules and the characteristics of customer orders to choose the ideal schedule for the production of preparations and the delivery of dishes to customers. | 5.0 | Test | |

| Shimmura et al. (2023) [32] Japan | To introduce service robots to a restaurant company to reduce work hours and improve service quality. | The robot led to a reduction in working hours, increased productivity, and improved employee motivation and collaboration. There was no significant difference in overall sales, but there was a significant difference in sales per person/hour. | 5.0 | Implemented | |

| Sultana et al. (2024) [33] India | To propose a quick-witted, intelligent order-handling system utilizing the Internet of Things (IoT) to enhance the overall dining experience. | It was observed that an increase in customer return rates, greater order accuracy, and improved resource management led to increased profitability and operational efficiency and enhanced service and customer loyalty. | 5.0 | Implemented | |

| Management | Blasi (2018) [34] Jordan | To present a schedule for the food industry using a fuzzy-based control system and focus on determining the number of ovens and workers needed for a certain job in the food manufacturing system, especially the pizza production industry. | It reduced customer waiting times and operational costs, improving production efficiency and preventing resource waste; it enhanced the quality of customer service by ensuring on-time deliveries in the desired quantity. | 4.0 | Test |

| Sun et al. (2018) [35] China | To propose a loss prevention method for the catering enterprises based on a machine learning algorithm. | It efficiently identified normal and exceptional service events that could lead to financial losses impacting profitability. The continuous analysis of operational data allowed for adjustments in service practices, improved employee and billing management, and provided greater profitability. | 4.0 | Implemented | |

| Tufano et al. (2018) [36] Italy | To propose an original computer-based multidisciplinary decision support tool for the design and configuration of a CEKI. | The system aided multiprofessional decision-making simultaneously with the evaluation of performance indicators and scenario simulation analyses. It achieved a 3.7% increase in net profit and an energy saving of 12.9%, along with a reduction in customer waiting time and the total cost of production. | 5.0 | Test | |

| Tom, Anaraud (2021) [37] USA | To present a Menu Management Decision Support Model (MMDSM) that applies the Fuzzy Multicriteria Decision-Making (FMCDM) approach to deal with the inherent imprecision in input using qualitative linguistic input values and obtain reliable outputs with increased decision options. | The AI with the tested model successfully produced reliable recommendations for a restaurant manager to make strategic decisions based on automated menu analysis. | 5.0 | Test | |

| Gomez-Talal et al. (2024) [38] Spain | To address the global food waste problem in restaurants by analyzing customer sales information provided by restaurant tickets to gain valuable insights into directing sales of perishable products and optimizing product purchases according to customer demand. | Big Data (BD) and ML technologies have aided in analyzing restaurant customer orders to target sales of perishable goods and optimize product purchases according to demand, thereby benefiting restaurant procurement management. | 5.0 | Test | |

| Groene, Zakharov (2024) [39] Germany | To propose an approach to work with F&B owners in creating and introducing machine learning (ML)-based sales forecasting tailored to the unique local aspects of the business. | The automation of sales forecasting by the AI model has demonstrated superiority over other forecasting models and has freed managers from repetitive tasks. | 4.0 | Test | |

| Hao et al. (2024) [40] USA | To investigate the integration of Blockchain technology into the food supply chain within the restaurant industry. | It indicated that the adoption of Blockchain significantly enhances traceability and trust in the food supply chain, which can increase customer satisfaction through perceived improvements in food safety, quality, and freshness. It was observed that the effects vary depending on the type of restaurant (casual or fine dining) and its location (tourist or residential areas). | 5.0 | Test | |

| Quality control | Bhatia (2020) [41] India | To present an IoT-inspired framework to analyze restaurants and food hubs from a food quality perspective. | The correlation analysis conducted identified the best model and demonstrated that the use of a system with game theory and IoT technology can be a viable approach to improve food quality control in restaurants, providing real-time evaluation and statistically reliable results. | 5.0 | Implemented |

| Bhatia, Manocha (2022) [42] India | To propose a novel notion of smart restaurants for assessing food quality using game theory. | The proposed use of AI, Fog Computing, and Cloud Computing technologies was effective in evaluating food quality in real-time, outperforming other decision-making techniques in terms of temporal and classification effectiveness, statistical efficiency, and reliability. | 5.0 | Test | |

| Sustainability | Aytaç, Korçak (2021) [43] Tukey | To propose an edge-oriented IoT architecture for Quick Service Restaurants. | The system was efficient in detecting anomalies and discrepancies in the disposal of food waste, as well as in estimating production in advance. Furthermore, the system was capable of making decisions based on the collected data, which resulted in a reduction in food waste. | 5.0 | Test |

| Eriksson et al. (2021) [44] Sweden | To evaluate the potential of a forecasting model to predict guest attendance during the start and throughout the pandemic. | Conventional forecasting methods (total number of students or the last number of meals served or the average number of meals served) were simple to use and presented the best results in 7 dining halls. However, the use of AI with a neural network model demonstrated the best performance in 11 of the 21 dining halls studied, proving to be a more sustainable and resilient option for the public food service sector. | 5.0 | Test | |

| Faezirad et al. (2021) [45] Iran | To propose a new model based on machine learning to reduce the food waste generated at major universities that provide food subsidies. | The model collected student reservation data, the attendance or no-show rate at the dining hall, and meal times. The analysis of this data enabled better adjustment of meal production and a reduction in total cost, potentially reducing food waste (not measured). | 5.0 | Test | |

| Gull et al. (2021) [46] Pakistan | To introduce a new approach by utilizing some low-cost sensors. | The system presented an accuracy rate of 92.65% for alerts concerning food deterioration signals and for the assessment of food wastage. | 5.0 | Test | |

| Malefors et al. (2021) [47] Sweden | To examine conventional forecasting methods (last-value forecasting, moving-average models) and more complex models (prophet model, neural network model), and calculate associated margins for all models. | The comparative evaluation of multiple machine learning (ML) methods revealed that the random forest algorithm yielded more accurate predictions than a simple artificial neural network (ANN). Furthermore, a significant cost reduction was observed with the implementation of ML-based forecasting. | 4.0 | Test | |

| Principato et al. (2023) [48] Italy | To demonstrate that by using digital tools to monitor food provisioning and management within canteens, it is possible to achieve a more sustainable food service management within industrial companies and to reduce the overall quantity of food produced and environmental impacts of food preparation and consumption, thus achieving economic benefits. | The utilization of the Winnow Waste Monitor system resulted in a 30% reduction in meal production waste over two years, whereas plate waste exhibited a marginal decrease. The optimal AI model for demand forecasting and data management was identified; furthermore, a significant reduction in estimated greenhouse gas emissions from food production was achieved, from −18.3% in 2018 to −30.7% in 2019. | 5.0 | Implemented | |

| Rodrigues et al. (2024) [49] Brazil | To propose four models meant to help food catering services predict food demand accurately and thus avoid overproducing or underproducing. | The demand forecasting models based on machine learning exhibited greater efficacy in mitigating food waste compared to traditional forecasting models (referencing the previous day’s figures or empirical prediction); the former demonstrated the capacity to accurately predict next-day demand, thereby contributing to the reduction in waste and costs. | 4.0 | Test | |

| Sigala et al. (2025) [50] Germany | To assess the effectiveness of an intervention employing an AI-based, fully automatic waste-tracking system for food waste reduction in HORECA establishments. | The AI-driven food waste analysis system assessed the total waste across different sites, identifying the restaurant with the highest waste at 151.9 g per meal. A significant portion of this waste, ranging from 45% to 73%, was considered avoidable, primarily due to overproduction and food left on consumers’ plates. Vegetables and prepared foods made up the largest volume of waste. With the exception of one hotel that saw an increase in waste, the intervention effectively reduced food waste by 23% to 51%. This reduction was especially notable in areas of food preparation and overproduction, resulting in a decrease in food waste costs per meal of up to 39%. The system proved to be suitable for quantifying food waste related to operational practices and demand forecasting, while also raising staff awareness about waste and enabling the implementation of corrective actions. | 5.0 | Test | |

| Turker (2025) [51] Turkey | To tackle food waste by analyzing daily campus data with machine learning and revealing strategic insights related to food variety and sustainability. | The analyses identified preferred food items, predicted meal quantities, and highlighted preferences across diverse consumption areas, utilizing high-performing models. | 5.0 | Implemented |

References

- FAO—Food and Agriculture Organization. Enhancing the Operational of Local and Traditional Food Markets in the Context of Transition to Sustainable Agrofood Systems; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- Campos, F.M.; Prado, S.D.; Kraemer, F.B.; Ferreira, F.R.; Carvalho, M.C.D.V.S. Scenario of Research on Food Service in Brazil. Rev. Nutr. 2017, 30, 1–12. [Google Scholar] [CrossRef]

- Pelloso, I.; Pelloso, A. Food Service One, 2nd ed.; Literare Books International: São Paulo, SP, Brazil, 2023. [Google Scholar]

- Hassoun, A.; Jagtap, S.; Trollman, H.; Garcia-Garcia, G.; Duong, L.N.K.; Saxena, P.; Bouzembrak, Y.; Treiblmaier, H.; Para-López, C.; Carmona-Torres, C.; et al. From Food Industry 4.0 to Food Industry 5.0: Identifying Technological Enablers and Potential Future Applications in the Food Sector. Comp. Rev. Food Sci. Food Safe 2024, 23, e370040. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Lei, Z.; Shi, J.; Luo, Z.; Cheng, M.; Wan, J. Intelligent Manufacturing from the Perspective of Industry 5.0: Application Review and Prospects. IEEE Access 2024, 12, 167436–167451. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-Working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Sindhwani, R.; Afridi, S.; Kumar, A.; Banaitis, A.; Luthra, S.; Singh, P.L. Can Industry 5.0 Revolutionize the Wave of Resilience and Social Value Creation? A Multi-Criteria Framework to Analyze Enablers. Technol. Soc. 2022, 68, 101887. [Google Scholar] [CrossRef]

- Khan, M.; Haleem, A.; Javaid, M. Changes and Improvements in Industry 5.0: A Strategic Approach to Overcome the Challenges of Industry 4.0. Green Technol. Sustain. 2023, 1, 100020. [Google Scholar] [CrossRef]

- Xiang, W.; Yu, K.; Han, F.; Fang, L.; He, D.; Han, Q.-L. Advanced Manufacturing in Industry 5.0: A Survey of Key Enabling Technologies and Future Trends. IEEE Trans. Ind. Inf. 2024, 20, 1055–1068. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards A Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0: Analysis and identification of current research trends. ASI 2022, 5, 27. [Google Scholar] [CrossRef]

- Barata, J.; Kayser, I. Industry 5.0—Past, Present, and Near Future. Procedia Comput. Sci. 2023, 219, 778–788. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; B, P.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A Survey on Enabling Technologies and Potential Applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Pereira, R.; Santos, N. Indústria 5.0: Reflexões Sobre Uma Nova Abordagem Paradigmática para a Indústria. In ENANPAD 2022; Associação Nacional de Pós-Graduação e Pesquisa em Administração: Maringá, Brazil, 2022; pp. 2177–2576. [Google Scholar]

- Islam, M.T.; Sepanloo, K.; Woo, S.; Woo, S.H.; Son, Y.-J. A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration. Machines 2025, 13, 267. [Google Scholar] [CrossRef]

- Singh, K.A.; Patra, F.; Ghosh, T.; Mahnot, N.K.; Dutta, H.; Duary, R.K. Advancing Food Systems with Industry 5.0: A Systematic Review of Smart Technologies, Sustainability, and Resource Optimization. Sustain. Futures 2025, 9, 100694. [Google Scholar] [CrossRef]

- Guruswamy, S.; Pojić, M.; Subramanian, J.; Mastilović, J.; Sarang, S.; Subbanagounder, A.; Stojanović, G.; Jeoti, V. Toward Better Food Security Using Concepts from Industry 5.0. Sensors 2022, 22, 8377. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Souza, M.T.D.; Silva, M.D.D.; Carvalho, R.D. Integrative Review: What Is It? How to Do It? Einstein 2010, 8, 102–106. [Google Scholar] [CrossRef] [PubMed]

- Anami, B.S.; Burkpalli, V.C. Color Based Identification and Classification of Boiled Food Grain Images. Int. J. Food Eng. 2009, 5, 1–19. [Google Scholar] [CrossRef]

- Junge, K.; Hughes, J.; Thuruthel, T.G.; Iida, F. Improving Robotic Cooking Using Batch Bayesian Optimization. IEEE Robot. Autom. Lett. 2020, 5, 760–765. [Google Scholar] [CrossRef]

- Ronzoni, M.; Accorsi, R.; Botti, L.; Manzini, R. A Support-Design Framework for Cooperative Robots Systems in Labor-Intensive Manufacturing Processes. J. Manuf. Syst. 2021, 61, 646–657. [Google Scholar] [CrossRef]

- Acosta, L.; González, E.J.; Rodríguez, J.N.; Hamilton, A.F.; Méndez, J.A.; Hernéndez, S.; Sigut, M.; Marichal, G.N. Design and Implementation of a Service Robot for a Restaurant. Int. J. Robot. Autom. 2006, 21, 273. [Google Scholar] [CrossRef]

- Tan, T.-H.; Chang, C.-S.; Chen, Y.-F. Developing an Intelligent E-Restaurant with a Menu Recommender for Customer-Centric Service. IEEE Trans. Syst. Man Cybern. C 2012, 42, 775–787. [Google Scholar] [CrossRef]

- Cheong, A.; Lau, M.; Foo, E.; Hedley, J.; Bo, J.W. Development of a Robotic Waiter System. IFAC-PapersOnLine 2016, 49, 681–686. [Google Scholar] [CrossRef]

- Li, X.; Jia, W.; Yang, Z.; Li, Y.; Yuan, D.; Zhang, H.; Sun, M. Application of Intelligent Recommendation Techniques for Consumers’ Food Choices in Restaurants. Front. Psychiatry 2018, 9, 415. [Google Scholar] [CrossRef]

- Roanes-Lozano, E.; Galán-García, J.L.; Aguilera-Venegas, G. A Prototype of a Functional Approach to Personalized Menus Generation Using Set Operations. Adv. Comput. Math. 2019, 45, 1881–1895. [Google Scholar] [CrossRef]

- Tallam, V.G.; Joseph, C. Counterflow Robot for Restaurants. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1371–1373. [Google Scholar] [CrossRef]

- Chen, C.; Lin, C.; Lai, C. Non-Contact Service Robot Development in Fast-Food Restaurants. IEEE Access 2022, 10, 31466–31479. [Google Scholar] [CrossRef]

- Huang, F.; Chuang, Y.-C.; Zhang, Y.-H.; Lu, B.; Xu, H.-L. A Dish Scheduling Model for Traditional Chinese Restaurants Based on Hybrid Multiple Criteria Decision-Making Algorithms and a Double-Layer Queuing Structure. Math. Probl. Eng. 2022, 2022, 4818158. [Google Scholar] [CrossRef]

- Shimmura, T.; Ichikari, R.; Okuma, T.; Oura, S. Catering Robot Introduction to a Restaurant Service to Improve Labor Productivity. J. Jpn. Ind. Manag. Assoc. 2024, 74, 167–176. [Google Scholar] [CrossRef]

- Sultana, A.; Billah, M.M.; Ahmed, M.M.; Aftab, R.S.; Kaosar, M.; Uddin, M.S. Applications of IoT-Enabled Smart Model: A Model For Enhancing Food Service Operation in Developing Countries. J. Appl. Eng. Technol. Sci. 2024, 5, 1123–1141. [Google Scholar] [CrossRef]

- Blasi, A. Scheduling Food Industry System Using Fuzzy Logic. J. Theor. Appl. Inf. Technol. 2025, 96, 6463–6473. [Google Scholar]

- Sun, Q.; Qiao, Y.; Zhou, H.; Wang, J.; Wang, N. A Loss Prevention Methodology for Catering Industry Based on Operation Data Analysis. Clust. Comput. 2018, 21, 923–931. [Google Scholar] [CrossRef]

- Tufano, A.; Accorsi, R.; Garbellini, F.; Manzini, R. Plant Design and Control in Food Service Industry. A Multi-Disciplinary Decision-Support System. Comput. Ind. 2018, 103, 72–85. [Google Scholar] [CrossRef]

- Tom, M.; Annaraud, K. Fuzzy Based Intelligent Decision Support Model for Restaurant Menu Management. Intell. Decis. Technol. 2021, 15, 387–396. [Google Scholar] [CrossRef]

- Gómez-Talal, I.; González-Serrano, L.; Rojo-Álvarez, J.L.; Talón-Ballestero, P. Avoiding Food Waste from Restaurant Tickets: A Big Data Management Tool. J. Hosp. Tour. Technol. 2024, 15, 232–253. [Google Scholar] [CrossRef]

- Groene, N.; Zakharov, S. Introduction of AI-Based Sales Forecasting: How to Drive Digital Transformation in Food and Beverage Outlets. Discov. Artif. Intell. 2024, 4, 1. [Google Scholar] [CrossRef]

- Hao, F.; Guo, Y.; Zhang, C.; Chon, K.K.S.K.-S. Blockchain=better Food? The Adoption of Blockchain Technology in Food Supply Chain. Int. J. Contemp. Hosp. Manag. 2024, 36, 3340–3360. [Google Scholar] [CrossRef]

- Bhatia, M. Game Theory Based Framework of Smart Food Quality Assessment. Trans. Emerg. Telecommun. Technol. 2020, 31, e3926. [Google Scholar] [CrossRef]

- Bhatia, M.; Manocha, A. Cognitive Framework of Food Quality Assessment in IoT-Inspired Smart Restaurants. IEEE Internet Things J. 2022, 9, 6350–6358. [Google Scholar] [CrossRef]

- Aytaç, K.; Korçak, Ö. IoT Based Intelligence for Proactive Waste Management in Quick Service Restaurants. J. Clean. Prod. 2021, 284, 125401. [Google Scholar] [CrossRef]

- Eriksson, M.; Malefors, C.; Secondi, L.; Marchetti, S. Food Waste Reduction and Economic Savings in Times of Crisis: The Potential of Machine Learning Methods to Plan Guest Attendance in Swedish Public Catering during the Covid-19 Pandemic. Socio-Econ. Plan. Sci. 2022, 82, 101041. [Google Scholar] [CrossRef]

- Faezirad, M.; Pooya, A.; Naji-Azimi, Z.; Amir Haeri, M. Preventing Food Waste in Subsidy-Based University Dining Systems: An Artificial Neural Network-Aided Model under Uncertainty. Waste Manag. Res. 2021, 39, 1027–1038. [Google Scholar] [CrossRef] [PubMed]

- Gull, S.; Bajwa, I.S.; Anwar, W.; Rashid, R. Smart eNose Food Waste Management System. J. Sens. 2021, 2021, 9931228. [Google Scholar] [CrossRef]

- Malefors, C.; Strid, I.; Hansson, P.-A.; Eriksson, M. Potential for Using Guest Attendance Forecasting in Swedish Public Catering to Reduce Overcatering. Sustain. Prod. Consum. 2021, 25, 162–172. [Google Scholar] [CrossRef]

- Principato, L.; Marchetti, S.; Barbanera, M.; Ruini, L.; Capoccia, L.; Comis, C.; Secondi, L. Introducing Digital Tools for Sustainable Food Supply Management: Tackling Food Loss and Waste in Industrial Canteens. J. Ind. Ecol. 2023, 27, 1060–1075. [Google Scholar] [CrossRef]

- Rodrigues, M.; Miguéis, V.; Freitas, S.; Machado, T. Machine Learning Models for Short-Term Demand Forecasting in Food Catering Services: A Solution to Reduce Food Waste. J. Clean. Prod. 2024, 435, 140265. [Google Scholar] [CrossRef]

- Sigala, E.G.; Gerwin, P.; Chroni, C.; Abeliotis, K.; Strotmann, C.; Lasaridi, K. Reducing Food Waste in the HORECA Sector Using AI-Based Waste-Tracking Devices. Waste Manag. 2025, 198, 77–86. [Google Scholar] [CrossRef] [PubMed]

- Turker, G.F. Reducing Food Waste in Campus Dining: A Data-Driven Approach to Demand Prediction and Sustainability. Sustainability 2025, 17, 379. [Google Scholar] [CrossRef]

- World Economic Forum. Future of Jobs Report 2025. 2025. Available online: https://reports.weforum.org/docs/WEF_Future_of_Jobs_Report_2025.pdf (accessed on 8 February 2025).

- Ansari, A.M.; Khan, M.R. Industry 5.0, Prospects and Challenges: An Indian Perspective. Int. J. Res. Manage. 2025, 7, 205–215. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y. Society 5.0 versus Industry 5.0: An Examination of Industrialization Models in Driving Sustainable Development from a Normative Stakeholder Theory Perspective. Sustain. Dev. 2023, 31, 3786–3795. [Google Scholar] [CrossRef]

- ABIA—Associação Brasileira da Indústria de Alimentos. Relatório Anual da Indústria de Alimentos. [S. l.]: ABIA 2024. Available online: https://www.abia.org.br (accessed on 28 July 2025).

- Digalwar, A.K.; Singh, S.R.; Pandey, R.; Sharma, A. In Transfer, Diffusion and Adoption of Next-Generation Digital Technologies; Sharma, S.K., Dwivedi, Y.K., Metri, B., Lal, B., Elbanna, A., Eds.; Industry 4.0 Implementation: Evidence from Indian Industries. IFIP Advances in Information and Communication Technology; Springer Nature: Cham, Switzerland, 2024; Volume 699, pp. 23–34. [Google Scholar] [CrossRef]

- Poldi, A. Inovação, Ciência e Regulação: A Tríade Que Impulsiona o Futuro da Alimentação. Forbis Brasil. 2025. Available online: https://forbes.com.br/forbesagro/2025/11/forbes-mulher-agro-inovacao-ciencia-e-regulacao-a-triade-que-impulsiona-o-futuro-da-alimentacao/ (accessed on 7 November 2025).

- Batistela Dos Santos, E.; Da Costa Maynard, D.; Zandonadi, R.P.; Raposo, A.; Assunção Botelho, R.B. Sustainability Recommendations and Practices in School Feeding: A Systematic Review. Komp Nutr. Diet. 2022, 2, 83–102. [Google Scholar] [CrossRef]

- Galunion—Consultoria em Foodservice. Pesquisa Alimentação Hoje: A Visão do Consumidor. Set.2022, 6. Available online: https://galunion.com.br/links-galunion/materiais/Pesquisa_Consumidor_GALUNION_6a_edicao.pdf (accessed on 25 May 2025).

- Dogru, T.; Line, N.; Mody, M.; Hanks, L.; Abbott, J.; Acikgoz, F.; Assaf, A.; Bakir, S.; Berbekova, A.; Bilgihan, A.; et al. Generative Artificial Intelligence in the Hospitality and Tourism Industry: Developing a Framework for Future Research. J. Hosp. Tour. Res. 2025, 49, 235–253. [Google Scholar] [CrossRef]

- IFR—International Federation of Robotics. World Robotics 2024 Report. Frankfurt: International Federation of Robotics. Available online: https://ifr.org/ifr-press-releases/news/record-of-4-million-robots-working-in-factories-worldwide (accessed on 28 July 2025).

- Anumudu, C.K.; Augustine, J.A.; Uhegwu, C.C.; Uche, J.N.; Ugwoegbu, M.O.; Shodeko, O.R.; Onyeaka, H. Smart Kitchens of the Future: Technology’s Role in Food Safety, Hygiene, and Culinary Innovation. Standards 2025, 5, 21. [Google Scholar] [CrossRef]

- Barykin, S.Y.; Kapustina, I.V.; Kalinina, O.V.; Dubolazov, V.A.; Esquivel, C.A.N.; Alyarovna, N.E.; Sharapaev, P. The Sharing Economy and Digital Logistics in Retail Chains: Opportunities and Threats. Acad. Strateg. Manag. J. 2021, 20, 1–14. [Google Scholar]

- Ellahi, R.M.; Wood, L.C.; Bekhit, A.E.-D.A. Blockchain-Based Frameworks for Food Traceability: A Systematic Review. Foods 2023, 12, 3026. [Google Scholar] [CrossRef] [PubMed]

| Service Perspective | Reference | Technology | Objective |

|---|---|---|---|

| Cooking | Anami, Burkpalli (2009) [21] | AI | Monitor cooking |

| Junge et al. (2020) [22] | Cobot | Automation cooking | |

| Ronzoni et al. (2021) [23] | Cobot | Automation processes cooking | |

| Customer Services | Acosta et al. (2006) [24] | Robot with AI | Collect utensils from tables |

| Tan et al. (2011) [25] | AI | Identify customers and recommend personalized menus | |

| Cheong et al. (2016) [26] | Robot with AI | Assist and serve customers | |

| Li et al. (2018) [27] | AI | Predict consumer food preferences, recommendations, and service personalization | |

| Roanes-Lozano et al. (2019) [28] | AI | Personalize menus to the customer’s dietary characteristics and the availability of ingredients in the restaurant | |

| Tallam, Joseph (2019) [29] | Robot with AI | Assist and serve customers | |

| Chen et al. (2022) [30] | Robot with AI | Serve customers | |

| Huang et al. (2022) [31] | AI | Choose the ideal schedule for the production and delivery of dishes to customers | |

| Shimmura et al. (2023) [32] | Robot with AI | Serve customers | |

| Sultana et al. (2024) [33] | IoT and QR code | Fulfilling customer orders and monitoring the traceability of the production chain | |

| Management | Blasi (2018) [34] | AI | Manage production schedule |

| Sun et al. (2018) [35] | ML | Loss prevention | |

| Tufano et al. (2018) [36] | BD * and ML * | Sales analysis, inventory, and purchasing management | |

| Tom, Annaraud (2021) [37] | AI | Menu engineering support | |

| Gómez-Talal et al. (2024) [38] | BD and ML | Analyze customer sales | |

| Groene, Zakharov (2024) [39] | AI | Sales forecasting | |

| Hao et al. (2024) [40] | Blockchain | Food supply chain | |

| Quality Control | Bhatia (2020) [41] | IoT | Food quality control |

| Bhatia, Manocha (2022) [42] | AI, Fog Computing, and Cloud Computing | Evaluation of food quality in real time | |

| Sustainability | Aytaç, Korçak (2021) [43] | AI, ML and IoT | Production quantity planning and monitoring food waste to reduce its generation |

| Eriksson et al. (2021) [44] | AI and ML | Predict guest attendance to reduce the food waste generated | |

| Faezirad et al. (2021) [45] | IoT | Predict guest attendance to reduce the food waste generated | |

| Gull et al. (2021) [46] | AI and ML | Monitor food deterioration signals for quality control and reduce the waste generated | |

| alefors et al. (2021) [47] | AI and ML | Predict guest attendance to reduce the food waste generated | |

| Principato et al. (2023) [48] | AI | Reduce the food waste generated | |

| Rodrigues et al. (2024) [49] | AI and ML | Predict guest attendance to reduce the food waste generated | |

| Sigala et al. (2025) [50] | AI | Food waste analysis system to reduce the waste generated | |

| Turker (2025) [51] | AI and ML | Predict guest attendance to reduce the food waste generated |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantarelli da Silva, R.; Bacharini Lima, L.; Batistela dos Santos, E.; Akutsu, R.d.C. The Use of Industry 4.0 and 5.0 Technologies in the Transformation of Food Services: An Integrative Review. Foods 2025, 14, 4320. https://doi.org/10.3390/foods14244320

Cantarelli da Silva R, Bacharini Lima L, Batistela dos Santos E, Akutsu RdC. The Use of Industry 4.0 and 5.0 Technologies in the Transformation of Food Services: An Integrative Review. Foods. 2025; 14(24):4320. https://doi.org/10.3390/foods14244320

Chicago/Turabian StyleCantarelli da Silva, Regiana, Lívia Bacharini Lima, Emanuele Batistela dos Santos, and Rita de Cássia Akutsu. 2025. "The Use of Industry 4.0 and 5.0 Technologies in the Transformation of Food Services: An Integrative Review" Foods 14, no. 24: 4320. https://doi.org/10.3390/foods14244320

APA StyleCantarelli da Silva, R., Bacharini Lima, L., Batistela dos Santos, E., & Akutsu, R. d. C. (2025). The Use of Industry 4.0 and 5.0 Technologies in the Transformation of Food Services: An Integrative Review. Foods, 14(24), 4320. https://doi.org/10.3390/foods14244320