1. Introduction

Maple syrup is a natural sweetener derived from boiling and concentrating the sap of maple trees, primarily

Acer saccharum (sugar maple) and

Acer rubrum (red maple) [

1,

2]. Its composition consists mainly of sucrose (about 96%), with trace amounts of hexoses and minerals. Maple syrup has evolved from a local sweetener to a globally recognized product with significant economic impact [

3,

4,

5,

6]. In 2022, Canada’s maple syrup industry provided 12,582 full-time jobs, contributed C

$1.13 billion to the GDP, and generated C

$235 million in taxes [

7]. The United States’ maple syrup crop value generally ranges from

$150 million to

$210 million annually. It remains a crucial economic sector in the Northeastern states, supporting rural jobs and income through direct, indirect, and induced contributions [

8,

9,

10,

11,

12]. Canada remains the leading producer, accounting for roughly 73% of global output, followed by the United States, with Vermont, New York, and Maine as the primary producers [

13]. Key importers include the United States, Germany, the United Kingdom, Japan, and Australia, reflecting the product’s growing international reach and branding as a natural, sustainable sweetener [

13].

Quality standards for maple syrup generally align with the principles defined by the United States Department of Agriculture (USDA) and the Canadian Food Inspection Agency (CFIA). The USDA standards for Grade A pure maple syrup is a voluntary classification system that requires syrup to have a density between 66.0 and 68.9 °Brix, a characteristic maple flavor free of off-flavors, uniform color, and clarity [

14]. Many U.S. States have their own regulations for pure maple syrup. Some states, like Vermont, have regulations which are mandatory for syrup sold in the retail marketplace. Additionally, Vermont and New Hampshire have adopted a higher minimum density of 66.9 °Brix [

15]. This density standard applies to all syrup sold directly to consumers in Vermont regardless ofwhere it was produced.

Syrup is classified into four color grades: Golden Delicate > 75.0% light transmittance (Tc), Amber Rich 50.0–74.9%Tc, Dark Robust 25.0–49.9%Tc, and Very Dark Strong < 25.0% Tc, based on light transmittance at 560 nm [

2,

14,

16,

17]. These grading parameters are crucial for consumer perception, trade, and regulatory compliance. The sensory and physicochemical quality of maple syrup can deteriorate through several mechanisms. Pre-processing and processing factors such as microbial growth in raw sap, prolonged storage before boiling, variations in processing temperature, and pH influence the development of color and flavor [

18,

19,

20,

21]. Excessive heating or oxidation during packaging and storage can cause the syrup to darken. Contamination at any stage of sap harvest or processing can lead to the formation of undesirable flavors [

22]. Inadequate filtration or poor equipment sanitation can also result in turbidity, sediment formation (“sugar sand”), or microbial contamination [

23,

24]. Maintaining the correct density is essential as u syrup below the density standard may ferment, while syrup above the density standard can lead to crystallization and color degradation [

25,

26,

27].

Compliance with quality standards is a continuing challenge for this high-value specialty sweetener. Recent reports from North American regulatory agencies have identified inconsistencies in maple syrup grading, particularly concerning color and flavor [

28,

29]. In Canada, out-of-compliance syrup inventories rose from 11% in 2010 to 21% in 2018, reflecting the growing difficulty of maintaining quality during high-volume production and variable environmental conditions [

30]. Given the globalization of the syrup trade and the rise in online marketing, assessing product compliance is increasingly relevant to both consumer protection and market integrity. Despite extensive research on maple syrup processing and composition [

31,

32,

33], there remains a limited understanding of how retail maple syrup, especially products sold online, aligns with official grading standards. This study, therefore, assesses the compliance of consumer-purchased pure maple syrup with established quality standards, focusing on color, clarity, density, and flavor. The primary research questions are:

Which type of compliance infractions are most or least common in the marketplace?

How likely is a consumer to receive an out-of-compliance maple syrup product from an online purchase?

Are compliance levels observed at the same or different rates between two different color grades of syrup within the same year?

Are compliance trends similar between different years using the same online product search terms?

What quality standards, education, and best practices can improve syrup quality in the marketplace?

The study hypothesis is that the overall color compliance level in a specific year will differ between two syrup color grades. Secondly, any density compliance infractions are more likely to occur at lower densities than at higher densities. The null hypothesis is that no difference is detected.

4. Discussion

4.1. Clarity Standards

The high level of compliance with clarity standards observed in the tests shows that clarity, a highly valued characteristic, was almost entirely maintained by producers, especially with Golden samples. This compliance demonstrates strong, stable quality, with only minor fluctuations. The light color of the Golden samples makes problems easier to detect visually than the Dark samples. This indicates that concerns remain about the detectability of clarity problems in Dark and Very Dark syrup samples. The dark color of the Dark grade can hinder producers from detecting cloudiness. In contrast, the Golden grade’s light appearance (high light transmittance) likely facilitated the identification and removal of cloudiness before packaging, thereby reducing the number of out-of-compliance products sold online. Daily processing variations, such as filter conditions and rinse water volume, can also affect syrup clarity [

22].

Filtration is the critical step in maple syrup production that removes sediments and sugar sand while maintaining syrup quality and clarity. Producers have relatively few filtration options, typically using cloth and paper filters for smaller operations, or filter presses with diatomaceous earth for larger producers. Producers achieve a relatively high rate of compliance with clarity expectations, indicating the robustness of existing practices. The statistical analysis of clarity data from 2021, 2023, and 2024 showed no significant differences between Golden and Dark syrup in any year (p = 0.914, 0.100, and 0.643, respectively). Although the 2023 comparison approached significance (p = 0.100), it did not meet the 0.05 threshold. Similarly, when evaluated across years, neither Golden (p = 0.789) nor Dark syrup (p = 0.566) exhibited statistically significant variation in clarity. The application of Fisher’s Exact Test to Golden syrup, given low cell counts, reinforces the need for cautious interpretation in some cases. Nonetheless, these results affirm that clarity, a key visual quality parameter, remains stable across syrup grades and production years, reflecting consistent production practices and effective quality control.

4.2. Color Standards

Statistical analysis revealed significant differences in color compliance between Golden and Dark maple syrup within each testing year. Golden syrup consistently showed the lowest compliance rates, with the most pronounced deviations occurring in 2021. These early results should be interpreted cautiously, as COVID-19-related laboratory access restrictions caused prolonged delays between sample acquisition and testing. During this period, samples were stored under mixed conditions, room temperature and refrigeration, which likely accelerated oxidative darkening, especially in HDPE plastic containers with higher oxygen permeability. This explains much of the reduced color-compliance rate observed in

Figure 7.

The mechanisms underlying such darkening are well documented. Morselli and Whalen (1989) noted that syrup stored in bulk or retail containers can darken due to (1) blending syrups with differing invert sugar contents, (2) oxygen-driven oxidation within partially permeable containers, and (3) the inherent instability of reverse-osmosis–concentrated sap [

34]. These processes, combined with extended storage during the pandemic, likely contributed to the elevated darkening observed in 2021. The economic implications of storage-related darkening are substantial, as a shift in hue that no longer fits the assigned grade can diminish market value and consumer trust [

34]. Bosley et al. (2020) [

35] reported that syrup stored in uncoated plastic jugs darkened at approximately 2.6% LT per month, whereas syrup stored in coated jugs darkened at approximately 0.8% LT per month. Reheating syrup prior to packing also lowers LT through oxidation reactions [

35]. Unfortunately, coated containers are no longer available to producers. The significant overall

p-value across years (6.57 × 10

−8) further confirms that grade-based differences are systematic rather than random.

In 2023, Golden and Dark syrups showed a significant difference in color compliance (p = 4.19 × 10−7), reflecting considerable variation in producers’ ability to achieve the correct color grade across categories. Just like in 2021, Dark syrup had higher compliance than Golden syrup, indicating that Golden syrup was more prone to deviations in light-transmittance standards. This pattern persisted in 2024, with a continued significant difference in compliance between Golden and Dark syrups (p = 4.33 × 10−4). Although overall compliance improved from 2021, Golden syrup still lagged behind Dark syrup in meeting USDA color standards, confirming that Golden syrup remains the more challenging grade for producers to produce and market within the required specifications over the years. Therefore, due to these statistically significant differences in color compliance, consumers buying Golden syrup are much more likely to receive a product that does not meet the USDA color standard than those purchasing Dark syrup.

The observed pattern of color non-compliance, particularly the darkening of Golden syrup, is consistent with earlier studies showing that syrup darkens during long-term storage [

36] or when stored in oxygen-permeable packaging [

34]. Sendak (1982) [

37] demonstrated that HDPE allows far greater oxygen and CO

2 transmission than glass, driving color development and pH change. However, CO

2 permeability is higher, and atmospheric oxygen is the dominant cause of oxidative darkening [

37]. Field studies such as those reported by Walters and Yawney (1978) showed darker, more variable syrup from sap collected through improperly installed plastic tubing [

38], and Perkins et al. (2020) showed that uncoated containers darkened syrup more than three times faster than coated ones [

35]. Long-term storage trials similarly found grade loss and flavor decline in warm conditions and significantly greater darkening in plastic than in glass or metal, primarily when temperature interacted with container type [

39,

40].

Although improvements in sap handling have reduced microbial-related darkening, Morselli and Whalen (1991) found that aseptic tapping consistently produced lighter syrup [

21]. The persistent non-compliance of Golden syrup in this study suggests that current issues arise primarily from post-production handling, packaging (oxidation), or grading practices rather than sap collection. The 2024 results confirm that Golden syrup again had significantly higher color non-compliance than Dark syrup (

p = 4.33 × 10

−4). These findings underscore the need for improved quality assurance in grading accuracy, packaging selection, and storage management, particularly for the lightest syrup grade.

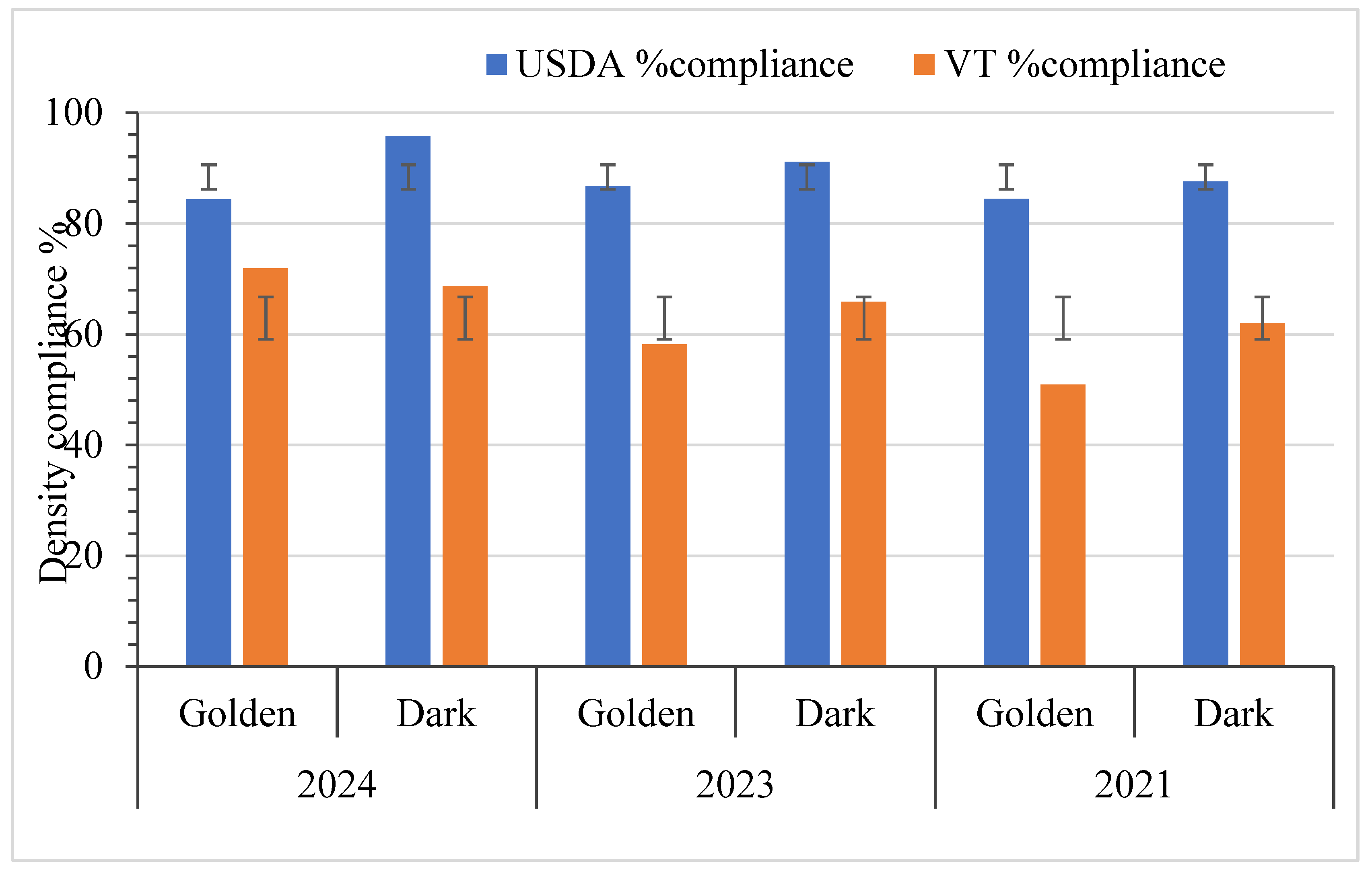

4.3. Density Standards

Ensuring that the density remains within an acceptable range is crucial for compliance with Grade A standards and for avoiding any quality issues arising from density that is too low (fermentation) or too high (crystallization). The density tests indicated that most results falling out of compliance were at the lower end of the density spectrum, specifically at 66.0 °Brix and 66.9 °Brix for the USDA and Vermont standards, respectively. Syrup below the lower density spectrum can support microbial growth and associated food safety risks, as well as result in a viscosity that appears “watery” to consumers. Henderson (2009) reported that Canadian producers packaged syrup below the legal density, suggesting that syrup with a density below 66 °Brix poses legal, quality, economic, and safety risks, including fermentation or molding, which can lead to additional reprocessing costs, unsellable products, customer loss, and recalls [

41]. Isselhardt and Cannella (2024) [

15] reported that significant compliance issues, such as failing to achieve a 66.0 °Brix concentration, may arise from inaccurate syrup temperature measurements during production or packaging. In a situation when syrup temperature is lower than the producer believes it to be, the hydrometer will float at a higher point and appear to the producer to be denser than it truly is, which would result in syrup being removed from the boiling evaporator prematurely [

15].

Statistical analysis showed no significant differences in density compliance between Golden and Dark syrup in 2021 or 2024. Within each grade, year-to-year variations were also not significant (Golden: p = 0.875; Dark: p = 0.271), suggesting stable density control practices across time and syrup types. This consistency reflects the practical application of standardized boiling and evaporation methods. These results also suggest that producers are not intentionally attempting to sell more syrup as Golden Delicate even if it does not meet the color grade. Bulk syrup buyers pay a higher price for Golden Delicate syrup compared to the darker grades, but such a price premium is not consistently observed for retail syrup sales. However, marginally lower compliance observed in specific Golden syrup batches, for example, 18 out of 116 in 2021, warrants ongoing monitoring due to the stricter consumer expectations and sensory sensitivity associated with this grade. In 2024, no statistically significant difference was found between Golden and Dark syrups in density compliance, indicating that syrup grade does not meaningfully affect the likelihood of consumers receiving an in- or out-of-compliance product. Of the samples determined to be out of grade for density, it was far more likely that they were below the standard than above it. This suggests an issue with producers accurately measuring syrup temperature, leading to syrup cooling enough to affect hydrometer readings.

4.4. Flavor Standards

Flavor evaluation showed that Golden syrup met compliance standards at very high rates, with some samples achieving complete compliance. Dark syrup, by contrast, displayed lower compliance, suggesting persistent challenges in identifying and managing flavor defects in this grade. The difference may reflect the greater ability of darker syrup to mask off-flavors, or an issue of producer education as to the sensory qualities of acceptable Dark syrup versus Dark syrup with a distinct defect. The flavor quality of maple syrup is influenced by factors such as tree species, sap chemistry, collection timing, and processing methods. The flavor of maple syrup is also affected during evaporation through complex reactions involving sugars, amino acids, minerals, and other precursors. Clean processing equipment and strict sanitation remain critical, and small residues in sap lines or tanks can alter the flavor profile during boiling. However, defining what constitutes a “good” maple flavor is challenging because no formal standards exist, and the wording of syrup quality standards lacks specificity. Producers often rely on personal experience to judge the acceptability of flavor, and their exposure to syrup from other operations varies widely. This variability likely influences the consistency and accuracy of flavor grading, particularly for more complex syrups produced late in the season.

Fisher’s exact test was used to assess flavor compliance due to the small sample sizes in 2024. Statistically significant differences were observed between Golden and Dark syrups in each year (2021: p = 0.003; 2023: p = 0.015; 2024: p = 0.001), with Dark syrup showing consistently lower compliance rates. For example, in 2021, 21% of Dark samples had flavors that failed to meet the minimum Grade A flavor standards, compared to only 7% of Golden samples. These findings suggest a strong correlation between syrup grade and flavor quality. However, within-grade comparisons across years showed no significant difference (Golden: p = 0.246; Dark: p = 0.557), indicating stability in flavor compliance within each syrup type despite seasonal variability. This suggests that consumers are likely to consistently receive appropriate, compliant flavors when purchasing Golden syrup products, but may experience more off-flavors when purchasing Dark-Robust syrup. Nevertheless, the persistently lower performance of Dark syrup highlights opportunities for improvement, particularly in handling, boiling, and filtration practices during late-season production. The most frequent market infraction observed was low compliance with color standards, often due to darkening after packaging, but flavor remains a critical quality factor for consumer satisfaction. To improve overall syrup quality, producers would benefit from targeted education on grading standards, quality control tools, and best practices in filtration, evaporation, and storage. Intake inspection and consumer awareness can further reinforce adherence across the supply chain. The significant difference in 2024 flavor compliance between Golden and Dark syrup (p = 0.001) supports the hypothesis that syrup grade impacts a consumer’s likelihood of receiving a compliant product. The null hypothesis is therefore rejected. This result may also reflect the complexity of assessing Dark syrup, as certain flavor variations can be more challenging to distinguish from off-flavors. Providing additional training and resources could help producers develop greater consistency in evaluating what is and is not acceptable flavor within the Dark grade.

4.5. Best Practices for Maple Compliance Testing

Managing environmental and procedural factors during production and packaging is crucial for reducing maple syrup darkening. Limiting excessive headspace in containers helps minimize oxidation and preserve the syrup’s color. Assigning a darker grade as you approach a color threshold can help prevent color compliance issues caused by slight color variations. These measures help producers meet standards while maintaining visual appeal and quality.

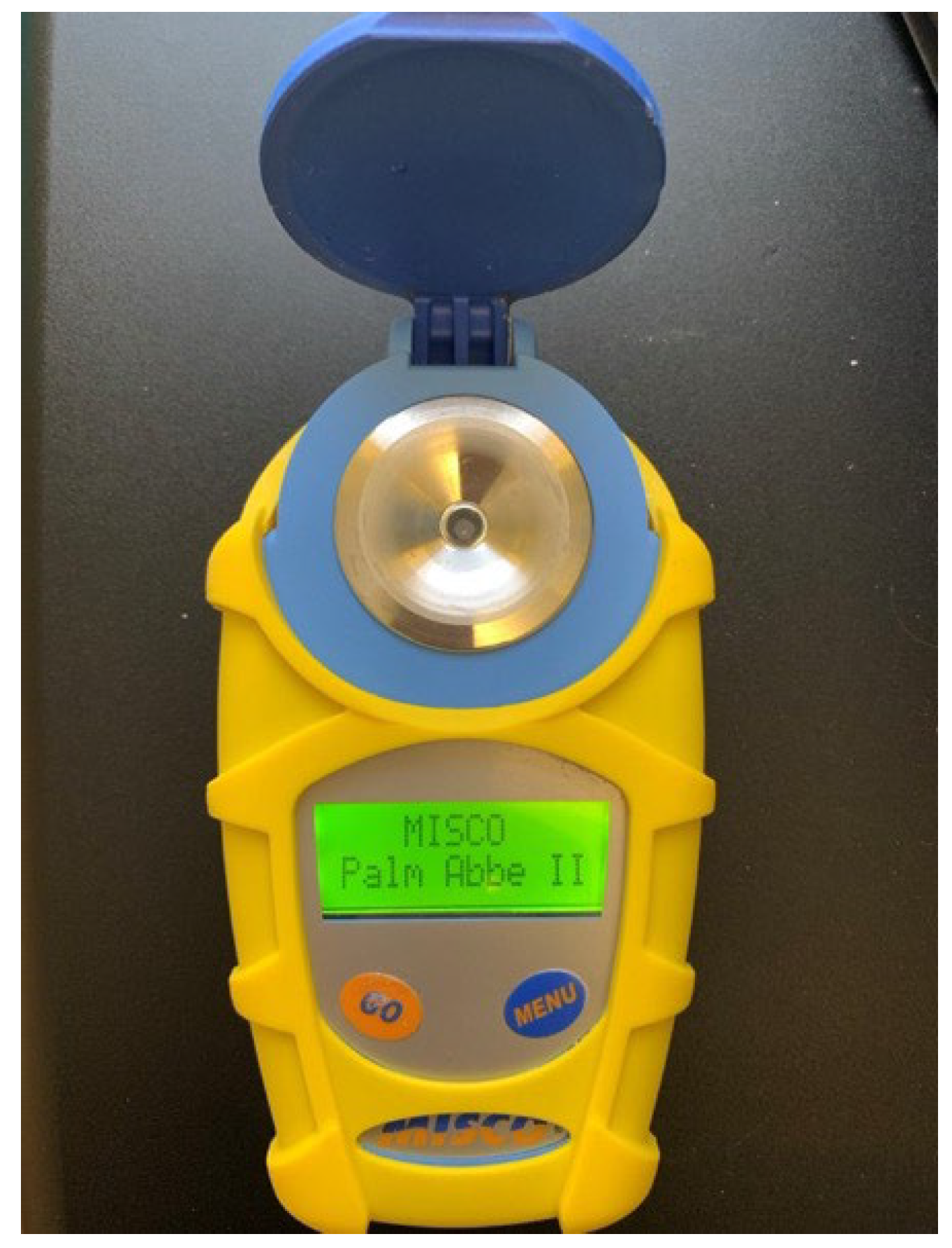

Producers should adjust density-testing targets to prevent the sale of low-density syrup and ensure they accurately measure the syrup temperature at which the hydrometer floats. Although packaging syrup at the lowest allowable density may yield the highest possible financial return, a slightly higher target will allow a reasonable margin for error. While this adjustment could reduce revenue, it might be acceptable at specific volumes. Therefore, finishing the syrup above 66.9 °Brix (for sales to Vermont) ensures it meets consumer and regulatory expectations. For accurate syrup density measurements, producers should use validated hydrometers and keep multiple instruments on hand to ensure reliability. Dirty, damaged, or cold hydrometers can lead to errors, and regular monitoring helps identify problems early. However, it is essential to acknowledge that most hydrometers used for maple production are designed with a precision of only 1.0 °Brix. This inherent limitation means readings should be interpreted with caution and, where possible, supplemented with higher-precision instruments or cross-checks. Careful attention to these details helps prevent over- or under-concentration, both of which can affect flavor, spoilage, crystallization, and overall usability.

Clarity is crucial for producing high-quality maple syrup, but no quantitative measure or tool exists to determine whether a sample meets the standard. To ensure clarity, select an appropriate filtration method and strictly follow the manufacturer’s guidelines, as this process removes sediments that can detract from the syrup’s clarity and consistency.

For flavor, the most critical step in accurate grading is experience in tasting a wide range of syrups. Given that most maple producers do not purchase syrup from others, the potential for tasting many different examples of syrup is low. Assembling a team of specialists with broad tasting experience can help achieve accurate and comprehensive sensory evaluations, which would be ideal but not necessarily practical for the average maple producer. Tasting at the time of production runs the risk of sensory, flavor, and aroma saturation, which can make a detailed analysis of syrup flavor difficult. Syrup samples can be collected per batch and tested for flavor compliance at a separate location, preferably at a different time. Both high-quality and off-flavor reference samples can assist in flavor grading.

Collaborating with other producers in grading provides valuable insights into industry standards and helps refine internal processes. Incorporating batch codes will help minimize losses due to quality issues, as they are easily identifiable. Using appropriate instruments to verify defects, accuracy, and limitations is crucial. Regular staff training and unbiased feedback are indispensable in preventing human error. Creating an inventory directory enables effective monitoring and quality control, allowing producers to identify areas for improvement and efficiently manage recalls when necessary.

5. Conclusions

Syrup color remains the most common area of noncompliance with Grade A standards, with Golden Delicate syrup showing disproportionately low color compliance issues, indicating that consumers buying Golden syrup are much more likely to receive a product that does not meet the USDA (and, in Vermont, legally required) color standard compared to those purchasing Dark syrup. These differences are likely due to post-packaging darkening, limitations in producer grading accuracy, and the Golden Delicate’s greater sensitivity to small changes in light transmittance. Flavor assessment also shows grade-dependent patterns: Golden Delicate syrup generally meets expected flavor profiles, while Dark robust syrup is more prone to off-flavors. In contrast, the clarity test showed compliance across grades, reflecting effective filtration practices. Density issues occur less often but seem related to differences between USDA and Vermont minimum thresholds and the limited precision of hydrometers, which may cause some syrups to fall just below the legal standard.

Because maple syrup is a high-value specialty sweetener, the industry recognizes that regulatory compliance and consistent sensory quality are essential to maintaining market reputation. Documenting retail-level compliance issues, including specific deficiencies in color, flavor, clarity, and density, is necessary for producers and sellers to improve production and grading practices and ensure a reliable consumer experience. Improving compliance requires targeted quality-control measures such as batch coding, which allows producers to trace and correct storage-related deviations; routine verification using reliable tools such as the Lovibond comparator for color and standardized sensory reference sets for flavor, to support more consistent grading; and ongoing training, which ensures that producers and staff can accurately identify defects and correctly apply USDA and Vermont grade definitions. It is also essential to cross-check grading sessions with neighboring producers or extension specialists to align individual grading practices with industry norms. Additionally, structured inventory monitoring, tracking container type, storage duration, and environmental conditions, enables timely interventions, including product rotation or recall when necessary.

The study faced several limitations, including inconsistent documentation of clarity-grading criteria. The reliance on subjective sensory evaluation, which required multiple evaluators and constant comparative sampling to resolve borderline flavor cases, is an approach that can lead to sensory fatigue and introduce variability. Statistical limitations also emerged from uneven sample sizes, necessitating the use of both Chi-square and Fisher’s exact tests. Future research should explore sensor-based, computer vision, or machine learning systems to reduce subjectivity in color and flavor assessment, thereby improving precision and supporting regulatory compliance. Strengthening these evaluation tools and grading practices is critical to ensuring that all syrup sold in Vermont, regardless of origin, meets Vermont’s legally enforceable quality standards and delivers a consistent, trustworthy product to consumers.