Research on High-Efficiency and No-Additive Physical Aging Equipment and Process of Baijiu Production Based on High-Speed Jet Catalysis

Abstract

1. Introduction

2. Theoretical Design of the Physical Aging Process and Equipment

2.1. Design of Aging Process

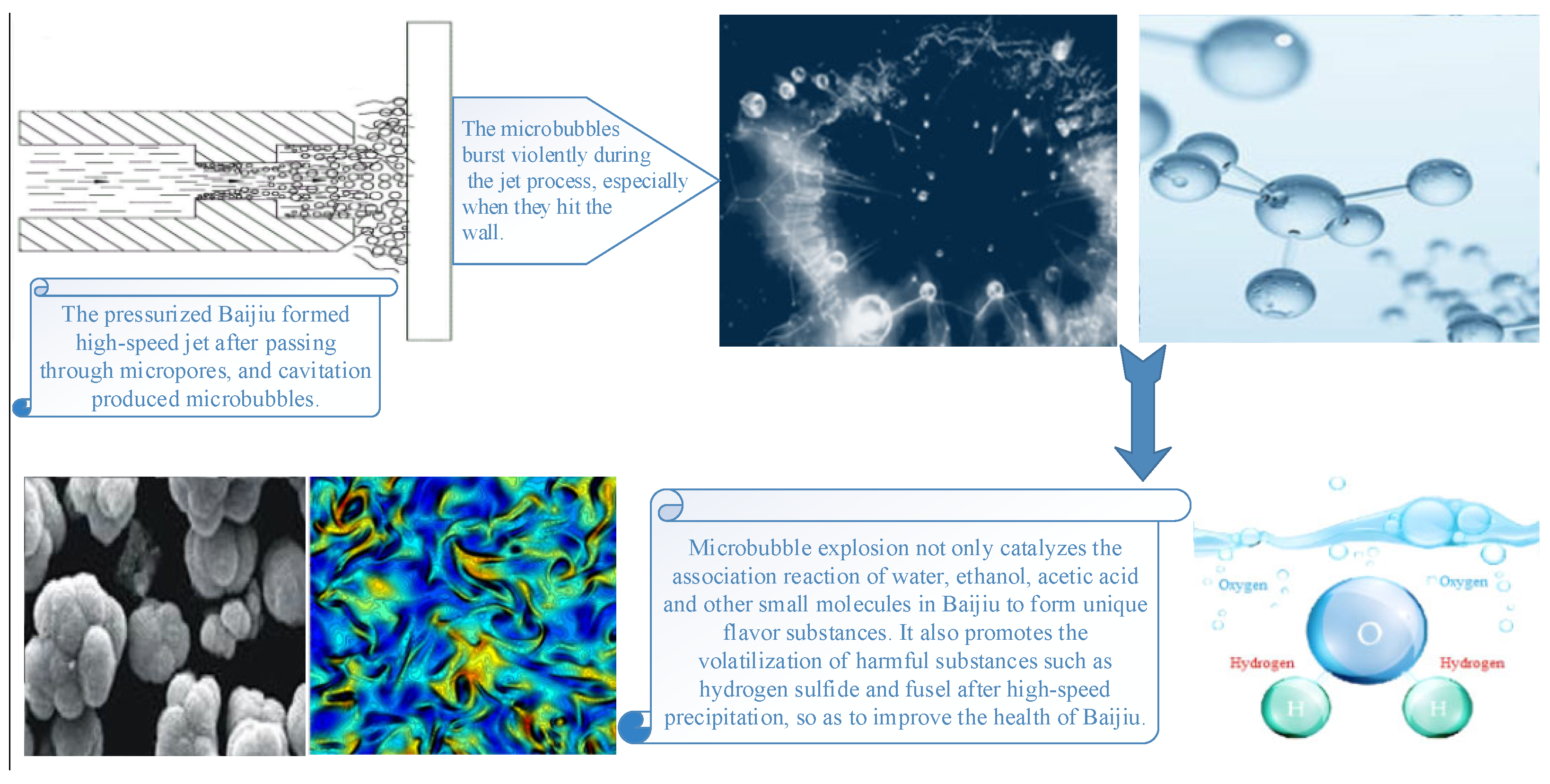

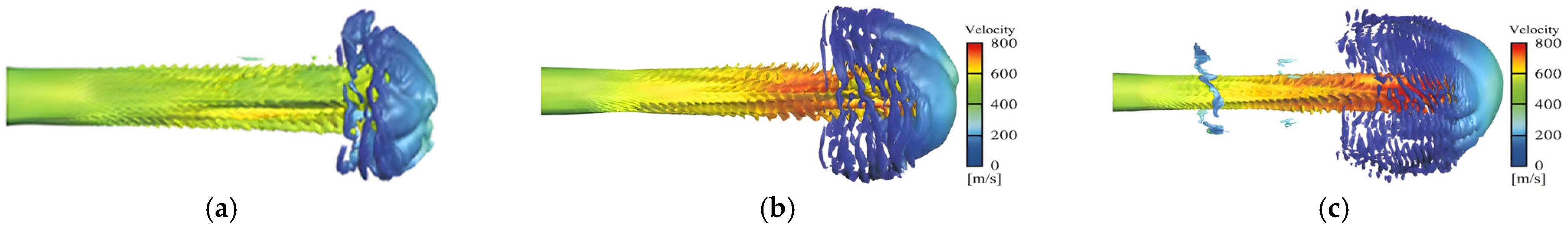

2.1.1. Jet Cavitation Mechanism

- (1)

- Jet cavitation number

- (2)

- Physicochemical properties of the wine body

2.1.2. Mechanism of Heterogeneous Association Catalytic Reaction

- (1)

- Bubble zone

- (2)

- Transition zone

- (3)

- Liquid Phase Region

2.1.3. Process Scheme Design

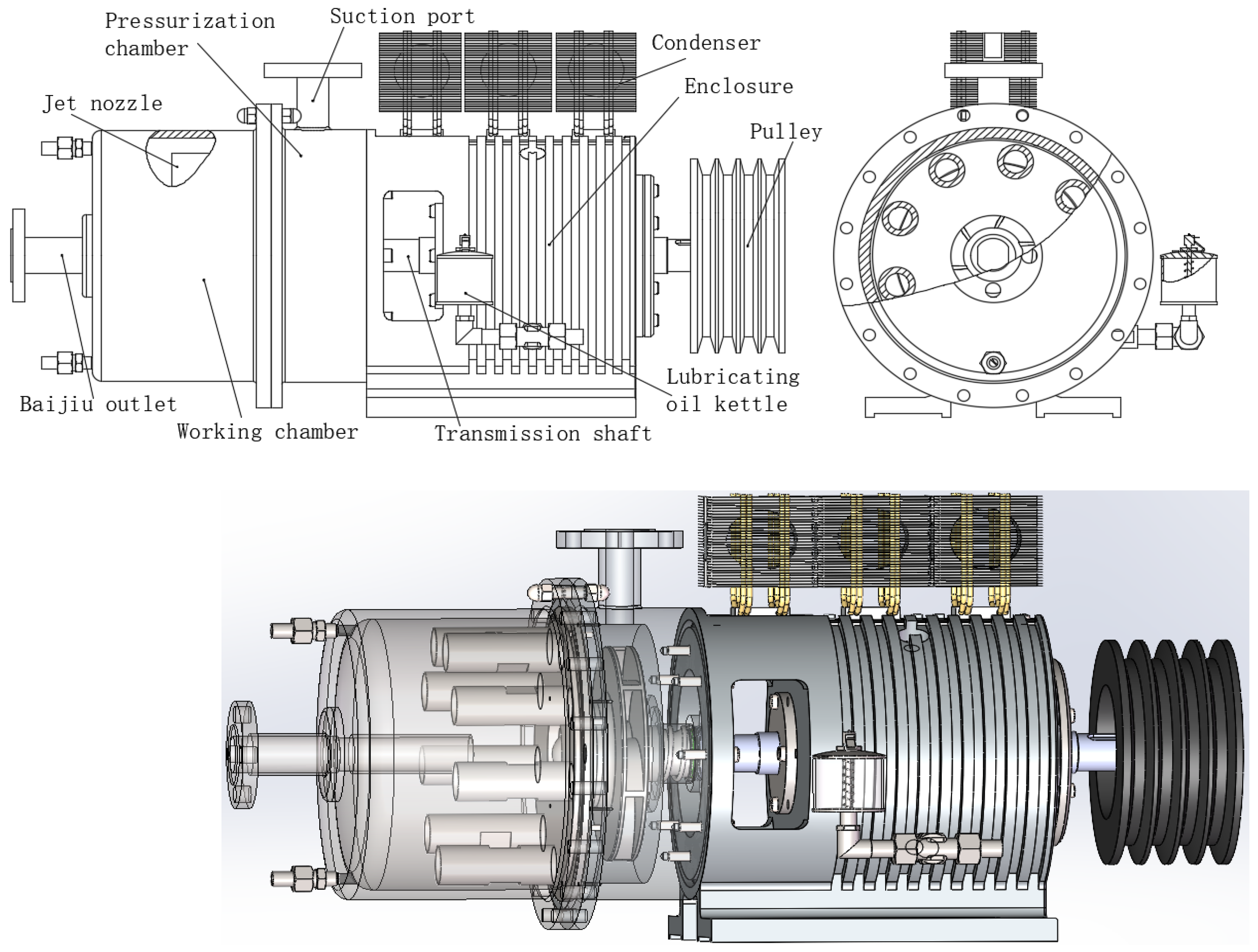

2.2. Structural Design of Aging Equipment

2.2.1. Overall Structure Design

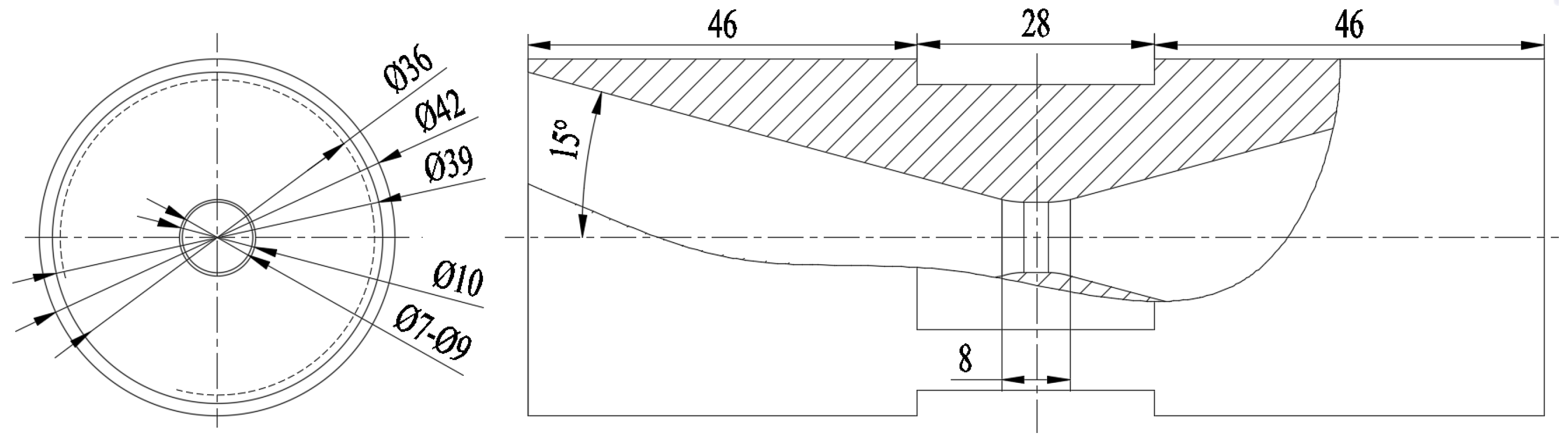

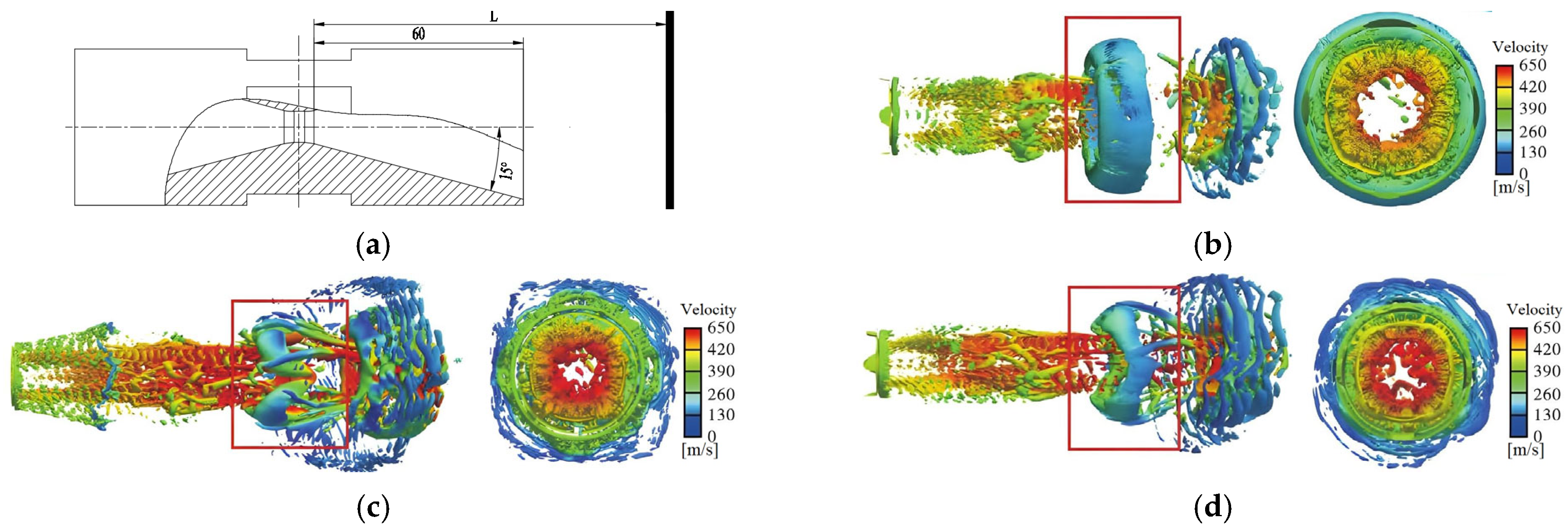

2.2.2. Theoretical Design of the Jet Nozzle and Reaction Chamber Structure

3. CFD Modeling and Optimization Design of Key Components

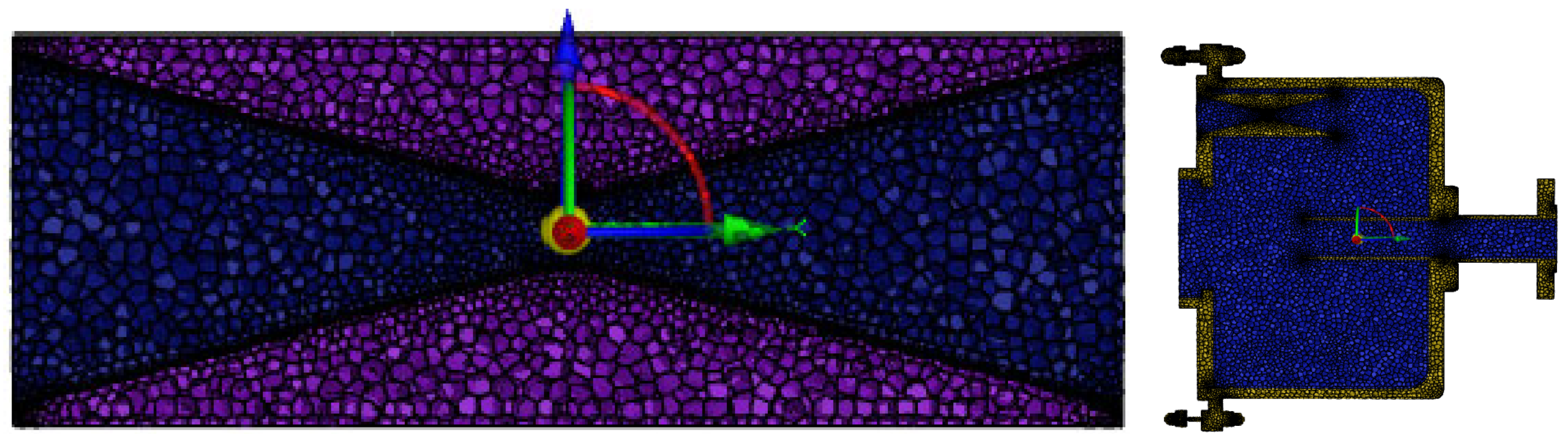

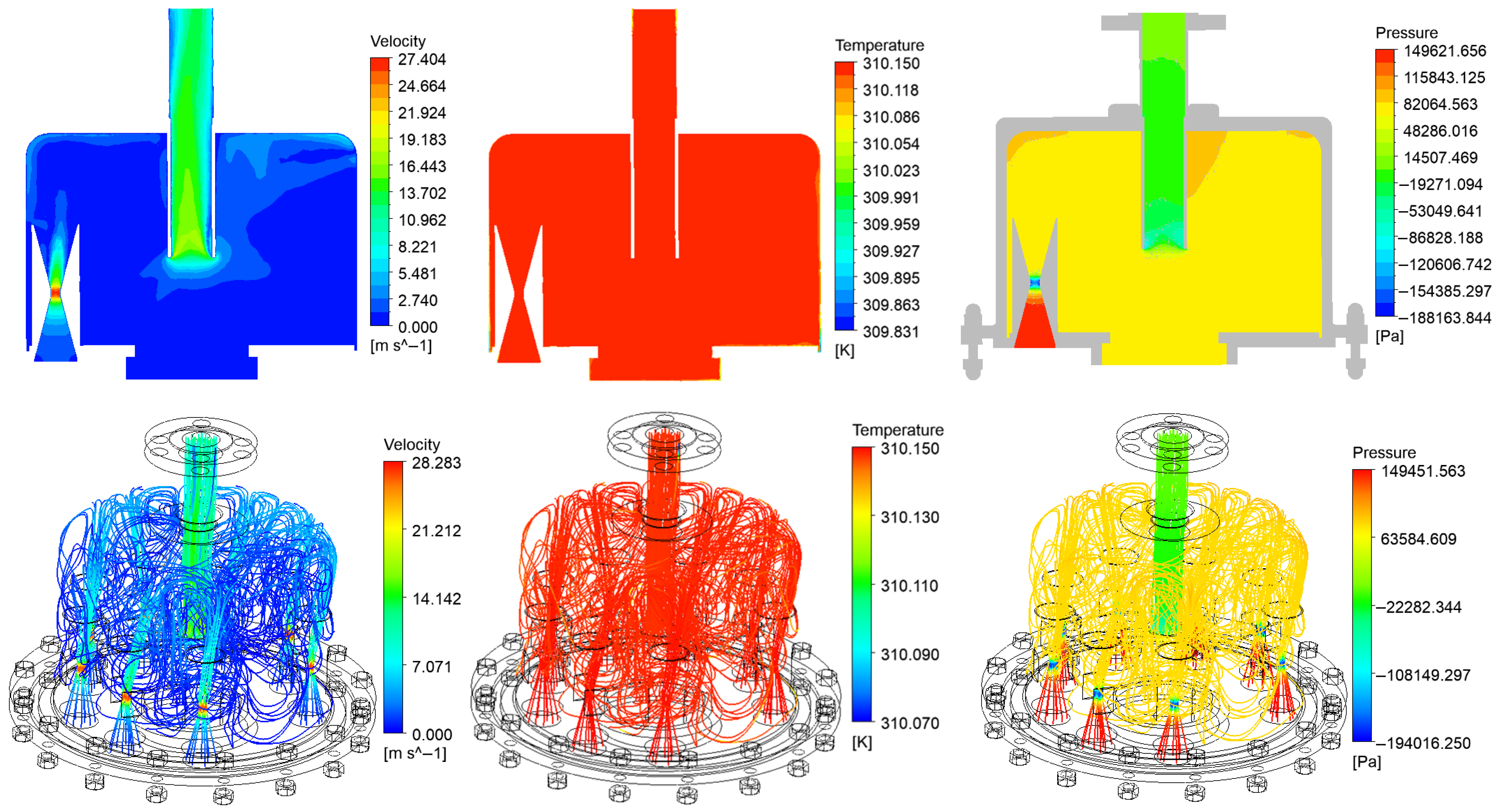

3.1. Physical Modeling and Boundary Condition Setting

3.2. Optimization of CFD Simulation Model

3.2.1. Optimization of the Conservation Sub-Model

3.2.2. Optimization of Turbulence Sub-Model

3.2.3. Optimization of the VOF Sub-Model

- (1)

- Optimization of continuity equation

- (2)

- Optimization of the Schnerr–Sauer equation

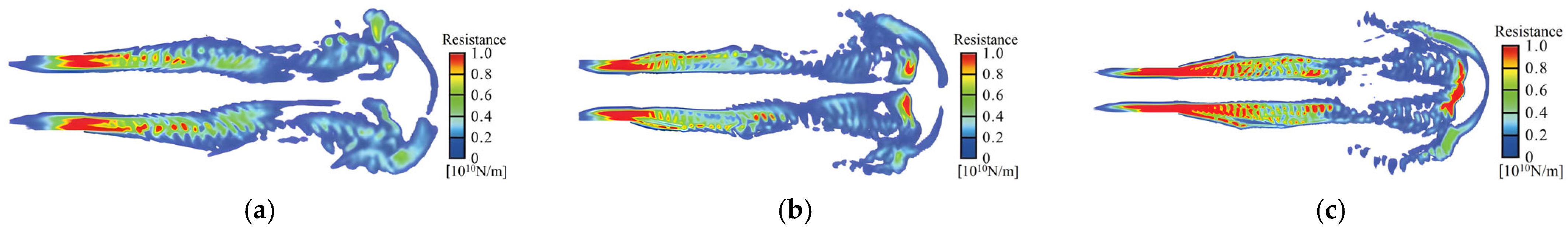

3.3. Optimization Design of Key Structures

3.3.1. Optimization of Nozzle Inner Diameter

3.3.2. Optimization of the Distance Between the Reaction Chamber Walls

3.3.3. Simulation Analysis of Chinese Baijiu Aging Process

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiong, F.K.; Hu, G.Z.; Liu, Z.B.; Xiao, H.W.; Huang, B. Investigation of Damage Mechanism in Baijiu Yeast during Spray Drying at the Molecular Scale. J. Agric. Food Chem. 2025, 73, 21072–21081. [Google Scholar] [CrossRef]

- Xiong, F.K.; Liu, Z.B.; Hu, G.Z.; Zhao, D.; Qu, D.Q. Optimisation of the Protection Process in Baijiu Yeast Spray Drying and Investigation of Its Micro-Nano Protection Mechanism. LWT-Food Sci. Technol. 2025, 227, 118000. [Google Scholar] [CrossRef]

- Han, B.L.; Ren, X.H.; Gong, H.C.; Zhang, S.F.; Zhou, W.T.; Wei, Y.H.; Fang, Y.L.; Xu, Q.; Bian, M.H. Effect of Compound Aging Treatment on the Quality of Nongxiangxing Baijiu. Lwt-Food Sci. Technol. 2025, 217, 117355. [Google Scholar] [CrossRef]

- He, Y.X.; Chen, S.; Tang, K.; Qian, M.; Yu, X.W.; Xu, Y. Sensory Characterization of Baijiu Pungency by Combined Time-Intensity (TI) and Temporal Dominance of Sensations (TDS). Food Res. Int. 2021, 147, 110493. [Google Scholar] [CrossRef]

- Fan, C.M.; Shi, X.; Pan, C.M.; Zhang, F.L.; Zhou, Y.Y.; Hou, X.G.; Hui, M. GC-IMS and GC/Q-TOFMS Analysis of Maotai-Flavor Baijiu at Different Aging Times. Lwt-Food Sci. Technol. 2024, 192, 115744. [Google Scholar] [CrossRef]

- Jiang, Q.X.; Chen, M.J.; Guo, W.; Hu, X.J.; Zhou, W.Q.; Zhao, F.; Xie, L.L.; Yang, H.L. Investigating the Effect of the Particle Size of Potter’s Clay on the Pore Structure of Pottery. Jom 2025, 77, 1–13. [Google Scholar] [CrossRef]

- Yang, H.L.; Hu, X.J.; Tian, J.P.; Xie, L.L.; Chen, M.J.; Huang, D. Exploring the Influence of Pottery Jar Formula Variables on Flavor Substances through Feature Ranking and Machine Learning: Case Study of Maotai-Flavored Baijiu. Foods 2025, 14, 1063. [Google Scholar] [CrossRef] [PubMed]

- Fan, G.S.; Fu, Z.L.; Teng, C.; Liu, P.X.; Wu, Q.H.; Rahman, M.K.R.; Li, X.T. Effects of Aging on the Quality of Roasted Sesame-Like Flavor Daqu. Bmc Microbiol. 2020, 20, 67. [Google Scholar] [CrossRef]

- Du, J.Y.; Xu, Z.X.; Sun, H.B.; Zhu, Y.F.; Zhang, J.; Huang, M.Q.; Liu, Y.; Liu, H.Q.; Sun, B.G.; Wu, J.H. Effect of a New Sea-Aging Method on the Flavor of Baijiu. Food Res. Int. 2025, 212, 116442. [Google Scholar] [CrossRef]

- Jiang, S.; Dai, W.; Chen, X.P.; Tan, W.J.; Wang, J.L.; Yu, Y.G.; Zheng, Q. Vintage Authentication Technology for Aged Baijiu: Acid-Ester Equilibrium. Curr. Res. Food Sci. 2025, 11, 101168. [Google Scholar] [CrossRef]

- Wang, R.J.; Yan, L.J.; Ding, F.; Xu, S.S.; Hu, W.Q.; Zhang, L.; Xu, B.Y.; Zhou, H.; Mu, D.D.; Li, X.J. From Mung Bean to Minglv-Flavor Baijiu: Unraveling the Signature Aroma Profile and Aging Dynamic. Food Chem. 2025, 494, 146132. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Li, Y.L.; An, D.; Fan, Z.B.; Zhang, R.; Shi, L.; Luo, C.X.; Feng, K.Y.; Chang, J.; Chu, X.G. Foodomics Analysis of Natural Aging and Gamma Irradiation Maturation in Chinese Distilled Baijiu by UPLC-Orbitrap-MS/MS. Food Chem. 2020, 315, 126308. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.L.; Gao, Y.C.; Wu, L.; Chen, S.; Xu, Y. Characterization of Key Aging Aroma Compounds in Aged Jiangxiangxing Baijiu and Their Formation Influencing Factors during the Storage Process. J. Agric. Food Chem. 2024, 72, 1695–1705. [Google Scholar] [CrossRef]

- Zhu, K.X.; Xiao, Q.; Yuan, S.Q.; Liu, J.; Shang, H.W.; Guo, M.Y.; Zhao, J.S. The Relationship between Microbial Diversity and the Physicochemical Characteristics of Pit Mud of Strong-Flavor Baijiu. Sci. Rep. 2025, 15, 29454. [Google Scholar] [CrossRef]

- Mao, F.J.; Huang, J.; Zhou, R.Q.; Qin, H.; Zhang, S.Y.; Cai, X.B.; Qiu, C.F. Succession of Microbial Community of the Pit Mud under the Impact of Daqu of Nongxiang Baijiu. J. Biosci. Bioeng. 2023, 136, 304–311. [Google Scholar] [CrossRef]

- Zhang, H.M.; Meng, Y.J.; Wang, Y.M.; Wang, Y.L.; Zhou, Q.W.; Li, A.J.; Liu, G.Y.; Li, J.X.; Xing, X.H. Prokaryotic Communities in Multidimensional Bottom-Pit-Mud from Old and Young Pits Used for the Production of Chinese Strong-Flavor Baijiu. Food Chem. 2020, 312, 126084. [Google Scholar] [CrossRef]

- Wei, J.; Fan, Z.B.; An, D.; Shi, L. Molecular Mechanism of Mare Nectaris and Magnetic Field on the Formation of Ethyl Carbamate during 19 Years Aging of Feng-Flavor Baijiu. Food Chem. 2022, 382, 132357. [Google Scholar] [CrossRef]

- Zheng, Q.; Tian, W.H.; Wang, S.S.; Liu, X.L.; Kong, Q.L.; Yue, L.; Yan, W.Q.; Zhang, Y.; Nong, L.; Xu, X.Y. Using GC-IMS and FTIR to Investigate the Effect of Ionizing Radiation on Volatile Compounds and Hydrogen Bonding of Strong-Flavor Baijiu. Food Chem.-X 2025, 27, 102452. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.H.; Tang, W.P.; Wang, Y.N.; Gan, X.; Yang, L.; Zhang, J.; Sun, Y.C.; Wang, Y.J.; Qin, H.J.; Wang, S.P. Investigating the Influence of 60Co Irradiation on the Aging Aroma Components of Soy Sauce Aroma Type Baijiu by Integrating E-Nose, GC-MS, GC-IMS, and Chemometric Methods. Food Chem.-X 2025, 29, 102704. [Google Scholar] [CrossRef]

- Li, X.F.; Dai, W.; Wang, J.L.; Yu, Y.G.; Zheng, Q. Thermodynamic Equilibrium-Driven Blending Technology for Baijiu Standardization. Food Chem. 2025, 493, 145960. [Google Scholar] [CrossRef]

- Geleynse, S.; Jiang, Z.H.; Brandt, K.; GarciaPerez, M.; Wolcott, M.; Zhang, X. Pulp Mill Integration with Alcohol-to-Jet Conversion Technology. Fuel Process. Technol. 2020, 201, 106338. [Google Scholar] [CrossRef]

- Jiang, X.Y.; Liu, D.F.; Yang, S.Z.; Cheng, X.; Xie, Y.Q. Evolution of Self-Assembled Amphiphilic Colloidal Particles in Strong-Flavor Chinese Baijiu. Food Chem. 2024, 461, 140883. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.J.; Zeng, Y.H.; Sun, Q.Y.; Zhang, W.H.; Wang, S.T.; Shen, C.H.; Shi, B. Insights into the Mechanism of Flavor Compound Changes in Strong Flavor Baijiu during Storage by Using the Density Functional Theory and Molecular Dynamics Simulation. Food Chem. 2022, 373, 131522. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wei, J.W.; Wang, Y.; Zhu, T.T.; Huang, M.Q.; Wu, J.H.; Xu, Y.Q.; Zhang, J.L.; Wang, B.W. A New Method to Predict the Content Changes of Aroma Compounds during the Aging Process of Niulanshan Baijiu Using the GM (1,1) Gray Model. Flavour Fragr. J. 2021, 37, 5–19. [Google Scholar] [CrossRef]

- Zhang, B.; Zheng, S.M.; Huang, M.Q.; Wu, Q.; Dong, W.; Wu, J.H.; Liu, H.Q.; Zhao, D.R.; Yu, Y.G.; Li, J.C. Analysis of Volatile Compounds in Xiangjiao Baijiu from Different Storage Containers and Years Based on HS-GC-IMS and DI-GC-MS. Food Chem.-X 2024, 24, 101976. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Zhuang, X.T.; Li, Z.G.; Zou, Y.F.; Pu, J.Z.; Wang, D.; Xu, Y. LC-MS/MS-Based Determination and Optimization of Linoleic Acid Oxides in Baijiu and Their Variation with Storage Time. Metabolites 2025, 15, 246. [Google Scholar] [CrossRef]

- Gao, M.X.; Han, X.L.; Yang, Y.F.; Wang, D.L. Characterization of Volatile Compounds in Aged Jiangxiangxing Baijiu by GC × GC-TOFMS and Means of the Sensomics Approach. Food Chem. 2025, 492, 145638. [Google Scholar] [CrossRef]

- Sun, X.Z.; Qian, Q.Q.; Xiong, Y.Q.; Xie, Q.Q.; Yue, X.X.; Liu, J.H.; Wei, S.X.; Yang, Q. Characterization of the Key Aroma Compounds in Aged Chinese Xiaoqu Baijiu by Means of the Sensomics Approach. Food Chem. 2022, 384, 132452. [Google Scholar] [CrossRef]

- Huang, H.; Gao, Y.C.; Wang, L.L.; Yu, X.W.; Chen, S.; Xu, Y. Maillard Reaction Intermediates in Chinese Baijiu and Their Effects on Maillard Reaction Related Flavor Compounds during Aging. Food Chem. X 2024, 22, 101356. [Google Scholar] [CrossRef]

- Wang, S.Y.; Li, C.; Li, Y.J.; Liu, G.Q.; Lu, Z.M.; Chai, L.J.; Xu, H.Y.; Shi, J.S.; Wang, S.T.; Shen, C.H.; et al. Evolution of Aroma Compounds in Round Soy Sauce Aroma Type Baijiu during Aging and the Effect of Aging Markers on the Lasting Aroma in Finished Glass. Food Chem.-X 2025, 25, 102193. [Google Scholar] [CrossRef]

- Qiu, W.; Ru, H.L.; Wang, J.L.; Kuang, J.M.; Yu, Y.G.; Zheng, Q. Odor Threshold Dynamics during Baijiu Aging: Ester-Acid Interactions. Lwt-Food Sci. Technol. Technol. 2025, 217, 117436. [Google Scholar] [CrossRef]

- Wu, Y.S.; Chen, H.; Sun, Y.; Huang, H.; Chen, Y.Y.; Hong, J.X.; Liu, X.X.; Wei, H.Y.; Tian, W.J.; Zhao, D.R.; et al. Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters. Foods 2023, 12, 3087. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Baijiu density (kg/m3) | 950 | Air density (kg/m3) | 1.205 |

| Baijiu viscosity (Pa/s) | 1.46 × 10−5 | Air viscosity (Pa/s) | 1.46 × 10−11 |

| Baijiu specific heat capacity (KJ/(kg·K)) | 3.8 | Air specific heat capacity (KJ/(kg·K)) | 1.005 |

| Component diffusion coefficient (m2/s) | 10−9 | Baijiu surface tension (N/m) | 0.028 |

| Thermal conductivity (w/(m·K)) | 0.25 | Baijiu steam viscosity (Pa/s) | 1.96 × 10−5 |

| Thermal conductivity (MPa) | 1 | Outlet pressure (MPa) | 0.1 |

| Equipment Name | Model | Manufacturer |

|---|---|---|

| Gas chromatography–mass spectrometry | 8890 GC/5977B MSD | Agilent Technology Co., Ltd.; Santa Clara, CA, USA. |

| Capillary column | DB-17ms | Agilent Technology Co., Ltd.; Santa Clara, CA, USA. |

| Ethyl heptanate | E305454 | Aladdin; Shenzhen, China. |

| SPME automatic injection handle | 57331 | Supelco; Chicago, IL, USA. |

| SPME extraction head | 57328-U | Supelco; Chicago, IL, USA. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Xiong, F.; Hu, G.; Xiao, H.; Zheng, J. Research on High-Efficiency and No-Additive Physical Aging Equipment and Process of Baijiu Production Based on High-Speed Jet Catalysis. Foods 2025, 14, 4019. https://doi.org/10.3390/foods14234019

Liu Z, Xiong F, Hu G, Xiao H, Zheng J. Research on High-Efficiency and No-Additive Physical Aging Equipment and Process of Baijiu Production Based on High-Speed Jet Catalysis. Foods. 2025; 14(23):4019. https://doi.org/10.3390/foods14234019

Chicago/Turabian StyleLiu, Zhongbin, Fengkui Xiong, Guangzhong Hu, Hongwei Xiao, and Jia Zheng. 2025. "Research on High-Efficiency and No-Additive Physical Aging Equipment and Process of Baijiu Production Based on High-Speed Jet Catalysis" Foods 14, no. 23: 4019. https://doi.org/10.3390/foods14234019

APA StyleLiu, Z., Xiong, F., Hu, G., Xiao, H., & Zheng, J. (2025). Research on High-Efficiency and No-Additive Physical Aging Equipment and Process of Baijiu Production Based on High-Speed Jet Catalysis. Foods, 14(23), 4019. https://doi.org/10.3390/foods14234019