Evaluation of the Nutritional, Rheological, Functional, and Sensory Properties of Cookies Enriched with Taro (Colocasia esculenta) Flour as a Partial Substitute for Wheat Flour

Abstract

1. Introduction

2. Materials and Methods

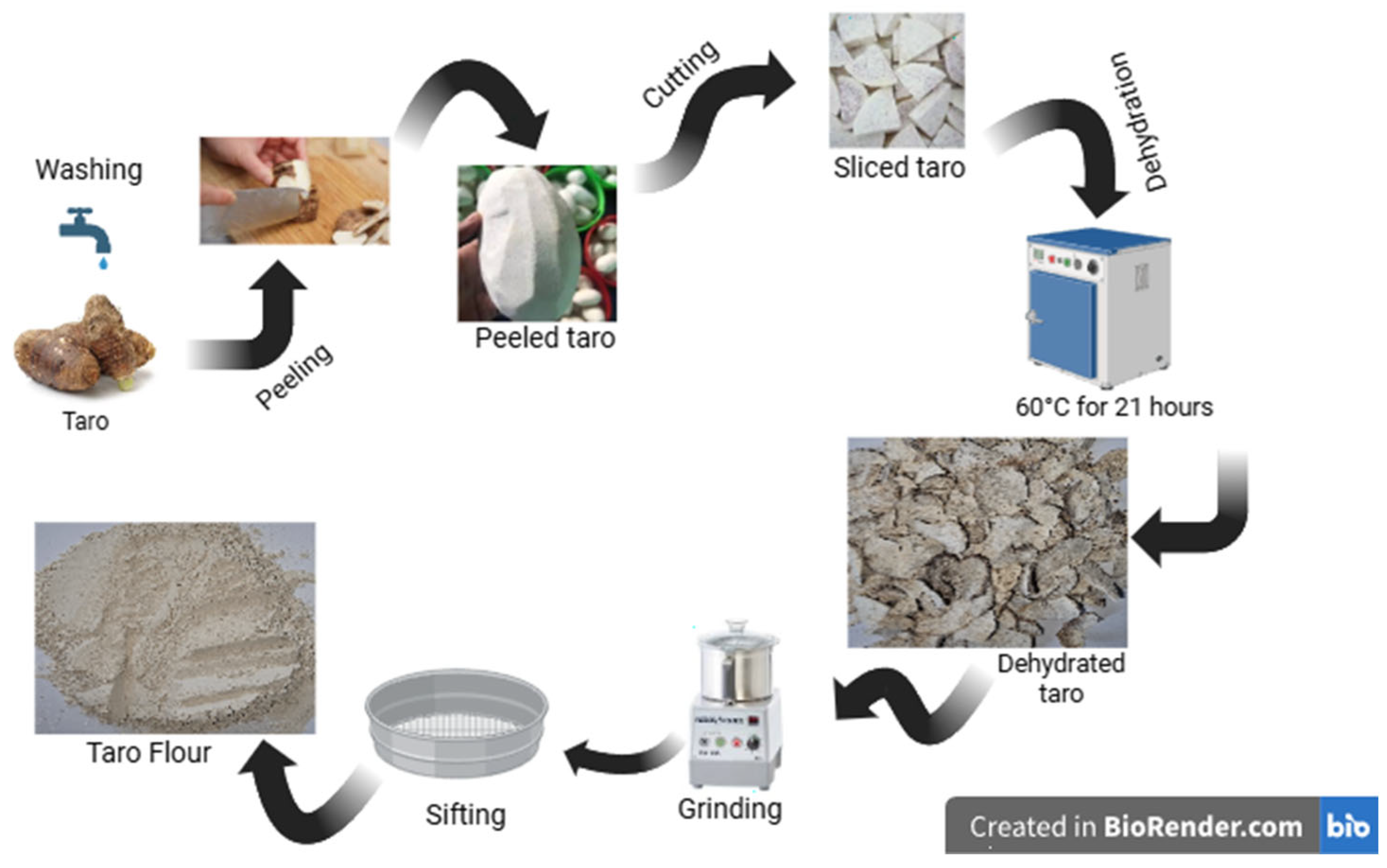

2.1. Preparation of Taro Flour

2.2. Preparation of Composite Flours

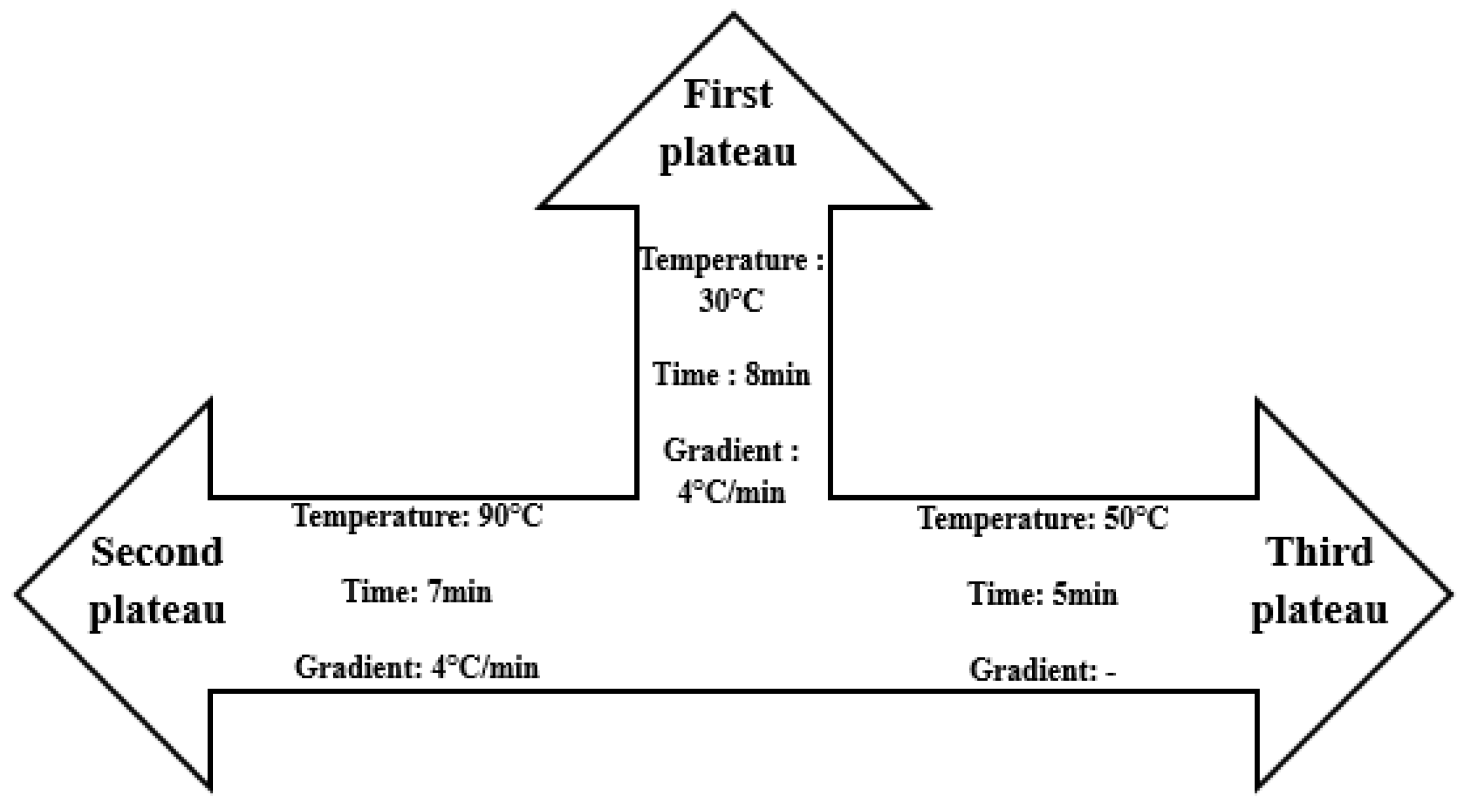

2.3. Analysis of the Rheological Parameters of Different Flours

2.4. Cookie Preparation

2.5. Determination of Proximate Composition

2.6. Determination of Macro- and Microelements in Different Samples of Flour and Cookies

2.7. Determination of Phytochemical Profile

2.7.1. Preparation of Alcoholic Extracts

2.7.2. Evaluation of Total Phenolic Content (TPC), Antioxidant Activity (AA), and Individual Polyphenols by HPLC

2.8. Physical Analyses Performed on the Cookies

2.8.1. Determination of Baking Yield

2.8.2. Diameter Increase

2.8.3. Thickness Increase

2.8.4. Spread Ratio (D/T)

2.9. Fourier Transform Infrared Spectroscopy (FTIR) of Composite Flours

2.10. Determination of Antinutritional Factors

2.10.1. Determination of Phytic Acid Content

2.10.2. Determination of Oxalate Content

2.11. Evaluation of Sensory Profils

2.12. Statistical Analysis

3. Results

3.1. Determination of Immediate Composition

3.2. Macro- and Microelements Contents in Different Samples of Flour and Cookies

3.3. Phytochemical Profile

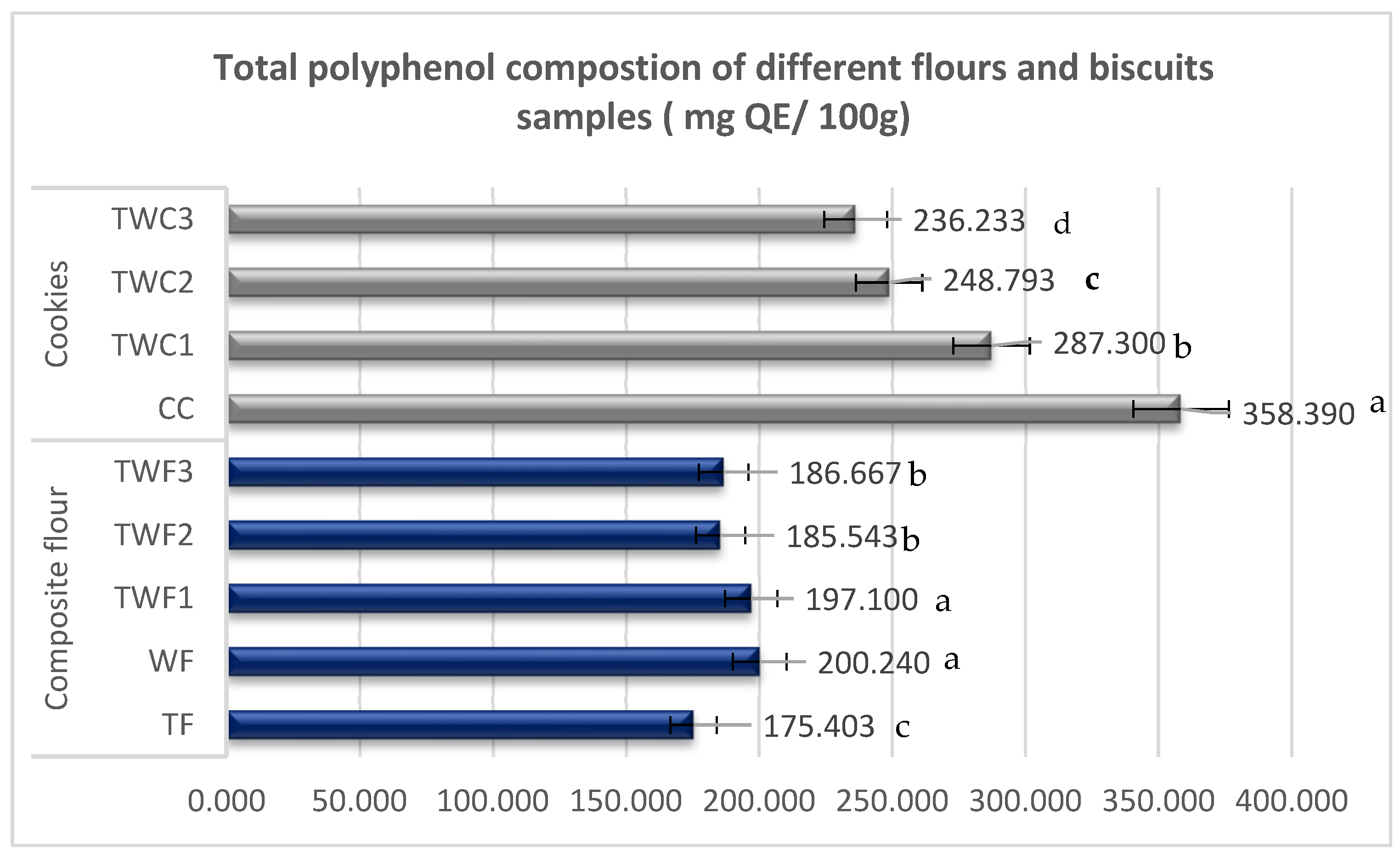

3.3.1. Total Polyphenol Composition of Different Flours and Biscuits Samples

3.3.2. Individual Polyphenols in Different Flours (WF, TF, TWF1, TWF2, and TWF3) Determined by HPLC

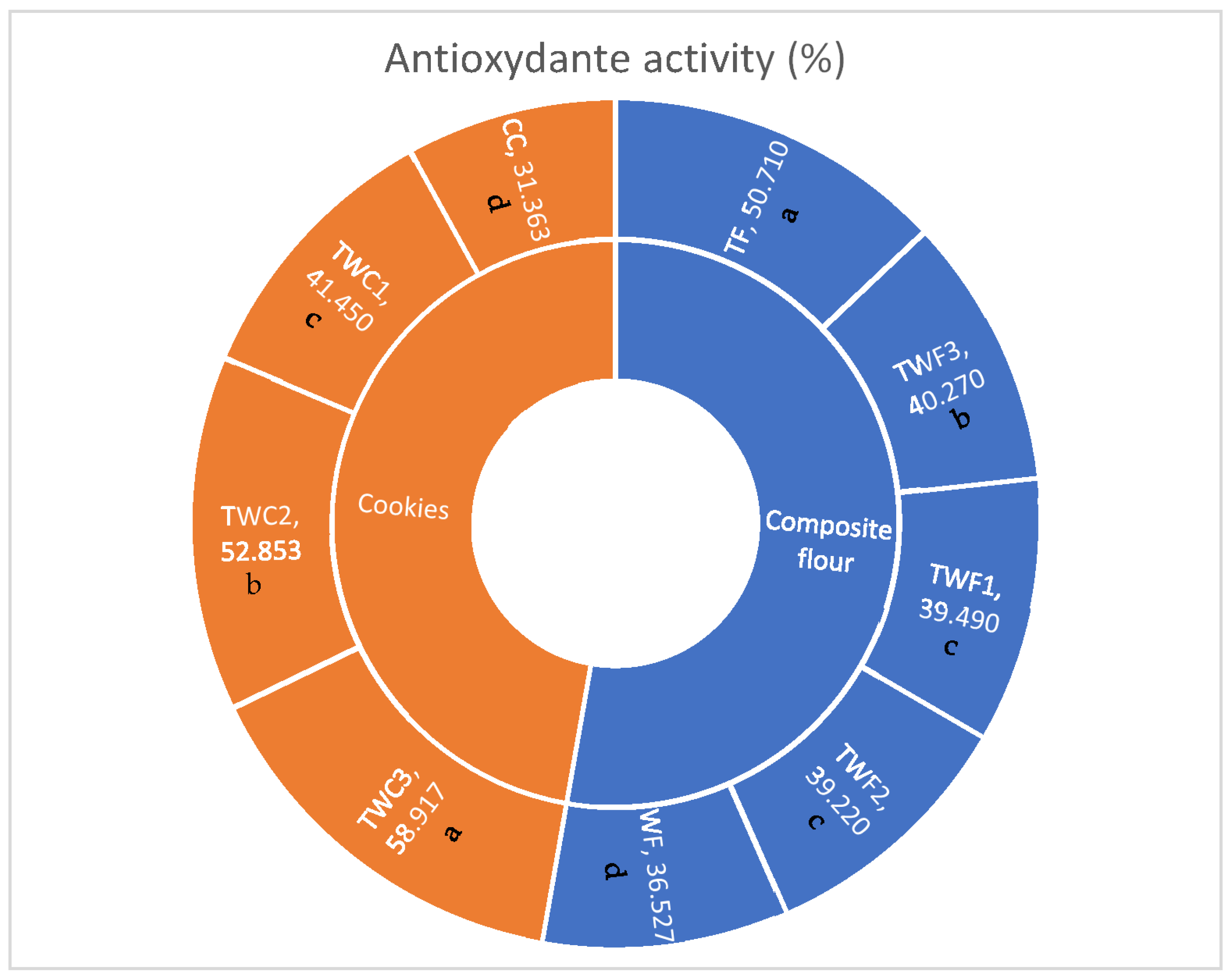

3.3.3. Antioxidant Activity

3.4. Rheological Analysis

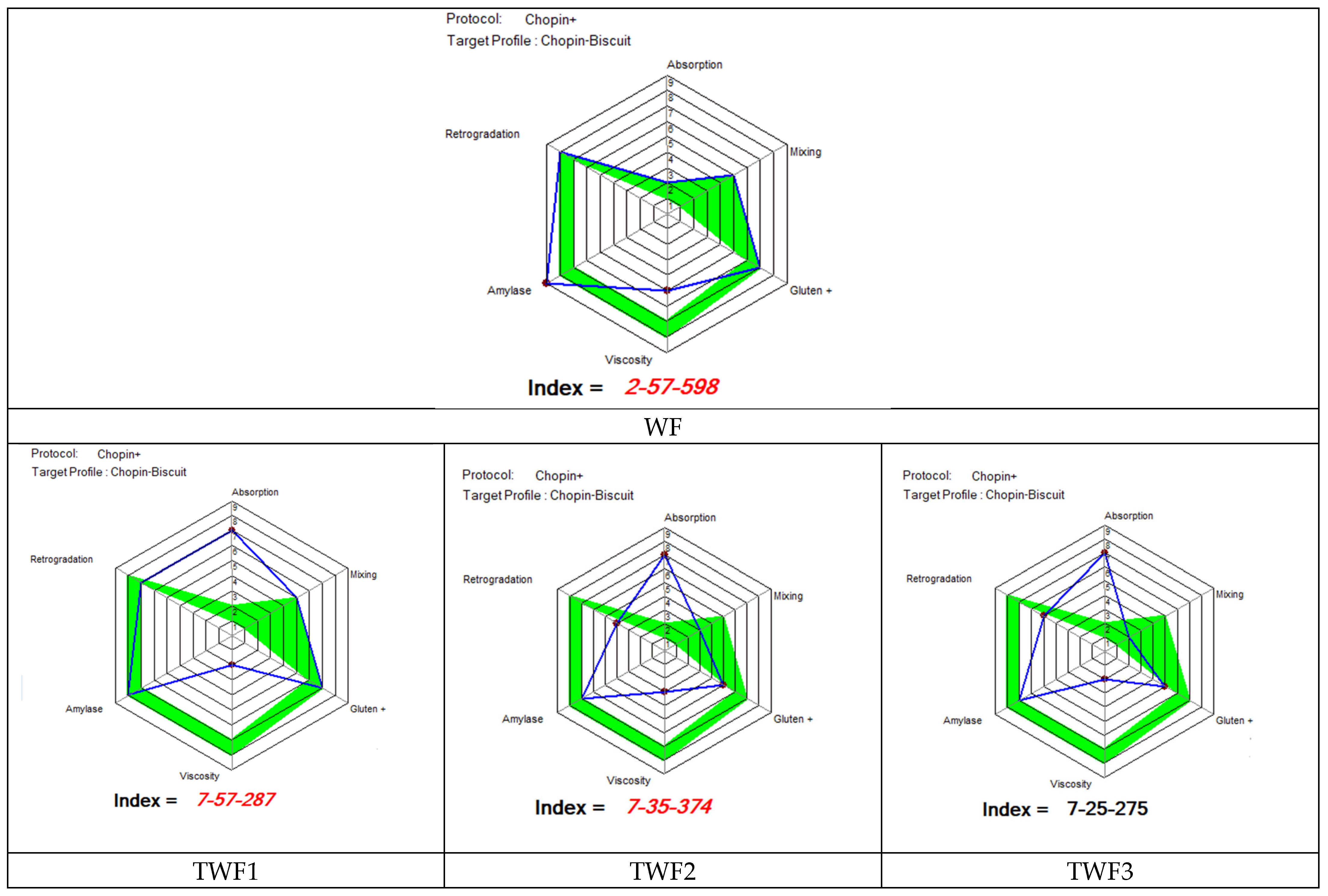

3.4.1. Mixolab Profiler Index

3.4.2. Dough Stability Time

3.5. Physical Analyses Performed on the Biscuits

3.6. Analysis of Correlation

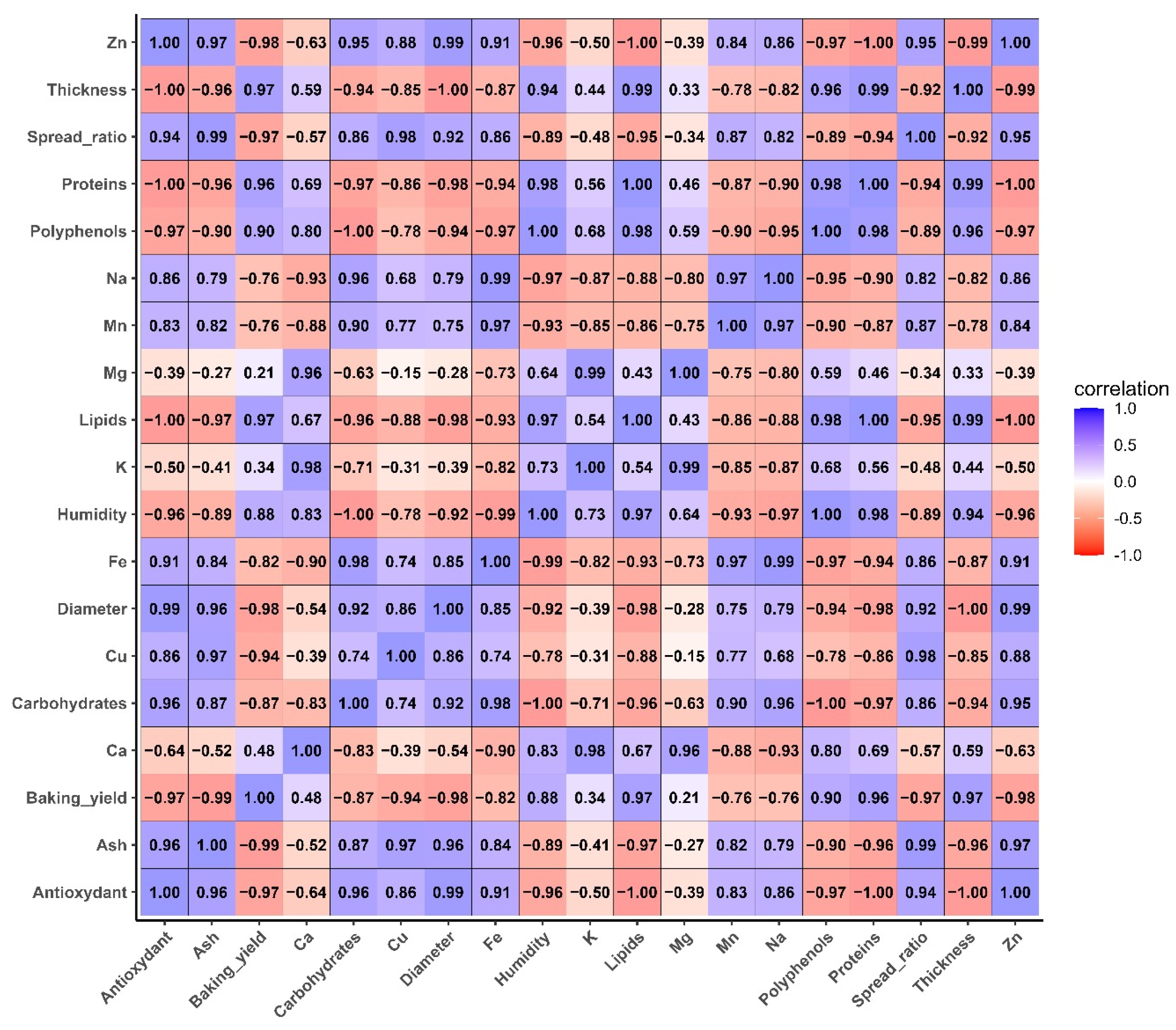

3.6.1. Analysis of Correlation Between Nutritional, Macro and Microelements, and Phytochemical Parameters in Composite Flours with Taro Flour

3.6.2. Analysis of Correlation Between Nutritional, Physical Analyses, Macro and Microelements, and Phytochemical Parameters in Enriched Biscuits

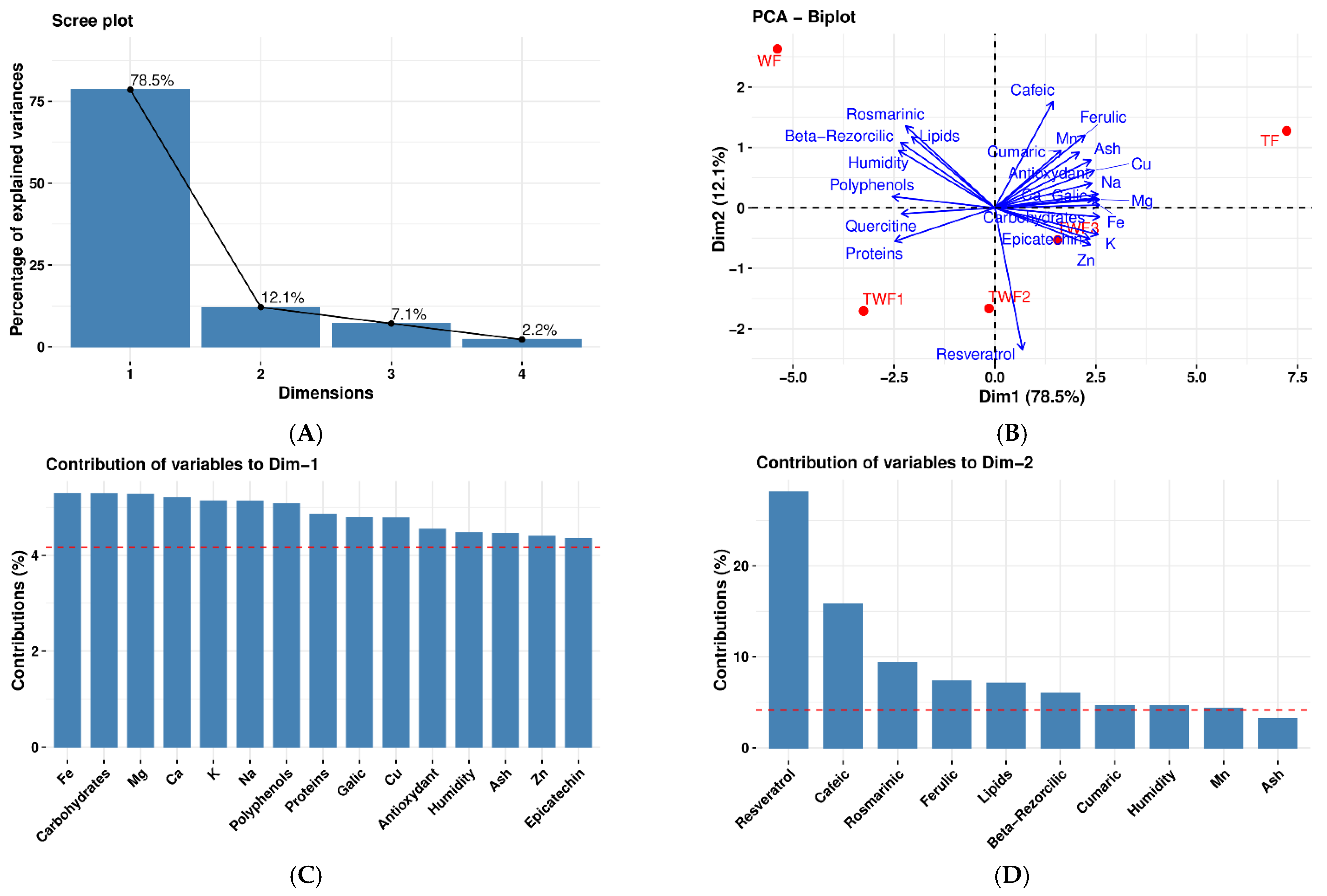

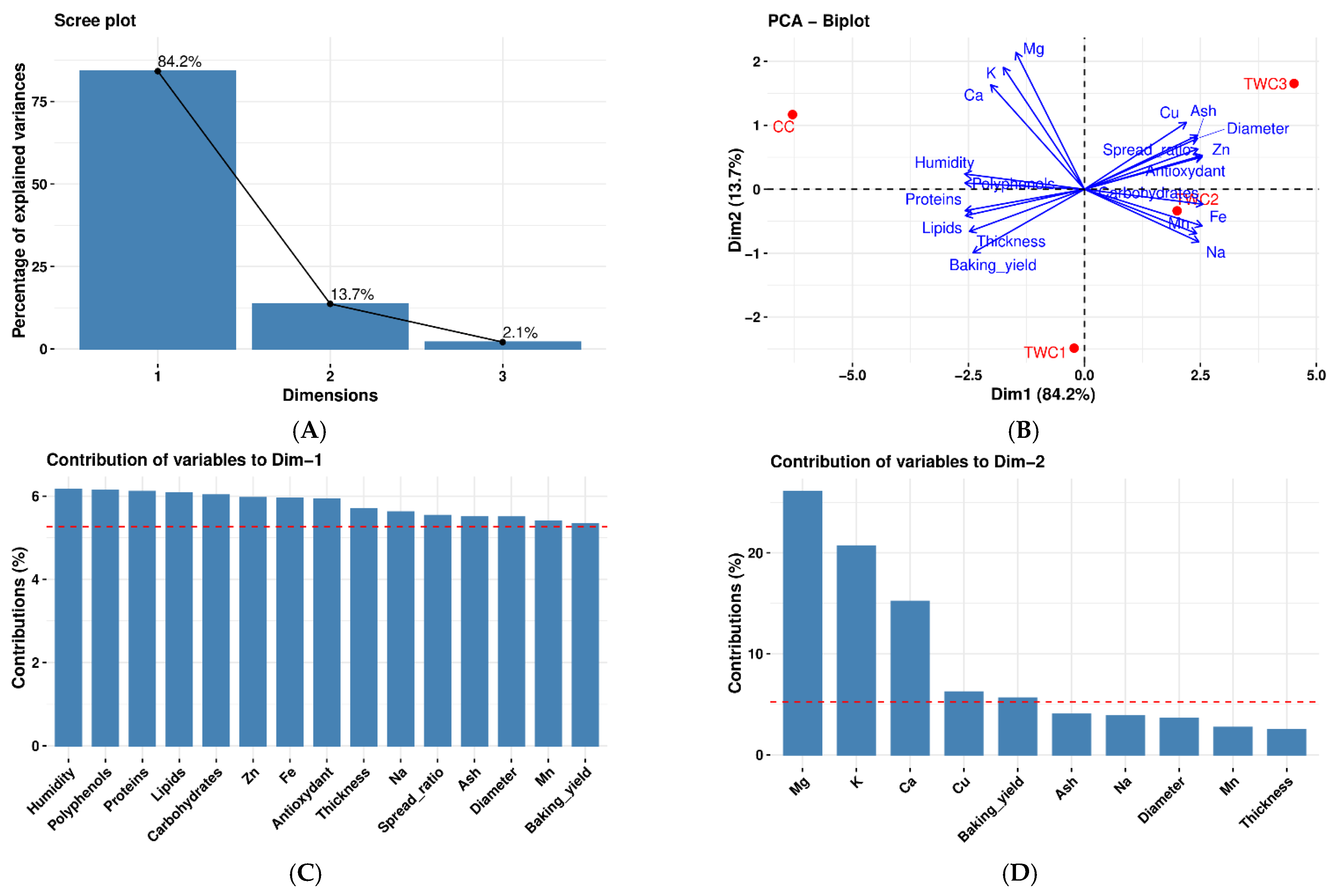

3.7. Principal Component Analysis and Cluster Analysis for Flours (WF, TF, TWF1, TWF2, and TWF3) and Biscuits (CC, TWC1, TWC2, and TWC3)

3.7.1. Principal Component Analysis for Flours (WF, TF, TWF1, TWF2, and TWF3)

3.7.2. Cluster Analysis for Flours (WF, TF, TWF1, TWF2, and TWF3)

3.7.3. Principal Component Analysis for Biscuits (CC, TWC1, TWC2, and TWC3)

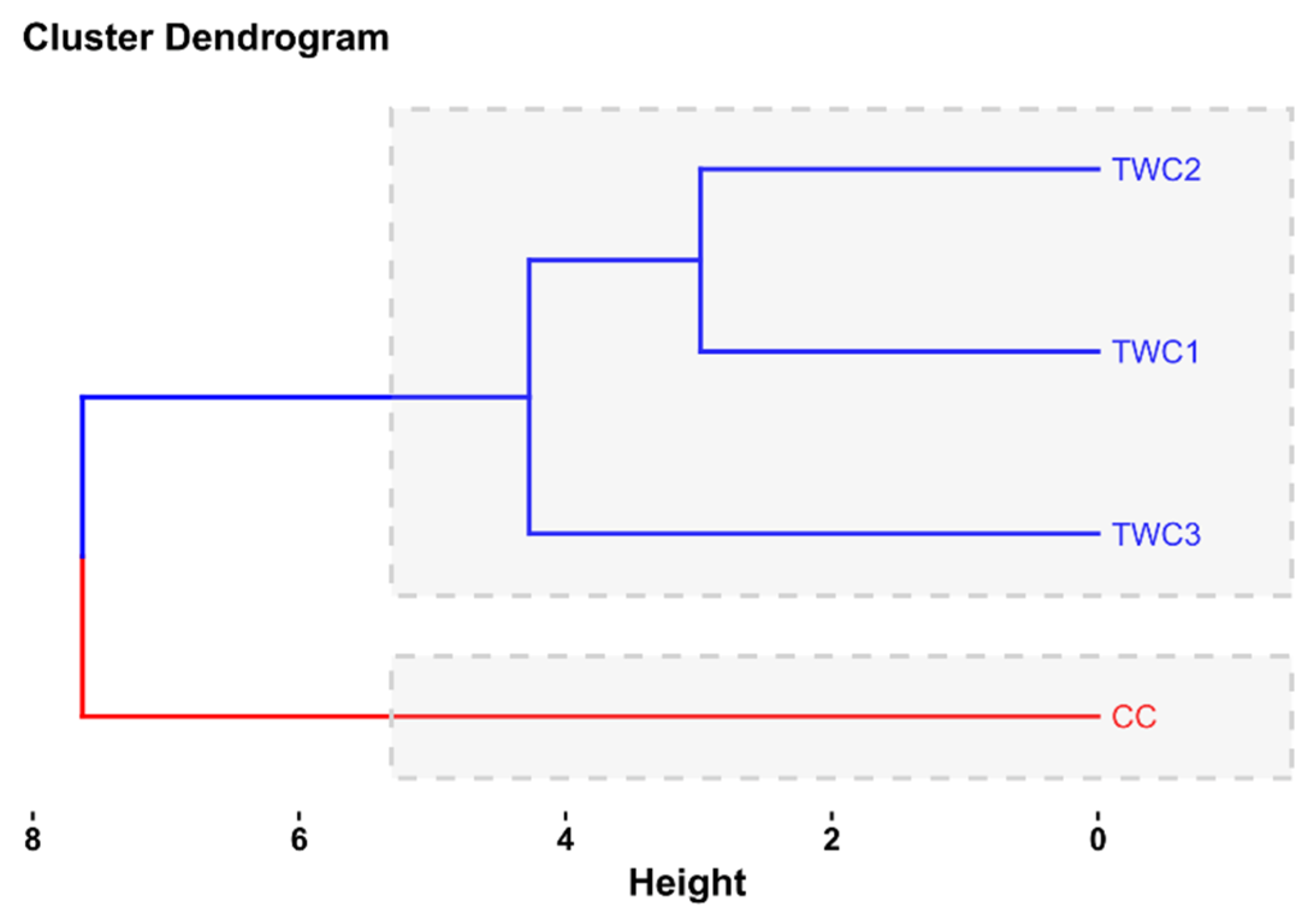

3.7.4. Cluster Analysis for Biscuits (CC, TWC1, TWC2, and TWC3)

3.8. Spectroscopy Analysis (FTIR) of Fortified Flours with Taro Flour

3.9. Antinutritional Factors

3.10. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saklani, A.; Kaushik, R.; Chawla, P.; Kumar, N.; Kumar, M. Effect of taro (Colocasia esculenta) enrichment on physicochemical and textural properties of cake. Int. J. Food Stud. 2021, 10, 14–15. [Google Scholar] [CrossRef]

- Giri, N.A.; Sajeev, M. Physico-mechanical and nutritional evaluation of taro (Colocasia esculenta) flour-based gluten-free cookies. Agric. Res. 2020, 9, 125–131. [Google Scholar] [CrossRef]

- Siddique, K.H.; Li, X.; Gruber, K. Rediscovering Asia’s forgotten crops to fight chronic and hidden hunger. Nat. Plants 2021, 7, 116–122. [Google Scholar] [CrossRef]

- Akwee, P.; Netondo, G.; Palapala, V.A. A critical review of the role of taro Colocasia esculenta L. (Schott) to food security: A comparative analysis of Kenya and Pacific Island taro germplasm. Sci. Agric. 2015, 9, 101–108. [Google Scholar] [CrossRef]

- Singla, D.; Singh, A.; Dhull, S.B.; Kumar, P.; Malik, T.; Kumar, P. Taro starch: Isolation, morphology, modification and novel applications concern—A review. Int. J. Biol. Macromol. 2020, 163, 1283–1290. [Google Scholar] [CrossRef] [PubMed]

- Kaushal, P.; Sharma, H.K. Convective dehydration kinetics of noodles prepared from taro (Colocasia esculenta), rice (Oryza sativa) and pigeonpea (Cajanus cajan) flours. Agric. Eng. Int. CIGR J. 2013, 15, 202–212. [Google Scholar]

- Alflen, T.A.; Quast, E.; Bertan, L.C.; Bainy, E.M. Partial substitution of wheat flour with taro (Colocasia esculenta) flour on cookie quality. RECEN 2016, 18, 202–212. [Google Scholar] [CrossRef]

- Ammar, M.; Hegazy, A.; Bedeir, S. Using of taro flour as partial substitute of wheat flour in bread making. World J. Dairy Food Sci. 2009, 4, 94–99. [Google Scholar]

- Emmanuel, C.; Osuchukwu, N.; Oshiele, L. Functional and sensory properties of wheat (Aestium triticium) and taro flour (Colocasia esculenta) composite bread. Afr. J. Food Sci. 2010, 4, 248–253. [Google Scholar]

- Mongi, R.; Ndabikunze, B.; Chove, B.; Mamiro, P.; Ruhembe, C.; Ntwenya, J. Proximate composition, bread characteristics and sensory evaluation of cocoyam-wheat composite breads. Afr. J. Food Agric. Nutr. Dev. 2011, 11, 5586–5599. [Google Scholar] [CrossRef]

- Sanful, R.E. Organoleptic and nutritional analysis of taro and wheat flour composite bread. World J. Dairy Food Sci. 2011, 6, 175–179. [Google Scholar]

- Saqib, A.; Asghar, A.; Saeed, F.; Afzaal, M.; Abbas Shah, Y.; Wani, A.W.; Ahmad, H.; Ijaz, A.; Akram, N.; Ndagire, C.T. Anti-nutritional and allergic components of taro: Recent updates & perspectives. Food Agric. Immunol. 2025, 36, 2485896. [Google Scholar] [CrossRef]

- Alexandra, S.; Jamora, N.; Smale, M.; Ghanem, M.E. The tale of taro leaf blight: A global effort to safeguard the genetic diversity of taro in the Pacific. Food Secur. 2020, 12, 1005–1016. [Google Scholar] [CrossRef]

- Ferreres, F.; Gonçalves, R.F.; Gil-Izquierdo, A.; Valentão, P.; Silva, A.M.; Silva, J.o.B.; Santos, D.; Andrade, P.B. Further knowledge on the phenolic profile of Colocasia esculenta (L.) Shott. J. Agric. Food Chem. 2012, 60, 7005–7015. [Google Scholar] [CrossRef]

- Arshad, M.U.; Anjum, F.M.; Zahoor, T. Nutritional assessment of cookies supplemented with defatted wheat germ. Food Chem. 2007, 102, 123–128. [Google Scholar] [CrossRef]

- Nagi, H.; Kaur, J.; Dar, B.; Sharma, S. Effect of storage period and packaging on the shelf life of cereal bran incorporated biscuits. Am. J. Food Technol. 2012, 7, 301–310. [Google Scholar] [CrossRef]

- Handbook, M.A. Rheological and Enzymatic Analysis; Chopin Applications Laboratory: Villeneuve-la-Garenne, France, 2009. [Google Scholar]

- Farzana, T.; Fatema, J.; Hossain, F.B.; Afrin, S.; Rahman, S.S. Quality improvement of cakes with buckwheat flour, and its comparison with local branded cakes. Curr. Res. Nutr. Food Sci. J. 2021, 9, 570–577. [Google Scholar] [CrossRef]

- Mounjouenpou, P.; Eyenga, S.N.N.N.; Kamsu, E.J.; Kari, P.B.; Ehabe, E.E.; Ndjouenkeu, R. Effect of fortification with baobab (Adansonia digitata L.) pulp flour on sensorial acceptability and nutrient composition of rice cookies. Sci. Afr. 2018, 1, e00002. [Google Scholar] [CrossRef]

- Methods No. 110/1; ICC: International Association for Cereal Science and Technology: Vienna, Austria, 2003.

- ISO 2171:2023; Cereals, Pulses and By-Products: Determination of Total Ash Yield by Incineration. International Organization for Standardization: Geneva, Switzerland, 2007.

- Horwitz, W.; Latimer, G.W. Official Methods of Analysis of AOAC International; AOAC international Gaithersburg: Gaithersburg, MD, USA, 2000; Volume 1. [Google Scholar]

- Plustea, L.; Negrea, M.; Cocan, I.; Radulov, I.; Tulcan, C.; Berbecea, A.; Popescu, I.; Obistioiu, D.; Hotea, I.; Suster, G. Lupin (Lupinus Spp.)-fortified bread: A sustainable, nutritionally, functionally, and technologically valuable solution for bakery. Foods 2022, 11, 2067. [Google Scholar] [CrossRef]

- Dossa, S.; Negrea, M.; Cocan, I.; Berbecea, A.; Obistioiu, D.; Dragomir, C.; Alexa, E.; Rivis, A. Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods 2023, 12, 2697. [Google Scholar] [CrossRef] [PubMed]

- Danciu, C.; Muntean, D.; Alexa, E.; Farcas, C.; Oprean, C.; Zupko, I.; Bor, A.; Minda, D.; Proks, M.; Buda, V. Phytochemical characterization and evaluation of the antimicrobial, antiproliferative and pro-apoptotic potential of Ephedra alata Decne. hydroalcoholic extract against the MCF-7 breast cancer cell line. Molecules 2018, 24, 13. [Google Scholar] [CrossRef]

- Obistioiu, D.; Cocan, I.; Tîrziu, E.; Herman, V.; Negrea, M.; Cucerzan, A.; Neacsu, A.-G.; Cozma, A.L.; Nichita, I.; Hulea, A. Phytochemical profile and microbiological activity of some plants belonging to the Fabaceae family. Antibiotics 2021, 10, 662. [Google Scholar] [CrossRef]

- Ciulca, S.; Roma, G.; Alexa, E.; Radulov, I.; Cocan, I.; Madosa, E.; Ciulca, A. variation of polyphenol content and antioxidant activity in some bilberry (Vaccinium myrtillus L.) populations from Romania. Agronomy 2021, 11, 2557. [Google Scholar] [CrossRef]

- Nandeesh, K.; Jyotsna, R.; Venkateswara Rao, G. Effect of differently treated wheat bran on rheology, microstructure and quality characteristics of soft dough biscuits. J. Food Process. Preserv. 2011, 35, 179–200. [Google Scholar] [CrossRef]

- McKie, V.A.; MccleAry, B.V. A novel and rapid colorimetric method for measuring total phosphorus and phytic acid in foods and animal feeds. J. AOAC Int. 2016, 99, 738–743. [Google Scholar] [CrossRef]

- Megazyme. Phytic Acid, Product Instructions; Megazyme Ltd.: Wicklow, Irland, 2025; Volume SKU: 700004327, K-PHYT, pp. 1–15. [Google Scholar]

- Owuamanam, C.; Okolue, B.; Nwosu, J.; Chika, C.; Ogueke, O.; Tobor, R. Thermal Treatment Effects on the Calcium Oxalate and Mineral Contents of Xanthosoma atrovirens (Ede Ocha): A Cocoyam Species; International Institute for Science, Technology & Education (IISTE): New York, NY, USA, 2013. [Google Scholar]

- ISO 6658:2017; Sensory Analysis—Methodology—Overall Guidelines. ISO: Geneva, Switzerland, 2017.

- Tekle, A. The Effect of Blend Proportion and Baking Condition on the Quality of Cookie Made from Taro and Wheat Flour Blend. Master’s Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2009. [Google Scholar]

- Wheat, S. Using of taro (Colocasia esculenta) flour as a partial substitute of wheat flour in biscuit making. Environ. Sci. 2019, 14, 235–246. [Google Scholar]

- Tari, T.A.; Singhal, R.S. Starch-based spherical aggregates: Stability of a model flavouring compound, vanillin entrapped therein. Carbohydr. Polym. 2002, 50, 417–421. [Google Scholar] [CrossRef]

- Quach, M.L.; Melton, L.D.; Harris, P.J.; Burdon, J.N.; Smith, B.G. Cell wall compositions of raw and cooked corms of taro (Colocasia esculenta). J. Sci. Food Agric. 2001, 81, 311–318. [Google Scholar] [CrossRef]

- Gibson, R.S.; Bailey, K.B.; Gibbs, M.; Ferguson, E.L. A review of phytate, iron, zinc, and calcium concentrations in plant-based complementary foods used in low-income countries and implications for bioavailability. Food Nutr. Bull. 2010, 31 (Suppl. S2), S134–S146. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Global Status Report on Blood Safety and Availability 2021; World Health Organization: Geneva, Switzerland, 2022.

- Volpe, S.L. Magnesium in disease prevention and overall health. Adv. Nutr. 2013, 4, 378S–383S. [Google Scholar] [CrossRef]

- Weaver, C.M. Potassium and health. Adv. Nutr. 2013, 4, 368S–377S. [Google Scholar] [CrossRef]

- Joint, F. Human Vitamin and Mineral Requirements; FAO/WHO: Rome, Italy, 2002. [Google Scholar]

- Njintang, Y.; Scher, J.; Mbofung, C. Physicochemical, thermal properties and microstructure of six varieties of taro (Colocasia esculenta L. Schott) flours and starches. J. Food Eng. 2008, 86, 294–305. [Google Scholar] [CrossRef]

- Adom, K.K.; Liu, R.H. Antioxidant activity of grains. J. Agric. Food Chem. 2002, 50, 6182–6187. [Google Scholar] [CrossRef] [PubMed]

- Shahidi, F.; Yeo, J. Bioactivities of phenolics by focusing on suppression of chronic diseases: A review. Int. J. Mol. Sci. 2018, 19, 1573. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.H. Health-promoting components of fruits and vegetables in the diet. Adv. Nutr. 2013, 4, 384S–392S. [Google Scholar] [CrossRef]

- Scalbert, A.; Johnson, I.T.; Saltmarsh, M. Polyphenols: Antioxidants and beyond. Am. J. Clin. Nutr. 2005, 81, 215S–217S. [Google Scholar] [CrossRef]

- Shahidi, F.; Ambigaipalan, P. Phenolics and polyphenolics in foods, beverages and spices: Antioxidant activity and health effects–A review. J. Funct. Foods 2015, 18, 820–897. [Google Scholar] [CrossRef]

- Russo, M.; Spagnuolo, C.; Tedesco, I.; Russo, G.L. Phytochemicals in cancer prevention and therapy: Truth or dare? Toxins 2010, 2, 517–551. [Google Scholar] [CrossRef] [PubMed]

- Baur, J.A.; Sinclair, D.A. Therapeutic potential of resveratrol: The in vivo evidence. Nat. Rev. Drug Discov. 2006, 5, 493–506. [Google Scholar] [CrossRef]

- Petersen, M.; Simmonds, M.S. Rosmarinic acid. Phytochemistry 2003, 62, 121–125. [Google Scholar] [CrossRef]

- Njintang, N.; Mbofung, C.; Kesteloot, R. Multivariate analysis of the effect of drying method and particle size of flour on the instrumental texture characteristics of paste made from two varieties of taro (Colocasia esculenta L. Schott) flour. J. Food Eng. 2007, 81, 250–256. [Google Scholar] [CrossRef]

- Antanas, S.; Alexa, E.; Negrea, M.; Guran, E.; Lazureanu, A. Studies regarding rheological properties of triticale, wheat and rye flours. J. Hortic. For. Biotechnol. 2013, 17, 345–349. [Google Scholar]

- Gómez, M.; Ronda, F.; Caballero, P.A.; Blanco, C.A.; Rosell, C.M. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007, 21, 167–173. [Google Scholar] [CrossRef]

- Hooda, S.; Jood, S. Organoleptic and nutritional evaluation of wheat biscuits supplemented with untreated and treated fenugreek flour. Food Chem. 2005, 90, 427–435. [Google Scholar] [CrossRef]

- Manley, D. Manley’s Technology of Biscuits, Crackers and Cookies; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Sharma, P.; Gujral, H.S. Cookie making behavior of wheat–barley flour blends and effects on antioxidant properties. LWT Food Sci. Technol. 2014, 55, 301–307. [Google Scholar] [CrossRef]

- Temesgen, M.; Retta, N. Nutritional potential, health and food security benefits of taro Colocasia esculenta (L.): A review. Food Sci. Qual. Manag. 2015, 36, 23–30. [Google Scholar]

- Rosell, C.M.; Collar, C.; Haros, M. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab. Food Hydrocoll. 2007, 21, 452–462. [Google Scholar] [CrossRef]

- Shewry, P.R.; Hey, S.J. The contribution of wheat to human diet and health. Food Energy Secur. 2015, 4, 178–202. [Google Scholar] [CrossRef]

- Alvarez-Jubete, L.; Arendt, E.K.; Gallagher, E. Nutritive value and chemical composition of pseudocereals as gluten-free ingredients. Int. J. Food Sci. Nutr. 2009, 60 (Suppl. S4), 240–257. [Google Scholar] [CrossRef]

- Adeola, A.A.; Ohizua, E.R. Physical, chemical, and sensory properties of biscuits prepared from flour blends of unripe cooking banana, pigeon pea, and sweet potato. Food Sci. Nutr. 2018, 6, 532–540. [Google Scholar] [CrossRef]

- Njintang, N.Y.; Scher, J.; Mbofung, C.M. Bakery Products and Snacks based on Taro. In Tropical Roots and Tubers; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 362–394. [Google Scholar]

- Mokhele, T.M. The Development of Amadumbe (Colocasia esculenta (L.) Schott)-Soya Composite Biscuits with Improved Nutritional and Sensory Properties. Master’s Thesis, University of South Africa, Pretoria, South Africa, 2018. [Google Scholar]

- Granato, D.; Santos, J.S.; Escher, G.B.; Ferreira, B.L.; Maggio, R.M. Use of principal component analysis (PCA) and hierarchical cluster analysis (HCA) for multivariate association between bioactive compounds and functional properties in foods: A critical perspective. Trends Food Sci. Technol. 2018, 72, 83–90. [Google Scholar] [CrossRef]

- Ohizua, E.R.; Adeola, A.A.; Idowu, M.A.; Sobukola, O.P.; Afolabi, T.A.; Ishola, R.O.; Ayansina, S.O.; Oyekale, T.O.; Falomo, A. Nutrient composition, functional, and pasting properties of unripe cooking banana, pigeon pea, and sweetpotato flour blends. Food Sci. Nutr. 2017, 5, 750–762. [Google Scholar] [CrossRef] [PubMed]

- Kaushal, P.; Kumar, V.; Sharma, H. Utilization of taro (Colocasia esculenta): A review. J. Food Sci. Technol. 2015, 52, 27–40. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I. Cookie making potential of composite flour containing wheat, barley and hemp. Czech J. Food Sci. 2015, 33, 545–555. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Chen, M.; He, Z. Effects of taro powder on the properties of wheat flour and dough. Food Sci. Technol. 2022, 42, e116221. [Google Scholar] [CrossRef]

- Wickramasinghe, M.A.; Nadeeshani, H.; Sewwandi, S.M.; Rathnayake, I.; Kananke, T.C.; Liyanage, R. Comparison of nutritional composition, bioactivities, and FTIR-ATR microstructural properties of commercially grown four mushroom species in Sri Lanka; Agaricus bisporus, Pleurotus ostreatus, Calocybe sp. (MK-white), Ganoderma lucidum. Food Prod. Process. Nutr. 2023, 5, 43. [Google Scholar] [CrossRef]

- Mandache, M.; Topală, C.M.; Vijan, L.E.; Cosmulescu, S. The Characterization of Peach Pomace and the Influence of Its Incorporation on the Chemical Composition of Biscuits. Appl. Sci. 2025, 15, 6983. [Google Scholar] [CrossRef]

- Zamora-Ledezma, C.; Martínez-Hernandez, J.M.; Elango, J.; Garcia-Garrido, J.; Morillas-Ruiz, J.M.; Díaz-Cruces, E.; Miró-Colmenárez, P.J.; Zamora-Ledezma, E. Trans Fats in Spanish Pastries and Their Influence on Mesenchymal Stem Cell Behavior In Vitro and Related Health Risks. Foods 2025, 14, 2247. [Google Scholar] [CrossRef]

- Dhaka, V.; Khatkar, B. Microstructural, thermal and IR spectroscopy characterisation of wheat gluten and its sub fractions. J. Food Sci. Technol. 2016, 53, 3356–3363. [Google Scholar] [CrossRef]

- Yang, T.; Wang, P.; Zhou, Q.; Wang, X.; Cai, J.; Huang, M.; Jiang, D. Investigation on the molecular and physicochemical changes of protein and starch of wheat flour during heating. Foods 2021, 10, 1419. [Google Scholar] [CrossRef]

- Adane, T.; Shimelis, A.; Negussie, R.; Tilahun, B.; Haki, G. Effect of processing method on the Proximate composition, mineral content and antinutritional factors of Taro (Colocasia esculenta, L.) growth in Ethiopia. Afr. J. Food Agric. Nutr. Dev. 2013, 13, 7383–7398. [Google Scholar]

- Akalu, Z.K.; Geleta, S.H. Comparative analysis on the proximate composition of tubers of Colocasia Esculenta, L. Schott and Dioscorea alata cultivated in Ethiopia. Am. J. Biosci. Bioeng. 2019, 7, 93–101. [Google Scholar] [CrossRef]

- Banti, M.; Atlaw, T.; Urugo, M.M.; Agza, B.; Hailu, D.; Teka, T.A. Characterization of taro (Colocasia esculenta) genotypes for nutrients, anti-nutrients, phytochemicals composition, and antioxidant potentials in Southwest Ethiopia. J. Agric. Food Res. 2025, 19, 101591. [Google Scholar] [CrossRef]

- Febles, C.; Arias, A.; Hardisson, A.; Rodrıguez-Alvarez, C.; Sierra, A. Phytic acid level in wheat flours. J. Cereal Sci. 2002, 36, 19–23. [Google Scholar] [CrossRef]

- Parmar, N.; Dahiya, S. Changes in Phytate Content of Newly Released wheat Varieties during Different Processing Methods. Int. J. Sci. Res. 2016, 391, 1572–1576. [Google Scholar]

- Ekop, A.; Obot, I.; Ikpatt, E. Anti-nutritional factors and potassium bromate content in bread and flour samples in Uyo metropolis, Nigeria. J. Chem. 2008, 5, 736–741. [Google Scholar] [CrossRef]

- McEwan, R. Anti-nutritional Constituent of Colocasia esculenta (Amadumbe): A traditional Crop Food in Kwazulu-Natal. Ph.D. Thesis, University of Zululand, Richards Bay, South Africa, 2008. [Google Scholar]

- Savage, G.; Catherwood, D. Determination of oxalates in Japanese taro corms using an in vitro digestion assay. Food Chem. 2007, 105, 383–388. [Google Scholar] [CrossRef]

- Zulkhairi, A.M.; Razali, M.; Umikalsum, M.; Norfaizal, G.M.; Athirah, A.A.; Aisyah, M.S. Determination of oxalates in corms of selected taro (Colocasia esculenta) varieties in malaysia using ultra high-performance liquid chromatography. Asian J. Chem. Sci 2020, 7, 28–37. [Google Scholar] [CrossRef]

- Lo, D.; HsinI, W.; WanJen, W.; RayYu, Y. Anti-nutrient components and their concentrations in edible parts in vegetable families. CABI Rev. 2018, 2018, 1–30. [Google Scholar] [CrossRef]

- Petroski, W.; Minich, D.M. Is there such a thing as “anti-nutrients”? A narrative review of perceived problematic plant compounds. Nutrients 2020, 12, 2929. [Google Scholar] [CrossRef]

- Olapade, A.A.; Adeyemo, M.A. Evaluation of cookies produced from blends of wheat, cassava and cowpea flours. Int. J. Food Stud. 2014, 3, 175–185. [Google Scholar] [CrossRef]

|  |  |  | ||||

| CC | TWC1 | TWC2 | TWC3 | ||||

| Ingredient | Quantity | Ingredient | Quantity | Ingredient | Quantity | Ingredient | Quantity |

| Wheat flour (WF) | 0.5 kg | Wheat flour (WF) | 0.5 kg | Wheat flour (WF) | 0.5 kg | Wheat flour (WF) | 0.5 kg |

| Taro flour (TF) | - | Taro flour (TF) | 0.050 kg | Taro flour (TF) | 0.100 kg | Taro flour (TF) | 0.150 kg |

| Butter | 0.250 kg | Butter | 0.250 kg | Butter | 0.250 kg | Butter | 0.250 kg |

| Baking powder | 0.008 kg | Baking powder | 0.008 kg | Baking powder | 0.008 kg | Baking powder | 0.008 kg |

| Yolk | 0.060 kg | Yolk | 0.060 kg | Yolk | 0.060 kg | Yolk | 0.060 kg |

| Milk | 20 mL | Milk | 20 mL | Milk | 20 mL | Milk | 20 mL |

| Sugar | 0.150 kg | Sugar | 0.150 kg | Sugar | 0.150 kg | Sugar | 0.150 kg |

| Parameters | Methods | References |

|---|---|---|

| Moisture and protein content (%) | Analyzed using ICC Standard Methods (2003) | [20] |

| Ash content (%) | Determined according to ISO Method No. 2171:2007 | [21] |

| Fat content (%) | Measured following AOAC Official Method (2000) | [22] |

| The carbohydrate content (g/100 g) | Calculated by difference: 100 − (moisture + ash + protein + fat) | [23] |

| Parameters | Samples Analyzed | Methods | Units |

|---|---|---|---|

| Total phenolic content (TPC) | All flour and cookie samples. | The total phenolic content (TPC) was determined using previously prepared alcoholic extracts, according to the Folin-Ciocâlteu method described by Danciu et al. (2018) [25] and Obistioiu et al. (2021) [26]. It should be noted that all determinations were performed in triplicate. | GAE/100 g (Milligrams of gallic acid equivalents (GAE) per 100 g) |

| Antioxidant activity (AA) | All flour and cookie samples. | The antioxidant activity was performed using the method described by Ciulca et al. [27] was used, with a few modifications. This method is based on the use of 2,2-diphenyl-1-picrylhydrazyl (DPPH) reagent (Sigma-Aldrich; Merck KGaA, Darmstadt, Germany). As part of the experiment, 1 mL (v/v) of alcoholic extract from each sample (1/10) and 2.5 mL of a 0.03% mM DPPH solution were mixed. The concentration of investigated extracts where 10, 5, 2.5, 1.25 and 0.67 mg/mL. The mixture was then incubated for 30 min at room temperature in a dark environment. The absorbance was then measured using a spectrophotometer (model Specord 205; Analytik Jena AG, Jena, Germany) at a wavelength of 518 Nm. Ethanol was used as a positive control in this study. Antioxidant activity was evaluated using the following equation: AA (%) = (Control Absorbance − Sample Absorbance/Control Absorbance) × 100 Where Control Absorbance refers to the absorbance values of the control, and Sample Absorbance refers to the absorbance values of the sample. | % |

| Individual polyphenols by HPLC | All flour samples. | In order to determine the individual levels of polyphenols in the different flour samples, the method described by [25] was used, with a few minor adjustments. In this study, a Shimadzu chromatograph was used, equipped with SPD-10A UV detector (Shimadzu, Kyoto, Japan), For the analysis, column Adsorbosphere UHS C18 5 μm, batch 007250 (Dr. Maisch, Ammerbuch, Germany) was used. The following chromatographic conditions were applied: Mobile phase A consisted of water acidified with formic acid to a pH of 3, Mobile phase B was created using a combination of acetonitrile acidified with formic acid to a pH of 3. The gradation program, which is the precise sequence of durations and intensities of light used in the photographic development process, was as follows: 0.01 to 20 min at 5% blue; 20.01 to 50 min at 5 to 40% blue; 50 to 55 min at 40 to 95% blue; 55 to 60 min at 95% blue. The solvent flow rate was measured at 0.3 mL/min at a temperature of 20 °C, while the wavelength used for the control ranged from 280 to 320 nm. The calibration curves were produced in the range of 20 to 50 μg/mL. It should be noted that all measurements were performed in triplicate. | mg/kg |

| Samples | Nutritional Characteristics | ||||

|---|---|---|---|---|---|

| Moisture | Ash | Proteins | Lipids | Carbohydrates | |

| (%) | (%) | (%) | (%) | (g/100 g) | |

| Composite flours | |||||

| TF | 10.38 ± 0.02 e | 2.58 ± 0.02 a | 6.76 ± 0.02 e | 1.3 ± 0.01 b,c | 78.98 ± 0.04 a |

| WF | 11.50 ± 0.1 a | 0.28 ± 0.02 e | 11.30 ± 0.04 a | 1.33 ± 0.01 a | 75.58 ± 0.05 e |

| TWF1 | 10.99 ± 0.02 b | 0.35 ± 0.01 d | 10.99 ± 0.02 b | 1.32 ± 0.01 b | 76.35 ± 0.01 d |

| TWF2 | 10.73 ± 0.06 c | 0.48 ± 0.01 c | 10.33 ± 0.02 c | 1.31 ± 0.01 b,c | 77.15 ±0.07 c |

| TWF3 | 10.53 ± 0.03 d | 0.76 ± 0.02 b | 9.99 ± 0.02 d | 1.30 ± 0.01 c | 77.43 ± 0.05 b |

| Cookies | |||||

| CC | 6.63 ± 0.01 a | 1.07 ± 0.01 d | 10.84 ± 0.02 a | 21.04 ± 0.04 a | 60.41 ± 0.04 c |

| TWC1 | 6.14 ± 0.02 b | 1.27 ± 0.01 c | 10.40 ± 0.01 b | 20.94 ± 0.02 b | 61.24 ± 0.04 b |

| TWC2 | 5.96 ± 0.04 c | 1.44 ± 0.03 b | 10.06 ± 0.03 c | 20.86 ± 0.02 c | 61.68 ± 0.01 a |

| TWC3 | 5.86 ± 0.04 d | 1.78 ± 0.01 a | 9.83 ± 0.03 d | 20.80 ± 0.02 d | 61.73 ± 0.08 a |

| Samples | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Galic | Epicatechin | Cafeic | Beta-Rezorcilic | Cumaric | Ferulic | Rosmarinic | Resveratrol | Quercitine | |

| (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | (mg/kg) | |

| TF | 146.72 ± 1.52 a | 22 ± 0.56 a | 4.76 ± 0.19 a | 3.63 ± 0.26 b | 3.51 ± 0.08 a | 3.9 ± 0.09 a | 1.43 ± 0.16 a | 3.49 ± 0.07 b | 7.39 ± 0.22 d |

| WF | 27.95 ± 0.17 e | 3.08 ± 0.15 e | 4.66 ± 0.05 a | 4.11 ± 0.11 a | 3.48 ± 0.02 a | 3.83 ± 0.08 a | 1.58 ± 0.07 a | ND | 20.61 ± 0.11 a |

| TWF1 | 58.97 ± 1 d | 5.28 ± 0.3 d | 4.37 ± 0.19 a | 3.88 ± 0.09 a,b | 3.41 ± 0.14 a | 3.82 ± 0.08 a | 1.49 ± 0.00 a | 2.2 ± 0.59 a,b | 16.09 ± 0.13 c |

| TWF2 | 62.21 ± 0.49 c | 17.97 ± 0.22 c | 4.47 ± 0.36 a | 3.75 ± 0.12 b | 3.5 ±0.24 a | 3.82 ± 0.07 a | 1.47 ±0.03 a | 2.71 ± 0.89 a | 17.04 ± 0.08 b |

| TWF3 | 67.21 ± 0.77 b | 19.37 ± 0.14 b | 4.74 ± 0.26 a | 3.7 ± 0.08 b | 3.49 ± 0.04 a | 3.84 ± 0.02 a | 1.45 ± 0.01 a | 1.32 ± 0.19 b | 17.27 ± 0.06 b |

| Samples | Thickness Increase (%) | Diameter Increase (%) | Baking Yield (%) | Spread Ratio (D/T) |

|---|---|---|---|---|

| CC | 29.24 ± 0.31 a | 5.93 ± 0.03 a | 88.14 ± 0.06 a | 10.7 ± 0.05 a |

| TWC1 | 26.18 ± 0.12 b | 5.98 ± 0.03 b | 87.94 ± 0.06 b | 11.14 ± 0.01 b |

| TWC2 | 21.09 ± 0.01 c | 6.11 ± 0.02 c | 87.59 ± 0.09 c | 11.26 ± 0.02 c |

| TWC3 | 18.95 ± 0.16 d | 6.16 ± 0.03 d | 87.19 ± 0.04 d | 11.88 ± 0.01 d |

| Samples | Antinutritional Characteristics | |

|---|---|---|

| Total Phytic Acid | Total Oxalate | |

| (mg/100 g) | (mg/100 g) | |

| Composite flours | ||

| TF | 119.4 ± 0.46 e | 66.73 ± 0.67 a |

| WF | 204.87 ± 1.26 a | 22.15 ± 0.67 e |

| TWF1 | 190.52 ± 0.36 b | 34.1 ± 1.1 d |

| TWF2 | 172.81 ± 1.44 c | 37.91 ± 0.55 c |

| TWF3 | 153.43 ± 1.37 d | 39.89 ± 0.34 b |

| Cookies | ||

| CC | 192.49 ± 0.14 a | 20.61 ± 0.67 d |

| TWC1 | 174.21 ± 1.14 b | 31.97 ± 0.89 c |

| TWC2 | 157.94 ± 1.15 c | 36.45 ± 0.71 b |

| TWC3 | 134.33 ± 0.52 d | 37.99 ± 0.83 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dossa, S.; Neagu, C.; Lalescu, D.; Negrea, M.; Stoin, D.; Jianu, C.; Berbecea, A.; Cseh, L.; Rivis, A.; Suba, M.; et al. Evaluation of the Nutritional, Rheological, Functional, and Sensory Properties of Cookies Enriched with Taro (Colocasia esculenta) Flour as a Partial Substitute for Wheat Flour. Foods 2025, 14, 3526. https://doi.org/10.3390/foods14203526

Dossa S, Neagu C, Lalescu D, Negrea M, Stoin D, Jianu C, Berbecea A, Cseh L, Rivis A, Suba M, et al. Evaluation of the Nutritional, Rheological, Functional, and Sensory Properties of Cookies Enriched with Taro (Colocasia esculenta) Flour as a Partial Substitute for Wheat Flour. Foods. 2025; 14(20):3526. https://doi.org/10.3390/foods14203526

Chicago/Turabian StyleDossa, Sylvestre, Christine Neagu, Dacian Lalescu, Monica Negrea, Daniela Stoin, Călin Jianu, Adina Berbecea, Liliana Cseh, Adrian Rivis, Mariana Suba, and et al. 2025. "Evaluation of the Nutritional, Rheological, Functional, and Sensory Properties of Cookies Enriched with Taro (Colocasia esculenta) Flour as a Partial Substitute for Wheat Flour" Foods 14, no. 20: 3526. https://doi.org/10.3390/foods14203526

APA StyleDossa, S., Neagu, C., Lalescu, D., Negrea, M., Stoin, D., Jianu, C., Berbecea, A., Cseh, L., Rivis, A., Suba, M., & Alexa, E. (2025). Evaluation of the Nutritional, Rheological, Functional, and Sensory Properties of Cookies Enriched with Taro (Colocasia esculenta) Flour as a Partial Substitute for Wheat Flour. Foods, 14(20), 3526. https://doi.org/10.3390/foods14203526