Advanced Bio-Based Smart Materials for Food Packaging: Applications, Safety, and Sustainability

1. Introduction

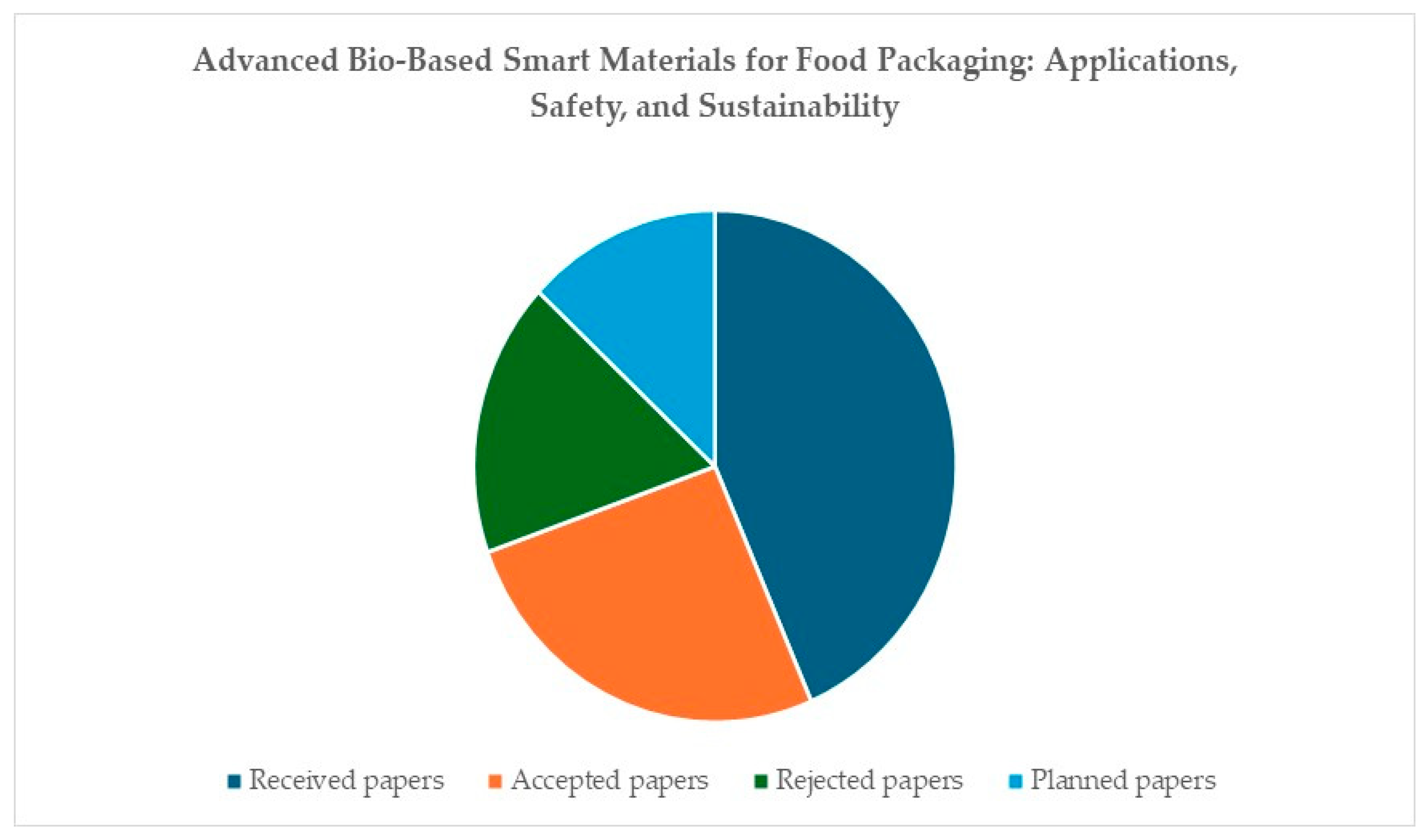

2. An Overview of Published Articles

3. Conclusions and Future Perspectives

Data Availability Statement

Conflicts of Interest

List of Contributions

- Safakas, K.; Lainioti, G.C.; Koutsodima, P.; Stathopoulou, P.; Ladavos, A. Development and Characterization of LDPE/EVA Films Incorporating Carvacrol Essential Oil with Antifungal Activity. Foods 2025, 14, 2069. https://doi.org/10.3390/foods14122069.

- Liu, X.; Xu, F.; Huang, X.; Sun, J.; Kan, J.; Liu, J. Preparation of Hydrophobic Purple Sweet Potato-Based Intelligent Packaging Films by Stearic Acid Coating and Heat Pressing Treatments. Foods 2025, 14, 1276. https://doi.org/10.3390/foods14071276.

- Ren, M.; Wang, N.; Lu, Y.; Wang, C. Preparation and Characterization of Antioxidative and pH-Sensitive Films Based on κ-Carrageenan/Carboxymethyl Cellulose Blended with Purple Cabbage Anthocyanin for Monitoring Hairtail Freshness. Foods 2025, 14, 694. https://doi.org/10.3390/foods14040694.

- Hei, H.; Tang, H.; Zhao, R.; Li, G.; Shi, F. Effect of Melatonin Treatment on Storage Quality and Antioxidant System of Postharvest Winter Jujube (Zizyphus jujube Mill. cv. Dongzao). Foods 2025, 14, 576. https://doi.org/10.3390/foods14040576.

- da Silva Simões, C.V.; Stamford, T.C.M.; Berger, L.R.R.; Araújo, A.S.; da Costa Medeiros, J.A.; de Britto Lira Nogueira, M.C.; Pintado, M.M.E.; Salgado, S.M.; de Lima, M.A.B. Edible Alginate–Fungal Chitosan Coatings as Carriers for Lacticaseibacillus casei LC03 and Their Impact on Quality Parameters of Strawberries During Cold Storage. Foods 2025, 14, 203. https://doi.org/10.3390/foods14020203.

- Panou, A.; Lazaridis, D.G.; Karabagias, I.K. Application of Smart Packaging on the Preservation of Different Types of Perishable Fruits. Foods 2025, 14, 1878. https://doi.org/10.3390/foods14111878.

References

- Seewoo, B.J.; Wong, E.V.S.; Mulders, Y.R.; Goodes, L.M.; Eroglu, E.; Brunner, M.; Gozt, A.; Toshniwal, P.; Symeonides, C.; Dunlop, S.A. Impacts associated with the plastic polymers polycarbonate, polystyrene, polyvinyl chloride, and polybutadiene across their life cycle: A review. Heliyon 2024, 10, e32912. [Google Scholar] [CrossRef] [PubMed]

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in Smart Packaging Concepts for Food: An Extensive Review. Foods 2020, 9, 1628. [Google Scholar] [CrossRef] [PubMed]

- Erginkaya, Z.; Kalkan, S.; Ünal, E. Use of Antimicrobial Edible Films and Coatings as Packaging Materials for Food Safety. In Food Processing: Strategies for Quality Assessment; Malik, A., Erginkaya, Z., Ahmad, S., Erten, H., Eds.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Jung, S.; Cui, Y.; Barnes, M.; Satam, C.; Zhang, S.; Chowdhury, R.A.; Adumbumkulath, A.; Sahin, O.; Miller, C.; Sajadi, S.M.; et al. Multifunctional Bio-Nanocomposite Coatings for Perishable Fruits. Adv. Mater. 2020, 32, 1908291. [Google Scholar] [CrossRef] [PubMed]

- Bansal, H.; Sundaramurthy, S.; Singh, S.; Arisutha, S.; Anant, R.; Mehta, S.K. Chapter 24—Environmental concern, health and safety aspects of polymer nanocomposite films and coatings. In Woodhead Publishing Series in Composites Science and Engineering, Polymer Nanocomposite Films and Coatings; Pandey, M., Deshmukh, K., Hussain, C.M., Eds.; Woodhead Publishing: Cambridge, UK, 2024; pp. 817–842. [Google Scholar] [CrossRef]

- Safakas, K.; Lainioti, G.C.; Koutsodima, P.; Stathopoulou, P.; Ladavos, A. Development and Characterization of LDPE/EVA Films Incorporating Carvacrol Essential Oil with Antifungal Activity. Foods 2025, 14, 2069. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Xu, F.; Huang, X.; Sun, J.; Kan, J.; Liu, J. Preparation of Hydrophobic Purple Sweet Potato-Based Intelligent Packaging Films by Stearic Acid Coating and Heat Pressing Treatments. Foods 2025, 14, 1276. [Google Scholar] [CrossRef] [PubMed]

- Ren, M.; Wang, N.; Lu, Y.; Wang, C. Preparation and Characterization of Antioxidative and pH-Sensitive Films Based on κ-Carrageenan/Carboxymethyl Cellulose Blended with Purple Cabbage Anthocyanin for Monitoring Hairtail Freshness. Foods 2025, 14, 694. [Google Scholar] [CrossRef] [PubMed]

- Hei, H.; Tang, H.; Zhao, R.; Li, G.; Shi, F. Effect of Melatonin Treatment on Storage Quality and Antioxidant System of Postharvest Winter Jujube (Zizyphus jujube Mill. cv. Dongzao). Foods 2025, 14, 576. [Google Scholar] [CrossRef] [PubMed]

- Nogueira, M.C.; Pintado, M.M.E.; Salgado, S.M.; de Lima, M.A.B. Edible Alginate–Fungal Chitosan Coatings as Carriers for Lacticaseibacillus casei LC03 and Their Impact on Quality Parameters of Strawberries During Cold Storage. Foods 2025, 14, 203. [Google Scholar] [CrossRef] [PubMed]

- Panou, A.; Lazaridis, D.G.; Karabagias, I.K. Application of Smart Packaging on the Preservation of Different Types of Perishable Fruits. Foods 2025, 14, 1878. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karabagias, I.K. Advanced Bio-Based Smart Materials for Food Packaging: Applications, Safety, and Sustainability. Foods 2025, 14, 3462. https://doi.org/10.3390/foods14203462

Karabagias IK. Advanced Bio-Based Smart Materials for Food Packaging: Applications, Safety, and Sustainability. Foods. 2025; 14(20):3462. https://doi.org/10.3390/foods14203462

Chicago/Turabian StyleKarabagias, Ioannis Konstantinos. 2025. "Advanced Bio-Based Smart Materials for Food Packaging: Applications, Safety, and Sustainability" Foods 14, no. 20: 3462. https://doi.org/10.3390/foods14203462

APA StyleKarabagias, I. K. (2025). Advanced Bio-Based Smart Materials for Food Packaging: Applications, Safety, and Sustainability. Foods, 14(20), 3462. https://doi.org/10.3390/foods14203462