An Upcycling Approach from Fruit Processing By-Products: Flour for Use in Food Products

Abstract

1. Introduction

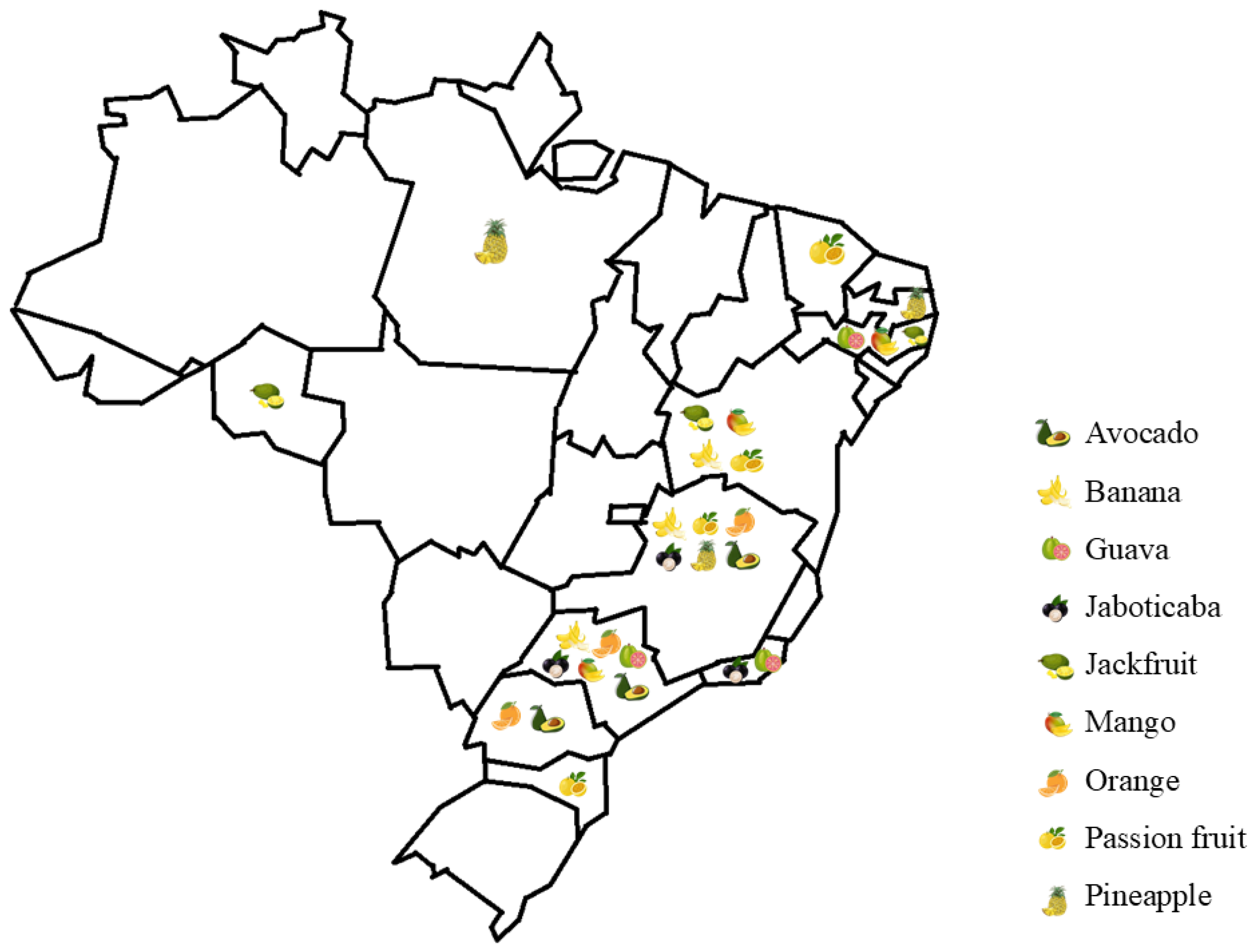

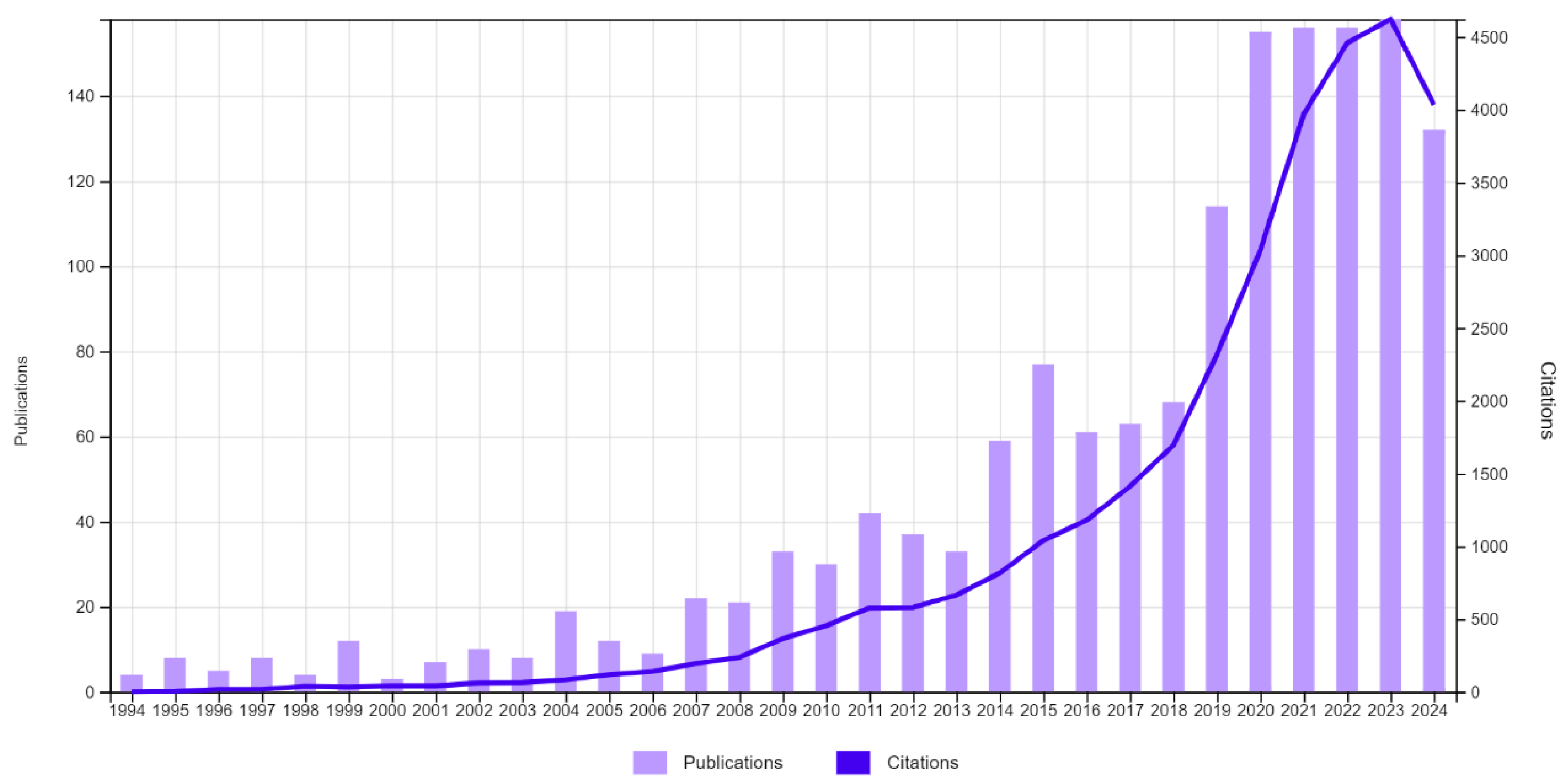

2. Bibliometric Analysis

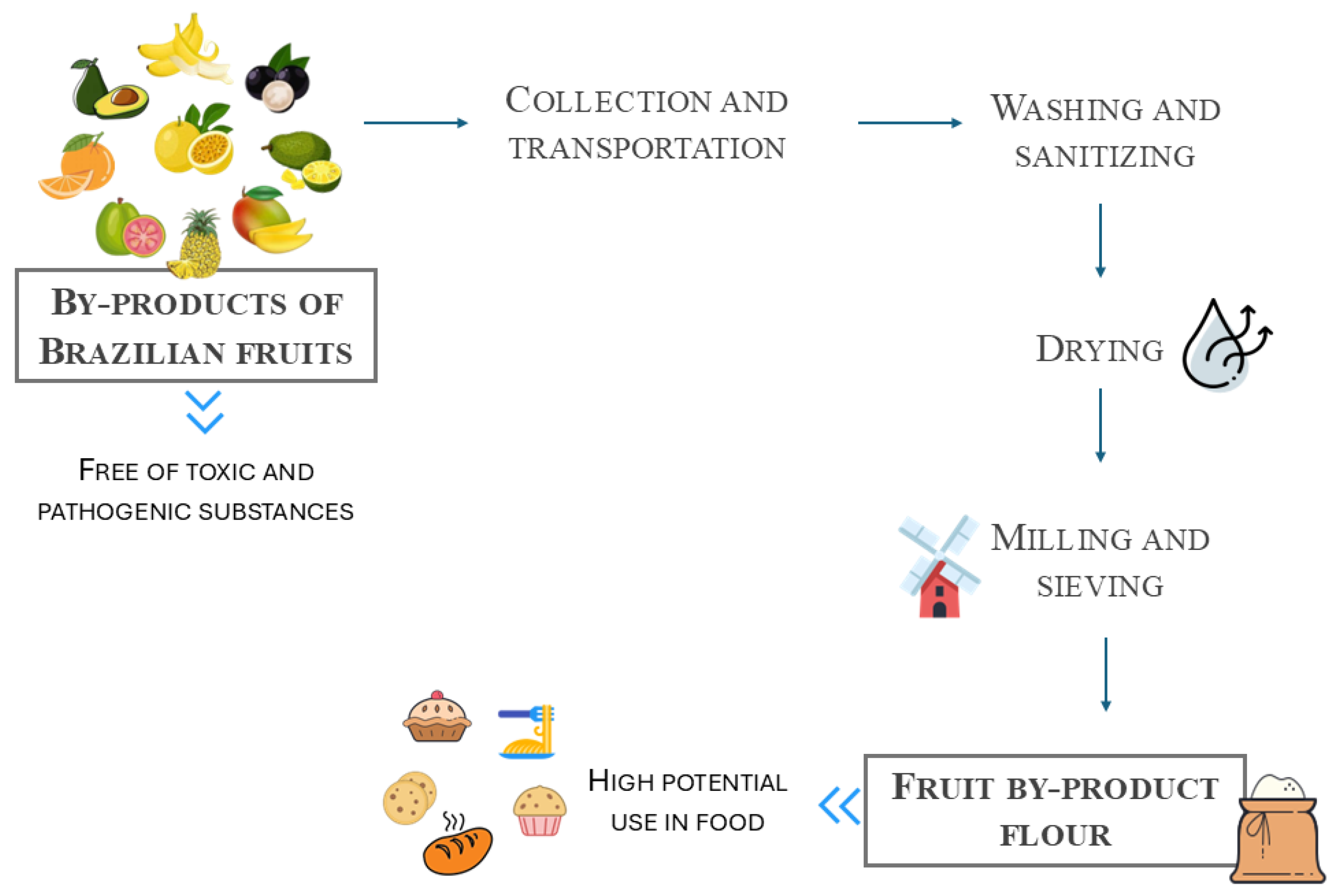

3. Potential Use of Flours from Fruit By-Products Vastly Found in Brazil as Ingredients in Food Formulations

3.1. Jaboticaba

| Formulated Product | By-Product Type | Amount of Added Flour (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Muffins | Peel | Substitution of 4.5, 9, 13.5, and 18% of wheat flour | 9 | Increased ash, moisture, and dietary fiber | Micheletti et al. [25] |

| Bread | Peel | Addition of 0, 5, 10 and 15% in formulation | 5 and 10 | Increase in moisture, minerals, and fiber | Ferreira et al. [27] |

| Bread | Peel and seed | Substitution of 10% of wheat flour | 10 | Increased fiber content | Faller et al. [28] |

| Cereal bar | Peel (mixed with soy okara) | Addition of 2.7, 5.4 and 8.1% in formulation | 2.7 | Increased protein and fiber content | Appelt et al. [29] |

| Cookies | Peel | Substitution of 30, 45 and 60% of total flour | 0.3 | Increase in fiber content | Zago et al. [30] |

3.2. Avocado

| Formulated Product | By-Product Type | Amount of Flour Added (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Cookie | Seed | Substitution of 5, 10 and 20% of wheat flour | 5 | Increased moisture, ash, and carbohydrates | Silva et al. [37] |

| Cookie | Pulp cake from oil extraction | Substitution of 10 and 50% of wheat flour | 10 | Increase in fiber, ash, and carbohydrates | Chaves et al. [36] |

| Weaning foods | Seed | 10, 15 and 20% in formulation | 15 | Increase in fiber, ash, and carbohydrates | Olaleye et al. [38] |

3.3. Guava

| Formulated Product | By-Product Type | Wheat Flour Replacement (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Bread | (whole fruit) | Substituting 10 and 20% of wheat flour | 20 | 2- to-3-fold increase in phenolic compounds | Alves and Perrone [44] |

| Bread | (whole fruit) | Substituting 10 and 20% of wheat flour | 20 | Increase in phenolic compounds and antioxidants. | Castelo-Branco et al. [45] |

| Biscuits | (whole fruit) | Substituting 2.5, 5, 7.5 and 10% of wheat flour | 5 | Increase in protein and fiber content | Zafar et al. [46] |

| Cookie | Peel | Substituting 30, 50 and 70% of wheat flour | 30 | Increase in fiber, ash, polyphenols and β-carotene | Bertagnolli et al. [48] |

| Cookie | Seed | Addition of 3, 6 and 9% | 6 | Increase in fiber, ash and iron | El-Din et al. [47] |

| Juice | Pulp and peel | 1, 3 and 5 | 1 | Increase in phenolic compounds, antioxidants | Silva et al. [49] |

3.4. Mango

| Formulated Product | By-Product Type | Wheat Flour Replacement (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Biscuit | Peel | Substitution of 5, 7.5, 10, 15 and 20% of wheat flour | 10 | Increase in dietary fiber, polyphenols and carotenoids | Ajila et al. [58] |

| Composite cake | Peel | Substitution of 10, 20, 30 and 40% of wheat flour | 20 | Increase in fiber, ash and fat | Das et al. [18] |

| Fusilli pasta | Kernel | Substitution of 5, 10 and 15% of semolina | 10 | Increase in phenolic content and antioxidant activity | Rudra et al. [54] |

| Bread | Kernel | Substitution of 5, 10, 15, 20 and 25% of wheat flour | <20 | Increased protein, dietary fiber, and phenolic compounds | Amin et al. [55] |

| Bread | Peel | Addition of 2.5, 5 and 7.5% to formulation | 5 | Increased polyphenols and carotenoids | Hasan et al. [57] |

| Bread | Peel | Addition of 1, 3 and 5% to formulation | 3 | Increased protein, dietary fiber, and phenolic compounds | Pathak et al. [56] |

3.5. Banana

| Formulated Product | By-Product Type | Amount of Flour Added (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Gluten-free rissol | Peel | 5 and 10% of rice flour substitution | 5% | Increase in fiber content | Gomes et al. [60] |

| Flatbread baladay | Peel | 5 and 10 | 10 | Higher fiber content, protein, fat and ash | Eshak [61] |

| Candy | Peel | 0, 5 and 10 | 0 | Increase in fiber content | Oliveira Neto et al. [62] |

| Cake | Peel | 5, 10 and 15% of wheat flour substitution | 5 | Higher humidity and total solids | Oliveira et al. [63] |

| Gluten-free biscuit | Pulp or peel | 3.5 to 19% of pulp flour and 3.5 to 9.5 of peel flour | 7.5% of pulp flour and 3.5% of peel flour | High levels of resistant starch, total phenolic compounds, total flavonoids and antioxidant activity | Leonel et al. [64] |

| Beef burger | Pulp or peel | 3% | 3% of green banana peel or pulp | Potential to substitute fat without hampering product quality | Bastos et al. [65] |

3.6. Jackfruit

| Formulated Product | By-Product Type | Amount of Flour Added (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Cappuccino | Seed | Substitution of 50, 75 and 100% of cocoa powder | 50 | Higher wettability and solubility | Spada et al. [69] |

| Rotini pasta | Seed | Substitution of 5, 10, 15 and 20% of wheat flour | 10 | Increase in dough firmness | Abraham and Jayamuthunagai [74] |

| Bread | Rind | Substitution of 5, 10 and 15% of wheat flour | 5 | Fiber increase | Feili et al. [75] |

| Bread | Rind | Substitution of 5, 10 and 15% of wheat flour | 5 | Fiber increase | Feili et al. [15] |

3.7. Orange

| Formulated Product | By-Product Type | Amount of Orange Flour Added (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Pearl millet for biscuit | Peel | 5, 10, 15 and 20% | 5 and 10% | Increased fiber content, ash, carbohydrates, and antioxidant activity | Obafaye and Omoba [77] |

| Burger | Peel | 3% and 2% | 3% | Did not impair sensory attributes and protect the product against bacterial proliferation | Mousa [79] |

| Pasta | Peel | 10% of wheat flour substitution | 10 | Improved phenolic content | Ademosun, Odanye and Oboh [17] |

| Cakes | Peel | 12.5 and 6.25% of wheat flour substitution | 12.5 | Increase in dietary fiber content | Oliveira et al. [80] |

| Bread | Peel | 3,6 and 9 of wheat flour substitution | 3 | Increase in ash content, fiber, carbohydrates, and phytochemicals levels | Okpala and Akpu [81] |

3.8. Pineapple

| Formulated Product | By-Product Type | Amount of Flour Added (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Cereal bar | Peel | Addition of 3, 6 and 9% to formulation | 6 | Increased crude fiber content | Damasceno et al. [85] |

| Cookies | Core | Replacement of 5, 10 and 15% wheat flour | 15 | Increased fiber | De Toledo et al. [88] |

| Muffins | Peel | Substitution of 13.3, 20 and 40% of rice flour | 13.3 or 40 | Increased fiber and improved overall acceptance | Brigagão et al. [86] |

| Yogurt | Peel | 1 | 1 | Decreased process time, improved fiber and decreased firmness. | Sah et al. [90] |

3.9. Passion Fruit

| Formulated Product | By-Product Type | Amount of Flour Added (%) | Amount Suggested (%) | Fortified Nutrients | Reference |

|---|---|---|---|---|---|

| Cookie | Peel | Substitution of 10, 20 and 30% of whole wheat flour | 30 | Increased fiber and ash | Garcia et al. [95] |

| Cookie | Albedo | Substitution of 3, 6 and 9% of wheat flour | 6 | Increase in fiber content, ash, and phenolic compounds | Ning et al. [16] |

| Stuffed cookie | Peel | Substitution of 5, 7.5 and 10% of wheat flour | 10 | High fiber content, protein, ash and lipids | Andrade et al. [96] |

| Cake | Albedo | Substitution of 10 and 20% of wheat flour | 10 | Increase in fiber content and decrease in carbohydrates. | Oliveira et al. [80] |

| Cake | Peel | Substitution of 7, 10 and 14% of wheat flour | 14 | Increased fiber content | Miranda et al. [94] |

| Gluten-free pasta | Peel | Substitution of 10 and 20% of rice and maize flour | 10 | Increased fiber content and ash | Ribeiro et al. [97] |

| Yogurt | Peel and seed | Addition of 2, 4, 6 and 8% to formulation | 2 | Increased fiber content, potassium, magnesium, and calcium | de Toledo et al. [98] |

| Cereal bar | Albedo | Addition of 3, 6 and 9% flour to formulation | 6 | Increased moisture and fiber | Bordim et al. [93] |

4. Discussion

4.1. Techno-Functional Characteristics of Fruit By-Product Flours

4.2. Applicability of Fruit By-Product Flours in Food Products

4.3. Quality and Safety Control in Fruit By-Product Flour Processing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Global Food Losses and Food Waste—Extent, Causes and Prevention; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011; ISBN 978-92-5-107205-9. [Google Scholar]

- Torres-León, C.; Ramírez-Guzman, N.; Londoño-Hernandez, L.; Martinez-Medina, G.A.; Díaz-Herrera, R.; Navarro-Macias, V.; Alvarez-Pérez, O.B.; Picazo, B.; Villarreal-Vázquez, M.; Ascacio-Valdes, J.; et al. Food Waste and Byproducts: An Opportunity to Minimize Malnutrition and Hunger in Developing Countries. Front. Sustain. Food Syst. 2018, 2, 52. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Food Waste Index Report 2024; United Nations Environment Programme: Nairobi, Kenya, 2024; ISBN 9789280741391. [Google Scholar]

- FAO. Voluntary Code of Conduct for Food Loss and Waste Reduction; FAO: Rome, Italy, 2022; ISBN 978-92-5-136030-9. [Google Scholar]

- Paula Junior, A.C.; Teixeira, E.; Mateus, R. Improving the Mechanical, Thermal and Durability Properties of Compressed Earth Blocks by Incorporating Industrial Waste and by-Products: A Systematic Literature Review. Constr. Build. Mater. 2024, 438, 137063. [Google Scholar] [CrossRef]

- Beal, T.; Massiot, E.; Arsenault, J.E.; Smith, M.R.; Hijmans, R.J. Global Trends in Dietary Micronutrient Supplies and Estimated Prevalence of Inadequate Intakes. PLoS ONE 2017, 12, e0175554. [Google Scholar] [CrossRef] [PubMed]

- Moshtaghian, H.; Bolton, K.; Rousta, K. Challenges for Upcycled Foods: Definition, Inclusion in the Food Waste Management Hierarchy and Public Acceptability. Foods 2021, 10, 2874. [Google Scholar] [CrossRef]

- Benvenutti, L.; Zielinski, A.A.F.; Ferreira, S.R.S. Jaboticaba (Myrtaceae cauliflora) Fruit and Its by-Products: Alternative Sources for New Foods and Functional Components. Trends Food Sci. Technol. 2021, 112, 118–136. [Google Scholar] [CrossRef]

- Socas-Rodríguez, B.; Álvarez-Rivera, G.; Valdés, A.; Ibáñez, E.; Cifuentes, A. Food By-Products and Food Wastes: Are They Safe Enough for Their Valorization? Trends Food Sci. Technol. 2021, 114, 133–147. [Google Scholar] [CrossRef]

- Moncalvo, A.; Marinoni, L.; Dordoni, R.; Garrido, G.D.; Lavelli, V.; Spigno, G. Waste Grape Skins: Evaluation of Safety Aspects for the Production of Functional Powders and Extracts for the Food Sector. Food Addit. Contam.—Part A Chem. Anal. Control. Expo. Risk Assess. 2016, 33, 1116–1126. [Google Scholar] [CrossRef]

- Rose, G.; Lane, S.; Jordan, R. The Fate of Fungicide and Insecticide Residues in Australian Wine Grape By-Products Following Field Application. Food Chem. 2009, 117, 634–640. [Google Scholar] [CrossRef]

- Rasheed, U.; Ain, Q.U.; Yaseen, M.; Fan, X.; Yao, X.; Tong, Z.; Liu, B. Modification of Bentonite with Orange Peels Extract and Its Application as Mycotoxins’ Binder in Buffered Solutions and Simulated Gastrointestinal Fluids. J. Clean. Prod. 2020, 267, 122105. [Google Scholar] [CrossRef]

- Vilas-Boas, A.A.; Pintado, M.; Oliveira, A.L.S. Natural Bioactive Compounds from Food Waste: Toxicity and Safety Concerns. Foods 2021, 10, 1564. [Google Scholar] [CrossRef]

- Vergara-Valencia, N.; Granados-Pérez, E.; Agama-Acevedo, E.; Tovar, J.; Ruales, J.; Bello-Pérez, L.A. Fibre Concentrate from Mango Fruit: Characterization, Associated Antioxidant Capacity and Application as a Bakery Product Ingredient. LWT 2007, 40, 722–729. [Google Scholar] [CrossRef]

- Felli, R.; Yang, T.A.; Abdullah, W.N.W.; Zzaman, W. Effects of Incorporation of Jackfruit Rind Powder on Chemical and Functional Properties of Bread. Trop. Life Sci. Res. 2018, 29, 113–126. [Google Scholar] [CrossRef] [PubMed]

- Ning, X.; Wu, J.; Luo, Z.; Chen, Y.; Mo, Z.; Luo, R.; Bai, C.; Du, W.; Wang, L. Cookies Fortified with Purple Passion Fruit Epicarp Flour: Impact on Physical Properties, Nutrition, in Vitro Starch Digestibility, and Antioxidant Activity. Cereal Chem. 2021, 98, 328–336. [Google Scholar] [CrossRef]

- Ademosun, A.O.; Odanye, O.S.; Oboh, G. Orange Peel Flavored Unripe Plantain Noodles with Low Glycemic Index Improved Antioxidant Status and Reduced Blood Glucose Levels in Diabetic Rats. J. Food Meas. Charact. 2021, 15, 3742–3751. [Google Scholar] [CrossRef]

- Das, P.C.; Khan, M.J.; Rahman, M.S.; Majumder, S.; Islam, M.N. Comparison of the Physico-Chemical and Functional Properties of Mango Kernel Flour with Wheat Flour and Development of Mango Kernel Flour Based Composite Cakes. NFS J. 2019, 17, 1–7. [Google Scholar] [CrossRef]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional Facts Regarding Commercially Available Gluten-Free Bread Worldwide: Recent Advances and Future Challenges. Crit. Rev. Food Sci. Nutr. 2023, 63, 693–705. [Google Scholar] [CrossRef]

- Larrosa, A.P.Q.; Otero, D.M. Flour Made from Fruit By-Products: Characteristics, Processing Conditions, and Applications. J. Food Process. Preserv. 2021, 45, 15398. [Google Scholar] [CrossRef]

- Ramírez-Pulido, B.; Bas-Bellver, C.; Betoret, N.; Barrera, C.; Seguí, L. Valorization of Vegetable Fresh-Processing Residues as Functional Powdered Ingredients. A Review on the Potential Impact of Pretreatments and Drying Methods on Bioactive Compounds and Their Bioaccessibility. Front. Sustain. Food Syst. 2021, 5, 654313. [Google Scholar] [CrossRef]

- Duarte, O.; Paull, R. Myrtaceae. In Exotic Fruits and Nuts of the New World; CABI: London, UK, 2015; pp. 51–95. [Google Scholar]

- Leite-Legatti, A.V.; Batista, A.G.; Dragano, N.R.V.; Marques, A.C.; Malta, L.G.; Riccio, M.F.; Eberlin, M.N.; Machado, A.R.T.; de Carvalho-Silva, L.B.; Ruiz, A.L.T.G.; et al. Jaboticaba Peel: Antioxidant Compounds, Antiproliferative and Antimutagenic Activities. Food Res. Int. 2012, 49, 596–603. [Google Scholar] [CrossRef]

- Fidelis, M.; Santos, J.S.; Escher, G.B.; Rocha, R.S.; Cruz, A.G.; Cruz, T.M.; Marques, M.B.; Nunes, J.B.; do Carmo, M.A.V.; de Almeida, L.A.; et al. Polyphenols in Jabuticaba [Myrciaria jaboticaba (Vell.) O.Berg] Seeds Exert Antioxidant Activity and Modulate Gut Microbiota of 1,2-Dimethylhydrazine-Induced Colon Cancer in Wistar Rats. Food Chem. 2021, 334, 127565. [Google Scholar] [CrossRef]

- Micheletti, J.; Soares, J.M.; Franco, B.C.; Almeida de Carvalho, I.R.; Candido, C.J.; dos Santos, E.F.; Novello, D. The Addition of Jaboticaba Skin Flour to Muffins Alters the Physicochemical Composition and Their Sensory Acceptability by Children. Braz. J. Food Technol. 2018, 21, e2017089. [Google Scholar] [CrossRef]

- Walker, R.; Tseng, A.; Cavender, G.; Ross, A.; Zhao, Y. Physicochemical, Nutritional, and Sensory Qualities of Wine Grape Pomace Fortified Baked Goods. J. Food Sci. 2014, 79, S1811–S1822. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, S.P.L.; Jardim, F.B.B.; da Fonseca, C.R.; Costa, L.L. Whole-Grain Pan Bread with the Addition of Jabuticaba Peel Flour. Cienc. Rural 2020, 50, e20190623. [Google Scholar] [CrossRef]

- Faller, A.L.K.; Duarte, P.A.; Paes, J.d.M.; Kamp, F.; Fialho, E.; Monteiro, M. Jabuticaba (Myrciaria jaboticaba) Peel and Seed Powder Associated with Bioprocessing Improves Functional and Nutritional Quality of Whole-Wheat Bread. Int. J. Food Sci. Technol. 2023, 58, 1411–1422. [Google Scholar] [CrossRef]

- Appelt, P.; Cunha, M.A.A.d.; Guerra, A.P.; Kalinke, C.; Lima, V.A.d. Development and Characterization of Cereal Bars Made with Flour of Jabuticaba Peel and Okara. Acta Sci. Technol. 2015, 37, 117. [Google Scholar] [CrossRef]

- Zago, M.F.C.; Caliari, M.; Soares Júnior, M.S.; Campos, M.R.H.; Batista, J.E.R. Uso Da Casca de Jabuticaba Na Produção de Cookies Para a Alimentação Escolar: Aspectos Tecnológicos e Sensoriais. Cienc. Agrotecnologia 2015, 39, 624–633. [Google Scholar] [CrossRef]

- Barbosa, R.I.; Ramírez-Narváez, P.N.; Fearnside, P.M.; Villacorta, C.D.A.; Carvalho, L.C.d.S. Allometric Models to Estimate Tree Height in Northern Amazonian Ecotone Forests. Acta Amaz. 2019, 49, 81–90. [Google Scholar] [CrossRef]

- Ding, H.; Chin, Y.W.; Kinghorn, A.D.; D’Ambrosio, S.M. Chemopreventive Characteristics of Avocado Fruit. Semin. Cancer Biol. 2007, 17, 386–394. [Google Scholar] [CrossRef]

- Ozdemir, F.; Topuz, A. Changes in Dry Matter, Oil Content and Fatty Acids Composition of Avocado during Harvesting Time and Post-Harvesting Ripening Period. Food Chem. 2004, 86, 79–83. [Google Scholar] [CrossRef]

- Barbosa-Martín, E.; Chel-Guerrero, L.; González-Mondragón, E.; Betancur-Ancona, D. Chemical and Technological Properties of Avocado (Persea americana Mill.) Seed Fibrous Residues. Food Bioprod. Process. 2016, 100, 457–463. [Google Scholar] [CrossRef]

- Mostert, M.E.; Botha, B.M.; Plessis, L.M.D.; Duodu, K.G. Effect of Fruit Ripeness and Method of Fruit Drying on the Extractability of Avocado Oil with Hexane and Supercritical Carbon Dioxide. J. Sci. Food Agric. 2007, 87, 2880–2885. [Google Scholar] [CrossRef]

- Alves Chaves, M.; Mendonça, C.R.B.; Dellinghausen Borges, C.; Maria Porcu, O. Elaboração de Biscoito Integral Utilizando Óleo e Farinha Da Polpa de Abacate. Bol. Cent. Pesqui. Process. Aliment. 2013, 31, 215–226. [Google Scholar] [CrossRef]

- Da Silva, I.G.; De Andrade, A.P.C.; Da Silva, L.M.R.; Gomes, D.S. Elaboration and Sensory Analysis of Cookies Made from Avocado Lump Flour. Braz. J. Food Technol. 2019, 22, e2018209. [Google Scholar] [CrossRef]

- Olaleye, H.T.; Oresanya, T.O.; Okwara, B.A. Quality Parameters of Weaning Food from Blends of Quality Protein Maize, Irish Potatoes and Avocado Seeds Flours. J. Food Process. Preserv. 2020, 44, e14738. [Google Scholar] [CrossRef]

- Bangar, S.P.; Dunno, K.; Dhull, S.B.; Kumar Siroha, A.; Changan, S.; Maqsood, S.; Rusu, A.V. Avocado Seed Discoveries: Chemical Composition, Biological Properties, and Industrial Food Applications. Food Chem. X 2022, 16, 100507. [Google Scholar] [CrossRef]

- IBGE Produção Agrícola—Lavoura Permanente. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/goiaba/br (accessed on 29 October 2024).

- Flores, G.; Wu, S.B.; Negrin, A.; Kennelly, E.J. Chemical Composition and Antioxidant Activity of Seven Cultivars of Guava (Psidium guajava) Fruits. Food Chem. 2015, 170, 327–335. [Google Scholar] [CrossRef]

- Almulaiky, Y.; Zeyadi, M.; Saleh, R.; Baothman, O.; Al-shawafi, W.; Al-Talhi, H. Assessment of Antioxidant and Antibacterial Properties in Two Types of Yemeni Guava Cultivars. Biocatal. Agric. Biotechnol. 2018, 16, 90–97. [Google Scholar] [CrossRef]

- Amaya-Cruz, D.M.; Rodríguez-González, S.; Pérez-Ramírez, I.F.; Loarca-Piña, G.; Amaya-Llano, S.; Gallegos-Corona, M.A.; Reynoso-Camacho, R. Juice By-Products as a Source of Dietary Fibre and Antioxidants and Their Effect on Hepatic Steatosis. J. Funct. Foods 2015, 17, 93–102. [Google Scholar] [CrossRef]

- Alves, G.; Perrone, D. Breads Enriched with Guava Flour as a Tool for Studying the Incorporation of Phenolic Compounds in Bread Melanoidins. Food Chem. 2015, 185, 65–74. [Google Scholar] [CrossRef]

- Castelo-Branco, V.N.; Lago, M.G.; Minuzzo, D.A.; Moura-Nunes, N.; Torres, A.G.; Nunes, J.C.; Monteiro, M. Bread Formulated with Guava Powder Was Enriched in Phenolic and Aroma Compounds, and Was Highly Acceptable by Consumers. J. Food Sci. Technol. 2016, 53, 4168–4178. [Google Scholar] [CrossRef]

- Zafar, M.A.; Kausar, T.; Mahmood, S. Formulation and Physicochemical and Sensorial Evaluation of Biscuits Supplemented with Guava Powder. Pure Appl. Biol. 2019, 8, 1588–1591. [Google Scholar] [CrossRef]

- El-Din, M.H.A.S.; Yassen, A.A.E. Evaluation and Utilization of Guava Seed Meal (Psidium guajava L.) in Cookies Preparation as Wheat Flour Substitute. Food/Nahr. 1997, 41, 344–348. [Google Scholar] [CrossRef]

- Bertagnolli, S.M.M.; Silveira, M.L.R.; Fogaça, A.d.O.; Umann, L.; Penna, N.G. Bioactive Compounds and Acceptance of Cookies Made with Guava Peel Flour. Food Sci. Technol. 2014, 34, 303–308. [Google Scholar] [CrossRef]

- Silva, T.V.B.; Iwassa, I.J.; Sampaio, A.R.; Ruiz, S.P.; Barros, B.C.B. Physicochemical, Antioxidant, Rheological, and Sensory Properties of Juice Produced with Guava Pulp and Peel Flour. An. Acad. Bras. Cienc. 2021, 93, e20191175. [Google Scholar] [CrossRef] [PubMed]

- Mwaurah, P.W.; Kumar, S.; Kumar, N.; Panghal, A.; Attkan, A.K.; Singh, V.K.; Garg, M.K. Physicochemical Characteristics, Bioactive Compounds and Industrial Applications of Mango Kernel and Its Products: A Review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2421–2446. [Google Scholar] [CrossRef]

- Das, P.C.; Sattar, S.; Jony, M.E.; Islam, M.N. Rehydration Kinetics of Flour from Dehydrated Mango Kernel. Food Res. 2018, 2, 474–480. [Google Scholar] [CrossRef]

- Ajila, C.M.; Aalami, M.; Leelavathi, K.; Rao, U.J.S.P. Mango Peel Powder: A Potential Source of Antioxidant and Dietary Fiber in Macaroni Preparations. Innov. Food Sci. Emerg. Technol. 2010, 11, 219–224. [Google Scholar] [CrossRef]

- Nur Azura, Z.; Radhiah, S.; Wan Zunairah, W.I.; Nurul Shazini, R.; Nur Hanani, Z.A.; Ismail-Fitry, M.R. Physicochemical, Cooking Quality and Sensory Characterization of Yellow Alkaline Noodle: Impact of Mango Peel Powder Level. Food Res. 2020, 4, 70–76. [Google Scholar] [CrossRef]

- Gaur Rudra, S.; Gundewadi, G.; Kaur, C.; Singh, G. Exploring Varietal Differences in Nutritional and Antioxidant Potential of Mango Kernel and Its Use for Enrichment of Pasta. Fruits 2019, 74, 227–235. [Google Scholar] [CrossRef]

- Amin, K.; Akhtar, S.; Ismail, T. Nutritional and Organoleptic Evaluation of Functional Bread Prepared from Raw and Processed Defatted Mango Kernel Flour. J. Food Process. Preserv. 2018, 42, e13570. [Google Scholar] [CrossRef]

- Pathak, D.; Majumdar, J.; Raychaudhuri, U.; Chakraborty, R. Characterization of Physicochemical Properties in Whole Wheat Bread after Incorporation of Ripe Mango Peel. J. Food Meas. Charact. 2016, 10, 554–561. [Google Scholar] [CrossRef]

- Hasan, M.M.; Islam, M.R.; Haque, A.R.; Kabir, M.R.; Hasan, S.M.K. Fortification of Bread with Mango Peel and Pulp as a Source of Bioactive Compounds: A Comparison with Plain Bread. Food Chem. Adv. 2024, 5, 100783. [Google Scholar] [CrossRef]

- Ajila, C.M.; Leelavathi, K.; Prasada Rao, U.J.S. Improvement of Dietary Fiber Content and Antioxidant Properties in Soft Dough Biscuits with the Incorporation of Mango Peel Powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar] [CrossRef]

- Amini Khoozani, A.; Birch, J.; Bekhit, A.E.D.A. Production, Application and Health Effects of Banana Pulp and Peel Flour in the Food Industry. J. Food Sci. Technol. 2019, 56, 548–559. [Google Scholar] [CrossRef]

- Gomes, S.; Vieira, B.; Barbosa, C.; Pinheiro, R. Evaluation of Mature Banana Peel Flour on Physical, Chemical, and Texture Properties of a Gluten-Free Rissol. J. Food Process. Preserv. 2022, 46, 14441. [Google Scholar] [CrossRef]

- Eshak, N.S. Sensory Evaluation and Nutritional Value of Balady Flat Bread Supplemented with Banana Peels as a Natural Source of Dietary Fiber. Ann. Agric. Sci. 2016, 61, 229–235. [Google Scholar] [CrossRef]

- De Oliveira Neto, J.O.; De Oliveira, E.N.A.; Feitosa, B.F.; De Oliveira Germano, A.M.L.; Feitosa, R.M. Use of Banana Peel in the Elaboration of Candy Mariola Type. Cientifica 2018, 46, 199–206. [Google Scholar] [CrossRef][Green Version]

- Oliveira, L.M.d.C.; Pereira, M.d.J.L.; Santos, D.d.C.; Leite, D.D.d.F.; Lima, T.L.B.; Gomes, J.P. Efeito Das Concentrações de Farinha de Cascas de Banana e de Sacarose Nas Características Físicas e Químicas de Bolos. Braz. J. Food Technol. 2020, 23, e2019314. [Google Scholar] [CrossRef]

- Leonel, M.; Dos Santos, T.P.R.; Leonel, S.; De Souza Santos, C.H.E.; Lima, G.P.P. Blends of Cassava Starch with Banana Flours as Raw Materials for Gluten-Free Biscuits. Semin. Agrar. 2021, 42, 2293–2311. [Google Scholar] [CrossRef]

- Bastos, S.C.; Pimenta, M.E.S.G.; Pimenta, C.J.; Reis, T.A.; Nunes, C.A.; Pinheiro, A.C.M.; Fabrício, L.F.F.; Leal, R.S. Alternative Fat Substitutes for Beef Burger: Technological and Sensory Characteristics. J. Food Sci. Technol. 2014, 51, 2046–2053. [Google Scholar] [CrossRef]

- Madruga, M.S.; De Albuquerque, F.S.M.; Silva, I.R.A.; Do Amaral, D.S.; Magnani, M.; Neto, V.Q. Chemical, Morphological and Functional Properties of Brazilian Jackfruit (Artocarpus heterophyllus L.) Seeds Starch. Food Chem. 2014, 143, 440–445. [Google Scholar] [CrossRef] [PubMed]

- Waghmare, R.; Memon, N.; Gat, Y.; Gandhi, S.; Kumar, V.; Panghal, A. Jackfruit Seed: An Accompaniment to Functional Foods. Braz. J. Food Technol. 2019, 22, e2018207. [Google Scholar] [CrossRef]

- Sousa, A.P.M.; Macedo, A.D.B.; Silva, A.P.d.F.; Costa, J.D.; Dantas, D.L.; Apolinário, M.d.O.; Santana, R.A.C.; Campos, A.R.N. Enriquecimento Proteico Dos Resíduos Da Jaca Por Fermentação Semissólida. Braz. Appl. Sci. Rev. 2020, 4, 987–997. [Google Scholar] [CrossRef]

- Spada, F.P.; Da Silva, P.P.M.; Mandro, G.F.; Margiotta, G.B.; Spoto, M.H.F.; Canniatti-Brazaca, S.G. Physicochemical Characteristics and High Sensory Acceptability in Cappuccinos Made with Jackfruit Seeds Replacing Cocoa Powder. PLoS ONE 2018, 13, e0197654. [Google Scholar] [CrossRef] [PubMed]

- Spada, F.P.; Zerbeto, L.M.; Ragazi, G.B.C.; Gutierrez, É.M.R.; Souza, M.C.; Parker, J.K.; Canniatti-Brazaca, S.G. Optimization of Postharvest Conditions to Produce Chocolate Aroma from Jackfruit Seeds. J. Agric. Food Chem. 2017, 65, 1196–1208. [Google Scholar] [CrossRef]

- Spada, F.P.; Balagiannis, D.P.; Purgatto, E.; do Alencar, S.M.; Canniatti-Brazaca, S.G.; Parker, J.K. Characterisation of the Chocolate Aroma in Roast Jackfruit Seeds. Food Chem. 2021, 354, 129537. [Google Scholar] [CrossRef]

- Spada, F.P.; de Alencar, S.M.; Purgatto, E. Comprehensive Chocolate Aroma Characterization in Beverages Containing Jackfruit Seed Flours and Cocoa Powder. Futur. Foods 2022, 6, 100158. [Google Scholar] [CrossRef]

- Spada, F.P.; Mandro, G.F.; da Matta, M.D.; Canniatti-Brazaca, S.G. Functional Properties and Sensory Aroma of Roasted Jackfruit Seed Flours Compared to Cocoa and Commercial Chocolate Powder. Food Biosci. 2020, 37, 100683. [Google Scholar] [CrossRef]

- Abraham, A.; Jayamuthunagai, J. An Analytical Study on Jackfruit Seed Flour and Its Incorporation in Pasta. Res. J. Pharm. Biol. Chem. Sci. 2014, 5, 1597–1610. [Google Scholar]

- Feili, R.; Zzaman, W.; Nadiah Wan Abdullah, W.; Yang, T.A. Physical and Sensory Analysis of High Fiber Bread Incorporated with Jackfruit Rind Flour. Food Sci. Technol. 2013, 1, 30–36. [Google Scholar] [CrossRef]

- FAOSTAT—Food and Agriculture Organization of the United Nations Statistical Database. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 13 September 2024).

- Obafaye, R.O.; Omoba, O.S. Orange Peel Flour: A Potential Source of Antioxidant and Dietary Fiber in Pearl-Millet Biscuit. J. Food Biochem. 2018, 42, 12523. [Google Scholar] [CrossRef]

- Galvan-Lima, Â.; Cunha, S.C.; Martins, Z.E.; Soares, A.G.; Ferreira, I.M.P.L.V.O.; Farah, A. Headspace Volatolome of Peel Flours from Citrus Fruits Grown in Brazil. Food Res. Int. 2021, 150, 110801. [Google Scholar] [CrossRef] [PubMed]

- Mousa, R.M.A. Development of 95% Fat-Free Hamburgers Using Binary and Ternary Composites from Polysaccharide Hydrocolloids and Fruit Peel Flours as Fat Replacer Systems. J. Food Process. Preserv. 2021, 45, 15457. [Google Scholar] [CrossRef]

- de Oliveira, V.R.; Preto, L.T.; de Oliveira Schmidt, H.; Komeroski, M.; Silva, V.L.d.; de Oliveira Rios, A. Physicochemical and Sensory Evaluation of Cakes Made with Passion Fruit and Orange Residues. J. Culin. Sci. Technol. 2016, 14, 166–175. [Google Scholar] [CrossRef]

- Okpala, L.C.; Akpu, M.N. Effect of Orange Peel Flour on the Quality Characteristics of Bread. Br. J. Appl. Sci. Technol. 2014, 4, 823–830. [Google Scholar] [CrossRef]

- Ancos, B.d.; Sánchez-Moreno, C.; Concepción, G. Production, Postharvest Science, Processing and Nutrition. In Handbook of Pineapple Technology; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Campos, D.A.; Ribeiro, T.B.; Teixeira, J.A.; Pastrana, L.; Pintado, M.M. Integral Valorization of Pineapple (Ananas comosus L.) By-Products through a Green Chemistry Approach Towards Added Value Ingredients. Foods 2020, 9, 60. [Google Scholar] [CrossRef]

- Brito, T.B.N.; Pereira, A.P.A.; Pastore, G.M.; Moreira, R.F.A.; Ferreira, M.S.L.; Fai, A.E.C. Chemical Composition and Physicochemical Characterization for Cabbage and Pineapple By-Products Flour Valorization. LWT 2020, 124, 109028. [Google Scholar] [CrossRef]

- Aparecida Damasceno, K.; Alvarenga Gonçalves, C.A.; Dos Santos Pereira, G.; Lacerda Costa, L.; Bastianello Campagnol, P.C.; Leal De Almeida, P.; Arantes-Pereira, L. Development of Cereal Bars Containing Pineapple Peel Flour (Ananas comosus L. Merril). J. Food Qual. 2016, 39, 417–424. [Google Scholar] [CrossRef]

- Brigagão, T.C.S.; Fortes, R.R.; Lourenço, C.O.; Carvalho, E.E.N.; Cirillo, M.Â.; Nachtigall, A.M.; Vilas Boas, B.M. Optimization of Gluten-free Muffins Made with Pineapple Peel, Banana Peel, and Pumpkin Seed Flours. J. Food Process. Preserv. 2021, 45, 16037. [Google Scholar] [CrossRef]

- Santos, D.I.; Martins, C.F.; Amaral, R.A.; Saraiva, J.A.; Vicente, A.; Mold, M. Novel Bio Ingredients for Functional Foods. Molecules 2021, 26, 3216. [Google Scholar] [CrossRef]

- de Toledo, N.M.V.; Nunes, L.P.; da Silva, P.P.M.; Spoto, M.H.F.; Canniatti-Brazaca, S.G. Influence of Pineapple, Apple and Melon by-Products on Cookies: Physicochemical and Sensory Aspects. Int. J. Food Sci. Technol. 2017, 52, 1185–1192. [Google Scholar] [CrossRef]

- Diaz-Vela, J.; Totosaus, A.; Cruz-Guerrero, A.E.; de Lourdes Pérez-Chabela, M. In Vitro Evaluation of the Fermentation of Added-Value Agroindustrial By-Products: Cactus Pear (Opuntia ficus-indica L.) Peel and Pineapple (Ananas comosus) Peel as Functional Ingredients. Int. J. Food Sci. Technol. 2013, 48, 1460–1467. [Google Scholar] [CrossRef]

- Sah, B.N.P.; Vasiljevic, T.; McKechnie, S.; Donkor, O.N. Physicochemical, Textural and Rheological Properties of Probiotic Yogurt Fortified with Fibre-Rich Pineapple Peel Powder during Refrigerated Storage. LWT 2016, 65, 978–986. [Google Scholar] [CrossRef]

- López-Vargas, J.H.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, Physico-Chemical, Technological, Antibacterial and Antioxidant Properties of Dietary Fiber Powder Obtained from Yellow Passion Fruit (Passiflora edulis Var. Flavicarpa) Co-Products. Food Res. Int. 2013, 51, 756–763. [Google Scholar] [CrossRef]

- Do Rosário, R.C.; Soares, S.D.; Martins, M.G.; Do Nascimento, F.D.C.A.; Silva Junior, J.O.C.; Teixeira-Costa, B.E.; Figueira, M.d.S.; Dos Santos, O.V. Bioactive, Technological-Functional Potential and Morphological Structures of Passion Fruit Albedo (Passiflora edulis). Food Sci. Technol. 2022, 42, 22222. [Google Scholar] [CrossRef]

- Bordim, J.; Amorim, J.; Sari, R.; da Silva, A.C.T.; Sotiles, A.R.; Pereira, E.A. Technological Use of Flour Obtained from the Byproducts of Passion Fruit Albedo and the Residue of the Extraction of the Star Fruit Juice in the Formulation of Cereal Bars. Orbital 2018, 10, 211–217. [Google Scholar] [CrossRef]

- Miranda, A.A.; Caixeta, A.C.A.; Flávio, E.F.; Pinho, L. Desenvolvimento e Análise de Bolos Enriquecidos Com Farinha Da Casca Do Maracujá (Passiflora edulis) Como Fonte de Fibras. Aliment. Nutr. Araraquara 2013, 24, 232. [Google Scholar]

- Garcia, M.V.; Milani, M.S.; Ries, E.F. Production Optimization of Passion Fruit Peel Flour and Its Incorporation into Dietary Food. Food Sci. Technol. Int. 2020, 26, 132–139. [Google Scholar] [CrossRef]

- Andrade, J.K.S.; De Barretto, L.C.O.; Denadai, M.; Narain, N.; Dos Santos, J.A.B. Harnessing Passion Fruit Peel Flour (Passiflora edulis f. Flavicarpa) for the Preparation of Stuffed Cookies. Acta Hortic. 2018, 1198, 205–212. [Google Scholar] [CrossRef]

- Ribeiro, T.H.S.; Bolanho, B.C.; Montanuci, F.D.; Ruiz, S.P. Physicochemical and Sensory Characterization of Gluten-Free Fresh Pasta with Addition of Passion Fruit Peel Flour. Cienc. Rural 2018, 48, e20180508. [Google Scholar] [CrossRef]

- de Toledo, N.M.V.; de Camargo, A.C.; Ramos, P.B.M.; Button, D.C.; Granato, D.; Canniatti-Brazaca, S.G. Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects. Beverages 2018, 4, 47. [Google Scholar] [CrossRef]

- Badia-Olmos, C.; Laguna, L.; Haros, C.M.; Tárrega, A. Techno-Functional and Rheological Properties of Alternative Plant-Based Flours. Foods 2023, 12, 1411. [Google Scholar] [CrossRef] [PubMed]

- López-Vargas, J.H.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Viuda-Martos, M. Quality Characteristics of Pork Burger Added with Albedo-Fiber Powder Obtained from Yellow Passion Fruit (Passiflora edulis Var. Flavicarpa) Co-Products. Meat Sci. 2014, 97, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Selani, M.M.; Bianchini, A.; Ratnayake, W.S.; Flores, R.A.; Massarioli, A.P.; de Alencar, S.M.; Canniatti Brazaca, S.G. Physicochemical, Functional and Antioxidant Properties of Tropical Fruits Co-Products. Plant Foods Hum. Nutr. 2016, 71, 137–144. [Google Scholar] [CrossRef]

- Arogba, S.S. Physical, Chemical and Functional Properties of Nigerian Mango (Mangifera indica) Kernel and Its Processed Flour. J. Sci. Food Agric. 1997, 73, 321–328. [Google Scholar] [CrossRef]

- Reis, L.C.R.d.; Facco, E.M.P.; Salvador, M.; Flôres, S.H.; Rios, A.d.O. Characterization of Orange Passion Fruit Peel Flour and Its Use as an Ingredient in Bakery Products. J. Culin. Sci. Technol. 2020, 18, 214–230. [Google Scholar] [CrossRef]

- AGÊNCIA NACIONAL DE VIGILÂNCIA SANITÁRIA. Instrução Normativa No 60, de 23 de Dezembro de 2019. Diário Oficial Da República Federativa Do Brasil 2019. Available online: https://cvs.saude.sp.gov.br/zip/U_IN-MS-ANVISA-60_231219.pdf (accessed on 30 December 2024).

- Mortensen, A.; Granby, K.; Eriksen, F.D.; Cederberg, T.L.; Friis-Wandall, S.; Simonsen, Y.; Broesbøl-Jensen, B.; Bonnichsen, R. Levels and Risk Assessment of Chemical Contaminants in Byproducts for Animal Feed in Denmark. J. Environ. Sci. Health 2014, 49, 797–810. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benvenutti, L.; Moura, F.M.; Zanghelini, G.; Barrera, C.; Seguí, L.; Zielinski, A.A.F. An Upcycling Approach from Fruit Processing By-Products: Flour for Use in Food Products. Foods 2025, 14, 153. https://doi.org/10.3390/foods14020153

Benvenutti L, Moura FM, Zanghelini G, Barrera C, Seguí L, Zielinski AAF. An Upcycling Approach from Fruit Processing By-Products: Flour for Use in Food Products. Foods. 2025; 14(2):153. https://doi.org/10.3390/foods14020153

Chicago/Turabian StyleBenvenutti, Laís, Fernanda Moreira Moura, Gabriela Zanghelini, Cristina Barrera, Lucía Seguí, and Acácio Antonio Ferreira Zielinski. 2025. "An Upcycling Approach from Fruit Processing By-Products: Flour for Use in Food Products" Foods 14, no. 2: 153. https://doi.org/10.3390/foods14020153

APA StyleBenvenutti, L., Moura, F. M., Zanghelini, G., Barrera, C., Seguí, L., & Zielinski, A. A. F. (2025). An Upcycling Approach from Fruit Processing By-Products: Flour for Use in Food Products. Foods, 14(2), 153. https://doi.org/10.3390/foods14020153