Mechanism and Data-Driven Grain Condition Information Perception Method for Comprehensive Grain Storage Monitoring

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Sources

2.2. Mechanism Driven Model

2.2.1. Mathematical Model

- 1.

- Continuity equation:

- 2.

- Momentum equation:

- 3.

- Energy equation:

- 4.

- Mass conservation equation:

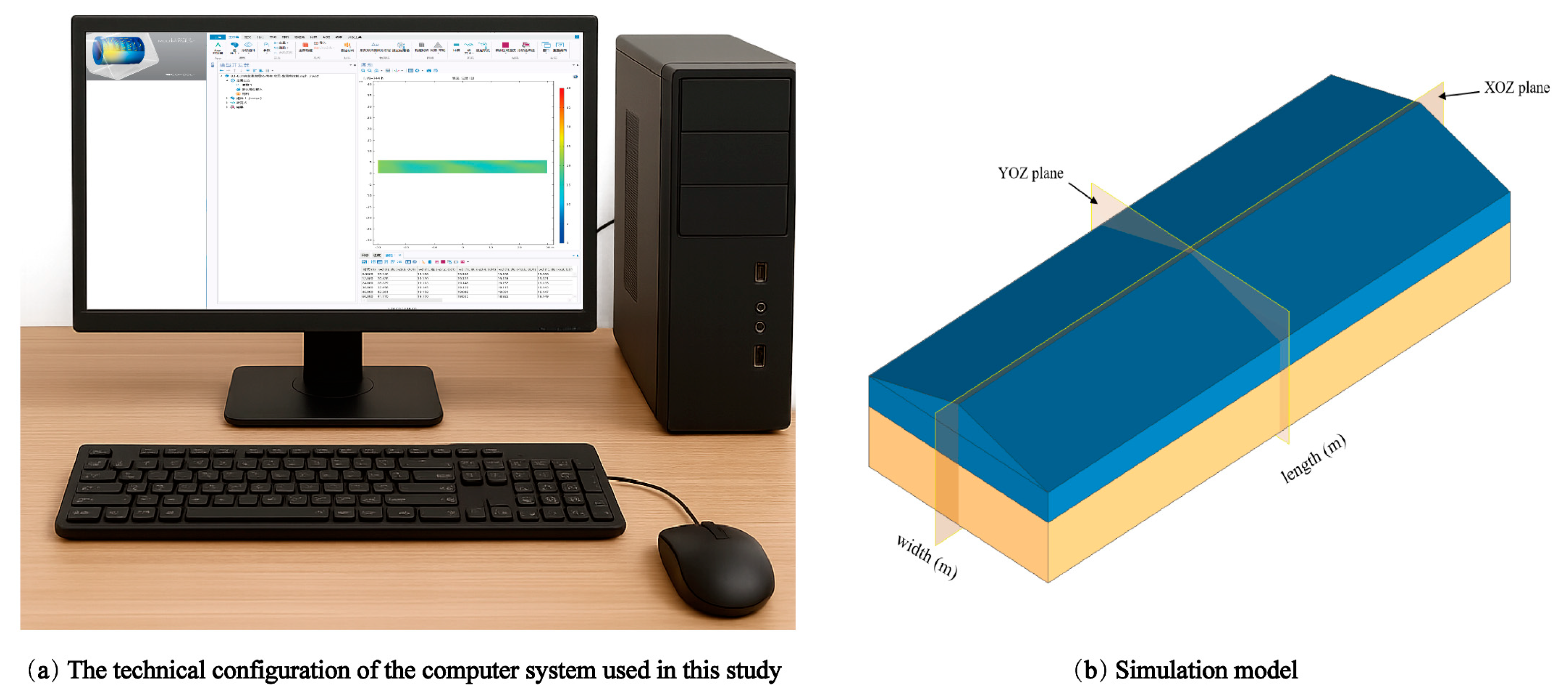

2.2.2. Simulation Model

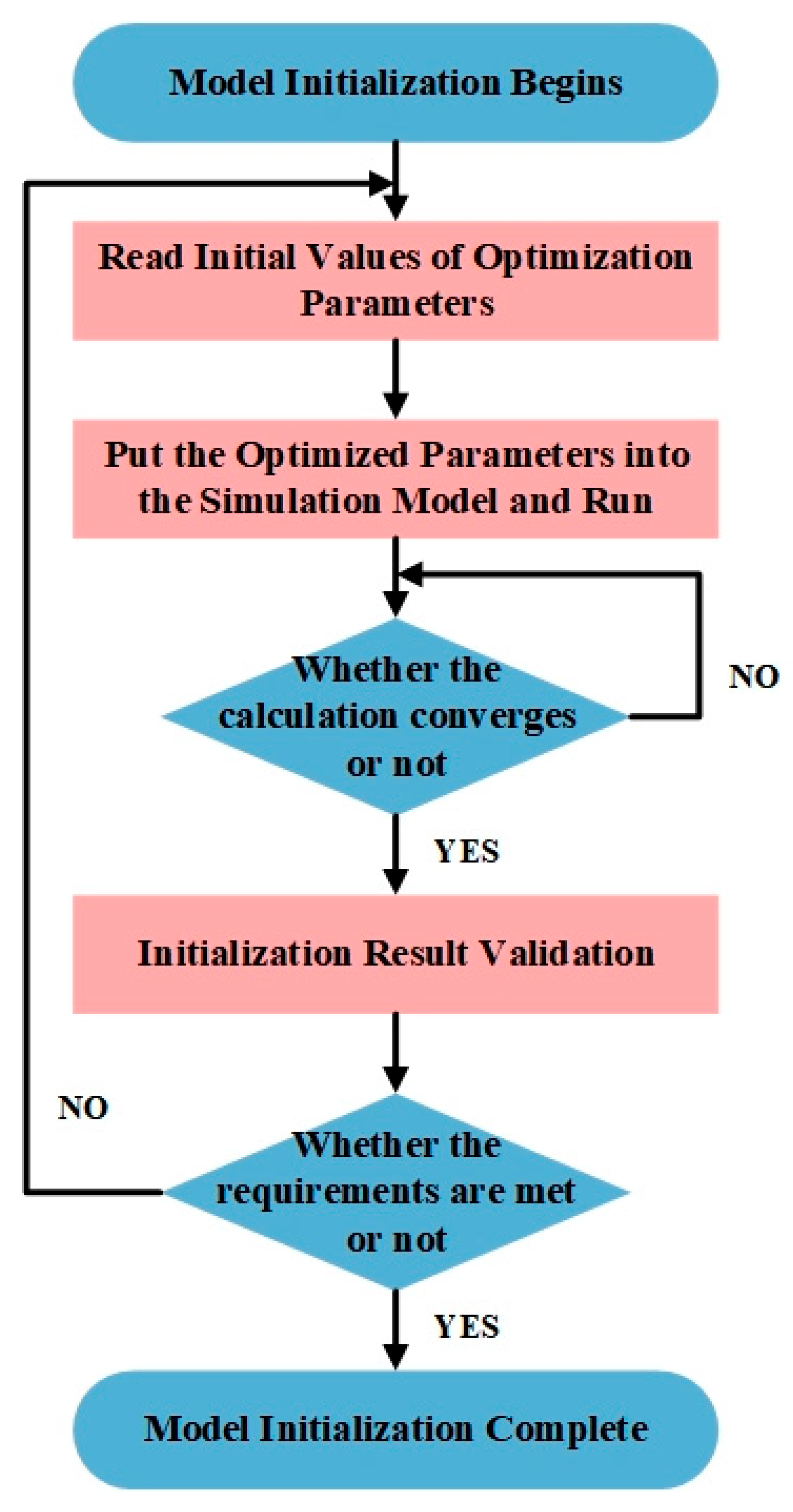

2.3. A Mechanism and Data-Driven Numerical Simulation Framework

2.4. Data Processing Methods

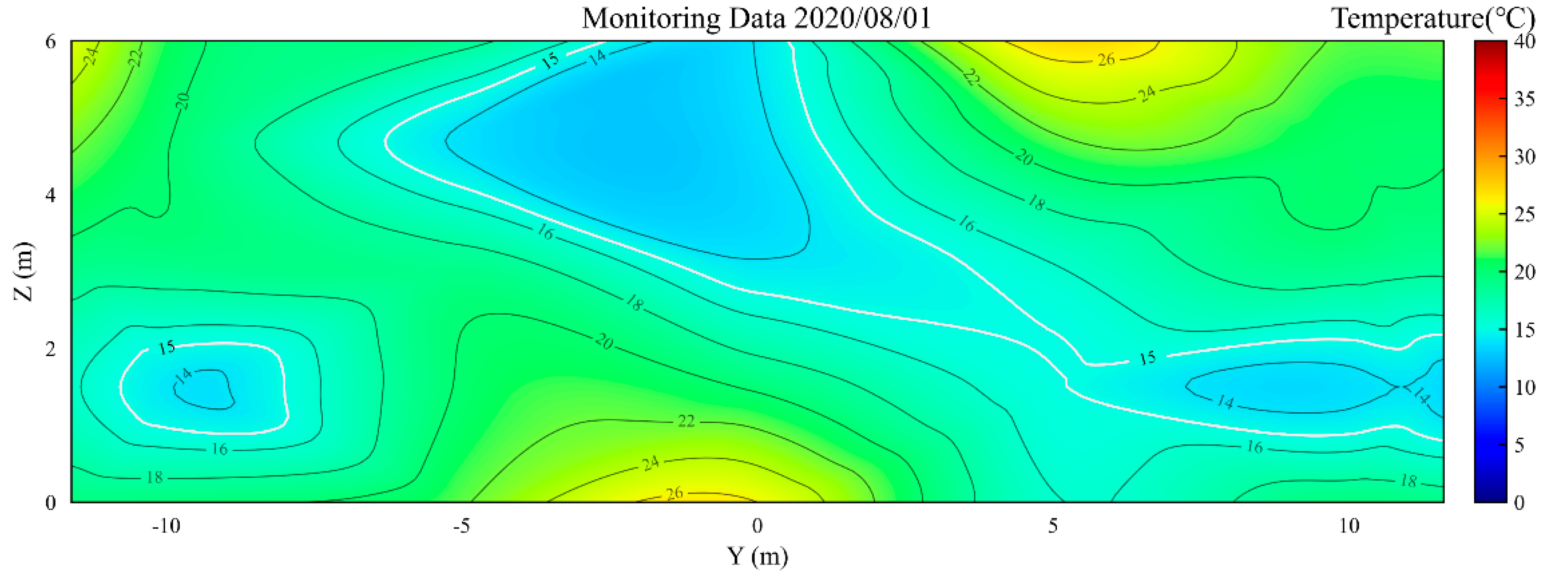

2.4.1. Monitoring Data

2.4.2. Simulating Data

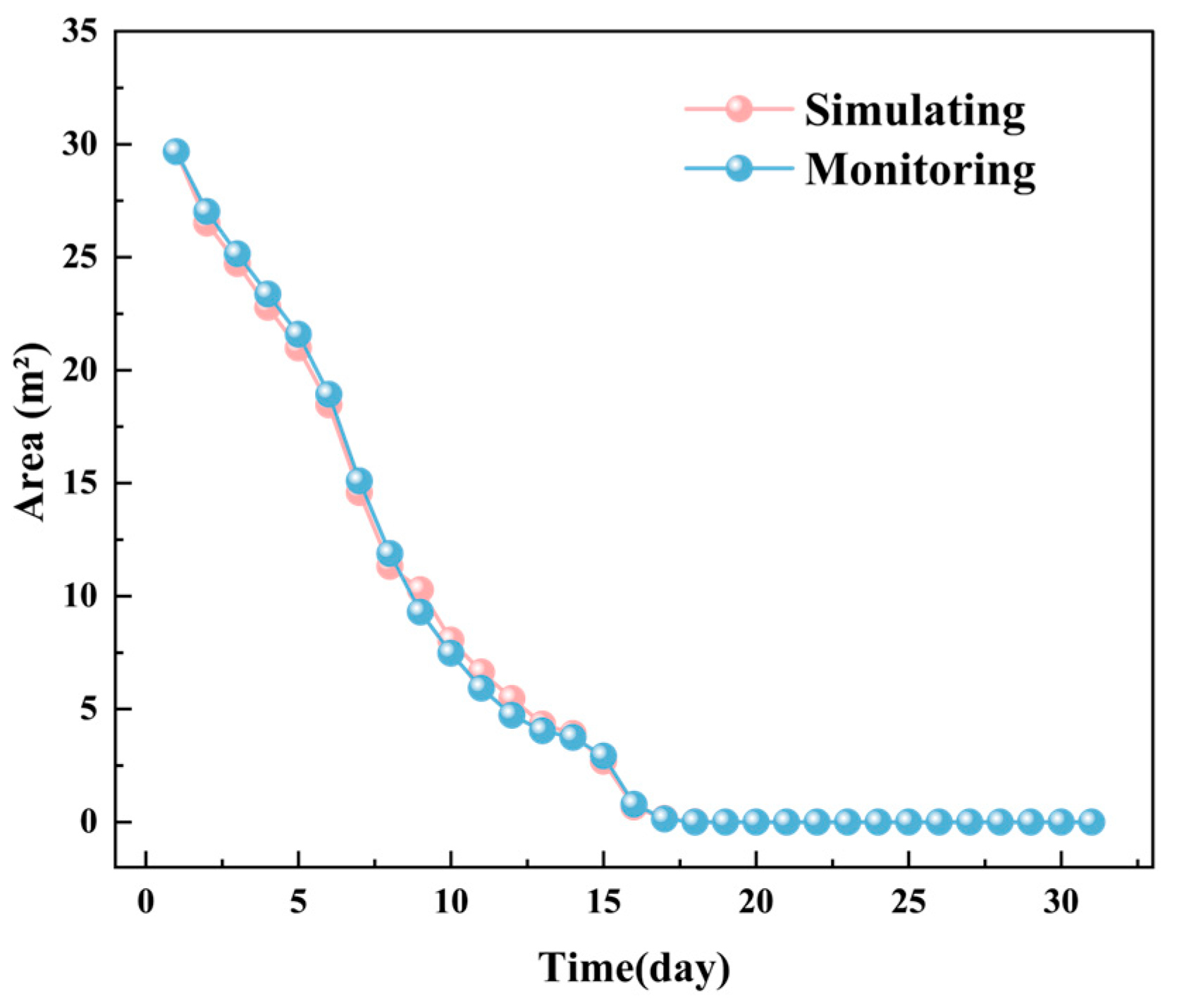

2.5. Model Validation Methods

3. Results and Discussion

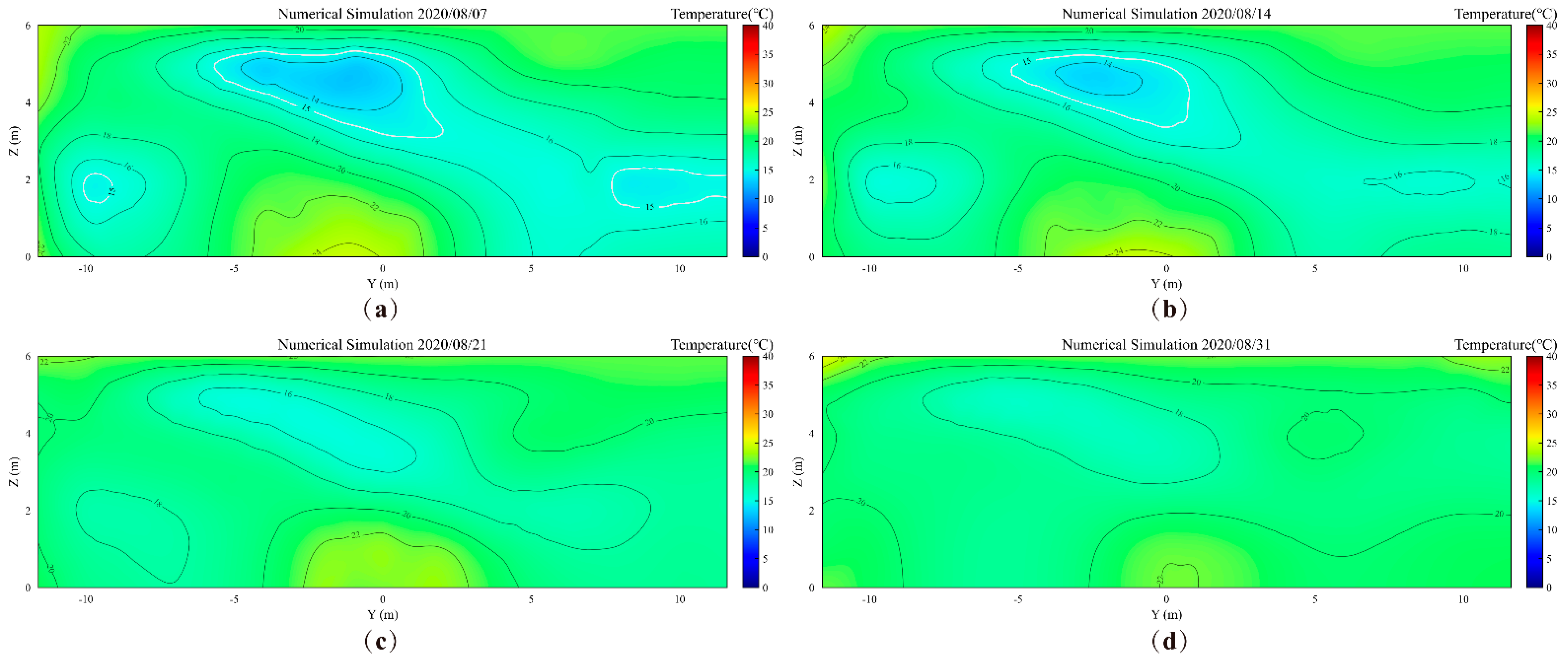

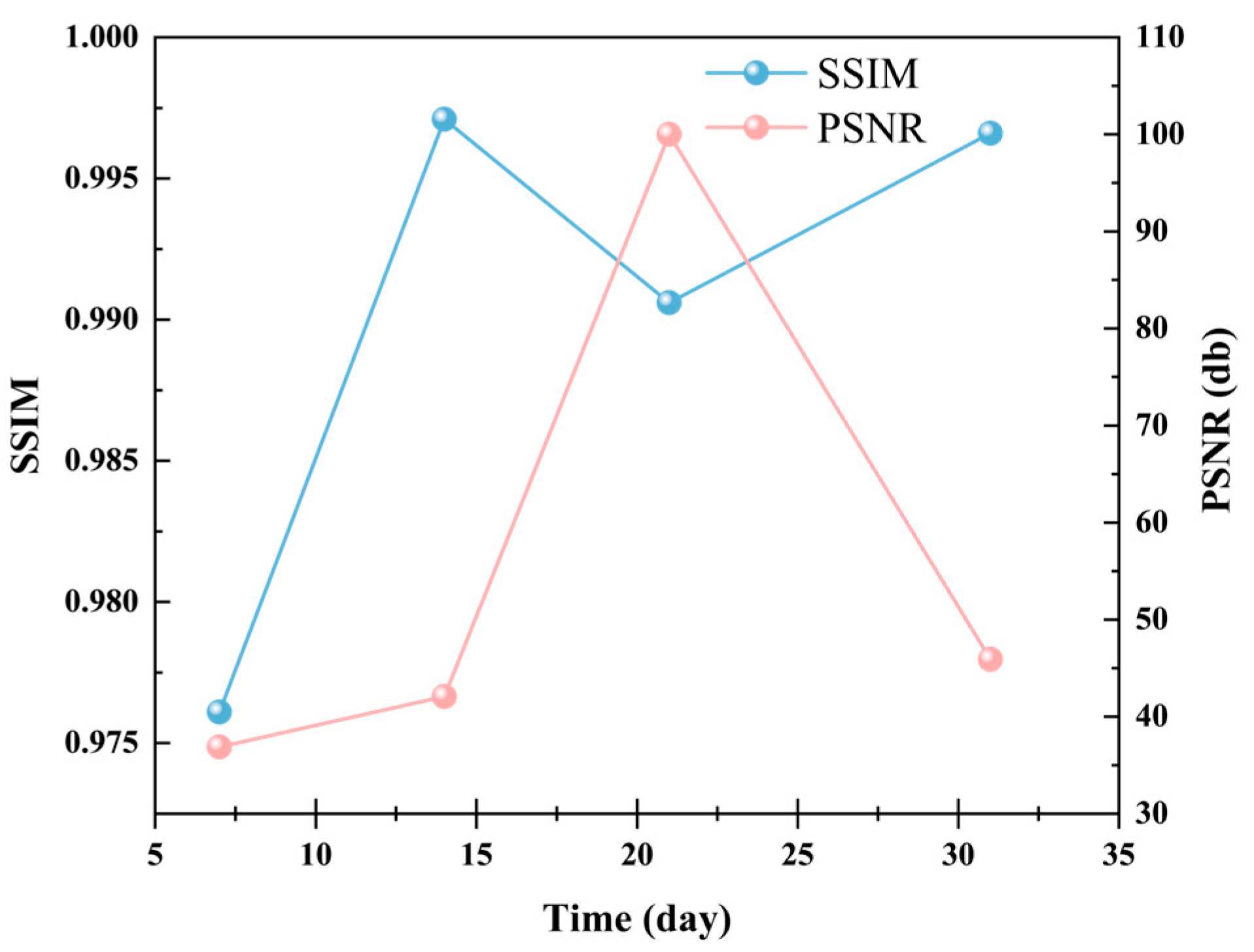

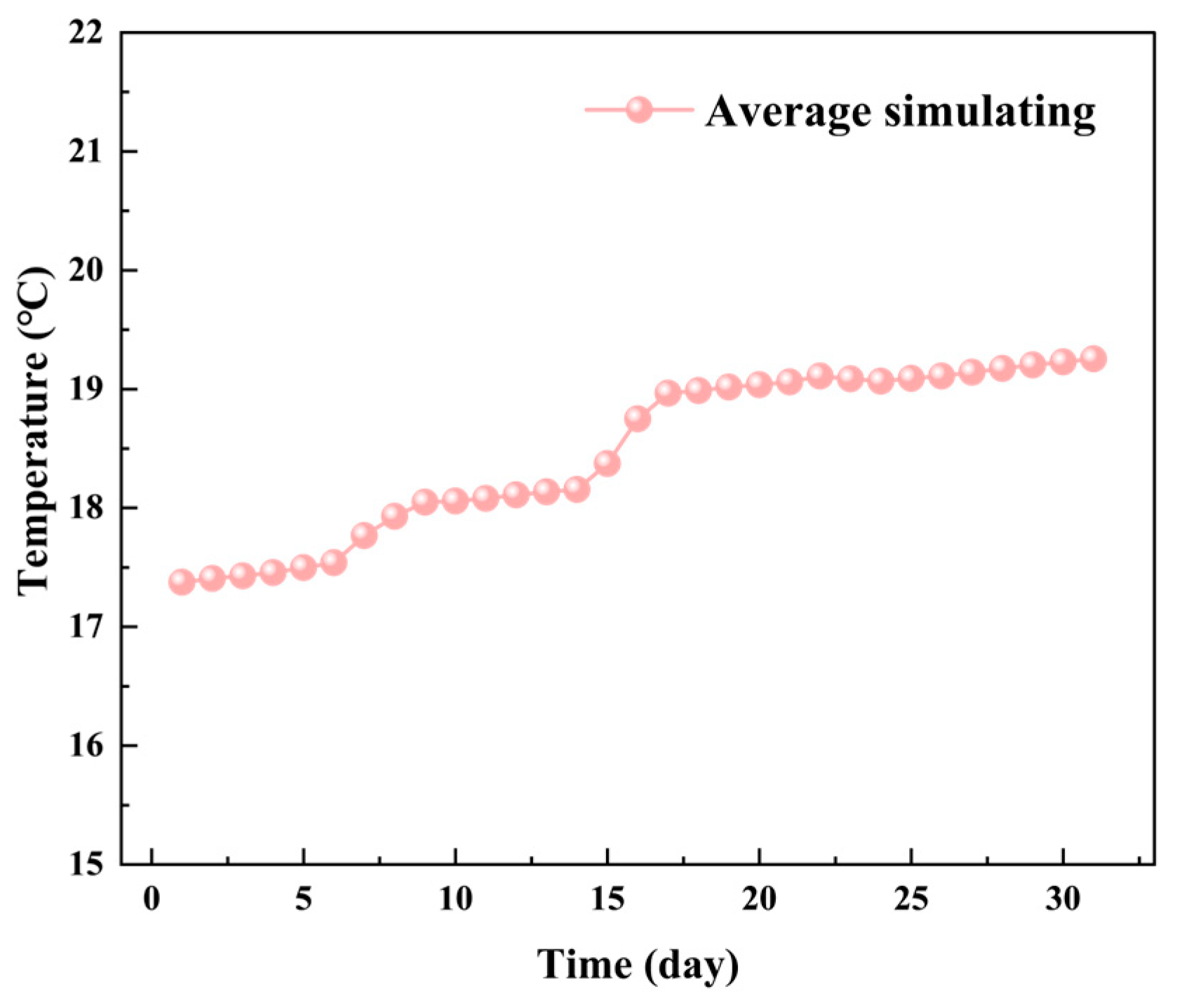

3.1. YOZ Plane-Model Validation Analysis

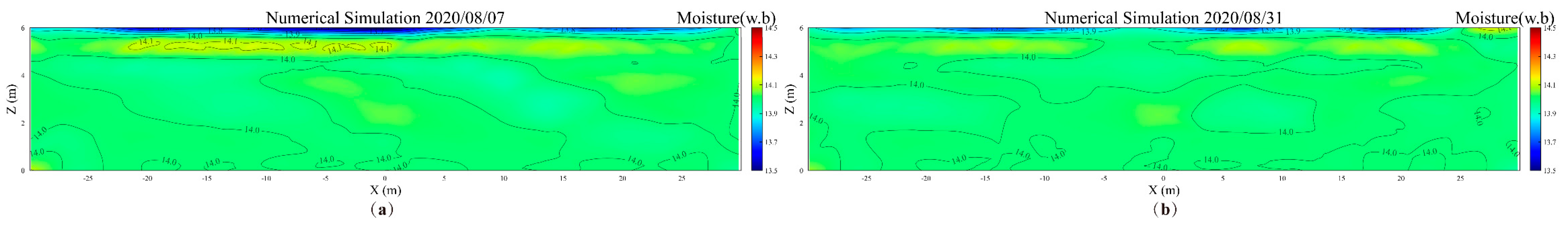

3.2. XOZ Plane- Multi-Field Interactions

3.2.1. Temperature

3.2.2. Moisture

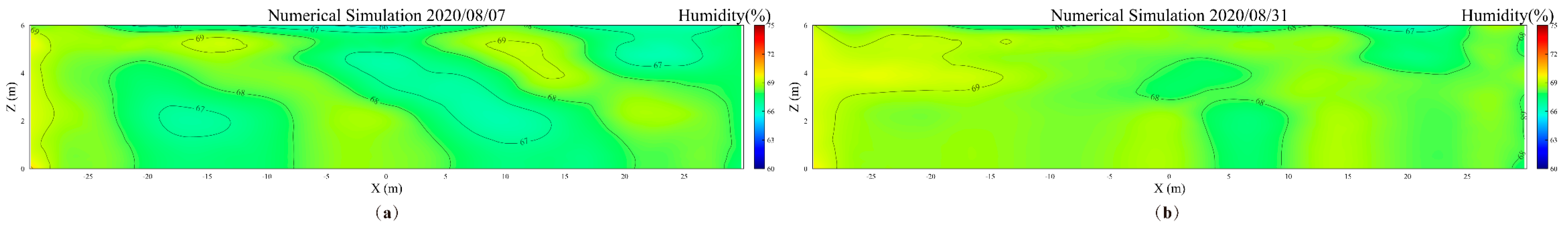

3.2.3. Humidity

4. Discussion and Future Work

4.1. Comparative Analysis with Existing Methods

4.2. Future Development Plan

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- National Food and Strategic Reserves Administration. Mobilization and Deployment Meeting on Deepening Reforms of the Grain Purchase, Sales and Reserve Management System and Mechanisms and on Implementing Regulatory Responsibilities. Available online: https://www.lswz.gov.cn/html/xinwen/2024-11/19/content_284772.shtml (accessed on 21 August 2025).

- The State Council the People’s Republic of China. Grain Security Guarantee Law of the People’s Republic of China. Available online: https://www.gov.cn/yaowen/liebiao/202312/content_6923387.html (accessed on 21 August 2025).

- Grain and Oil Storage Management Regulations. Available online: https://www.lswz.gov.cn/html/xxgk/gkml/2018-07/05/238677/files/354f5248b3724558a69e8ccf8c0e593d.pdf (accessed on 21 August 2025).

- National Bureau of Statistics. National Bureau of Statistics Announcement on 2024 Grain Output Data. Available online: https://www.stats.gov.cn/zwfwck/sjfb/202412/t20241213_1957744.html (accessed on 1 October 2025).

- Wu, Y.; Wu, W.; Chen, K.; Zhang, J.; Liu, Z.; Zhang, Y. Progress and Prospective in the Development of Stored Grain Ecosystems in China: From Composition, Structure, and Smart Construction to Wisdom Methodology. Agriculture 2023, 13, 1724. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, W.; Liu, Z.; Wu, Y.; Han, F.; Xu, W. Development and verification of a graphical detection system for multi-field interactions in stored grain based on LF-NMR. Biosyst. Eng. 2024, 241, 15–27. [Google Scholar] [CrossRef]

- Ziegler, V.; Paraginski, R.T.; Ferreira, C.D. Grain storage systems and effects of moisture, temperature and time on grain quality—A review. J. Stored Prod. Res. 2021, 91, 101770. [Google Scholar] [CrossRef]

- Wang, X.; Wu, W.; Yin, J.; Zhang, Z.; Wu, Z.; Zhang, H. Analysis of wheat bulk mould and temperature-humidity coupling based on temperature and humidity field cloud map. Trans. CSAE 2018, 34, 260–266. [Google Scholar]

- Wu, Z.; Zhang, Q.; Yin, J.; Wang, X.; Zhang, Z.; Wu, W.; Li, F. Interactions of multiple biological fields in stored grain ecosystems. Sci. Rep. 2020, 10, 9302. [Google Scholar] [CrossRef]

- National Public Service Platform for Standards Information. Technical Specifications for Digital Temperature-Sensing Cables for Grain Monitoring and Control. Available online: https://std.samr.gov.cn/hb/search/stdHBDetailed?id=8B1827F23BC8BB19E05397BE0A0AB44A (accessed on 21 August 2025).

- Javed, M.; Sajid, M.; Yousaf, H.M.Z.; Hassan, G.; Mahmood, H. Facile and Low-Cost Temperature Compensated Humidity Sensor and Signal Conditioning System. IEEE Sens. J. 2021, 21, 14906–14914. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, H.; Li, C.; Wang, J.; Cai, W.; Fan, Q.; Zhou, J.; Wen, Y.; Qu, B.; Mi, W. A Service Life Evaluation Method for Temperature and Humidity Sensors. Chinese Patent Application No. 118566613A, 16 August 2022. [Google Scholar]

- Dotto, G.L.; Pinto, L.A.A.; Moreira, M.F.P. Determination of the effective thermal diffusivity in a porous bed containing rice grains: Effects of moisture content and temperature. Heat. Mass. Transf. 2016, 52, 887–896. [Google Scholar] [CrossRef]

- Ismail, M.A.; Douglass, M.P.; Stenning, B.C. Modelling and Simulation Moisture Transfer in Wheat Stored in a Simulated Sealed Pit. Int. J. Food Eng. 2008, 4. [Google Scholar] [CrossRef]

- Xie, N.; Cai, J.; Huang, S.; Zhang, H. Methods for Monitoring of Mold Harm Activities in Stored Grain. Cereal Feed. Ind. 2011, 16–19. [Google Scholar] [CrossRef]

- Wu, W.; Cui, H.; Han, F.; Liu, Z.; Wu, X.; Wu, Z.; Zhang, Q. Digital monitoring of grain conditions in large-scale bulk storage facilities based on spatiotemporal distributions of grain temperature. Biosyst. Eng. 2021, 210, 247–260. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, K.; Cai, Y.; Fang, Y.; Wang, S. A comparative study on the efficacy of two different types of intracranial stent retrievers based on finite element simulation. Sci. Rep. 2025, 15, 10592. [Google Scholar] [CrossRef]

- Bharathi, V.S.K.; Jian, F.; Jayas, D.S. Study on 300 t of wheat stored in corrugated steel bin for two years in Canada. Part I—Temperature and moisture profiles of the grain. J. Stored Prod. Res. 2023, 100, 102057. [Google Scholar] [CrossRef]

- Anukiruthika, T.; Jayas, D.S. Mathematical modeling for management of stored-grain ecosystems: Approaches, opportunities, and research needs. J. Stored Prod. Res. 2024, 106, 102304. [Google Scholar] [CrossRef]

- Jian, F.; Jayas, D.S. The Ecosystem Approach to Grain Storage. Agric. Res. 2012, 1, 148–156. [Google Scholar] [CrossRef]

- Moses, J.A.; Jayas, D.S.; Alagusundaram, K. Climate Change and its Implications on Stored Food Grains. Agric. Res. 2015, 4, 21–30. [Google Scholar] [CrossRef]

- Lee, C.; Lee, G. Humidity Sensors: A Review. Sens. Lett. 2005, 3, 1–15. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, Z.; Wang, X.; Song, J.; Wu, W. Numerical Simulation and Experimental Study of Deep Bed Corn Drying Based on Water Potential. Math. Probl. Eng. 2015, 2015, 539846. [Google Scholar] [CrossRef]

- Wu, Y.; Fu, D.; Yin, H.; Xu, X.; Zhao, C.; Liu, J.; Wu, W. Establishment of Mathematical Model of Accumulated Temperature of Corn Based on Multi-Parameter Controllable Thin-Layer Drying Experiment and Its Tool Chart. J. Chin. Cereals Oils Assoc. 2020, 35, 114–120. [Google Scholar]

- Yin, J.; Wu, Z.; Zhang, Z.; Wu, X.; Wu, W. Analysis of the formation mechanism of partial condensation for the stored grain in steel squat silo based on Multi-fields coupling theory. J. Chin. Cereals Oils Assoc. 2015, 30, 90–95. [Google Scholar]

- Wu, W.; Wu, Y.; Chen, K.; Cui, H.; Zhang, Z.; Yin, J.; Xu, Q.; Wu, X. The digital intelligence method for stored grain supervision based on mechanism and data. Sci. Technol. Cereals Oils Foods 2023, 31, 11–17. [Google Scholar]

- Cui, H.; Wu, W.; Wu, Z.; Lan, T.; Dou, J. Method to detect granary state based on statistical characteristics of grain temperature. Trans. CSAE 2020, 36, 320–330. [Google Scholar]

- Lu, Y.; Li, X.; Wu, W.; Cui, H.; Xu, Y.; Han, F.; Li, Z.; Feng, B.; Shi, J.; Zhang, J. Development of basic data manual for intelligent analysis of grain condition. Sci. Technol. Cereals Oils Foods 2023, 31, 47–55. [Google Scholar]

- Li, X.; Wu, W.; Guo, H.; Wu, Y.; Li, S.; Wang, W.; Lu, Y. Smart Grain Storage Solution: Integrated Deep Learning Framework for Grain Storage Monitoring and Risk Alert. Foods 2025, 14, 1024. [Google Scholar] [CrossRef] [PubMed]

- Thorpe, G.R.; Whitaker, S. Local mass and thermal equilibria in ventilated grain bulks. Part II: The development of constraints. J. Stored Prod. Res. 1992, 28, 29–54. [Google Scholar] [CrossRef]

- Thorpe, G.R.; Whitaker, S. Local mass and thermal equilibria in ventilated grain bulks. Part I: The development of heat and mass coservation equations. J. Stored Prod. Res. 1992, 28, 15–27. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Z.; Li, F.; Cao, Y.; Zhang, Z.; Zhao, H. Overview of mathematical models and numerical simulations in the stored grain ecosystem. J. Chin. Cereals Oils Assoc. 2016, 31, 157–162. [Google Scholar]

- Carrera-Rodríguez, M.; Martínez-González, G.M.; Navarrete-Bolaños, J.L.; Botello-Alvarez, J.E.; Rico-Martínez, R.; Jiménez-Islas, H. Transient numerical study of the effect of ambient temperature on 2-D cereal grain storage in cylindrical silos. J. Stored Prod. Res. 2011, 47, 106–122. [Google Scholar] [CrossRef]

- Wang, X. Study on Mechanism and Model of Microbial Field and Multi-Fields Interaction in Grain Bulk. Ph.D. Thesis, Jilin University, Changchun, China, 2019. [Google Scholar]

- Thorpe, G.R. Moisture diffusion through bulk grain. J. Stored Prod. Res. 1981, 17, 39–42. [Google Scholar] [CrossRef]

- Yin, J. Research on Multi-Fields Coupling Model of Wheat Grain and Condensation Prediction. Ph.D. Thesis, Jilin University, Changchun, China, 2015. [Google Scholar]

- Avila-Acevedo, J.G.; Tsotsas, E. Transient natural convection and heat transfer during the storage of granular media. Int. J. Heat. Mass. Tran. 2008, 51, 3468–3477. [Google Scholar] [CrossRef]

- Sun, L. Experimental Study on the Bearing and Thermal Performance of “Structure Insulation” Integrated Wall Panel in Grain Warehouse. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2020. [Google Scholar]

- Khankari, K.K.; Patankar, S.V.; Morey, R.V. A mathematical model for natural convection moisture migration in stored grain. Trans. ASABE 1995, 38, 1777–1787. [Google Scholar] [CrossRef]

- Thorpe, G.R. Modelling ecosystems in ventilated conical bottomed farm grain silos. Ecol. Model. 1997, 94, 255–286. [Google Scholar] [CrossRef]

- Thorpe, G.R. The application of computational fluid dynamics codes to simulate heat and moisture transfer in stored grains. J. Stored Prod. Res. 2008, 44, 21–31. [Google Scholar] [CrossRef]

- Quemada-Villagómez, L.I.; Molina-Herrera, F.I.; Carrera-Rodríguez, M.; Calderón-Ramírez, M.; Martínez-González, G.M.; Navarrete-Bolaños, J.L.; Jiménez-Islas, H. Numerical Study to Predict Temperature and Moisture Profiles in Unventilated Grain Silos at Prolonged Time Periods. Int. J. Thermophys. 2020, 41, 52. [Google Scholar] [CrossRef]

- Parti, M.; Dugmanics, I. Diffusion Coefficient for Corn Drying. Trans. ASAE 1990, 33, 1652–1656. [Google Scholar] [CrossRef]

- Rho, H.; Jang, Y.S.; Bae, H.; Cha, A.N.; Lee, S.H.; Ha, J.S. Fanless, porous graphene-copper composite heat sink for micro devices. Sci. Rep. 2021, 11, 17607. [Google Scholar] [CrossRef]

- Song, F.; Zhang, G.; Ramanathan, V.; Leung, L. Trends in surface equivalent potential temperature: A more comprehensive metric for global warming and weather extremes. Proc. Natl. Acad. Sci. USA 2022, 119, e2117832119. [Google Scholar] [CrossRef]

- Wang, F.; Tian, N.; Ren, L.; Zhang, K.; Wang, J.; Zhang, Y. Quantitative investigation of moisture migration during microwave drying of coal slime dough through simulation and tracer analysis. Sci. Rep. 2025, 15, 11308. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, H.; Yang, K.; Wang, K. Numerical simulation of coupled heat and moisture transfer and yellowing of stored rice during storage in silo. Trans. CSAE 2022, 38, 297–307. [Google Scholar]

- Sabbahi, R.; Azzaoui, K.; Rhazi, L.; Ayerdi-Gotor, A.; Aussenac, T.; Depeint, F.; Taleb, M.; Hammouti, B. Factors Affecting the Quality of Canola Grains and Their Implications for Grain-Based Foods. Foods 2023, 12, 2219. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Liu, X.; Feng, B.; Zhou, Q.; Deng, G.; Long, H.; Cao, J.; Guo, S.; Ji, G.; Xu, Z.; et al. Construction of a novel Wheat 55 K SNP array-derived genetic map and its utilization in QTL mapping for grain yield and quality related traits. Front. Genet. 2022, 13, 978880. [Google Scholar] [CrossRef] [PubMed]

| Structural Parameters | Value/Feature |

|---|---|

| Warehouse type | Flat warehouse |

| Wall Thickness | 50 cm |

| Eave Height (Exterior) | 9.13 m |

| Eave Height (Interior) | 9.0 m |

| Roof Thickness | 20 cm |

| Grain Filling Height | 6 m |

| Parameter | Formulas/Values | Unit |

|---|---|---|

| Specific heat capacity of maize [34] | ||

| Thermal conductivity of maize [34] | ||

| Density of maize [34] | ||

| Specific heat capacity of air [36] | ||

| Thermal conductivity of air [36] | ||

| Density of air [36] | ||

| Tortuosity [37] | - | |

| Kinetic viscosity [37] | ||

| Heat transfer coefficient of the warehouse wall [38] | ||

| Heat transfer coefficient of the warehouse roof [38] |

| Time (Day) | Different Approaches | Area (m2) |

|---|---|---|

| 2nd day | Monitored | 27.02 |

| Simulated | 26.51 |

| Methods | Mechanism Driven Method | Data Driven Method | MDD Framework |

|---|---|---|---|

| Data Acquisition | Obtain multi-parameter numerical values (e.g., temperature, humidity, moisture) | Only obtain temperature data | Obtain high-precision, holistic temperature, humidity, and moisture data |

| Accuracy Reliability | A maximum deviation of 1.5 °C compared to experimental data (using mean initialization) [47]. | Proposes a computer algorithm for monitoring stored grain using temperature data, achieving an average accuracy of 94% [16]. | Employs a novel Parameter initialization method, ensuring high-precision alignment with experimental or monitored conditions to minimize discrepancies. The maximum deviation between simulated results and monitored data is 0.45 m2, demonstrating high accuracy. The simulated results align closely with monitored data (<0.5), validating the reliability of the simulation. The quality of simulated contour maps is thoroughly validated, with SSIM values above 0.97 confirming the accuracy. |

| Simulated values deviate from experimental values across different storage durations. At t = 336 h, the deviation reaches 2.0 °C, while at t = 576 h, it reduces to 0.1 °C [36]. | The grain storage state classification model achieves an accuracy of 97.38%, outperforming baseline models. The temperature prediction model (3DCNN-LSTM) demonstrates high accuracy with MAE = 0.24 °C and RMSE = 0.28 °C [29]. | ||

| Limitation | During the storage process, the experimental conditions are influenced by external disturbances, whereas the simulation lacks real-time adjustments and interventions. The substantial differences arise between the simulated and experimental results, leading to unreliable numerical simulation outcomes. | Can only obtain temperature data, which is limited and lacks comprehensive humidity and moisture information. | Grain Species: The model only focuses primarily on corn. Omission of Porosity: The model does not account for spatial variations in porosity. Limited Simulation Duration: The simulation is limited to a one-month period (8.1–8.31). Warehouse Types: The study primarily focuses on flat. |

| Parameter | Statistical Metric | Maximum Deviation | Evaluation Description |

|---|---|---|---|

| Total Area of Low Temperature Zone in YOZ Plane | Total Area (m2) | ≤0.45 m2 | The maximum deviation between simulated results and monitored data is 0.45 m2, demonstrating high accuracy. |

| Average Temperature in YOZ Plane | Average Temperature (°C) | < 0.5 °C | The simulated results align closely with monitored data (<0.5), validating the reliability of the simulation. |

| Quality and similarity of Contour Maps | PSNR, SSIM Values | SSIM > 0.97 | The quality of simulated contour maps is thoroughly validated, with SSIM values above 0.97 confirming the accuracy. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Zhang, J.; Li, X.; Zhang, Y.; Wu, W.; Xu, Y. Mechanism and Data-Driven Grain Condition Information Perception Method for Comprehensive Grain Storage Monitoring. Foods 2025, 14, 3426. https://doi.org/10.3390/foods14193426

Wu Y, Zhang J, Li X, Zhang Y, Wu W, Xu Y. Mechanism and Data-Driven Grain Condition Information Perception Method for Comprehensive Grain Storage Monitoring. Foods. 2025; 14(19):3426. https://doi.org/10.3390/foods14193426

Chicago/Turabian StyleWu, Yunshandan, Ji Zhang, Xinze Li, Yaqiu Zhang, Wenfu Wu, and Yan Xu. 2025. "Mechanism and Data-Driven Grain Condition Information Perception Method for Comprehensive Grain Storage Monitoring" Foods 14, no. 19: 3426. https://doi.org/10.3390/foods14193426

APA StyleWu, Y., Zhang, J., Li, X., Zhang, Y., Wu, W., & Xu, Y. (2025). Mechanism and Data-Driven Grain Condition Information Perception Method for Comprehensive Grain Storage Monitoring. Foods, 14(19), 3426. https://doi.org/10.3390/foods14193426